Page 1

medTester 5000C

Biomedical Tester

Operators Manual

PN 2243153

February 2006

2006 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and workmanship for one full

year from the date of original purchase. During the warranty period, we will repair or, at our option,

replace at no charge a product that proves to be defective, provided you return the product,

shipping prepaid, to Fluke Biomedical. This warranty does not apply if the product has been

damaged by accident or misuse or as the result of service or modification by other than Fluke

Biomedical. IN NO EVENT SHALL FLUKE BIOMEDICAL BE LIABLE FOR

CONSEQUENTIAL DAMAGES.

Only serialized products and their accessory items (those products and items bearing a distinct serial

number tag) are covered under this one–year warranty. PHYSICAL DAMAGE CAUSED BY

MISUSE OR PHYSICAL ABUSE IS NOT COVERED UNDER THE WARRANTY. Items such

as cables and nonserialized modules are not covered under this warranty.

Recalibration of instruments is not covered under the warranty.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state, province to province, or country to country. This warranty is limited to repairing the

instrument to Fluke Biomedical’s specifications.

Warranty Disclaimer

Should you elect to have your instrument serviced and/or calibrated by someone other than Fluke

Biomedical, please be advised that the original warranty covering your product becomes void when

the tamper-resistant Quality Seal is removed or broken without proper factory authorization. We

strongly recommend, therefore, that you send your instrument to Fluke Biomedical for factory

service and calibration, especially during the original warranty period.

Page 3

Notices

All Rights Reserved

Copyright 2006, Fluke Biomedical. No part of this publication may be reproduced, transmitted,

transcribed, stored in a retrieval system, or translated into any language without the written

permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and

other printed materials for use in service training programs and other technical publications. If you

would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for

damage. If damage is found, stop unpacking the instrument. Notify the carrier and ask for an agent

to be present while the instrument is unpacked. There are no special unpacking instructions, but be

careful not to damage the instrument when unpacking it. Inspect the instrument for physical

damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email

techservices@flukebiomedical.com or call 1-800- 648-7952 or 1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical

damage is found, retain all packing materials in their original condition and contact the carrier

immediately to file a claim. If the instrument is delivered in good physical condition but does not

operate within specifications, or if there are any other problems not caused by shipping damage,

please contact Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and items

bearing a distinct serial number tag) are eligible for partial refund and/or credit. Nonserialized

parts and accessory items (e.g., cables, carrying cases, auxiliary modules, etc.) are not eligible

for return or refund. Only products returned within 90 days from the date of original purchase are

eligible for refund/credit. In order to receive a partial refund/credit of a product purchase price on

a serialized product, the product must not have been damaged by the customer or by the carrier

chosen by the customer to return the goods, and the product must be returned complete (meaning

with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not

returned within 90 days of purchase, or products which are not in “as new” and resalable condition,

are not eligible for credit return and will be returned to the customer. The Return Procedure (see

below) must be followed to assure prompt refund/credit.

Page 4

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee

of 15 %. Products returned in excess of 30 days after purchase, but prior to 90 days, are

subject to a minimum restocking fee of 20 %. Additional charges for damage and/or missing

parts and accessories will be applied to all returns.

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to

our factory location. When you return an instrument to Fluke Biomedical, we recommend using

United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure

your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost

shipments or instruments that are received in damaged condition due to improper packaging or

handling.

Use the original carton and packaging material for shipment. If they are not available, we

recommend the following guide for repackaging:

Use a double–walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive material

around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent material

around the instrument.

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material

Authorization (RMA) number, obtained from our Order Entry Group at 1-800-648-7952 or 1425-446-6945.

Repair and calibration:

To find the nearest service center, goto www.flukebiomedical.com/service or

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-99 FLUKE (1-888-993-5853)

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s

manufacturing specifications when it was shipped from the factory. Calibration measurements are

Page 5

traceable to the National Institute of Standards and Technology (NIST). Devices for which there

are no NIST calibration standards are measured against in-house performance standards using

accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may result in

electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any

injuries sustained due to unauthorized equipment modifications.

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment by

Fluke Biomedical. Changes made to the information in this document will be incorporated in

new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use

or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its

affiliated dealers.

Manufacturing Location

The medTester 5000C is manufactured in Everett, WA, U.S.A.

Page 6

Page 7

Biomedical Test System

Contents

Table of Contents

1: GENERAL INFORMATION

SAFETY CONSIDERATIONS .......................................................... 1-1

General.....................................................................................1-1

Safety Symbols ........................................................................1-1

Introduction ..................................................................................1-2

How to Use This Manual...............................................................1-3

If You’ve Used The medTester 5000C Before... ......................1-3

If You’re New to The medTester 5000C... ...............................1-3

Where to Find Help ..................................................................1-4

Features........................................................................................1-5

Electrical Safety Testing .........................................................1-5

Performance Testing ...............................................................1-5

Manual Measurements............................................................. 1-5

Automatic Measurements........................................................1-5

Computer Control..................................................................... 1-6

medCheck ................................................................................1-6

medTester 5000C Optional Modules ............................................1-7

Features......................................................................................1-11

Optional Accessories .................................................................1-11

medTester 5000C Instrument Specifications ............................ 1-12

Line Voltage and Measurements ...........................................1-12

Leakage Current ....................................................................1-12

Equipment Current................................................................. 1-13

Resistance .............................................................................1-13

Isolated Power ....................................................................... 1-13

Toolbox ..................................................................................1-14

Test Receptacle..................................................................... 1-14

Ground Fault Circuit Interrupter............................................ 1-15

Performance Waveforms........................................................1-15

General Specifications ...............................................................1-16

ECG Connections ................................................................... 1-16

Data Input and Output ...........................................................1-16

RS-232C Serial Interface Parameters....................................1-16

Real Time Clock.....................................................................1-16

Accessories ................................................................................ 1-17

medTester 5000C Module Upgrades .....................................1-19

2: INSTALLATION

Factory Default Settings ..............................................................2-1

Power-Up Sequence .....................................................................2-2

Initialization..................................................................................2-3

Page 8

Date and Time Setup ................................................................... 2-3

Audio Transducer......................................................................... 2-4

Enabling Modules ......................................................................... 2-5

Confirming Module Installation ............................................... 2-7

3: INSTRUMENT FAMILIARITY

Know Your medTester 5000C ...................................................... 3-1

Top Panel Controls, Displays, and Connectors....................... 3-1

Rear Panel Controls, Displays, and Connectors ..................... 3-3

Power Up ................................................................................. 3-4

Navigating the Menus ............................................................. 3-4

4: MANUAL TESTS

Performing Manual Tests ........................................................... 4-35

Printing Manual Measurements ............................................ 4-35

Line Voltage .......................................................................... 4-35

Leakage Current.................................................................... 4-36

ECG Lead Leakage ................................................................ 4-38

Equipment Current ................................................................ 4-42

Resistance............................................................................. 4-42

Isolated Power and Ground Fault Test ................................. 4-44

Toolbox.................................................................................. 4-45

5: AUTOSEQUENCES

What Is an Autosequence ............................................................ 5-1

Description of Standard Safety Autosequences ......................... 5-2

Autosequence Selection ......................................................... 5-3

Standard Safety Autosequence Names .................................. 5-4

Autosequence Device Prompts ............................................... 5-5

Autosequence Steps .................................................................... 5-7

System Line Voltage ............................................................... 5-8

Power Cord Resistance........................................................... 5-8

Leakage Current Measurements............................................. 5-9

Equipment Current Measurement ........................................... 5-9

ECG Performance Waveforms ............................................... 5-10

End-of-Test Prompts.............................................................. 5-11

Test Tag Printer ......................................................................... 5-13

Optional Monitoring Autosequences ......................................... 5-15

Line Voltage Monitor ............................................................. 5-16

Environmental Monitor .......................................................... 5-17

Toolbox Monitors ....................................................................... 5-19

Temperature Monitor ............................................................ 5-19

Humidity Monitor ................................................................... 5-21

