Page 1

D

D

yDtira(M©[r

OinsaniMta IMlamMI

F^qoir^Hl

Page 2

NOTE

This manual documents the Model 8026B and Its assemblies at the revision levels

shown In Appendix A. If your Instrument contains assemblies with different revision

letters, it will be necessary for you to either update or i>acfcdate this manual. Refer to

the supplemental change/errata sheet for newer assemblies, or the backdating stieet

In Appendix A for older assemblies.

8026B

Digital

Multimeter

P/N 646414

JUNE 1982

ei982,

John Fluke Mfg. Co., Inc.,

All rights reserved. Litho in

Instruction Manual

IFLUKEI

U.S.A.

Page 3

Dear Customer:

Congratulations! We at Flulce are proud to present you with tiie Model8026 B Multimeter.

This instrument represents the very latest in integrated circuit and display technology. As a

result, the end product is a rugged and reliable instrument whose performance and design

exhibit the qualities of a finely engineered lab instrument.

To fully appreciate and protect your investment,

the manual. As always. Fluke stands behind your 8026B with a full 2-year warranty and a

worldwide service organization. If the need arises, please don't hesitate to call on us.

Thank you for your trust and confidence.

John Fluke Mfg. Co., Inc.

we

suggest you take a few moments to read

Page 4

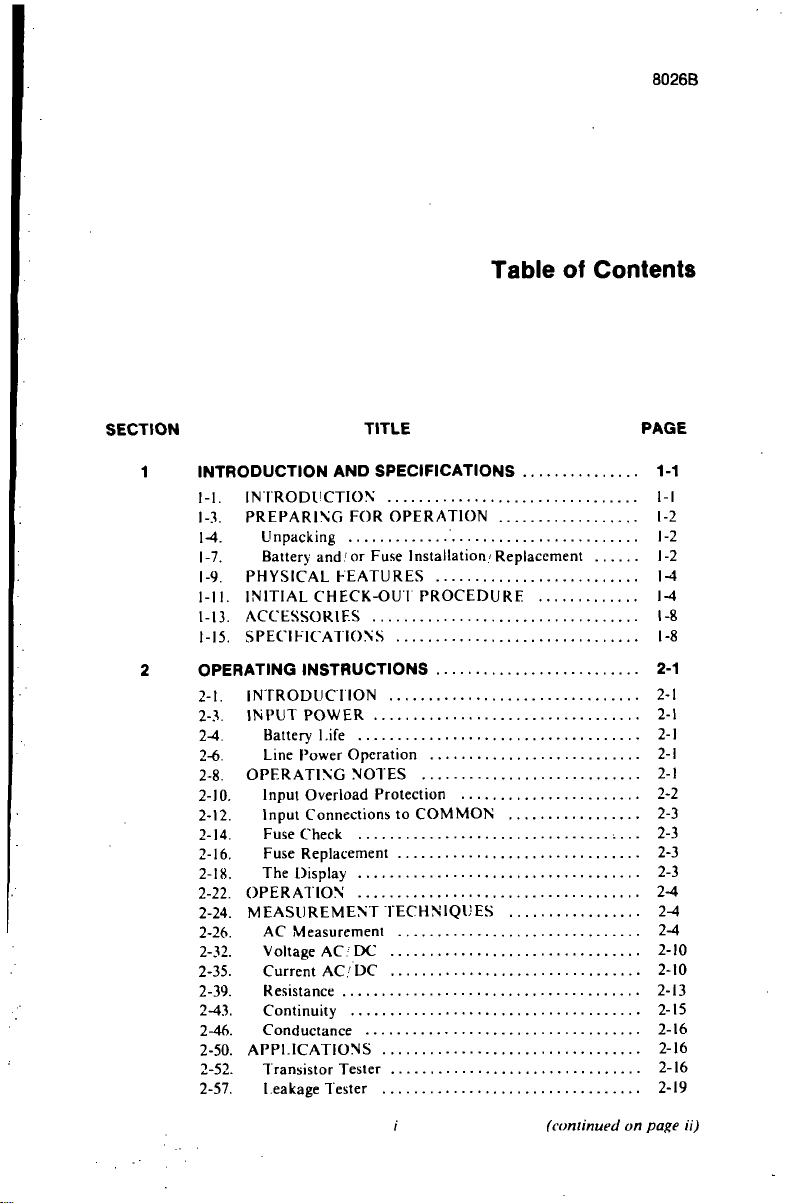

8026B

Table of Contents

SECTION TITLE PAGE

1 INTRODUCTION AND SPECIFICATIONS 1-1

1-1. INTRODUCTION 1-1

1.1.

PREPARING FOR OPERATION 1-2

1-4. Unpacking 1-2

1-7. Battery and'or Fuse Installation/Replacement 1-2

1-9. PHYSICAL FEATURES 1-4

1-11.

INITIAL CHECK-OUI PROCEDURE 1-4

1-13. ACCESSORIES 1-8

1-15. SPECIFICATIONS 1-8

2 OPERATING INSTRUCTIONS 2-1

2-1.

jNTRODUCnON 2-1

2-.V INPUT POWER 2-1

2-1.

Battery Life 2-1

2-6.

Line Power Operation 2-1

2-8. OPERATING NOTES 2-1

2-10. Input Overload Protection 2-2

2-12. Input Connections to COMMON 2-3

2-14. Fuse Check ;... 2-3

2-16. Fuse Replacement 2-3

2-18.

The Display 2-3

2-22. OPERATION 2-4

2-24. MEASUREMENT TECHNIQUES 2-4

2-26. AC Measurement 2-4

2-32.

Voltage AC DC 2-10

2-35.

CurremAC.'DC 2-10

2-39. Resistance 2-13

2-43. Continuity 2-15

2-46. Conductance 2-16

2-50. APPLICATIONS 2-16

2-52. Transistor Tester 2-16

2-57.

leakage Tester 2-19

;• (continued on page ii)

Page 5

8026B

TABLE OF CONTENTS, continued

SECTION TITLE PAGE

3 THEORY OF OPERATION 3-1

3-1.

INTRODUCTION 3-1 .

3-3. OVERAI.l. FUNCTIONAL DESCRIPI ION 3-1

3-8. BLOCK DIAGRAM ANALYSIS 3-1

3-9. A/ V Converter 3-1

3-18. Input Signal Conditioners 3-6

4 MAINTENANCE 4-1

4-1.

INTRODUCTION 4-1

4-3,

SERVICE INFORMATION 4-1

4-7.

GENERAL INFORMAIION 4-2

4-8.

Access Information 4-2

4-17.

Cleaning 4-5

4-19.

Battery/Backup Fuse Replacement 4-5

4-21.

PERFORMANCE TES I 4-6

4-23.

Initial Procedure 4-6

4-25.

Display lest 4-6

4-27.

Resistance/Conductance lest 4-7

4-29.

Continuity Test 4-7

4-31.

DC Voltage Test 4-8

4-33.

AC Voltage Test 4-8

4-35.

DC Current 1 est 4-9

4-37.

CALIBRATION 4-10

4-40.

IROUBLESHOOTING 4-11

5 LIST OF REPLACEABLE PARTS 5-1

5-1.

INTRODUCTION 5-1

5^. HOW TO OBTAIN PARTS 5-1

6 ACCESSORY INFORMATION 6-1

6-1.

INTRODUCTION 6-1

6-3. DELUXE CARRYING CASE (C-90) 6-1

6-5. TEMPERATURE PROBE (80T-I50C and 80T-I50K) . 6-1

6-6. Introduction 6-1

6-8. Specifications , 6-1

6-9. CURRENT TRANSFORMER (801-600) 6-4

6-10. Introduction 6-4

6-12. Specifications 6-4

6-13. HIGH VOLTAGE PROBE (80K-6) 6^

6-14. Introduction 6-4

6-16. Specifications 6-4

6-17. HIGH VOLTAGE PROBE (80K-40) 6-4

6-18. Introduction 6-4

6-20. Specifications 6-4

6-21.

HIGH FREQUENCY PROBE (83RF) 6-5

// (continued on page iii)

Page 6

8026B

TABLE OF CONTENTS, continued

SECTION TITLE PAGE

6-22. Introduction 6-5

6-24. Specifications 6-5

6-25. HIGH FREQUENCY PROBE (85RF) 6-5

6-26. Introduction 6-5

6-28. Specifications 6-5

6-29. BATTERY ELIMINATOR (A81-115) 6-6

6-31.

CURRENT SHUNT (80J-10) 6-6

6-32. Introduction 6-6

6-34. Specifications 6-7

6-35. AC/TX'CURRENT PROBE (Y8100) 6-7

6-36. Introduction 6-7

6-39. .Specifications 6-7

6-40. AC CURRENT TRANSFORMER (Y810I) 6-8

6-41 Introduction 6-8

6-43. Specifications 6-8

6^. SAFETY DESIGNED TEST LEAD SF I (Y8132) .... 6-8

6^6. DEI.U.XF TEST LEAD SET (Y81-34) 6-8

6-48. SLIM FLEX TEST LEAD SEI (Y8140) 6-8

7 SCHEMATIC DIAGRAIMS 7-1

APPENDIX A A-1

Page 7

8026B

List of Tables

TABLE TITLE PAGE

1-1

1-2

1-3

2-1

2-2

4-1

4-2

4-3

4-4

4-5

4-6

5-1

5-2.

5-3

5^.

6-1

8026B Controls. Indicators and Connectors 1-6

8026B Accessones 1-9

8026B Specifications 1-9

Input Overload Limits 2-2

Voltage/Current Capability of Resistance Ranges 2-15

List of Recommended Test Equipment 4-2

Resistance/ Conductance Checks 4-7.

DC Voltage Checks 4-8.

AC Voltage Test 4-9.

DC Current (mA) Checks 4-10

Troubleshooting Guide 4-12

8026B Final Assembly 5-3.

AI Main PCB Assembly 5-6.

A2 Annunciator PCB Assembly 5-10

Federal Supply Codes for Manufacturers 5-12

A8I Model Numbers and Input Power 6-6

Page 8

8026B

List of illustrations

FIGURE TITLE PAGE

I-I. Removing the Battery Cover 1-3

I-2. Battery Removal 1-4

1-3. Controls, Indicators and Connectors 1-5

2-1.

Volts Operation 2-5

2-2.

Current Operation 2-6

2-3.

Resistance Operation 2-7

2-4.

Conductance Operation 2-8

2-5. Continuity Operation 2-9

2-6.

Waveform Conversion 2-11

2-7.

Voltage Measurement Error Calculations 2-12

2-8. Current Measurement Error Calculations 2-14

2-9. Conductance-to-Resistance Conversion 2-17

2-10. Transistor Beta Test Fixture 2-18

3-1.

Model 8026B Simplified Block Diagram 3-3

3-2. Dual Slope A/ D Converter 3-4

3-3. Input Signal Conditioners 3-8

4-1.

Calibration Adjustment Locations 4-3

4-2.

LCD Display Assembly 4-4

5-1.

8026B Final Assembly 5-5

5-2. Al Main PCB Assembly 5-9

5-3. A2 Annunciator PCB Assembly 5-11

6-1.

8026B Accessories 6-2

v/v;

Page 9

8026B

Section 1

Introduction and Specifications

1-1.

INTRODUCTION

1-2. Your John Fluke Model 8026B is a pocket-size digital multimeter that is ideally

suited for application in the field, lab, shop or home. Some of the features of your

instrument are:

• All VOM functions plus conductance and continuity (8 in all) are included as

standard.

DC Voltage - 100 /iV to lOOOV

AC Vohage - IOO ^lV to 750V

DC Current - I /lA to 2000 mA

AC Current - 1 jiA to 2000 mA

Resistance - 0. in - 20 Mn

Diode Test

Conductance - O.I ns to 200 ns and .001 ms to 2 ms (S = Siemens = 1/n).

Continuity - Provides an immediate audible indication when continuity is

detected.

• True rms ac measurement for signals up to 10 kHz.

• CONDUCFANCE - Allows fast, accurate, noise-free resistance measurements up

to 10,000 Mn.

• An easy-to-read high contrast 3 1/2 digit liquid crystal display.

• Each range has: .

Full auto-polarity operafion

Overrange indication

Effective protection from overloads

• Dual slope integration measurement technique to ensure noise-free measurements.

• Easy calibration - few adjustments.

1-1

Page 10

8026B

Lightweight - 369 grams (13 ounces).

Up to 200 hours of continuous operation can be expected from a single,

inexpensive, 9V, alkaline battery (transistor radio/calculator type).

Low battery voltage automatically detected and displayed.

Line operation is possible using a Model A81 Battery Eliminator (see Section 6.

Accessories).

Protected test leads - finger guards on the probes and shrouded contacts on the

connectors discourage accidental contact with circuit voltages.

A full line of accessories that extend the range and scope of your instrument.

1-3. PREPARING FOR OPERATION

1-4. Unpacking

1-5. Your 8026B was packed and shipped in an especially designed protective container.

This manual, the multimeter, one 9V battery, and two test leads (one red and one black)

should be packed in the shipping container. Check your shipment thoroughly. If anything

is wrong with your shipment, contact the place of purchase immediately. If satisfaction is

not obtained, contact the nearest John Fluke Service Center. A list of these service centers

is located at the end of this manual.

1-6. If reshipment is necessary, please use the original shipping container.

container is not available, a new one can be obtained from the John Fluke Mfg. Co., Inc.

Please state the instrument model number when requesting a new shipping container.

1-7. Battery and/or Fuse Installation/Replacement

1-8. Your 8026B is designed to operate on a single, inexpensive, 9V battery ofthe

transistor radio/calculator variety (NEDA 1604). When you receive your 8026B the

battery will not be installed in the DMM. Once the battery is installed, you can expect a

typical operating life of up to 2(X) hours with an alkaline battery or IOO hours with a

carbon-zinc battery. When the battery has exhausted about 80% of its useful life, the BT

indicator will appear in the upper left corner of the display. Your 8026B will operate

properly for at least 20 hours after BT appears. Use the following procedure to install or

replace the battery and to replace the fuse.

WARNING

TO AVOID ELECTRICAL SHOCK HAZARDS REMOVE THE INPUT SIGNAL

AND THE TEST LEADS FROM THE INPUT TERMINALS, AND SET THE

POWER SWITCH TO OFF BEFORE OPENING THE BATTERY

COMPARTMENT.

1.

Set the 8026B power switch to OFF.

2.

Remove the test leads from external circuit connections and from the 8026B

input terminals.

