Page 1

March 2015

© 2015 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies.

721Ex

Pressure Calibrator

Users Manual

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

This Fluke product will be free from defects in material and workmanship for three years from the date of purchase. This

warranty does not cover fuses, disposable batteries, or damage from accident, neglect, misuse, alteration, contamination, or

abnormal conditions of operation or handling. Resellers are not authorized to extend any other warranty on Fluke’s behalf.

To obtain service during the warranty period, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries

do not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of

liability may not apply to you.

11/99

Page 3

Table of Contents

Title Page

Introduction .................................................................................................................... 1

Contact Fluke ................................................................................................................. 1

Safety Information .......................................................................................................... 2

Ex-Hazardous Areas ................................................................................................. 4

Measuring Pressure .................................................................................................. 4

Symbols ......................................................................................................................... 5

Standard Equipment....................................................................................................... 6

Product Features ............................................................................................................ 6

Display ....................................................................................................................... 9

Language Selection ................................................................................................... 11

Home Menu Functionality .......................................................................................... 11

Backlight Use ............................................................................................................ 11

Zero Function ............................................................................................................ 11

Menus ........................................................................................................................ 12

SWITCHTEST ........................................................................................................... 12

i

Page 4

721Ex

Users Manual

%ERROR .................................................................................................................. 15

MINMAX ................................................................................................................... 18

SET UNITS ............................................................................................................... 19

CONTRAST .............................................................................................................. 20

Lock and Unlock Configurations (CFG) .................................................................... 20

AUTO OFF ................................................................................................................ 21

RESOLUTION ........................................................................................................... 22

PROBE TYPE ........................................................................................................... 22

DAMP ....................................................................................................................... 24

Measure Pressure ......................................................................................................... 25

Media Compatibility ....................................................................................................... 25

Measurements ............................................................................................................... 26

Transmitter Calibration .................................................................................................. 27

mA Input Function ..................................................................................................... 27

Pressure-to-Current Transmitter Calibration ............................................................. 27

Ranges and Resolution ............................................................................................. 29

Maintenance .................................................................................................................. 30

Replace the Batteries ................................................................................................ 30

Clean the Product ..................................................................................................... 31

User-Replaceable Parts and Accessories ..................................................................... 32

Specifications ................................................................................................................ 34

Environmental ........................................................................................................... 34

Electrical and Temperature Measurement (1 year) ................................................... 34

Physical .................................................................................................................... 35

ii

Page 5

List of Tables

Table Title Page

1. Symbols ................................................................................................................................. 5

2. Product Features ................................................................................................................... 8

3. Display Functions .................................................................................................................. 10

4. Ranges and Resolutions ....................................................................................................... 29

5. Approved Batteries ................................................................................................................ 30

6. User-Replaceable Parts and Accessories ............................................................................. 32

iii

Page 6

721Ex

Users Manual

iv

Page 7

List of Figures

Figure Title Page

1. Product Interface ................................................................................................................... 7

2. Display................................................................................................................................... 10

3. Pressure Switch Connection ................................................................................................. 13

4. Percent Error Function Connection ....................................................................................... 16

5. Temperature Measurement with RTD Probe ......................................................................... 24

6. Measure Current ................................................................................................................... 26

7. Pressure-to-Current Transmitter Connections ....................................................................... 28

8. Battery Replacement ............................................................................................................. 31

9. User-Replaceable Parts and Accessories ............................................................................. 33

v

Page 8

721Ex

Users Manual

vi

Page 9

Introduction

The 721Ex Pressure Calibrator (the Product) is a simple

to use and versatile pressure calibrator. The two internal

pressure sensors are configured with different pressure

measurement ranges. One range for lower pressure (P1)

and one range for higher pressure (P2). The Product

features inputs for mA, switch contacts, and an RTD

probe.

1

Page 10

721Ex

Users Manual

Safety Information

A Warning identifies conditions and procedures that are

dangerous to the user. A Caution identifies conditions

and procedures that can cause damage to the Product or

the equipment under test.

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Only assemble and operate high-pressure

systems if you know the correct safety

procedures. High-pressure liquids and

gases are hazardous and the energy from

them can be released without warning.

• Read all safety information before you use

the Product.

• Carefully read all instructions.

• Only operate the Product in non-hazardous

areas or classified areas where this device

is certified to operate.

• Use the correct terminals, function, and

range for measurements.

• Do not apply more than the rated voltage,

between the terminals or between each

terminal and earth ground.

• Do not touch voltages > 30 V ac rms, 42 V

ac peak, or 60 V dc.

• Remove all probes, test leads, and

accessories before the battery door is

opened.

• Do not exceed the Measurement Category

(CAT) rating of the lowest rated individual

component of a Product, probe, or

accessory.

• Do not use and disable the Product if it is

damaged.

• Remove the input signals before you clean

the Product.

• Use only specified replacement parts.

• Have an approved technician repair the

Product.

• Use the Product only as specified, or the

protection supplied by the Product can be

compromised.

• Only change batteries in an area known to

be non-hazardous.

2

Page 11

Pressure Calibrator

Safety Information

• The battery door must be closed and

locked before you operate the Product.

