Page 1

729/729 FC

Automatic Pressure Calibrator

Users Manual

May 2017 Rev. 1, 8/20

© 2017-2020 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for three years from the date of purchase. This

warranty does not cover fuses, disposable batteries, or damage from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not authorized to extend any other warranty on Fluke’s behalf.

To obtain service during the warranty period, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries

do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Table of Contents

Title Page

Introduction .................................................................................................................... 1

Contact Fluke ................................................................................................................. 2

Safety ............................................................................................................................. 2

Standard Equipment....................................................................................................... 3

Buttons ........................................................................................................................... 5

The Display .................................................................................................................... 8

Triple-Function Display .............................................................................................. 12

RTD Connection ........................................................................................................ 13

Pressure Module Connection .................................................................................... 13

Fluke Connect Device Connection ............................................................................ 14

Ports ............................................................................................................................... 15

Download the Fluke Connect

Enable the Fluke Connect App ..................................................................................... 18

Setup Menu .................................................................................................................... 19

App ................................................................................ 17

i

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

729/729 FC

Users Manual

Manage FC Devices (729 FC Only) .......................................................................... 19

Locator ...................................................................................................................... 19

729 Information ......................................................................................................... 20

729 Setup ................................................................................................................. 21

Manage Users ........................................................................................................... 22

Manage Test Results ................................................................................................ 23

Manage Screen Shots .............................................................................................. 23

Manage Custom Tasks ............................................................................................. 24

Maintenance Menu ................................................................................................... 24

Drain Water (Condensation) ................................................................................. 24

Keypad Test ......................................................................................................... 26

Exhaust ................................................................................................................ 26

Tasks Menu ................................................................................................................... 26

Pressure Transmitter (P/I) ......................................................................................... 27

Pressure Switch (SW) ............................................................................................... 29

Current to Pressure Test (I/P) ................................................................................... 31

Pressure Leak Test ................................................................................................... 34

Pressure Transmitter (P/V) ....................................................................................... 35

Pressure Transmitter (P/P) ...................................................................................... 35

HART Functionality ........................................................................................................ 37

Loop Power +24V ON ............................................................................................... 38

Enable HART 250Ω .................................................................................................. 40

HART Menu ................................................................................................................... 40

HART Data ............................................................................................................... 40

HART Service ........................................................................................................... 41

PV Zero Trim ........................................................................................................ 41

mA Output Trim .................................................................................................... 41

Trim to Applied Values ......................................................................................... 41

Set Fixed mA Output ............................................................................................ 42

ii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

Contents (continued)

Re-range Transmitter ............................................................................................ 42

Device Diagnostics ............................................................................................... 42

Calibrate (Ad hoc) ...................................................................................................... 42

Adjust .................................................................................................................... 43

PV Zero Trim ........................................................................................................ 43

mA Output Trim .................................................................................................... 43

Trim to Applied Values .......................................................................................... 44

As Left .................................................................................................................. 44

Find Task by Tag ....................................................................................................... 44

Bus Polling ................................................................................................................ 44

Measure Mode ............................................................................................................... 44

Current Measurement ................................................................................................ 45

Volts Measurement .................................................................................................... 45

Pressure Measurement ............................................................................................. 46

Autostep and Auto Ramp the Output Value ............................................................... 49

Autostep .................................................................................................................... 49

Auto Ramp the Output ............................................................................................... 50

Temperature Measurement ....................................................................................... 51

Source mA Mode ....................................................................................................... 52

4 to 20 mA Simulation ............................................................................................... 52

Log ................................................................................................................................. 54

Communication with a PC .............................................................................................. 54

The Battery ..................................................................................................................... 56

Charge the Battery .................................................................................................... 56

Battery Life ................................................................................................................ 56

Maintenance ................................................................................................................... 57

Clean the Product ...................................................................................................... 57

Clean the Pump Valve ............................................................................................... 57

In Case of Difficulty .................................................................................................... 59

iii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

729/729 FC

Users Manual

Battery Replacement ................................................................................................ 60

Update Product Firmware ......................................................................................... 61

Calibration Data ........................................................................................................ 61

Service Center Calibration or Repair ........................................................................ 61

Error Messages ......................................................................................................... 62

HART Commands ..................................................................................................... 68

Documenting Functionality ........................................................................................ 69

Strap .............................................................................................................................. 69

Hanger Accessory ......................................................................................................... 71

User-Replaceable Parts and Accessories ..................................................................... 72

Specifications ................................................................................................................ 74

Pressure Specification .............................................................................................. 74

Electrical Specification .............................................................................................. 74

Product Models ......................................................................................................... 76

Mechanical Specification .......................................................................................... 79

Environmental Specification ...................................................................................... 79

Safety ........................................................................................................................ 79

iv

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Introduction

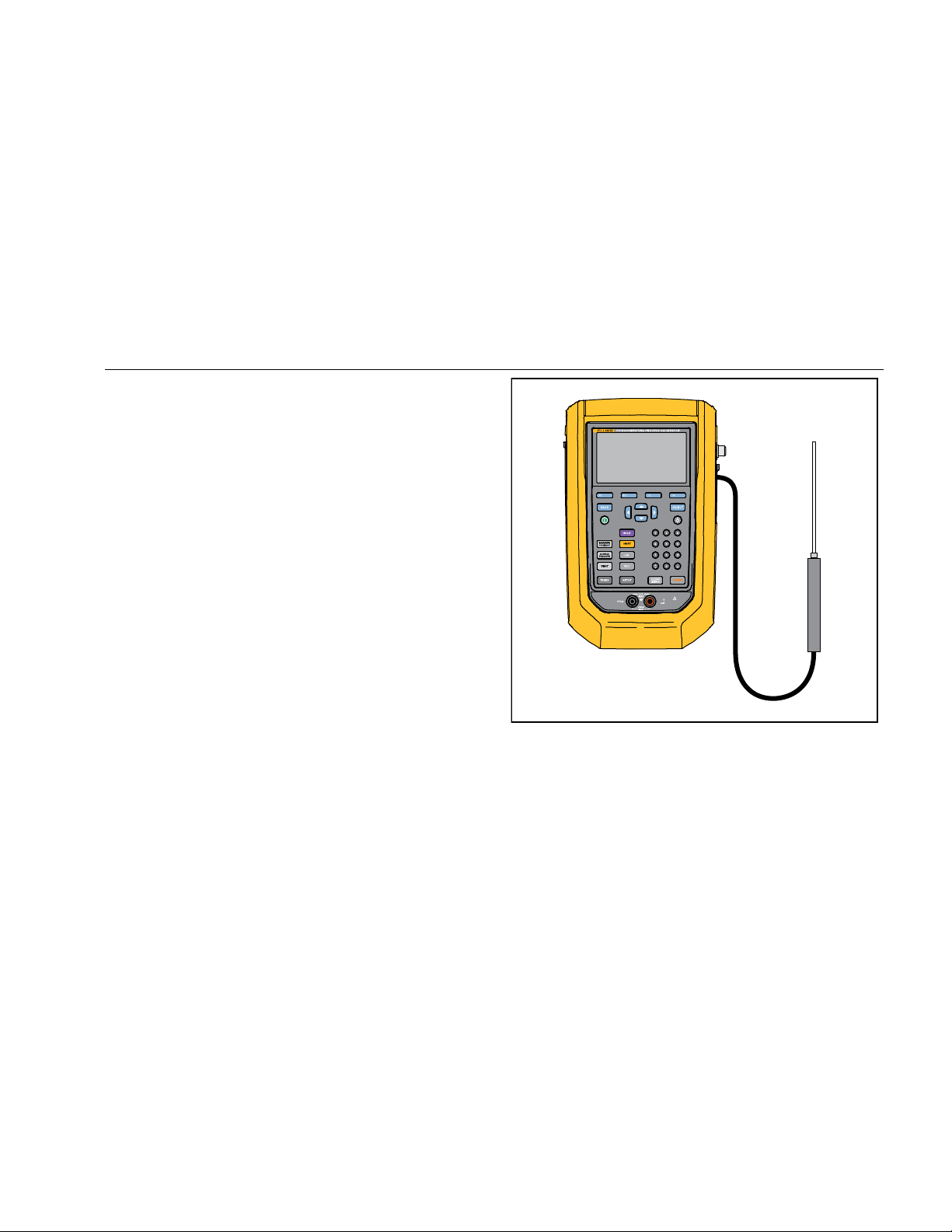

The Fluke 729 and 729 FC Automatic Pressure

Calibrators (the Product)

calibration tools for lab or field use. This battery-operated

product performs automatic pressure calibration of

transmitters, pressure switches, and gauges. The

automatic functions are done by the Product or by

downloaded tasks from calibration-management software

(CMS). The Product also supplies basic HART

communicator functions when used with HART-capable

transmitters. “FC” designates Fluke Connect

this manual.