6: CUSTOMIZE YOUR MEDTESTER

How to Customize a Preprogrammed Safety Autosequence ...... 6-1

Page 9

Biomedical Test System

Contents

What You See in an Autosequence..........................................6-2

How to Customize....................................................................6-3

Customizing a Blank Safety Autosequence ................................. 6-7

Test Record Header......................................................................6-7

Customizing Your Autosequence Prompts................................... 6-8

Turning Prompts On and Off .........................................................6-9

Renaming Prompts .....................................................................6-10

Pausing .......................................................................................6-11

Test Tag Configuration...............................................................6-11

Summary of Stored Records....................................................... 6-12

Customizing Bar Code Record Data Entry .................................6-13

Resetting Autosequences to Default Settings........................... 6-14

Printing Your medTester 5000C Configuration ..........................6-15

Customize medTester 5000C Options........................................6-15

7: PERFORMANCE WAVES

Outputting Performance Waves ...................................................7-1

Waveform Groups .........................................................................7-2

Running Waveforms from The WAVES Menu................................7-4

Conducting Waveform Tests in Safety Autosequences...............7-5

8: MEMORY

Introduction .................................................................................. 8-1

Viewing A Single Record ..............................................................8-2

Printing Records ...........................................................................8-2

Print A Single Record............................................................... 8-2

Print A Range of Records.........................................................8-3

Print All Records ......................................................................8-3

Print Records by Type..............................................................8-3

Printing A Summary of Records...............................................8-5

Printing Failed Test Records ...................................................8-5

Configuring Your Printer...............................................................8-5

Deleting Records .....................................................................8-6

Erasing Memory, All Records, and Checklists ........................8-6

Checking Contents of Memory ..................................................... 8-6

Searching for Records .................................................................. 8-7

Searching for Records with Test Failures............................... 8-8

Printing Checklists ..................................................................8-8

Keyboard Shortcut Commands.....................................................8-9

9: DEFIBRILLATOR MODULE

Defibrillator Autosequences......................................................... 9-1

Defibrillator Autosequence Names..........................................9-3

Running Defibrillator Autosequence Tests .................................. 9-5

Pretest Device Prompts ........................................................... 9-6

Page 10

Test Sequence......................................................................... 9-7

Posttest Prompts................................................................... 9-12

Customizing Defibrillator Autosequences ................................. 9-12

Make Your Own Autosequence ............................................. 9-12

10: IV PUMP MODULE

IV Pump Autosequences............................................................ 10-1

Basic Test Format ................................................................. 10-1

IV Pump Analyzers ................................................................ 10-2

IV Pump Autosequence Names ................................................. 10-4

Running IV Pump Autosequences.............................................. 10-7

Select the Autosequence...................................................... 10-7

Pretest Device Prompts ........................................................ 10-7

IV PUMP TESTS.......................................................................... 10-9

Infutest 2000 Series D........................................................... 10-9

IPT-1 .................................................................................... 10-12

IPT-MC ................................................................................. 10-12

IDA 4 Plus ............................................................................ 10-13

Pressure Test (Infutest, IPT-1, IPT-MC and IDA 4 Plus) ..... 10-17

Posttest Prompts................................................................. 10-18

Customizing IV Pump Tests..................................................... 10-22

Make Your Own Autosequence ........................................... 10-22

Making an Autosequence.................................................... 10-23

Infutest ................................................................................ 10-23

IPT-1 .................................................................................... 10-25

IPT-MC ................................................................................. 10-26

Print Your Autosequence .................................................... 10-26

Reinitialize Factory Default Settings .................................. 10-26

11: MEDCHECK MODULE

Tap Your medTester’s Potential ................................................ 11-1

What’s a Checklist? ................................................................... 11-2

Understanding and Using Checklists ........................................ 11-3

You’ve Made a Checklist—Now What? ...................................... 11-6

Running Checklists in medTester 5000C .................................. 11-6

Find a Checklist..................................................................... 11-7

Run a Checklist ..................................................................... 11-7

Items in a Checklist .............................................................. 11-9

View or Print a Checklist .................................................... 11-12

Remote Control of Fluke Biomedical Testers ......................... 11-13

12: REMOTE OPERATION

Local Versus Remote Mode ....................................................... 12-1

Communicating through medTester Serial Ports ................. 12-1

Communications Settings ..................................................... 12-2

Page 11

Biomedical Test System

Contents

Local Input Mode ........................................................................12-3

Local Output for Records and Tags ...........................................12-4

Record Output........................................................................12-5

Test Tag Output .....................................................................12-5

Remote Mode.............................................................................. 12-6

Going Remote ........................................................................12-6

File Transfer Protocol ............................................................12-9

Remote Commands List ...........................................................12-12

Port Diagnostics ....................................................................... 12-17

13: THE WEDGE ADAPTER

Features of the Wedge ...............................................................13-1

Serial Port Expansion .................................................................13-2

Keyboard Interface.....................................................................13-2

Port Configuration ......................................................................13-2

Installing the Wedge...................................................................13-4

Disassembly of the medTester 5000C’s Feet and Tilt Bail ...13-5

Attaching the Wedge to the medTester 5000C .....................13-5

Operating the Wedge .................................................................. 13-7

Wedge Port Names ................................................................13-7

Enabling The Wedge ..............................................................13-7

Configuring Wedge Ports .......................................................13-7

Configuring One Port for Two Purposes ..............................13-11

Setting Baud Rates................................................................... 13-11

Setting Output Ports.................................................................13-13

14: ESU MODULE

ESU Autosequences ...................................................................14-1

ESU Autosequence Names ....................................................14-4

Running ESU Autosequence Tests.............................................14-5

Pretest Device Prompts ......................................................... 14-6

Test Sequence ....................................................................... 14-7

ESU Test Types......................................................................14-7

ESU Autosequence Descriptions..............................................14-10

Posttest Prompts ................................................................. 14-14

Customizing ESU Autosequences ............................................ 14-15

Make Your Own Autosequence ...........................................14-15

SPO2 MODULE

SPO2 Autosequences .................................................................15-1

SPO2 Autosequence Names .................................................. 15-4

Running SPO2 Autosequence Tests...........................................15-6

Pretest Device Prompts ......................................................... 15-8

Test Sequence ....................................................................... 15-9

Probe Test............................................................................15-12

Page 12

For the Oxitest PLUS: .............................................................. 15-13

For CardioSat 100: ................................................................... 15-16

For the Index 2XL:.................................................................... 15-19

Posttest Prompts................................................................. 15-22

Customizing SPO2 Autosequences.......................................... 15-22

Make Your Own Autosequence ........................................... 15-22

Configuring for Your SPO2 Simulator.................................. 15-23

Making an Autosequence.................................................... 15-23

16: TRANSCUTANEOUS

PACEMAKER (PACER) MODULE

Pacer Autosequences ................................................................ 16-1

Pacer Autosequence Names ................................................. 16-3

Running Pacer Autosequence Tests.......................................... 16-4

Pretest Device Prompts ........................................................ 16-5

Test Sequence....................................................................... 16-6

Posttest Prompts................................................................. 16-14

Customizing Pacer Autosequences ......................................... 16-15

Make Your Own Autosequence ........................................... 16-15

17: NON-INVASIVE BLOOD

PRESSURE (NIBP) MODULE

NIBP Autosequences ................................................................. 17-1

NIBP Autosequence Names .................................................. 17-3

Running NIBP Autosequence Tests........................................... 17-4

Pretest Device Prompts ........................................................ 17-5

Test Sequence....................................................................... 17-6

Posttest Prompts................................................................. 17-11

Customizing NIBP Autosequences .......................................... 17-12

Make Your Own Autosequence ........................................... 17-12

Page 13

Chapter 1

General Information

In this chapter you will learn how to use this manual,

where to get help, and about medTester 5000C Features

and Specifications.

SAFETY CONSIDERATIONS

General

This instrument and related documentation must be reviewed for

familiarization with safety markings and instructions before you operate the

instrument. Refer to the medTester 5000C Operators Manual for operating

instructions.