• Do not improperly apply pressure. Vacuum

should not be applied to any gauge

pressure sensor. The Product display

shows “OL” when an inappropriate

pressure is applied. If “OL” is shown on

any pressure display, the pressure should

be reduced or vented immediately to

prevent Product damage or possible

personnel injury. “OL” is shown when the

pressure exceeds 110 % of the nominal

range of the sensor or when a vacuum in

excess of 2 PSI is applied on gauge range

sensors.

• Push the ZERO button to zero the pressure

sensor when vented to atmospheric

pressure.

• Check entity parameters before making

any connections to this Product.

• Remove the batteries if the Product is not

used for an extended period of time, or if

stored in temperatures that exceed the

battery manufacturer’s specifications. If

the batteries are not removed, battery

leakage can damage the Product.

• Replace the batteries when the low battery

indicator shows to prevent incorrect

measurements.

• Be sure that the battery polarity is correct

to prevent battery leakage.

• Repair the Product before use if the battery

leaks.

• Use only specified replacement parts.

3

Page 12

721Ex

Users Manual

Ex-Hazardous Areas

An Ex-hazardous area as used in this manual refers to an

area made hazardous by the potential presence of

flammable or explosive vapors. These areas are also

referred to as hazardous locations.

The Product has been designed for use in Ex-Hazardous

Areas. These are areas where potentially flammable or

explosive vapors may occur. These areas are referred to

as hazardous (classified) locations in the United States,

as Hazardous Locations in Canada, as Potentially

Explosive Atmospheres in Europe and as Explosive Gas

Atmospheres by most of the rest of the world. The

Product is designed as intrinsically safe. This means that

connecting the Product to equipment that is used within

intrinsically-safe circuits will not cause an ignition-capable

arc as long as the entity parameters are suitably

matched.

Warning

To prevent possible personal injury, check

entity parameters before making any

connections to this device.

Measuring Pressure

Warning

For safe operation and maintenance of the

Product, Refer to the table of ranges and

resolutions at the back of the manual for

information about overpressure and burst

pressure ratings. Pressure sensors can be

damaged and personnel injury can occur due

to improper application of pressure. Vacuum

should not be applied to any gauge pressure

sensor. The Product display shows “OL”

when an inappropriate pressure is applied. If

“OL” is seen on any pressure display, reduce

or vent pressure immediately to prevent

equipment damage or possible personnel

injury. “OL” is shown when pressure >120 %

of the nominal range of the sensor or when a

vacuum >2 PSI is applied on gauge range

sensors.

4

Page 13

Symbols

Symbols used on the Product or in this manual are shown in Table 1.

Table 1. Symbols

Symbol Description Symbol Description

Pressure Calibrator

Symbols

Risk of Danger. Important information. See

Manual.

Hazardous voltage. Risk of electric shock.

Conforms to European Union directives.

Conforms to ATEX requirements

Conforms to relevant Australian EMC standards.

Battery

Conforms to relevant South Korean EMC Standards.

This product complies with the WEEE Directive

(2002/96/EC) marking requirements. The affixed label

indicates that you must not discard this

electrical/electronic product in domestic household

waste. Product Category: With reference to the

equipment types in the WEEE Directive Annex I, this

product is classed as category 9 "Monitoring and

Control Instrumentation" product. Do not dispose of

this product as unsorted municipal waste. Go to

Fluke’s website for recycling information.

