Page 1

Process and temperature

switch applications with

the 740 Series DPCs

Application Note

This note discusses appli-

cations for process

switches and calibrating

temperature switches

using the Fluke 740 Series

Documenting Process

Calibrators (DPCs). Let’s

begin by looking at what a

process switch is and

what it does.

Process switches

A process switch is a device that

can sense a process variable —

such as temperature or pressure

— and change the state of one or

more sets of switch contacts

when that variable reaches a

predetermined value. This value

is called a setpoint. A switch can

have multiple setpoints. Let’s look

at some important c

how proc

pairs, and a pair is either nor

mally open or normally closed.

“Normally” means without ener-

ization — just the way the

g

contacts would be on the shelf or

if you disconnected the power

ires from the switch.

w

four sets of contacts — two

normally open and two normally

closed. But, there are many

variations. A single switch may

operate just one set of contacts,

or it may operate multiple sets

ess switches work.

Contacts. Contacts come in

Many process switches have

onc

epts of

of normally open and normally

closed contacts. You select which

contacts to use based on the

desired output for a given condition and a given failsafe condition.

Control logic. You must think

of switch actuation and contact

state separately. Actuating the

typical process switch means

opening one set of contacts and

closing another at the same time.

Whether actuation opens or

closes a set of contacts depends

on whether you are using the

normally open or normally closed

contacts and whether the switch

is in an activated or deactivated

state during normal operation.

Failsafe operation is the first

criterion to assess when deciding

which set of contacts to use. For

example, you should use normally

closed contacts if breaking the

circuit will result in a failsafe

condition. Because loss of power

and an open circuit (via a broken

circuit wire, broken connection,

or intentional operation) have the

same effect on circuit operation,

the normally open contacts would

orrect ones to use. Upon

e the c

b

loss of power, these contacts

will open. So, you would want

them to b

operations and to open when

operations go into alarm or

ontrol change c

c

a high level sw

ily close c

a high level condition. Good control practic

opposite.

e closed for normal

onditions

It is not true that, for example,

itch w

ontacts when you reach

es usually dictate the

.

ill nec

essar

What about actuation? You

might want the switch to failsafe

upon loss of level in a cooling

tank. So, normal level would activate the switch (compared to its

shelf position). Upon loss of level,

the switch deactivate — that is, it

will assume the same state that

it would be in if it were on the

shelf. For an example of this

control logic, look at a typical

toggle-style light switch. You will

notice the word “ON” under the

toggle handle and the word OFF

above it. To reveal the word “ON,”

you must flip the switch up. If the

toggle mechanism were to fail

mechanically — which could

happen if, for example, it were to

melt due to arcing — the toggle

handle would drop into the “OFF”

position due to gravity. That is the

failsafe position of these switches.

It’s common to implement process

switches the same way.

Setpoint. A switch may have

multiple setpoints

many level switches come with

low-low, low, high, and highhigh sets of contacts — each with

its own setpoint.

But, it can get more c

than that, depending on the

required control scheme and the

type of sw

many ways to accommodate

complex switching schemes —

including the use of an analog

transmitter serves as the input to

a virtual switch (implemented in

software).

