Page 1

Victoreen® 8000

NERO® mAx

Users Manual

December 2006

Manual No. 8000-100-1 Rev. 9

©2006 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: General Information................................................................................... 1-1

1.1 Product Description ..................................................................................... 1-1

1.2 New Features of Firmware 2.3..................................................................... 1-3

1.3 Specifications............................................................................................... 1-4

1.4 Battery Operation and Charging.................................................................. 1-5

1.5 Printing......................................................................................................... 1-6

1.6 Scope Output............................................................................................... 1-6

1.7 Procedures, Warnings, and Cautions .......................................................... 1-7

1.8 Receiving Inspection.................................................................................... 1-8

1.9 Storage........................................................................................................ 1-8

Section 2: Operation.................................................................................................... 2-1

2.1 Description................................................................................................... 2-1

2.2 General........................................................................................................ 2-1

2.3 Using the NERO mAx.................................................................................. 2-5

2.3.1 LCD Backlight Control............................................................................ 2-6

2.3.2 Measured Quantities .............................................................................. 2-7

2.4 Quick Start................................................................................................... 2-9

2.5 Modes of Operation ................................................................................... 2-10

2.5.1 Radio Mode.......................................................................................... 2-12

2.5.2 Mammo Mode ...................................................................................... 2-17

2.5.3 Fluoro Mode......................................................................................... 2-20

2.5.4 AMSE Mode......................................................................................... 2-25

2.5.5 CT Exposure Mode............................................................................... 2-28

2.5.6 Exp Mode............................................................................................. 2-30

2.5.7 HVL Mode ............................................................................................ 2-32

2.5.8 Cal Mode..............................................................................................2-43

2.5.9 Setup Mode.......................................................................................... 2-44

2.5.10 Unit ID .................................................................................................. 2-46

Section 3: Calibration.................................................................................................. 3-1

3.1 General........................................................................................................ 3-1

3.2 Calibration Check ........................................................................................ 3-1

i

Page 4

Section 4: Troubleshooting ........................................................................................ 4-1

4.1 General........................................................................................................ 4-1

4.2 Modes of Operation ..................................................................................... 4-2

4.2.1 Radio Mode............................................................................................ 4-2

4.2.2 Mammo Mode ........................................................................................ 4-5

4.2.3 Fluoro Mode ........................................................................................... 4-5

4.2.4 AMSE Mode........................................................................................... 4-6

4.2.5 Exposure Mode & CT Exposure Mode................................................... 4-6

4.2.6 HVL Mode .............................................................................................. 4-6

4.3 Error Messages ...........................................................................................4-7

4.4 Power Up Diagnostic Messages................................................................ 4-11

4.5 Waveforms - Overshoot............................................................................. 4-12

4.6 Waveforms - Partial kV Waveforms........................................................... 4-14

4.7 Waveforms - Self Rectified ........................................................................ 4-16

4.8 Waveforms - Dental with Filament Preheat................................................ 4-16

Section 5: Maintenance............................................................................................... 5-1

5.1 Fuse Replacement....................................................................................... 5-1

5.2 Battery Replacement ................................................................................... 5-1

5.3 Routine Cleaning......................................................................................... 5-2

Appendix A: Temperature and Pressure .......................................................................A-1

A.1 Temperature and Pressure..........................................................................A-1

Appendix B: mA Limits vs. kV........................................................................................B-1

B.1 mA Limits vs. kV..........................................................................................B-1

Appendix C: Exposure and Rate Resolution and Limits..............................................C-1

C.1 Exposure and Rate Resolution and Limits...................................................C-1

Appendix D: CT Exposure Resolution...........................................................................D-1

D.1 CT Exposure Resolution..............................................................................D-1

Appendix E: Ion Chamber of Sensitive Volume............................................................E-1

E.1 Ion Chamber of Sensitive Volume ...............................................................E-1

Appendix F:

Replacement Parts .................................................................................... F-1

F.1 Replacement Parts......................................................................................F-1

F.2 Accessories ................................................................................................. F-2

ii

Page 5

General Information

Product Description

1

Section 1

General Information

1.1 Product Description

To proceed directly to "Quick Start", go to Section

2.4.

To proceed directly to "Setup Mode", go to Section

2.5.9.

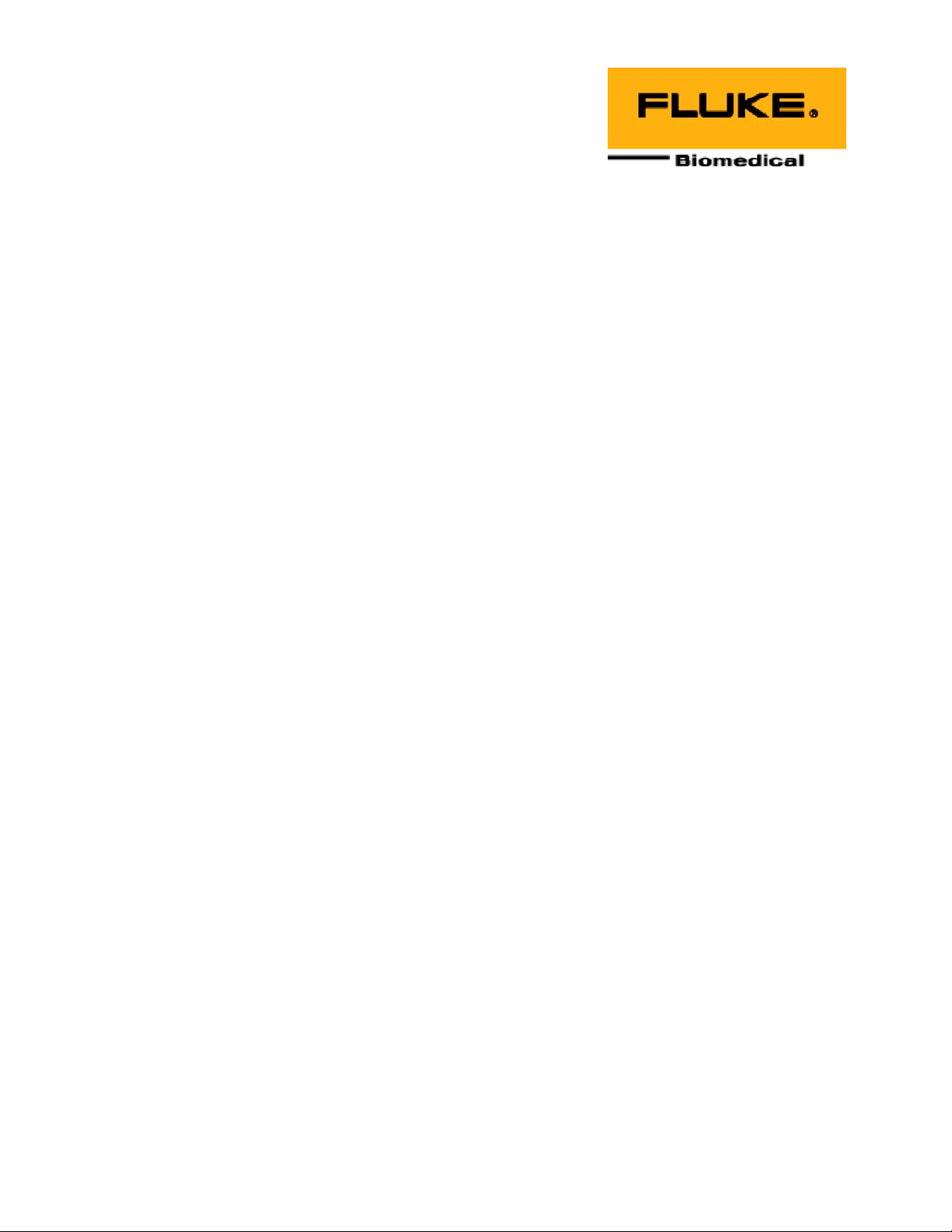

The Victoreen NERO™ mAx Model 8000, Non-invasive Evaluator of Radiation Output, uses an

innovative system of menus and softkeys to provide an intuitive, user friendly operating environment. All

measurement modes and options are displayed on the NERO mAx’s LCD and all functions are controlled

by the 5 softkeys beneath the display and the 3 keys to the right of the display.

NOTE

The NERO mAx consists of the NERO mAx control console, detector, detector cable, filter slides, AC

adapter, HVL plates, manual, Microsoft® Excel Add-in and carrying case.

The NERO mAx control console is compact and easy to use. The sophisticated electronics necessary to

provide highly accurate, reproducible measurements while maintaining an intuitive, user friendly operating

system are in the NERO mAx control console. The NERO mAx’s rechargeable battery is also housed in

the control console. The front panel of the control console contains a backlit 240 x 64 pixel, dot matrix

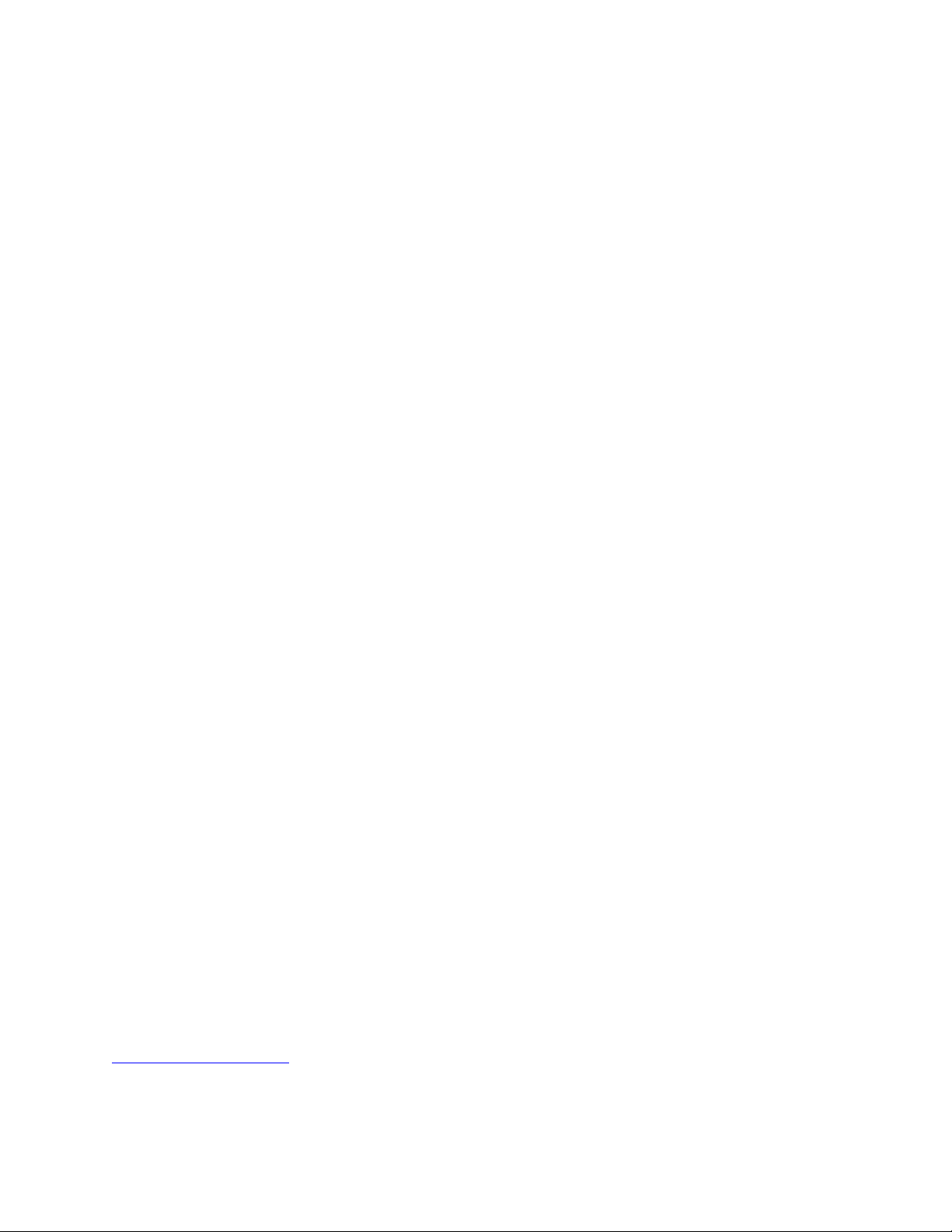

LCD display and eight push buttons. Connectors for power input, RS-232, printer, scope output and the

NERO mAx detector are located on the control console’s rear panel.