Safety Symbols

The symbol to the left is the operators manual symbol. When

!

you see this symbol on the instrument, refer to the operators

manual.

WARNING! Denotes a hazard. WARNING! calls attention to a procedure,

practice, or the like, which, if not correctly performed or adhered to, could

result in personal injury. Do not proceed beyond a WARNING! sign until the

indicated conditions are fully understood and met.

CAUTION. Denotes a hazard. CAUTION calls attention to a procedure,

practice, or the like, which, if not correctly performed or adhered to, could

result in damage to or destruction of part or all of the instrument. Do not

proceed beyond a CAUTION sign until the indicated conditions are fully

understood and met.

1-1

Page 14

medTester 5000C

Operators Manual

Introduction

This manual is written for the biomedical technician or clinical engineer

responsible for testing hospital equipment, or the plant maintenance

technician responsible for maintenance records.

The medTester 5000C is an automated biomedical equipment test system and

a portable data acquisition unit that can be controlled with a computer. You

can expand the capabilities of the base model by adding modules that let you

store test records to memory and print them out.

The medTester 5000C is designed to measure electrical current and resistance

as they relate to electrical safety. It measures conditions that might cause

injury for compliance with the specifications set forth by ANSI, NFPA, and

AAMI.

The medTester 5000C base model automates repetitive tasks with safety

autosequences for medical equipment, including lead tests on patient

monitors, as well as general electrical devices. You can customize

autosequences to meet your specific testing needs.

With the addition of optional modules (for example, the RS-232/Printer

module, 100 Record Memory module, Expanded Memory module, and the

Waveform/Extended Testing module) your medTester 5000C becomes even

more powerful. The Waveform/Extended Testing module gives you

additional safety autosequences and performance wave and arrhythmia

generation capabilities. Individual defibrillation and IV pump modules offer

safety and performance testing autosequences for those devices.

With the Data Transfer module, you can transfer stored equipment test

record files to a compatible database program, Computerized Maintenance

Management System (CMMS) or Equipment Management System (EMS).

The medCheck module enables the downloading of test checklists and the

uploading of data to your database, CMMS, or EMS.

Finally, in addition to operating your medTester 5000C in the local mode

from the keyboard, bar code port, or the optional external keyboard, you can

also operate it from a remote location. Remote operation can take place from

a remote personal computer or from a compatible terminal device.

With the Wedge adapter, you can expand the number of serial ports to

control several external instruments without changing setups. In addition, you

can connect a PC-style keyboard to the Wedge adapter for entering data more

easily.

1-2

Page 15

Biomedical Test System

General Information

The medTester 5000C—reliable safety and performance testing. Capable of

managing your entire equipment program.

How to Use This Manual

Your medTester 5000C Operators Manual is designed for you. Whether you

are an experienced medTester operator or someone new to medTester, please

read this section before using your medTester 5000C.

If You’ve Used The medTester 5000C Before...

The medTester 5000C has been substantially upgraded to best satisfy your

needs. It now uses a new firmware release that offers increased reliability and

more consistent and stable data storage. RAM in the medTester 5000C is

dynamic, and data retrieval is simplified. In addition, some features that you

may be using have been enhanced with new features for your convenience.

Note in particular these chapters:

• Chapter 1 introduces the medTester 5000C’s enhanced features.

1

• Chapter 3 shows you how to navigate the medTester’s menus.

• Chapter 6 helps you customize autosequences.

• Chapters 11 and 12 bring you up to date on medCheck checklists

remote operation of the medTester 5000C.

If You’re New to The medTester 5000C...

Welcome to the medTester 5000C! It is the easy-to-use electrical safety and

performance analyzer with a high-quality data collection and retrieval

system—all designed to make your job easier and more productive. While the

ideal recommendation to a new user is to read the entire manual, we know

that you want to start using your new medTester now. Before you do, please

review Chapters 1 to 3 to learn about the medTester 5000C. Other chapters

of interest to you might be:

• Chapter 4 for information about basic medTester 5000C safety

test measurements.

• Chapter 5 for autosequences.

1-3

Page 16

medTester 5000C

Operators Manual

Where to Find Help

If you have questions not answered in this manual, please refer to the

following Fluke Biomedical sources:

• medTester 5000C Service Manual, Part No. 2243166.

• Fluke Biomedical Customer Service Department. Telephone

800-648-7952

• Safe current limits for electromedical apparatus, (ANSI/AAMI ES1),

© 1993, Association for the Advancement of Medical

Instrumentation.

ISBN 1-57020-007-6.

AAMI Phone: 800-332-2264.

• Standard for Health Care Facilities, (NFPA 99), 1993 Edition,

© 1993, National Fire Protection Association, February 12, 1993,

NFPA.

NFPA Phone: 800-344-3555.

1-4

Page 17

Biomedical Test System

General Information

Features

The medTester 5000C is an automated biomedical equipment test system

designed for you to do electrical safety and performance testing. With the

medTester, you can run customizable automatic sequences of tests, called

autosequences. You can print stored test records or upload them to a

computer. A computer can operate a medTester 5000C from a remote

location. This section defines some basic concepts behind the testing that this

manual describes.

Electrical Safety Testing

The medTester 5000C measures electrical current and resistance related to

electrical safety. Electrical safety testing is the measurement of electric

conditions that could result in injury to operators of that equipment or to

patients. All measurements you make with the medTester 5000C comply with

specifications set forth by ANSI, NFPA, and AAMI.

Performance Testing

Performance testing verifies that equipment performs to manufacturer

specifications. Different types of medical equipment require tests that are

unique to its operation—patient monitors, defibrillators, and IV pumps, to

name just a few. The medTester 5000C provides ECG waveforms for

performance testing of patient monitors. With optional autosequence

modules, you can use analyzers to test the performance of defibrillators, IV

pumps, electrosurgical units, pulse oximeter analyzers and more.

1

Manual Measurements

You can always perform safety measurements on any electrical equipment

directly from the medTester keyboard. Measurements appear on the display

continuously until you escape from the test. Instructions for conducting

manual tests are in Chapter 4, Manual Tests.

Automatic Measurements

One of the strengths of the medTester 5000C is the ability to automate

testing using autosequences. Autosequences are collections of tests that

execute as a group. Ten safety autosequences ship with the medTester 5000C

base model, each of which you can customize to meet your needs. With the

Waveform/Extended Testing Module, you receive an additional five

customizable safety autosequences, five ECG performance waveform and

arrhythmia groups, and line monitor and environmental autosequences.

1-5

Page 18

medTester 5000C

Operators Manual

Prompts in the autosequence ask you for information that aids in test

reporting. The pretest prompts, for example, can ask you for the model and

serial number of the equipment you’re testing, the test location, operator

code, and physical condition of the EUT (equipment under test). Posttest

prompts can ask you to schedule the next test date, input comments about the

tests, or prepare a test tag.

With the Memory Module and RS-232/Printer Module installed on your

medTester 5000C, you can store test records to memory and print them from

the medTester’s printer port. Additional autosequence modules are available

for performance testing defibrillators, IV pumps, and more. See Chapter 5,

Autosequences.

Computer Control

You can remotely control your medTester 5000C from a personal computer

or compatible terminal device through a serial communication port and

appropriate communication software. Once connected and in remote control of

the medTester 5000C, you send remote commands to the medTester 5000C

to do safety and performance tests, with the results returned to the computer.

Some medTester 5000C users prefer to accumulate the test data for

equipment before reporting stored records. Then at their convenience they

upload the data to an equipment database program, Computerized

Maintenance Management System, or Equipment Management System (EMS)

on a computer. This is accomplished through a serial port on the

medTester 5000C and the medTester 5000C’s Data Transfer Module. Chapter

12, Remote Operation, discusses the methods you can use to control the

medTester 5000C and to manage test data.