. For example,

omplex

itch used. There are

From the Fluke Digital Library @ www.fluke.com/library

Page 2

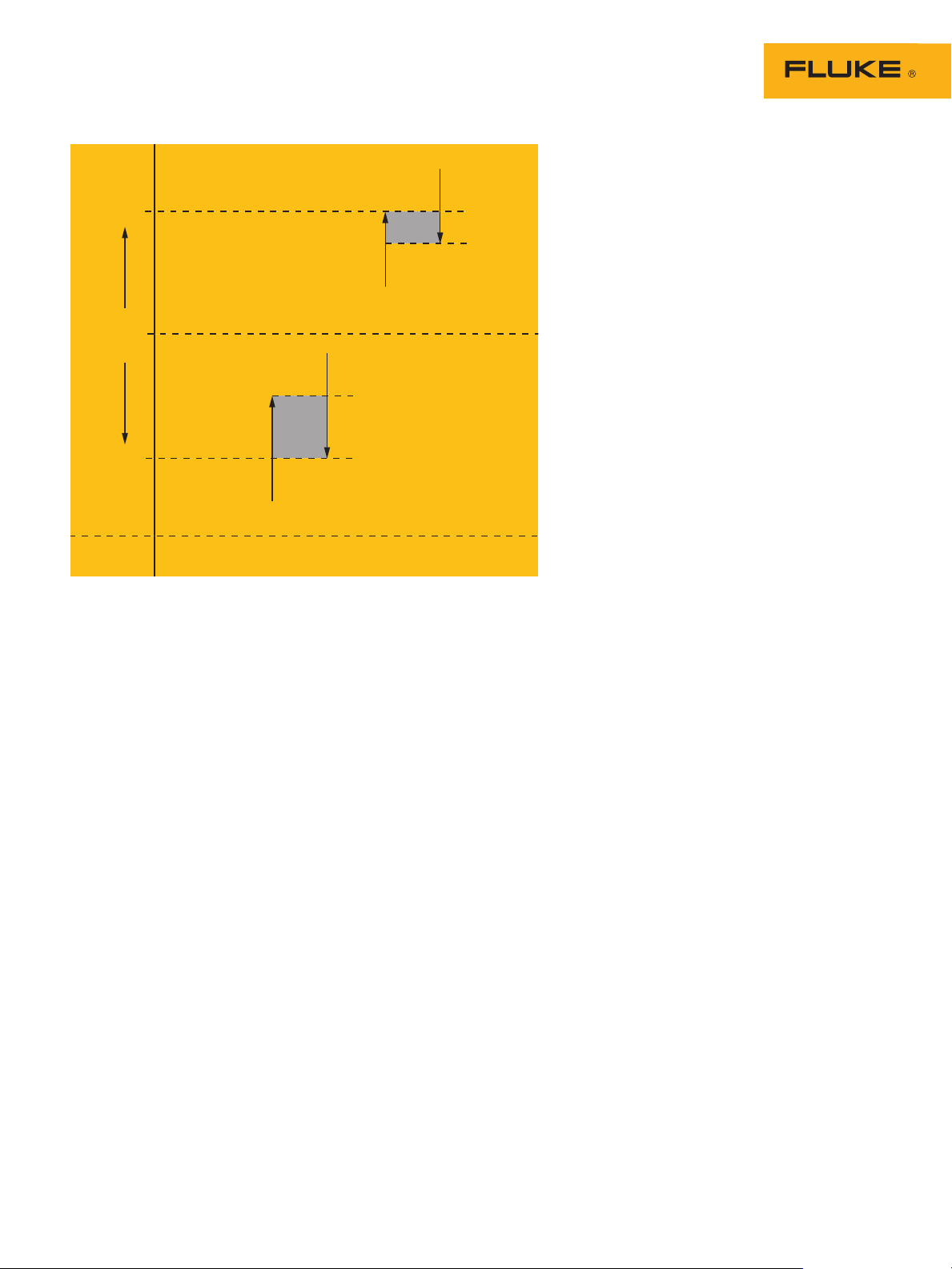

Deadband

Open

High Limit

Process

Variable

Low Limit

Setpoint

Reset

Closed

50

°C

20 °C

Deadband

Closed

Reset

Setpoint

Open

Figure 1. 2-point switch with settings for low and high setpoints.

Here’s an example of a complex application. A level switch

may allow a “normal” indication

(such as a light) to display at any

level up to 82 %. At 82 %, the

switch causes normal indication

to go off — placing the indication

between a normal state and an

alarm state. At 85 %, the switch

y trigger a high level alarm

ma

light. At 90 %, the switch may

trigger a high-high level alarm

t

light plus an audio alarm

93 %, it ma

y trigger a feed valve

. A

closure. At 95 %, it may trigger

7 %,

t 9

dump valve operation

y trigger drain pump opera

it ma

tion. At 98 %, it may actuate

. A

isolation doors in the room c

taining the tank

. And those

actions are just for high level.