1-1

Page 6

Victoreen 8000

Operators Manual

Figure 1-1.Control Console Front Panel

Figure 1-2. Control Console Rear Panel

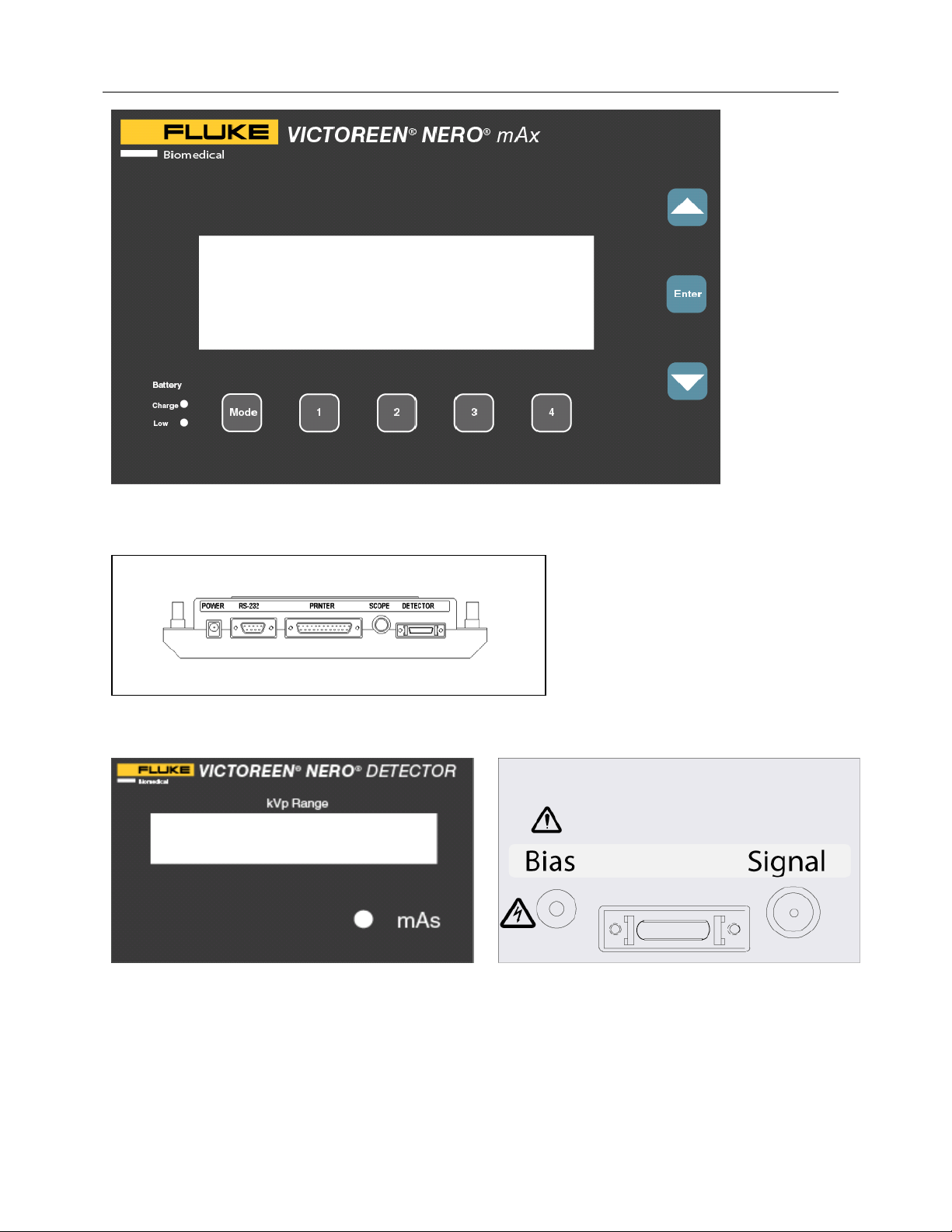

The NERO mAx detector contains sensors for simultaneously measuring kV, exposure or rate and

invasive mA or mAs. Solid-state detectors are used to measure kV. An ion chamber, located in the top

of the detector, is used for exposure/rate measurements. In addition, connectors for an external ion

chamber are provided on the rear panel of the 8000 detector. The NERO mAx detector’s interface

connector is also located on the detector’s rear panel. The front panel has a keyed opening for the model

8000-filter slides and a connector for mAs leads.

1-2

Page 7

General Information

Product Description

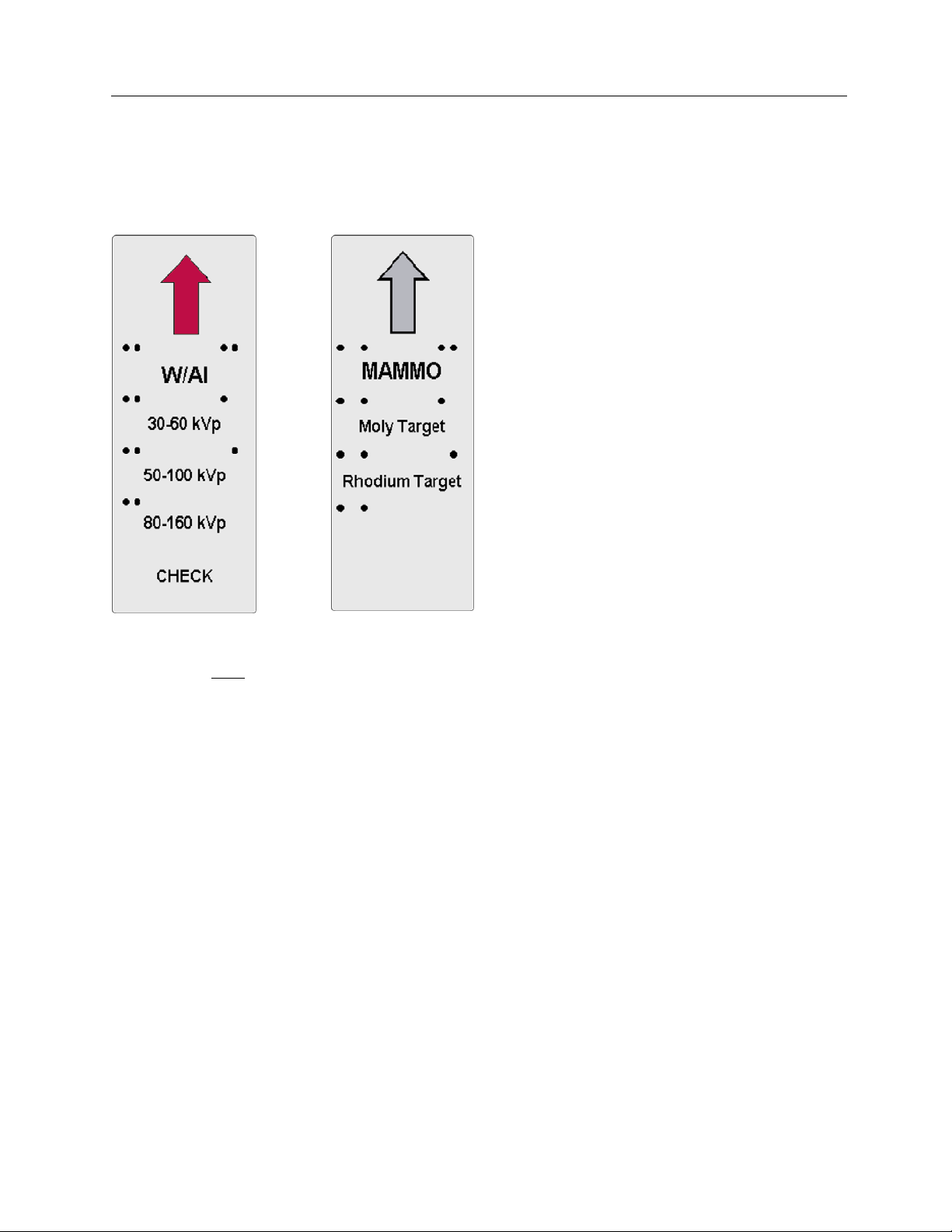

The NERO mAx filter cards contain the various filters needed to accurately measure kilovoltage. Each

filter card is coded so that the NERO mAx “knows” which filter is in use and its position. The NERO mAx

also verifies that the filter card is valid for the selected measurement mode. In addition, the filter cards

are keyed so that they may only be inserted one way. The W/Al filter card is labeled with the kVp ranges

for which it is calibrated. The Mammo filter card is labeled for the x-ray tube targets for which it is

calibrated.

The serial numbers of the NERO mAx control console unit, detector and filter cards must be matched in

order to obtain accurate results. Since the control console unit, detector and filter cards are calibrated

together, they

must be used together for accurate measurements.

1

1.2 New Features of Firmware Release 2.3

This release adds several new features to the Radiographic mode that give the NERO mAx greater

flexibility when making kV and exposure time measurements on all types of radiographic and dental x-ray

machines.

1. The %kV setting provides more time measurement options:

• Time measurements from 90%, 80%, and 75% of the peak kV.

• Pulse counting and zero crossing settings for single-phase generator time measurements.

2. User settable measurement delay allows:

• kV overshoot portion of waveform to be excluded from kV analysis.

• Exclusion of x-ray generator preheat pulses from kV and time analysis.

More information on these new features may be found in “Using a Measurement Delay” and “Using %kV

and Exposure Time Measurements” at the end of Section 2.5.1--Radio Mode.

1-3

Page 8

Victoreen 8000

Operators Manual

1.3 Specifications

Kilovoltage

Measured during the first 480 ms of exposure

Accuracy: 0.5 kV or ± 1%

Reproducibility: 0.5 kV or ± 1%

Range: W/Al 30 - 60 kV

50 - 100 kV

80 - 160 kV

Mo/Mo 22 - 35 kV

Mo/Rh 22 - 40 kV

Mo/Al 22 - 49 kV

Rh/Rh 25 - 49 kV

Rh/Al 25 - 49 kV

Time To Display

Radio & Mammo: 3 seconds for 0.1 second exposure

1 second for each 32 ms of exposure time

Fluoro & AMSE: 15 seconds for all exposures

Time

Measured during entire exposure at 90% rise/fall of waveform.

Accuracy: 1 ms

Range: 1 ms to 60 sec

Exposure/Exposure & Rate

Measured during entire exposure; kVp corrected.

Accuracy: ± 5%

Reproducibility: (Radio & Mammo Modes) ± 2% or 2 mR

Range: 1 mR minimum

mAs and mA

Measured during entire exposure

Accuracy: ± 2%

Reproducibility: ± 1% or 0.2 mAs

Range: 1 - 1000 mA

HVL

Accuracy: ± 5%

Range: .1 - 99.9 mmAl

Physical

Display: 240 x 60 pixel, super twist LCD w/ccfl backlight

Power: 115 or 230 VAC External Supply. Rechargeable internal batteries supply more than

4 hours of continuous service with overnight charge.