5

Page 14

721Ex

Users Manual

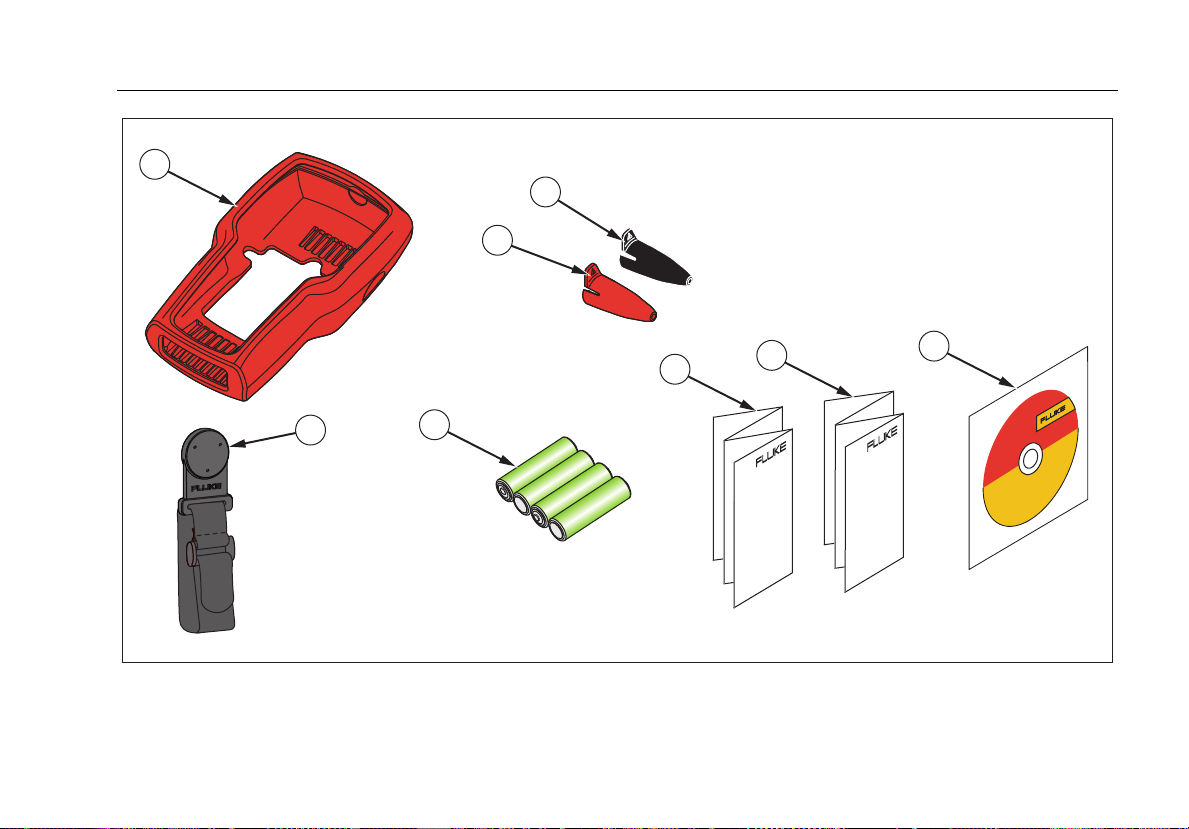

Standard Equipment

Make sure that the Product shipment is complete. It must

include:

• The Product

• Product Manuals CD

• Getting Started Manual

• Quick Reference Guide

• Test leads

• Carry case

• Calibration certificate

Product Features

Figure 1 and Table 2 shows the location of the buttons,

pressure controls, connection ports, and electrical inputs.

6

Page 15

Pressure Calibrator

Product Features

2

F1 F2 F3

1

ZERO

6

5

8

7

3

11

10

4

9

Figure 1. Product Interface

hvf001.eps

7

Page 16

721Ex

Users Manual

Table 2. Product Features

Item Description

Power button. Turns on and off the Product

Function buttons. Used to configure the Product. These keys correspond to messages on the display.

Zero button. Zeros pressure measurements.

Backlight button. Push to turn the backlight on or off.

COMMON input

Input terminals to measure current and a contact closer for switch test.

Low pressure port [P1]

High pressure port [P2]

RTD probe connector

Firmware programming connector (for factory use only)

Battery door

8

Page 17

Pressure Calibrator

Product Features

Notes

When is pushed to turn on the Product, a

short startup self-check routine is run. During

that routine, the display shows the current

firmware revision level, auto-shutdown status,

and the range of the internal pressure sensors.

A maximum of 5 minutes warm-up is necessary

for the product to reach rated accuracy. A longer

warm-up period can be necessary for large

changes in ambient temperature. See the “Zero

Function Use” section for more about zeroing

the pressure sensor displays. It is recommended

that pressure ranges be zeroed each time the

Product is started.

Display

The display has two main regions:

• The menu bar (located at the bottom of the screen) is

used with the function buttons to access the Product

menu.

• The main display has a maximum of three process

measurement sub-regions.

These sub-regions will be referred to as the UPPER,

MIDDLE and LOWER displays. Figure 2 shows the

location of the different display fields. Table 3 describes

them.

9

Page 18

721Ex

Users Manual

Table 3. Display Functions

Figure 2. Display

hvf007.eps

Item

Number

Units

Primary

Parameters

Span

Indicator

Pressure

Units

e Description

Nam

Shows what is being

measured.

Shows the percent of the

4 mA to 20 mA span. (For

mA functions only.)

Shows one of 17 pressure

units available for display.

Shows the unit of measure

for the display.

10

Page 19

Pressure Calibrator

Product Features

Language Selection

The user interface is available in three languages:

• English

• Norwegian

• German

To select a language:

1. Turn the Product off.

2. Hold down , , and simultaneously.

3. As the Product powers up, the display shows the

language in the top left corner of the display. Repeat

the procedure to show each subsequent language.

Once the necessary language is shown, the Product

user interface stays in that language until another

language is chosen.

Home Menu Functionality

There are three options for the Home Menu:

• P1/P2

• mA/RTD

• MENU

These options are shown across the bottom of the

display.

From anywhere within the menu structure, push to get

back to the Home Menu.

Backlight Use

Push to toggle on and off the backlight.

Zero Function

In pressure mode and when the pressure is within the

zero limit, The Product zeros pressure on any port that is

currently shown on the display. The zero limits are within

10 % of the full-scale range of the selected sensor. If the

display shows “OL,” the zero function will not operate.

11

Page 20

721Ex

Users Manual

Menus

There are 11 sub menus that can be accessed from

(Main Menu). Push to go to the next menu selection.

For the last menu, push (DONE) to return to the Main

Menu.

The 11 sub-main menus are:

• SWITCHTEST

• %ERROR

• MINMAX

• SET UNITS

• CONTRAST

• LOCK CFG

• AUTO OFF

• RESOLUTION

• HART

• PROBE TYPE

• DAMP

Push , , or , depending on the menu, to toggle

through each parameter of an active menu. The individual

menus are explained in the subsequent sections.

SWITCHTEST

To access the SWITCHTEST menu, push .

SWITCHTEST is shown on the menu bar.

Connect a pressure switch to the Product as shown in

Figure 3.

For all connections in this manual:

Warning

To prevent possible electrical shock, fire, or

personal injury, check entity parameters

before making any connections to this

Product.