This same sw

might c

itch, or another,

ontrol low level operations. In some configurations, you

might ha

ve separate sw

each setpoint

.

itches for

on

-

Setpoint tolerance. This is

the amount of error you can have

between the desired setpoint and

the one you actually set. It’s not

always easy to calibrate a switch

directly on the desired setpoint —

for a variety of reasons. For

example, if you must open a

valve when the temperature

reaches 3

point tolerance might allow you

consider the switch calibrated if

it trips w

setpoint

expressed in engineering units or

ent

in perc

-

ent, that normally means

perc

percent of the control

explain band b

ent of the setpoint value.

c

Direction. Switch actuation

(and, therefore, c

tional, due to hysteresis

Sometimes, the hysteresis value

can exc

e. For non-critical applications

anc

with wide setpoint tolerances,

you can probably ig

. But, standard practice is to

sis

observe direction when calibrating a setpoint

calibrate a low level switch, you

do so with the level dropping.

rees, your set

3 deg

1

ithin 5 deg

olerances may be

. T

. When expressed in

rees of the

elow), not in per

band (we

ontrol) is direc

.

eed the setpoint toler

nore hystere

. When you

When you calibrate a high level

switch, you do so with the level

rising. This is standard practice

with all process variables, not

just level — you get a more accurate calibration by accounting for

hysteresis.

Trip. This is the value at

which the switch will change the

state of a given set of contacts.

Where a switch trips is a function

of its setpoint and direction. For a

pressure switch with a setpoint

of 500 PSI, the switch should trip

at 500 PSI as pressure rises. Trip

is also called “set.” The opposite

of that is reset

.

Reset. Some switches reset

automatically, while others

require a manual reset

. In either

case, the reset will not occur until

the switch actuator has moved in

the direction opposite its triggering direction enough to overcome

hysteresis (and/or deadband —

see below) and allow the switch

to change contact states back to

normal. An exception to this is

when the switch is used to indicate a normal condition. For such

switches, reset is usually not an

issue.

Hysteresis. This is the tendency of the switch to stay in the

last position it was in. This

means that when you are calibrating a switch to trip at 500

PSI, the hysteresis of the switch

may cause it to trip at 501 PSI

when you are increasing pressure

and 499 PS

I when you are

decreasing pressure. If this is a

ontrol

high pressure sw

itch (c

function requires a trip on rising

pressure), you would calibrate it

to trip at 500 PS

I on an increas

ing pressure input and let the

498 PSI trip serve as the maxi-

mum reset value.

Band.This is the area around

the setpoint where the switch is

or exam

. F

ontrolling the proc

c

ple, if the sw

-

tank to maintain a level between

ess

itch will control a

-

6 feet of water and 9 feet of

water, it has a band of 3 feet

.

-

2 Fluke Corporation Process and temperature switch applications with the 740 Series DPCs

Page 3

related to reset. Deadband pre-

ENTER

V

RTD

MEAS

SOURCE

mA

mA

RTD

V

30

0

V

MAX

30V MAX

TC

Fluke 741/743

To Limit

To Limit Switch

Thermocouple

Input

vents a switch from cycling

around a setpoint. Hysteresis provides some deadband,

automatically. But for some

proc

enough to prevent undesirable

on/off cycling. So, many switches

have additional deadband intentionally designed into them. That

deadband may be fixed, fixed

selectable, or variable. For example, an electronic thermostat used

for a heat pump may have a fixed

selectable deadband of 1.5

deg

the low and high points of operation

will control a tank to maintain a

level between 6 feet of water

and 9 feet of water, it has a calibration range of 6 to 9 feet. The

switch itself might have an actual

range of 0 to 50 feet — this range

would appear on the nameplate

of the switch.

Testing a temperature

switch

The switch in the following

example is a temperature switch

with a type K thermocouple input

and a low temperature setpoint of

20 °C. This switch functions in

much the same way as the thermostat in your home. The Low

Limit example in Figure 1 illustrates the terminology.

open contacts of this switch.