1-4

Page 9

Size:

Console: 9.00" x 9.12" x 3.25" (22.86 mm x 23.17 mm x 8.26 mm)

Detector: 6.56" x 3.70" x 2.58" (16.66 mm x 9.4 mm x 6.55 mm)

Slides Only: 2.4" x 6.25" x 0.31" (6.1 mm x 15.88 x 0.8 mm)

Operating Conditions:

10° C to 40°C (50° F to 104° F)

Maximum 90% relative humidity (non-condensing)

Weight:

Console: 4 lbs. 9.0 oz. (2.067 kg)

Detector: 1 lb. 10.4 oz. (with slide) (.747 kg)

Slides Only: 2.9 oz. & 3.2 oz. (.090 kg & .094 kg)

HVL Set

2.30 mm, 1.0 mm, 0.3 mm

Calibration

W/Al calibrated with 4.5 millimeters of Aluminum total filtration

Mo/Mo calibrated with 30 microns of Molybdenum filtration

Mo/Rh calibrated with 25 microns of Rhodium filtration

Mo/Al calibrated with 1 millimeter of Aluminum filtration

Rh/Rh calibrated with 25 microns of Rhodium filtration

Rh/Al calibrated with 1 millimeter of Aluminum filtration

General Information

Specifications

1

1.4 Battery Operation and Charging

The NERO mAx has an internal rechargeable battery which provides up to four hours of continuous

operation depending upon usage. The NERO mAx draws twice as much power from its from its battery

when it is actively making measurements than it does when in an idle state with its backlight off. To

conserve and extend battery life, the NERO mAx incorporates several power saving features. The

display backlight automatically turns off after one minute of inactivity. The backlight turns on when any

key is pressed or an exposure is made while in any measurement mode. In addition, the NERO mAx

exits from any measurement mode after five minutes of no activity. Pressing the ENTER key restores the

NERO mAx to its previous measurement mode.

The NERO mAx utilizes two levels of protection to assure reliable operation when the battery charge

becomes low. The first level of protection is a warning that is displayed when there is approximately 20

minutes of battery life remaining. During this time, the AC adapter may be plugged into the NERO mAx to

continue operation without interruption. The second level occurs when the battery charge is insufficient to

guarantee proper operation. When this occurs, the low battery indicator in the lower left corner of the

front panel illuminates and the instrument shuts down, becoming inoperable. When this happens, the AC

adapter can be plugged into the NERO mAx to restore operation. The NERO mAx “remembers” what

mode it was in before it shut down and returns to that mode upon power up. Pressing the ENTER key

returns the NERO mAx to its measurement mode.

The battery is charged whenever the NERO mAx is connected to its AC adapter and the adapter is

plugged into a suitable power source. When the power switch is on, the battery is charged at a low rate

that is enough to sustain the battery’s charge. When the power switch is off, the battery is charged at a

high rate.

To fully charge the battery, make sure that the NERO mAx is turned OFF, plug the AC adapter into the

rear of the NERO mAx console and plug the adapter into a suitable power source. The green battery

1-5

Page 10

Victoreen 8000

Operators Manual

charge indicator on the front panel of the NERO mAx console illuminates when the battery is charging.

When the battery charge indicator is off, the battery is charged. It may take up to 16 hours to fully

recharge a severely discharged battery.

1.5 Printing

All of the exposure results displayed by the NERO mAx may be printed automatically if desired. The

data that is sent to the printer includes the NERO mAx’s mode of operation and selected options, the

current time and date, and the measured data. The NERO mAx uses a standard IBM compatible PC

printer cable.

With the NERO mAx turned off, plug the computer end of a standard IBM compatible PC printer cable into

the printer port at the rear of the NERO mAx then plug the printer end of the cable into the printer and turn

the printer on. Plug the AC adapter into the 8000 if needed (see Section 1.4--Battery Operation and

Charging) and turn the instrument on. From the readout menu, select setup screen and turn the

automatic printing on as follows:

SETUP CLOCK − > OFF

CAL PRINT − > ON

HVL UNITS − > R

EXP AIR −−− > 20.5 C 734 mmHg

CT EXP DATE −−> Oct. 10, 1996

AMSE TIME −−> 10 30 45

MODE SELECT ON/OFF

From the SETUP screen, use the SELECT softkey (under column 1) to select PRINT. When PRINT is

selected, the print selection blinks and a highlight (reverse video) extends across the other display field.

Press the ON/OFF softkey (under column 2) to turn automatic printing to ON. Now, whenever a

measurement is made, all of the measured results that are displayed on the NERO mAx’s screen will also

be sent to the printer.

If the printer is off line, out of paper or is otherwise non functional, the NERO mAx will display a printer

error message and printing will be disabled. If the printer becomes functional and returns to an on line

status with no errors, the NERO mAx will resume printing with the next exposure.

To turn automatic printing off, follow the procedure outlined above and toggle PRINT to OFF.

1.6 Scope Output

The NERO mAx scope output provides a real time output of the radiation waveform from the NERO mAx

detector. This output is from the less filtered detector; “channel A”. This signal can have a maximum

amplitude of approximately 5 volts. This signal is always available at the scope output BNC connector.

The NERO mAx does not need to be in a kVp measurement mode to provide a real time scope output,

but the NERO mAx detector must be in the beam.

To use the real time scope output, connect the NERO mAx’s scope output to an oscilloscope input using

a suitable BNC cable. Set the oscilloscope horizontal deflection controls to the desired sweep period and

adjust the scope to trigger on a positive slope. Some experimentation will be necessary to get the trigger

level and the vertical deflection adjusted properly. Generally, exposures made at the top of the selected

kV range will have signals above one volt and exposures made near the bottom of the selected kV range

will have signals in the tens of millivolts.

1-6

Page 11

General Information

Procedures, Warnings, and Cautions

1

1.7 Procedures, Warnings, and Cautions

The equipment described in this manual is intended to be used for the detection and measurement of

ionizing radiation. It should be used only by persons who have been trained in the proper interpretation of

its readings and the appropriate safety procedures to be followed in the presence of radiation.

Although the equipment described in this manual is designed and manufactured in compliance with all

applicable safety standards, certain hazards are inherent in the use of electronic and radiometric

equipment.

WARNINGS and CAUTIONS are presented throughout this document to alert the user to potentially

hazardous situations. A WARNING is a precautionary message preceding an operation that has the

potential to cause personal injury or death. A CAUTION is a precautionary message preceding an

operation that has the potential to cause permanent damage to the equipment and/or loss of data.

Failure to comply with WARNINGS and CAUTIONS is at the user’s own risk and is sufficient cause to

terminate the warranty agreement between Fluke Biomedical and the customer.

Adequate warnings are included in this manual and on the product itself to cover hazards that may be

encountered in normal use and servicing of this equipment. No other procedures are warranted by Fluke

Biomedical. It shall be the owner’s or user’s responsibility to see to it that the procedures described here

are meticulously followed, and especially that WARNINGS and CAUTIONS are heeded. Failure on the

part of the owner or user in any way to follow the prescribed procedures shall absolve Fluke Biomedical

and its agents from any resulting liability.

Indicated battery and other operational tests must be performed prior to each use to assure that the

instrument is functioning properly. If applicable, failure to conduct periodic performance tests in

accordance with ANSI N323-1978 (R1983) Radiation Protection Instrumentation Test and

Calibration, paragraphs 4.6 and 5.4, and to keep records thereof in accordance with paragraph 4.5 of the

same standard, could result in erroneous readings or potential danger. ANSI N323-1978 becomes, by

this reference, a part of this operating procedure.

Warning Summary

The following WARNINGS are provided for your reference and may appear throughout the NERO mAx

manual:

Extreme caution should be used when making

connections to the mAs terminals of the X-ray

generator or detector. Improper connections may

result in injury, damage to the NERO mAx, and/or

damage to the x-ray generator. Tube current (mA

and mAs) measurements should only be made by

persons familiar with the calibration and repair of xray machines.

An electric shock hazard exists between the ion

chamber bias connector and ground.

WARNING

WARNING

1-7

Page 12

Victoreen 8000

Operators Manual

Caution Summary

The following CAUTIONS are provided for your reference and may appear throughout the NERO mAx

manual:

Use extreme caution when connecting to the mAs

terminal of the detector.

If line voltage surges beyond 15% of normal, a

power line conditioner must be used, otherwise

damage to the charging circuit will occur.

Note Summary

In the event of a transient induced lockup of the

Model 8000 NERO mAx, it is necessary to reset the

unit by cycling its power (turning it off then on).

After reset, the unit will power up in its normal

operating mode.

1.8 Receiving Inspection

CAUTION

CAUTION

NOTE

Upon receipt of the package:

1. Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier

and notify Fluke Biomedical at 440.248.9300.

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good order.

1.9 Storage

If the unit is to be stored prior to use, pack it in the original container, if possible, and store in an

environment free of corrosive materials, fluctuations in temperature and humidity, and vibration and

shock.

Prior to use, check the condition and functionality of the device. Also check that the calibration is still

valid. Periodic recalibrations are usually required by individual radiation safety and/or quality assurance

programs. Please consult your local radiation safety or quality assurance office if you have any

questions.

1-8

Page 13

Operation

Description

2

Section 2

Operation

2.1 Description

The NERO mAx consists of the NERO mAx control console, detector, detector cable, filter slides, AC

adapter, HVL plates, manual, Microsoft Excel Add-in and carrying case.

The NERO mAx control console is compact and easy to use. The sophisticated electronics necessary to

provide highly accurate, reproducible measurements while maintaining an intuitive, user-friendly operating

system are contained in the NERO mAx control console. The NERO mAx’s rechargeable battery is also

housed in the control console. The front panel of the control console contains a backlit 240 x 64 pixel, dot

matrix LCD display and eight push buttons. Connectors for power input, RS-232, printer, scope output

and the NERO mAx detector are located on the control console’s rear panel. The ON/OFF switch is

located on the right side of the control console.

The NERO mAx detector contains sensors for simultaneously measuring kV, exposure or rate and

invasive mA or mAs. Solid-state detectors are used to measure kV. An ion chamber, located in the top

of the detector, is used for exposure/rate measurements. In addition, connectors for an external ion

chamber are provided on the rear panel of the 8000 detector. The NERO mAx detector’s interface

connector is also located on the detector’s rear panel. The front panel has a keyed opening for the model

8000-filter slides and a connector for mAs leads.

The NERO mAx filter cards contain the various filters needed to accurately measure kilovoltage. Each

filter card is coded so that the NERO mAx “knows” which filter is in use and its position. The NERO mAx

also verifies that the filter card is valid for the selected measurement mode. In addition, the filter cards

are keyed so that they may only be inserted one way. The W/Al filter card is labeled with the kVp ranges

that it is calibrated for. The Mammo filter card is labeled for the x-ray tube targets that it is calibrated for.

The serial numbers of the NERO mAx control console unit, detector and filter slides must be matched in

order to obtain accurate results. The control console unit, detector and filter slides are calibrated

together, and

must be used together for accurate measurements.

2.2 General

Positioning the Control Console

Position the NERO mAx control console on a stable, flat surface within 25 feet of the detector. If a printer

is to be used with the NERO mAx it should also be placed on a stable, flat surface.

