Page 1

Page 2

maintenance manual

John Fluke Mfg.

Co.,

Inc.

P.O.

Box

43210 Mountlake Terrace, Washington 98043

/

/

Page 3

Table

of

Contents

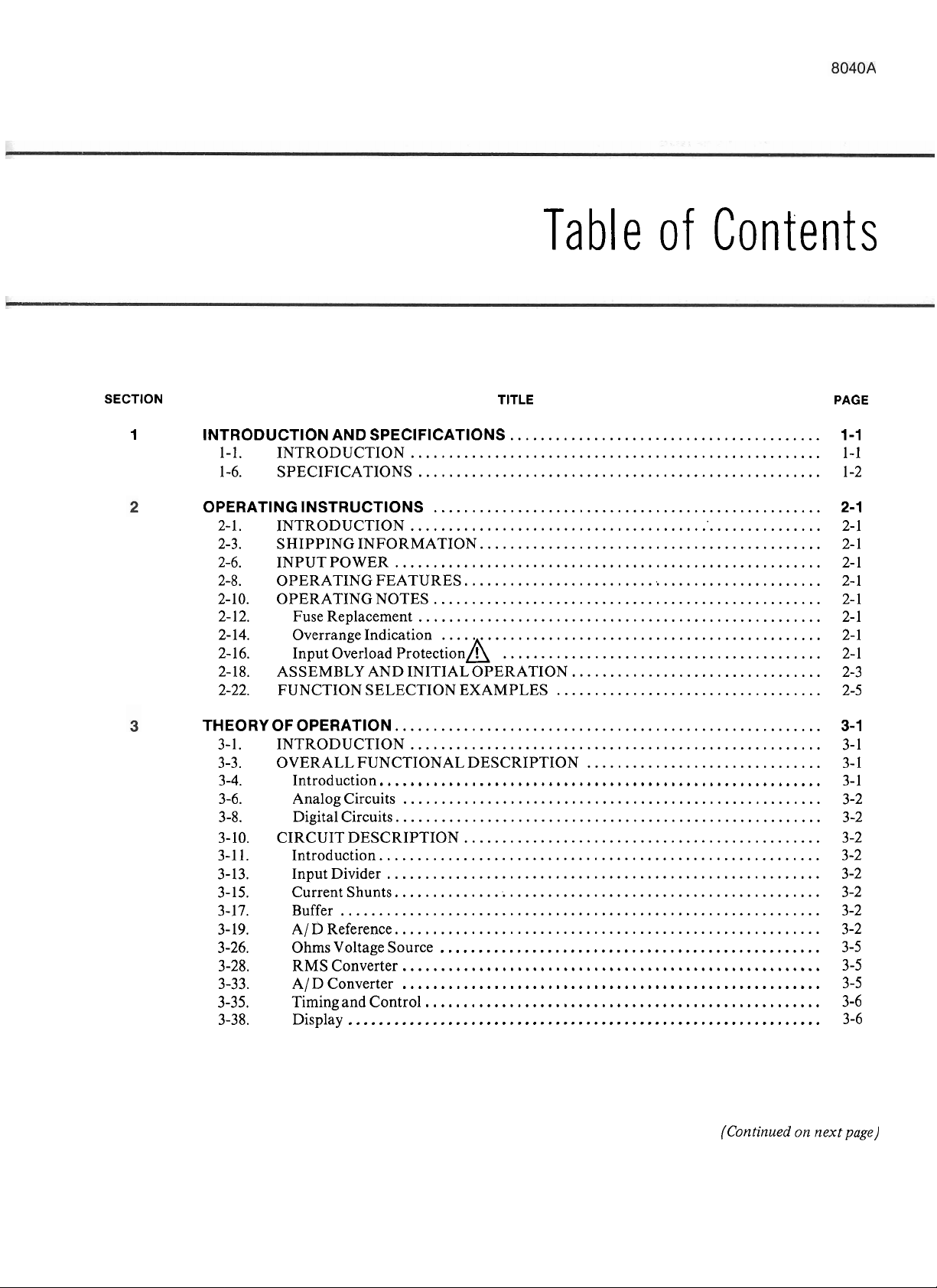

SECTION

1

INTRODUCTION AND SPECIFICATIONS

1.1

.

INTRODUCTION

.

1.6

OPERATING INSTRUCTIONS

2.1

2.3

2.6

2.8

2.10

2- 12

2- 14

2.16

2.18

2.22

THEORY OF OPERATION

3.1

3.3

3.4

3.6

3.8

3.10

3-1 1

3.13

3.15

3.17

3.19

3.26

3.28

3.33

3.35

3.38

SPECIFICATIONS

.

INTRODUCTION

.

SHIPPING INFORMATION

.

INPUTPOWER

.

OPERATING FEATURES

.

OPERATING NOTES

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

Fuse Replacement

Overrange Indication

Input Overload ~rotectlbiA

ASSEMBLY AND INITIAL OPERATION

FUNCTION SELECTION EXAMPLES

INTRODUCTION

OVERALL FUNCTIONAL DESCRIPTION

Introduction 3-1

Analog Circuits

Digital Circuits

CIRCUIT DESCRIPTION

Introduction

Input Divider

Current Shunts

Buffer

A/ D Reference

Ohms Voltage Source 3-5

RMSConverter 3-5

A/DConverter 3-5

Timing and Control 3-6

Display 3-6

...............................................................

..............................................................

......................................................

.....................................................

...................................................

.......................................................

.............................................

........................................................

.........................

...................................................

.....................................................

........................................................

......................................................

..........................................................

.......................................................

........................................................

...............................................

..........................................................

.........................................................

........................................................

........................................................

..................................................

.......................................................

.......................................................

....................................................

TITLE PAGE

.........................................

;

.....................

...........................................

..........................................

.................................

...................................

...............................

1-1

1-1

1-2

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-1

2-3

2-5

3-1

3-1

3-1

3-2

3-2

3-2

3-2

3-2

3-2

3-2

3-2

(Continued on next page)

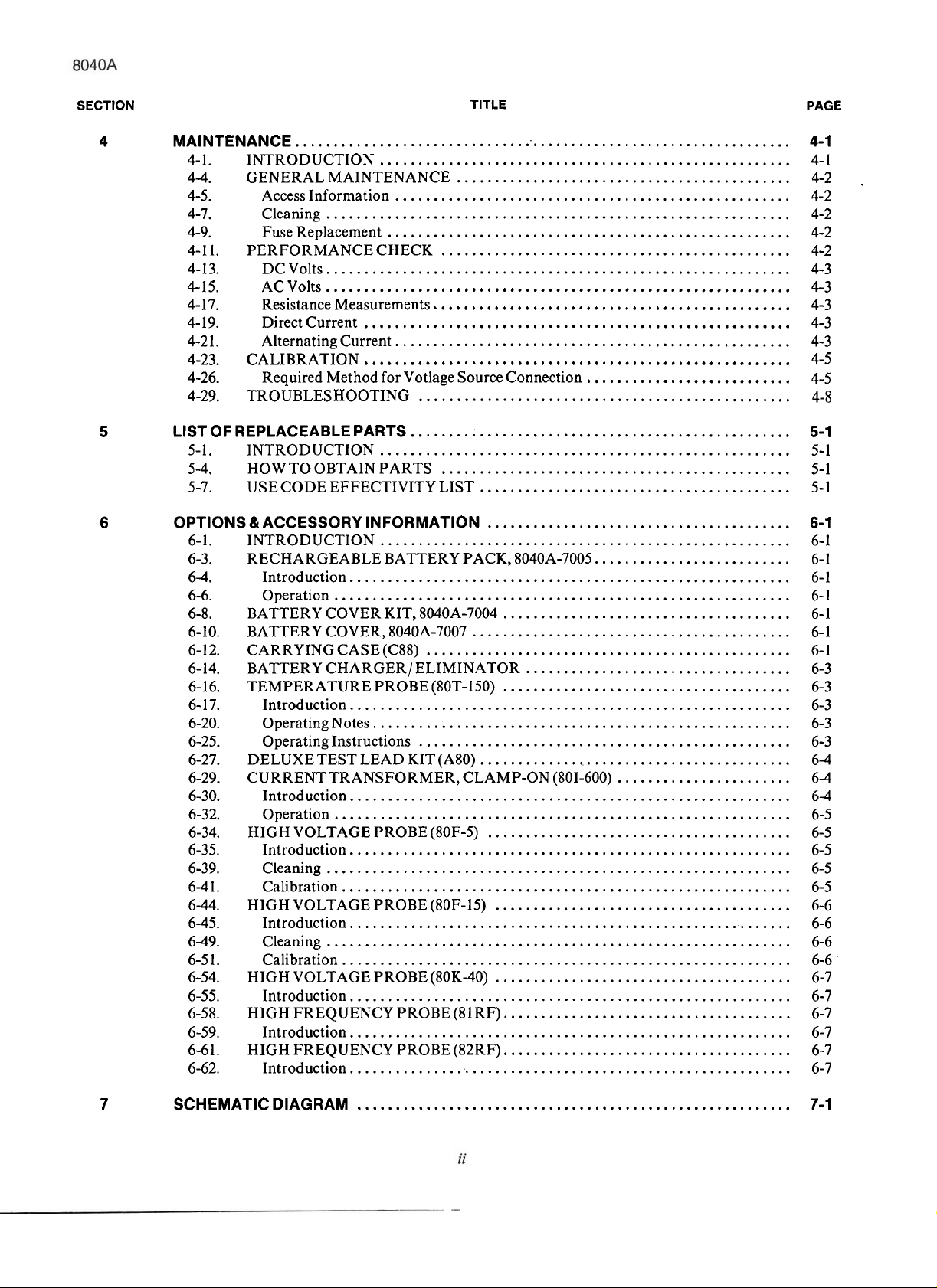

Page 4

SECTION

TITLE

PAGE

4 MAINTENANCE

4-1

.

INTRODUCTION

4-4

.

GENERAL MAINTENANCE

4-5

.

4-7

.

4-9

.

4-1

1 . PERFORMANCE CHECK

.

4-13

4-15

.

4-17

.

4-19

.

1

.

4-2

4-23 . CALIBRATION 4-5

4-26

.

4-29 . TROUBLESHOOTING

5 LISTOFREPLACEABLEPARTS

5.1

.

INTRODUCTION

5.4

.

HOW TO OBTAIN PARTS

.

5.7

6 OPTIONS & ACCESSORY INFORMATION

6.1

6.3

6.4

6.6

6.8

6.10

6.12

6.14

6.16

6- 17

6.20

6.25

6.27

6.29

6.30

6.32

6.34

6.35

6.39

6-4 1

6.44

6.45

6.49

6-5

6.54

6.55

6.58

6.59

6.61

6.62

USE CODE EFFECTIVITY LIST

.

INTRODUCTION

.

RECHARGEABLE BATTERY PACK, 8040A.7005

.

.

.

BATTERY COVER KIT, 8040A-7004

.

BATTERY COVER, 8040A-7007

.

CARRYING CASE (C88)

.

BATTERY CHARGER/ ELIMINATOR

.

TEMPERATURE PROBE (80T-150)

.

.

.

.

DELUXE TEST LEAD KIT (A80)

.

CURRENT TRANSFORMER, CLAMP-ON (801-600)

.

.

.

HIGH VOLTAGE PROBE (80F-5)

.

.

.

.

HIGH VOLTAGE PROBE (80F-15)

.

.

1

.

.

HIGH VOLTAGE PROBE (80K-40)

.

.

HIGH FREQUENCY PROBE (81 RF)

.

.

HIGH FREQUENCY PROBE (82RF)

.

.................................................................

......................................................

............................................

Access Information

Cleaning

Fuse Replacement

.............................................................

....................................................

.....................................................

..............................................

DCVolts

ACVolts 4-3

Resistance Measurements 4-3

Directcurrent 4-3

Alternating Current

.............................................................

.............................................................

...............................................

........................................................

....................................................

........................................................

Required Method for Votlage Source Connection 4-5

.................................................

..................................................

......................................................

..............................................

......................................................

Introduction

Operation

...........................................................

............................................................

................................................

Introduction

OperatingNotes

Operating Instructions

Introduction

Operation

Introduction

Cleaning

Calibration

Introduction

Cleaning

Calibration

Introduction

Introduction

Introduction

..........................................................

.......................................................

.................................................

..........................................................

............................................................

..........................................................

.............................................................

...........................................................

..........................................................

.............................................................

...........................................................

..........................................................

..........................................................

..........................................................

...........................

.........................................

........................................

..........................

......................................

..........................................

...................................

......................................

.........................................

.......................

........................................

.......................................

.......................................

......................................

......................................

4-1

4-1

4-2

4-2

4-2

4-2

4-2

4-3

4-3

4-8

5-1

5-1

5-1

5-1

6-1

6-1

6-1

6-1

6-1

6-1

6-1

6-1

6-3

6-3

6-3

6-3

6-3

6-4

6-4

6-4

6-5

6-5

6-5

6-5

6-5

6-6

6-6

6-6

6-6

6-7

6-7

6-7

6-7

6-7

6-7

.

'

7

SCHEMATIC DIAGRAM

.........................................................

7-1

Page 5

List

of

.