These c

switch actuation, which will

occur with a drop in temperature.

This sw

adjustable reset. The contacts

will re-open upon automatic

reset, which oc

perature moves back up and past

the setpoint in an amount greater

than its deadband

is a minimum of 1 °C and maximum of 3 °C across the range of

the sw

DPC to calibrate the switch,

follow these step-by-step instruc

tions. Keystroke entries for the

DPC are surrounded by quotation

mark

Deadband. This is closely

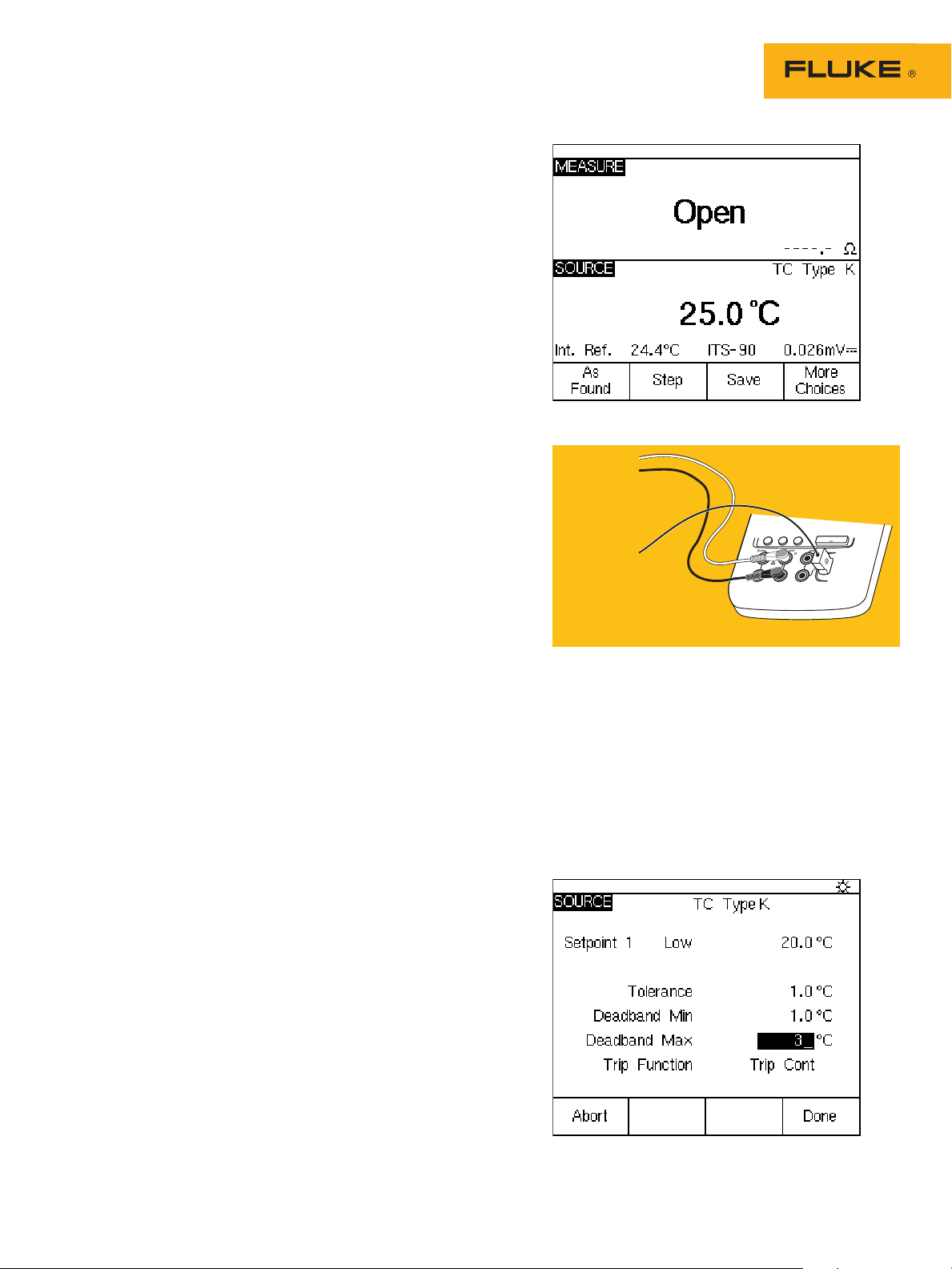

1. Beginning in the power up

state of the calibrator, or

Measure mode, depress the

“ohms/continuity” key twice

to enable continuity mode.

esses, hysteresis is not

2. Simulate the temperature

input.

a. Depress the

“MEAS/SOURCE” key

once to obtain the

Source mode.

b. Depress the “TC/RTD”

key, move the cursor with

the “

↓” key to “K” and

NTER” to select

rees or 3 degrees.

Range. This is specified with

. For example, if the switch

depress “E

a type K thermocouple.

c. Depress “ENTER” again to

select “Linear T.”

d. Enter a temperature out-

put of “25” and depress

“ENTER.”

e. Depress the

“MEAS/SOURCE” key to

obtain the split screen

display. The display of the

74X should be as per

Figure 2.

3. Connect the DPC, per

Figure 3.

4. Take As Found

measurements.

a. Select the “As Found”

softkey.

b. Move the cursor to “1 Pt.