Positioning the Detector

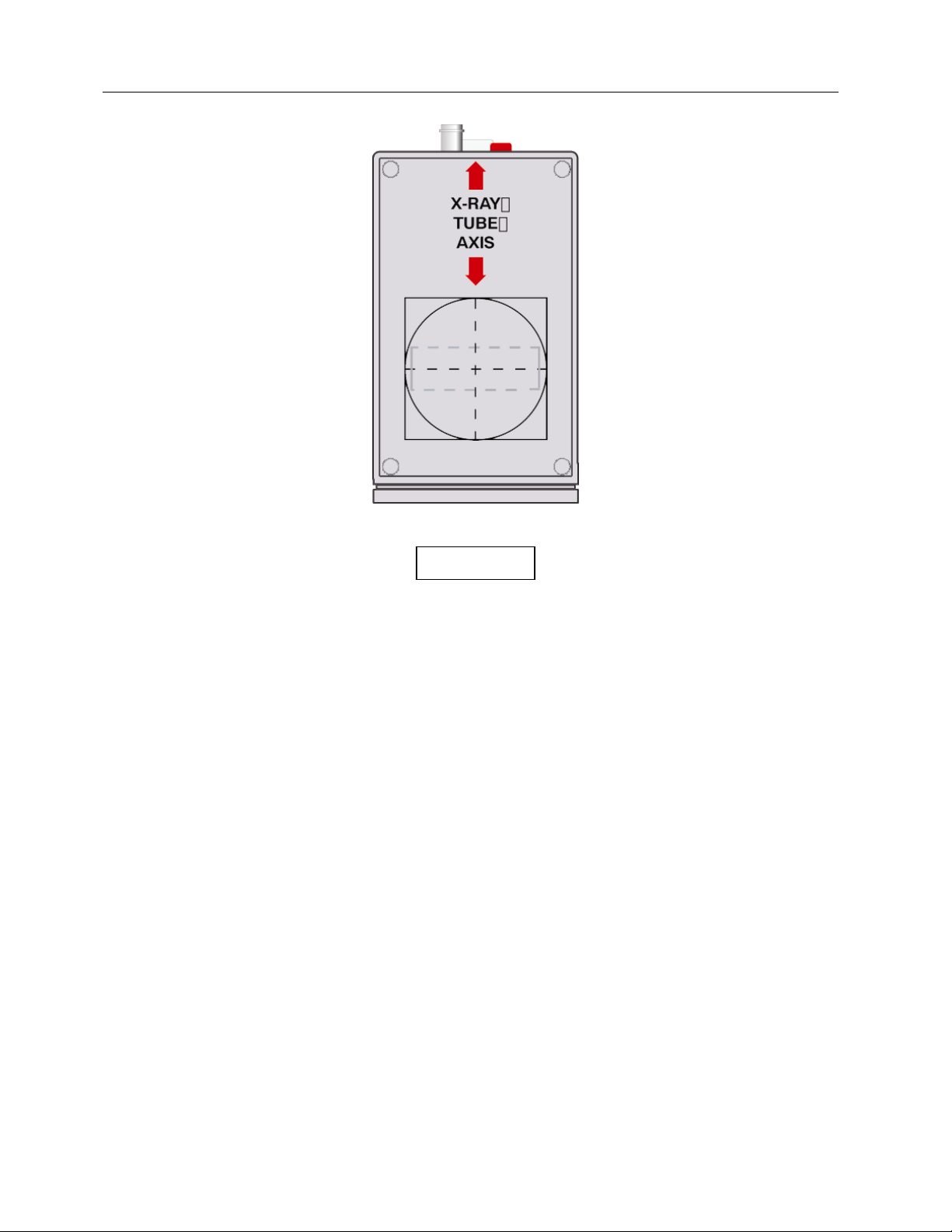

Correct and reproducible positioning of the NERO mAx detector in the x-ray beam is very important in

obtaining accurate and reproducible results from the NERO mAx. Fluke Biomedical has printed several

alignment marks on top of the detector to assure correct, reproducible positioning of the detector.

The black circle is the minimum collimated beam size required for accurate exposure, rate and kVp

measurements. This circle defines the diameter of the NERO mAx’s internal ion chamber.

2-1

Page 14

Victoreen 8000

Operators Manual

NOTE

The dashed gray rectangle is the minimum

collimated beam size required for accurate kVp

measurements only. This rectangle outlines the

NERO mAx’s kV detectors. Exposure and rate

results from an x-ray beam collimated to this area

will be incorrect because the beam is not

illuminating all of the internal ion chamber.

The black square and the dashed black crosshairs are alignment marks to aid in positioning the NERO

mAx detector in the x-ray beam.

The red arrows on the detector indicate the axis of the detector that should be aligned with the x-ray tube

axis for the most accurate measurements. This minimizes any heel effect.

Radiographic

Install the W/Al filter slide in the detector and set the filter slide to the desired kVp range. Position the

detector under the x-ray tube with the top of the detector facing up. Align the detector along the axis of

the x-ray tube to minimize heel effect. Set x-ray tube SDD (normally 26 inches) and collimate the beam

size to the round or square alignment marks on the top of the detector. Align the x-ray beam by making

the light field crosshairs coincident with the crosshairs on the top of the detector.

Dental

Set the detector on a flat, stable surface and position the x-ray tube so that the cone is just above the

detector's top surface.

2-2

Page 15

Operation

General

NOTE

2

Do not rest the cone on the detector. This may

depress the top of the ion chamber and cause

incorrect exposure measurements.

Make sure that the detector is aligned along the axis of the x-ray tube and that the tube is perpendicular

to the detector's top surface and is centered over the detector crosshairs.

Mammography

Install the Mammo filter slide in the detector and set the filter slide for the x-ray machine’s target material.

Position the detector under the x-ray tube with the top of the detector facing up. Align the detector along

the axis of the x-ray tube to minimize heel effect. Set x-ray tube SSD (normally 26 inches) and collimate

the beam size to the square alignment marks on the top of the detector. Line up the front edge of the

square alignment mark on the top of the detector with the front edge (toward the chest wall) of the

collimated x-ray beam.

Fluoroscopy

Install the W/Al filter slide in the detector and set the filter slide to the desired kVp range. The kVp range

is the range closest to the detector front panel.

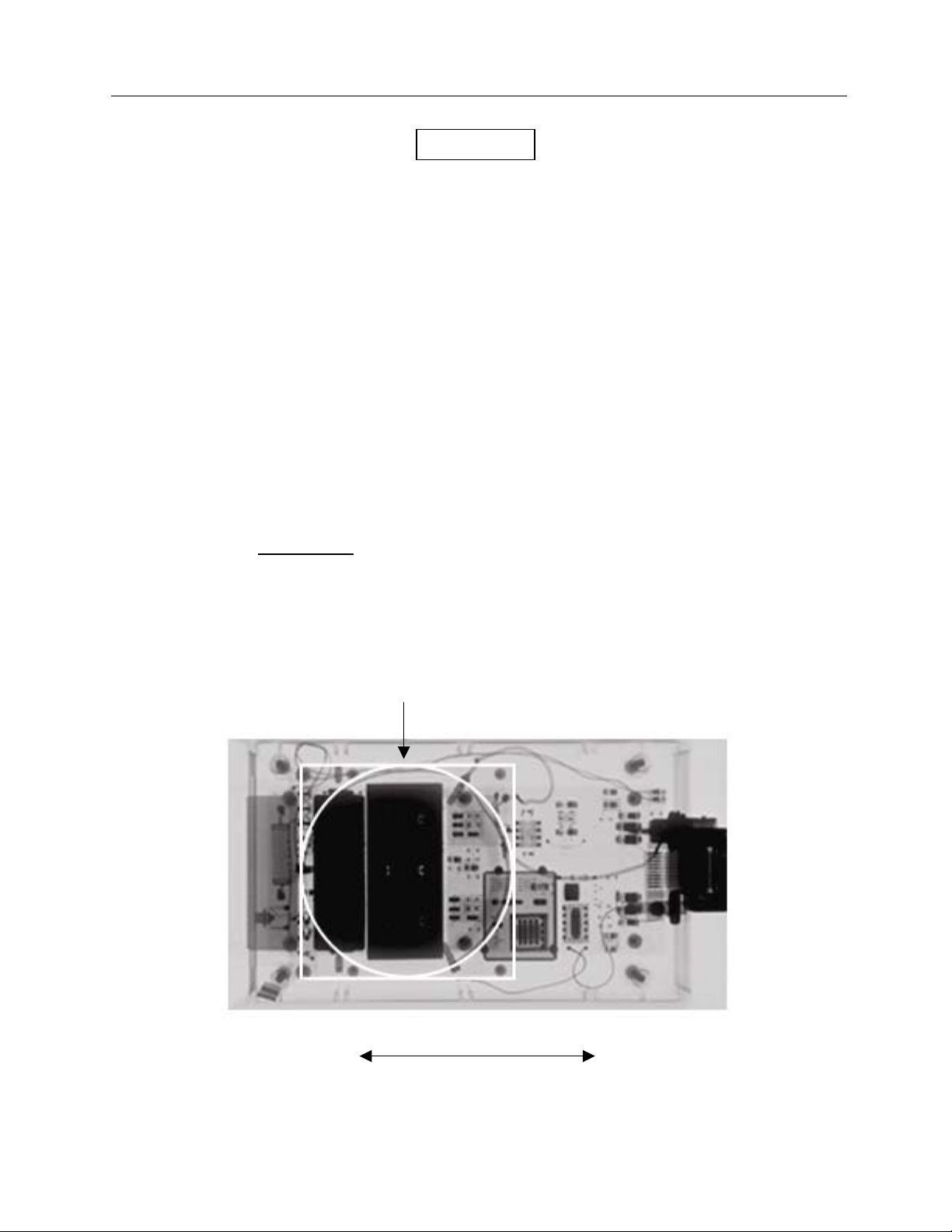

Position the detector

ray tube) and align the detector along the axis of the x-ray tube to minimize heel effect. Using the

centering marks provided on the table (or other centering methods), center the detector over the x-ray

beam. Don protective clothing and energize the fluoroscope to view the detector on the fluoro screen.

Move the fluoroscope so that the lead shield containing the NERO mAx’s detector diodes (opaque

rectangle) is centered on the screen.

upside down on the table (the top of the detector must be positioned toward the x-

Collimate to this area

X-Ray Tube Axis

Fluoro Detector Positioning

2-3

Page 16

Victoreen 8000

Operators Manual

For automatic brightness control machines, place appropriate shielding over the detector to drive the

output to its maximum. A folded lead apron, gloves or a lead sheet may be used. For manual systems,

set the machine for its maximum output and use appropriate shielding to protect the image intensifier.

Other Applications

The basic principles are the same for other applications. In general, the detector should be located 18 to

40 inches from the x-ray source. The detector should be aligned with the x-ray tube axis with the top of

the detector facing the x-ray source. The detector should be in the center of the x-ray beam and the

beam should be collimated to the round or square alignment marks on the top of the detector.

For chest x-ray machines, the detector may be strapped or taped to the table in front of the film cassette.

For panoramic dental machines, the detector may be strapped or taped to the film cassette holder.

Inserting the Filter Slide

The NERO mAx filter slides are inserted into the front of the detector. The filter slides are keyed so that

they may only be inserted one way. To insert the filter slide, place the filter slide in the opening in the

front of the detector and gently push. The slide will click into place at each of its positions. Move the filter

slide until the desired kVp range (W/Al) or target material (Mammo) is closest to the detector front panel

(below “kVp RANGE”).

Connections to the NERO mAx

The NERO mAx detector and control console are connected to each other via a 25-foot cable. The

NERO mAx power should be turned

an external ion chamber to the detector or connecting the mAs leads.

off when connecting the detector to the control console, connecting

mAs Connections

Extreme caution should be used when making

connections to the mAs terminals of the X-ray

generator. Improper connections may result in

injury, damage to the NERO mAx, and/or damage

to the x-ray generator. Tube current (mA and

mAs) measurements should only be made by

persons familiar with the calibration and repair of xray machines.

Two mAs cables are provided with the NERO mAx; 12-ft. long mAs leads and 12-ft. long mAs extension

leads. The mAs leads are black, with a miniature phone plug at one end and alligator clips at the other

end, the mAs extension leads have clear insulation with two banana plugs at one end and alligator clips

at the other end. The miniature phone jack of the black mAs leads plugs into the mAs jack on the front

panel of the NERO mAx detector. The alligator clips may then be connected to the generator’s mAs

terminals. If the black mAs leads have insufficient length, the mAs extension leads may be used to

provide additional length. The mAs extension leads may be used in two ways; the extension lead banana

jacks may be plugged into the generator’s mAs terminals (if the generator has banana jacks) or the

extension leads may be reversed and the alligator clips can be clipped to the generator’s mAs terminals.