If you use other Fluke Biomedical analyzers, such as the Impulse 4000 or IPT1, you can control them with the medTester 5000C. By connecting an

analyzer to the medTester 5000C’s COM2 port, you gain a two-way

communication link. This link lets the medTester 5000C control the

operation of the analyzer. Test data that the analyzer collects is then returned

to storage in the medTester 5000C.

medCheck

The medTester 5000C medCheck Module unleashes the power of the

medTester 5000C to become the centerpiece of a total equipment

management solution. medCheck lets you download checklists from, and

upload checklist test data to, your equipment management software system.

1-6

Page 19

Biomedical Test System

General Information

Checklists are complete sets of preventive maintenance procedures for

equipment testing. They can contain prompts to the medTester 5000C user to

make physical inspections of the EUT and to take individual safety

measurements. A checklist can include one or more safety and performance

autosequences that automatically execute. Checklist test record data is then

uploaded to the user’s equipment management database program,

Computerized Maintenance Management System. See Chapter 11, medCheck

Module, for more information.

medTester 5000C Optional Modules

The medTester 5000C offers several modules as options. (See the table later

in this chapter.) If your medTester 5000C includes any of these modules, they

are listed under the

Enter these menu commands:

1. From the main menu, press:

UTIL menu. To access the menu, do the following:

1

UTIL

F5

2. Press the right arrow to scroll to the remaining menus.

MODULES

3. Press:

NOTE

F3

For further information about using medTester 5000C menus

and function keys, see Navigating the Menus, in Chapter 3,

Instrument Familiarity.

Whenever you attempt to select a module that is not installed, this message

appears in the display:

MODULE NOT INSTALLED

1-7

Page 20

medTester 5000C

Operators Manual

These modules are software enabled for use by the medTester’s firmware.

The firmware is held in EPROM (erasable programmable read-only memory).

When you purchase one or more of the modules described below, you receive

a 3.5-inch floppy diskette containing the software functions of the module.

To load the module software, attach the appropriate serial cable from a

communications port on your personal computer to a communications port

on the medTester.

Once this connection is made, you receive instructions for enabling the

module in the medTester 5000C’s EEPROM (electrically erasable

programmable read-only memory).

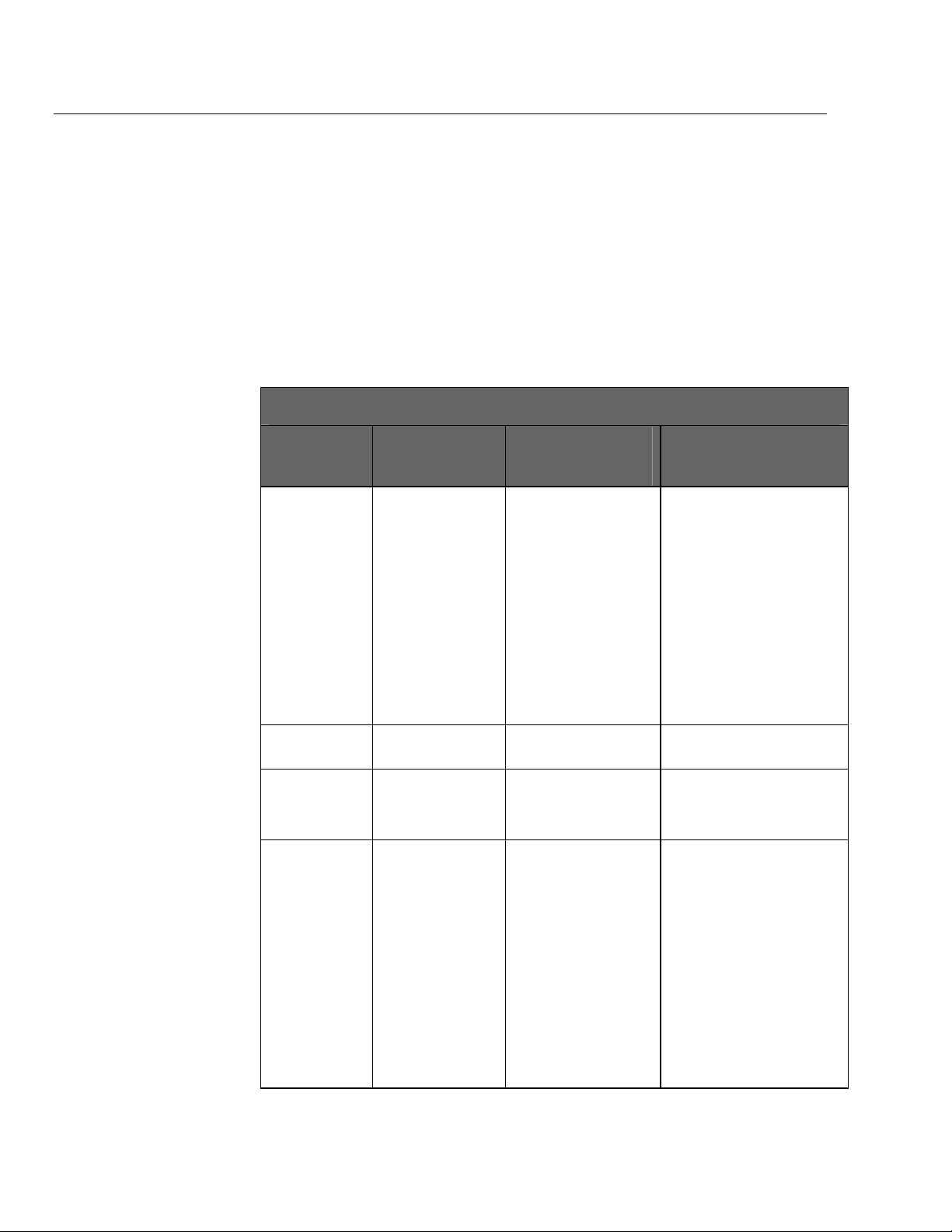

medTester 5000C Modules

medTester

5000C

Module Name

RS-232/Printer

Memory—

100 Records

Memory—

Expanded

Waveform/

Extended Testing

Functions Enabled medTester

Prerequisites for Use of

Module

• Use of COM1 and

COM2 serial ports.

• Use of the parallel

printer port.

• Test record

storage.

• Storage of

autosequence and

medCheck data.

• Five (5) additional

safety

autosequences.

• ECG performance

waveforms.

• ECG arrhythmias.

• None • Remote operation of the

• RS-232/Printer Module • Storing of test records.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• RS-232/Printer Module.

• Memory—100 Records

Module.

Required for...

medTester 5000C from a

personal computer or

compatible terminal device.

• Two-way communication

between the

medTester 5000C and a Fluke

Biomedical analyzer or tester.

• Input from an optional

keyboard, bar code scanning

gun.

• Printing test record output.

• Autosequence testing.

• Use of medCheck.

• Adding more customized

safety autosequences.

• Outputting ECG waveforms to

patient monitors.

• Outputting ECG arrhythmias to

patient monitors.

1-8

• Line monitor test.

• Environmental test.

• Periodic measurements of line

voltage.

• Measuring ground potential

and resistance between a

common ground point and

multiple points in a room.