Product key features and benefits include:

• Automatic pressure calibration of transmitters,

pressure switches and pressure gauges.

• Source and measure pressure to test and calibrate

pressure sensors, transmitters, and other pressure

instruments.

are portable field pressure

®

®

throughout

• Source and simulate milliamp signals while

measuring pressure for testing current to pressure

converters (I/P).

• HART (Highway Addressable Remote Transducer)

communication to configure and perform trim on

HART smart-pressure transmitters.

• Provides Loop Power and simultaneously measures

mA output from a connected device.

• Measures pressure with any of 50 Fluke-750P Series

pressure modules.

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

729/729FC

Users Manual

• Document automated as-found/as-left procedures to

satisfy quality regulations or audits with DPCTrack2

software.

• Advanced features like auto step and auto ramp

allow tests of devices automatically.

• The pressure switch test automatically ramps

pressure up and down across expected switch trip

setting to calibrate pressure switches.

• Fluke Connect (FC) built into FC models.

2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 9

Automatic Pressure Calibrator

Standard Equipment

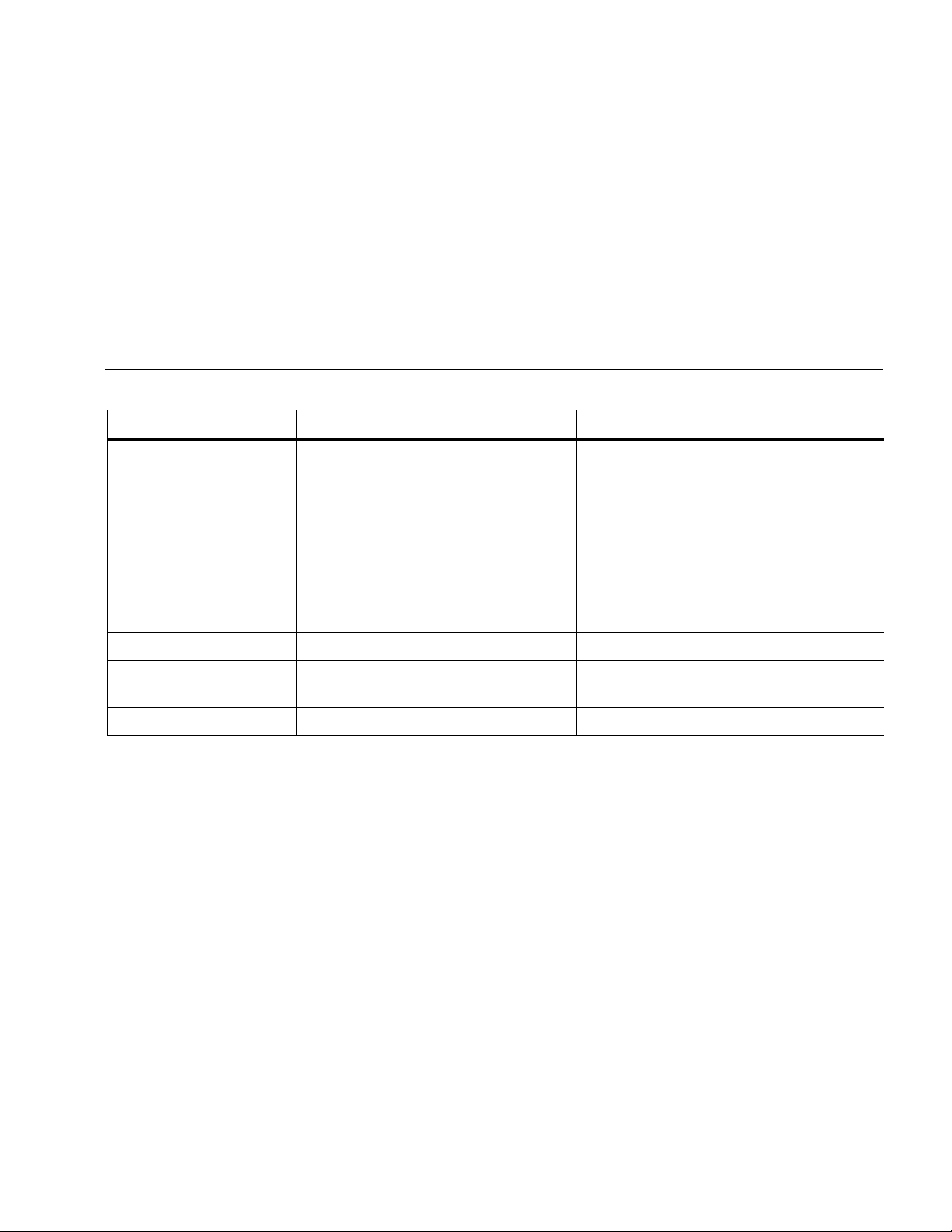

Standard Equipment

Figure 1 and Table 1 show standard equipment.

1

7

2

8

13

12

11

4

3

10

9

14

5

15

16

6

17

idj016.emf

Figure 1. Standard Equipment

3

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

729/729FC

Users Manual

Table 1. Standard Equipment

No. Equipment No. Equipment

729 or 729 FC Automatic Pressure Calibrator

AC/DC converter

Mains line cable

Rechargeable Li-ion Battery

Stackable test lead set

AC280 Sure Grip hook set (red and black)

Alligator clips (red and black)