WARNING

The opposite end of the mAs extension leads are to be connected to the alligator clips at the end of the

black mAs leads. When using the mAs extension leads, care should be used to make sure that the leads

are not shorted together when they are connected.

2-4

Page 17

Operation

General

The mAs leads should always be connected in the ground return of the high voltage transformer.

Damage to the generator or the NERO mAx or inaccurate measurements may result if the mAs leads are

connected to any point other then the ground return of the x-ray tube current. Tube current

measurements should only be made on generators providing open and short circuit protection of the

metering circuit and where the circuit operates near ground potential. The polarity of the mAs input signal

is not important because a full wave bridge is used in the NERO mAx mAs input circuit.

2

Printer Connections

When using the NERO mAx with a printer, both the printer and the NERO mAx should be turned off prior

to connection. The NERO mAx uses a standard IBM PC printer cable. For more information on printing

with the NERO mAx, see Section 1.5--Printing.

AC Adapter

The AC adapter may be plugged into the NERO mAx at any time. For more information on using the AC

adapter with the NERO mAx, see Section 1.4--Battery Operation and Charging.

Scope Output

The NERO mAx’s scope output may be connected to a suitable oscilloscope at any time. For more

information regarding the real time scope output, see Section 1.6--Scope Output.

2.3 Using The NERO mAx

The NERO mAx uses an innovative system of menus and softkeys to provide an intuitive, user-friendly

operating environment. All measurement modes and options are displayed on the NERO mAx’s LCD and

all functions are controlled by the 5 softkeys beneath the display and the 3 keys to the right of the display.

2-5

Page 18

Victoreen 8000

Operators Manual

The NERO mAx display is divided into 5 columns, each column corresponds to the push button (softkey)

directly beneath it. The left most column is the “MODE” column that is used to select the NERO mAx’s

operating mode. The remaining four columns (1 through 4) display various options for each mode.

A highlight (reverse video block) denotes the selected menu element in each column. A blinking highlight

(reverse video block) locates the “active” menu column and highlights the selected menu element in that

column.

Legends, which describe the function of each softkey, appear along the bottom of the display. These

legends are separated from the rest of the display by a horizontal line. The time and date may be

displayed in the upper right corner of the display.

There are eight push buttons on the front panel of the NERO mAx. The five buttons directly beneath the

display are “softkeys”, their functions change according to the NERO mAx’s mode of operation. These

softkeys are used to select the NERO mAx’s mode of operation and various options within each mode.

These softkeys are also used to increment numerical values such as time or date. The “MODE” softkey

has two functions. First, it may be used to select the NERO mAx’s operating mode. Second, it may be

used to exit from any active measurement mode.

The “UP” and “DOWN” keys to the right of the display are also used to select the NERO mAx’s mode of

operation and various options within each mode. The “UP” and “DOWN” buttons move the highlight up

and down within each selected column to select various options. When the “UP” button is pressed, the

highlight moves up one menu element and wraps around when it reaches the top of the column and

returns to the bottom. When the “DOWN” button is pressed, the highlight moves down one menu element

and wraps around when it reaches the bottom. If only two options are available, the highlight toggles

between the two selections. In the calibration and setup modes, the “UP” and “DOWN” buttons are used

to toggle between options or to increment and decrement numeric values.

The “ENTER” button to the right of the display is used to initiate data acquisition and measurement with

options that have been selected. It also is used to accept numeric data in situations requiring data entry.

Each of the NERO mAx’s operating modes has a menu. All available menu options for each mode are

displayed in columns 1 through 4 above each softkey. All menus are left justified. This means that

changes made in columns on the left (such as the MODE column) may affect the columns of options to

the right. Softkey legends appear along the bottom of the display and as the menu options change, the

softkey legends change. The left most menu column is the ‘mode’ column, which displays the available

operating modes. The legend above the “MODE” softkey never changes, as this key always selects the

mode of operation of the NERO mAx.

Pressing the softkey under any column (MODE, 1 - 4) moves the blinking highlight into that menu column,

thereby selecting that column, and moves the highlight up through the available options. The highlight

wraps around when it reaches the top of the column and returns to the bottom. If only two options are

available, the highlight toggles between the two selections. In the calibration and setup modes, some of

the softkeys are used to toggle between options or to increment numeric values.

To make a measurement with the NERO mAx, simply highlight the desired measurement mode and

options and press the enter button. For more information on a specific measurement mode, see the

manual section that applies to that mode or x-ray generator type.

All of the NERO mAx’s operating modes are described in "Modes of Operation", following "Quick Start".

2.3.1 LCD Backlight Control

As a power saving feature, the NERO mAx LCD backlight turns off after one minute of no activity. The

backlight turns back on when any button is pressed. When the NERO mAx backlight turns off while

exposure results are being displayed, the backlight may be restored without affecting the displayed

exposure results by pressing any key except the MODE key. Pressing the mode key exits from the active

measurement mode and returns to the menu screen, erasing all exposure data.

2-6

Page 19

Operation

Using the NERO mAx

2

2.3.2 Measured Quantities

kV

The NERO mAx calculates kVp from the ratio between two differentially filtered detector channels (A&B).

When an x-ray exposure is made, the NERO mAx samples the two detector channels simultaneously at a

rate of 100,000 samples per second. The detector waveforms are digitized by a pair of 100 kHz 16 bit

A/D converters and stored in memory.

The NERO mAx has sufficient memory to store up to 480 milliseconds of waveform data. For

radiographic exposures that exceed 480 milliseconds in length, the NERO mAx stores the first 320

milliseconds of the waveform and the last 160 milliseconds. This method allows storage of both the rising

and falling edges of the x-ray waveform. In the fluoro and AMSE modes, the NERO mAx stores a 480millisecond sample of the x-ray waveform after the SAVE key is pressed.

A delay of up to 999 milliseconds may be used to delay the start of kV data acquisition in the Radio and

Mammo modes. This delay may be used to skip events that occur at the beginning of an exposure, such

as an overshoot or undershoot. When a delay is used, only the kV data acquisition is effected.

Exposure, mAs and time measurements are not delayed and are measured over the entire exposure.

After the exposure is complete, the NERO mAx searches the stored channel A and B waveforms for ratio

peaks, when a peak is found it is stored. These peaks are then averaged and the average kVp is

calculated. While the NERO mAx searches for ratio peaks, it also looks for the highest peak, when the

highest peak is found it is stored and peak kV is calculated. Effective kV is calculated from the ratio of the

integrated A and B waveforms which is analogous to the density ratio in the kVp film cassette.

When calculating kVp average in the radiographic mode, the NERO mAx only includes peaks that are

above the selected %kV in its kVp average calculation. When ZERO or 1ØPULSE are selected, the

NERO mAx includes all detected peaks in the kVp average calculation.

The NERO mAx calculates kV as a function (F) of the ratio between the two detector channels, A and B

(r). The calculations used to calculate kV peak, kV effective and kVp average are summarized below:

kVp Average = F (r), where r is the average peak ratio B/A

kV Peak = F (r), where r is the peak ratio B/A

kV Effective = F (r), where r is the ratio

The calibration information that the NERO mAx uses to calculate kV is stored in nonvolatile memory in the

NERO mAx control console.

∑

B/A

∑

Time

The NERO mAx measures exposure time by determining the time between the first and last passage

through a preset percentage of kVp average. To accomplish this, the NERO mAx calculates the detector

ratio that corresponds to the preset percentage of the exposure's kVp, then measures the time between

those points on the rising and falling edges of the ratio waveform. In the Radiographic mode, the

percentage of kVp average over which the NERO mAx measures radiographic exposure time may be

selected using the %kV key. In the Mammographic mode, the percentage is fixed at 90% of kVp

average.

In the radiographic mode, when 75%, 80%, or 90% kV is selected, the NERO mAx measures exposure

time between the 75%, 80%, or 90% points on the kV waveform. When zero crossing (ZERO) is

selected, the NERO mAx measures radiographic exposure time from the moment x-rays are detected

until they are no longer detected. When 1ØPULSE is selected, the NERO mAx counts the number of xray pulses in a pulsed or single-phase radiographic exposure. This is primarily for use with single phase

full and half wave rectified generators.

In pulsed and single-phase applications when time is measured in pulses (1ØPULSE), use of a

measurement delay may introduce errors in the pulse count because the NERO mAx does not count

pulses during the delay time. In pulsed and single-phase applications when time is measured at a

2-7

Page 20

Victoreen 8000

Operators Manual

percentage of kV, use of a measurement delay can also introduce errors. If the delay terminates between

pulses, when no x-rays are present, the NERO mAx waits until the beginning of the next pulse to begin

timing. If the delay terminates during a pulse, when x-rays are present, the NERO mAx begins timing

immediately.

When a delay is used in making measurements in the Radio and Mammo Modes, the NERO mAx

calculates exposure time differently. If a positive measurement delay is used in making a measurement,

the NERO mAx includes the delay time in its calculated exposure time. In addition, the exposure time

may be slightly longer than the exposure time between the selected %kV points on the kV waveform.

This is because the Model 8000 does not store the leading edge of the x-ray output waveform; it waits for

the specified delay time before acquiring kVp data. Because of this, the %kV point on the rising edge of

the kV waveform is not stored and the rise time of the waveform appears to be instantaneous. The

difference between the actual and measured exposure times is the rise time between zero and the

specified %kV. When a negative measurement delay is specified, the NERO mAx does not include the

delay time in the measured exposure time. The measured exposure time is from the beginning of data

acquisition or the %kV point on the first rising edge after the delay until passage through the %kV point on

the falling edge of the kV waveform.

More information on using the %kV function or using a measurement delay may be found at the end of

the Radio Mode section under "Using %kV and Exposure Time Measurements" or "Using a Measurement

Delay".

Exposure and Exposure Rate

The NERO mAx measures exposure by integrating the signal from an ion chamber (either internal or

external) and applying the proper conversion factor(s) to calculate exposure (R or Gy). Exposure rate is

calculated by sampling the integrated charge from the ion chamber at one-second intervals and dividing

the integrated charge by the sample period and applying the proper conversion factor(s). In the Pulsed

Fluoro and AMSE modes, the NERO mAx calculates exposure per pulse or frame by sampling the

integrated charge from the ion chamber at one second intervals and dividing by the number of pulses or

frames that it counts in a one second interval and applying the proper conversion factor(s). The NERO

mAx's ion chamber is internally vented and all exposure and rate measurements are corrected for air

density based upon user entered temperature and pressure.

The NERO mAx’s internal ion chamber is factory calibrated to provide accurate exposure and rate

measurements over the entire kVp range of the NERO mAx. These exposure and rate measurements

are adjusted by applying energy dependent correction factors that are determined by comparison to

applicable N.I.S.T. techniques.

In addition to the factory calibration, a user entered multiplier is available for exposure and rate

measurements made with the NERO mAx’s internal ion chamber.

When using external ion chambers, exposure and rate are calculated using the user entered calibration

factor (R/nC or Gy/nC) for the selected chamber. When making measurements in the CT Exposure mode

with a CT chamber, user entered beam width is also used in calculating exposure and rate.

mAs and mA

The NERO mAx measures mAs by integrating the signal from the mAs input during an x-ray exposure.

To calculate mA, the integrated signal from the mAs input is sampled at one-second intervals and divided

by the sample period. In the Pulsed Fluoro and AMSE modes, the NERO mAx calculates mAs per pulse

or frame by sampling the integrated signal from the mAs input at one second intervals and dividing by the

number of pulses or frames that it counts in a one second interval. The mA(s) circuitry is factory

calibrated using a calibrated current source and is not user adjustable.

HVL

In the HVL mode, the NERO mAx calculates half value layer based upon a series of exposure or rate

measurements made with varying thicknesses of aluminum absorbers placed in the x-ray beam. The

exposure or rate measurements may be made using the NERO mAx’s internal ion chamber or an external

2-8

Page 21

Operation

Using the NERO mAx

ion chamber. HVL is calculated using a linear regression of the natural log of the normalized exposure

versus absorber thickness in millimeters of aluminum. Below is the formula used by the NERO mAx to

calculate half value layer.