Illustrations

FIGURE

TITLE

Control. Indicator and Connector Locations

Function Selection Examples

8040A Block Diagram

Simplified Buffer Circuit 3-3

Simplified

RMS Converter Representation 3-5

Simplified RMS Converter Circuit

Dual-Slope

Calibration Adjustment Controls 4-4

Required Method for Voltage Source Connection

Waveform at U26 Pin 8 for In Range and Overrange Inputs

Waveforms at TP1. Q10. C22 and U14 for In Range and Overrange Inputs

Oscilloscope Connections for Troubleshooting

A/ D Reference Circuit

A/ D Conversion Timing for VAC or VDC Inputs

.......................................................

.............................................................

...........................................................

....................................................

.....................................................

...................................................

....................................................

...........................................

............................

.......................................

...............................

..................

.........................................

PAGE

2-2

2-5

3-1

3-4

3-6

3-7

4-5

4-9

4-10

4-11

MainPCBAssembly ............................................................... 5-4

Digital Conditioner PCB Assembly

Analog Converter PCB Assembly

8040AAccessories

Initial

CaseTemperature above Ambient versus Meter Reading above Ambient

Maximum RF Signal Limits (V RMS) at Probe Tip

DeluxeTestLeadKit

801-600 Current Transformer

80F-5VoltageDivider

80F-

15 Voltage Divider

80K-40VoltageDivider

81RFHighFrequencyProbe

82RF High Frequency Probe

.................................................................

..............................................................

........................................................

.............................................................

............................................................

............................................................

........................................................

.........................................................

..................................................

....................................................

..................................... 6-4

iii

..............

5-8

5-10

6-2

6-4

6-4

6-5

6-5

6-6

6-7

6-7

6-7

Page 6

List

TABLE TITLE PAGE

of

Tables

Accessories

Control. Indicator and Connector Description

8040A Maximum Allowable Input Overload Conditions

Buffer Gain Configuration.

Recommended Test Equipment

DCVoltage

AC Voltage Performance Check 4-3

Resistance Performance Check

Direct Current Performance Check

DC Voltage Calibration

Ohms Calibration

LowFrequencyACVCheck

HighFrequencyACVCheck

Direct Current Accuracy Check

Battery

......................................................................

.........................................

.................................

kR Function

..............................................

......................................................

......................................................................

.....................................................

......................................................

...................................................

............................................................

.................................................................

........................................................

........................................................

......................................................

Charger/ Eliminator Input Power Configurations

................................

1 . 1

2-3

2-4

3-2

4-1

4-3

4-3

4-4

4-6

4-7

4-8

4-8

4-8

6-3

8040A Ranges for Current Transformer (801-600)

.......................................

6-5

Page 7

Section

1

Introduction

1-1. INTRODUCTION

1-2. The Model 8040A Multimeter provides the control applications.

accuracy and portability required in today's field service

work.

A

display from glare when operating the 8040A in adverse

lighting conditions. The small size and battery power add

to the portability; yet the fold-away stand allows the

instrument to be positioned at a convenient angle for

bench top use.

1-3.

five functions which provides measurement resolution to

0.01 ohms on the 200 ohm rangeand I0 microvolts on the Insure that the correct form of the model number is used

200 millivolt range.

The 8040A offers 20,000 count resolution in all temperature probe and A81 battery chargerleliminator,

sunshade

AC

protects

voltage and current measure- when ordering either of these accessories.

the

41/2

digit

LED

ments are made using true rms conversion techniques for

improved accuracy in communications and industrial

1-4. Several

8040A to expand its' capabilities. A list of these

accessories is provided in Table 1-1 while more detail

about

1-5.

are configured at the factory for particular applications.

&

each

Note that two of the accessories, the 80T-150

Specifications

accessories

one

is

provided

are

available

in

Section

6.

for

use

with the

ACCESSORY

801 -600

80F-5

8OF-15

80K-40

81

RF

82R

F

~OT-I~OC

80T-150F

C88

A80

8040A-

7004K

Table

DESCRIPTION

Clamp-on current probe; 2 to 600 amps

High voltage probe; 5

High voltage probe; 15 kV

High voltage probe; 40 kV

High frequency probe; 20 kHz to

100 MHz

High frequency probe;

500 MHz

Temperature probe;

-58'

F

to

+302'

Carrying case

Deluxe test lead kit

A battery cover kit; includes 4

size alkaline batteries

kV

100 kHz to

-50'~ to

F

+I

50'~

"C"

1-1.

ACCESSORIES

ACCESSORY

8040A7005K

8040A7007

K

A81-115

A81 -1 00

~81-230-~

A81-230

DESCRIPTION

A rechargeable Ni-Cad battery pack

(batteries come secured in the battery

cover)

A battery cover intended for use with

alkaline batteries (batteries not included:

Battery

50

Battery

50 to 60 Hz line source

Battery chargerleliminator for 230V,

50 to 60 Hz line source

plug)

Battery chargerleliminator for 230V,

50 to 60 Hz line source (European

type plug)

chargerleliminator for 11 5V,

to

60 Hz line source

charger/eliminator for IOOV,

(U.S.

type

Page 8

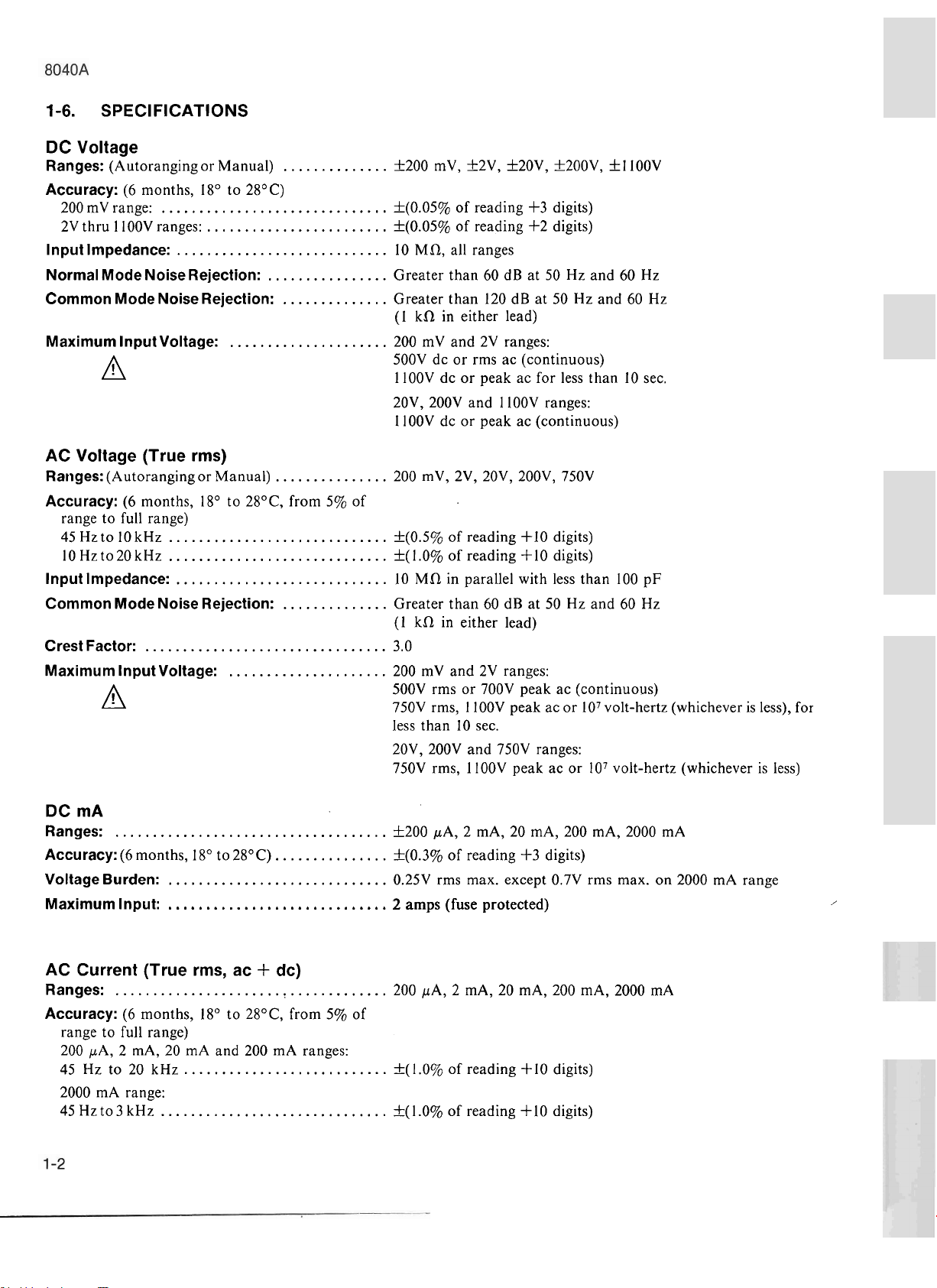

1-6.

DC Voltage

Ranges:

Accuracy:

Input Impedance:

Normal Mode Noise Rejection:

Common Mode Noise Rejection:

Maximum Input Voltage:

SPECIFICATIONS

(Autorangingor Manual)

(6 months, 18" to 28°C)

200 mV range:

1

2V thru

lOOV ranges:

..............

..............................

........................

............................

................

..............

.....................

A

AC Voltage (True rms)

Ratiges:

Accuracy:

Input Impedance:

Common Mode Noise Rejection:

Crest Factor:

Maximum Input Voltage: .....................

(Autoranging or Manual)

(6 months, 18' to 28OC, from 5% of

range to full range)

45 Hzto 10 kHz

10 Hz to 20 kHz

.............................

.............................

............................

................................

...............

..............

A

31200 mV, *2V, f20V, f 200V, f I

+(0.05% of reading f 3 digits)

f(0.05% of reading

10

MR,

all ranges

Greater than 60 dB at 50 Hz and 60 Hz

Greater than 120 dB at 50 Hz and 60 Hz

(1 kR in either lead)

200 mV and 2V ranges:

500V dc or rms ac (continuous)

1

IOOV dc or peak ac for less than 10 sec.

20V, 200V and 1 IOOV ranges:

1

IOOV dc or peak ac (continuous)

200 mV, 2V, 20V, 200V, 750V

+(0.5% of reading +I0 digits)

f

(1.0% of reading +I0 digits)

10 MR in parallel with less than 100 pF

Greater than 60 dB at 50 Hz and 60 Hz

(1

kR

in either lead)

3.0

200 mV and 2V ranges:

500V rms or 700V peak ac (continuous)

750V rms,

less than 10

20V, 200V and 750V ranges:

750V rms, 1 IOOV peak ac or

1100V peak ac or lo7 volt-hertz (whichever is less), for

sec.

+

2

digits)

IOOV

lo7

volt-hertz (whichever is less)

DC mA

Ranges:

Accuracy:

Voltage Burden:

Maximum Input:

AC Current (True rms, ac + dc)

Ranges:

Accuracy:

range to full range)

200

45 Hz to 20 kHz

2000 mA range:

45 Hz to 3 kHz

....................................

(6 months, 18" to 28°C)

...............

.............................

.............................

....................................

(6 months, 18" to 28"C, from 5% of

pA, 2 mA, 20 mA and 200 mA ranges:

...........................

..............................

+200 PA, 2 mA, 20 mA, 200

-t(0.3% of reading +3 digits)

0.25V rms max. except 0.7V rms max. on 2000 mA range

2 amps (fuse protected)

200 pA,2 mA,20 mA,200 mA,2000 mA

f

(1.0% of reading +lo digits)

+(1.0% of reading +10 digits)

mA,

2000 mA

,

Page 9

Voltage Burden:

Crest Factor:

Maximum Input:

Resistance

Ranges:(AutorangingorManual).

Accuracy:

Maximum CurrentThrough Unknown:

Open Circuit Voltage:

Maximum Inputvoltage:

General

Maximum Common Modevoltage:

Operating Temperature Range:

Temperature Coefficient:

StorageTemperatureRange:

Relative Humidity:

Line:

Battery:

(6 months, 18" to 28°C)

.......................................

.....................................

.............................

................................

.............................

..............

...............

........................

.................

............

...............

.....................

.................

...........................

.........

0.25V rms max. except 0.7V max. on 2000 mA range

3.0

2 amps rms (fuse protected)

2000, 2 kn, 20 k0, 200 k0, 2000 kfl, 20 Mf2

f

(0.2% of reading +3 digits) except 20 M0 range

f

(0.5% of reading +3 digits)

0.5 mA on 200n range

5 volts

All ranges, 25OV ac or IOOV dc

500V dc or peak ac

0°C to +50°C

<I 1 10 of applicable accuracy specification per

(0°C to 18"C, 28°C to 50°C)

-40°C to +70°C (without batteries), -40°C to +50°C (with

Ni-Cad batteries)

0 - 80% to +35"C, 0 - 70% to +50°C

1001 115/230V, 48-66

8W (charging) max.

Rechargeable Ni-Cad pack

charge, typical recharge time 14 hr. of ambient temperature

<30°C to achieve full charge). Non-rechargeable 4 alkaline

"C" cells provide 14 hr. operation (typical).

Hz,

I W (instrument only)

(8

hr. typical operation from full

oc

Size:

Weight:

.......................................

.....................................