12

Page 21

Pressure Calibrator

Product Features

F1 F2 F3

ZERO

Use low volume tubing

when possible

Figure 3. Pressure Switch Connection

Pressure

Switch

hvf017.eps

To do a switch test:

1. Use the P1 or P2 pressure input connections to

connect the Product to the input of the switch.

Connect the contact output of the switch to the COM

and mA terminals of the Product. The polarity of the

terminals does not matter.

2. Connect the pump to the Product and the pressure

switch.

3. Make sure the vent on the pump is open.

4. Push to select P1 or P2 depending on how the

Product is connected.

5. Zero the Product if necessary.

6. Close the vent after the Product is zeroed.

7. If connected to a normally closed switch, the top of

the display will read “CLOSE”.

8. Slowly apply pressure with the pump until the switch

opens.

Note

In the SWITCHTEST mode the display update

rate is increased to help capture changing

pressure inputs. Even with this enhanced

sample rate pressurizing, the test should be

done slowly to ensure accurate readings.

13

Page 22

721Ex

Users Manual

9. Once the switch is open, “OPEN” will be shown.

Bleed the pump slowly until the pressure switch

closes.

At the top of the display it will now read, “SW OPENED

AT” and show the pressure at which the switch opened.

hix044.eps

hix043.eps

14

Page 23

10. Push the “NEXT” option to view when the switch

closed, and the dead band.

Pressure Calibrator

Product Features

hix046.eps

hix045.eps

11. Push the “NEW TEST” option to clear the data and

do another test.

12. Push to en

d the test and return to the main menu.

%ERROR

The Product features a unique function which can

calculate pressure vs. milliamp error as a percentage of

the 4 mA - 20 mA loop span. The %ERROR mode uses

all three screens and has a unique menu structure. It

simultaneously shows pressure, mA, and percent error.

See Figure 4.

15

Page 24

721Ex

Users Manual

-

F1 F2 F3

ZERO

External

Loop Supply

16

Figure 4. Percent Error Function Connection

hvf019.eps

Page 25

Pressure Calibrator

Product Features

Example:

A pressure transmitter under test is 30 psi (2 Bar) FullScale and outputs a corresponding 4 mA to 20 mA signal.

Program a 0 psi to 30 psi pressure span into the Product

and the Product calculates and shows the deviation or

%Error from the expected 4 mA to 20 mA output. This

eliminates the need for manual calculations and helps

when it is difficult to set an exact pressure.

To use the %ERROR function:

1. Push to access the menus.

2. Push to step through the menu until %ERROR is

shown on the menu bar.

3. Push to open the %ERROR screen.

4. Push to scroll through the port choices (P1 or P2).

5. Push to configure the pressure range settings.

6. Use the arrow keys to set the 100 % point of the

desired pressure range, select DONE SET when

finished.

7. Use the arrow keys to set 0 % point and select

DONE SET. The % ERROR mode is now ready to

use.

Note

The 0 % and 100 % point will be saved in nonvolatile memory until they are changed again by

the user.

hmq054.eps

17

Page 26

721Ex

Users Manual

MINMAX

The Product has a min/max feature to capture the

minimum and maximum values of any displayed

parameter. To use the MINMAX menu:

1. Push to access the menus.

2. Push to step through the menu until MINMAX is

shown on the menu bar.

3. Push to toggle the display through the min and

max values that are stored in the min/max registers.

These readings are live so that the new min/max

values will be recorded while in this mode.

hix055.eps

hix056.eps

To reset the min/max registers, push for “CLEAR”.

These registers are also cleared at power-up or when the

configuration is changed. Push to exit MIN MAX and

see live measurements.

18

Page 27

Pressure Calibrator

Product Features

SET UNITS

Use the SET UNITS menu to select the measurement

units for each port. To use this menu:

1. Push to access the menus.

2. Push to step through the menu until SET UNITS is

shown on the menu bar.

3. Push to select the necessary unit. The choices

are:

• inHg 0 °C

• mmHg 0 °C

• kg/cm

• mmH

• mmH

• ftH

2

O 4 °C

2

O 20 °C

2

O 60 °F

2

• psi

• inH2O 4 °C

• inH

• inH

• cmH

• cmH

O 20 °C

2

O 60 °F

2

O 4 °C

2

O 20 °C

2

• bar

• mbar

• MPa

• kPa

19

Page 28

721Ex

Users Manual

4. Push to move through each function (P1, P2, or

RTD) and change to the desired units.