c. Switch Test” with the “

↓”

key and depress “ENTER.”

You should now see the

switch test setup screen.

.

We will be using the normally

ontacts w

ill close upon

Enter the setpoint

5.

a. Depress “Enter” and enter

a setpoint of “20” °C, then

depress “ENTER” again.

The Setpoint Type is set

for low and the Set State

itch does not ha

ve

is a short by default —

perfect for this particular

test. (If these conditions

curs as the tem

-

were different, we would

change them here.).

These setup conditions

. The deadband

describe a switch that has

a setpoint of 20 °C and

closes a set of contacts as

itch.

To set up the Fluke 740 Series

-

s.

3 Fluke Corporation Process and temperature switch applications with the 740 Series DPCs

long as the input temperature to the switch is

below 20 °C.

b. Depress the “Done”

softkey.

Figure 2. MEASURE/SOURCE split screen, contacts open.

Figure 3. Connecting the DPC.

6. Enter the setpoint tolerance and deadband

settings.

a. Move the cursor to tolerance and enter a

setpoint tolerance of “1” °C.

b. Move the cursor to Deadband Min and

enter a minimum deadband of “1” °C.

Move the cursor to D

.

c

eadband Max and

enter a maximum deadband value of 3

The test setup screen should now be as

” softkey

ure 4. D

per Fig

Figure 4. Test setup screen.

epress the “D

one

.

C

°

.