Page 21

Biomedical Test System

General Information

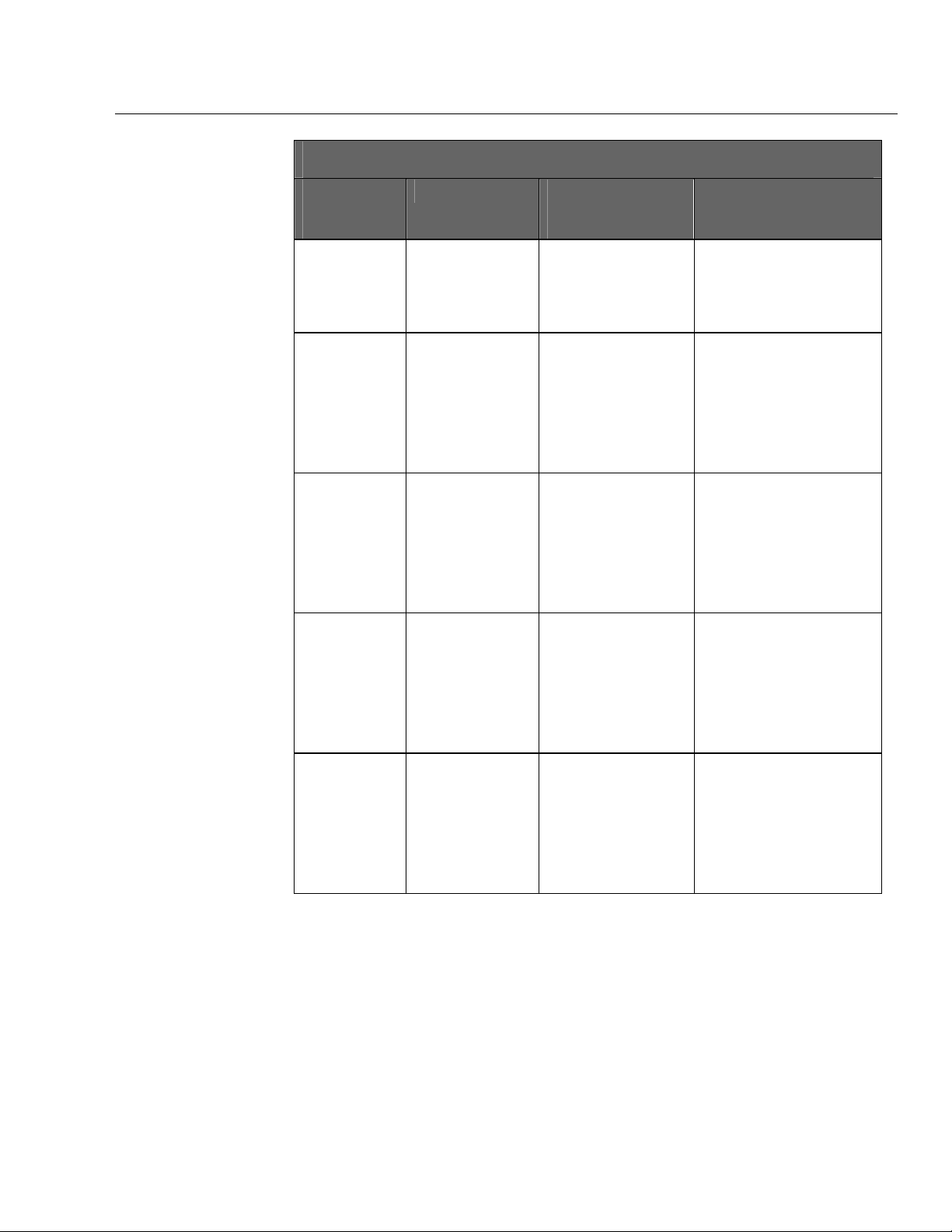

medTester 5000C Modules

1

medTester

5000C

Module Name

Data Transfer

medCheck

Defibrillator

IV Pump

Functions Enabled medTester

Prerequisites for Use of

Module

• File Transfer

Protocol used to

transfer checklists

into and out of the

medTester 5000C.

• Checklists • RS-232/Printer Module.

• Defibrillation

autosequences.

• IV Pump

autosequences.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• Memory—100 Records

Module.

• Expanded Memory

Module.

• Data Transfer Module.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• Expanded Memory

Module.

• Data Transfer Module.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• Expanded Memory

Module.

Required for...

• Checklist usage.

• Communicating checklists

between an equipment

management database system

and the medTester 5000C.

• 20 autosequences for testing

defibrillators with the Fluke

Biomedical Impulse 4000

defibrillator analyzer.

• Including defibrillator

autosequences in checklists.

• 10 autosequences for testing

IV pumps with the Fluke

Biomedical pump tester.

• Including IV pump

autosequences in checklists.

• Data Transfer Module.

ESU

• ESU

autosequences.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• Expanded Memory

Module.

• Data Transfer Module.

• 10 autosequences for testing

electrosurgical units with Fluke

Biomedical analyzers.

• Including ESU autosequences

in checklists.

1-9

Page 22

medTester 5000C

Operators Manual

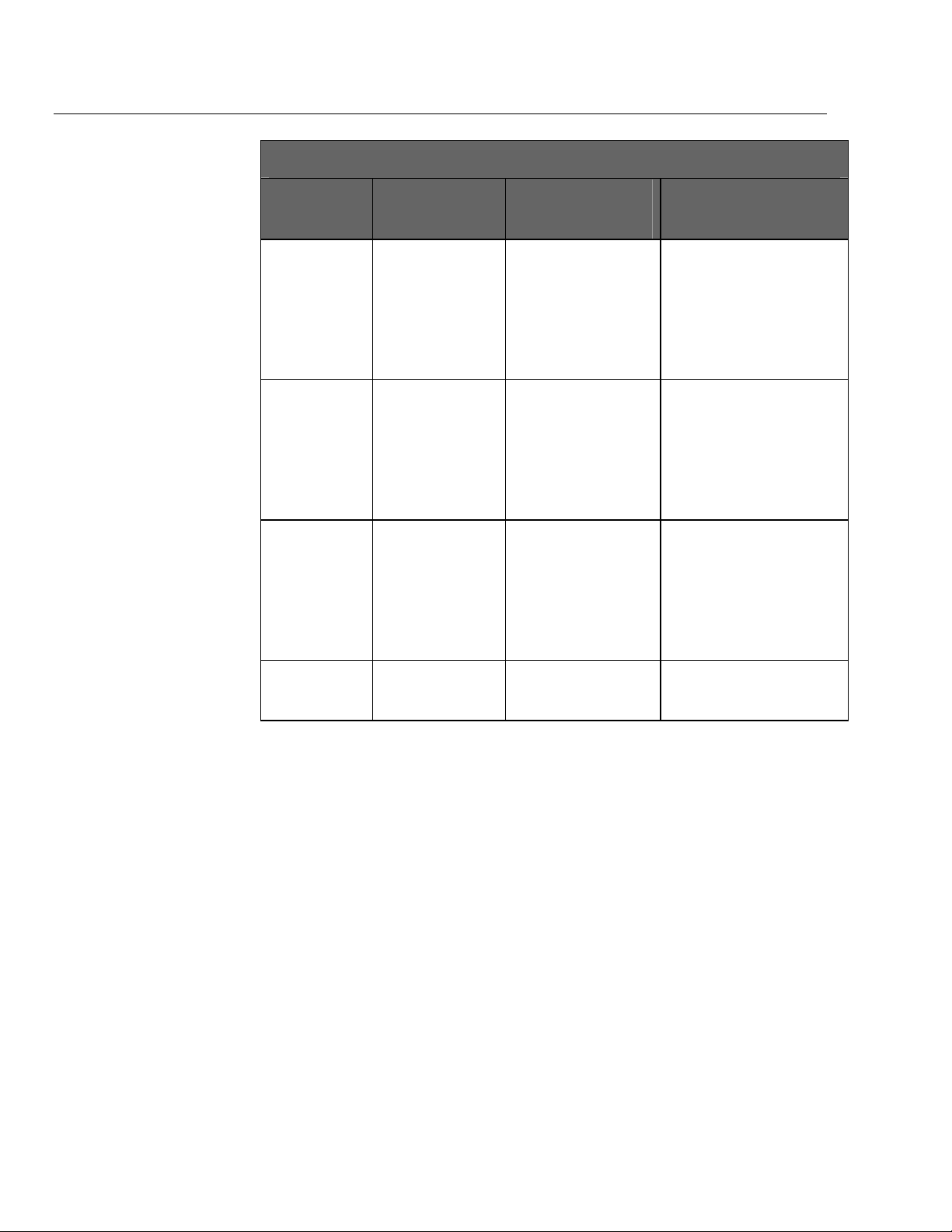

medTester 5000C Modules

medTester

5000C

Module Name

SPO2

Pacer

NIBP

Functions Enabled medTester

Prerequisites for Use of

Module

• SPO2

autosequences.

• Transcutaneous

Pacemaker

autosequences.