5. Push when finished with units selection.

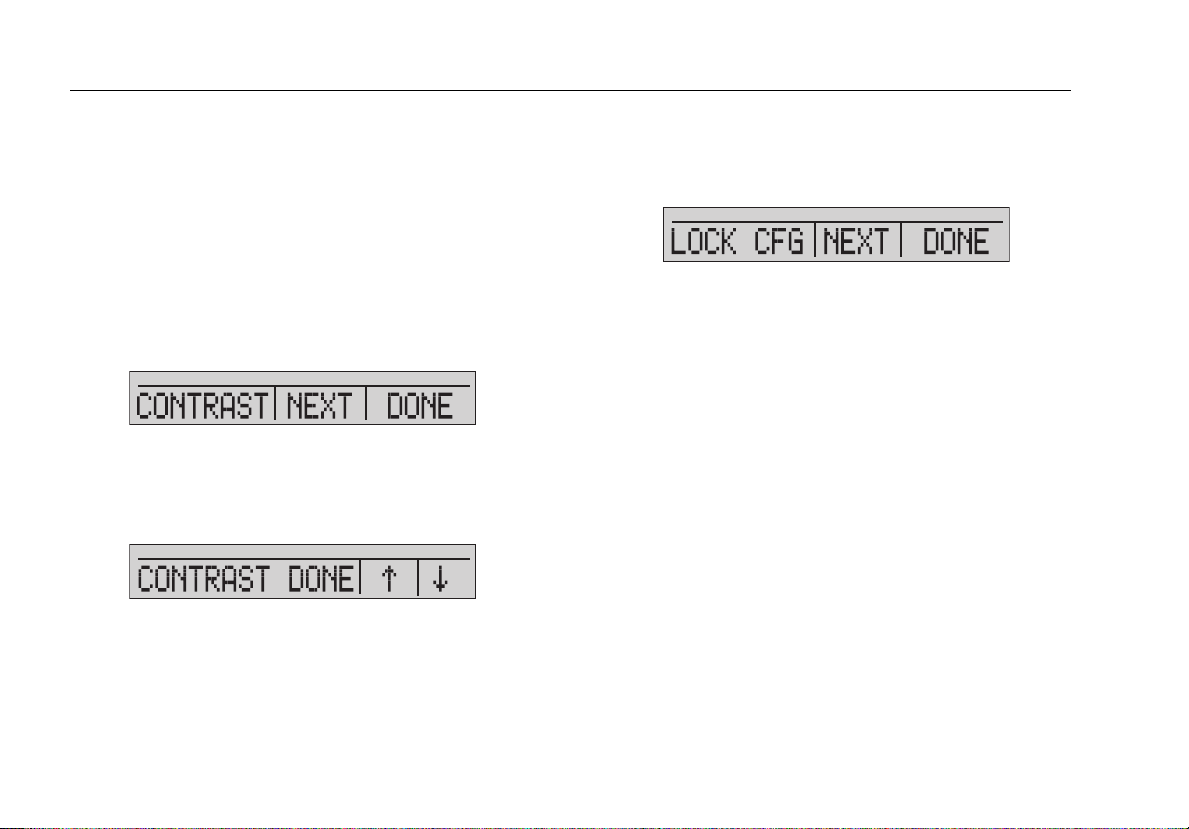

CONTRAST

Use the Contrast menu to adjust the display contrast.

1. Push to access the menus.

2. Push to step through the menu until CONTRAST

is shown on the menu bar.

3. Push to access the Contrast menu.

hix024.eps

4. Push and repeatedly to adjust the display

contrast to the necessary level. Push to finish the

adjustment and go home as shown below.

hix025.eps

Lock and Unlock Configurations (CFG)

Use the LOCK CFG or UNLOCK CFG options of the

Configuration Lock Menu (CONFIG), shown below, to

lock or unlock the display configuration.

hix026.eps

When the LOCK CFG option is pushed, the menu display

goes home and the menu configuration option on the

Main Menu is locked. All menus are locked with the

exception of:

• MINMAX

• CONTRAST

• CONFIG

20

Page 29

Pressure Calibrator

Product Features

You will also notice that some menu choices disappear

when the LOCK CFG is used.

When the UNLOCK CFG option is selected, the

configuration is unlocked and the menu display goes to

the subsequent menu.

AUTO OFF

The Product can be set to automatically power off after a

chosen number of minutes. This function can also be

disabled. To set the auto off parameters:

1. Push to access the menus.

2. Push to step through the menu until AUTO OFF is

shown on the menu bar.

3. Push on the Auto Off Main Menu shown below.

hix031.eps

4. Push or to select the number of minutes before

the Product turns off or scroll down to 0 to disable

Auto Off as shown below.

hix032.eps

5. Push to set the parameters and go to the main

menu. The auto off time is reset when a key is

pushed.

21

Page 30

721Ex

Users Manual

RESOLUTION

To choose between a low or high resolution display:

1. Push to access the menus.

2. Push to step through the menu until

RESOLUTION is shown on the menu bar.

3. Push to select the Resolution menu.

4. Push or to turn low resolution on or off.

5. Push when finished.

hmq062.eps

PROBE TYPE

To select an external RTD probe for use with the Product:

1. Push to access the menus.

2. Push to step through the menu until PROBE is

shown on the menu bar.

hix035.eps

3. Push on to select the Probe type. The probe

choices are:

• P100-385

• P100-392

• P100-JIS

22

Page 31

Pressure Calibrator

Product Features

4. Push to select the necessary probe type (see the

figure below). Push to store the change and go to

the Main Menu.

Note

The default probe type is PT100-385.

SELECT RTD PROBE TYPE

hix036.eps

5. Connect the RTD Probe.

The standard probe has a 10-inch insertion depth with a

¼-inch diameter stainless steel sheath. See Figure 5.

Note

The factory default type is PT100-385 so if the

Product is used with the Fluke 720 RTD Probe

(pn 4366669), it is not necessary to set the

probe type. Connect the probe to the Product

and configure the display to read temperature.

The display shows “OL” when the measured

temperature is outside the nominal

measurement range of the RTD function (below

°

C or above 150 °C).