1-2

I f

the original

Page 11

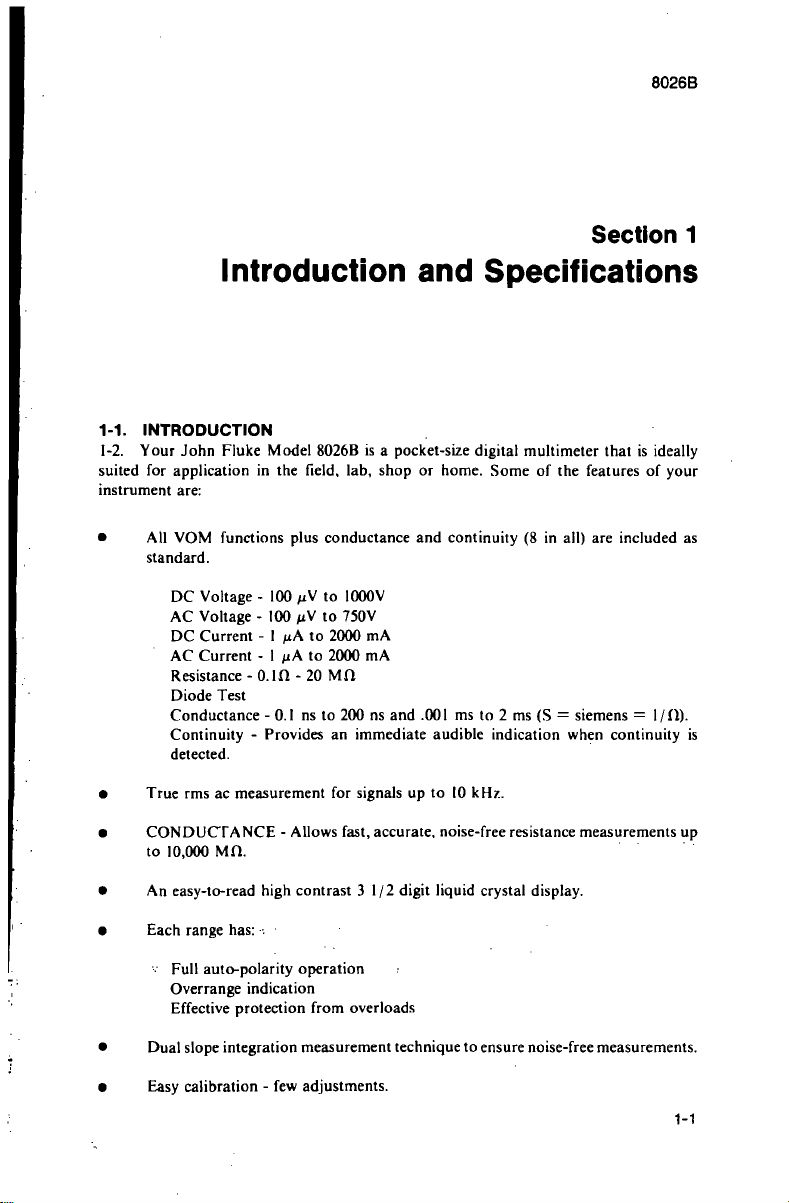

3.

Open the battery compartment on the bottom of the 8026B using the method

shown in Figure 1-1.

4.

Tilt the battery out as shown in Figure 1-2.

5.

If fuse Fl is to be replaced, use a pointed tool such as a probe tip or small

screwdriver to pry FT from its holder. Replace the defective fuse with fuse type

AGX2.

(Instruments that accomodate metric fuses use 5 x 20 mm 2A 250V type F.)

6. Disconnect the battery clip from the battery.

7.

Press the battery clip onto the replacement battery and return both to the

battery compartment.

8. Make sure the battery leads are routed by the broad side ofthe battery and fully

within the confines ofthe battery compartment before sliding the cover into place.

WARNING

DO NOT OPERATE THE 8026B UNTIL THE BATTERY COVER IS IN PLACE

AND FULLY CLOSED.

USE THUMBS TO PUSH

BATTERY COVER FROM

8026B CASE. INDEX

FINGERS SHOULD BE

USED TO PREVENT

COVER FROM

FLYING AWAY.

8026B

BACK SIDE OF 8026B

Figure 1-1. Removing the Battery Cover

1-3

Page 12

8026B

\

lp^

/^

1

.••r

%^

'^v^i>

" . . .

1^

•^r>--j

:i;s:W

Figure 1-2. Battery Removal

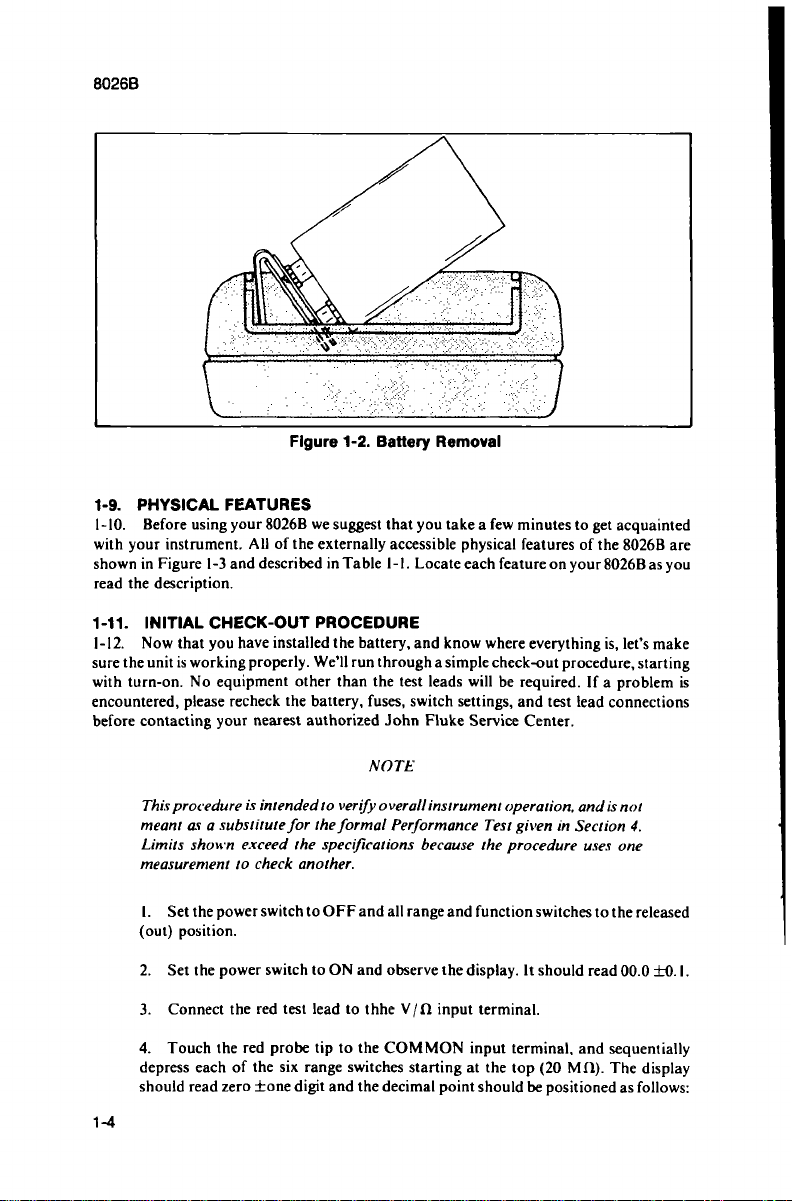

1-9. PHYSICAL FEATURES

1-10. Before using your 8026B we suggest that you take a few minutes to get acquainted

with your instrument. All of the externally accessible physical features of the 8026B are

shown in Figure 1-3 and described in Table 1-1. Locate each feature on your 8026B as you

read the description.

1-11.

INITIAL CHECK-OUT PROCEDURE

1-12. Now that you have installed the battery, and know where everything is, let's make

sure the unit is working properly. We'll run through a simple check-out procedure, starting

with turn-on. No equipment other than the test leads will be required. If a problem is

encountered, please recheck the battery, fuses, switch settings, and test lead connections

before contacting your nearest authorized John Fluke Service Center.

NOTE

This

procedure is intendedto verify overall instrument operation, andisnot

meant as a substitute for the formal Performance Test given in Section 4.

Limits shown e.xceed the specifications because the procedure uses one

measurement to check another.

1.

Set the power switch to OFF and all range and function switches to the released

(out) position.

2.

Set the power switch to ON and observe the display. It should read 00.0 ±0.1.

3.

Connect the red test lead to thhe V/n input terminal.

4.

Touch the red probe tip to the COMMON input terminal, and sequentially

depress each of the six range switches starting at the top (20 Mn). The display

should read zero ±one digit and the decimal point should be positioned as follows:

1-4

Page 13

8026B

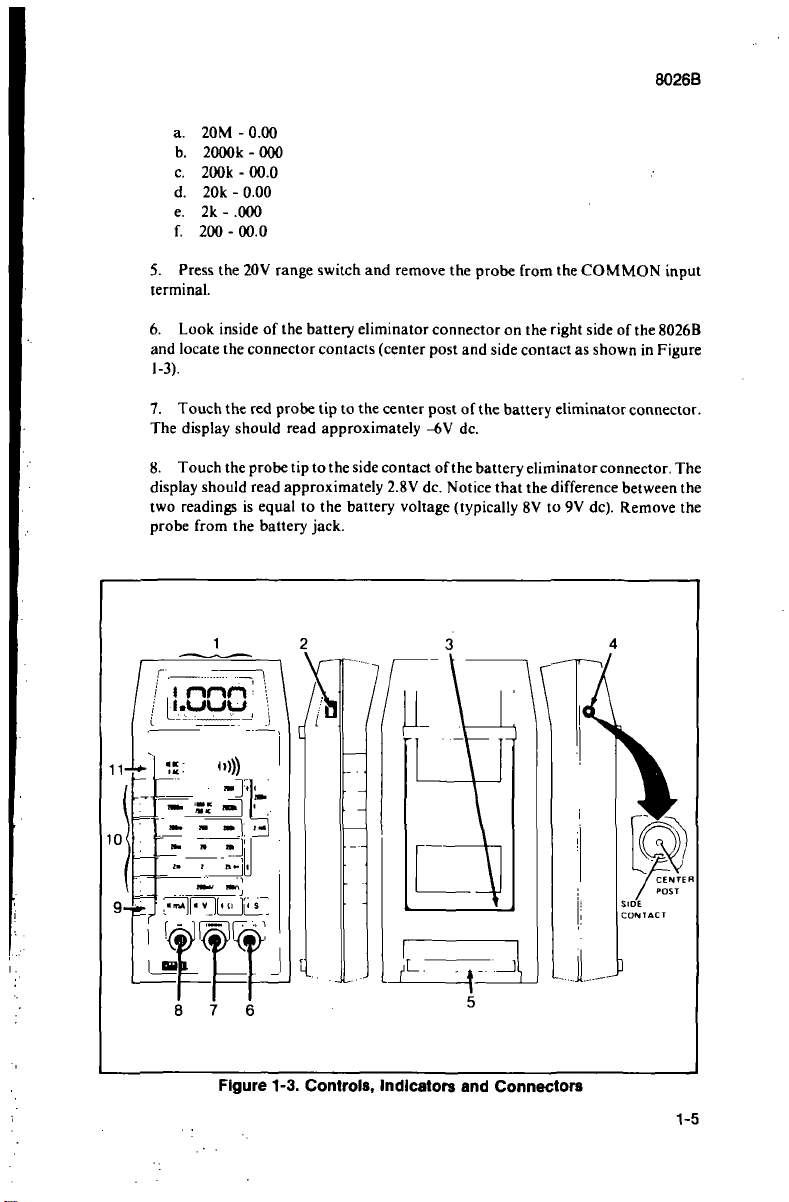

a. 20M - 0.00

b.

2000k - 000

c. 200k - 00.0

d. 20k - 0.00

e. 2k - .000

f. 200 - 00.0

5.

Press the 20V range switch and remove the probe from the COMMON input

terminal.

6. Look inside of the battery eliminator connector on the right side of the 8026B

and locate the connector contacts (center post and side contact as shown in Figure

1-3).

7.

Touch the red probe lip to the center post of the battery eliminator connector.

The display should read approximately -6V dc.

8. Touch the probe tip to the side contact ofthe battery eliminator connector. The

display should read approximately 2.8V dc. Notice that the difference between the

two readings is equal to the battery vohage (typically 8V to 9V dc). Remove the

probe from the battery jack.

9-f

, I

non

[_l.tM«OW

'%

i^

8 7 6

Figure 1-3. Controls, Indicators and Connectors

...u

1-5

Page 14

8026B

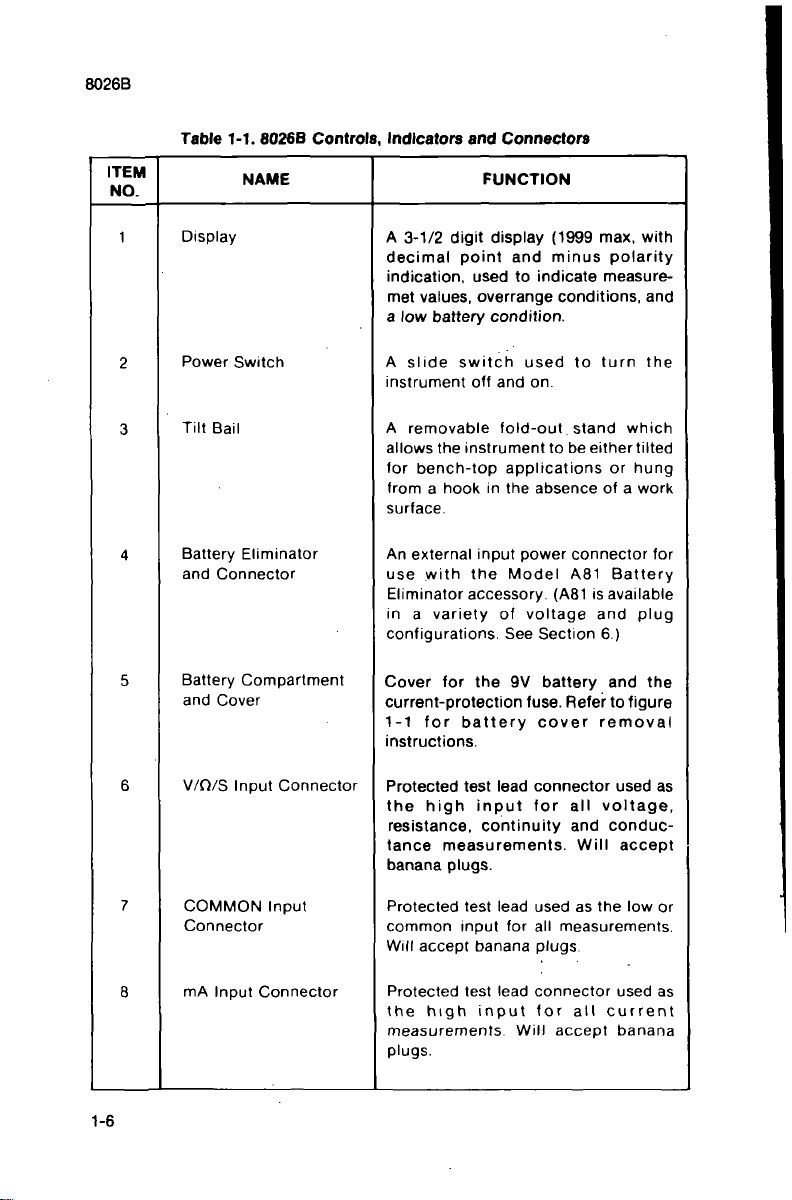

Table 1-1. 8026B Controls, Indicators and Connectors

ITEM

NO.