Page 4

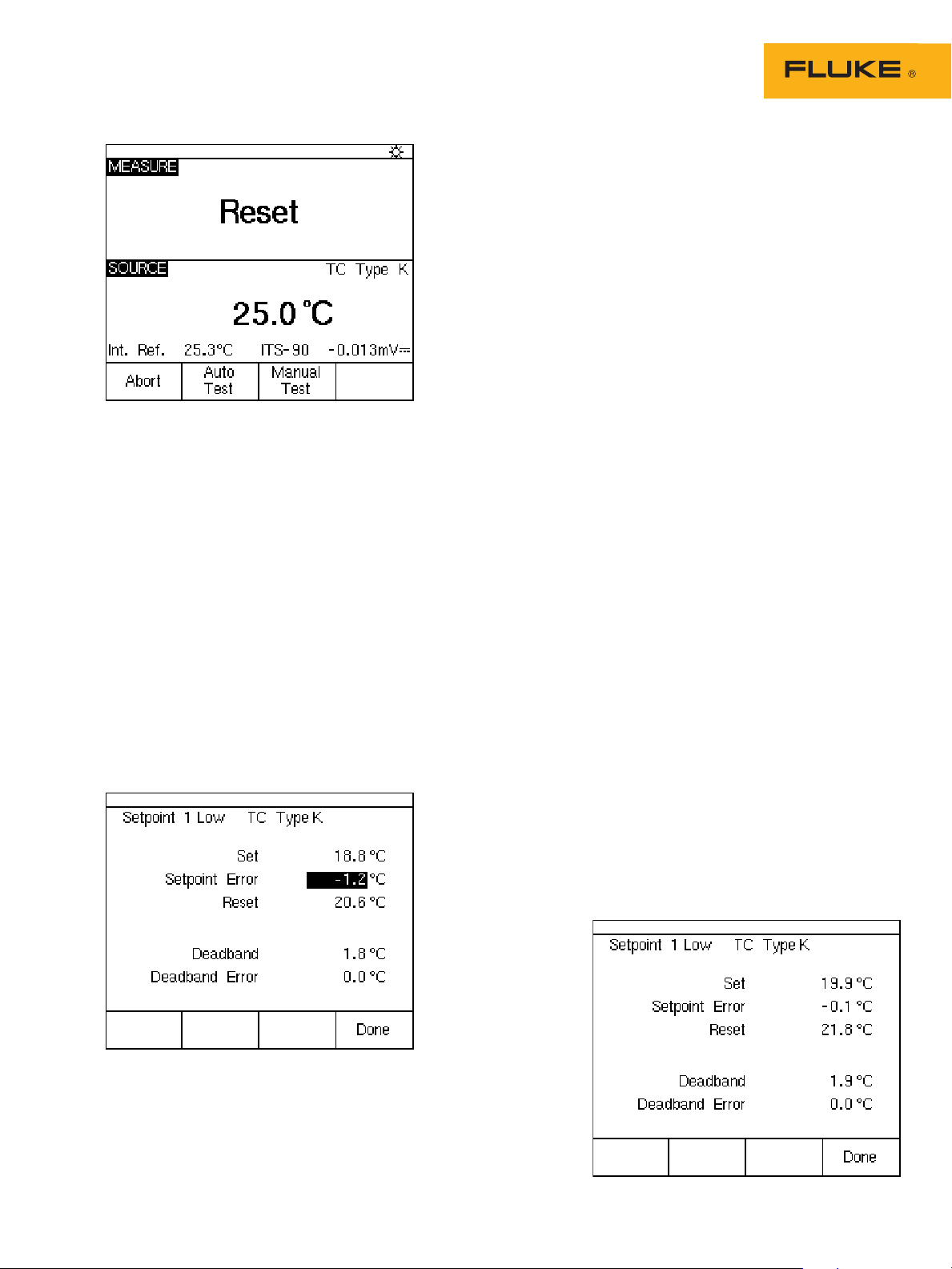

Figure 5. MEASURE/SOURCE split screen, contacts reset.

7. You should now see the split screen

(Figure 5). Select the “Auto Test” softkey

and the “Continue” softkey. The DPC will

now ramp the simulated thermocouple

potential into the limit switch back and

forth past the nominal setpoint and record

the sourced temperature values for the

actual setpoint, and then show that value

in the upper left-hand corner of the DPC

display. Once that is done, the DPC will

then test the reset point of the switch by

ramping the simulated thermocouple

potential into the switch back and forth

past the nominal (21 °C - 23 °C) expected

reset value. Once that value is recorded,

you should be presented with a post test

summary similar to that in Figure 6. Errors

exceeding test tolerance are recorded in

inverse video.

8. Enter Tag information.

a. Depress the “Done” soft-

key and enter the Tag

information for your test.

b. Depress the “Done” soft-

key when tag entry is

complete.

9. Adjust setpoints or reset

points.

a. If the switch failed any of

the test parameters, it is

necessary to adjust the

set and/or reset points. To

do that, first select the

“adjust” softkey.

b. Depress the “Step Size”

softkey, then enter a step

size of “.1” °C.

c. Depress the “Done”

softkey.

d. Depress the “

↓” key until

the DPC source value is

20 °C (the setpoint).

e. Slowly adjust the setpoint

on the limit switch until

the measure screen toggles from reset to set.