-40

23

Page 32

721Ex

Users Manual

F1 F2 F3

ZERO

RTD Probe

DAMP

Turn on or off Damping with the DAMP menu selection.

When damping is on, the Product shows a running

average from ten measurements. The Product makes

approximately three indications per second.

To use the Damping function:

1. Push to access the menus.

2. Push to step through the menu until DAMP is

shown on the menu bar.

3. Push to select the DAMP menu.

4. Push or to turn on or off the DAMP function.

5. Push when finished.

hvf016.eps

Figure 5. Temperature Measurement with RTD Probe

24

hmq064.eps

Page 33

Pressure Calibrator

Measure Pressure

Measure Pressure

To measure pressure, connect the Product with the

correct fitting and select a pressure port. The Product has

two internal sensors. Make sure to choose the sensor

based on working pressures and accuracy.

Warning

To prevent personal injury:

• Pressure sensors can be damaged

and/or personnel injury can occur due to

improper application of pressure. Refer

to Table 4 for information on

overpressure and burst pressure ratings.

Vacuum should not be applied to any

gauge pressure sensor. The Product

display shows “OL” when an

inappropriate pressure is applied. If “OL”

is shown on any pressure display, the

pressure should be reduced or vented

immediately to prevent Product damage

or possible personnel injury. “OL” is

shown when the pressure exceeds 110 %

of the nominal range of the sensor or

when a vacuum in excess of 2 PSI is

applied on gauge range sensors.

• Push Z to zero the pressure sensor

when vented to atmospheric pressure.

Note

To ensure accuracy of the Product, the Product

must be zeroed before a device is calibrated.

See the “Zero Function Use” section.

Media Compatibility

The Product has a media-isolated sensor to prevent

sensor contamination. Whenever possible, clean dry air is

the media of choice. If this is not possible, make sure the

media is compatible with the sensor. For the 16 PSIG and

36 PSIG range, use media compatible with Silicon, Pyrex,

RTV, Gold, Ceramic, Nickel, and Aluminum. For all other

ranges, use media compatible with 316 Stainless Steel.

25

Page 34

721Ex

Users Manual

Measurements

Use the input terminals on the front of the Product to

measure current. Current is measured in mA and

percentage of range. The range on the Product is set at

0 % at 4 mA and 100 % at 20 mA.

Use the RTD connector and an RTD probe to measure

temperature.

From the main menu, push to select mA or RTD. This

function will only work on the LOWER screen.

Note

The display shows “OL” when the measured

current is more than the nominal range of

current measurement (24 mA).

F1 F2 F3

ZERO

4 to 20mA

Figure 6. Measure Current

Device

Under

Te st

hvf011.eps

26

Page 35

Pressure Calibrator

Transmitter Calibration

Transmitter Calibration

mA Input Function

The mA input function reads back the 4 mA to 20 mA

output from the device being calibrated. This can be done

passively. The device under test directly generates 4 mA

to 20 mA and can be read by the Product.

hvf047.eps

Pressure-to-Current Transmitter Calibration

To calibrate a pressure-to-current transmitter (P/I):

1. Connect the Product and the pump to the transmitter.

See Figure 7.

2. Apply pressure with the pump.

3. Measure the current output of the transmitter.

4. Ensure the reading is correct. If not, adjust the

transmitter as necessary.

Note

Use low-volume tubing when possible.

27

Page 36

721Ex

F1 F2 F3

ZERO

Users Manual

External

Loop Supply

Figure 7. Pressure-to-Current Transmitter Connections

-

hvf018.eps

28

Page 37

Pressure Calibrator

Transmitter Calibration

Ranges and Resolution

Ranges and resolutions for the Product are shown in Table 4.

Table 4. Ranges and Resolutions

Range (PSI) 16 36 100 300 500 1000 1500 3000 5000

Burst Pressure 60 120 400 1200 2000 4000 6000 9000 10000

Proof Pressure

(PSI)

Engineering Unit Factor

psi 1 16 36 100 300 500 1000 1500 3000 5000

bar 0.06894757 1.1032 2.4821 6.8947 20.684 34.474 68.947 103.42 206.84 344.74

mbar 68.94757 1103.2 2482.1 6894.8 20684 34474 68948 N/A N/A N/A

kPa 6.894757 110.32 248.21 689.48 2068.4 3447.4 6894.8 10342 20684 34474

MPa 0.00689476 0.1103 0.2482 0.6894 2.0684 3.4474 6.8948 10.342 20.684 34.474

kg/cm2 0.07030697 1.1249 2.5311 7.0307 21.092 35.153 70.307 105.46 210.92 351.53

cmH20 @ 4 °C

cmH20 @ 20 °C

mmH20 @ 4 °C

mmH20 @ 20 °C

inH20 @ 4 °C

inH20 @ 20 °C

inH20 @ 60 °F

mmHg @ 0 °C

inHg @ 0 °C

• Proof pressure - maximum allowable pressure without a shift in calibration.

• Burst pressure - sensor damaged or destroyed; some risk of personnel injury.