6.4 cm high x 14.5 cm long x 12.4 cm wide

(2.5" x 5.7" x

1.0 kg (2.2 pounds)

4.9")

Page 10

Section

2

2-1. INTRODUCTION

2-2.

regarding the correct operation of the Model

Multimeter. It is recommended that the contents of this

section be read and understood before attempting to

operate the instrument. Should any difficulties arise

during operation, please contact your nearest John Fluke

Sales Representative, or the John Fluke Mfg. Co., Inc.,

P.O. Box 43210 Mountlake Terrace WA, 98043,

Telephone (206) 774-221

is located at the back of this manual.

2-3. SHIPPING INFORMATION

2-4. The 8040A was packed and shipped in a foam

container especially designed to provide adequate

protection. Upon receipt, inspect the instrument for

possible shipping damage.

2-5. If reshipment of the instrument is necessary, the

original container should be used. If the original

container is not available, a new one can be obtained

from the John Fluke Mfg. Co., Inc. Please reference the

instrument model number when requesting a new

shipping container.

2-6. INPUT POWER

2-7. Operating power for the standard 8040A

instrument comes from four, non-rechargeable, alkaline

"C"

hours of instrument operation. Optionally available

power sources include rechargeable Ni-Cad batteries and

a battery

with rechargeable batteries will typically operate for 8

hours; recharging, using the

approximately

This section of the manual contains information

8040A

I. A list of sales representatives

size batteries. The power source typically provides 14

charger/eliminator. The instrument equipped

charger/eliminator, takes

14

hours with the instrument turned off.

Operating

2-8. OPERATING FEATURES

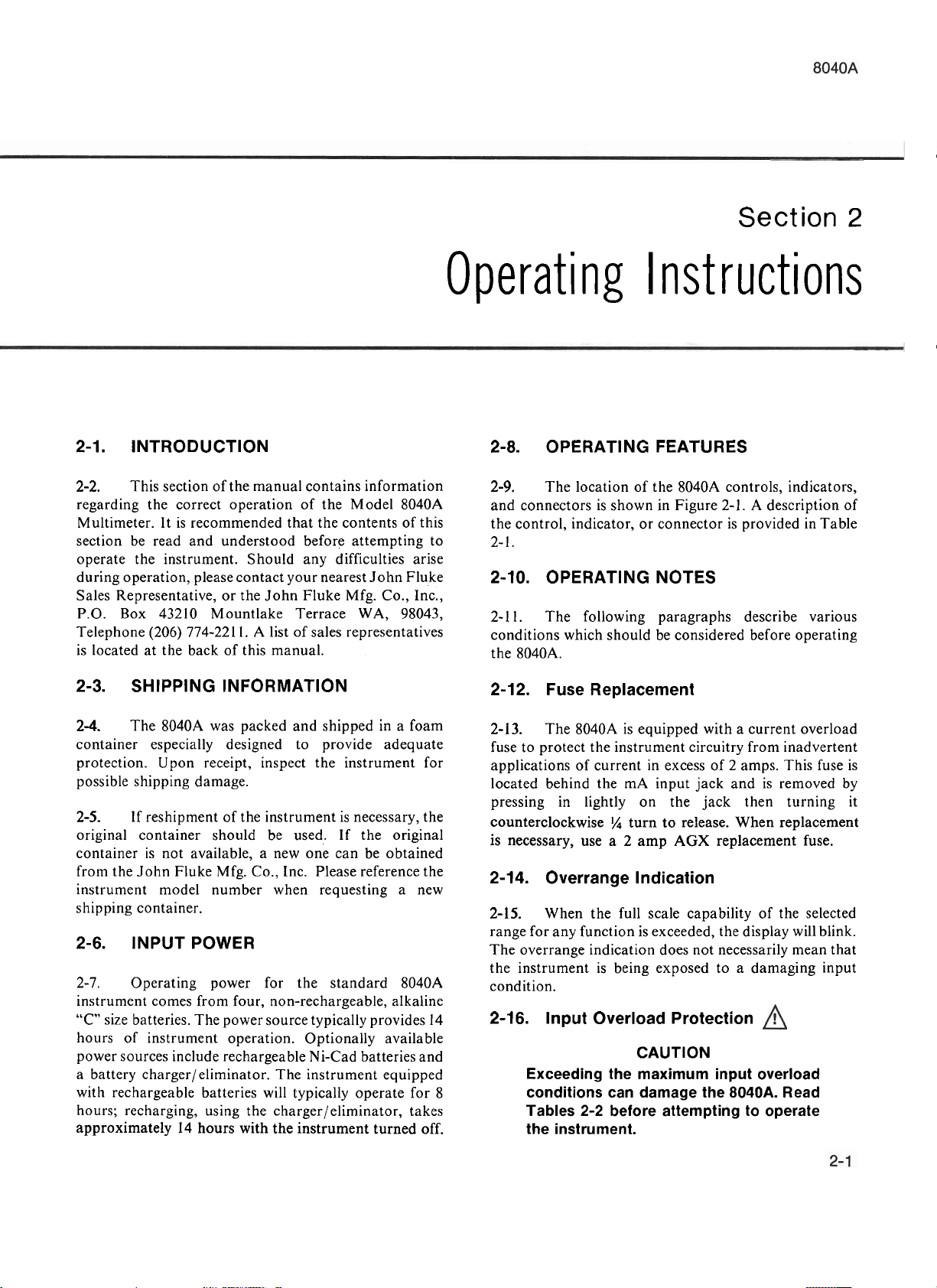

2-9.

and connectors is shown in Figure 2-1. A description of

the control, indicator, or connector is provided in Table

2-1.

2-10. OPERATING NOTES

2-11. The following paragraphs describe various

conditions which should be considered before operating

the

2-12. Fuse Replacement

2-13.

fuse to protect the instrument circuitry from inadvertent

applications of current in excess of 2 amps. This fuse is

located behind the

pressing in lightly on the jack then turning it

counterclockwise

is necessary, use a

2-14. Overrange Indication

2-15. When the full scale capability of the selected

range for any function is exceeded, the display will blink.

The overrange indication does not necessarily mean that

the instrument is being exposed to a damaging input

condition.

2-16. Input Overload Protection

The location of the 8040A controls, indicators,

8040A.

The 8040A is equipped with a current overload

Exceeding the maximum input overload

conditions can damage the

Tables

the instrument.

2-2

l

nst ructions

rnA input jack and is removed by

1/4

turn to release. When replacement

2

amp

AGX

replacement fuse.

CAUTION

8040A.

before attempting to operate

Read

Page 11

1

2

8

LEFT SlDE

RIGHT SlDE

2-2

Figure

12

2-1.

CONTROL, INDICATOR AND CONNECTOR LOCATIONS

11

10

9

Page 12

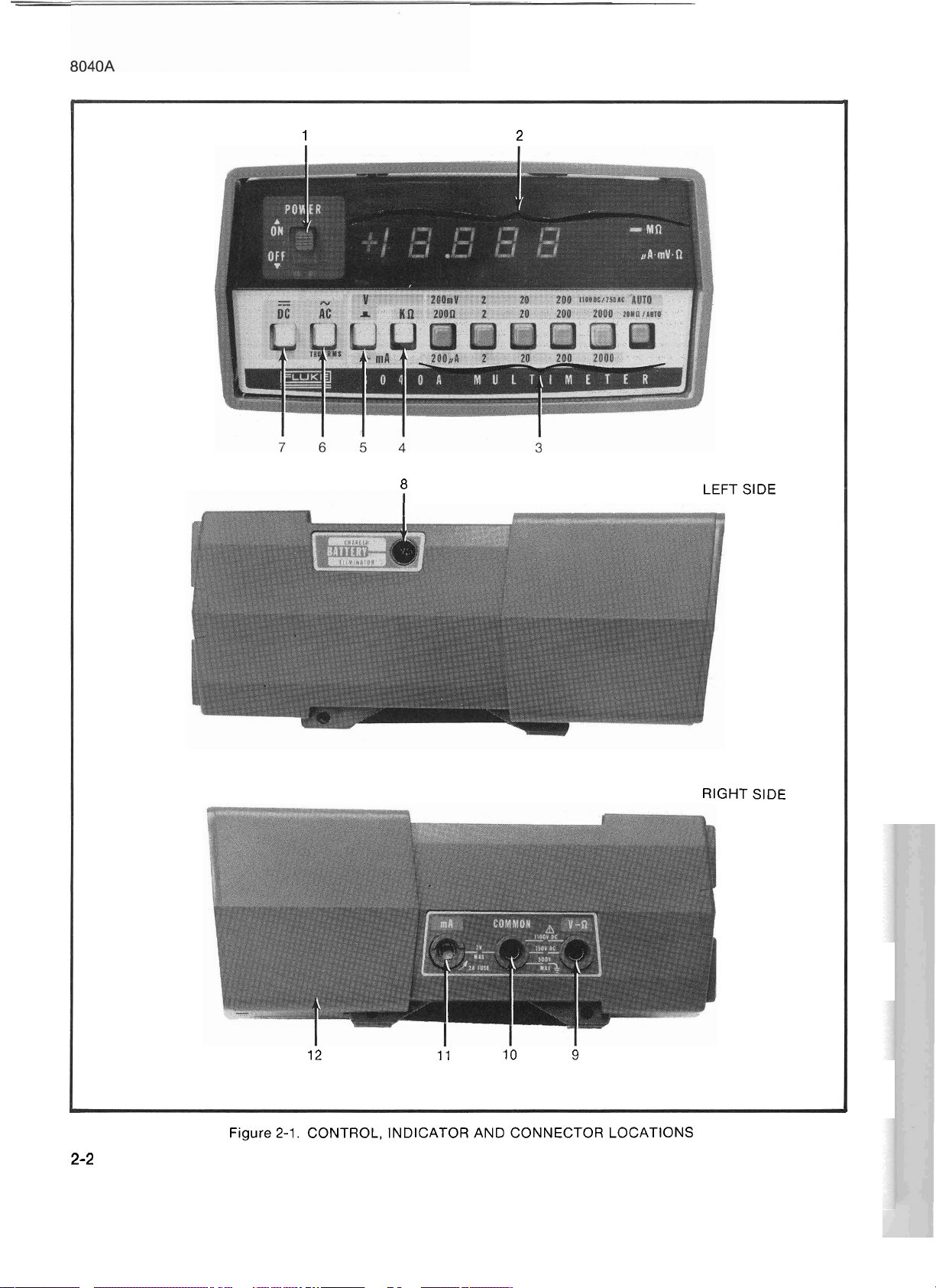

Table

2-1.

CONTROL, INDICATOR AND CONNECTOR DESCRIPTION

8040A

ITEM

NUMBER

1

2

3

4

5

6

7

NAME

POWER switch

Display

Range switches

ka

V

mA

YY

AC

-

---

DC

DESCRIPTION

Separates the power source (batteries or battery eliminator) from

8040A circuitry.

A 4% digit display (19999 maximum) of the measured input,

including decimal point and polarity sign when appropriate.

The units annunicators

applicable range

Provide pushbutton selection of one of five ranges for each

function,

DC Voltage: 200 mV, 2,20,200,1 IOOV, or AUTO

AC Voltage: 200

AC or DC Current: 200

Resistance: 200s2, 2,20,200,2000 ka, or 20 M8IAUTO

Selects resistance measurement mode of operation.

Works in conjunction with the DC and AC switches to select the

voltage function (out position) or current function (in position).

This switch, in conjunction with item 5, selects ac voltage or

alternating current measurement capability.

This switch, in conjunction with item

direct current measurement capability.

i.e.,

(Ma or FA. mV 8) light when the

is

selected.

mV, 2,20,200,750V rms, or AUTO

PA, 2,20,200, or 2000 mA

5,

selects dc voltage or

8

10

11

12

BATTERY CHARGER/

ELIMINATOR

9

V-s2

COMMON

m

A

Sunshade

Jack provided for connection of the chargerleliminator

accessory.

Jack for high (red) lead connection to

and resistance measurements.

Jack for low (black) lead connection to

Jack for high (red) lead

measurements (2A FUSE behind; push in and twist

to remove).

Shade slides forward to improve the readability of the displays in

bright light environments.