Depress the “

↑” key until

the DPC measure screen

toggles to Reset. If the

DPC toggles from set to

reset between 21 °C and

23 °C, the deadband

should be correctly set.

If it does not toggle properly, adjust the reset point

until it toggles within that

band.

f. Verify the set and reset

points toggle correctly, by

depressing the “

“

↑” keys to slew the DPC

↓” and

source temperature across

the set and reset values.

g. Once that is complete,

depress the

“Done”

softkey.

10. Confirm the As Left settings.

a. Depress the “As Left”

softkey.

b. Confirm the test settings.

c. Depress the “Done”, “Auto

Test” and “Continue” soft-

keys. Monitor the DPC as

it performs the As Left

evaluation.

d. Once the post test sum-

mary is displayed, review

the results. If all results

are in normal video (as in

Figure 7), the As Left test

passes.

e. Depress the “Done” soft-

key, and “D ne

” again to

save the Tag information.

. If there were inverse

f

ideo indications of a fail-

v

ure, repeat the

adjustments performed in

Step 9 until a passing

result is obtained.

11. Review results in memory,

a. Depress the “Done”

and “Review Memory”

softkeys.

b. Move the cursor to the tag

entry associated with this

test and depress “ENTER.”

c. Move the cursor to the As

Found entry and depress

“Enter” to review your As

Found result.

d. Depress the “Done”

softkey.

e. Move the cursor to the As

Left entry and depress

“Enter” to review that

.

result

f. Depress the “Done” soft-

key, then depress the

“Tag” softkey to review

your Tag information.

Figure 6. Post-test summary, with reverse video.

4 Fluke Corporation Process and temperature switch applications with the 740 Series DPCs

Figure 7. Post-test summary, with all results normal.

Page 5

Other switch tests

In the preceding step by step

description, the switch has been

removed from its operational circuit and the switch contact

closure is monitored to determine

state change.

You can perform this test with

the switch installed in its circuit.

In this instance, the switch contacts will open and close and you

can use the 740 Series DPC to

measure the presence or absence

of system voltage (e.g. 120VAC) as

switch contacts change state. A

typical example would be measuring the voltage applied to a

heater as controlled by the output

of the switch. The 740 series

DPCs can work with dc voltage in

addition to the continuity and ac

voltage examples previously

described.

Our examples in this application note have been for

temperature switches. The 740

series DPCs allow you to test

pressure switches, too — in fact,

in 11 different engineering units.

Pressure switch tests are similar

to temperature switch tests — you

vary the process variable (source)

at the input, and monitor for a

change of state at the output. You

need to use a hand pump to

source pressure into a pressure

module and the switch. You can

manually document the results

by depressing the “Accept Point”

soft key when the test has been

completed.

With the 740 series DPCs, you

can source and measure many

key variables. And these tools are

useful for calibrating any process

switch. Of course, you will need

to supply your own inputs for

many types of process variables —

such as level, flow, and pH. The

principles of switch operation outlined here apply universally.

For detailed information on

calibrating pressure switches,

reference Fluke Application

Note 2069058.

Fluke. Keeping your world

K

.

E or

up and running

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The N

For more information call:

In the U.S.A. (800) 443-5853 or

ax (425) 446-5116

F

In Europe/M-East/Africa (31 40) 2 675 200 or

Fax (31 40) 2 675 222

In Canada (8

Fax (905) 890-6866

From other c

ax +1 (425) 446-5

F

Web access: http://www.fluke.com

©2004 Fluke Corporation. All rights reserved.

Printed in U

etherlands

LU

F

00) 36-

ountries +1 (425) 446-5500 or

6

1

1

/2004 1263879 A-US-N Rev D

. 7

.A

.S

5 Fluke Corporation Process and temperature switch applications with the 740 Series DPCs

Loading...

Loading...