Page 1

PROFESSIONAL REVIEW

Research lab reduces process

control pressure calibration

time by 40 %

Job role: Process Controls

Technician

Company: Scientific research lab

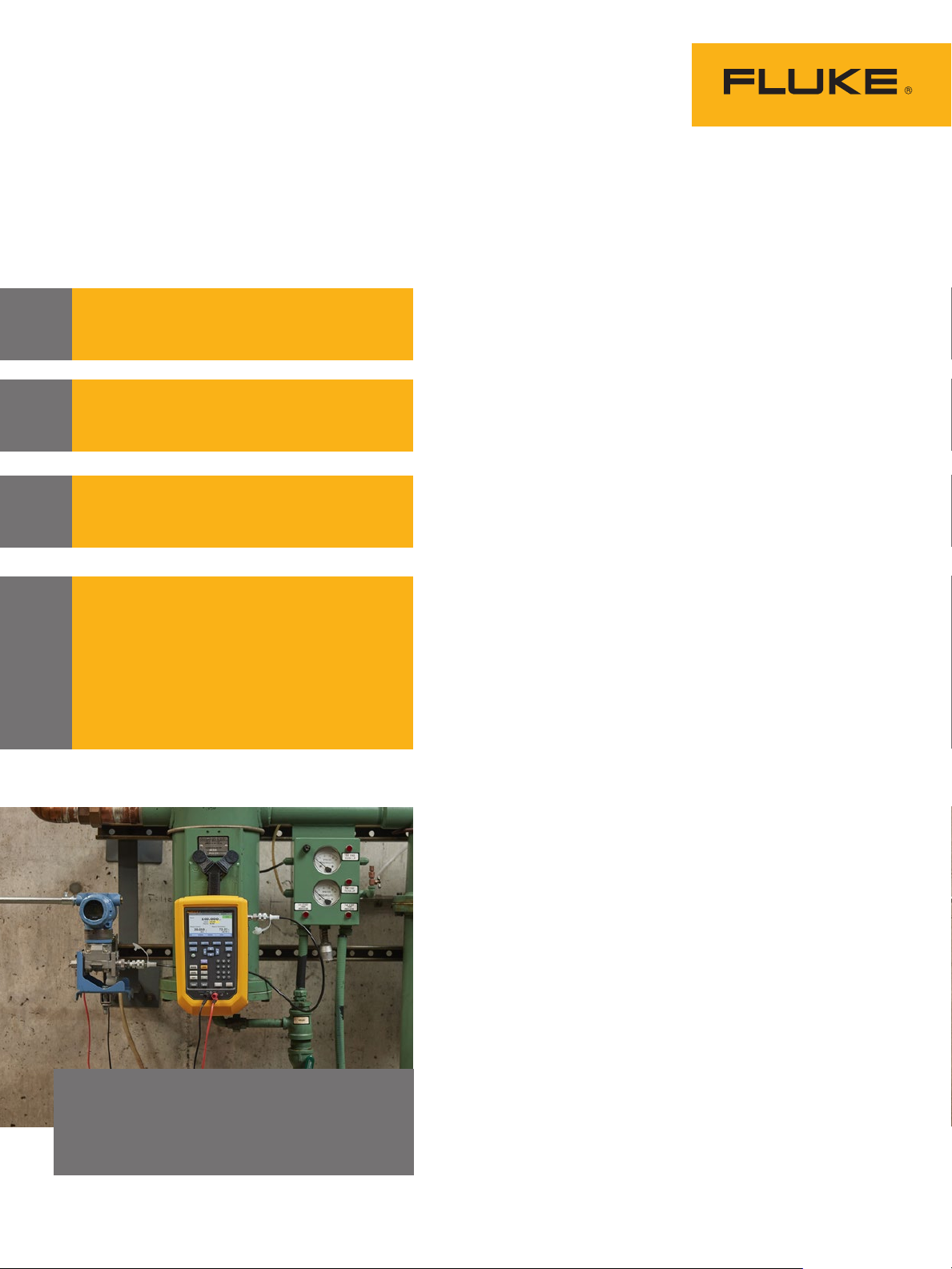

Tools: Fluke 729 Automatic

Pressure Calibrator

Key benefits:

• Reduces calibration time

by 40 %.

• Increases accuracy.

• Saves repetitive stress from not

having to use a hand pump.

The automatic pump on the 729 pressure

calibrator reduces hand pump instrument

error as well as reducing calibration time

“

by about 40 %.”

Keeping processes running

smoothly in a scientific research

lab that produces neutrons

requires stringent calibration

of hundreds of process control

instruments. The lab employs

many different types of instrumentation that control vacuum

and pressure for processes used

in cutting edge scientific and

engineering research projects.

To maintain the highest level of

research accuracy and integrity,

the devices are pressure calibrated as needed (sometimes

multiple devices per week)

to ensure they are operating

according to specifications.

“Our neutron beam facility,

which consists of the linear

accelerator, cryogenic plant,

and target facility, is operated

by various software and process

controls,” says a process control

technician for the facility.

“We calibrate a number of pressure transducers, strain gauges,

pressure switches, and signal

conditioning boards as part of

new installations, preventive

maintenance, and troubleshooting. Accuracy is vital for

successful operation.”

For many years, the lab had

calibrated those devices using

the Fluke 744 Documenting

Process Calibrator. However,

in 2017, that same process control technician attended a trade

show where he saw a demonstration of a new Fluke 729

Automatic Pressure Calibrator.

“I was very interested to see

that the 729 had an automatic

pump built into the device,”

says the technician. “It’s like

a one-stop shop to accomplish

our calibrations, versus having

to carry multiple components

like a hand pump and a vacuum

pump.”

The technician notes that, not

only does the automatic pump

save time, it is more ergonomic

because he no longer has to

pump up the pressure by hand.

This can significantly reduce

wear and tear on technicians

over several calibrations. “When

we check our pressure transducers we have to pump it up

as high as 300 psi. I just enter

the pressure required and the

729 automatically pumps up to

that level. The automatic pump

on the 729 reduces hand pump

instrument error and reduces

calibration time by about 40 %,”

the technician adds.

Additional capabilities such as

the ability to measure, source,

and simulate 4 to 20 mA signals

also increases efficiency. “The

729 allows us to take voltage readings on our pressure

transmitter signal conditioners

at the same time we measure

pressure, which saves having to

carry another meter,” the technician explains.

Each incremental unit of time

savings adds up with hundreds

of control devices that need

calibrating to support dozens

of research projects running at

a time in the facility. “We don’t

have a calibration production

quota, we just calibrate the

instruments as needed; but the

Fluke 729 definitely allows us

to do more in a day than we

would normally be able to do,”

the technician concludes.

©2017 Fluke Corporation. Specifications subject to change without notice. 11/2017 6010215a-en

Modification of this document is not permitted without written permission from Fluke Corporation.

Loading...

Loading...