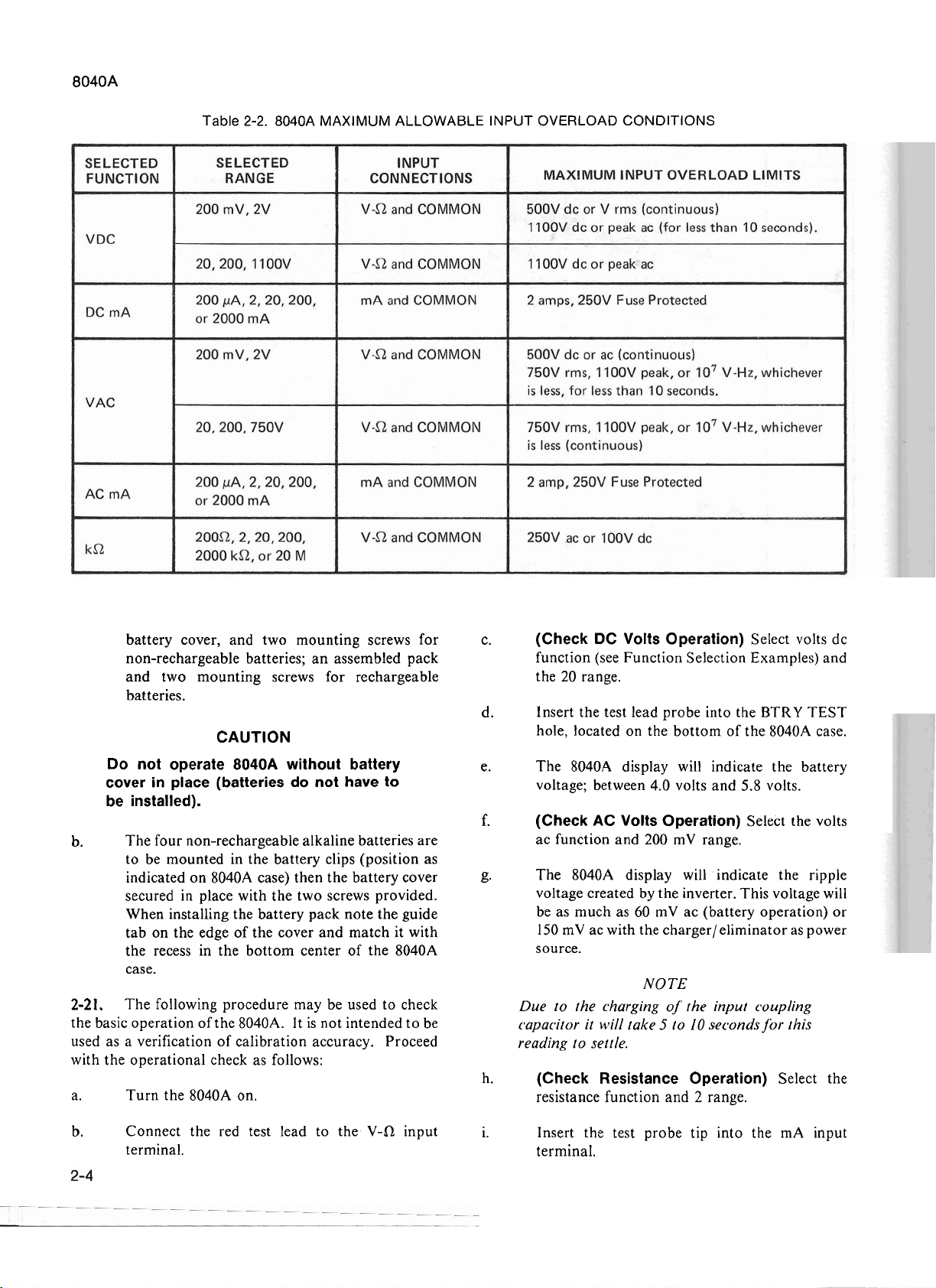

2-17. The overload protection varies with the range

and function selected. The maximum allowable input

overload condition for each function and range is given in

r able

2-2.

2-18.

ASSEMBLY AND INITIAL OPERATION

2-19. It is recommended that the assembly and initial

operation of the

8040A be done in accordance with the

following procedure. No test equipment is required to

8040A for voltage (ac or dc)

8040A for all functions.

conrlection to 8040A for current (ac and dc)

'/4

turn and pull

perform this procedure; all signals observed are generated by the

instrument operational evaluation when the

8040A. This procedure may be used as an

8040A is

being used in locations away from normal calibration

equipment.

2-20. Assemble the 8040A as follows:

a. Remove the contents of the box marked

BATTERY COVER. (Four

"C" size batteries, a

Page 13

8040A

Table

2-2.

8040A MAXIMUM ALLOWABLE INPUT OVERLOAD CONDITIONS

battery cover, and two mounting screws for

non-rechargeable batteries; an assembled pack

and two mounting screws for rechargeable

batteries.

CAUTION

Do not operate

8040A

without battery

cover in place (batteries do not have to

be installed).

b.

The four non-rechargeable alkaline batteries are

to be mounted in the battery clips (position as

indicated on

8040A case) then the battery cover

secured in place with the two screws provided.

When installing the battery pack note the guide

tab on the edge of the cover and match it with

the recess in the bottom center of the

8040A

case.

2-21.

the basic operation of the

The following procedure may be used to check

8040A. It is not intended to be

used as a verification of calibration accuracy. Proceed

with the operational check as follows:

a. Turn the 8040A on.

c.

(Check DC Volts Operation)

Select volts dc

function (see Function Selection Examples) and

the 20 range.

d.

Insert the test lead probe into the

BTRY

TEST

hole, located on the bottom of the 8040A case.

e. The 8040A display will indicate the battery

voltage; between 4.0 volts and 5.8 volts.

f.

(Check

AC

Volts Operation)

Select the volts

ac function and 200 mV range.

€5 The 8040A display will indicate the ripple

voltage created by the inverter. This voltage will

be as much as 60

mV ac (battery operation) or

150 mV ac with the charger/eliminator as power

source.

NOTE

Due to the charging oJ the inpur c~oupling

capacitor it will take 5 to

I

reading

h.

o settle.

(Check Resistance Operation)

10

secondsfbr this

Select the

resistance function and 2 range.

b. Connect the red test lead to the V-0 input

terminal.

I.

Insert the test probe tip into the mA input

terminal.

Page 14

j.

k.

The 8040A display will indicate 0.100

(Check

test lead to the

DC

mA Operation)

mA input terminal.

+2

Connect the red

1. Select the dc mA function and 2 range.

digits.

0.

P.

(Check AC mA Operation)

Select the ac mA

function.

The 8040A display will indicate the same as step

n

(mA input is dc coupled).

m. Place the test probe tip into the BTRY TEST

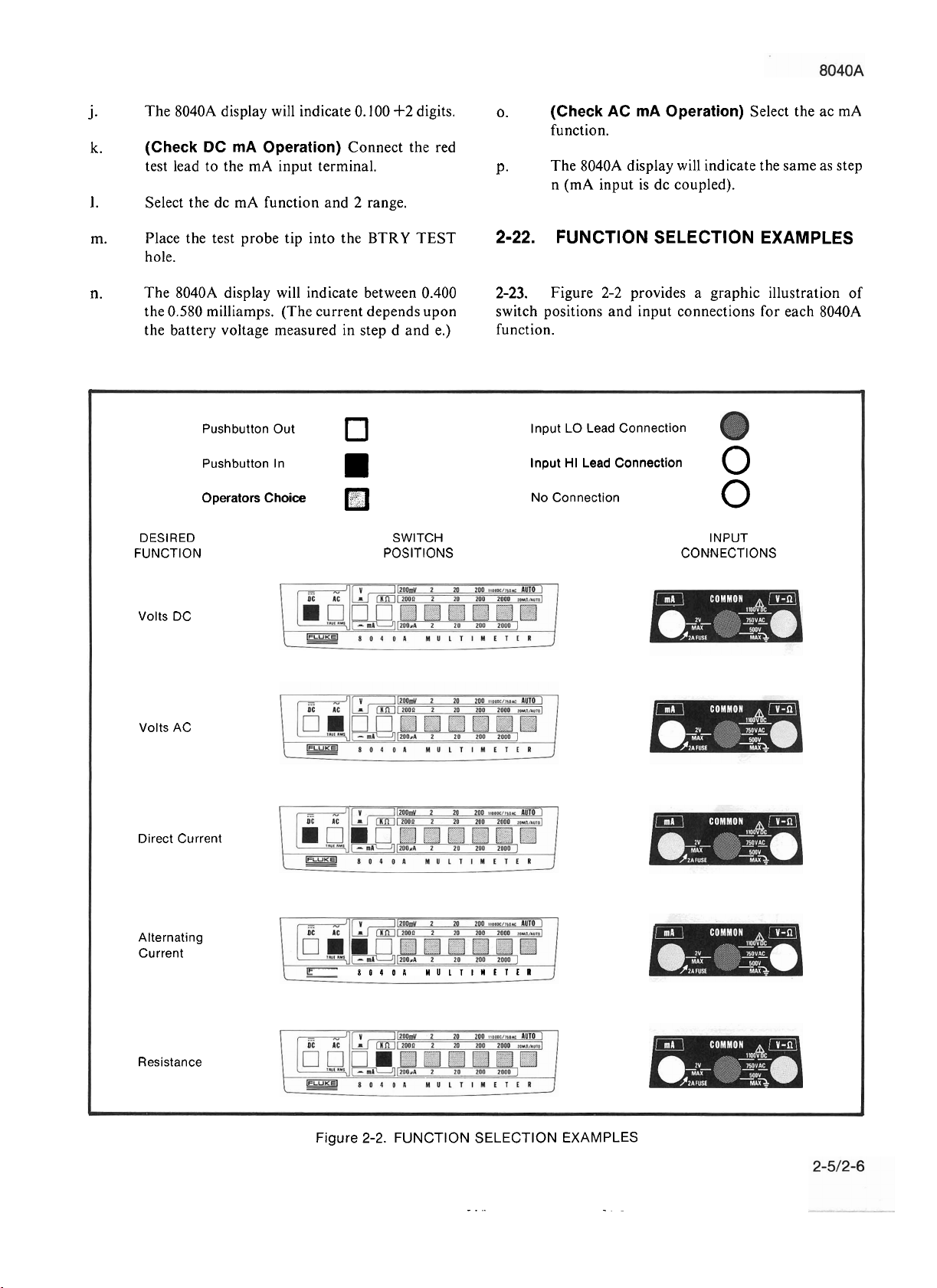

2-22.

FUNCTION SELECTION EXAMPLES

hole.

n. The 8040A display will indicate between 0.400

the 0.580

milliamps. (The current depends upon

the battery voltage measured in step d and e.)

Pushbutton Out Input LO Lead Connection

Pushbutton In

Operators Cho~ce

DESIRED SWITCH INPUT

FUNCTION POSITIONS CONNECTIONS

Volts DC

2-23.

switch positions and input connections for each

function.

Figure

Input HI Lead Connection

NO

Connection

2-2

provides a graphic illustration of

8040A

0

O

Volts AC

D~rect Current

Alternating

Current

Res~stance

Figure

80401

2-2.

MULTIMCTCR

FUNCTION SELECTION EXAMPLES

-.

.

-

Page 15

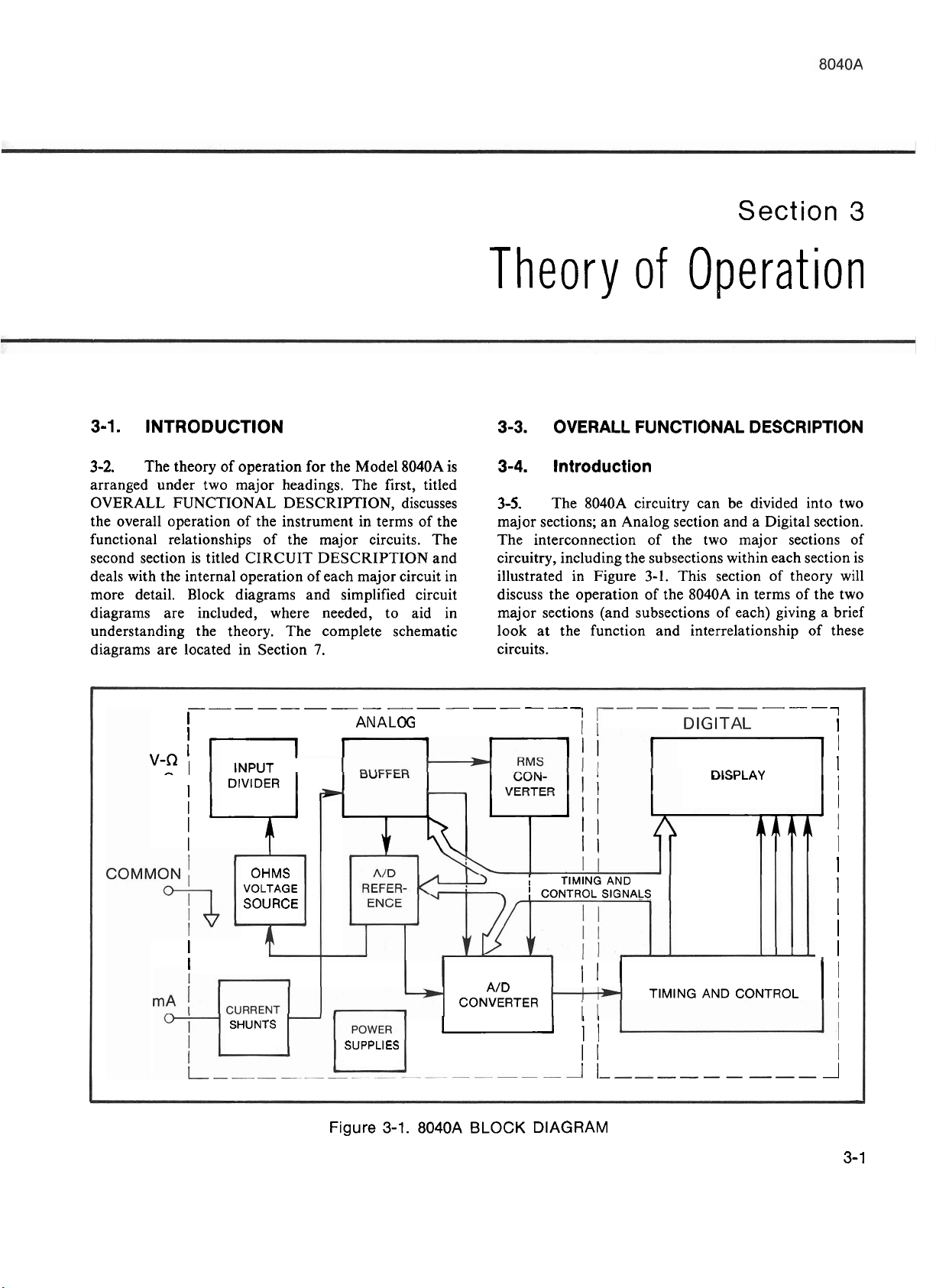

Section

3

3-1.