• Non-Invasive Blood

Pressure

autosequences.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• Expanded Memory

Module.

• Data Transfer Module.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• Expanded Memory

Module.

• Data Transfer Module.

• RS-232/Printer Module.

• Memory—100 Records

Module.

• Expanded Memory

Module.

• Data Transfer Module.

Required for...

• 10 autosequences for testing

SPO2 monitors with Fluke

Biomedical analyzers.

• Including SPO2

autosequences in checklists.

• 10 autosequences for testing

transcutaneous pacemakers

with the Fluke Biomedical

Impulse 4000.

• Including Pacer

autosequences in checklists.

• 10 autosequences for testing

Non-Invasive Blood Pressure

monitors with the Fluke

Biomedical CuffLink.

• Including NIBP pump

autosequences in checklists.

Bar Code

(hardware)

• Scanning of bar

code data into test

record.

• None • Scanning of data.

1-10

Page 23

Biomedical Test System

General Information

Features

• Fully automated electrical safety testing

• 12–lead ECG/arrhythmia simulation

• Dedicated “autosequence” testing for performance testing of

defibrillators, infusion pumps, etc.

• 20-ampere testing with GFCI protection

• Meets ANSI/AAMI ES1–1993 test load requirements

• Load current measurement

• Programmable test limits

• Automatic record storage

• Bar code compatibility

1

Optional Accessories

• External RS-232 Keyboard

• Bar Code Scanner (requires Wedge adapter)

• Wedge Adapter (eight 25-pin serial ports as well as AT or PS/2

keyboard port)

• Mini PC-Style Keyboard (AT or PS/2, requires Wedge adapter)

• Label Printer

1-11

Page 24

medTester 5000C

Operators Manual

medTester 5000C Instrument Specifications

Line Voltage and Measurements

• Hot to Neutral.

• Neutral to Ground.

• Hot to Ground.

• Range: 200.0 V RMS.

• Accuracy: ±5% of range.

Leakage Current

Leakage current is measured through a 1 kΩ AAMI load RMS or DC

measured and displayed in microamperes. These tests can be thought of as

measuring the voltage, in millivolts across the same load.

Leakage Current Measurements

• Case external.

• Case internal.

• External.

• ECG—Leads are RL, RA, LA, LL, and V1-V6 tied together:

1. To ground, all leads or individual leads.

2. Lead to lead, individual leads to all other leads together.

3. Lead isolation (RMS only), all leads or individual leads.

This test is with line voltage applied from the lead(s) to

ground, current limited by 120 kΩ.

1-12

Note

If you receive abnormally high leakage current measurements

with V1-V6 leads tied together, you can inspect individual V

leads by removing the other leads. This procedure allows you to

isolate the lead with a high leakage current reading.

Page 25

Biomedical Test System

µ

General Information

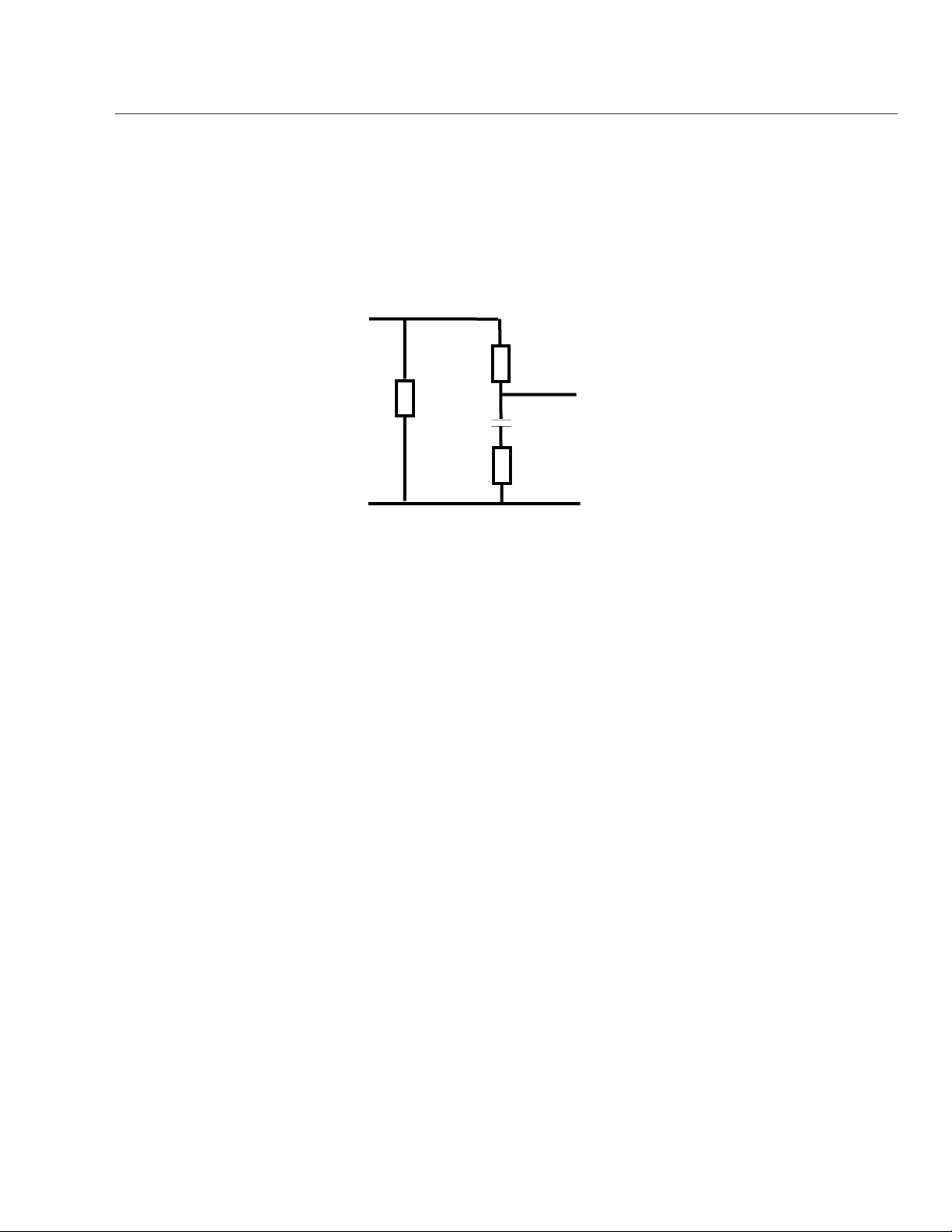

AAMI Load

• Simulated patient load recommended by the Association for the

Advancement of Medical Instrumentation (AAMI), Safe Current

Limits Standard (ANSI/AAMI ES1-1993) (revision of the earlier

ANSI/AAMI ES1-1985 and SCL-12/78).

• AAMI Load drawing:

1

LEAKAGE

CURRENT

INPUT

1 KΩ

10 KΩ

0.015

100 Ω

F

OUTPUT TO

METER

CIRCUIT

• Frequency Response: ANSI/AAMI ES1-1993

• Test Load Impedance: 1000 ohms +/- 1% @ DC

(ANSI/AAMI ES1-1993)

• Ranges—2000 µA and 200 µA.

• Range—20.00 A RMS.

• Accuracy—± 1.0% of reading DC and from 48 Hz to 1kHz

± 2.5% of reading 1 kHz to 100 kHz

± 5.0% of reading 100 kHz to 1 MHz

Equipment Current

Equipment current measures the current used by the EUT plugged into the

test receptacle:

• Range—20.00 A RMS.

• Accuracy—±5% of range.

Resistance

Resistance tests measure resistance with the four-terminal test method:

• Measurements—Power cord and external.

• Range—2 Ω.

• Accuracy—±1% of range.

• Test Current—100 mA

Isolated Power

This feature allows the use of the Fluke Biomedical Model 202A Isolation Test

Module to make current measurements on an isolated power system. For

more information, see Chapter 4, Manual Tests.

1-13

Page 26

medTester 5000C

Operators Manual

Toolbox

Toolbox allows for the use of external measurement adapters for:

• Tachometer—with a range of 100 to 20,000 RPM.