One set of TP220 test probes (red and black) Soft carrying case

USB communication cable: 3 ft (1 m) Type A

plug for host (PC) to Mini-B plug for device

Nylon hose 1/8 in diameter, 3.5 ft length Traceable calibration report with data

Fitting, 1/8 in NPT-Female x 1/4 in NPTFemale

Tube fitting, male connector (qty 2), 1/8 in

NPT male connector, 1/8 in hose

Not

Shown

Fitting, 1/8 in NPT-Female X M20-Female

Fitting, 1/4 in BSP-Female X 1/8 in NPT-Female

Hanger Kit

Hose to drain condensed water generated from

the Product. 1/8 in diameter, 1 ft length

Hose for leakage test. 1/8 in diameter, 2 in

length

Adjustable quick-release strap for hanging the

Product

Printed multilingual Safety Information

PTFE Tape

International AC Adapter Kit

4

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

Automatic Pressure Calibrator

Buttons

Buttons

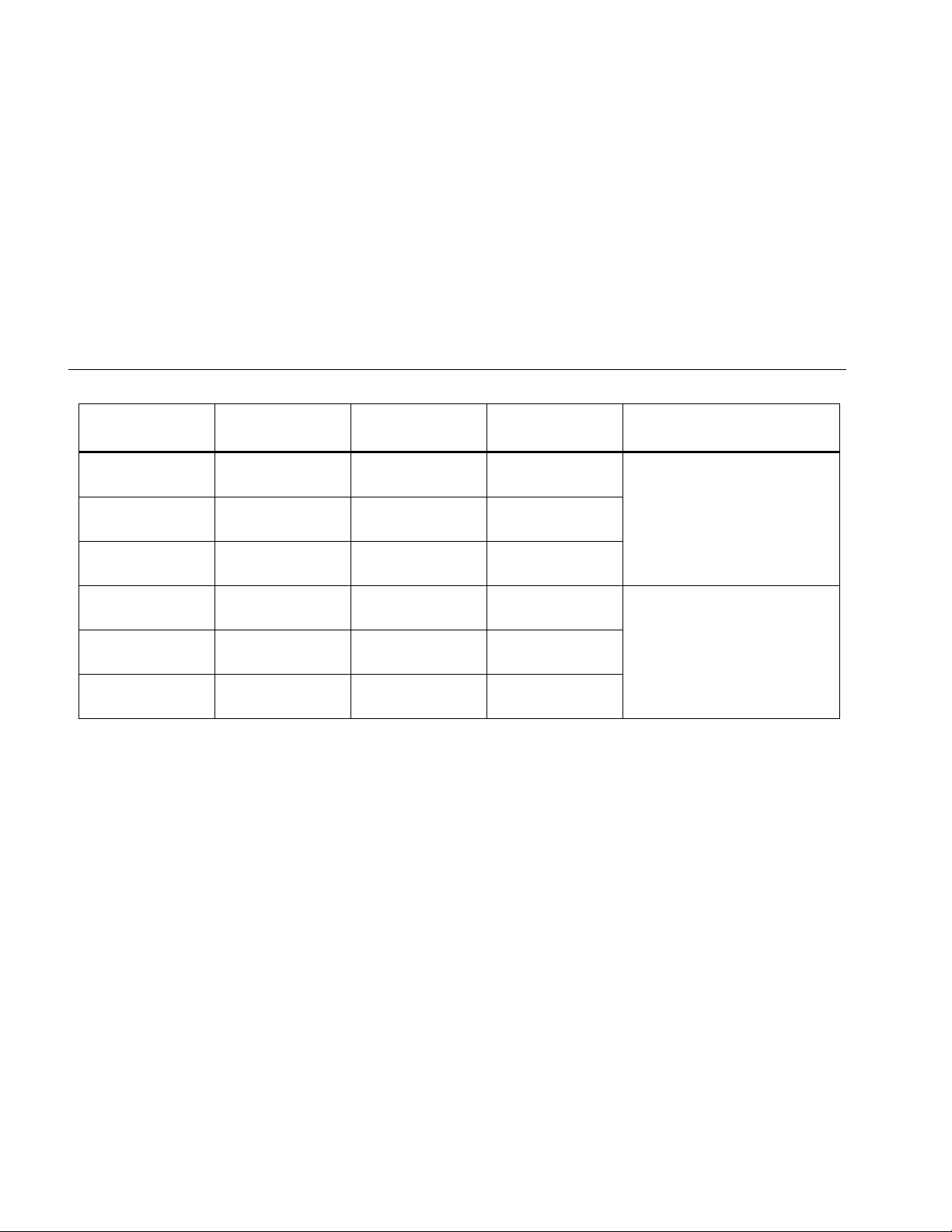

See Figure 2 and Table 2 for the Product buttons and the softkeys.

3

2

1

18

17

16

15

14

13

12

4

10

11

Figure 2. Buttons

5

6

7

9

8

idj001.emf

5

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 12

729/729FC

Users Manual

Table 2. Buttons

Number Description Number Description

Power button. Push to turn on or turn off

the Product.

BACK button. Push to move to the

previous user interface (UI) screen. When

navigating through the screens, BACK can

move out of most screens and with

repeated pushes, can take you all the way

to the startup screen.

F1-F4 softkeys. Performs the specified

function of the label above each softkey on

the display. These labels change

throughout the UI.

Arrow buttons. Push to move the display

cursor left, right, up, or down. Cursor

highlights in yellow over the selection.

SELECT button. Push to make a selection

on the UI. This button cannot confirm

number or character choices (push

ENTER).

Display brightness button. Push to change the

display brightness from dim to bright and back again.

Numeric keypad. Used when a numeric entry is

necessary.

ENTER button. Push to make a selection on the UI.

Only ENTER confirms numbers and characters.

Confirm all editable items with ENTER.

CLEAR (ZERO) button. Push to clear highlighted

entry. When PI/PV/IP/SWT starts, push to zero the

pressure reading.

mA button. Push to select the mA measure function.

6

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Automatic Pressure Calibrator

Buttons

Table 2. Buttons (cont.)

Number Description Number Description

SOURCE PRESSURE button. Use this function

to output (source) a target pressure from the

Product. Use the arrows to select the Setpoint

field and enter the values with the number

buttons.

VDC button. Push to select the measure dc

voltage function.

SETUP button. Push to enter the Setup menu

to change operating parameters. See Setup

Menu.

TASKS button. Push to enter the Tasks menu.

See TASKS Menu.

VENT button. Push to release pressure at the

internal pressure port. VENTING shows on the

display as the Product vents. VENTED shows

after venting is complete.

MEASURE PRESSURE button. Use this function

for pressure measurement mode.

HART button. Push to enter HART

communication mode.

HOLD button. Push to freeze the reading on the

display. Push it a second time to release the hold

on the display. Push and hold to capture the

screen and save into memory.

7

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 14

729/729FC

Users Manual

The Display

Figure 3 and Table 3 explain the display.

2 3 4 5 6

1

8

13

12

11

10

Figure 3. The Display

7

8

9

idj014.emf

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Automatic Pressure Calibrator

The Display

Table 3. The Display

Number Description Number Description

Step size indicator Pressure units indicator

External display shows selected device that is

connected. The device can be a pressure module,

Setpoint indicator

temperature probe, process variable (PV) of

connected HART device, or Fluke Connect

secondary device reading.

Fluke Connect on indicator (729 FC only) Softkey indicator

HART on indicator Current, voltage, or pressure switch display

24 volt loop power active indicator Main display with measured or sourced value

Battery charge level Time and date display

Pressure port status

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

729/729FC

Users Manual

The display can also show different configurations:

Typically, the display does not show the third functions, see

Figure 4. See Triple-Function Display.

• The upper display for the internal pressure has these

different functions:

o VENT

o SOURCE

o MEASURE

• The lower display shows these different functions:

o Measure Current

o Source Current

o Simulate Current

o Measure VDC

o Switch

idj017.bmp

Figure 4. Typical Dual-Function Display

10

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

Automatic Pressure Calibrator

The Display

The screen has two sections:

The upper display shows the internal pressure controller

status and includes:

• Mode: Measure, Source, and Vent

• Pressure Value: Current measured pressure and unit

• Status: Shows nothing in measure mode, NOT READY,

STABLE in source mode, and VENTING, VENTED in

vent mode.

• Setpoint: Current setpoint for source function.

• Step Size: The step size when B (Step Up) and

C (Step Down) are pushed when sourcing

pressure.

The lower display shows the electrical status and includes:

• Mode: Measure Current, Source Current, Simulate

Current, Measure V dc, and Switch.

• Reading: Current reading from measure functions or

setpoint for source functions.

• Switch State: Shows the pressure reading when the

switch contacts open and close.

• Percent: Shows the percentage value of 4 mA to 20 mA

or 1 V to 5 V in measure functions.

• Status: Shows Open circuit detected in mA source

mode.

11

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

729/729FC

Users Manual

Triple-Function Display

When the third function (RTD, External Pressure

Module, HART Transmitter, or FC secondary device) is

connected, the Product changes to triple-function display

automatically. In the subsequent triple-function display,

the original bottom half of the display is divided into two

parts:

• The left display continues to show the electrical

measurement display.

• The right display shows the model name, reading,

and units from the selected third function. See

Figure 5. The figure shows a transmitter device

(3051C).