3-2.

arranged under two major headings. The first, titled

OVERALL FUNCTIONAL DESCRIPTION, discusses

the overall operation of the instrument in terms of the

functional relationships of the major circuits. The

second section is titled CIRCUIT DESCRIPTION and

deals with the internal operation of each major circuit in

more detail. Block diagrams and simplified circuit

diagrams are included, where needed, to aid in

understanding the theory. The complete schematic

diagrams are located in Section

INTRODUCTION

The theory of operation for the Model 8040A is

7.

-

-

-

-

-

-

-

-

-

- - -

v-n

I

I

I

I

I

I

INPUT

DIVIDER

ANALOG

I

I

OHMS

VOLTAGE

SOURCE

I

I

SHUNTS

SUPPLIES

-

Theory

3-3.

3-4.

3-5.

major sections; an Analog section and a Digital section.

The interconnection of the two major sections of

circuitry, including the subsections within each section is

illustrated in Figure

discuss the operation of the

major sections (and subsections of each) giving a brief

look at the function and interrelationship of these

circuits.

-

OVERALL FUNCTIONAL DESCRIPTION

Introduction

The 8040A circuitry can be divided into two

-

-

1

of

Operation

3-1.

This section of theory will

8040A in terms of the two

---

DISPLAY

A

i

TIMING AND

I

CONTROL SIGNALS

A/D

CONVERTER

I I

II

I

I

I

I

TIMING AND CONTROL

A

1

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

1

Figure

3-1.

8040A

BLOCK

DIAGRAM

3-

1

Page 16

3-6. Analog Circuits

3-7. The Analog portion of the 8040A circuitry

consists of an Input Divider, Buffer, RMS Converter,

Ohms Voltage Source, A/ D Reference, Current Shunts,

Power Supplies and

measured are connected to the Analog circuitry via the

V-R or

proportional to the applied input, is developed by the

Input Divider, Current Shunts, Buffer and RMS

Converter and applied to the

voltage equivalent of the applied input charges a

capacitor in the

input. A reference voltage, opposite in polarity to the

voltage representing the applied input, is then connected

to the

at a constant rate. The time it takes the capacitor to

discharge is therefore proportional to the applied input.

the Digital section of

and displays it as a digital representation of the input

circuit.

mA terminals. A dc voltage, directly

A/D causing the charged capacitor to discharge

A/D Converter. The inputs to be

A/D Converter. This dc

AID to a level proportional to the

8040A circuitry measures the time

3-8. Digital Circuits

3-9. The Digital section consists of Timing and

Control and Display circuits. The Timing and Control

Signals connect the dc voltage representing the input

being measured to the A/ D for 100 ms then disconnect

it and apply the reference voltage. At the time the

reference voltage is applied the Timing and Control

circuit starts counting the number of cycles of the

Crystal Oscillator occur until the A/ D sends a signal to

the Timing and Control circuit indicating that the

capacitor has been discharged to zero. The number of

cycles of oscillator signal that occurred is presented on

the display as the value of the unknown input being

measured by the

8040A.

be connected in series with the unknown resistance

applied to the

The Ohms Source Voltage is applied to this voltage

divider and the voltage drop across the unknown

resistance is measured by the

value of the resistance.

V-R terminal to form a voltage divider.

8040A to calculate the

3-15. Current Shunts

3-16. The Current Shunts are a set of series connected

resistors. The unknown current applied to the mA

terminal develops a voltage proportional to the

current, across the portion of the shunt resistors selected

by the range switch. The

developed across the shunt resistor and displays the

value of the input current.

8040A processes the voltage

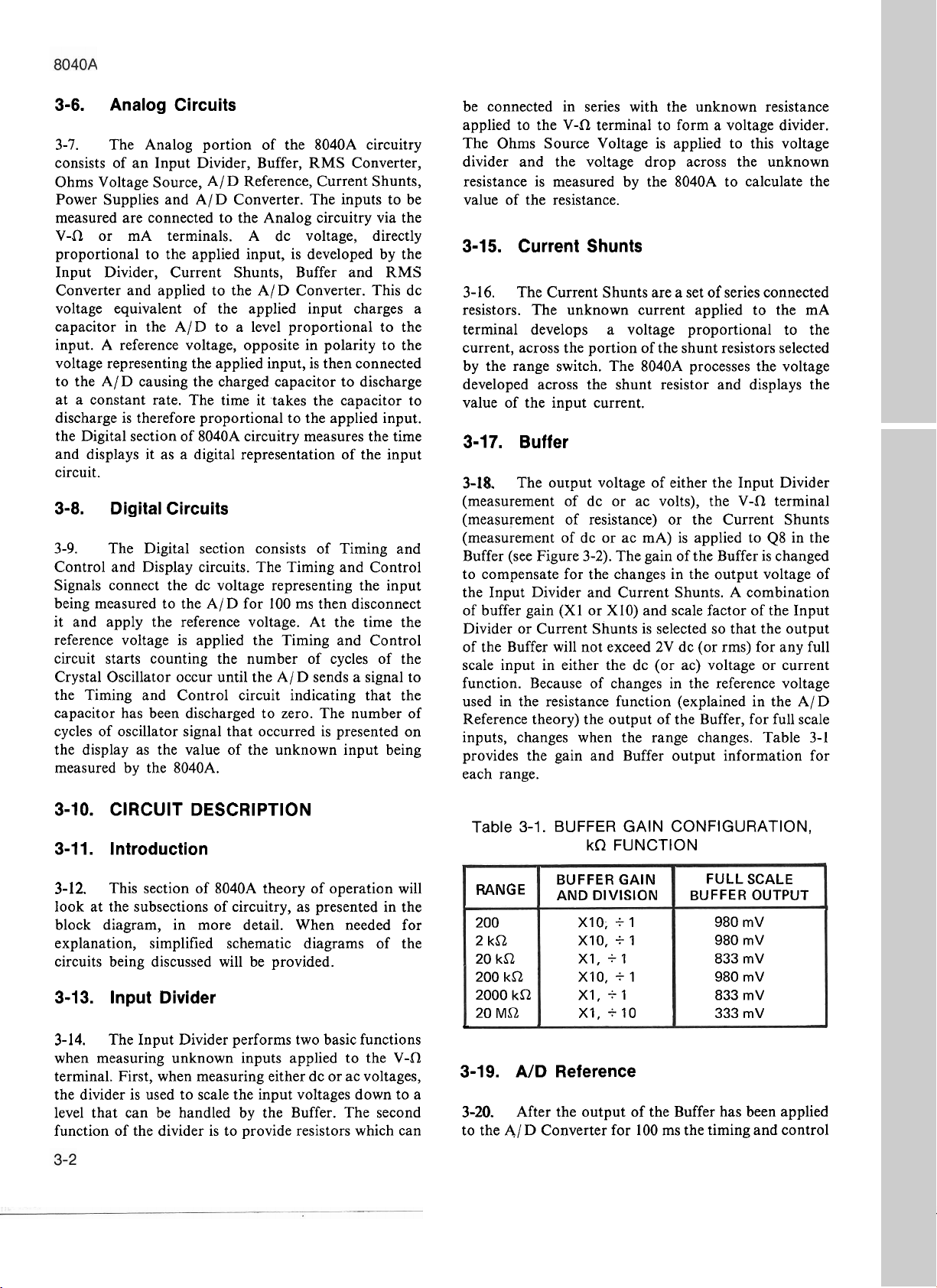

3-17. Buffer

3-18.

(measurement of dc or ac volts), the

(measurement of resistance) or the Current Shunts

(measurement of dc or ac

Buffer (see Figure 3-2). The gain of the Buffer is changed

to compensate for the changes in the output voltage of

the Input Divider and Current Shunts. A combination

of buffer gain

Divider or Current Shunts is selected so that the output

of the Buffer will not exceed 2V dc (or rms) for any full

scale input in either the dc (or ac) voltage or current

function. Because of changes in the reference voltage

used in the resistance function (explained in the

Reference theory) the output of the Buffer, for full scale

inputs, changes when the range changes. Table 3-1

provides the gain and Buffer output information for

each range.

The output voltage of either the Input Divider

V-R terminal

mA) is applied to 48 in the

(XI or X10) and scale factor of the Input

A/D

3-10. CIRCUIT DESCRIPTION

3-11. Introduction

3-12.

look at the subsections of circuitry, as presented in the

block diagram, in more detail. When needed for

explanation, simplified schematic diagrams of the

circuits being discussed will be provided.

This section of 8040A theory of operation will

3-13. Input Divider

3-14. The Input Divider performs two basic functions

when measuring unknown inputs applied to the

terminal. First, when measuring either dc or ac voltages,

the divider is used to scale the input voltages down to a

level that can be handled by the Buffer. The second

function of the divider is to provide resistors which can

V-R

Table

-

3-1.

RANGE

200

2

kfi

20

kfi

200

ka

2000

kc2

20 Ma

BUFFER GAlN CONFIGURATION,

kn

FUNCTION

BUFFER GAIN

AND DIVISION

XIO,

+

XIO,

+

XI,

+

1

XIO,

+

XI,

+I

XI, +I0

3-19. AID Reference

3-20.

to the

After the output of the Buffer has been applied

A/

D Converter for 100 ms the timing and control

1

I

I

FULL SCALE

BUFFER OUTPUT

980 mV

980 mV

833 mV

980 mV

833 rnV

333 mV

Page 17

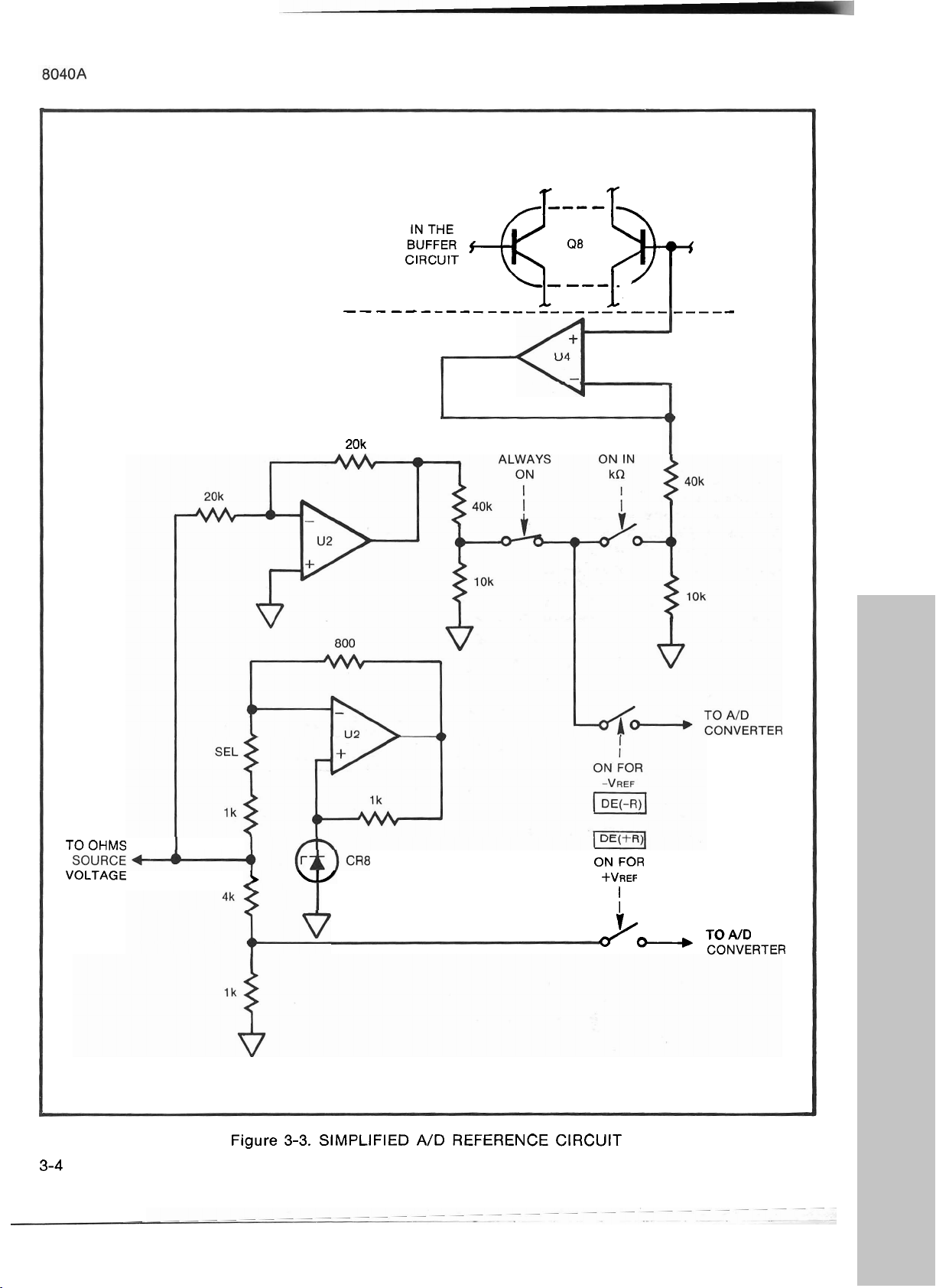

signals disconnect the Buffer output and connect the

appropriate

simplified schematic diagram of the

circuit.