()

BxAHVL +∗= ln

Where: x = Normalized dose at Half Value Layer (0.5)

A = Slope of ln(x) vs. mmAl

B = Intercept of ln(x) vs. mmAl (Usually very close to zero)

2.4 Quick Start

Locate a suitable radiographic x-ray generator. Set the generator for approximately 80 kV, 100 mA, .1

seconds or 10 mAs.

2

CAUTION

Make sure the NERO mAx is turned off.

Plug the detector cable into the back of the NERO mAx at the connector marked DETECTOR.

Plug the other end of the detector cable into the NERO mAx detector.

Insert the W/Al filter slide into the front filter slot of the NERO mAx detector at the 50 - 100 kVp position.

The filter slide will click into place.

Place the detector on the x-ray table at approximately 26” SDD. Make sure that the top of the detector is

facing the x-ray tube and the detector is aligned with the x-ray tube axis.

Plug the AC adapter into the NERO mAx and plug the adapter into a suitable AC power outlet.

Turn on the NERO mAx.

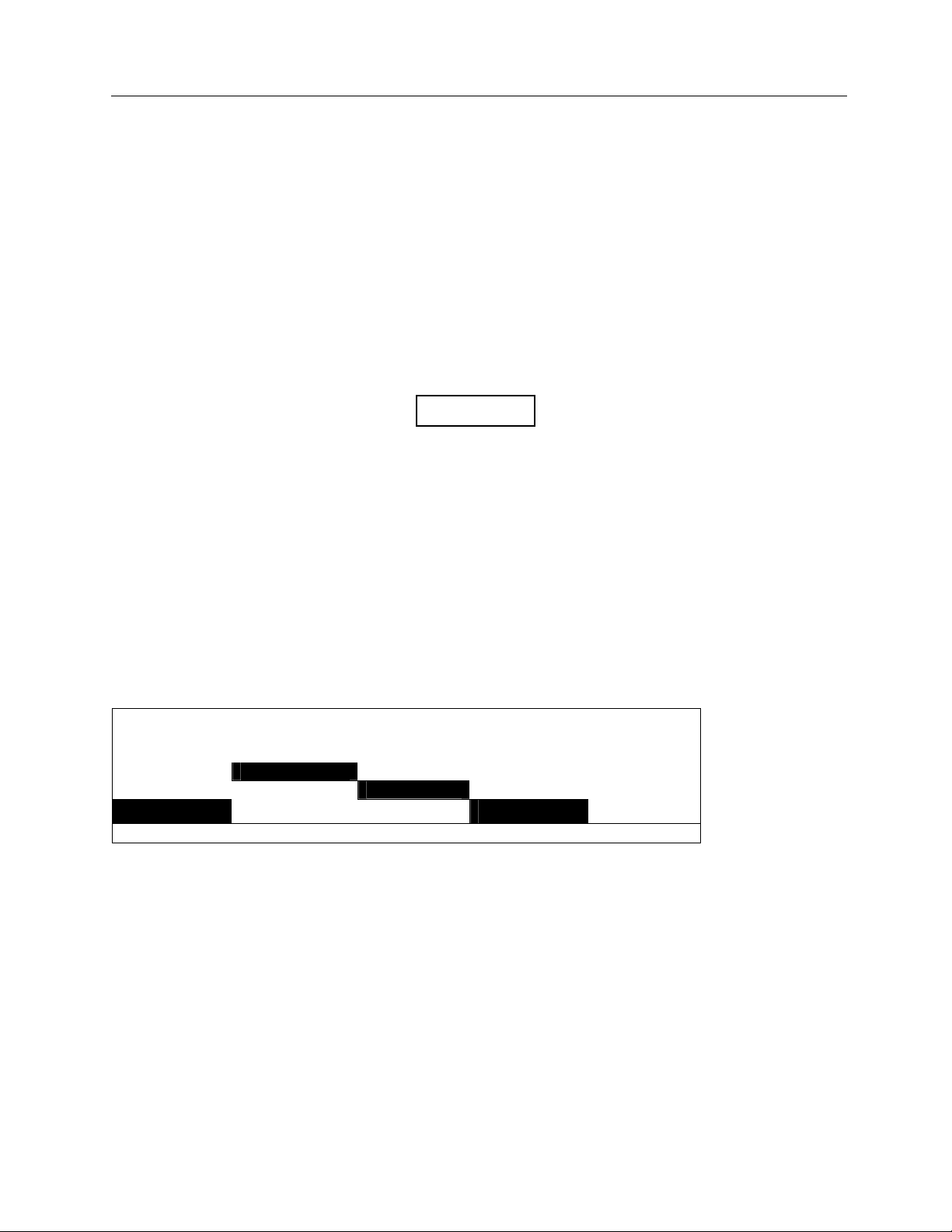

After the NERO mAx performs its power up diagnostics, the main menu screen is displayed.

EXP

CT EXP 1Ø PULSE

AMSE ZERO

FLUORO 75%

MAMMO 80% LOW

RADIO 90% HIGH +10 ms

MODE %kV SENS DELAY

a. Press the MODE button, the reverse video highlight in the mode column of the display (far left

column above the mode key) will start blinking.

b. Press the down arrow key until RADIO is highlighted.

c. Press the "1" key until 75% is highlighted.

d. Press the "2" key to toggle sensitivity between high and low, set the sensitivity to LOW.

e. Press the "3" key to change the measurement delay. Using the up and down arrow keys, set the

delay to +10 milliseconds.

f. Press the ENTER button.

Please wait a moment while the NERO mAx prepares to measure an exposure.

When the NERO mAx beeps and displays MAKE EXPOSURE, make an exposure.

2-9

Page 22

Victoreen 8000

Operators Manual

Wait a moment while the 8000 analyzes the exposure then displays the measured kVp, exposure, time

and mAs (mAs will be zero because the mAs input was not used).

80.0

79.2

81.1

RADIO 75% LOW + 10 ms Please

MODE %kV SENS DELAY Wait…

The 8000 will immediately display Please Wait… in the lower right corner of its screen while it prepares to

take another exposure.

After the 8000 beeps and displays Make Exposure in the lower right corner of the display, another

exposure may be made.

To stop making exposures and return to the main menu screen, press the MODE button.

kVp Avg

kV Eff

kV Peak

100

392

0.0

msec

mR

mAs

2.5 Modes of Operation

The NERO mAx Nero has ten modes of operation as listed below (in selection order):

1. RADIO

2. MAMMO

3. FLUORO

4. AMSE

5. CT EXP

6. EXP

7. HVL

8. CAL

9. SETUP

10. UNIT ID

The NERO mAx's mode of operation is controlled from the main screen. When the menu cursor (blinking

reverse video) is moved to a mode selection, by pressing the mode key or using the up and down arrow

keys, all of the options available for that mode are displayed. Pressing a softkey (1 thru 4) moves the

menu cursor into the selected menu column and starts it blinking. Pressing the softkey again will move

the blinking menu cursor up through the column of available options. Pressing the up and down arrow

keys moves the blinking menu cursor up or down through the selected column of available options. After

options have been highlighted, the enter key is pressed to start the selected mode with the selected

options. Pressing the mode key at any time returns to the mode select screen.

UNIT

SETUP

CAL

HVL

EXP

CT EXP

AMSE ZERO

FLUORO 75%

MAMMO 80%

RADIO 90%

MODE %kV

1Ø PULSE

LOW

HIGH 10 mS

SENS DELAY

NERO mAx Operating Modes

Radio Mode

Radio mode is used to make measurements on tungsten target, aluminum filtered radiographic x-ray

generators. Radio mode simultaneously measures kVp, exposure, exposure time and mAs from a single

radiographic exposure. Radiographic mode may also be used to verify the NERO mAx’s kV calibration.

2-10

Page 23

Operation

Modes of Operation

2

Mammo Mode

Mammo mode is used to make measurements on mammographic x-ray generators. Mammo mode

simultaneously measures kVp, exposure, exposure time and mAs from a single mammographic

exposure.

Fluoro Mode

Fluoro mode is used to make measurements on fluoroscopic x-ray generators. Fluoro mode supports

both continuous fluoro and pulsed fluoro measurements. In the continuous fluoro mode, the NERO mAx

measures kVp, exposure rate (R/min) and mA. In the pulsed fluoro mode, the NERO mAx measures

kVp, exposure rate (R/min and mR/pulse) and mAs/pulse.

AMSE Mode

AMSE mode is used for Automated Measurement of Sequential Exposures. This mode is used to

measure the output of CINE X-ray generators. In AMSE mode, the NERO mAx measures kVp, exposure

rate (mR/frame), mAs/frame and time/frame (mS/frame).

CT Exposure Mode

CT Exposure mode is used to make CT exposure measurements using the Victoreen 6000-100 or 6000200 CT ion chamber. A CT probe must be connected to the NERO mAx detector’s external ion chamber

input in this mode. The exposure is calculated using the user entered beam width (in mm) and the CT

probe’s calibration factor (Rcm/nC). This mode functions in the same manner as the Exposure Mode with

the addition of beam width entry.

Exposure Mode

Exposure mode is used to make exposure and rate measurements using the NERO mAx’s internal ion

chamber or an external ion chamber. The exposure is calculated using the selected ion chamber’s stored

calibration factor.

HVL Mode

In the HVL mode, the NERO mAx calculates half value layer based upon a series of exposure or rate

measurements made with varying thicknesses of aluminum absorbers placed in the x-ray beam. A

minimum of two exposures are required and up to ten exposures may be used. The exposure or rate

measurements may be made using the NERO mAx’s internal ion chamber or an external ion chamber.

Exposure and rate are calculated using the selected ion chamber’s calibration factor and when using a

CT chamber, beam width.

Calibrate Mode

The Calibrate mode is used to enter and store calibration factors for ion chambers used with the NERO

mAx. Calibration factors are available for the NERO mAx’s internal chamber and external chambers,

including the Victoreen CT chamber.

Setup Mode

The Setup Mode is used to setup various features of the NERO mAx. From the setup screen the user

can set the instruments internal real time clock, set the temperature and pressure used in air density

correction of exposure measurements, select exposure units of either Roentgens or Grays, turn automatic

printing on or off, turn the clock display on or off and select normal or reverse video on screen clock

display.

Unit ID

Displays the NERO mAx’s serial number, firmware part number and revision.

2-11

Page 24

Victoreen 8000

Operators Manual

2.5.1 Radio Mode

Radio mode is primarily used to make measurements on tungsten target, aluminum filtered radiographic

x-ray machines. Radio mode simultaneously measures kVp, exposure, exposure time and mAs from a

single radiographic exposure. A measurement delay of up to 999 milliseconds may be used to delay the

start of kV data acquisition in order to skip over waveform anomalies at the beginning of an exposure.

See "Using a Measurement Delay" (at the end of this section) for more information on using a

measurement delay. The percentage of peak kV over which exposure time is measured may be selected

from 90%, 80%, or 75% of the kV peak. In addition, exposure time may be measured between zero

crossings or x-ray pulses may be counted (for single-phase generators). See "Using %kV and Exposure

Time Measurements" (at the end of this section) for more information about using %kV.

Generally, to measure radiographic exposures, choose a filter card (kV) setting such that the measured

(or expected) kV is in the upper end of the filter range. For instance, use the 50 - 100 kVp range instead

of the 80 - 160 kVp range to make measurements at 80 kVp. Staying in the upper end of the filter's kVp

range improves the signal to noise performance of the NERO mAx and allows the NERO mAx to "receive"

more of the radiation output that improves its measurements accuracy. Also, start out in low sensitivity, if

a channel A or B overrange occurs, switch to the next kVp filter range. If the NERO mAx does not

respond to an exposure and displays "MAKE EXPOSURE", switch to high sensitivity.