1

2

3

4

5

NAME

Display

Power Switch

Tilt Bail

Battery Eliminator

and Connector

Battery Compartment

and Cover

FUNCTION

A 3-1/2 digit display (1999 max, with

decimal point and minus polarity

indication,

met values, overrange conditions, and

a low battery condition.

A slide switch used to turn the

instrument off and on.

A removable fold-out stand which

allows the instrument to be either tilted

tor bench-top applications or hung

from a hook in the absence of a work

surface.

An external input power connector for

use with the Model A81 Battery

Eliminator accessory. (A81 is available

in a variety of voltage and plug

configurations. See Section 6.)

Cover for the 9V battery and the

current-protection fuse. Refer to figure

1-1 for battery cover removal

instructions.

used to indicate measure-

1-6

6

7

8

V/n/S Input Connector

COMMON Input

Connector

mA Input Connector

Protected test lead connector used as

the high Input for all voltage,

resistance, continuity and conductance measurements. Will accept

banana plugs.

Protected test lead used as the low or

common input for all measurements.

Will accept banana plugs

Protected test lead connector used as

the high input for all current

measurements Will accept banana

plugs.

Page 15

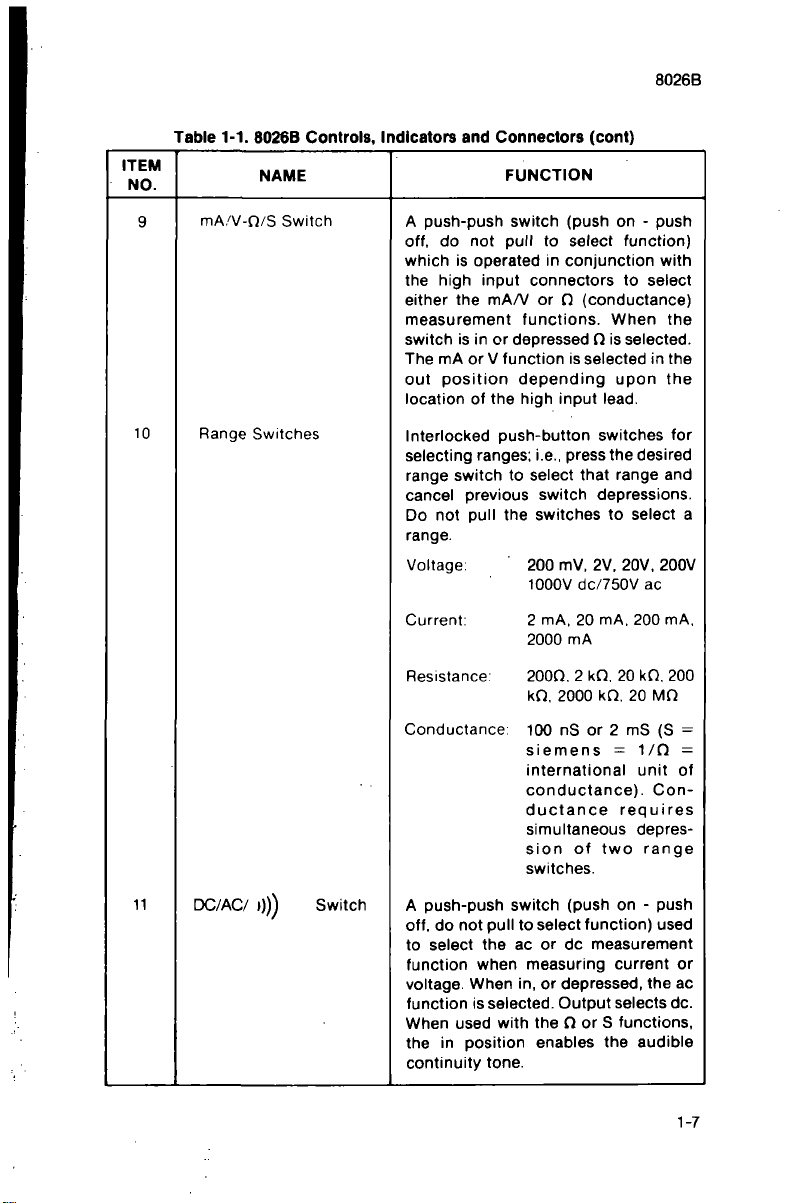

Table 1-1. 8026B Controls, Indicators and Connectors (cont)

ITEM

NO.

NAME

FUNCTION

8026B

10

mA,'V-0/S Switch

Range Switches

A push-push switch (push on - push

off, do not pull to select function)

which is operated in conjunction with

the high input connectors to select

either the mA/V or Q (conductance)

measurement functions. When the

switch is in or depressed O is selected.

The mA or V function is selected in the

out position depending upon the

location of the high input

Interlocked push-button switches for

selecting ranges; i.e., press the desired

range switch to select that range and

cancel previous switch depressions.

Do not pull the switches to select a

range.

Voltage: 200 mV, 2V, 20V, 200V

1000V dc/750V ac

Current: 2 mA, 20 mA. 200 mA.

2000 mA

Resistance: 2000. 2 kO, 20 kO. 200

kO.

Conductance: 100 nS or 2 mS (S =

Siemens = 1/0 =

international unit of

conductance).

ductance requires

simultaneous depression of two range

switches.

lead.

2000 kO. 20 MO

Con-

DC/AC/ I))) Switch

A push-push switch (push on - push

off. do not pull to select function) used

to select the ac or dc measurement

function when measuring current or

voltage. When in, or depressed, the ac

function is selected. Output selects dc.

When used with the O or S functions,

the in position enables the audible

continuity tone.

1-7

Page 16

8026B

9. Depress the lower function button (n) and sequentially depress each of the six

range switches. The display should read I as the most significant digit with no other

numbers shown. This is the standard overrange indication. Notice that the decimal

point changes position with the range switch settings just as it did in step 4 of this

procedure.

10.

Touch the red probe tip to the COMMON input terminal, and sequentially

press each of the range buttons. The display should read zero at each range setting.

Lead resistance may be sufficient to cause one or two tenths

(0.1

or 0.2n) indication

on the 200n range.

11.

Touch the red probe tip to the mA input connector and press the 200n switch.

The display should read 99.0 to lOI.O.

12.

Press the 2 kn switch. The display should read .099 to.

101.

Remove the probe

from the mA input connector.

13.

Simultaneously depress the 2000 kn and the 20 Mn range switches. This

selects the 200 nS range. The display should read 00.0 to OI.O (minimum

conductance, maximum resistance).

14.

Touch the red probe tip to the COMMON input connector. An overrange

indication should be displayed since conductance is the reciprocal of resistance.

15.

Connect the black test lead to the COMMON input connector.

16.

Depress both AC/ DC switch and the 750V ac range switch. Set the mA/ V-n

switch to the voltage (out) position.

WARNING

THE LOCAL LINE VOLTAGE IS MEASURED IN THE FOLLOWING STEP. BE

CAREFUL NOT TO TOUCH THE PROBE TIPS WITH YOUR FINGERS, OR TO

ALLOW THE PROBE TIPS TO CONTACT EACH OTHER.

17.

Measure the local ac line voltage at a convenient output receptacle. The

voltage should be displayed with I volt resolution.

18.

If the 8026B has responded properly to this point, it is operational and ready

for use.

1-13. ACCESSORIES

I-14. Table 1-2 lists the accessories available for use with the Model 8026B. Detailed

information about each accessory is provided in Section 6.

1-15. SPECIFICATIONS

I-16. Table 1-3 lists the 8026B specifications.

1-8

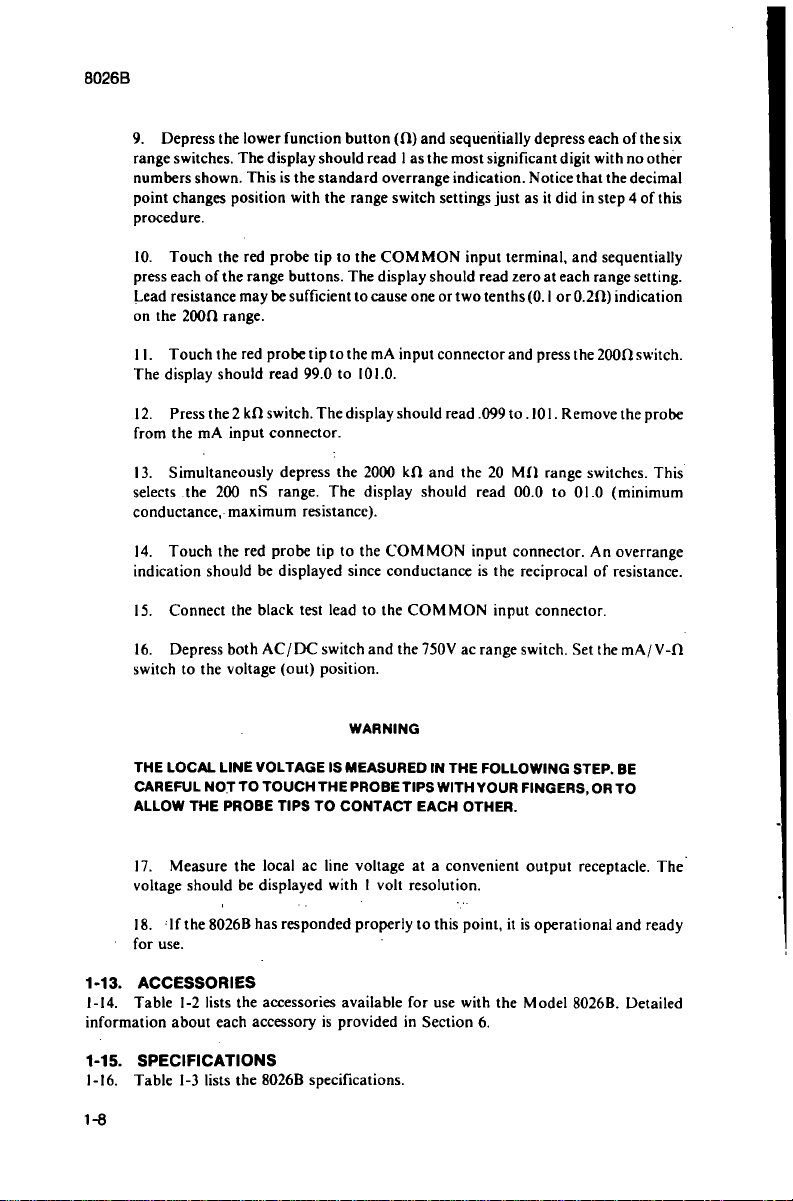

Page 17

ACCESSORY

Table 1

-2.

8026B Accessories

8026B

DESCRIPTION

A81

C-90

80T-150C

80T-150F

801-600

80K-6

80K-40

80J-10

83RF

85RF

Y8100

Y8101

Y8132

Y8134

Y8140

Table 1-3. 8026B Specifications

The following specifications assume a

operating temperature of

to 80% unless otherwise noted.

FUNCTIONS

DC VOLTS

RANGE

±200 mV

±2V

±20V

±200V

± 1000V

18°

C to 28° C (64° F to 82°

DC Volts, AC Volts, DC Current, AC

Current, Resistance, Conductance, and

Continuity.

RESOLUTION

lOO^V

1 mV

10 mV

100 mV

IV

Battery Eliminator

Vinyl Carrying Case

Temperature Probe °C

Temperature Probe °F

Current Transtormer 2" jaws

High Voltage Probe

High Voltage Probe

Current Shunt

High Frequency Probe

High Frequency Probe

AC/DC Current Probe

Current Transformer 7/16" jaws

Safety Designed Test Lead Set

Deluxe Test Lead Set

Slim Flex Test Lead Set

1-year

calibration cycle and an

F)

at a relative humidity up

ACCURACY

±(0.1%

of reading -1-1 digit)

Overvoltage Protection 1000V dc or peak ac on all ranges.

Input Impedance 10 MO, all ranges.

Normal Mode Rejection Ratio >60 dB at 50 Hz and 60 Hz.

Common Mode Rejection

Ratio (1 kO unbalance) >100 dB at dc, 50 Hz and 60 Hz.

Response Time Less than one second.

1-9

Page 18

8026B

Table 1-3. 8026B Specifications (cont)

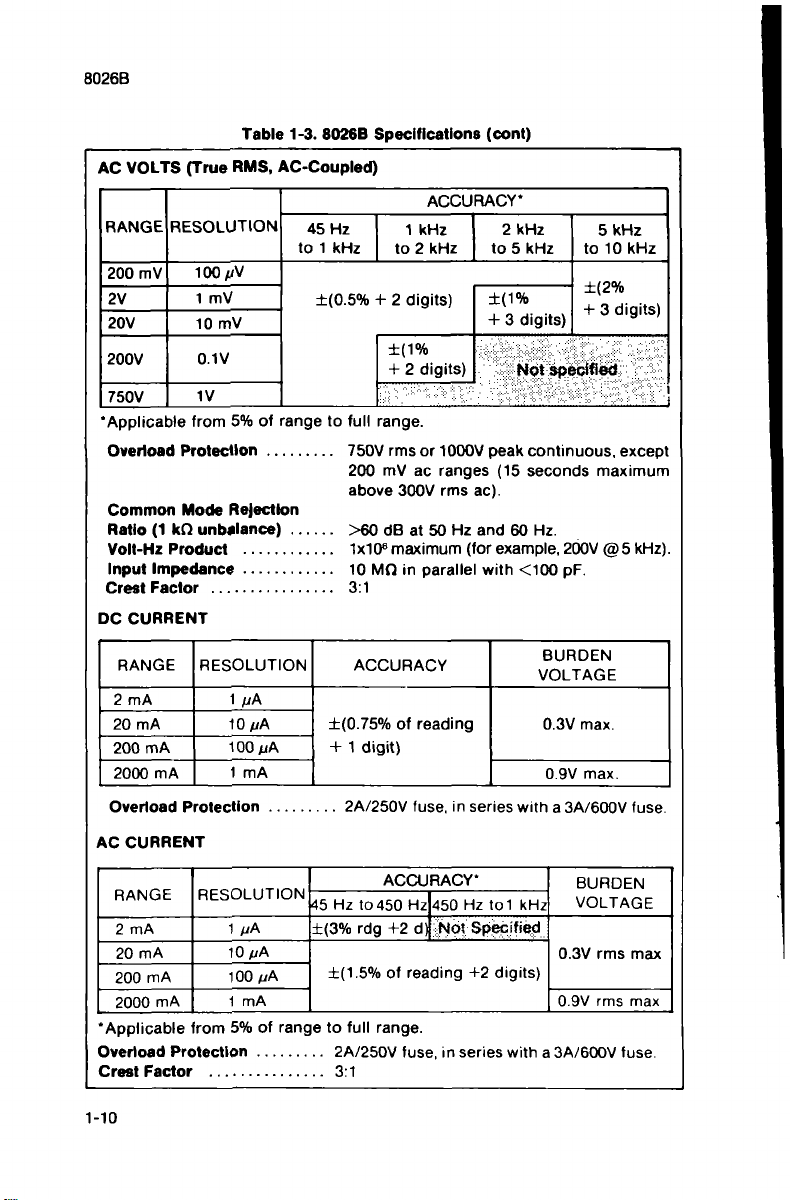

AC VOLTS (True RMS, AC-Coupled)

ACCURACY*

RANGE

200 mV

2V

20V

200V

750V

'Applicable from 5% of range to full range.