When more than one third function is available, use the

arrow keys to highlight the device (in yellow) in the right

display. Then use the softkeys to select the device to

show.

idj022.bmp

Figure 5. Triple-Function Display

12

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

Automatic Pressure Calibrator

The Display

RTD Connection

The display can show RTD temperature measurements in

the selected unit (C/F) as the third-function. When the

temperature unit field highlights, push the softkey to toggle

the temperature setting. The ohms reading shows.

Note

The Product supports PT100-385 RTD only.

Pressure Module Connection

The Product automatically detects external pressure module

installation or removal. Move the cursor to the unit type and

push E to configure the pressure-unit type (it can be

different from the pressure unit of internal pressure). Change

the unit type of the internal pressure to automatically change

the unit type of the pressure module.

Figure 6 shows a pressure module as the third function.

• When you plug in an external pressure module, the

pressure-unit type defaults to the internal pressure unit

type.

• When you remove or install an external pressure

module, the zero offset resets.

Figure 6. Triple-Function Display with External Pressure

Module Connected

idj020.bmp

13

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

729/729FC

Users Manual

Fluke Connect Device Connection

The display shows connected FC device measurements as

the third-function.

See Setup Menu for information to manage secondary FC

devices.

14

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Automatic Pressure Calibrator

Ports

Ports

Figure 7 and Table 4 show the Product ports.

Left Right

1

7

2

6

Bottom

3

4

5

8

Figure 7. Product Ports

9

idj013.emf

15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

729/729FC

Users Manual

Table 4. Product Ports

Number Description

Battery charger/universal power supply port. Use the battery charger for bench-top applications that have ac

line power available. Use the battery charger to charge the battery while installed in the Product.

USB port – Used for communication between the Product and a PC.

Push to drain condensation (see Maintenance Menu).

Drain port fitting connector.

External temperature port for RTD Temperature Probe

External pressure module port

Pressure connection

COM Port

Measure, source, and simulate mA; measure V dc and supply loop power.

16

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 23

Automatic Pressure Calibrator

Download the Fluke Connect App

Download the Fluke Connect App

To download the Fluke Connect App, see Figure 8.

iOS

Android

idj025.emf

Figure 8. Download the Fluke Connect App

17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

729/729FC

Users Manual

Enable the Fluke Connect App

To enable the Fluke Connect App on your phone, see Figure 9.

21

™

Connect

3

4

idj027.emf

Figure 9. Enable the Fluke Connect App

18

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Automatic Pressure Calibrator

Setup Menu

Setup Menu

Use the multi-page Setup menu to configure the Product

features.

Note

For some of the submenu functions, the Product

password is required. The default password is

1234.

To access the Setup menu, push S.

The Setup menu includes submenus for Product

configuration. The submenus are:

1. 729 Information

2. 729 Setup

3. Manage Users

4. Manage Test Results

5. Manage Screen Shots

6. Manage Custom Tasks

7. Maintenance

Push the arrow buttons, R, or E to access these

submenus. Alternatively, push the corresponding number

button for access. Push F to go to the previous menu.

To clear all stored files, push D (Clear All Files).

Enter the Product password to use this function. This

action clears all stored test results, screen shots, and

custom tasks.

The subsequent sections explain the Setup menu and

submenus.

Manage FC Devices (729 FC Only)

1. Enter the Setup menu.

2. Push B (Manage FC Device) to set 729 FC as

the primary device and discover other units that have

Fluke Connect. The connected product shows on the

display.

Push C (Enable Fluke Connect) to set 729 FC as

the secondary device so it can be discovered by the

Fluke Connect App on smart phone.

Locator

When the Product shows several FC devices on the

Fluke Connect screen, highlight a product and push

B (Locator). This causes the Fluke Connect button

on the listed product to flash repeatedly. The FC device

exits locator mode automatically or when B

(Locator) is pushed again.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 26

729/729FC

Users Manual

729 Information

The 729 Information submenu is an information-only

screen that shows information about the Product. The

screen shows:

• The Product model (729 or 729 FC)

• Serial Number

• Firmware Revision

• The last calibration date of the Product pressure

components.

• The last calibration date of the Product electrical

components.

There are also softkeys at the bottom of this screen.

These are:

• A - Calibrate Pressure – Follow the prompts

on the screen and the Product takes you through a

procedure that calibrates the pressure components

of the Product. Enter the Product password to use

this function. D (Options) lets you save the

calibration, go back a step, skip a step, or move to

the next section. See Calibration Manual for details.

• B - Calibrate Electrical – Follow the prompts

on the screen and the Product takes you through a

procedure that calibrates the electrical components

of the Product. Enter the Product password to use

this function. D (Options) lets you save the

calibration, go back a step, skip a step, or move to

the next section. See Calibration Manual for details.

• C - Battery Information – An information-only

screen that shows if the battery is present, the

remaining battery charge level, battery temperature,

and battery voltage.

• D - Change Password – Use to change the

password for advanced functions.

20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

Automatic Pressure Calibrator

Setup Menu

729 Setup

The 729 Setup submenu shows the information in

Table 5.

Table 5. 729 Setup Menu

Menu Parameter Function

Push E and use the arrows to

select the UI language: English,

Language

Date and Time

Simplified Chinese, Traditional

Chinese, French, German, Italian,

Portuguese, Spanish, Russian,

Japanese, or Korean.

Push E and use the arrows to

access the Date and Time menu.

Once inside the menu, use the

arrows to select a parameter and

use the number keys to make

changes to these settings. For am or

pm, push R. Once you make

changes, push D (Done) to

store the new parameters. The

timestamp saves with any stored

results.

Table 5. 729 Setup Menu (cont.)

Menu Parameter Function

Set the format of the date. Use

Date Format

Time Format

Number Format

Temperature Unit

the softkeys to select

yyyy-mm-dd, mm/dd/yyyy, or

dd/mm/yyyy.

Push the necessary softkey to

select 12-hour or 24-hour time

format. The format changes in

the Date Format menu. E or

R also changes the format.

Push the necessary softkey to

select a decimal point or comma

for the numbering format. E or

R also changes the format.

Push the necessary softkey to

[1]

select between °C or °F. E or

R also changes the units.

21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 28

729/729FC

Users Manual

Table 5. 729 Setup Menu (cont.)

Menu Parameter Function

The Product has a programmable

Auto Battery Timeout feature to

save the battery charge. Push the

arrow keys to highlight this line.

Push E or R to reach the

Auto Battery

Timeout

PCM Resolution

HART

Communication

Fluke Connect Enable/Disable

timeout menu. The choices are:

• Never

• 5 minutes

• 10 minutes

• 15 minutes

• 30 minutes

• 60 minutes

Choices are High and Low. High

resolution is the normal state, and

Low reduces the resolution one

digit.

Enable/Disable

Manage Users

The Manage Users submenu controls access to add or

delete Product user names from this menu:

• Add a new user: push A (New):

Use the onscreen keyboard to add a new user. Push

the softkeys for Capslock ON (or OFF), Backspace,

and to complete the entry (Done).

1. Push the arrows to highlight each letter.

2. Push R or E to choose the letter.

3. When finished, push D (Done) to return to

the Manage Users screen.

• Delete an existing user: push the arrows to

highlight a user and the push D (Delete).

[1] Disabled in Japanese models.

22

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 29

Automatic Pressure Calibrator

Setup Menu

Manage Test Results

The Product saves test results as found and as left and

saves calibration results.

1. In the Setup menu, push the arrow buttons to

highlight Manage Test Results.

2. Push E to show a list of tests. The tests are

designated by date and time, Tag ID, and serial

number.

3. Push the arrow buttons and E or R to view the

selected test results.

4. Push A to select the As Found or As Left test

result.

5. Push D to redo the calibration and save a new

test result.

To delete all test results:

1. Go to the Manage Test Results screen.

2. Push D (Delete All).

3. Confirm to delete all records.

4. Push C (OK) to delete all records or D

(Cancel) to escape the deletion process.