Radio mode may also be used to make measurements on dental x-ray generators. When using the

NERO mAx with dental x-ray machines, follow the instructions in section "Positioning the Detector" to

properly locate the detector. Generally, low sensitivity should be used, however if the NERO mAx does

not respond to an exposure, switch to high sensitivity. Select the proper %kV for the type of generator

being tested, generally ZERO or 1ØPULSE modes are needed for self-rectified generators, 75%, 80%, or

90% may be needed for three phase and medium to high frequency generators. If necessary, use a

measurement delay in order to disregard any filament preheat effects at the beginning of an exposure.

See "Using a Measurement Delay" and "Using %kV and Exposure Time Measurements" at the end of this

section for more information about using the %kV and measurement delay functions.

To make a radiographic measurement

Make sure that the Model 8000 is turned off. Plug one end of the Model 8000's detector cable into the

Model 8000 detector. Plug the other end of the detector cable into the Model 8000's detector connector.

Insert the W/Al filter card into the detector and place the filter card in the correct position for the kV range

to be measured. Place the Model 8000 detector on the x-ray table with the top of the detector facing the

x-ray tube. Position the detector so that the detector is centered in the beam and is aligned with the x-ray

tube axis. If mAs measurements are to be made, plug the mAs cable into the 8000 detector's mAs input

and connect the mAs leads to the generators mAs terminals. For more information on positioning the

Model 8000 detector, see section "Positioning the Detector".

WARNING

Extreme caution should be used when making

connections to the mAs terminals of the X-ray

generator or detector. Improper connections may

result in injury, damage to the NERO mAx, and/or

damage to the x-ray generator.

If results are to be printed, plug the printer cable into the printer port at the rear of the Model 8000 then

plug the other end of the printer cable into the printer and turn the printer on (see Section 1.5--Printing).

Plug the AC adapter into the 8000 if needed (see Section 1.4--Battery Operation and Charging) and turn

the instrument on.

2-12

Page 25

Operation

Modes of Operation

EXP

CT EXP 1Ø PULSE

AMSE ZERO

FLUORO 75%

MAMMO 80% LOW

RADIO 90% HIGH 10 ms

MODE %kV SENS DELAY

Select the RADIO mode, %kV, high or low sensitivity and measurement delay, then press the ENTER

key. To use a measurement delay, press the DELAY key to select and increment the delay. The delay

may also be incremented or decremented by pressing the up or down keys when the delay is selected.

Select the interval, as a percentage of kV peak, over which exposure time is measured, using the %kV

key. ZERO selects measurement between the zero crossings on the rising and falling edges of the kV

waveform. 1ØPULSE selects the single-phase pulse counting mode for exposure time measurement.

The measurement delay and %kV settings are retained from one exposure to the next.

Please wait…

FILTER = 50 - 100

RADIO 75% LOW 10 ms

MODE %kV SENS DELAY

2

Please wait while the Model 8000 prepares to take an exposure. Note that the selected filter kV range is

displayed. The kV filter range may be changed at any time without exiting from the measurement mode.

If the Model 8000 detects a fault condition such as an invalid filter card or position, an error message is

displayed and the user must correct the error to continue (see Section 4.3--Error Messages--for more

information). When the Model 8000 is ready for an exposure, it will beep and prompt for an exposure.

MAKE EXPOSURE

FILTER = 50 - 100

RADIO 75% LOW 10 ms

MODE %kV SENS DELAY

Make an exposure. If nothing happens, there is insufficient x-ray intensity to make a measurement. To

remedy this situation, switch to high sensitivity, switch to the next lower kVp filter range (if possible),

increase mA or decrease the distance between the x-ray tube and Model 8000 detector.

ANALYZING DATA

FILTER = 50 - 100

RADIO 75% LOW 10 ms

MODE %kV SENS DELAY

Please wait while the NERO mAx analyzes the exposure data.

80.0

kVp Avg

100

msec

2-13

Page 26

Victoreen 8000

Operators Manual

79.2

81.1

RADIO 75% LOW 10 ms Please

MODE %kV SENS DELAY Wait…

After data analysis is complete, kV, exposure, time and mAs are displayed. If an overrange is detected

an error message is displayed. If the calculated kV is above or below the selected filter kV range, "High"

or "Low" is displayed instead of kV and measured time may be "----". If the NERO mAx cannot find the

selected %kV on the kV waveform, a %kV TOO LOW message is displayed (see Section 4.3--Error

Messages--for more information). Please wait while the Model 8000 prepares for the next exposure. If

the Model 8000 detects a fault condition such as an invalid filter card or position, an error message is

displayed and the user must correct the error to continue (see Section 4.3--Error Messages--for more

information).

80.0

79.2

81.1

RADIO 75% LOW 10 ms MAKE

MODE %kV SENS DELAY EXPOSURE

The Model 8000 is now ready to take another exposure. Pressing the mode key at any time exits from

this measurement mode and returns to the mode selection screen.

kV Eff

kV Peak

kVp Avg

kV Eff

kV Peak

392

0.0

100

392

0.0

mR

mAs

msec

mR

mAs

As a power saving feature, the Model 8000's display backlight turns off after one minute of no activity.

The backlight turns back on when any button is pressed or an exposure is made. In addition, after five

minutes of no activity, the 8000 exits from any measurement mode and returns to the mode selection

screen.

Using A Measurement Delay

A measurement delay may be used to postpone the start of data acquisition in order to skip over

waveform anomalies (such as overshoots or preheat effects) that may occur at the beginning of an

exposure.

When a delay is used, the NERO mAx waits for the specified delay time after its radiation threshold is

exceeded before starting data acquisition. Data acquisition starts immediately after the delay time has

elapsed if radiation is above the NERO mAx radiation threshold. If no radiation is detected after the delay

time has elapsed, data acquisition is delayed for up to one second after the delay time has elapsed. If no

radiation is detected for one second after the delay time has elapsed, the NERO mAx assumes that no

exposure has occurred and displays the “DELAY TOO LONG” message.

The delay range is from -999 to +999 milliseconds, and the polarity of the measurement delay only affects

how exposure time measurements are performed.

2-14

Page 27

Operation

Modes of Operation

2

When a negative measurement delay is specified, the NERO mAx does not include the delay time in the

measured exposure time. A negative measurement delay should be used in cases when x-ray generator

filament preheat pulses or other waveform anomalies should be excluded from kV and exposure time

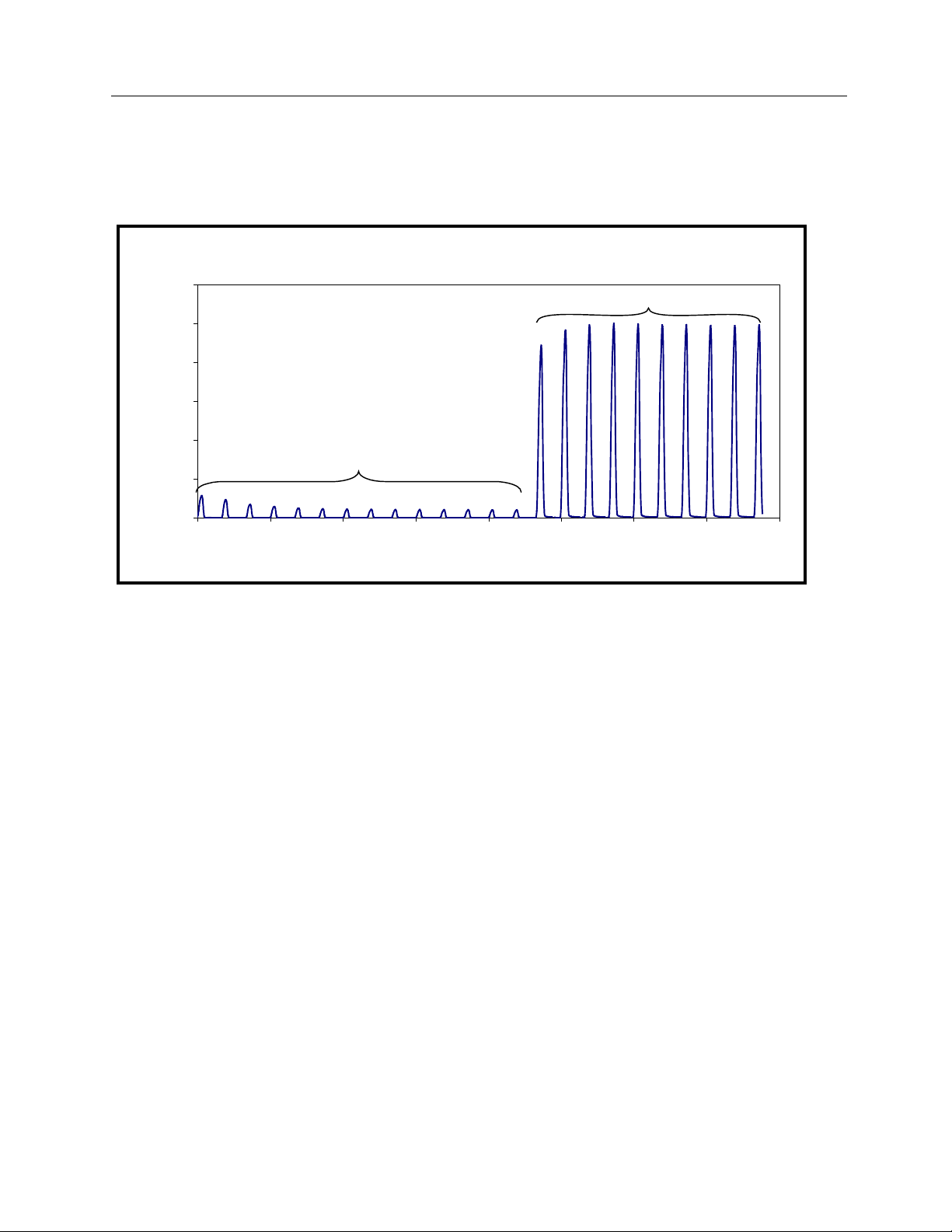

measurements. In the example shown below, a 10-pulse exposure is preceded by 14 filament preheat

pulses. Using a -230 millisecond delay to skip over the filament preheat pulses results in a measured