Overioad Protection 750V rms or 1000V peak continuous, except

Common Mode Rejection

Ratio (1 kO unbalance) >60 dB at 50 Hz and 60 Hz.

Voll-Hz Product IxW maximum (for example, 200V @ 5 kHz).

Input Impedance 10 MO In parallel with <100 pF.

Crest Factor 3:1

DC CURRENT

RESOLUTION

100

A/V

1 mV

10 mV

0.1V

IV

45 Hz

to 1 kHz

±(0.5%

1 kHz 2 kHz

to 2 kHz to 5 kHz

+ 2 digits)

±(1%

-I-

2 digits)

±(1%

-F 3 digits)

ywitW^^0&^;:-xM

:mmmB

200 mV ac ranges (15 seconds maximum

above 300V rms ac).

5 kHz

to 10 kHz

±(2%

-F 3 digits)

mmm-

RANGE

2 mA

20 mA

200 mA

2000 mA

Overioad Protection

AC CURRENT

RANGE

2 mA

20 mA

200 mA

2000 mA

'Applicable from 5% of range to full range.

Overioad Protection 2A/250V fuse, in series with a 3A/600V fuse.

Crest Factor 3:1

1-10

RESOLUTION

1 pA

10

M

100A(A

1 mA

RESOLUTION

1 pA

10

A/A

100/yA

1 mA

ACCURACY

±(0.75%

+ 1 digit)

45 Hz to 450 Hz

±(3%

±(1.5%

of reading

2A/250V fuse, in series with a 3A/600V fuse.

ACCURACY-

450 Hz tol kHz

rdg +2 d)

jNpt Specjfie^

of reading -t-2 digits)

BURDEN

VOLTAGE

0.3V max.

0.9V max.

BURDEN

VOLTAGE

0.3V rms max

0.9V rms max

Page 19

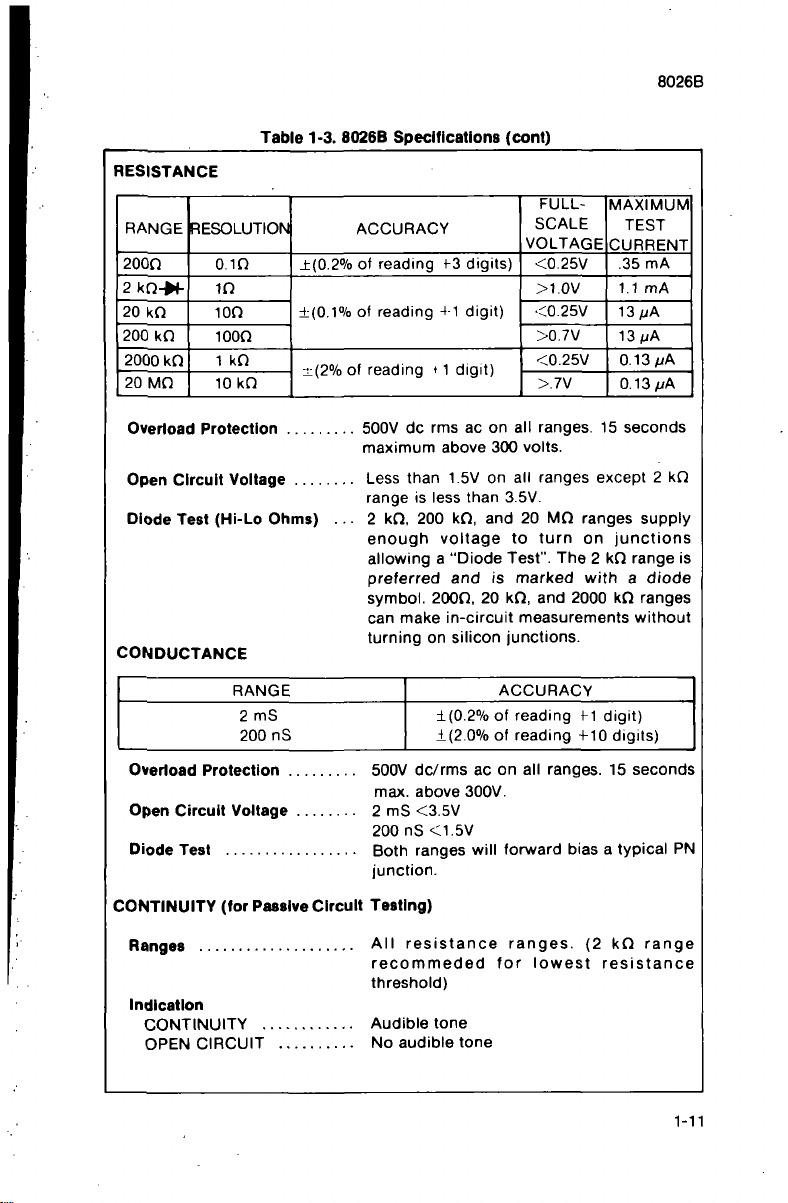

RESISTANCE

RANGE

200n

RESOLUTION

2kn-w-

20 kO

200 kO

2000 kO

20 MO

Table 1-3. 8026B Specifications (cont)

ACCURACY

0.1O

±(0.2%

of reading 1-3 digits)

in

±(0.1%

ion

of reading +^ digit)

loon

1 kn

10 kn

:v(2%

of reading * i digit)

FULL-

SCALE

VOLTAGE

<0.25V

>1.0V

<0.25V

>0.7V

<0.25V

>.7V

8026B

MAXIMUM

TEST

CURRENT

.35 mA

1.1 mA

13/JA

13A(A

0.13/iA

0.13

A/A

Overioad Protection

Open Circuit Voltage

Diode Test (Hi-Lo Ottms)

CONDUCTANCE

RANGE

2 mS

200 nS

Overioad Protection .

Open Circuit Voltage

Diode Test

CONTINUITY (for Passive Circuit Testing)

Ranges All resistance ranges. (2 kn range

Indication

CONTINUITY Audible tone

OPEN CIRCUIT No audible tone

500V dc rms ac on all ranges. 15 seconds

maximum above 3(X) volts.

Less than 1.5V on all ranges except 2 kn

range is less than 3.5V.

2 kn, 200 kn, and 20 Mn ranges supply

enough voltage to turn on junctions

allowing a "Diode Test". The 2 kn range is

preferred and is marked with a diode

symbol.

200n, 20 kn, and 2000 kn ranges

can make in-circuit measurements without

turning on silicon junctions.

ACCURACY

±(0.2%

of reading fl digit)

±(2.0%

of reading +10 digits)

500V dc/rms ac on all ranges. 15 seconds

max. above 300V.

2 mS <3.5V

200 nS <1.5V

Both ranges will forward bias a typical PN

junction.

recommeded for lowest resistance

threshold)

1-11

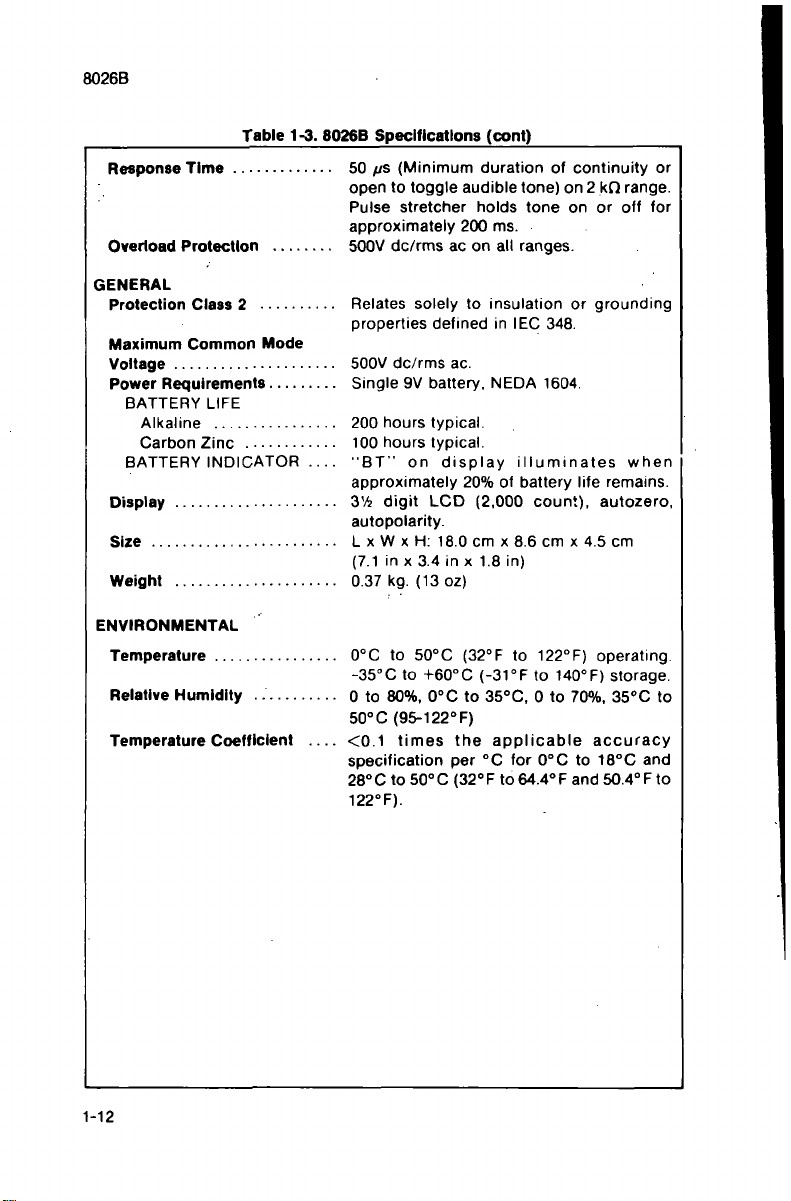

Page 20

8026B

Response Time

Overioad Protection

Table 1-3. 8026B Specifications (cont)

50 ps (Minimum duration of continuity or

open to toggle audible tone) on 2 kO range.

Pulse stretcher holds tone on or off for

approximately 200 ms.

. 500V dc/rms ac on all ranges.

GENERAL

Maximum Common Mode

Voltage

Power Requirements

BATTERY LIFE

Carbon Zinc

BATTERY INDICATOR ..

DisDiav

Size

Weight

ENVIRONMENTAL

Temperature

Relative Humidity

Temperature Coefficient ..

. Relates solely to insulation or grounding

properties defined in lEC 348.

. 500V dc/rms ac.

.. Single 9V battery, NEDA 1604.

.. 200 hours typical.

.. 100 hours typical.

"BT"

on display illuminates when

approximately 20% of battery life remains.

.. 3% digit LCD (2,000 count), autozero,

autopolarity.

.. L X W X H: 18.0 cm x 8.6 cm x 4.5 cm

(7.1 in X 3.4 in x 1.8 in)

.. 0.37 kg. (13 oz)

.. 0°C to 50°C (32° F to 122°F) operating.

-35°C to +60°C (-31 °F to 140°F) storage.

.. 0 to 80%, 0°C to 35°C, 0 to 70%, 35°C to

50° C

(95-122° F)

.. <0.1 times the applicable accuracy

specification per °C for 0°C to 18°C and

28°C to 50°C (32°F to64.4°F and 50.4°F to

122°F).

1-12

Page 21

8026B

Section 2

Operating Instructions

2-1.

INTRODUCTION

2-2.

To fully use the measurement capabilities of your 8026B, a basic understanding of

its measurement techniques and limitations is required. This section of the manual

provides that infonnation. plus a few applications that may prove useful. For example, did

you know your 8026B will provide direct-reading dc current gain (beta) measurements for

both N PN and PN P transistors? Read this section ofthe manual, to find out how it's done.

2-3.

INPUT POWER

2-4.

Battery Life

2-5.

The 8026B is designed to operate on an single, inexpensive 9V battery of the

transistor radio/calulator variety (NEDA 1604). If an alkaline battery is used, a typical

operating life of up to 200 hours can be expected. Carbon-zinc batteries will have a useful

life of up to 100 hours, in either event, the 8026B will display a Bl (in upper, left-hand

corner) when the battery has exhausted approximately 80% of

appears, the battery is capable of properly operating the 8026B for at least another 20

hours.

its

useful life. When Bl first

CAUTION

To ensure multimeter operation within the accuracy specifications, the tiattery

should t>e replaced when the voltage measured at the center of the tiattery

eliminator connector falls below -3.00 volts (with respect to the COMMON

Input). It the battery voltage falls to a point where the"BT" is displayed and the

digital display Is Inactive or no longer responds to an Input signal, the battery

should be replaced Immediately to prevent damage to the LCD.

2-6.

Line Power Operation

2-7.

You can operate your 8026B from line power by using the A81 Battery Eliminator

Accessory. Refer to Section 6 for additional information about the A8I.

2>8.

OPERATING NOTES

2-9.

The following paragraphs will familiarize you with the capabilities and limitations

of your Model 8026B and instruct you in routine operator maintenance.

2-1

Page 22

8026B

2-10. Input Overload Protection

CAUTION

Exceeding the maximum Inpul overload limits can damage your Instrument.

transient overload protection circuit

against short duration high energy pulses.

protection

pulses, and about 0.6 watts average

rate pulses, such

components;

replacement,

flameproof fusible resistor. Use exact replacement

2-11.

Each measurement function and its associated ranges are equipped with input

to

approximatly iWe pulses

as

RJ1 - RJ4, Rl and R2. If any of

use

those Irom

only Fluke parts

Is

designed Into

The

per

lor

lower amplitude

a TV set, can

to

ensure product safety.

components used limit

second

for 6 KV, 10

damage

these components require

to

the

8026B

to

microsecond

pulses.