Manage Screen Shots

The Product can take screen shots of any screen and

store them.

To take a screen shot:

1. Bring up the screen to save.

2. Push and hold H. The Product shows File Saved.

To view the screen shots:

1. From the Setup menu, push the arrows to highlight

Manage Screen Shots.

2. Push E or R. The Product shows a list of

screenshots and their time and date stamps.

3. Use the arrows to highlight a screen shot.

4. Push E or R and the screen shot is shown. The

screen shows: You are reviewing a screen copy!

over the saved screen.

5. Push D to delete the individual screen.

23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

729/729FC

Users Manual

Manage Custom Tasks

Use this submenu to delete custom tasks (see Tasks

Menu). To delete a single task, use the arrow to select a

custom task and push A (Delete). To delete all of

the tasks, push D (Delete All).

Maintenance Menu

Maintenance has these sections:

• Drain Water (condensation)

• Keypad Test

• Pressure Sensor Characterize (see Calibration

Manual)

• Supply Sensor Self Calibration (see Calibration

Manual)

• Exhaust

Drain Water (Condensation)

To drain condensation from the Product, see Figure 10:

1. Connect the hose to collect drained water.

2. Push D (Continue).

3. The display shows Creating pressure, please

standby. The pump works to establish a pressure.

4. To let the water out, use a small-tipped tool, such as

a small Philips screwdriver, to push the DRAIN

button on the side of the Product.

5. Push D to repeat the drain operation.

6. When finished with water drain, push in on the fitting

to release the hose.

24

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Automatic Pressure Calibrator

Setup Menu

idj030.emf

Figure 10. Drain Water from Product

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

729/729FC

Users Manual

Keypad Test

Use this screen to check the Product buttons. Push any

button and verify the onscreen response.

For the power button, push and hold for 2 seconds.

Exhaust

The Exhaust function releases all pressure inside the

Product including the pressure reservoir. This reservoir

keeps the pressure stable and provides pressure if only

small pressure steps are necessary. Push A for

Exhaust.

Tasks Menu

Tasks let you set up calibration and measurement tasks

to save and recall for later use.

To go to the Tasks menu, push T. The Tasks menu

has these submenus:

• Pressure Transmitter (P/I)

• Pressure Switch (SW)

• Current to Pressure Test (I/P)

• Pressure Leak Test

• Pressure Transmitter (P/V)

• Pneumatic Pressure Transmitter (P/P)

Note

P/P tasks require a pressure module connected

to the Product.

26

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 33

Automatic Pressure Calibrator

Tasks Menu

Pressure Transmitter (P/I)

Use this function to calibrate a P/I transmitter (pressure to

current) with current measurement. See Figure 11 for

connections:

1. From page 1 of the Tasks menu, push the arrows to

highlight Pressure Transmitter (P/I).

2. Push E or R.

3. From this screen, use the arrows, numeric keypad,

and E to change the values of the Source

Pressure and Measure Current.

4. Push B (PV Calibrate) if HART is enabled and

PV calibration is necessary.

5. Push C to turn on (or off) 24 V loop power.

6. Once these values are specified, push D

(Continue).

7. From this second screen, use the arrows, numeric

keypad, and E to change the values of the

Tolerance of Range, Test Strategy, Auto Settling

Time, and Transfer Function.

8. Push A to change the Transfer Function to

Square Root or Linear.

9. To select the Test Strategy, highlight the parameter

and push R. Highlight the applicable listed test

strategy and push E.

10. Push B (Save as Customized) to store this

task for later use.

11. Once you enter the parameters, push D

(Continue).

12. Push B (Manual Test) or D (Auto Test).

13. Push C to adjust. Go to 0%, 50%, and 100%.

14. Push A (As Left) to do the As Left test.

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 34

729/729FC

Users Manual

idj005f.emf

Figure 11. Pressure Transmitter (P/I) Task Connections

28

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 35

Automatic Pressure Calibrator

Tasks Menu

Pressure Switch (SW)

Use this feature to calibrate a pressure switch. See

Figure 12 for connections:

1. From page 1 of the Tasks menu, push the arrows to

highlight Pressure Switch (SW).

2. Push E or R.

3. From this screen, use the arrows, numeric keypad,

and E to change the values of these parameters:

• Setpoint

• Tolerance

• Min Deadband

• Max Deadband

• Max Pressure

• Switch Type

Note

Make sure to push E after EACH value

change.

You can save these settings as a customized task.

Push B (Save as Customized). Recall this

customized task from the Tasks menu.

4. Once you enter the parameters, push D

(Continue).

5. Push D (Auto Test) or B (Manual Test)

to do the As Found switch test. The test runs.

After the test runs, the results show on the display.

To save the test results:

1. Push D (Done).

2. Push E to edit the Tag information.

3. Push D (Done).

4. Move the cursor to the S/N field (Serial Number).

5. Push E to edit the S/N information.

6. Push D (Done).

7. Move the cursor to the User ID field.

8. Push A (User List) to select a user.

9. Push D (Done).

10. Adjust the switch and push B(Step Up)

and C(Step Down) to verify.

11. Push A (As Left) to do the As Left test.

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 36

729/729FC

Users Manual

30

Use low volume tubing

when possible

Figure 12. Switch Test Connections

Pressure

Switch

idj008.emf

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 37

Automatic Pressure Calibrator

Tasks Menu

Current to Pressure Test (I/P)

Use this feature to calibrate a current to pressure (I/P)

converter with current source and pressure

measurements. See Figures 13 and 14:

1. From page 1 of the Tasks menu, push the arrows to

highlight Current to Pressure Test (I/P).

2. Push E or R.

3. From this screen, use the arrows, numeric keypad,

and E to change the values of the source current

and measure pressure.

Note

Make sure to push E after EACH value

change.

4. Once you enter the values, push D (Continue).

Tolerance of Range, Test Strategy, and Auto Settling

Time can be set from here.

To save these settings as a customized task, push

B (Save as Customized). You can then recall

the saved task from the Tasks menu.

5. Once you enter the parameters, push D

(Continue).

6. Push B (Manual Test) or D (Auto Test).

7. Adjust with C to go to 0%, 50%, and 100%.

8. Push A (As Left) to do the As Left test.

31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

729/729FC

Users Manual

I/P Transducer

Out

Pressure

In

Module

idj009.emf

Figure 13. Current to Pressure Test (I/P) with External Pressure Module

32

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

Automatic Pressure Calibrator

Tasks Menu

I/P Transducer

In

Out

idj009a.emf

Figure 14. Current to Pressure Test (I/P) with Internal Connections

33

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 40

729/729FC

Users Manual

Pressure Leak Test

Use this feature to test a pressure device for leaks. For

connections, see Figure 15:

1. From this screen, use the arrows, numeric keypad, and

E to change the values of these parameters:

• Setpoint (Pressure value)

• Settling Time

• Test Time

Note

Make sure to push E after EACH value change.

2. Push D (Continue). When the pressure leak test

completes, the Product shows the results. Results

include Start Pressure, End pressure, Test time, and

Leak rate.

34

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

Automatic Pressure Calibrator

Tasks Menu

Pressure Transmitter (P/V)

Use this feature to calibrate a pressure to voltage

transmitter with voltage measurement. For connections, see

Figure 11.

1. From page 1 of the Tasks menu, push the arrows to

highlight Pressure Transmitter (P/V).

2. Push E or R.

3. From this screen, use the arrows, numeric keypad, and

E to change the values of the source pressure and

measure voltage.

Push D (Continue) to edit these other

parameters:

• Tolerance of Range

• Test Strategy

• Auto Settling Time

• Transfer Function A (Linear or Square

Root).

Push B (Save as Customized) to save these

settings as a customized task. Recall these customized

tasks from the Tasks menu at any time.