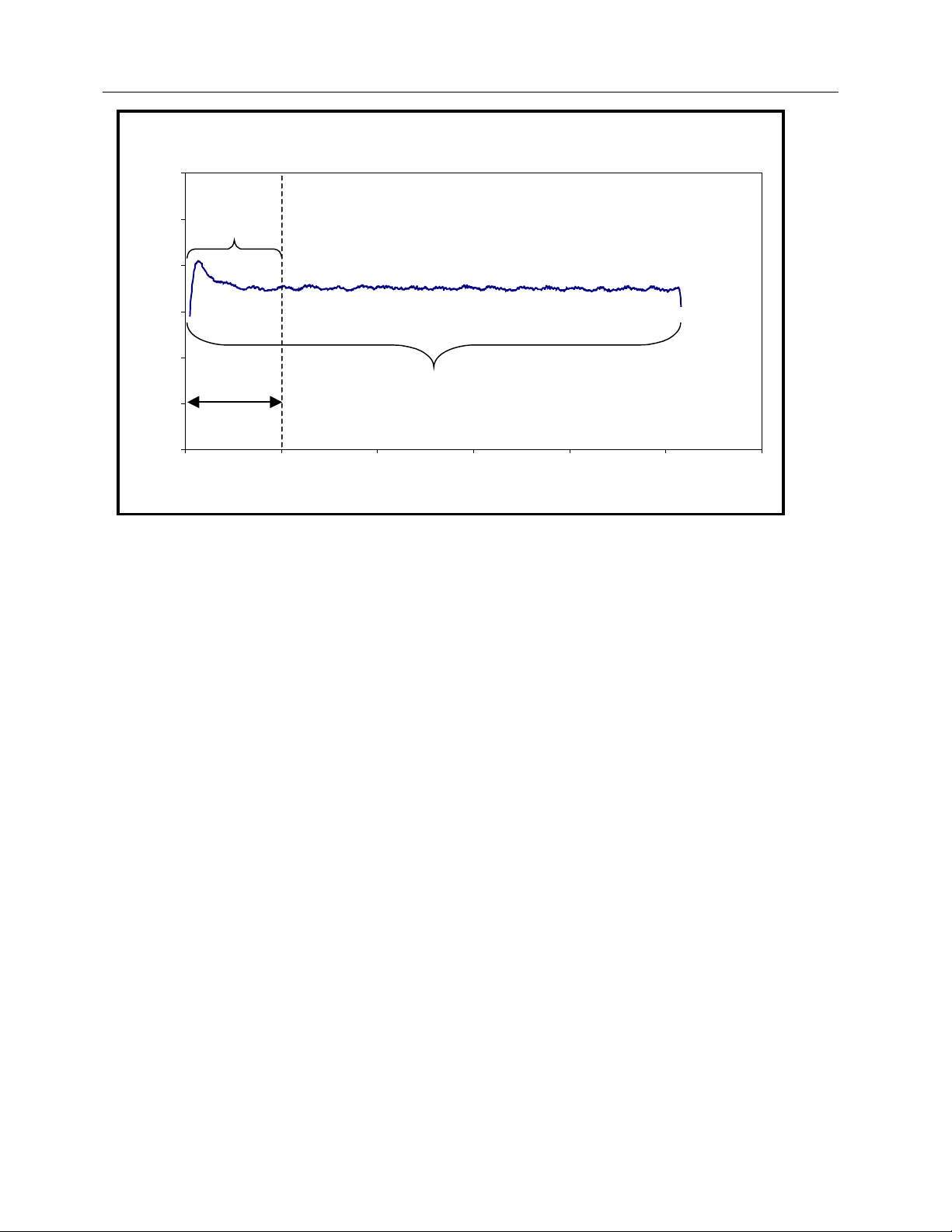

Negative Measurement Delay

Relative Radiation

120%

100%

80%

60%

40%

20%

0%

0 50 100 150 200 250 300 350 400

A negative delay is used to skip over

filament preheat pulses

msec

Exposure time measured

with a negative delay

exposure time of 10 pulses.

An example showing this use of a measurement delay can also be found in troubleshooting Section 4.8-Waveforms - Dental With Filament Preheat.

When the measurement delay is positive, the NERO mAx includes the delay time in its measured

exposure time. A positive measurement delay should be used in cases when the kV waveform contains

leading edge overshoot or other waveform anomalies that should be excluded from kV measurements but

included in the exposure time measurement. In the example shown below, an overshoot occurs in the

first few milliseconds of a 50-millisecond exposure. Using a +10 millisecond delay to skip the overshoot

results in a measured kVp of 72 versus 82 and an exposure time of approximately 50 milliseconds.

2-15

Page 28

Victoreen 8000

Operators Manual

Positive Measurement Delay

120

A positive delay

100

is used to skip

overshoots

80

60

kV

40

Exposure time measured with positive delay

20

10 mill isecond

delay

0

0 102030405060

msec

An example showing this use of a measurement delay can be found in troubleshooting Section 4.5-Waveforms - Overshoot.

When a positive measurement delay is used in making a measurement in the Radio or Mammo mode,

the measured exposure time may be slightly longer than the exposure time between the selected %kV

points on the kV waveform. This is because the Model 8000 does not store the leading edge of the x-ray

output waveform when a measurement delay is used; it waits for the specified delay time before acquiring

waveform data. As a result of this, the %kV point on the rising edge of the kV waveform is not stored and

the time from exposure start to this point cannot be subtracted from the total time.

When exposure time is measured in pulses (1ØPULSE), use of a measurement delay may cause an error

in the pulse count because no pulses are counted during the delay time. The polarity of the delay has no

effect on pulse counting; for example, the number of pulses counted with a -10 millisecond delay is the

same as the number counted with a +10 millisecond delay.

When using a measurement delay in pulsed and single-phase applications, care must be used in

determining the correct delay period. If x-rays are detected at the end of the delay period, such as during

a pulse, the NERO mAx begins timing immediately. If no x-rays are detected at the end of the delay

period, such as between pulses, the NERO mAx waits up to one second for the beginning of the next

pulse to begin timing. As a result of this, the delay period should terminate prior to the first x-ray pulse to

be included in data analysis.

The NERO mAx Excel Add-In should be used to view radiation and kV waveforms to determine the

optimum measurement delay to use. Information on using the NERO mAx Excel Add-In to view

waveforms may be found in the NERO mAx Toolkit for Excel Instruction Manual. In addition, a digital

storage oscilloscope may be connected to the scope output on the rear panel of the NERO mAx readout

to view radiation output waveforms. Information on using the NERO mAx scope output may be found in

Section 1.6 of the NERO mAx instruction manual.

2-16

Page 29

Operation

Modes of Operation

2

Using %kV and Exposure Time Measurements

The %kV setting determines how the NERO mAx measures exposure time. When 75%, 80%, or 90% kV

is selected, the NERO mAx measures exposure time between the 75%, 80%, or 90% points on the kV

waveform. For best results when selecting 75%, 80%, or 90% kV, make sure that the percentage of the

kV waveforms peak kV is within the selected filter range. If the %kV or the measured kV is too low, a

"%kV TOO LOW" error message will be displayed.

When zero crossing (ZERO) is selected, the NERO mAx measures radiographic exposure time from the

moment x-rays are detected by the NERO mAx until they are no longer detected. This corresponds to the

time between first and last passage through the NERO mAx internal radiation detection threshold of the

channel A radiation signal. When using zero crossing, measured exposure times may be lengthened by

cable charging or by output filter capacitors used in some single phase generators to smooth the

generator’s output waveform.

When 1ØPULSE is selected, the NERO mAx counts the number of x-ray pulses in a pulsed or singlephase radiographic exposure. Pulses are detected by counting each passage through the NERO mAx

internal radiation detection threshold of the rising and falling edges of the pulses on channel A radiation

signal. This is primarily for use with single-phase full and half-wave rectified generators. Pulse counting

may not function properly on single-phase generators employing output filter capacitors to smooth the

generator’s output because the generator’s output may not drop to zero between pulses. Additionally,

use of a measurement delay may cause an error in the pulse count. For more information, see "Using a

Measurement Delay".

When calculating kVp average, the NERO mAx only includes peaks that are above the selected %kV in

the kVp average calculation. When ZERO or 1ØPULSE are selected, the NERO mAx includes all

detected peaks in the kVp average calculation.

2.5.2 Mammo Mode

Mammo mode is used to make measurements on mammographic generators. Mammo mode

simultaneously measures kVp, exposure time and mAs from a single mammographic exposure.

Exposure time in the Mammo mode is measured between the first and last passage through the 90%

points on the kV waveform. A measurement delay of up to 999 milliseconds may be used to delay the

start of kV data acquisition in order to skip over waveform anomalies at the beginning of an exposure.

See "Using a Measurement Delay" (at the end of this section) for more information on using a

measurement delay.

To make a mammographic measurement

Make sure that the NERO mAx is turned off. Plug one end of the NERO mAx’s detector cable into the

NERO mAx detector. Plug the other end of the detector cable into the NERO mAx’s detector connector.

Insert the MAMMO filter card into the detector and place the filter card in the correct position for the x-ray

tube target material. Place the NERO mAx detector on the x-ray table with the top of the detector facing

the x-ray tube. Position the detector so that the detector is centered in the beam and is aligned with the

x-ray tube axis. If mAs measurements are to be made, plug the mAs cable into the NERO mAx detector’s

mAs input and connect the mAs leads to the generators mAs terminals. For more information on

positioning the NERO mAx detector, see section "Positioning the Detector".

Extreme caution should be used when making

connections to the mAs terminals of the X-ray

generator or detector. Improper connections may

result in injury, damage to the NERO mAx, and/or

damage to the x-ray generator.

WARNING

2-17

Page 30

Victoreen 8000

Operators Manual

If results are to be printed, plug the printer cable into the printer port at the rear of the NERO mAx then

plug the other end of the printer cable into the printer and turn the printer on (see Section 1.5--Printing).

Plug the AC adapter into the NERO mAx if needed (see Section 1.4--Battery Operation and Charging)

and turn the instrument on.

EXP

CT EXP

AMSE

FLUORO Mo 30μ

MAMMO LOW RHODIUM Rh 25μ

RADIO HIGH MOLY Al 1MM 0 ms

MODE SENS TARGET FILTER DELAY

Select the MAMMO mode, high or low sensitivity, target and filter and shot delay, then press the ENTER

key. To use a measurement delay, press the DELAY key to select and increment the shot delay. The

measurement delay may also be incremented or decremented by pressing the up or down keys when the

delay is selected. The measurement delay is retained from one exposure to the next and can only be

reset to zero by the user.

Please wait…

FILTER = 22 - 35

MAMMO HIGH MOLY Mo 30μ 0 ms

MODE SENS TARGET FILTER DELAY

Please wait while the NERO mAx prepares to take an exposure. Note that the selected filter kV range is

displayed. If the NERO mAx detects a fault condition such as an invalid filter card or position, an error

message is displayed and the user must correct the error to continue (see Section 4.3--Error Messages-for more information). When the NERO mAx is ready to take an exposure it will beep and prompt for an

exposure.

MAKE EXPOSURE

FILTER = 22 - 35

MAMMO HIGH MOLY Mo 30μ 0 ms

MODE SENS TARGET FILTER DELAY

Make an exposure. If nothing happens, there is insufficient x-ray intensity to make a measurement. To

remedy this situation, switch to high sensitivity, increase mA or decrease the distance between the x-ray

tube and NERO mAx detector.

ANALYZING DATA

FILTER = 22 - 35

MAMMO HIGH MOLY Mo 30μ 0 ms

MODE SENS TARGET FILTER DELAY

Please wait while the NERO mAx analyzes the exposure data.

2-18

Page 31

Operation

Modes of Operation

2

24.8

24.3

27.3

MAMMO HIGH MOLY Mo 30μ MAKE

MODE SENS TARGET FILTER EXPOSURE

After data analysis is complete, kV, exposure, time and mAs are displayed. If an overrange is detected

an error message is displayed. If the calculated kV is above or below the selected filter kV range, “High”

or “Low” is displayed instead of kV and measured time may be “----“ (see Section 4.3--Error Messages-for more information). Please wait while the NERO mAx prepares for the next exposure. If the NERO

mAx detects a fault condition such as an invalid filter card or position, an error message is displayed and

the user must correct the error to continue (see Section 4.3--Error Messages--for more information).

The NERO mAx is now ready to take another exposure. Pressing the mode key at any time exits from

this measurement mode and returns to the mode selection screen.

24.8

24.3

27.3

MAMMO HIGH MOLY Mo 30μ Please

MODE SENS TARGET FILTER Wait…

As a power saving feature, the NERO mAx’s display backlight turns off after one minute of no activity.

The backlight turns back on when any button is pressed or an exposure is made. In addition, after five

minutes of no activity, the NERO mAx exits from any measurement mode and returns to the mode

selection screen.

kVp Avg

kV Eff

kV Peak

kVp Avg

kV Eff

kV Peak

226.5

240.3

19.9

226.5

240.3

19.9

msec

mR

mAs

msec

mR

mAs

Using A Measurement Delay

A measurement delay may be used to postpone the start of data acquisition in order to skip over

waveform anomalies (such as overshoots) that may occur at the beginning of an exposure. The delay

range is from -999 to +999 milliseconds, and the polarity of the measurement delay only affects how

exposure time measurements are performed.

When the measurement delay is positive, the NERO mAx includes the delay time in its measured

exposure time. A positive measurement delay should be used in cases when the kV waveform contains