• Temperature—with a range of 0 to 200°F or

0 to 100°C.

• Humidity—ranging from 15% to 90% relative.

For more information about Toolbox, see Chapter 4, Manual Tests.

Test Receptacle

The medTester 5000C has a test receptacle on the top panel into which the

equipment under test (EUT) is plugged. The test receptacle supplies power to

the EUT. The EUT must be powered through the test receptacle whenever

you measure the following:

• Leakage current—All case and ECG lead measurements.

• Equipment current.

• Power cord resistance.

Test receptacle power is normal except during case and ECG leakage tests

(not including isolation tests). For these tests you can set the power to the

following conditions, each of which is indicated by annunciator LEDs on the

top panel:

• Ground—closed or open.

• Polarity—normal or reversed.

• Neutral—closed or open.

Note

During case internal leakage, ground is always open.

Current is supplied at a maximum instantaneous level of 20 amps.

CSA Label

On the back of the medTester 5000C, you can see a label which specifies the

conditions under which the test receptacle can operate:

• 1840 VA, 16 A continuous operation.

• Up to 19 A for no longer than two (2) minutes. Then powered off

for eight (8) minutes (20 percent of duty cycle).

1-14

Page 27

Biomedical Test System

General Information

Ground Fault Circuit Interrupter

The test receptacle is protected by a ground fault circuit interrupter. In the

event of a fault in the EUT (when the test receptacle is powered on) which

causes a current imbalance in the hot and neutral lines of greater than 5 mA,

the interrupter triggers. Under this condition, the interrupter turns off the test

receptacle and all test connections, and the medTester prompts you to correct

the fault and continue.

Performance Waveforms

The medTester 5000C generates ECG waves and arrhythmias to test the

performance of patient monitors in those medTesters that have the

Waveform/Extended Testing Module installed. You can find information

about conducting waveform tests in Chapter 7, Performance Waves.

Specifications for waveforms and arrhythmias are:

ECG Performance Test Waves (Lead I, Vp-p)

• Square Wave—2 Hz, 1 mV

• DC Pulse—4 Seconds, 1 mV

• Sine Wave—0.5, 10, 40, 60, and 100 Hz, 1 mV

• Square Wave—1 kHz, 1 mV

• Triangle—2 Hz, 1 mV

• CMRR—60-Hz sine wave with 1–kΩ imbalance in LA

• Normal Sinus—30, 60, 120, 240 BPM.

Arrhythmias

1

• Atrial fibrillation

• Second degree A-V Block, Type 1

• Premature atrial contractions

• Missed beat at 80 and 120 BPM

• PVC 1 left

• PVC 2 right

• Multifocal PVCs

• PVC 1, R on T

• A pair of PVCs

• Run of 5 PVCs

• Run of 11 PVCs, MF

• Right bundle branch block

• Ventricular tachycardia

• Ventricular fibrillation

• Asystole

1-15

Page 28

medTester 5000C

Operators Manual

General Specifications

Parameter Specification

Power Requirement: 115 V ±10%, 60 Hz only

Temperature Ranges:

Display: 80-character (40 x 2 lines) backlit Liquid

Weight: 5 kg (11 lb)

Dimensions: 25.4 cm L x 35.0 cm W x 10.2 cm H

ECG Connections

Waveforms generated for performance testing can be output through the

binding posts on the medTester 5000C’s top panel or the ECG High-Level

Output located on the medTester 5000C’s back panel.

Operating: 15° to 35°C (59° to 95°F)

Storage: 0° to 50°C (32° to 122°F)

Crystal Display

(10 in L x 13.8 in W x 4 in H)

ECG Binding Posts

• 10 posts, American Hospital Association color–coded,

• RL, RA, LA, LL, V1-V6,

• Compatible with both 3.2–mm and 4.0–mm pins and disposable

snap electrodes.

High-Level ECG Output

• ¼" phone jack,

• 1–volt nominal.

Data Input and Output

• Top panel keyboard (QWERTY-type)—48 characters.

• Bar code reader (optional).

• RS-232C serial ports (2) for computer interface or auxiliary test

instrument control, expansion to an additional eight (8) ports with

the Wedge Adapter.

• Parallel printer port (1).

RS-232C Serial Interface Parameters

• Baud—300, 600, 1200, 2400, 4800, 9600, 19200.

• Stop Bits—1.

• Parity—Off.

• Data Length—8 bits.

Real Time Clock

Real time clock is kept internal to the instrument.

1-16

Page 29

Biomedical Test System

General Information

Accessories

1

Standard

• 20/15–amp Adapter

• Two Kelvin Cable

• Two Ground Pin Adapters

• Operator Manual

• Accessory Pouch

Optional

• Interface Cable, medTester to

PC

• Interface Cable, medTester

5000C to Patient Simulator

• Interface Cable, AT-Style PC

Adapter Cable

• Interface Cable, medTester to

Impulse 3000

• Interface Cable, medTester to

Impulse 4000

• Interface Cable, medTester to

Oxitest Plus/Plus7

• Interface Cable; medTester to

Infutest 2000 Series D

• Interface Cable; medTester

Wedge to IDA 4 Plus

• Interface Cable; medTester to

RF303RS. Requires adapter

2391789.

• Adapter; for medTester to

RF303RS with 2238659

• Interface Cable, medTester to

PC/454A/CuffLink; Impulse

4000 to PC

• Interface Cable, medTester to

SigmaPace™ 1000/402A/PC/

IPT-MC/Index 2XL/IDA 4

Plus (IDA 4 Plus to Wedge use

2201042); Impulse 4000 to PC

• Interface Cable, medTester to

IPT-1

• Interface Cable, medTester to

IPT-MC

• Printer Cable, medTester to

TLP-1 & TLP-2 Test Label

Printer

2195732

2392617

2242165

2243153

2392871

RS-232; Female DB25 to

Female DB25

RS232; Right Angle DIN to

Female DB25

RS232; DB9 to DB25, for

use w/2392186

RS232, Straight DIN to

Female DB25

RS232; Female DB25 to

Female DB25

RS232; Female DB25 to

mini DIN

RS232; Female DB25 to

Female DB25

RS232; Female DB9 to

Female DB25

RS232; Male DB9 to

Female DB9

Adapter; Male DB9 to

Female DB25

RS232; Female DB25 to

Female DB25

RS232; Female DB25 to

Female DB9

RS232; Female DB25 to

Male DB25

RS232; Female DB25 to

Female DB9*

Serial Cable;

Part #

Part #

2392186

2200808

2199233

2199346

2200252

2237730

2237604

2201042

2238659

2391789

2392186

2200102

2392251

2201042

2200717

1-17

Page 30

medTester 5000C

Operators Manual

Optional (continued)

• Printer Cable, medTester to

standard PC printer

• TLS Test Tag Printer Kit

Serial Cable; Male DB25 to

Centronics

Printer, white and yellow

Part #

2200577

2245515

vinyl labels, black vinyl

printer ribbon, serial cable,

adapter and US power

source

• TLP-1/2 Printer Paper, Yellow

• TLP-1/2 Printer Paper, Blue

• TLP-1/2 Printer Paper, White

• TLS Label Roll Vinyl White

• TLS Label Roll Vinyl Yellow

• TLS Label Roll Vinyl Orange

• TLS Label Roll Vinyl Red

• TLS Label Roll Vinyl Blue

• TLS Label Roll Vinyl Green

• TLS Printer Ribbon Vinyl

2220045

2220038

2220023

2243893

2243902

2243916

2243925

2243933

2243940

2243957

Black

• Adapter DB-9 M to DB-25 F

• Service Manual

• Wedge Adapter

• PC Wedge Laser Barcode Gun

• Mini PC-style Keyboard

• Multi-purpose Hard-Sided

Carrying Case (contains “Pick

& Pluck” foam)

• Multi-purpose Hard-Sided

Carrying Case (contains “Pick

& Pluck” foam)

* Part #2200102 will interface with the IPT-MC directly for the medTester ONLY.