Pressure Transmitter (P/P)

To calibrate a pressure-to-pressure transmitter, use this

feature. This feature requires a pressure module to

measure pressure output from a connected transmitter.

To use the function, see Figure 15:

1. From page 1 of the Tasks menu, push the arrows

to highlight Pressure Transmitter (P/P).

2. Push E or R.

3. From this screen, use the arrows, numeric keypad,

and E to change the values of the source

pressure and measure pressure.

4. Push D (Continue) and these parameters

can be edited:

• Tolerance of Range

• Test Strategy

• Auto Settling Time

5. Push B (Save as Customized) to save these

settings as a customized task. Recall this

customized task from the Tasks menu at any time.

35

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

729/729FC

Users Manual

Pneumatic

Transmitter

In Out

+

Pressure

Module

idj026.emf

Figure 15. Pressure Transmitter (P/P) Connections

36

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 43

Automatic Pressure Calibrator

HART Functionality

The Product interfaces with HART devices. It can:

• View and modify transmitter setup and data that

includes:

o Write Lower Range Value (LRV)

o Write Upper Range Value (URV)

o Write PV Unit

o Write Message and Descriptor

o Write Damping Value

o Write Date

• Perform service features including:

o PV Zero Trim

o mA Output Trim

o Trim to Applied Values

o Set Fixed mA Output

o Re-range Transmitter

o Device Diagnostics

• Perform HART calibration without using a Task (Ad

hoc)

• Perform HART calibration from a downloaded Task

37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

729/729FC

Users Manual

Push G and the Product searches (polls) the bus to find

any connected HART devices. From this screen, there are

these softkeys:

A - Communicator Only

B - Loop Power +24V ON

C - Enable HART 250Ω

D - Restart BUS Polling

Once Polling finds the transmitter(s), move the cursor to the

desired tag number and select D (Continue) to select.

Loop Power +24V ON

The Product supplies loop power at 24 V dc to a current

transmitter disconnected from the system. To supply 24 V

loop power:

1. From the HART menu, push B (Loop Power

+24V ON). The Product polls the bus to see if a

transmitter is connected.

2. With the transmitter disconnected from normal loop

power, connect the Product test leads in series with the

instrument current loop as shown in Figure 16.

3. The mA display shows measure loop current.

38

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 45

Automatic Pressure Calibrator

HART Functionality

TEST DC PWR

+–+–

–+

idj029.emf

Figure 16. Connection with Loop Power Enabled

39

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 46

729/729FC

Users Manual

Enable HART 250Ω

The Product has a selectable 250 Ω HART resistor to

facilitate use with HART devices. Enable the HART resistor

when you connect the Product to a HART device. The

HART resistor defaults to OFF.

To turn on or off the HART resistor, push C (Enable

HART 250Ω) or (Disable HART 250Ω).

HART Menu

The HART menu has these functions that configure and

calibrate a HART device:

• HART Data

• HART Service

• Calibrate (Ad Hoc)

• Find Task by Tag

• Bus Polling

From the HART menu, push A (Disconnect) to

disconnect from HART communication, or push D

(Continue) to continue to the highlighted entry.

HART Data

The HART data screen shows information about the

connected HART device. Push B (Page Up) or C

(Page Down) where necessary.

You can modify certain fields that include:

• Tag ID

• PV Unit Type

• Lower Range Value (LRV)

• Upper Range Value (URV)

• Damping

• Message

• Descriptor

• Date

40

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

Automatic Pressure Calibrator

HART Menu

HART Service

HART Service includes these submenus:

• PV Zero Trim

• mA Output Trim

• Trim to Applied Values

• Set Fixed mA Output

• Re-range Transmitter

• Device Diagnostics

Highlight the HART Service menu selection and push

D (Continue). When you enter some of the

submenus, a warning tells you to remove the loop from

AUTOMATIC control. Push D (Continue).

PV Zero Trim

This function sets the digital pressure value of the

transmitter to zero.

1. Push C (Trim Zero) to trim the PV output value to

zero.

2. Push D (Done) when completed.

mA Output Trim

In the mA output trim screen, you can adjust the transmitter

output.

1. Start with the 4 mA range. Push A (Fetch) to get

the current measured mA value.

2. Push B (Trim 4 mA) to send the measured value

for correction. Push C (Next Point). The Product

moves to the 20 mA range.

3. Repeat steps 1 and 2.

4. When complete, push C to return to the previous

point or D (Done).

Trim to Applied Values

1. Enter the LRV pressure value necessary in the Setpoint

entry and then push E and let the pressure settle.

2. Push B (Trim LRV) to trim the lower range of

pressure applied.

3. Enter the necessary URV pressure value in the

Setpoint entry and push E and let the pressure

settle.

4. Push C (Trim URV) to trim the upper range of

pressure applied.

41

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 48

729/729FC

Users Manual

Set Fixed mA Output

Enter the necessary mA value to output from the connected

transmitter.

• Push B (Step Up 4mA) to increase mA output in

4 mA steps.

• Push C (Step Down 4mA) to decrease mA output

in 4 mA steps.

Re-range Transmitter

Change the Upper Range Value (URV) and the Lower

Range Value (LRV) of the connected transmitter from this

screen.

1. Enter the Upper Range Value (PV URV) necessary.

2. Push E to select.

3. Push C (Send) to change the URV.

4. Enter the Lower Range Value (PV LRV) necessary.

5. Push E to select.

6. Push C (Send) to change the LRV.

Device Diagnostics

Select Device Diagnostics to send the self-diagnostics

command to the connected transmitter and view the

transmitter Self Test result.

Calibrate (Ad hoc)

Calibrate (Ad Hoc) calibrates a connected HART device

without a downloaded task.

The opening screen shows the task type and

source/measure configuration for the device. The

transmitter HART configuration is copied into this

configuration screen. Correct as needed for your test.

1. Push B (PV Calibrate) to change the measure

from mA to the PV source value of the transmitter.

2. Push C (Disable/Enable Loop Power).

3. Push D (Continue) to continue to second

configuration screen. These choices are shown:

• Tolerance of Range

• Test Strategy

• Auto Settling Time

• Transfer Function

42

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 49

Automatic Pressure Calibrator

HART Menu

These softkeys are active:

A – Linear/Square Root Selection

B – Save as Customized

C – Leak Test

D – Continue

The next screen starts the As Found Calibration. These

softkeys are active:

A – Abort

B – Manual Test

D – Auto Test

Test results show after all strategy points have recorded the

measurements. Measurements in specification show as

black. Measurements out of specification show as red.

1. Push D (Done) or A (Abort).

2. Enter the Tag ID, serial number of the device, and the

User ID.

3. Push D (Done)

Adjust

Push B (HART Adjust). These choices are shown:

• PV Zero Trim

• mA Output Trim

• Trim to Applied Values

PV Zero Trim

To set the digital pressure value of the Product to zero:

1. Push C (Trim Zero).

2. Push D (Done).

mA Output Trim

From the mA output trim screen, you can fetch the current

PV value and send this value to the transmitter to adjust the

PV to the correct mA output.

1. Starting with the 4 mA range, push A (Fetch) to

get the current measured mA value.

2. Push B (Trim 4mA) to send the measured value

for correction.

3. Push C (Next Point). The Product moves to the

20 mA range.

4. Repeat steps 1, 2, and 3.

5. When complete, push Cto return to the previous

point or D (Done).

43

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 50

729/729FC

Users Manual

Trim to Applied Values

1. Enter the LRV pressure value necessary in the Setpoint

entry and let the pressure settle.

2. Push B (Trim LRV) to trim to the lower range of

pressure applied.

3. Enter the URV pressure value necessary in the

Setpoint entry and let the pressure settle.

4. Push C (Trim URV) to trim to the upper range of

pressure applied.

As Left

Push D (As Left). Repeat the procedure from As

Found.

Calibration results save to the Test Results menu.