70.3089 1124.9 2531.1 7030.9 21093 35154 70309 N/A N/A N/A

70.4336 1126.9 2535.6 7043.4 21130 35217 70434 N/A N/A N/A

703.089 11249 25311 70309 N/A N/A N/A N/A N/A N/A

704.336 11269 25356 70434 N/A N/A N/A N/A N/A N/A

27.68067 442.89 996.50 2768.1 8304.2 13840 27681 41521 83042 N/A

27.72977 443.68 998.27 2773.0 8318.9 13865 27730 41595 83189 N/A

27.70759 443.32 997.47 2770.8 8312.3 13854 27708 41561 83123 N/A

51.71508 827.44 1861.7 5171.5 15515 25858 51715 77573 N/A N/A

2.03602 32.576 73.297 203.60 610.81 1018.0 2036.0 3054.0 6108.1 10180

35 70 200 600 1000 2000 3000 6000 7000

29

Page 38

721Ex

Users Manual

Maintenance

Replace the Batteries

If the batteries discharge too far, the Product

automatically shuts down to prevent battery leakage.

Warning

To prevent possible electrical shock, fire, or

personal injury:

• Remove the batteries if the Product is

not used for an extended period of time,

or if stored in temperatures above 50 °C.

If the batteries are not removed, battery

leakage can damage the Product.

• Replace the batteries when the low

battery indicator shows to prevent

incorrect measurements.

• Be sure that the battery polarity is

correct to prevent battery leakage.

• Repair the Product before use if the

battery leaks.

• The battery door must be closed and

locked before you operate the Product.

• Only change batteries in an area known

to be non-hazardous.

To change the batteries, see Figure 8:

1. Turn off the Product.

2. Turn the Product so that the display is down.

3. With a flat-head screwdriver, remove the battery door

screw.

4. Replace the four AA batteries with new batteries.

Make sure that the polarity on the batteries is correct.

See Table 5 for a list of approved batteries.

5. Replace the battery door.

6. Tighten the battery door screw.

Table 5. Approved Batteries

Battery Manufacturer

(All Batteries Alkaline 1.5 V)

Duracell MN1500

Rayovac Max Plus 815

Eveready (Energizer) E91

Panasonic LR6XWA

Type

30

Page 39

Pressure Calibrator

Maintenance

Clean the Product

Caution

To avoid damaged to the Product:

• Do not use solvents or abrasive

cleansers.

• Do not allow water into the case.

Clean the Product with a soft cloth dampened with water

or water and mild soap.

Figure 8. Battery Replacement

hvf061.eps

31

Page 40

721Ex

Users Manual

User-Replaceable Parts and Accessories

Warning

To prevent possible electrical shock, fire, or

personal injury, use only specified

replacement parts.

User-replaceable parts are listed in Table 6 and shown

in Figure 9 . For more information about these items,

contact a Fluke representative. See the “Contact Fluke”

section of this manual.

Table 6. User-Replaceable Parts and Accessories

Item Description

Red Holster

TL7X Probe Cap, Red 3986579

TL7X Probe Cap, Black 3986568

TPAK80-4-2002, Magnet

Strap

TPAK80-4-8001, Strap 9

inches

Part

Number

4497306

669952

669960

Item Description

Not Shown

Not Shown

Not Shown

Not Shown

Not Shown

AA Alkaline Batteries 376756

Safety Sheet 4561164

Quick Reference Guide 4561158

Users Manual CD 4561173

Rubber Feet 4364579

Fluke-720RTD Probe for 721

and 719Pro

Test Lead Set Variable

Alligator Clip, Red Variable

Alligator Clip, Black Variable

Part

Number

4366669

[1] See www.fluke.com for more information about the

test leads and alligator clips available for your

region.

[1]

[1]

[1]

32

Page 41

Pressure Calibrator

User-Replaceable Parts and Accessories

1

3

2

6

4

5

7

8

hvf065.eps

Figure 9. User-Replaceable Parts and Accessories

33

Page 42

721Ex

Users Manual

Specifications

(15 °C to 35 °C unless otherwise noted)

Environmental

Operating Temperature ............................ -10 °C to +45 °C (14 °F to +113 °F)

Storage

With Batteries ........................................ Per battery manufacturer’s specification, not to exceed storage specification without batteries.

Without Batteries ................................... -20 °C to +60 °C (-4 °F to +140 °F)

Altitude ...................................................... 2000 m

Power Requirements ............................... 6 V dc

Batteries .................................................... 4 AA batteries (alkaline)

Battery Life ................................................ >35 hours, typical usage

Electrical and Temperature Measurement (1 year)

Function Range Resolution Accuracy

mA Measure 0 to 24 mA 0.001 mA

*Temperature measure

(RTD/Ohms)

-40 °C to 150 °C (-40 °F to 302 °F) 0.01 °C, 0.01 °F

*Temperature measurement requires optional 720RTD Pt-100 RTD probe available as an accessory.