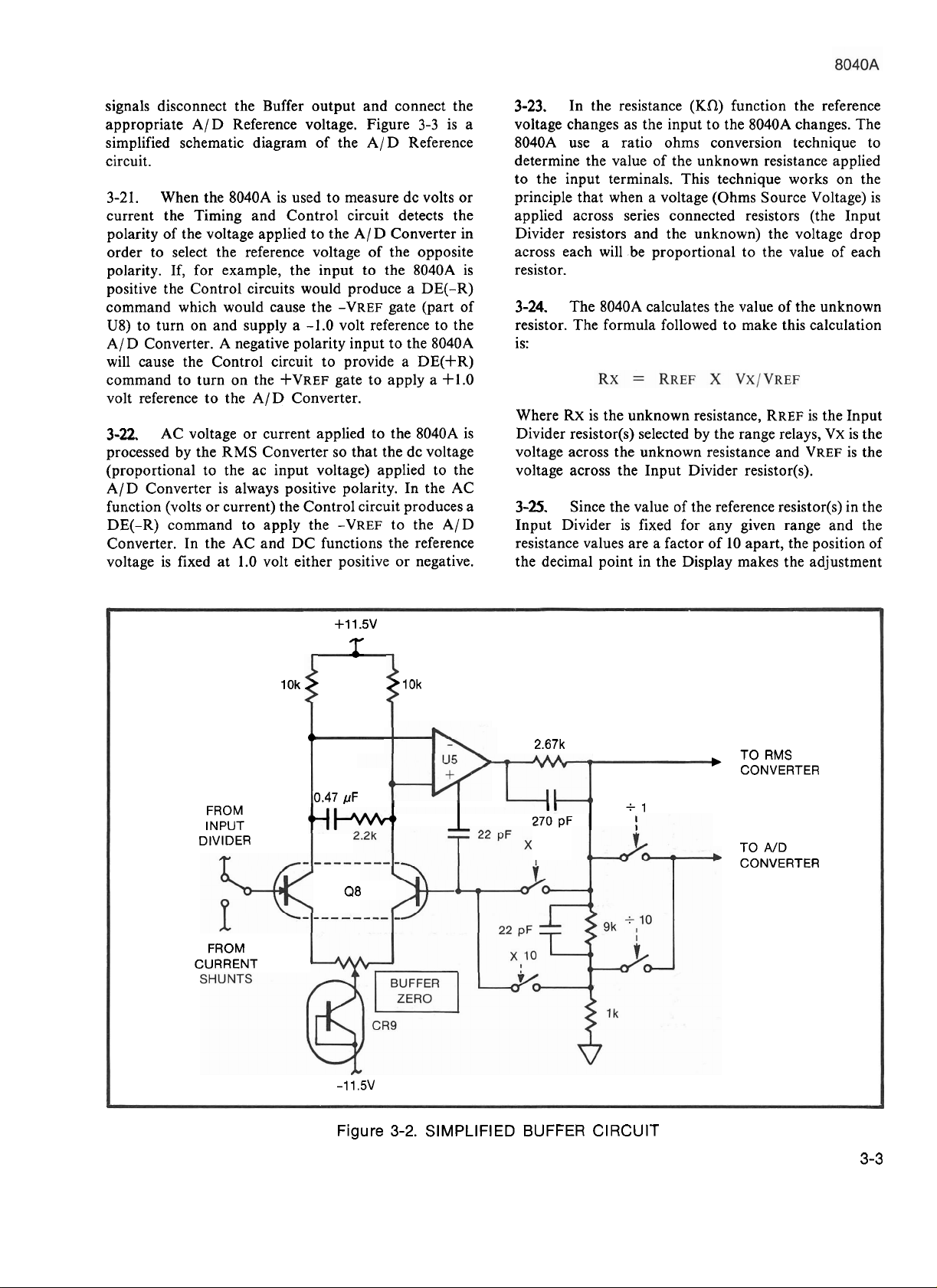

3-21.

current the Timing and Control circuit detects the

polarity of the voltage applied to the A/

order to select the reference voltage of the opposite

polarity. If, for example, the input to the

positive the Control circuits would produce a

command which would cause the -VREF gate (part of

U8) to turn on and supply a -1.0 volt reference to the

A/ D Converter. A negative polarity input to the

will cause the Control circuit to provide a DE(+R)

command to turn on the +VREF gate to apply a 4-1.0

volt reference to the A/D Converter.

3-22.

processed by the RMS Converter so that the dc voltage

(proportional to the ac input voltage) applied to the

A/D Converter is always positive polarity. In the AC

function (volts or current) the Control circuit produces a

DE(-R) command to apply the -VREF to the A/D

Converter. In the AC and DC functions the reference

voltage is fixed at 1.0 volt either positive or negative.

A/D Reference voltage. Figure 3-3 is a

AID Reference

When the 8040A is used to measure dc volts or

D

Converter in

8040A is

DE(-R)

8040A

AC voltage or current applied to the 8040A is

3-23.

voltage changes as the input to the

8040A use a ratio ohms conversion technique to

determine the value of the unknown resistance applied

to the input terminals. This technique works on the

principle that when a voltage (Ohms Source Voltage) is

applied across series connected resistors (the Input

Divider resistors and the unknown) the voltage drop

across each will be proportional to the value of each

resistor.

3-24. The 8040A calculates the value of the unknown

resistor. The formula followed to make this calculation

is:

Where RX is the unknown resistance, RREF is the Input

Divider

voltage across the unknown resistance and VREF is the

voltage across the Input Divider

3-25.

Input Divider is fixed for any given range and the

resistance values are a factor of 10 apart, the position of

the decimal point in the Display makes the adjustment

In the resistance

resistor(s) selected by the range relays, Vx is the

Since the value of the reference resistor(s) in the

(KR)

function the reference

8040A changes. The

resistor(s).

+11.5v

T

10k 10k

41

0.47 pF

FROM

INPUT 270 pF

DIVIDER

Q8

FROM

CURRENT

2.67k

+

.

TO

RMS

CONVERTER

1

TO

A/D

CONVERTER

-1 1.5V

Figure

3-2.

SIMPLIFIED BUFFER CIRCUIT

3-3

Page 18

IN

THE

BUFFER

CIRCUIT

f++!!-ii

-

---

-)-

-

---------

20k

---------------

----

-

3-4

TO OHMS

VOLTAGE

Figure

3-3.

SlMPLl

FlED

A/D

REFERENCE CIRCUIT

ON FOR

+VREF

I

I

v

d-

TO

A/D

CONVERTER

Page 19

for the RREF term in the formula. The 8040A directly

reads the value of

output to the

VREF is determined by algebraically adding

positive voltage) to a negative equivalent of the ohms

source voltage. The resulting voltage is VREF and is

applied to the

application of

Vx and applies the resulting Buffer

AID Converter for 100 ms. The value of

VX (a

A/D Converter at the end of the 100 ms

Vx.

3-31.

~ulti~lier-Divider function is performed using a LogAntilog circuit. The base-emitter voltage of a transistor

is almost perfectly logarithmically related to the

collector current.

obtain two times the log of the input; then by taking the

antilog we obtain a voltage proportional to the square of

the input

In the 8040A implicit conversion method the

By

putting two transistors in series we

(Vi2).

3-26.

3-27.

positive voltage source in the

ational amplifier

schematics in Section 7) make up the unity gain buffer

amplifier that supplies the ohms source voltage. The

Ohms Voltage Source circuit is used exclusively in the

resistance measurement function.

3-28.

3-29. An rrns amplitude is that value of alternating

current or voltage that results in the same power

dissipation in a given resistance as dc current or voltage

of the same numerical value. The mathematical formula

for determining the rms value of an ac voltage is:

Where Vi is the value of the ac voltage at any given

instant. The

instantaneous voltage and computes the rrns value of the

input signal.

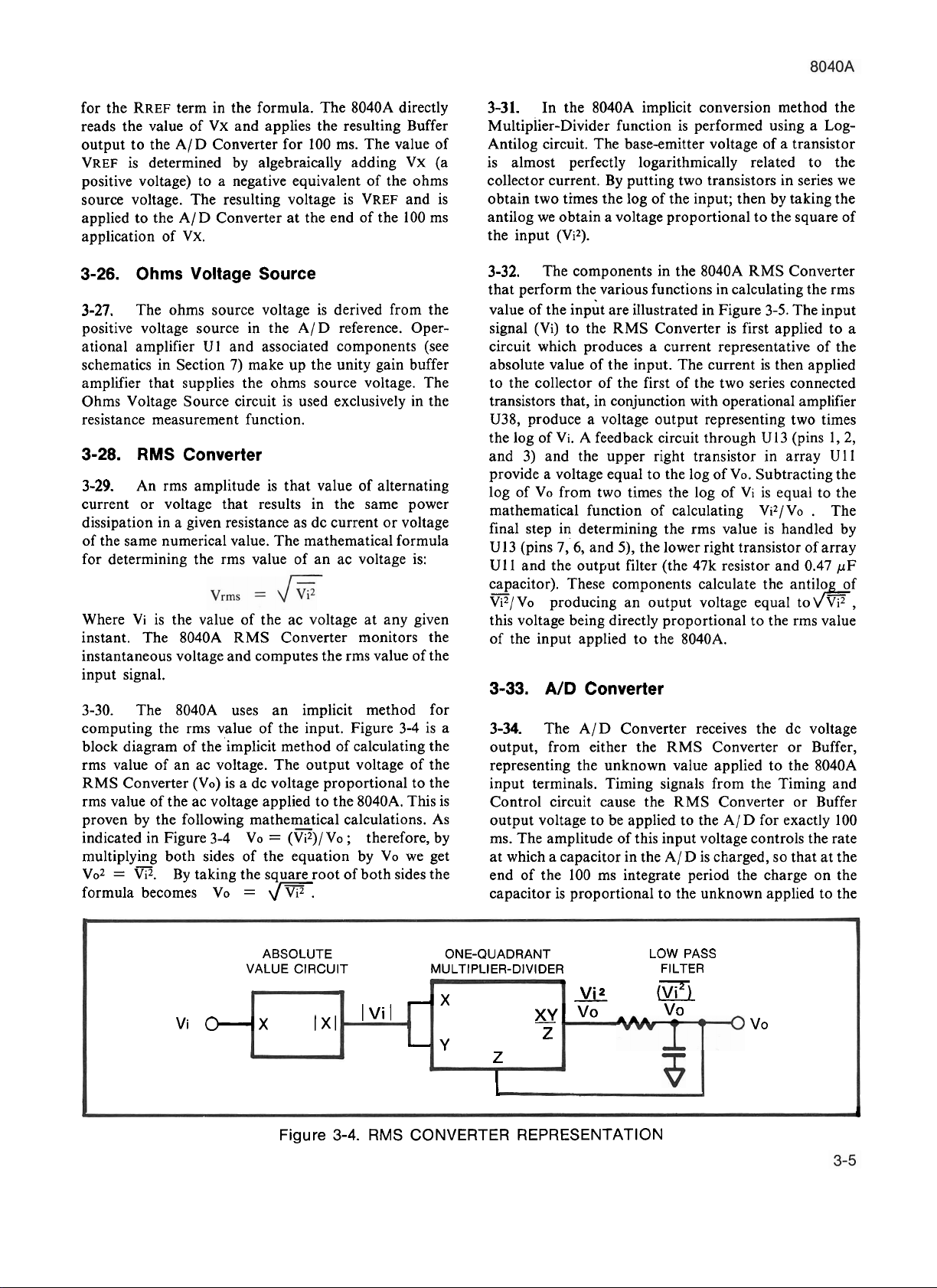

3-30. The 8040A uses an implicit method for

computing the rrns value of the input. Figure 3-4 is a

block diagram of

rms value of an ac voltage. The output voltage of the

RMS Converter (VO) is a dc voltage proportional to the

rrns value of the ac voltage applied to the

proven by the following mathematical calculations. As

indicated in Figure 3-4 Vo

multiplying both sides of the equation by Vo we get

Vo2

formula becomes Vo

Ohms

The ohms source voltage is derived from the

Voltage Source

AID reference. Oper-

U1 and associated components (see

RMS Converter

8040A RMS Converter monitors the

the'implicit method of calculating the

8040A. This is

=

(K)/VO ; therefore, by

=

Vi2. By taking the square root of both sides the

=

m.