Fast repetition

the

protection

(R2 Is a

ensure safety.)

protect

the

special

overload protection. The overload limits for each function and range are given

1.

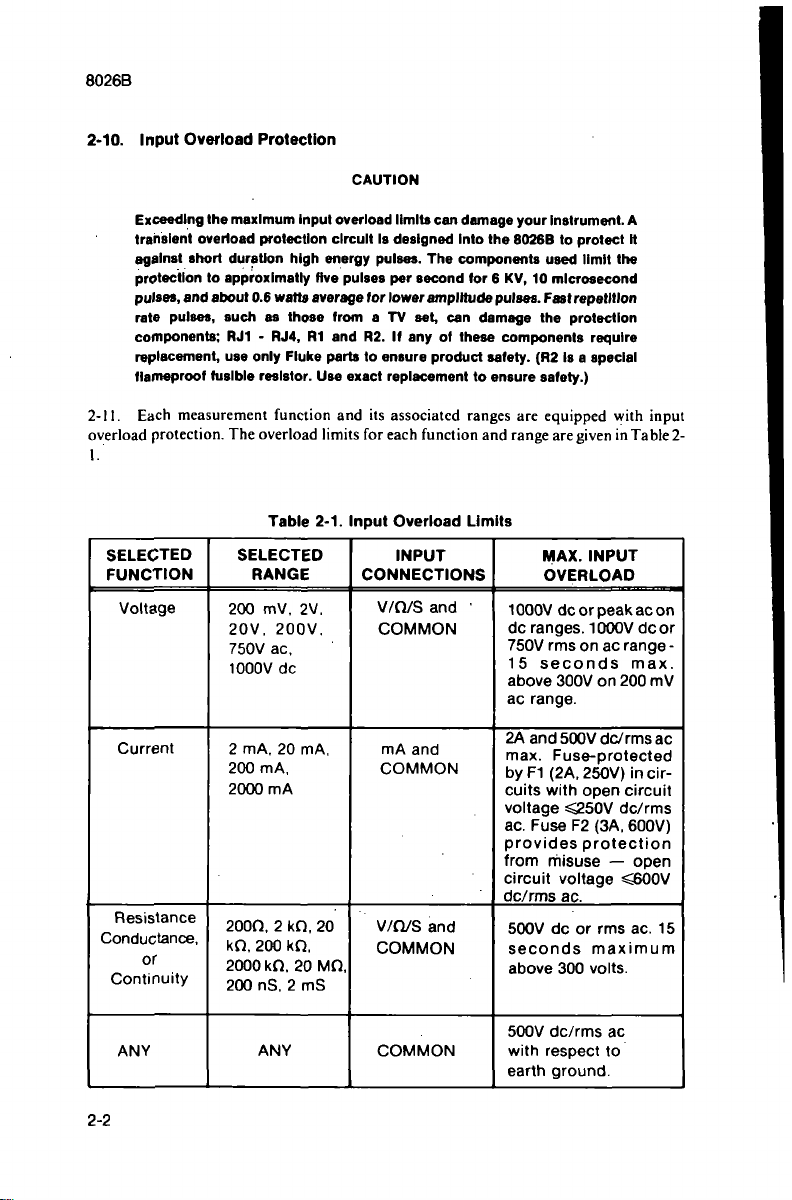

Table 2-1. Input Overload Limits

SELECTED

FUNCTION

Voltage

SELECTED

RANGE

200

mV, 2V,

20V, 200V.

750V

ac,

1000V

dc

INPUT

CONNECTIONS

V/n/S and

'

COMMON

MAX. INPUT

OVERLOAD

10OOV dc

or

peak ac on

dc ranges. 1000V dcor

750V rms on

ac

15 seconds

above 300V on 200 mV

ac range.

Current

2 mA, 20 mA,

200 mA,

2000

mA

mA and

COMMON

2A and 500V dc/rms ac

max. Fuse-protected

byFI (2A, 250V) in circuits with open circuit

voltage

^50V

ac. Fuse

F2

(3A, 600V)

provides protection

from niisuse — open

circuit voltage C600V

dc/rms

ac.

Resistance

Conductance,

or

Continuity

200n, 2 kn,

kn,

200 kn,

2000 kn,

200 nS,

20 Mn,

2 mS

20

V/n/S

and

COMMON

500V

dc or rms ac. 15

seconds maximum

above 300 volts.

A

It

in

Table

range

max.

dc/rms

2-

-

2-2

ANY

ANY

COMMON

500V dc/rms

with respect

to

earth ground.

ac

Page 23

8026B

2-12.

Input Connections to COMMON

WARNING

TO AVOID ELECTRICAL SHOCK AND /OR INSTRUMENT DAMAGE DO

NOT CONNECT THE COMMON INPUT TERMINAL TO ANY SOURCE OF

MORE THAN 500 VOLTS DC OR RMS AC ABOVE EARTH GROUND.

2-13.

The 8026B may be operated with the COM MON input terminal at a potential of up

to 500V dc or 500V rms ac above earth ground, if this limit is exceeded, instrument

damage may occur. This, in turn, may result in a safety hazard for the operator.

2-14. Fuse Check

2-15.

The current (mA) function contains two fuses. Check them as follows:

1.

Complete the set up steps for the RESISTANCE (n) function and select the 2

kn range.

2.

Touch the red test probe to the mA input jack so that the V-n input and m.A

input are connected together.

3.

If the display reads approximately .100 kn, both fuses are good.

4.

If the display reads overrange (a I followed by blank digits), one or both fuses

need replacement. See the following paragraph for replacement instructions.

2-16. Fuse Replacement

2-17.

All ac and dc current ranges are fuse protected. Two series fuses are used:

1.

FI, 2A@ 250V, replaceable at the battery compartment (see section 1 "Battery

or Fuse Installation/Replacement").

2.

F2, 3A@ 600V backup fuse (see section 4, Battery/Backup Fuse

Replacement).

2-18. The Display

2-19. The Front Panel Display on your 8026B is a 3-1/2 digit Liquid Crystal Display.

The 1/2 digit is the extreme left digit location. So, the displayed value can range from000

through 1999. For convenience, in discussion, the 1999 is rounded to 2000. The decimal

point position is determined by selected range and is not affected by the measurement

function selected. Polarity, on the other hand is only used for the dc voltage and current

measurement functions. A minus sign indicates that the input signal is negative with

respect to the COMMON input terminal. Positive inputs are indicated by the absence of

the minus sign.

NOTE

The minus sign (-) may flash momentarily as the 8026 B comes out of an

overrange condition. This will most likely be seen in the ohms mode as the

open circuit lest leads are applied to an in-range resistance value. If the

minus sign remains on for in-range ohms readings, the circuit is live (a

negative voltage

etc.),

and incorrect resistance readings will he observed.

is

pre.sent at the input terminals due to charged capacitors,

2-3

Page 24

8026B

2-20. The Display has two abnormal status indicators, one for low battery power and

one for instrument overrange. A "BT" is displayed when approximately 80% of the

battery's life is exhausted (battery replacement is indicated). And, a "I" followed by three

blanked digits is displayed (decimal point may be present) as an overrange indication. This

does not necessarily mean that the instrument is being exposed to a damaging input

condition. For example, when measuring resistance an open-input will cause an overrange

indication.

NOTE

When the 8026B is powered with the A8I Battery Eliminator the "BV

indicator may come on. However, instrument operation will he normal.

2-21.

1'he liquid crystal display used in the 8026B is a rugged and reliable unit which will

give years of satisfactory service. Display life can be extended by observing the following

practices:

1.

Protect the display from extended exposure to bright sunlight.

2.

Keep the voltmeter out of high temperature, high humidity environments, such

as,

the dash of a car on a hot, sunny day. Otherwise, the display may temporarily

turn black. Recovery occurs at normal operating temperature.

3.

Note that the display operation may be slowed in extremely low temperature

environments. No damage will occur to the LCD, but response time is greatly

increased. Recovery occurs at normal operating temperature.

2-22.

OPERATION

2-23.

The five figures, 2-1 through 2-5, each illustrate one ofthe measurement functions

ofthe Model 8026B. Each figure has two parts. The top part shows your 8026B as it should

look when ready to perform that type of nieasurement. The bottom part ofthe figure lists,

in sequential order, the steps you should perform to make that type of measurement with

your 8026B. To operate your 8026B turn to the operation figure corresponding to the

measurement function desired and perform the steps listed in the figure. Operate the

Model 8026B in accordance with the Input Overload Protection and the Input

Connections to COMMON portions of the Operating Notes presented earlier in this

section.

2-24. MEASUREMENT TECHNIQUES

2-25.

The following paragraphs offer you techniques that improve the measurement

accuracy of your 8026B. While these techniques are in general use throughout the

electronics industry, these paragraphs offer specifiee information for use with your 8026B.

2-26. AC Measurement

2-27.

The 8026B employs a true rms ac converter for ac signal measurements. The true

rms value of an ac signal may be defined as the equivalent dc value that dissipates the same

amount of heat in a resistor as the relative ac signal. Consider the following example: a

light bulb is energized with an ac signal and the brightness is measured. The ac source is

then removed from the light bulb and replaced by a variable dc source. The level of the dc

signal is adjusted so that the brightness of the light bulb is the same as it was for the ac

signal. This dc level is equivalent to the rms value of the ac signal. This cumbersome

method is not practical for handheld multimeters, so an active log-antilog analog

computation is continuously performed on the input signal.

2-4

Page 25

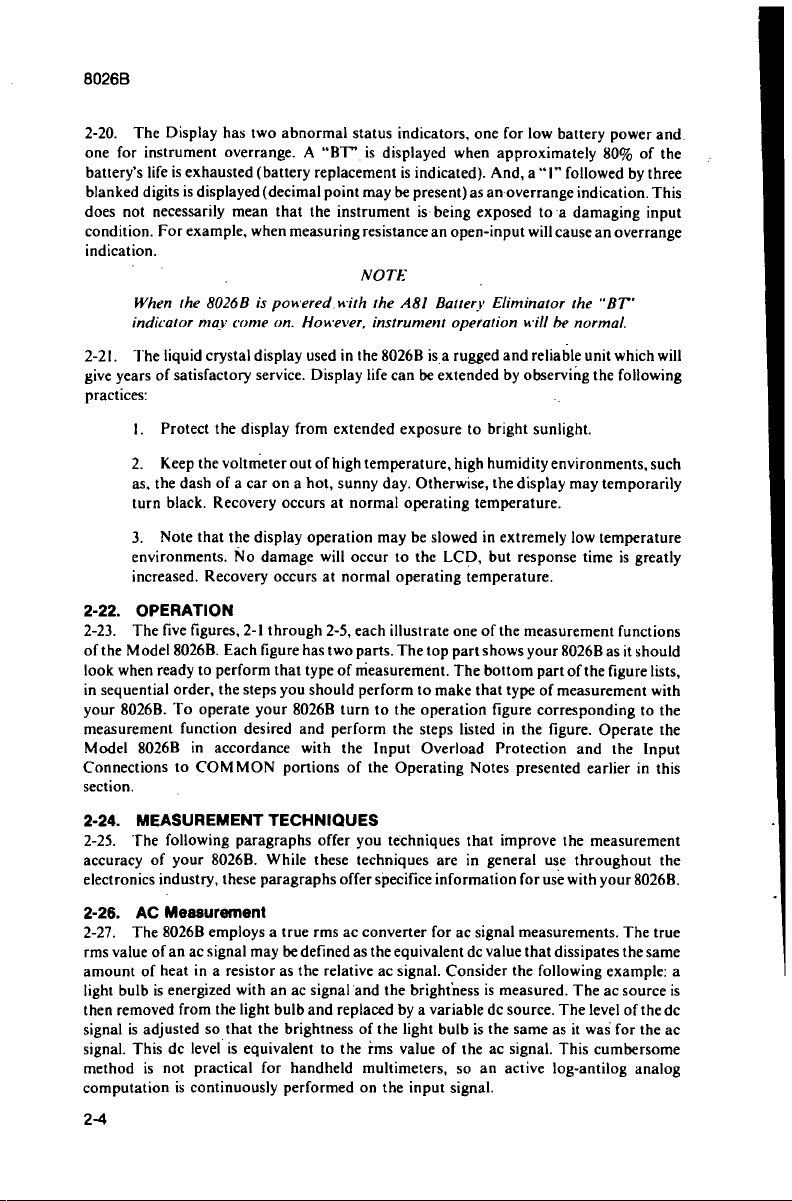

VOLTS (V)

OUT FOR DC

(IN FOR AC)

IN FOR 20V

RANGE

OUT FOR V

FUNCTION

*NOTE: The function switches are push-push type. Do not pull them to the out

position.

• Connect the test leads as shown above.

• Depress the switch beside the range desired (20V is shown selected).

• Set the AC/DC switch out for DC or in For AC (DC is shown selected).

8026B

• Ensure that all other switches are at the out or off positions.

WARNING

TO AVOID ELECTRICAL SHOCK AND/OR INSTRUMENT DAMAGE, DO

NOT CONNECT THE 8026B TERMINALS TO SOURCES THAT EXCEED THE

FOLLOWING LIMITS WHEN MEASURING VOLTAGES:

COMMON:

V-n-S:

TERMINAL (INTHE AC FUNCTION, 200 mV RANGE, SOURCES GREATER

THAN 300V DC OR RMS AC SHOULD NOT BE CONNECTED LONGER THAN

IS SECONDS).

• Connect the test leads to the circuit being measured.

• Read the measured value on the display. The minus sign will appear if

the V-n-S terminal is negative with respect to the COMMON terminal.