Find Task by Tag

Downloaded tasks from DPCTrack2 or other supported

software are shown. Use the up and down arrows to scroll

through the tasks. Push B (Page Up) or C

(Page Down) where necessary. Push D (Recall) to

recall the highlighted task.

Bus Polling

Bus Polling goes back into the bus polling screen and scans

for connected HART devices.

If no HART device is found after Polling has completed,

push D (Restart Bus Polling) to restart bus polling to

search of the Product BUS for HART devices. The Product

locates the device.

Measure Mode

The measure mode has these functions:

• mA dc measure

• mA dc source

• mA dc simulate

• V dc measure

• Switch (continuity)

The lower left of the display shows the operation mode.

44

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

Automatic Pressure Calibrator

Measure Mode

Current Measurement

The Product measures 0 mA to 24 mA.

Move the cursor to highlight Measure Current. Push

C to Source Current. Push D to Simulate

Current.

+–

Figure 17. VDC Measurement Connections

Volts Measurement

The Product measures 0 V dc to 30 V dc. Figure 17 shows

measurement connections for voltage measurements.

idj004f.emf

45

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 52

729/729FC

Users Manual

Pressure Measurement

The Product supports the 700P and 750P series pressure

modules. See Accessories. Before you use a pressure

module, read its instruction sheet. The modules are different

in how they are used, zeroed, what types of process

pressure media are allowed, and accuracy specifications.

Figure 18 shows gage and differential modules. Differential

modules also operate in gage mode when you leave the low

fitting open to atmosphere.

To measure pressure, attach the applicable pressure

module for the process pressure you will test as described

in the module’s instruction sheet.

To measure pressure:

W Warning

To prevent personal injury, shut off the valve

and slowly bleed off the pressure before

attaching the pressure module to the pressure

line to avoid a violent release of pressure in a

pressurized system.

Low

Differential

High

Gage

hhb001.emf

Figure 18. Gage and Differential Pressure Modules

46

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 53

Automatic Pressure Calibrator

Measure Mode

WCaution

To prevent possible damage to the Product or

to equipment under test:

• Never apply more than 10 lb-ft. of torque

between the pressure module fittings, or

between the fittings and the body of the

module.

• Always apply correct torque between the

pressure module fitting and connecting

fittings or adapters.

• Never apply pressure above the rated

maximum printed on the pressure module.

• Use the pressure module only with

specified materials. See the printing on the

pressure module or the pressure module

instruction sheet for the acceptable

material compatibility.

Connect a pressure module to the Product as shown in

Figure 19. The pressure module shows on the display after

several seconds once installed.

The Product automatically senses the pressure module

attached and sets its range accordingly.

Note

Before doing a task that sources or measures

pressure, zero the Product.

1. With the pressure module highlighted in the third

screen, push D (Zero External) to zero the

pressure. When zeroing absolute pressure modules,

enter the current barometric pressure when the

displayed value turns to yellow highlight

2. Zero the pressure. See the module’s Instruction Sheet.

Modules can have different zeroing procedures that

depend on module type.

47

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 54

729/729FC

Users Manual

Isolation

Valve

Gage

Module

Differential

Module

HL

Tank

Idj010.emf

Figure 19. Pressure Module Connections

48

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 55

Automatic Pressure Calibrator

Measure Mode

Autostep and Auto Ramp the Output Value

Autostep and Auto Ramp can automatically adjust the value

of source functions for pressure or current.

Autostep

To configure the Product to make a sequence of steps that

run automatically:

1. Connect the Product to the test circuit.

2. From the main screen, push A (Autostep).

3. Set the Product for the necessary source function:

• B (Pressure)

• C (Current)

4. From this screen, use the arrows, numeric keypad, and

E to change the values of Start and End Values, and

Number of Steps and time per step.

5. Select the Repeat Mode:

• B (One Time)

• C (Repetitive)

6. Select the Step Style:

• B (Sawtooth)

• C (Triangle)

7. Push D (Start).

8. The Product automatically starts the step function. The

softkey label changes to Stop Step.

9. To Push the Stop Step softkey to stop the automatic

step function.

10. Push the Done softkey to continue normal operation.

49

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 56

729/729FC

Users Manual

Auto Ramp the Output

When ramped, the source sweeps up or down in value. Use

the Auto Ramp feature to verify a switch or alarm, or when a

smooth increase or decrease of the output function is

necessary. Set the Product to ramp up Pressure or Current.

1. From the main screen, push D (Auto Ramp).

2. Set the Product for the necessary source function:

• B (Pressure)

• C (Current)

3. Use the arrows, numeric keypad, and E to change

the Start Values, End Values, and Slew Rate (Ramp

Time).

4. Select the Repeat Mode:

• B (One Time)

• C (Repetitive)

5. Select the Step Style:

• B (Sawtooth)

• C (Triangle)

6. Push D (Start).

While the signal ramps, the output adjusts to the value. The

selection of endpoints and ramp time determines the size of

steps. For example, if you set the Product to ramp from

1 mV to 1 V over 10 seconds, the output adjusts in

approximately 25 mV steps. The Ramp function continues

until you get the selected limit.

50

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 57

Automatic Pressure Calibrator

Measure Mode

Temperature Measurement

To measure temperature with an RTD probe accessory,

connect the probe into the RTD port on the right of the

Product. Make sure the correct probe type is used. Use

Fluke-720RTD, PN 4366669 or the Fluke-720URTDA,

PN 4382695.

The standard probe has a 10-inch insertion depth with a

¼-inch diameter stainless steel sheath. See Figure 20.

Note

The factory default type is PT100-385 so if the

Product is used with the Fluke 720 RTD Probe

(PN 4366669), it is not necessary to set the probe

type. Connect the probe to the Product and

configure the display to read temperature.

The display shows “OL” when the measured

temperature is outside the nominal measurement

range of the RTD function (below -40 °C or above

150 °C).

Figure 20. Temperature Probe Connection

RTD Probe

idj015.emf

51

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 58

729/729FC

Users Manual

Source mA Mode

The operation mode (for example, measure or source)

shows on the display. If the Product is not in mA source

mode, push M.

To source mA:

1. Connect the test leads as necessary.

2. Key in the necessary output value (for example, to

source 5.5 mA, push 5.5E).

3. Push E.

4. To change the output value, record a new value and

then push E.

4. To set the output value in the present source function,

push P then enter the desired value and push E.

5. To turn off sourcing completely, select another function.

Note

Use the source current function to drive a current

input device. This is different from the loop power

function in which the Product is powering a

process instrument.

4 to 20 mA Simulation

To configure the Product as a load on a current loop:

1. Move the cursor to the analog function indicator and

push D (Simulate Current).

2. Enter the necessary value.

3. Connect an external loop supply to the mA port as

shown in Figure 21.

52

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 59

Automatic Pressure Calibrator

Measure Mode

+

Loop

Power

Supply

+24

UUT

–

idj011.emf

Figure 21. Connections to Simulate a 4 to 20 mA Transmitter

53

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 60

729/729FC

Users Manual

Log

Users can record a series of pressure or mA

measurements for later upload to a host computer. The

Product records a maximum of 8000 readings, depending

on the reading rate, duration, and how much memory is in

use for other functions such as tasks or stored results.

Record the reading rate and duration in minutes.

To log data:

1. From the main screen, push B (Log). Adjust

the Reading Rate and Duration with the arrow

buttons and then push E to select parameters

from the Log screen.

2. Choose the Log Source from any of the available

measured values with A, B, or C.

The log source can be internal pressure, external

pressure, mA, V dc, HART PV, or temperature.

3. For Reading Rate: push E to adjust the reading

rate from 1 /m to 60 /m.

4. For Duration: use the numeric keypad to record the

duration in minutes, followed by E. The maximum

depends on the reading rate and how much memory

is available to log data.

5. Push D (Start) to begin. The Product logs the

measured values of the selected source for the preselected duration. Push A (Abort) to stop

logging.