3-32. The components in the 8040A RMS Converter

that perform the various functions in calculating the rrns

value of the

signal (Vi) to the RMS Converter is first applied to a

circuit which produces a current representative of the

absolute value of the input. The current is then applied

to the collector of the first of the two series connected

transistors that, in conjunction with operational amplifier

U38, produce a voltage output representing two times

the log of Vi. A feedback circuit through U 13 (pins

and 3) and the upper right transistor in array U11

provide a voltage equal to the log of Vo. Subtracting the

log of Vo from two times the log of Vi is equal to the

mathematical function of calculating

final step in determining the rrns value is handled by

U13 (pins

U11 and the output filter (the 47k resistor and 0.47

capacitor). These components calculate the antilo of

V/VO

this voltage being directly proportional to the rms value

of the input applied to the

3-33.

3-34. The AID Converter receives the dc voltage

output, from either the RMS Converter or Buffer,

representing the unknown value applied to the

input terminals. Timing signals from the Timing and

Control circuit cause the RMS Converter or Buffer

output voltage to be applied to the

ms. The amplitude of this input voltage controls the rate

at which a capacitor in the

end of the 100 ms integrate period the charge on the

capacitor is proportional to the unknown applied to the

inpit are illustrated in Figure 3-5. The input

Vi2/Vo . The

7,6,

and

5),

the lower right transistor of array

producing an output voltage equal to&,

8040A.

AID

Converter

A/ D for exactly 100

A/D is charged, so that at the

1,2,

pF

8040A

Vi

O---X

ABSOLUTE

VALUE

CIRCUIT

I

XI

I

Vi

I

ONE-QUADRANT

MULTIPLIER-DIVIDER

-

X

-

Y

XY

z

3

Vi2

-

VO

z

I

Figure 3-4. RMS CONVERTER REPRESENTATION

LOW

FILTER

-

(vi2)

vo

PASS

vo

b

Page 20

8040A. At the end of the 100 ms integrate period the

input to the

AID is then connected to the AID

Reference. The reference voltage is selected, by the

Timing and Control circuit, to be opposite in polarity

from the output of the Buffer or RMS Converter. The

reference voltage causes the capacitor in the

AID

Converter to discharge at a constant rate. The time,

called read period, that it takes the capacitor to

discharge is directly proportional to the unknown input

applied to the

8040A. Figure

3-6

illustrates the charge-

discharge cycle of the A/D capacitor for ac or dc volts

or current inputs. The charge-discharge cycle of the

A/ D capacitor in the

Ki2

function is unique because the

reference voltage is inversely related to the unknown

resistance value. This causes the discharge rate (slope)

during the read period to change with the input.

3-35. Timing and Control

3-36.

with the

an analog representation of the unknown input into a

digital representation. Signals from the Timing and

Control circuit select the Buffer gain and the signal path

for processing the unknown input. Correct timing of

these signals is derived from a 1

oscillator.

The Timing and Control circuit, in conjunction

A/D Converter output, change what has been

MHz

crystal controlled

3-37.

All of the digitizing process (the actual counting

of the oscillator pulses during the read period) takes

place in the custom integrated circuit

U25.

The pulses

accumulate, during the read period, in decade counters

within the custom chip. The number in each decade

counter is converted to a four-bit binary code. Strobe

signals, generaed by the custom chip, then cause the

binary code for one decade counter at a time to be sent

to the Display circuitry where the same strobe signal

causes one of the LEDs of the display to be

to display

that number.

strobed on

3-38. Display

3-39.

through ST7) some of which are used by the Display

circuits to turn on the LEDs one at a time. The four-bit

binary coded digit information applied to the Display is

first changed, by

the binary code to seven driver signals; one for each

segment in the LEDs. The seven segment drive signals

are connected in parallel to each of the display digits.

The strobe signals allow only one display LED to light

at a time. The strobe signal causes the digit in the display

corresponding to the digit with the same significant

value transmitted from the Timing and Control circuit

to appear in the correct position.

The custom chip provides strobe signals

U27

(see schematic in Section

7),

(ST@

from

20k

I

I

I

I

I

I CIRCUIT

I

I

ABSOLUTE VALUE

VOLTAGE-TO-CURRENT

Figure

I

I

I

I

I

I

3-5.

SIMPLIFIED RMS

2

X

LOG

OR

SQUARING

CIRCUIT

I

I

LOG FEEDBACK

I

CIRCUIT

I

I

CONVERTER

I

I

I

I I

CIRCUIT

40k

AND OUTPUT

FILTER

CIRCUIT

,

1

FILTER

1

I

I

I

Page 21

AID INTEGRATOR

OUTPUT VOLTAGE

CLOCK

OSCILLATOR

SIGNAL

INTEGRATE PERIOD

SLOPE is proportional to the

instrument input signal

t

I

I

A

\

I

I

wL

100

ms READ PERIOD

TIME is proportional

the instrument, input

signal

t

I

ZERO

LEVEL

J

to

I

J

J

Figure

3-6.

DUAL-SLOPE AID CONVERSION TIMING FOR VAC OR VDC INPUTS

Page 22

Section

Maintenance

WARNING!

THESE SERVICING INSTRUCTIONS ARE FOR USE BY QUALIFIED PERSONNEL ONLY. TO

AVOID ELECTRIC SHOCK, DO NOT PERFORM ANY SERVICING OTHER THAN THAT

CONTAINED IN THE OPERATING INSTRUCTIONS UNLESS YOU ARE QUALIFIED TO DO SO.

4

4-1,

4-2.

on service, general maintenance, performance tests,

calibration, and troubleshooting. The performance test

is recommended as a preventative maintenance tool, and necessary to maintain the

should be executed when it is necessary to verify that the equipment is not available, other equipment having

instrument is operating within the specification limits.

INTRODUCTION

This section of the manual contains information

Table 4-1. RECOMMENDED

NOMENCLATURE

AC Calibrator

DC Calibrator

DC Current

Cali brator

Voltage Range: 0 to 750V ac

Frequency Range: 45

Voltage Accuracy: 45 Hz to

Voltage Range: 0 to 1 100V dc

Accuracy:

Current Range:

Accuracy: 0.03%

MINIMUM

calibration interval of 6 months is recommended to

insure that the

stated in Section 1.

A

4-3.

equivalent specifications may be used.

Table 4-1 lists the recommended test equipment

TEST

USE SPECIFICATIONS

Hz

to 120 kHz

10 kHz .

10kHzto120kHz

-

+

0.005%

0 to 2 mA

8040A

performs within the specifications

EQUIPMENT

.

.

. . 0.1%

.

. .

.

0.2%

8040A.

If the specified

RECOMMENDED

EQUIPMENT

John Fluke

Model

and 5205A

John Fluke

Model 33308

John Fluke

Model 33308

5200A

DC Current

brator

Cali

Digital Multimeter

Resistor Decade

Oscilloscope

Counter

2

-

mA to 2A

0.03%

%

Current Range:

Accuracy:

DC Voltage Accuracy: 0.1

Resistance Accuracy: 20.04%

General Purpose with 10 Mi2 probe

-

+25 ppm at 1 MHz

John Fluke

Model 382A

John Fluke

Model 8040A

ESI DB62

Tektronix 465

John Fluke

Model 1900A

Page 23

4-4. GENERAL MAINTENANCE

4-5. Access Information

4-6.

the interior of the 8040A:

1.

Use the following procedure to gain access to

Set the POWER switch to OFF and disconnect

the battery charger eliminator, if attached.

9.

10. The A4 pcb can be removed with upward

Remove the circuit shield covering the A4

(Input) pcb and switches for inspection or

troubleshooting purposes. One screw holds it in

place.

pressure and a gentle rocking motion.

2.

3.

Remove the fuse from the mA jack (press in,

turn counterclockwise

Remove the two screws holding the battery

holder to the rear of the instrument and remove

the holder and batteries.

'/4

turn to release).

NOTE

The rechargeable batteries are secured to the

battery holder and are removed as one unit.

4.

Remove the screw from the center of the rear

panel of the instrument case and slide the

8040A out of the case.

NOTE

Do not attempt to remove the sunshade

when the

8040A

is in the case. The sunshade

does not have to be removed to slide the

instrument out

There are two wires connecting the

8040A circuitry to the battery contactors

in the case. Use care not to place

excessive strain on these wires.

of the case.

CAUTION

11. When reassembling the 8040A, protect the

flexible lands by first folding the switch section

of the

towards the vertical A2 and A3 pcbs. Tip the

bottom edge of the front panel up to clear the

switches. Insure that the A2 and A3 boards fit

into the plastic board edge retainers on each

side.

4-7. Cleaning

4-8.

alcohol or a mild solution of detergent and water. Clean

dust from the circuit board with low pressure dry air.

Contaminates can be washed from the circuit board

with demineralized water and a soft brush (avoid getting

excessive amounts of water on the switches).

4-9. Fuse Replacement

Clean the front panel and case with denatured

Do not use aromatic hydrocarbons or

chlorinated solvents for cleaning. These

solutions will react with the plastic

materials of the instrument.

A1 pcb then the display section up

CAUTION

5.

6.

7.

8.

Unplug the battery power wires from the 8040A

circuit board.

Loosen the two screws securing the circuit

board to the top of the front panel. DO NOT

REMOVE THEM!

Remove the two screws securing the circuit

board to the bottom of the front panel.

Set the 8040A, front panel up, on a flat surface

and gently lift the bottom edge of the front

panel up to clear the switch buttons. Gently lay

the switch and display sections of the

down on the flat surface.

CAUTION

Do not bend the circuit board backwards

past the flat position as damage to the

flex joints may occur.

A1 pcb

4-10. A fuse, located behind the mA input jack,

provides protection against current inputs that exceed 2

amps. When replacement is required, use only a AGX 2

amp fuse as a replacement. This fuse is removed by

pressing in on the

counterclockwise

4-11. PERFORMANCE CHECK

4-12.

verifying that the overall operation of the

within required limits. This procedure can be used as a

acceptance test for receiving inspection and as a periodic

maintenance -check. Refer to Table 4-1 for the test

equipment

8040A fail to meet the requirements of these checks

calibration and/or troubleshooting will be necessary.

See Table 4-1 for recommended calibration equipment.

Perform this procedure under environmental conditions

of 23

The performance check provides a means of

recodmended for these checks. Should the

f

5OC at relative humidity less than 80%.

mA input terminal then turning it

'/4

turn to release.

8040A is

Page 24

WARNING

REFER TO THE REQUIRED METHOD

FOR VOLTAGE SOURCE CONNECTION

(THIS SECTION) FOR VOLTAGE SOURCE

CONNECTION PROCEDURE.

4-14.

voltage source (see Table

be applied to the

This procedure requires the output of a dc

4-l), set to specified levels, to

8040A V-R and COMMON input

while the display is observed to be within specific limits.

Select the DC V function then refer to Table 4-2 for the

ranges and inputs for the performance check.

limits. Select the DC mA function then refer to Table

4-5 for the ranges and inputs for the current check.

4-21. Alternating Current

4-22.

not be checked because the accuracy of the shunts is

established by the direct current check and the

frequency response is determined by the ac converter

which is checked during the ac voltage check.

Table

The alternating current mode of operation need

4-3.

AC VOLTAGE PERFORMANCE CHECK

8040A

RANGE

ACVOLTS

INPUT

INPUT

FREQ

8040ADlSPLAY

LIMITS

Table

4-2.

DC VOLTAGE PERFORMANCE CHECK

8040A

RANGE

200 mV

2

2

20

20

200

200

1100

dc

1100

dc

DC VOLTS

INPUT

190.00 mV

1.900V

0.90V

19.00V

9.00V

190.00V

50.00V

10OO.OOV

450.00V

8040A DISPLAY

LIMITS

to

to

to

to

to

to

to

to

to

190.1 3

1.901 2

0.9007

19.012

9.007

190.12

50.05

1000.7

450.4

189.87

1.8988

0.8993

18.988

8.993

189.88

49.95

999.3

449.6

4-16. During this procedure ac voltage levels at

specified frequencies are applied to the

8040A V-R and

COMMON inputs and the displays observed to be

within'specific limits. Select the AC V function then

refer to Table

4-3

for the ranges and inputs for the

performance check.

4-17. Resistance Measurements

4-18.

be applied to the

the display observed to be within specified limits. Select

the

and inputs for the performance check.

This procedure calls for precision resistance to

8040A V-R and COMMON inputs and

KR function then refer to Table

4-4

for the ranges

4-19. Direct Current

4-20. This procedure calls for known values of direct

current to be applied to the

inputs and the display observed to be within specified

8040A mA and COMMON

200 mV

200 mV

200 mV

2

2

?

20

20

20

200

200

750

750

Table

8040A

RANGE

AUTO

AUTO

AUTO

2000 k!2

200i-L

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

1

190.0 mV

190.0 mV

190.0 mV

1.900V

0.900V

1.900V

19.00V

8.00V

19.00V

190.0V

190.0V

750V

750V

4-4.