500V DC OR RMS AC WITH RESPECT TO EARTH GROUND.

lOOOV DC OR 750V RMS AC WITH RESPECT TO THE COMMON

Figure 2-1. Volts Operation

2-5

Page 26

8026B

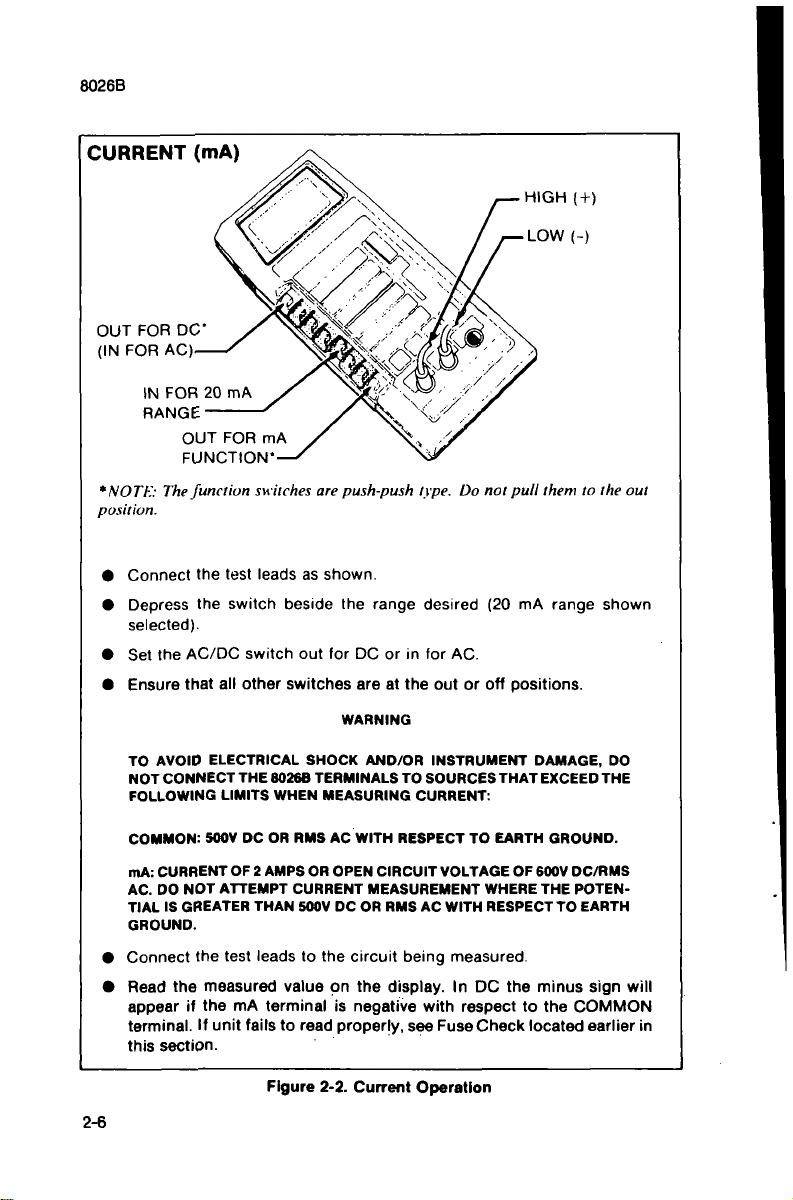

CURRENT (inA)

OUT FOR DC

(IN FOR AC)

IN FOR

RANGE

OUT FO

FUNCTION

*NOTE:

The

position.

• Connect the test leads as shown.

• Depress the switch beside the range desired (20 mA range shown

• Set the AC/DC switch out for DC or in for AC.

• Ensure that all other switches are at the out or off positions.

function switches are push-push type. Do not pull them to the out

selected).

WARNING

TO AVOID ELECTRICAL SHOCK AND/OR INSTRUMENT DAMAGE, DO

NOT

CONNECT

FOLLOWING LIMITS WHEN MEASURING CURRENT:

COMMON:

mA:

CURRENT

AC.

DO NOT ATTEMPT CURRENT MEASUREMENT WHERE THE POTENTIAL IS GREATER THAN

GROUND.

• Connect the test leads to the circuit being measured.

• Read the measured value on the display. In DC the minus sign will

appear if the mA terminal Is negative with respect to the COMMON

terminal.

this section.

2-6

THE 8026B

SOOV

DC OR RMS AC WITH RESPECT TO EARTH GROUND.

OF 2

If unit falls to read properly, see Fuse Check located earlier in

TERMINALS

AMPS

OR OPEN

SOOV

DC OR

Figure 2-2. Current Operation

TO SOURCES THAT EXCEED

CIRCUIT VOLTAGE

RMS

AC WITH RESPECT

OF 6(X)V

TO

DC/RMS

EARTH

THE

Page 27

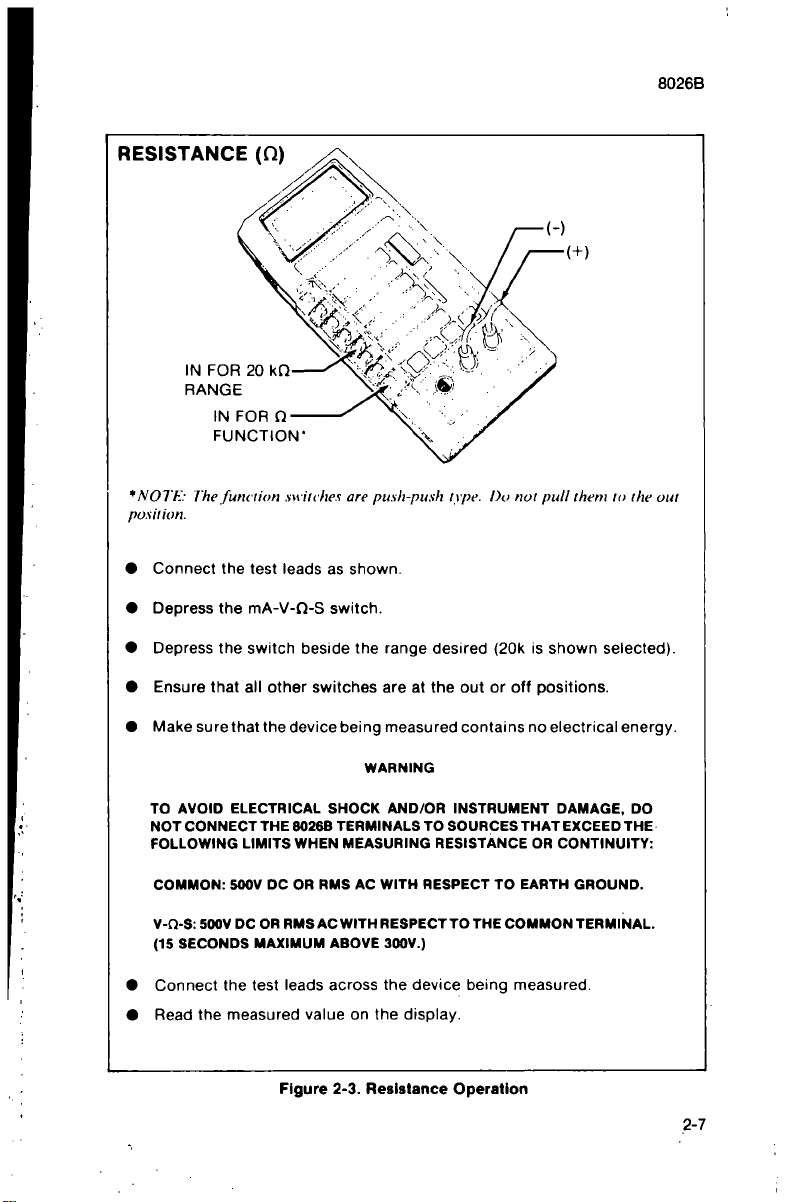

RESISTANCE (Q) /<\

IN FOR 20 kn

RANGE

IN FOR n

FUNCTION

*NOTE: The function switches are push-push type. Do not pull them to the out

position.

• Connect the test leads as shown.

• Depress the mA-V-O-S switch.

• Depress the switch beside the range desired (20k is shown selected).

8026B

• Ensure that all other switches are at the out or off positions.

• Make sure that the device being measured contains no electrical energy.

WARNING

TO AVOID ELECTRICAL SHOCK AND/OR INSTRUMENT DAMAGE, DO

NOT CONNECT THE 8026B TERMINALS TO SOURCES THAT EXCEED THE

FOLLOWING LIMITS WHEN MEASURING RESISTANCE OR CONTINUITY:

COMMON:

V-n-S:

(15 SECONDS MAXIMUM ABOVE SOOV.)

• Connect the test leads across the device being measured.

• Read the measured value on the display.

SOOV DC OR RMS AC WITH RESPECT TO EARTH GROUND.

SOOV DC OR RMS AC WITH RESPECT TO THE COMMON TERMINAL.

Figure 2-3. Resistance Operation

2-7

Page 28

8026B

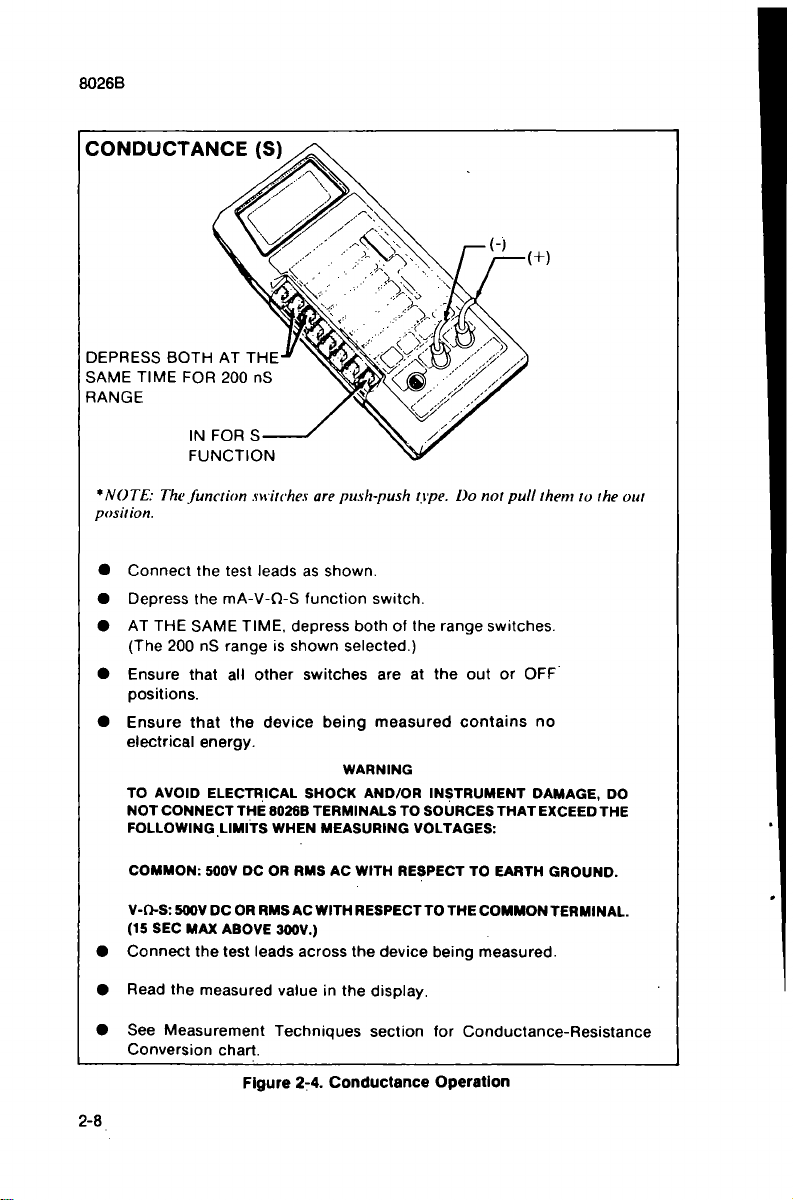

CONDUCTANCE (S)

DEPRESS BOTH AT THE

SAME TIME FOR 200 nS

RANGE

IN FOR S —

FUNCTION

*NOTE: The function switches are push-push type. Do not pull them to the out

position.

Connect the test leads as shown.

Depress the mA-V-O-S function switch.

AT THE SAME TIME, depress both of the range switches.

(The 200 nS range is shown selected.)

Ensure that all other switches are at the out or OFF

positions.

Ensure that the device being measured contains no

electrical energy.

WARNING

TO AVOID ELECTRICAL SHOCK AND/OR INSTRUMENT DAMAGE, DO

NOT CONNECT

FOLLOWING LIMITS WHEN MEASURING VOLTAGES:

THE 8026B

TERMINALS

TO SOURCES

THAT

EXCEED

THE

COMMON:

V-O-S:

(15 SEC MAX ABOVE SOOV.)

Connect the test leads across the device being measured.

Read the measured value in the display.

See Measurement Techniques section for Conductance-Resistance

Conversion chart.

2-8

SOOV

SOOV

DC OR RMS AC WITH RESPECT TO EARTH GROUND.

DC

OR RMS AC WITH RESPECT TO THE COMMON

Figure 2-4. Conductance Operation

TERMINAL.

Page 29

CONTINUITY

IN FOR

AUDIBLE TONE

IN FOR 2 kn FUNCTION

IN FOR n FUNCTION

*NOTE:

The

position.

• Connect the test leads as shown.

• Depress the mA-V-n-S function switch.

• Depress the 2 kn range switch.

function switches are push-push type. Do not pull them to the out

8026B

• Depress the AC/DC function switch.

• Ensure that all other switches are at the out position.

• Ensure that the device being measured contains no

electrical energy.

WARNING

TO AVOID ELECTRICAL SHOCK AND/OR INSTRUMENT DAMAGE, DO

NOT

CONNECT

FOLLOWING LIMITS WHEN MEASURING CONDUCTANCE:

COMMON:

V-n-S:

SOOV DC OR RMS AC WITH RESPECT TO THE COMMON

(15 SEC MAX ABOVE SOOV.)

• Connect the leads to the circuit being measured.

• Continuity between the test leads will cause the audible tone to sound.

THE 6026B

SOOV

DC OR RMS AC WITH RESPECT TO EARTH GROUND.

Figure 2-5. Continuity Operation

TERMINALS

TO SOURCES

THAT

EXCEED THE

TERMINAL.