±0.015 % of rdg ±0.002 mA

±0.015 % of rdg ±0.02 Ω; ±0.1 °C (±0.2 °F)

±0.25 °C (± 0.45 °F) combined uncertainty when us

720 RT

D probe accessory

ing

34

Page 43

Physical

Dimensions (with holster) ......................... (H x W x D) (20 x 11 x 5.8) cm, (7.9 x 4.3 x 2.3) in

Weight (with holster) ................................ 0.539 kg (1 lb 3 oz)

Ingress Protection ..................................... IEC 60529 - IP40

Connectors/Ports

Pressure .............................................. Two, 1/8 in NPT

RTD ..................................................... RTD probe

Temperature Effect (all functions) ............. No effect on accuracy on all functions from 15 °C to 35 °C

Add ±0.002

% Full Scale/°C for temps outside of 15 °C to 35 °C

Pressure Calibrator

Specifications

35

Page 44

721Ex

Users Manual

1-year Specifications Low Pressure Sensor High Pressure Sensor

Model

721Ex1601

721Ex1603

721Ex1605

721Ex1610

721Ex1615

721Ex1630

721Ex1650

Calibrator

Description

16 PSIG, 100 PSIG

16 PSIG, 300 PSIG

16 PSIG, 500 PSIG

16 PSIG, 1000

PSIG

16 PSIG, 1500

PSIG

16 PSIG, 3000

PSIG

16 PSIG, 5000

PSIG

Range

Sensor 1

-14 psi + 16 psi

-0.97 bar to

1.1 bar

Resolution

Sensor 1

0.001 psi,

0.0001 bar

Accuracy

Sensor 1

0.025 % of

full scale

Range

Sensor 2

-12 psi to +100 psi

-0.83 bar to

6.9 bar

-12 psi to +300 psi

-0.83 bar to 20 bar

-12 psi to +500 psi

-0.83 bar to

34.5 bar

0 psi to +1000 psi

0.00 bar to 69 bar

0 psi to +1500 psi

0.00 bar to

103.4 bar

0 psi to +3000 psi

0.00 bar to

200 bar

0 psi to +5000 psi

0.00 bar to

345 bar

Resolution

Sensor 2

0.01 psi

0.0001 bar

0.01 psi

0.001 bar

0.01 psi

0.001 bar

0.1 psi

0.001 bar

0.1 psi

0.001 bar

0.1 psi

0.01 bar

0.1 psi

0.01 bar

Accuracy

Sensor 2

0.025 % of full

scale

0.035 % of full

scale

36

Page 45

Pressure Calibrator

1-year Specifications Low Pressure Sensor High Pressure Sensor

Specifications

Model

721Ex3601

721Ex3603

721Ex3605

721Ex3610

721Ex3615

721Ex3630

721Ex3650

Calibrator

Description

36 PSIG, 100 PSIG

36 PSIG, 300 PSIG

36 PSIG, 500 PSIG

36 PSIG, 1000

PSIG

36 PSIG, 1500

PSIG

36 PSIG, 3000

PSIG

36 PSIG, 5000

PSIG

Range

Sensor 1

-14 psi + 36 psi

-0.97 bar to

2.48 bar

Resolution

Sensor 1

0.001 psi,

0.0001 bar

Accuracy

Sensor 1

0.025 % of full

scale

Range

Sensor 2

-12 psi to +100 psi

-0.83 bar to

6.9 bar

-12 psi to +300 psi

-0.83 bar to 20 bar

-12 psi to +500 psi

-0.83 bar to

34.5 bar

0 psi to +1000 psi

0.00 bar to 69 bar

0 psi to +1500 psi

0.00 bar to

103.4 bar

0 psi to +3000 psi

0.00 bar to

200 bar

0 psi to +5000 psi

0.00 bar to

345 bar

Resolution

Sensor 2

0.01 psi

0.0001 bar

0.01 psi

0.001 bar

0.01 psi

0.001 bar

0.1 psi

0.001 bar

0.1 psi

0.01 bar

0.1 psi

0.01 bar

0.1 psi

0.01 bar

Accuracy

Sensor 2

0.025 % of

full scale

0.035 % of

full scale

37

Page 46

721Ex

Users Manual

Electromagnetic Compatibility (EMC) ........... IEC 61326-1 (Portable); IEC 61326-2-2, CISPR 11, Group 1, Class A

Group 1 equipment: group 1 has intentionally generated and/or use conductively coupled radiofrequency energy which is necessary for the internal functioning of the equipment itself.

Class A equipment is equipment suitable for use in all establishments other than domestic and

those directly connected to a low voltage power supply network which supplies buildings used

for domestic purposes. Caution - There may be potential difficulties in ensuring electromagnetic

compatibility in other environments, due to conducted and radiated disturbances.

USA (FCC) – 47 CFR 15 subpart B, this product is considered an exempt device per clause

15.103

Applies to use in Korea only. Class A Equipment (Industrial Broadcasting & Communication

Equipment)

[1] This product

and the seller or

environments and is not to be used in homes.

Ex-Haza

Entity Parameters ......................................... MEASUREMENT JACKS:

rdous Area Markings .......................

Ex ia IIB T3 Gb (Ta= -10… +45 °C)

KEMA 10 ATEX 0168X

Ex ia IIB T3 Gb (Ta= -10…+45 °C)

II 2 G IECEX CSA 10.0013X

Manufactured by Martel Electronics, Inc.,

3 Corporate Park Dr.

Derry, NH, USA

Ui = 30 V; Li = 80 mA; Pi = 750 mW; Ci = 0 μF; Li = 0 mH

Uo = 7, 14 V; lo = 1,12 mA; Po = 2 mW: Co = 240 μF; Lo = 1 H

Circular Connector: FOR USE WITH LTP100A RTD PROBE ONLY

[1]

meets requirements for industrial (Class A) electromagnetic wave e

user should take notice of it. This equipment is intended for use in bu

quipment

siness

38

Loading...

Loading...