RESISTANCE PERFORMANCE CHECK

RESISTANCE

INPUT

SHORT

SHORT

OPEN

1.0 Ma

1

OOn

1

.OO

5.00 ki-L

10.0 kc2

100 kc2

500 kQ

10.0

Use a good quality shorting bar between the

50Hz

5 kHz

20 kHz

50 Hz

10 kHz

20 kHz

50 Hz

5 kHz

20 kHz

50 Hz

20 kHz

50 Hz

13 kHz

@

@

kS1

MQ

188.95to191.05

188.95

188.00

1.8895

0.8945

1.8800

18.895

7.950

18.800

0.89405

188.00

745.2

741.5

8040A DISPLAY

00.00

Lead Res Value

Flashing

997.7

99.77

.9977

4.987

9.977

99.77

498.7

9.947

and COMMON-input terminals.

2

Connect the test leads that will be used to connect

the

8040A

to the decade resistance source. Place

the short at the end of the test leads that will be

connected to the resistance source. Note the

resistance value indicated on the

3

Add the lead resistance value to the input resistance

value to determine the correct

8040A

8040A

to

to

to

to

to

to

to

to

to

to

to

to

LIMITS

to

00.03

+I

.8888

to

1002.3

to

100.23

to

1.0023

to

5.013

to

10.023

to

100.23

to

501.3

to

10.058

display.

display.

191.05

192.00

1.91 05

0.9055

1.9200

19.1 05

8.050

19.200

0.9055

192.00

7.548

7.585

@

@

@

V-a

Page 25

4-4

Figure

4-1.

CALIBRATION ADJUSTMENT CONTROLS

Page 26

8040A

RANGE

Table

4-5.

DIRECT CURRENT

PERFORMANCE CHECK

DIRECT CURRENT

l

NPUT

8040A

LIMITS

ground connection will insure that voltage potential,

harmful to the calibration or repair technician, will not

be present on the instrument's common circuits.

DISPLAY

WARNING

+I

89.40

to

+I

200

pA

2

20

200

2000

+I

90.0

+I

.900

+I

9.00

+I

90.0

+I900

pA

mA

mA

mA

mA

+I

.8940

+18.940

+I

89.40

+1894.0

90.60

to

+I

.9060

to

+19.060

to

+I

90.60

to

+1906.0

NOTE

In the AC

mA function inputs to the 8040A

are dc coupled this aIIows this function to be

checked with a dc

mA input. Do t.his by

seIecting the AC mA function and 2 range.

+1.9

Apply

mA dc to the mA input. The

8040A display should read between 1.8800

and 1.9200.

4-23.

CALIBRATION

4-24. Calibration of the Model 8040A should be done

after repairs have been made to the electronic circuitry

or when the performance check indicates the unit is not

operating within the specification. Table 4-1 provides a

list of test equipment required to calibrate this

instrument. These procedures should be performed

under environmental conditions of 23

f

5OC at a relative

humidity of less than 80%.

Insure that the voltage source connection method illustrated in Figure

4-2

is used. Other connection methods may

cause hazardous voltages to be present

on the

8040A

common circuits.

DO NOT CONNECT

GROUND

GROUND AND OUTPUT

LINK BETWEEN

LOW

4-25.

It is recommended that the 8040A circuit board

remain folded up and attached to the front panel. All

adjustments and test points are accessible through the

open sides of the folded up unit. The location of each

calibration adjustment is illustrated in Figure 4-1. The

steps of this procedure must be performed in the order

presented.

NOTE

The physical position of some components

may affect the ac calibration of the

instrument. Avoid moving the components,

especially after the calibration procedure has

been completed.

4-26.

Required Method for Voltage Source

Connection

4-27.

When a DMM is opened for servicing, the

voltage source connections to it must be made in the

manner shown in Figure 4-2. This method is required

for PERSONAL SAFETY. Since a DMM has no earth

ground connection in itself, the earth ground connection

must be

suplied from the voltage source. The earth

Figure

4-28.

1.

4-2.

REQUIRED METHOD

SOURCE CONNECTION

FOR

VOLTAGE

Perform the 8040A calibration as follows:

On the

8040A

select the AC

mA

function and

range.

2.

3.

Connect the positive lead of the test equipment

voltmeter to TPI on the

to the

8040A COMMON input terminal.

8040A and the low lead

Adjust R42 for a voltmeter reading of -0.001 to

+0.001 volts.

\,

4. Disconnect the teht,equipment voltmeter.

5.

Select the DC V function.

2

Page 27

8040A

Table 4-6. DC VOLTAGE CALIBRATION

I

STEP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

*

Reverse the polarity of the applied input

RANGE

200 mV

200 rnV

2

2

2

2

2

200

rnV

200 mV

Repeat steps 8 and 9 until the tolerance is equal

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

INPUT

SHORT

OPEN

-1.9000V

+I

0.0000v

-1.9000V

-1.8000V

+I 90.00 mV

1

-190.00 mV

+190.00V

+I

+I

OPEN

+lOOO.OV

SHORT

-1OOO.OV"

.9000V

.9000V

9.000V

ADJUST

-

-

R31

R38

-

-

-

R60

1

R60

R

-

-

-

R3

-

-

(1000

9

volts) by decreasing the voltage source output to zero, inverting the

8040A

DISPLAY

00.00

00.00

-1

+I

.oooo

-1 .go00

-1.8000

+I

1

-190.00

in

+I

+I

+I

00.00

+1000.0

00.00

-1 000.0

.go00

.go00

90.00

each polarity.

90.00

.go00

9.000

output lead at the voltage source output jacks, then increase the voltage to

Voltage Source Connection).

i

ANNUNCIATOR

mV

L!

mV

L!

-

-

-

-

rnV

L!

1

mV

L!

-

-

-

rnV

L!

-

rnV

C?

-

1000

volts (see Required Method for

pA

pA

pA

pA

pA

pA

TOLERANCE

-00.02

-01

exactly

exactly

-.0002

-1.8998

-1.7998

+189.98

1

-189.98

exactly

+I

.8998

+18.998

-01

exact1 y

-00.02

-999.8

.OO

.OO

to

+00.02

to

+01

-1.9000

+I

.9000

to

+.0002

to

-1.9002

to

-1.8002

to

+190.02

to

-1 90102

+I

90.00

to

+1.9002

to

+19.002

to

+01

1000.0

to

+00.02

to

-1 000.2

>

.OO

.OO

6. Select the ranges and apply (using the 15. Apply 4-100 mV dc to the mA input terminal.

recommended method) the inputs indicated in

Table 4-6. Observe the

within the tolerances described and, when

necessary, make the adjustments indicated.

7. Disconnect the dc voltage source from the

8040A input.

8040A for a display

NOTE

fie fuse holder (mA input terminal) and fuse

should be connected to the positive plug on a

GR

type connector so that the fuse will be

-

-

held in the proper place when negative

terminal is plugged into the

COMMON

input terminal. This should be done for all

8. Select the KR function.

9.

Select the ranges and apply the inputs indicated 16. Note the 8040A display.

inputs to the 8040A mA terminal.

in Table 4-7. Observe the 8040A for a display

within the tolerances described and, when 17. Apply -100

mV dc to the mA input terminal.

necessary, make the adjustments indicated.

18. Adjust R86 to obtain a display within three

10. Disconnect the resistance source from the

8040A.

11.

Select the AC mA function.

19.

digits of the value of the display noted in

step 16.

Repeat steps 13 through 18 until all parameters

are met.

12. Select the 2 range. 20. Select the AC V function and the 2 range.

13. Connect the positive lead of the test equipment 21. Short the V-R and COMMON terminal

voltmeter to TP2 and the low lead to the together.

COMMON input terminal.

22. Turn RlOO fully clockwise then adjust it

14. Adjust R66 for a voltmeter reading of -0.070 to counterclockwise until the

$0.070 volts.

between 0.0180 and 0.0120.

8040A display is

Page 28

8040A

.

STEP

1

2

RANGE

AUTO

AUTO

l

NPUT

SHORT

SHORT

Table 4-7.

@

@

ADJUST

-

-

OHMS

8040A

DISPLAY

00.00

Lead Res.

CALIBRATION

ANNUNCIATOR

mV

mV

51 pA

51 . PA

00.00

-

Value

O

@

0

@

@

-

mV

-

mV

-

-

-

-

M51

mV

M51

.

51 . pA

51 pA

51 pA

exact1

exactly

exactly

exactly

.9995

9.995

99.95

999.5

9.985

99.98

-

3

4

5

6

7

9

10

11

12

13

2000

20051

AUTO

AUTO

AUTO

8

AUTO

AUTO

AUTO

AUTO

AUTO

AUTO

1 M51

1 0051

M51

1

10051

kR

1.0

10 k51

100 kR

1.0 M51

10 M51

10051

OPEN

R47

R 10

R47

R10

-

-

-

-

-

-

-

1000.0

100.00

1000.0

100.00

1.0000

10.000

100.00

1000.0

10.000

100.00

18.888

Flashing

Use a good quality shorting bar between the

@

Connect the test leads that will be used to connect the

@

V-51

and COMMON input terminals.

8040A

to the decade resistance source. Place the short

at the end of the test leads that will be connected to the resistance source. Note the resistance value indicated

8040A

on the

Add the lead resistance value to the input resistance value to determine the correct

@

Add the lead resistance value to the tolerance figures.

@

display.

8040A

display.

TOLERANCE

to

00.02

y

1000.0

100.00

1000.0

100.00

to

1.0005

to

10.005

to

100.05

to

1000.5

to

10.01 5

to

100.02

@

@

@

@

@

23. Turn R88 fully counterclockwise. Note the

8040A display; it should stop changing as the

control reaches full counterclockwise rotation.

NOTE

If

the display does not stop changing center

R88

24.

then return to step

through step

23.

Turn R88 clockwise slowly until the 8040A

13

and repeat

display changes by 1 or 2 digits.

25. Select the AC mA function and the 2 range.

26.

Connect a voltmeter to TP2 and verify that the

voltage level is between -0.070 and

-I-0.070 volt

dc.

NOTE

If

the level at

limits repeat steps

TP2

is not within the specified

14

through

26.

27. Select the AC V function and 2 range.

Apply 1.0000V ac at 200

Hz

to the 8040A V-R

input terminal. Note the display.

Apply 0.1000V ac at 200

Hz

to the V-R input.

Adjust RlOO until the 8040A display indicate

one-tenth of the reading observed in step 28.

Repeat steps 28 through 30 until no adjustment

of RlOO is required to obtain a one-tenth

display.

Apply 1.0000V ac at 200

Hz

to the V-R input.

Adjust RlOl for an 8040A display of exactly

1

.oooo.

Apply 0.1000V ac at 200

Hz

to the V-R input.

The 8040A display should be between 0.0999

and 0.1001.

Apply 0.0100V ac at 200

Hz

to the V-R input.

The 8040A display should be between oh099

and 0.0104.

\

Page 29

38.

Apply 1.9000V ac at 200 Hz to the V-R input.

50. Remove all inputs from the 8040A V-R input.

39.

The 8040A display should be between 1.8980

and 1.9020.

40.

Press the AUTO range switch and apply the

voltages indicated in Table 4-8. Observe the

8040A for a display within the limits indicated.

Table

4-8.

INPUT

10.0 mV

100 mV

1.00V

at

10.OV

at

l00V

at

750V

at

LOW

at

200

at

200

200

200

200

200

FREQUENCY AC V CHECK

DISPLAY

Hz

Hz

Hz

Hz

Hz

Hz

9.93

99.95

0.9995

9.9993

99.93

749.3

to

10.07

to

100.05

to

1.0005

to

10.007

to

100.07

to

75.07

41. Select the 750 AC range.

42. Apply 500V ac at 10k Hz to the V-R input.

51.

52.

Select the DC mA function.

Select the ranges indicated in Table 4-10 and

apply the associated current input to the

mA

input. Observe the 8040A for a display within

the limits indicated.

53. Select the AC mA function and the 2 range.

54. Apply -I-1.9 mA DC to the mA input.

55. The 8040A display should be between 1.8800

and 1.9200.

Table

4-10.

DIRECT CURRENT ACCURACY CHECK

RANGE

200 PA

2 mA

20 mA

200 mA

2000 mA

INPUT

+I

90 /.LA

+I

.9 mA

+I9 mA

+I

90 mA

+I

900 mA

DISPLAY

+I

89.40

+I

.8940

+I

8.940

+I

89.40

+I

894.0

to

+190.60

to

+I

to

+I

to

+I

to

+I

.9060

9.060

90.60

906.0

43. Adjust C3 for an 8040A display between 499.7

and 500.3.

44.

Disconnect the input from the V-R input.

45. Select the 200 range.

46. Apply lOOV ac at 10k Hz to the V-R input.

47.

Adjust C2 for an 8040A display between 99.96

and 100.04.

48.

Repeat steps 41 through 47 until both displays

are within specification limits.

49.

Press the AUTO range switch and apply the

voltages indicated in Table 4-9. Observe the

8040A for a display within the limits indicated.

Table

4-9.

INPUT

100 mV

1.00V

at

10.OV

at

I

OOV

at

500V

at

500V

at

HIGH FREQUENCY AC V CHECK

DISPLAY

at

20

20

20

20

20

5

kHz

kHz

kHz

kHz

kHz

kHz

99.30

.9930

9.930

99.30

496.5

498.0

to

to

to

to

to

to

503.5

502.0

100.70

1.0070

10.070

100.70

4-29.

TROUBLESHOOTING

4-30. The following information should be kept in

mind while doing repair work on the

8040A. Inattention

to these precautions may lead to instrument damage.

1.

MOS type integrated circuits can be damaged by