Results show after the Product logs the data. Push

A (Abort) or D (Done). If you push D

(Done), enter Tag, S/N, and a User ID. The Product

saves the results and are recalled under the

Setup>Manage Test Results menu. Upload the logged

Product data to DPCTrack2 for review in a graphical

report.

Communication with a PC

Download procedures from a PC to the Product and

upload test results to a PC from the Product. A PC,

Microsoft Windows, USB cable (supplied), and Fluke

DPCTrack2 application software, or a qualified Fluke

partner’s software are required. See the DPCTrack2

Users Manual for further instructions. See Figure 22 for

54

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 61

Automatic Pressure Calibrator

Communication with a PC

USB Port

idj006f.emf

Figure 22. Connection to a PC

55

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 62

729/729FC

Users Manual

The Battery

The Product features a rechargeable battery. Charge the

battery while it is inside or outside of the Product. This

allows you to have more than one fully charged battery on

hand.

Charge the Battery

Before the Product is used, charge the battery. To charge

the battery while in the Product, connect the battery

charger to the Product.

The battery fully charges in 8 hours.

To charge the battery outside of the Product, see

Figure 24 for battery access:

1. Place the Product face down.

2. Lift the Product stand to expose all screws.

3. Remove the six screws with a Phillips screwdriver.

4. Pull off the back.

5. Remove the battery.

6. Connect the battery charge to the input on the

battery.

The battery charge indicator (top-right of display) shows

while the battery is outside of the Product. Solid green

bars show the level of charge on the battery. When all

bars are illuminated and solid, the battery is fully charged.

The bars progressively illuminate to show that the battery

is currently charging.

Battery Life

The battery charge indicator shows on the upper right of

the display.

Table 6 shows the typical operation time for a new, fully

charged battery. Product performance meets its

specification until the battery charge indicator reads

empty.

Table 6. Typical Battery Life

Operation Modes Battery Life

Measure, continuous 20 Hours

Measure and source,

with loop power on,

continuous

Typical intermittent

operation

10 Hours

>16 Hours

56

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 63

Automatic Pressure Calibrator

Maintenance

Maintenance

XW Warning

To prevent possible electrical shock, fire, or

personal injury:

• Have an approved technician repair the

Product.

• Do not operate the Product with covers

removed or the case open. Hazardous

voltage exposure is possible.

• Remove the input signals before you

clean the Product.

• Use only specified replacement parts.

• Run “Exhaust” before you open the battery

door.

Clean the Product

Clean the Product and pressure modules with a soft cloth

dampened with water or water and mild detergent.

WCaution

To prevent possible damage to the Product,

do not use solvents or abrasive cleansers.

Clean the Pump Valve

1. Remove the battery door (see Battery Replacement)

and locate the pump valve caps, see Figure 23 ().

2. Use a small screwdriver to remove the two valve

retention caps located in the oval shaped opening on

the underside of the Product.

3. Gently remove the spring and O-ring assembly.

4. Set aside the valve assemblies and clean out the

valve body with a cotton swab soaked in isopropyl

alcohol (IPA).

5. Repeat this process several times with a new cotton

swab until there is no sign of residue.

6. Run the pump for a few seconds.

7. Clean the O-ring assembly and O-ring on the

retention caps with IPA and inspect the O-rings

closely for any cuts, nicks, or wear. Replace if

necessary.

57

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 64

729/729FC

Users Manual

8. Inspect the springs for wear or loss of tension. They

should be approximately 3.8 mm (0.15 in) long in the

relaxed state. If they are shorter, the O-ring will not

seat properly. Replace if necessary.

9. Clean and inspect all parts and then reinstall the

O-ring and spring assemblies into the valve body.

10. Reinstall the retention caps and gently tighten the

cap.

11. Seal the output of the Product and pump up the unit

to at least 50 % of its rated pressure.

12. Release the pressure and repeat several times to

ensure that the O-rings seat properly.

The Product is now ready for use.

1

idj031.emf

Figure 23. Pump Valve

58

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 65

Automatic Pressure Calibrator

Maintenance

In Case of Difficulty

XW Warning

To prevent possible electrical shock, fire, or

personal injury, do not use the Product if it

operates abnormally. Protection may be

impaired. When in doubt, have the Product

serviced.

If the Product does not turn on, check the battery charge.

Disconnect the battery charger. If the Product receives

power, the power button is illuminated. If the button is

illuminated, but the Product does not turn on, have the

Product serviced. See Contact Fluke.

59

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 66

729/729FC

Users Manual

Battery Replacement

Replace the battery when it no longer holds a charge for

the rated interval. The battery normally lasts for up to 300

charge/discharge cycles. To order a replacement battery,

see Contact Fluke and User-Replaceable Parts.

Note

Take spent batteries to a qualified recycler or

hazardous materials handler for disposal.

Contact an authorized Fluke Service Center for

recycling information.

To replace the battery, see Figure 24:

1. Push S and select Maintenance.

2. Push A(Exhaust) to release Product internal

pressure.

3. Turn the Product Off.

4. Remove test leads.

5. Make sure the Product is unplugged from its charger.

6. Turn the Product over.

7. Lift up the bail and remove the six screws with a

Phillips screwdriver.

8. Lift off the back battery cover.

9. Replace the battery.

10. Replace the back cover and screws.

idj007.emf

Figure 24. Replace the Battery

60

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 67

Automatic Pressure Calibrator

Maintenance

Update Product Firmware

To update the Product firmware version:

1. Turn on the Product.

2. Connect the USB cable (provided) to a PC (see

Figure 23).

4. Click on “Find your software”.

5.

Search for “729”.

6.

On the results page, select the Software

Downloads tab.

7. Click on the necessary software link.

8. Read the instructions on this page.

9. Download the Firmware file.

10. Click on the Firmware exe file.

Calibration Data

The date of the last calibration and verification shows on

the sticker on the calibration certificate and on the

Instrument Information screen in screen in the Setup

menu. The CAL. STATUS number on the sticker should

always match the Calibration Status number in the

calibration screen. Only qualified personnel should

calibrate the Product.

Service Center Calibration or Repair

Only qualified service personnel must do calibration,

repairs, or service not included in this manual. If the

Product fails, examine the battery pack first, and replace

it if necessary.

Make sure to operate the Product in accordance with the

instructions in this manual. If the Product is faulty, send a

description of the failure with the Product. Pressure

modules do not need to accompany the Product unless

the module is faulty also. Be sure to pack the Product

securely, in the original shipping container if it is

available. See Contact Fluke and the Warranty

Statement.

61

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 68

729/729FC

Users Manual

Error Messages

The Product display shows error messages when the

Product fails to meet certain conditions or there is a

Table 7. Error Messages

Error Message Explanation Potential Root Cause and Solution

Too many errors Too many errors, the error queue overflow.

Cannot read file Failed to read file from file system.

Cannot recall procedure Failed to recall downloaded procedure.

Cannot store results Failed to store task results.

problem with the configuration of the Product or test. See

Table 7 to troubleshoot these issue.

Clear the errors with the Product user

interface

1. File corrupted, delete the file and try

again.

2. Data flash memory failure, the main

PCA needs service.

1. The downloaded procedure contains an

illegal configuration.

2. File corrupted, download the procedure

again.

1. Not enough space, delete some files

and run the task again.

2. Delete all results and run the task again.

62

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 69

Automatic Pressure Calibrator

Maintenance

Table 7. Error Messages (cont.)

Error Message Explanation Potential Root Cause

Filesystem fatal error

Cannot save screen Failed to save screen into filesystem.

Calibration error when

(name of step)

HART command failed (command

dependent explanation)

Lost connection to PCM The link to the PCM is broken.

Lost connection to EMM The link to EMM is broken.

PCM temperature too high

Failed to load filesystem from flash

memory when startup.

Calibration failed at current step.

Error returned from HART device of

previous command.