Fluke 805, 810 Brochure

Get Answers

Now.

Get Answers

Now.

Mechanical Troubleshooting with

In the world of mechanical

maintenance, vibration remains

one of the earliest indicators

of a machine’s health.

Whether it’s the rumble of worn bearings or the

shaking, shimmying, or thumping of loose, misaligned, or unbalanced parts, machines have a tale

to tell.

For years, mechanical teams faced a tough

choice: complex vibration analysis systems, expensive vibration consultants, or relying on the trained

ears of seasoned technicians using stethoscopes or

even screwdrivers to divine the problem.

Now you can get fast, accurate and actionable

answers with revolutionary vibration testers from

Fluke. These tools redefine vibration testing for

mechanical troubleshooting and predictive maintenance, and help you:

• Quickly and reliably understand machinery

health and condition severity

• Increase efficiency by working against a priori-

tized list of problems

• Take control of downtime costs by anticipating

problems earlier and identifying root causes of

recurring failures

• Bridge skill gaps of the maintenance team

Fluke Vibration Tools

Vibration testing has never been easier. Intuitive

measurement procedures and automated diagnosis

allows all personnel to conduct vibration checks,

and perform expert diagnosis with minimal training.

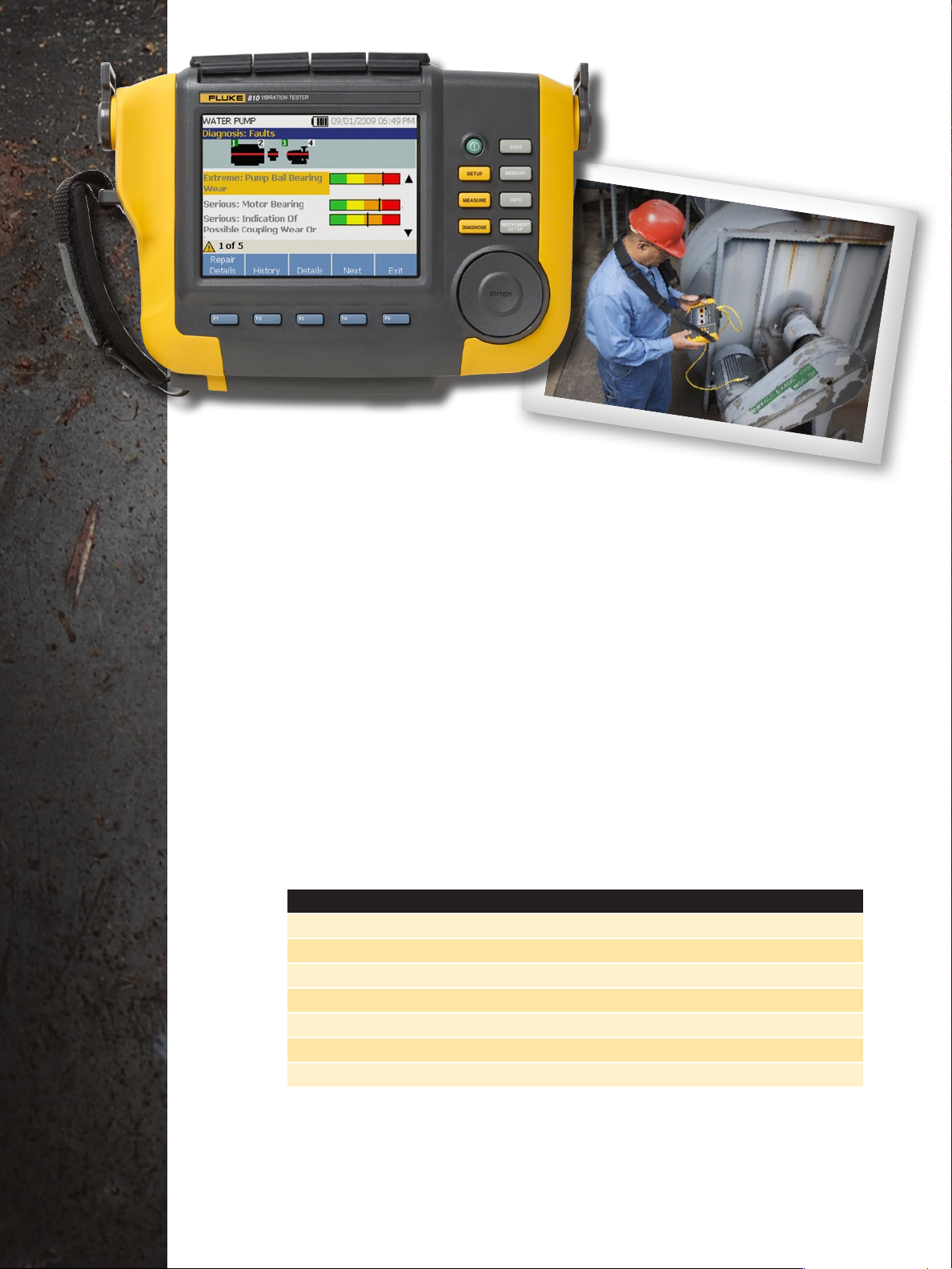

Fluke 810 Vibration Tester:

Take a vibration expert along

The Fluke 810 Vibration Tester is the most advanced troubleshooting

tool for mechanical maintenance teams who need an answer now. The

unique diagnostic technology puts the expertise of a vibration analyst in

your hands so you can quickly locate and diagnose common mechanical problems. A simple step-by-step process reports on machine faults the

first time measurements are taken, without prior measurement history.

• Unique diagnostic technology identifies and locates the most common

mechanical faults: bearings, misalignment, unbalance and looseness

• Fault severity scale helps you prioritize maintenance work

• Repair recommendations advise technicians on corrective action

• Real-time tips and guidance for new users with on-board context-sensitive help

• Laser tachometer for accurate machine running speed promotes confident diagnoses

• Tri-axial accelerometer reduces measurement time by 2/3 over single

axis accelerometers

• 4 GB expandable on-board memory provides enough space for your

machinery’s data

• Viewer PC Software expands data storage and tracking capacity

Use the Fluke 810 to diagnose most common equipment:

Motors

Fans and blowers

Belt and chain drives

Gearboxes

Pumps

Compressors

Spindles

Loading...

Loading...