2-9

Page 30

8026B

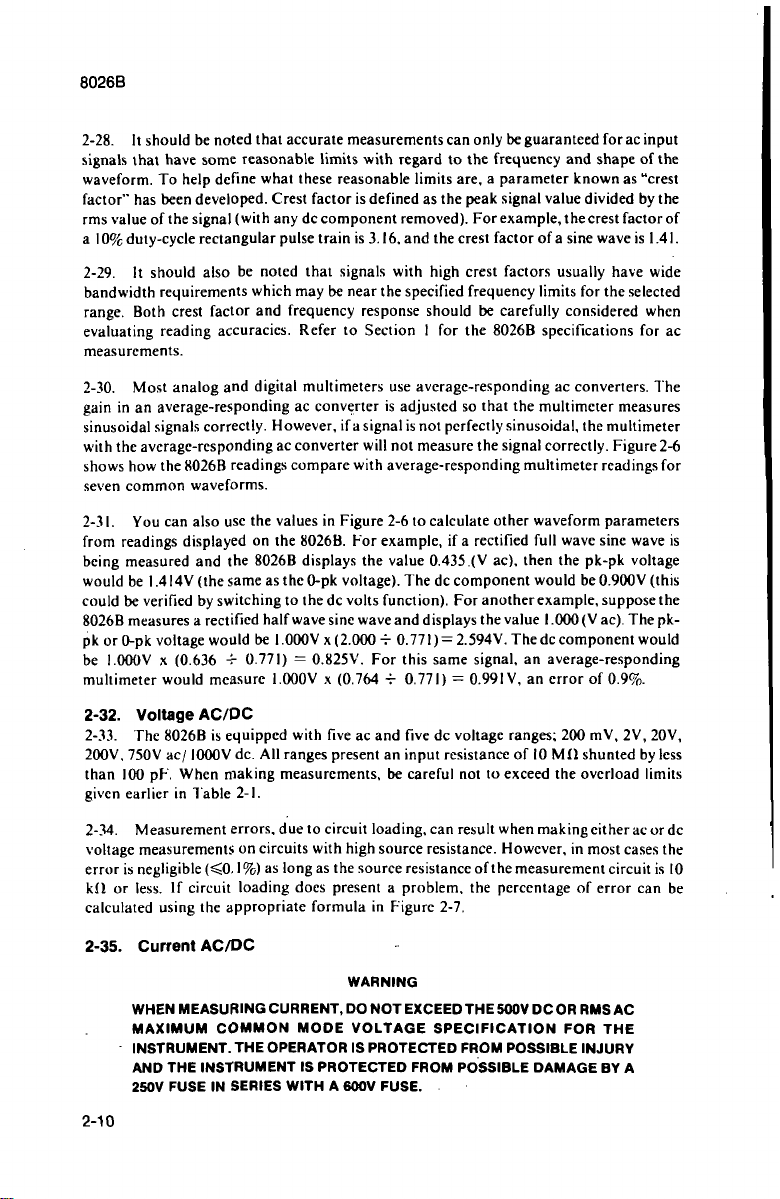

2-28.

It should be noted that accurate measurements can only be guaranteed for ac input

signals that have some reasonable limits with regard to the frequency and shape ofthe

waveform. To help define what these reasonable limits are. a parameter known as "crest

factor" has been developed. Crest factor is defined as the peak signal value divided by the

rms value of the signal (with any dc component removed). Forexample, the crest factor of

a

10%

duty-cycle rectangular pulse train is 3.16, and the crest factor of a sine wave is 1.41.

2-29. It should also be noted that signals with high crest factors usually have wide

bandwidth requirements which may be near the specified frequency limits for the selected

range. Both crest factor and frequency response should be carefully considered when

evaluating reading accuracies. Refer to Section 1 for the 8026B specifications for ac

measurements.

2-30. Most analog and digital multimeters use average-responding ac converters. The

gain in an average-responding ac converter is adjusted so that the multimeter measures

sinusoidal signals correctly. However, if a signal is not perfectly sinusoidal, the multimeter

with the average-responding ac converter will not measure the signal correctly. Figure 2-6

shows how the 8026B readings compare with average-responding multimeter readings for

seven common waveforms.

2-31.

You can also use the values in Figure 2-6 to calculate other waveform parameters

from readings displayed on the 8026B. For example, if a rectified full wave sine wave is

being measured and the 8026B displays the value 0.435 (V ac). then the pk-pk vohage

would be

1.414V

(the same as the 0-pk voltage). The dc component would be 0.900V (this

could be verified by switching to the dc volts function). For another example, suppose the

8026B measures a rectified half wave sine wave and displays the value 1.000

pk or 0-pk voltage would be

1 OOOV

x (2.000

-=-

0.771) = 2.594V. The dc component would

(V

ac). The pk-

be l.tXWV X (0.636 -r 0.771) = 0.825V. For this same signal, an average-responding

multimeter would measure I.OOOV x (0.764 -=- 0.771) = 0.991V, an error of 0.9%.

2-32.

Voltage AC/DC

2-33.

The 8026B is equipped with five ac and five dc voltage ranges; 200 mV, 2V, 20V,

2(X)V. 750V ac/

ICMXIV

dc. All ranges present an input resistance of 10 Mil shunted by less

than IOO pF. When making measurements, be careful not to exceed the overload limits

given earlier in lable 2-1.

2-34. Measurement errors, due to circuit loading, can result when making either ac or dc

voltage measurements on circuits with high source resistance. However, in most cases the

error is negligible «0.1%) as long as the source resistance of the measurement circuit is 10

kn or less. If circuit loading does present a problem, the percentage of error can be

calculated using the appropriate formula in Figure 2-7.

2-35. Current AC/DC

WARNING

WHEN MEASURING CURRENT, DO NOT EXCEED THE

MAXIMUM COMMON MODE VOLTAGE SPECIFICATION FOR THE

INSTRUMENT. THE OPERATOR IS PROTECTED FROM POSSIBLE INJURY

AND THE INSTRUMENT IS PROTECTED FROM POSSIBLE DAMAGE BY A

250V FUSE IN SERIES WITH A SOOV FUSE.

2-10

SOOV

DCOR RMS AC

Page 31

8026B

AC-COUPLED

INPUT

WAVEFORM

SINE

PK

1

RECTIFIED SINE

(FULLWAVEI

RECTIFIED SINE

(HALF WAVEl

^/\/\p^K

SQUARE

O' . PK PK

RECTIFIED

SQUARE

PK PK-i

RECTANGULAR

PULSt

"^r^ rn +

-M Y U- t

D - X, Y

K Vl3 - D'

TRIANGLE

SAWTOOTH

PK

0^^ PK^K

PEAK VOLTAGES

PK-PK

2

8?8

1

414

2.000

2000

1

414

2.000

3464

0-PK

1.414

1

414

2 000

1.000

1.414

2.000

1.732

DISPLAY HtADINGS

AC COMPONENT ONLY

RMS CAL

AVE SENSING

1

0.421

0 764

1111

0.786

2 22IK

0.960

RMS SENSING

000

(80268)

1.000

0 435

0 771

1.000

0.707

2K

1.000

DC

COMPONENT

ONLY

0 000

0 900

0 636

0.000

0.707

2D

0000

DC AND AC

TOTAL RMS

TRUE RMS =

\''ac' • dc

=

1.000

1

000

1.000

1.000

1.000

2\^

1

000

NOTE:

High Frequency waveforms with fairly abrupt transitions (such as a

5 kHz pulse with a 10% duty cycle) have spectral components that are

beyond the specified frequency limits for the selected range. Be sure to take

this into account when evaluating measurements.

Figure 2-6. Waveform Conversion

2-11

Page 32

8026B

1.

DC VOLTAGE MEASUREMENTS

Loading Error in % = 100 x Rs^ (Rs + 10')

Where: Rs = Source resistance in ohms of circuit

2.

AC VOLTAGE MEASUREMENTS

First, determine input impedance, as follows:

Zin

Where: Zin — effective input impedance

Rin = 10' ohms

Cin = 100 X 10-" Farads

F = frequency in Hz

Then,

determine source loading error as follows:

being measured.

lO:

v/l + (2n F 'Rin'O'

Loading Error in %

Where: Zs = source impedance

Zin = input impedance (calculated)

"Vector algebra required

Figure 2-7. Voltage Measurement Error Calculations

2-36. Four ac and four dc current ranges are included on the 8026B; 2 mA, 20 mA, 200

mA, and 2000 mA: Each range is diode protected to 2 amps and fuse protected above 2

amps.

If either fuse blows, refer to fuse replacement information given earlier in this

section.

2-37.

In high elearical noise environments (near ignition switches, fiourescent lights,

relay switches, etc.) unstable or erroneous readings (exceeding specifications) may occur.

The effect is most obvious when measuring low level current on the 2 mA range. If an

2-12

100 xZs

Zs + Zin

Page 33

8026B

erratic or erroneous reading is suspected, temporarily jumper the V/n connector to the

mA connector. This is recommended for the 2 mA and 20 mA ranges only.

CAUTION

To avoid pos8lt>le Instrument damage and/or erroneous measurements

remove the temporary V/O-to-mA jumper l>efore attempting voltage or

resistance measurements.

2-38.

Full-scale burden voltage (voltage drop across the fuse and current shunt) for all

ranges except 2000 mA is less than 300 mV. The 2000 mA range has a full-scale burden

voltage of less than 900 mV. These voltage drops can affect the accuracy of a current

measurement, if the current source is unregulated and the shunt plus fuse resistance

represents a significant portion (l/IOOO or more) of the source resistance. If burden

voltage does present a problem, the percentage of error can be calculated using the

formula in Figure 2-8. This error can be minimized by using the highest current range that

gives the necessary resolution. For example, if 20 mA is measured on the 2000 mA range

the burden voltage is approximately 5 mV.

2-39. Resistance

2-40. Six direct reading resistance scales are provided on the 8026B: 20 Mn, 2000 kn,

200 kn, 20 kn, 2 kn and 200n. All scales employ a two-wire measurement technique. As a

result, test lead resistance may influence measurement accuracy on the 200n range. To

determine the error, short the test leads together and read the lead resistance. Correct the

measurement by subtracting the lead resistance from the measurement reading. The error

is generally on the order of 0.2 to 0.3 ohms for a standard pair of test leads.

2-41.

In-circuit resistance measurements can be made using the 200n, 20 kfl and 2000

kn ranges. The full scale measurement voltage produced on these ranges is not sufficient

to forward bias silicon diode/ emitter-base junctions, and thus, enables resistance values to

be measured without removing diodes and transistors from the circuit. Conversely, the 2

kn, 200 kn, and 20 Mn ranges produce a measurement voltage sufficient to forward bias a

P-N junction. These ranges enable both diode- and transistor-junction checks to be made

conveniently. Full scale voltage and short circuit current for each resistance range is given

in Table 2-2. All values shown are referenced to the COMMON input terminal; i.e., the

V/n/S terminal is positive.

NOTE

A

ny change (greater than one or two digits) in apparent resistance when test

leads are reversed may indicate either the presence of a diode junction or a

voltage in the circuit.

CAUTION

Tum test circuit power off and discharge all capacitors before attempting Inclrcult resistance measurements.

2-13

Page 34

8026B

Es-r-

Es = Source voltage

RL

= Load resistance + Source resistance

1^

= Measured current (display reading in mA)

EB

= Burden voltage (calculated), i.e.. Display reading

expressed asa%offull-scale(100x

FULL-SCALE

^

times full-scale burden voltage for selected range. See

Table.

RANGE

2 mA to 200 mA

2000 mA

MAXIMUM

BURDEN VOLTAGE

0.3V

0.9V

Maximum current error due to Burden Voltage:

Error in %

Error in mA

= 100

EBX'M

Es -EB

X

=B

ES-EB

Example: Es = 14V, RL = 90, I^/I = 1497 mA,

Eg = 100

1497

X 0.9 (from Table)

2000

749% X 0.9 ^ 0.674V

Error in % = 100

.674

14-674 ' 13.326

100

.674

5.06%

Increase displayed current by 5.06% to obtain true current.

2-14

Error in mA

_ .674 X 1497 1009

14 - .674 13.326

76 mA

Increase displayed current by 76 mA to obtain true current.

Figure 2-8. Current Measurement Error Calculations

Page 35

Table 2-2. Voltage/Current Capability of Resistance Ranges

RANGE

FULL-SCALE

VOLTAGE (TYPICAL)

SHORT CIRCUIT

CURRENT (TYPICAL)

8026B

20 Mn

2000 kn

200 kn

20 kn

2kn-w2oon

2-42. Three of the 8026B resistance ranges have a high enough open-circuit voltage to

turn on a silicon junction. These ranges (2 kn. 200 kn, and 20 Mn) can be used to check

silicon diodes and transistors. The 2 kn range is preferred for this function and is marked

with a diode symbol. The open-circuit voltage of the three alternate ranges (200n, 2 kn,

and 2 Mn) is not high enough to turn on a silicon junction. Use these three ranges to make

in-circuit resistance measurements. For all resistance ranges, the V/n/S input terminal is

positive with respect to the COMMON input terminal.

2-43. Continuity

2-44. Audibly confirmed continuity measurements may be made using any of the

resistance or conductance ranges. The 2 kn range is recommended for this mode since it

provides the lowest resistance threshold, approximately 110 ohms. On this range a

measured resistance lower than 110 ohms initiates the audible tone. To determine the

exact threshold, use a variable resistor and observe the display reading at which the tone

switches on and/ or off. Note that in this mode resistance or conductance readings are also

displayed. However, high resistance ranges and the 200 nS range may exhibit noisy or

drifting readings due to ambient signal noise.

2-45.

Intermittent open or short circuits with a duration of at least 50

the 2 kn range. A continuously intermittent connection is heard as a series of beeps. A

series of beeps (due to environmental noise) is also encountered when a measurement is

near the threshold of the selected range. The approximate thresholds for the continuity

ranges are as follows:

+800 mV

+200 mV

+800 mV

+200 mV

+ 1.1V

+55 mV

+0.12

A/A

+0.12

AiA

+ 12AiA

+^2^^

+ 1.0 mA

+0.3 mA

jus

are detectable in

RANGE

200 nS

2mS

20 MO

2000 kn

200 kn

20 kn

2kn

20on

THRESHOLD

900 kilohms

110 ohms

900 kilohms

900 kilohms

9 kilohms

9 kilohms

110 ohms

360 ohms

2-15

Page 36

8026B

2-46. Conductance

2-47.

The conductance ranges, (2(X) nS and 2 mSjare included on the 8026B for making

both conductance and resistance measurements. When either range is selected the display

reads the measurement resuhs in terms of conductance

required, refer to the conductance-to-resistance conversion information given in F'igure

2-9.

2-48.

The 200 nS range is intended for use in making fast, accurate, high-resistance

measurements from 5 Mn to 10,000 Mn. Ordinarily, resistance measurements within this

range are plagued by noise pick-up and require careful shielding. However, by measuring

the resistance in terms of conductance, standard test leads are adequate for the 8026B to

make noise-free measurements up to 10,000 Mn. High value resistors, and low leakage

components (i.e., diodes, etc.) are natural candidates for the 200 nS conductance range.

Refer to applications later in this section for additional information.

2-49. The 2 rriS range, in terms of resistance, starts at 500n and goes up to 1 Mn. It is

intended for use in making either resistance measurements or direct-reading dc current

gain (beta) measurements on transistors. Beta measurements require the use of a special

test fixture, and are discussed later in this section under applications.

2-50. APPLICATIONS

2-51.

The applications described in the following paragraphs are suggested as useful

extensions of the 8026B measurement capabilities. However, they are not intended as the

equivalent of a manufacturer's recommended test methods. Rather, they are intended to

provide repeatable and meaningful indications which will allow operator to make sound

judgments concerning the condition of the device being tested; i.e., good, marginal, or

defective.

(1

/ n). if resistance readings are

2-52. Transistor Tester

NOTE

The transistor tester described in the following paragraphs provides

approximate test information. Beta is measured using a VCE of about 2

and an IC of about 200 fiA. The test method is very useful for making

comparative and matching measurements.

2-53.

Select the 2 mS range, plug the fixture shown in Figure 2-10 into the V/n/S and

COMMON input terminals, and you have tranformed your 8026B into a transistor tester.

Now, plug a transistor into the test socket and the 8026B will determine the following:

1.

Transistor type (NPN or PNP).

2.

Collector-to-emitter leakage (ICEs).

3.

Beta from 1 to KKX) without changing range.

2-16

V

Page 37

*mS-to-kO

2

mS

(I'mS

inS

k(^

c

o

ro

ID

o

o

O

o

3

<

•

3

•

20-]

1

0;

05-

02-

0.1;

005-

0

03-

0

01;

0

005-

0

002-

0

001

-

Conversi

o

*

S=

Siemens

of conductance

mho.

to

I

•nS-to-kQ

Range

200

nS

(1000/nS

nS

un

200-

100;

50-

20-

10 =

5-

2-

1;

0 5-

02-

0 1-

Range

-

= kO)

-5

:i

-2

-5

= 10

-20

-50

= 100

-200

-

-500

=1000

on Scales

li\=International unit

= 1

formerly known as the

=Mn)

-i

= 10

r20

L

-50

= 100

-200

-500

= 1000

-2000

-

-sooo

= 10000

NO.

1

2

3

4

5

6

7

a

9

Find the approximate resistance value using one of

the scales

the most significant digit

the vertical NO. column, and

horizontal NO. row. The number

coordinates represents

value.

at

left. Then,

on

of

the

For example, a reading

the table below, locate

the display reading

the

next digit

at

the intersecting

unknown resistance

of

52.0 nS

is

equal

19.2 Mn. Decimal point location is determined from

the scale approximation.

Interpolation Table (I/no.)

.0

1

.500

.333

.250

.200

.167

.143

.125

111

.1

.909

.476

.323

.244

196

.164

.141

.123

.110

.2

.833

.455

.313

.238

.192

.161

.139

122

.109

.3

.769

.435

.303

233

.187

137

.108

159

121

.4

.714

.417

294

.227

.185

156

135

.119

.106

.5

.667

.400

.286

.222

182

.154

.133

.118

.105

.6

625

.385

.278

.217

.179

.152

.132

.116

.104

on

on the

to

.7

588

.370

.270

.213

.175

.149

.130

115

.103

.8

.556

.375

263

.208

.172

.147

.128

.114

.102

.9

.526

.345

.256

.204

.169

.145

.127

.112

.101

s

ho

a>

CD

Page 38

SCHEMATIC

TRANSISTOR

UNOER

TEST

TEST

FIXTURE

s

ro

a>

03

»

o

OB

«

M

3

CONSTRUCTION DETAIL

3/16" HOLE

»C >

B >

»E >

WIRE TO BASE

CONTACT OF

TRANSISTOR SOCKET

BETA

^

'CEs

I

Rl

TRANSISTOR

PLUG INTO

COMMON AND

V/Kn/nS INPUT

TERMINALS

Jl

SOCKET

BANNANA PLUQ

CONNECTOR 0.75"

SPACING GENERAL

RADIO TYPE 274 MB

WIRE TO

SWITCH ARM

Page 39

8026B

2-54. Transistor type is determined by setting the switch on the fixture to BETA and

observing the display. If a low reading (^.010) is obtained, reverse the test fixture at the

input terminals. Ifthe collector is now positioned at the COMMON input terminal, the

transistor is a PNP type. An NPN type will have its collector positioned at the V/n/S

input terminals. If the transi.stor is defective the indications will be as follows regardless of

fixture position:

1.

A shorted transistor will cause an overload indication.

2.

An open transistor will read 0.001 or less.

2-55.

After the transistor fixture is properly positioned, set the switch to ICEs for the

leakage test. The transistor is turned off in this test (base shorted to emitter), and should

appear as a very low conductance (high resistance) from collector-to-emitter. Therefore,

the lower the reading, the lower the leakage. Silicon transistors that read more than 0.002

(6 fiA) should be considered questionable.

2-56. Beta is determined by setting the fixture switch to BEl'A, and observing the

display. Mentally shift the decimal point three places to the right and read beta directly.

For example, a display reading of 0.127 indicates a dc current gain (beta) of 127.

NOTE

Beta is a termperature sensitive parameter. Therefore, repeatable readings

can only he obtained by allowing the transistor lo stabilize at the ambient

temperature while being tested. A void touching the transistor's case with

your fingers.

2-57. Leakage Tester

2-58.

The 200 nS conductance range effectively extends the resistance measurement

capability of the 8026B (up to 10,000 Mil) to the point where it can be used to provide

useful leakage measurements on passive components. For example, you can detect leaky

diodes, cables, connectors, printed circuit boards (pcbs), etc. Inallcases, the lest voltage is

<I.5V dc.

2-59. RESISTIVE COMPONENTS

2-60. Leakage testing on purely resistive components such as cables and pcbs is

straightforward. Select the 200 nS range, install the test leads in the V.'H/S and

COM MON input terminals, connect the leads to the desired test points on the unit-underlest, and read leakage in terms of conductance. If an overrange occurs, select a resistance

range that provides an on-scale reading.

NOTE

Under high humidity conditions (>80'.c) conductance measurements may

be in error. To ensure accurate measurements connect clean test leads to the

8026 B

and (with the leads open) read the residual leakage in nanosiemens.

Correct subsequent measurements by subtracting the residual from ihe

readings. (Finger prints or other contamination on the pch may also cau.se

residual conductance readings.)

2-19

Page 40

8026B

2-61.

DIODES

2-62. Diode leakage (I^) tests require that the diode junction be reverse biased when

being measured. This is accomplished by connecting the anode of the diode to the

COM MON input terminal and its cathode to the V/ n/ S input terminal. Leakage can then

be read in terms of conductance. In the event of an overrange, select a resistance range that

provides an on-scale reading.

NOTE

Like all general-purpose multimeters, the 8026B generates and uses radio

frequency energy. It

radio or television reception. If interference does occur, try moving the

8626B to a different location, plugging the radio or television into a

different socket, or reorienting the antenna.

is

possible for radio frequency energy to interfere with

2-20

Page 41

8026B

Section 3

Theory of Operation

3-1.

INTRODUCTION

3-2. This section ofthe manual contains an overall functional description followed by a

block diagram analysis ofthe 8026B. A detailed schematic of the8026B appears in Section

7.

3-3. OVERALL FUNCTIONAL DESCRIPTION

3-4. The Model 8026B as shown in Figure .3-1, is a hand-held 8 function digital

multimeter. It features a total of

six, dc current-four, ac current-four, and conductance-two); with overload protection for

all ranges.

3-5.

Operation centers around a custom LSI chip, Ul, which contains a dual slope a/d

converter and a display driver. Peripherals to U1 include range and function switches,

input signal conditioners, and the display. When an input signal is applied to the 8026B it is

routed through the range switches to one of four input signal conditioners as determined

by the function switch setting. Each conditioner scales and converts the input to an

acceptable dc input level (-0.2 to +0.2V dc) that is presented to the a/d converter.

26

measurement ranges (dc volts-five, ac volts-five, ohms-

3-6. Timing for the overall operation of the a/d converter is derived from an external

quart/ crystal whose frequency is a multiple ofthe local line frequency. This allows the

conditioned dc input data to be integrated over an integral number of power line cycles,

thus optimizing both common mode and normal mode rejection.

3-7. Digitized measurement data is presented to the display as four decoded digits (seven

segments) plus polarity. Decimal point position on the display is determined by the range

switch settings.

3-8. BLOCK DIAGRAM ANALYSIS

3-9. A/D Converter

3-10. Ihe entire analog-to-digital conversion process is accomplished by a single custom

A/D Converter and Display Driver IC. Ul. The IC employs the dual slope method of a/d

conversion, and requires a series of external components to establish the basic timingand

referenece levels required for operation. Ihese include an integrating capacitor, an

autozero capacitor, and a fiying capacitor (for applying a reference level of either

3-1

Page 42

8026B

polarity). Since the power consumed for display operation is very low. the IC also contains

the latches, decoders, and drivers required for the display.

3-11.

The digital control portion of the a/d conversion process is an internal function of

Ul.

and is keyed to the external crystal frequency. As a result, the conversion process is

continuously repeated, and the display is updated at the end of every conversion cycle.

3-12. A simplified circuit diagram of the analog portion of the a/d converter is shown in

Figure 3-2. Each of the switches shown represent analog gates which are operated by the

digital section of the a/d converter. Basic timing for switch operation and. therefore, a

complete measurement cycle is also included in the figure.

3-13.

Any given measurement cycle performed by the a/d converter can be divided into

three consecutive time periods, autozero (AZ), integrate (INFEG), and read. Both

autozero and integrate are fi.xed time periods whose lengths are multiples of the clock

frequency. A counter determines the length of both time periods by providing an overfiow

at the end of every 10,000 clock pulses. The read period is a variable time which is

proportional to the unknown input voltage. The value of the voltage is determined by

counting the number of clock pulses that occur during the read period.

3-14. During autozero a ground reference is applied as an input to the a/d converter.

Under ideal conditions the output of the comparator would also go to zero. However,

input-offset-voltage errors accumulate in the amplifier loop, and appear at the

comparator output as an error voltage. This error is impressed across the AZ capacitor

where it is stored for the remainder of the measurement cycle. The stored level is used to

provide offset voltage correction during the integrate and read periods.

3-15.

The integrate period begins at the end ofthe autozero period. As the period begins,

the AZ switch opens and the INTEG switch closes. This applies the unknown input voltage

to the input of the a/ d converter. The voltage is buffered and passed on to the integrator to

determine the charge rate (slope) on the INTEG capacitor. By the end ofthe fixed integrate

period the capacitor is charged to a level proportional to the unknown input voltage. Ihis

voltage is translated to a digital indication by discharging the capacitor at a fixed rate

during the read period, and counting the number of clock pulses that occur before it

returns to the original autozero level.

3-16. As the read period begins, the INTEG switch opens and the read switch closes. Ihis

applies a known reference voltage to the input ofthe a/d converter. The polarity ofthis

voltage is automatically selected to be opposite that ofthe unknown input voltage, thus,

causing the INTEG capacitor to discharge at a fixed rate(slopc). When the charge is equal

to the initial starting point (autozero level), the read period is ended. Since the discharge

slope is fixed during the read period, the time required for discharge is proportional to the

unknown input voltage.

3-17. The autozero period and. thus, a new measurement cycle begins at the end ofthe

read period. At the same time the counter is released for operation by transferring its

contents (previous measurement value) to a seriijs of latches. This stored data is then

decoded and buffered before being used for driving the liquid crystal display.

3-2

Page 43

(n

-n

c

3

In

OD

(0

3

n

a.

n

S

5

5

3

V/n/S

COMM

mA

/

/

' 1

RANGE

SWITCHES

/

/

n

mA

.

VOLTAGE

DIVIDER

OHMS

CONVERTER

CONTINUITY

ANNUNCIATOR

AC

CONVERTER

-

/

mA

CURRENT

SHUNT

/

/

RANGE

SWITCHES

0 or 1 /n

V ac

V

ac/mA

ac

V dc

FUNCTION

SWITCHES

DC

ANALOG

DATA

DECIMAL

POINT

A/D

CONVERTER

AND

DISPLAY

DRIVER

i

he.-»-'1

DISPLAY

SK

3N

>

AL

CONDITIC

)NEF

^S

§

ro

Page 44

i

I

a

c

S.

CO

o

?

O

%

I

EXTERNAL

INPUTS

± REF

(FLYING

CAPACITOR)

UNKNOWN

INPUT

VOLTAGE

±

READH

INTEG

AZ

BUFFER

AMP

COMPARATOR

INTEGRATOR

AZ

TO

DIGITAL

"CONTROL

LOGIC

INTEG

-H(—

Page 45

INTEG READ AZ

±.20

u

lO

o

•o

•

AZ

I

>

D

O

S

<

a.

o

a

o

CJI

COUNTER

OUTPUT

'An integral number of line cycles for optimum

Common mode and normal mode rejection.

10,000 I

-W I

—1

1000

2000

00

o

ro

o>

•D

Page 46

8026B

3-18. Input Signal Conditioners

3-19. The a/d converter requires two externally supplied input voltages to complete a

measurement cycle. One is reference voltage and the other is an unknown dc voltage w ithin

the range of -0.2 to +0.2V dc. If the function being measured is other than a dc voltage

within the ±0.2 range, it must be scaled and/ or conditioned before being presented to the

a/d converter, for example, higher dc levels must be divided; ac inputs must be divided,

rectified, and filtered; and resistance and current inputs must be scaled and converted to dc

voltlagc levels. The following paragraphs describe the input signal conditioners used for

each of the 8026B measurement functions.

3-20. VOLTAGE MEASUREMENT

3-21.

Both the ac and dc voltage ranges use an over-voltage-protected, 10 Mn input

divider as shown in Figure 3-3 A. Under normal conditions, assuming a dc input level on

the proper range, the divider output is a 0.2 to +0.2V dc signal, and

10) ratio of the input signal. If the VAC function is selected, the divider output is ac

coupled to an rms ac convener whose dc output is equivalent to the rms level of the ac

inputs. The conditioned signal for the selected function (V ac or V dc) is then passed

through a filter before being presented to the a/d converter as the unknown input.

3-22. CURRENT MEASUREMENT

3-23.

Current measurements are made using a fuse protected, switchable, four-terminal

current shunt (0. Kl, Ul, lOn, or lOOn) to f>erform the current-to-voltage conversion

required by the a/d converter. See Figure 3-3B. The voltage

selected shunt may be either ac or dc depending upon the selected function, mA AC or m A

DC.

if the input current is dc and the dc function is selected, the 1 R drop is pas.sed through

a low-pass filter, and presented as the unknown input to the a/ d converter. H owever. if the

input current is ac and the AC function is .selected, the I R drop is proces.sed by the ac

converter before going to the low-pass filter.

input voltage proportional to the current passing through the selected shunt.

I n

either event the a/ d converter receives a dc

is

an exact

(power-of-

(1

R) drop produced across the

3-24. RESISTANCE MEASUREMENTS

3-25.

Resistance measurements are made using a ratio technique as shown in Figure 3-

iC.

When the n function is selected, a simple series circuit is formed by the internal

reference voltage, a reference resistor from the voltage divider (selected by range switches),

and the external unknown resistor. Ihe ratio ofthe two resistor values is equal to the ratio

of their respective voltage drops. Therefore, since the value of one resistor is known, the

value of the second can be determined by using the voltage drop across the known resistor

as a reference. This determination is made directly by the a/d converter.

3-26. Overall operation ofthe a/ d converter during a resistance measurement is basically

as described earlier in this section, with one exception. The reference voltage present

during a voltage measurement is replaced by the voltage drop across the referenc-e resistor.

This allows the vohage across the unknown resistor to be read during the integrate period,