Part #2201042 will interface with the IPT-MC directly to medTester OR through the Wedge accessory.

2391789

2243166

2245264

2245092

2245061

Fits medTester with Wedge

(29” L x 18” W x 10½” H)

2248606

Fits medTester without

Wedge (19” L x 14” W x

2248587

7¾” H)

1-18

Page 31

Biomedical Test System

General Information

medTester 5000C Module Upgrades Part #

Factory Installed

• Module 2, Service, RS-232/Printer

• Module 3, Service, 100 Records

• Module 4, Service, Expanded Memory

• Module 5, Service, Waves/Extended Test

• Module 6, Service, Data Transfer

• Module 7, Service, medCheck

• Module 8, Service, Defibrillator

• Module 9, Service, IV Pump, IPT

• Module 10, CMMS Interface

• Module 11, Service, ESU

• Module 12, Service, SPO2

• Module 13, Service, Pacer

• Module 14, Service, NIBP

2246094

2246100

2246117

2246121

2246139

2246142

2246156

2246163

2246174

2246188

2246195

2246206

2246214

1

Field Installed

• Module 2, Field, RS232/Printer

• Module 3, Field, 100 Records

• Module 4, Field, Expanded Memory

• Module 5, Field, Waves/Extended Test

• Module 6, Field, Data Transfer

• Module 7, Field, medCheck

• Module 8, Field, Defibrillator

• Module 9, Field, IV Pump, IPT

• Module 10, Field, CMMS Interface

• Module 11, Field, ESU

• Module 12, Field, SPO2

• Module 13, Field, Pacer

• Module 14, Field, NIBP

2246238

2246245

2246250

2246261

2246277

2246289

2246292

2246303

2246315

2246326

2246332

2246344

2246359

1-19

Page 32

medTester 5000C

Operators Manual

1-20 2-1

Page 33

Chapter 2

Installation

In this chapter you will find information about the default

(factory) settings, power-up sequence, setting the time and

date, and using the beeper.

Factory Default Settings

The medTester 5000C is shipped from the Fluke Biomedical factory with the

settings described below.

FACTORY DEFAULT SETTINGS

Condition Name Default Setting(s)

Headers

Prompts

Pause

Tag

Record Summary

Bar Code

Stored entries

Baud Rates

Temperature Scale

• All headers are cleared.

• Header #1 is set to active.

• All prompts are set to ON.

• Renameable prompts set to the default

names: CONTROL#, SERIAL#, PHYSICAL

INSPECTION#, COMMENTS.

• Set to none.

• All items set to ON.

• Fields are set with the following name and

character width:

• CONTROL#, 12 characters

• MANF, 12 characters

• MODEL, 12 characters

• SERIAL#, 12 characters

• LOC, 12 characters

• OP CODE, 3 characters

• All prompts set for single entry.

• OP CODE, LOC, NEXT TEST DUE DATE

are cleared.

• Both COM ports set to 9600.

• Set to Fahrenheit scale.

Page 34

medTester 5000C

Operators Manual

FACTORY DEFAULT SETTINGS

Condition Name Default Setting(s)

Output

Printer Page

Beeper

Memory

Wedge Adapter

• RECORD and TAG output set to:

• COM1–OFF

• COM2–OFF

• PRINTER–ON

• Set to 60 lines for records.

• Set to 5 lines for tags.

• KEYS set to three (3).

• ALERT set to six (6).

• Erased for both test records and checklists.

• Disabled

Power-Up Sequence

When you turn on the medTester 5000C, the following power-up sequence

takes place:

1. Introductory Message—These items below appear in the

medTester 5000C display:

• The text FLUKE BIOMEDICAL MEDTESTER 5000C.

• The serial number.

• The firmware version number.

2. Tests—The medTester tests the condition of its internal

battery and the condition of the line voltage into which the

medTester 5000C is connected. A message appears on the

medTester display only if the medTester detects an irregular

condition. See the list of error messages and conditions below.

After the message appears, you can press

F5 CONTINUE to

continue any remaining tests. If no message displays, menu

one appears similar to this one:

00/00/00 MENU 1 00:00:00

AUTO

F1

MANUAL

F2

WAVES

F3

CHECK

F4

UTIL

F5

2-2

Page 35

Biomedical Test System

Installation

medTester 5000C Power-Up Condition Messages

Message Condition Indicated

LOW BATTERY, SERVICE REQUIRED! Internal battery (used for memory and clock

backup) level is low.

LOW LINE VOLTAGE! Hot to neutral is less than (<) 90 V.

HIGH LINE VOLTAGE! Hot to neutral is greater than (>) 135 V.

OPEN GROUND OR ISOLATED POWER SYSTEM! Hot to ground differs from neutral to ground by

more than 50 V.

REVERSE POLARITY OUTLET! Neutral to ground is greater than (>) 70 V and hot

to ground less than (<) 35 V.

Initialization

You can initialize your medTester with two different local keyboard

commands which you can type at the main menu.

• INIT + Enter—Initializes autosequences and custom features with

YES or NO prompts for each section. This initialization command

does not erase test records or checklists from memory

2

• INITALL + Enter—Initializes the entire instrument with no

exceptions. All test records and checklists are erased from memory

with this option.

Date and Time Setup

Date uses the month/date/year format, and time uses the hour:minute:second

format. Note that time is entered in the 24-hour format. To reset the date and

time:

UTIL

1. Enter menu commands:

See note below.

2. Enter the date and time directly from the keyboard, or…

F5

Use the keyboard left and right arrow keys to move to the desired

month/date/year or hour/minute/second data entry point.

3. Enter the desired data from the keyboard, or use the up/down

keys to increment or decrement the data.

CLOCK

F4

2-3

Page 36

medTester 5000C

Operators Manual

After entering date and time, insert a thin, non-metallic device in

4.

the “clock set enable switch” slot (labeled on the right side of the

medTester) to depress the switch and enter the following menu

STORE

command to store this information:

F5

Press Esc to escape this procedure and to keep current settings.

Note

There is an INIT, F4, menu to initialize the date and time of a

new instrument. The “clock set enable switch” must be pressed

as in step 4 above, to save this initialization.

Audio Transducer

The medTester 5000C comes with an audio transducer that beeps whenever

data is entered from the keyboard or during an alert situation. You can adjust

the volume of the beeper:

UTIL

1. Enter menu commands:

2. To change the beeper volume of keyboard entries or to change

the volume of an alert, press either

VOLUME

3. Press

F3

to increase the volume to the desired level for

F5

KEYS

F1

BEEPER

F5

or

ALERT

F2

keys or alert, depending upon which beeper key you pressed

above. Volume Levels are 0-6 with 0 inaudible and 6 the loudest.

4. Test the beeper level by entering the menu command:

TEST

F4

5. After entering beeper volume, enter the following menu

command to store this information:

STORE

F5

2-4

Press Esc to escape this procedure and to keep current settings.

Page 37

Biomedical Test System

Installation

Enabling Modules

If it should become necessary to reinstall modules 2 through 14, perform the

steps described below. You need to install each module from its separate

diskette. Installation requires running a program on an IBM-compatible

personal computer.

Note

You MUST install the modules that you have received in

numerical order, starting with Module 2, or the lowest numbered

module you have. Installing modules in numerical order will lead

to a successful installation.

1. Use the medTester 5000C COM1 port.

2. Decide on a computer COM port—(COM1 through COM4).

2

3. Decide on a baud rate—(300, 600, 1200, 2400, 4800, 9600, or

19200).

4. To change the medTester baud rate from MAIN MENU 1:

A. Press F5 UTIL, then F1 BAUD;

B. Select the COM1 port;

C. Press F4 BAUD until the desired baud rate is displayed;

D. Press F5 STORE; Press Esc twice to return to MAIN MENU 1.

Note

If Module 2 (RS-232/Printer) has not yet been installed, the

medTester baud rate is not selectable and can not be adjusted. It

is permanently set to 9600. After you install Module 2, you can

change the baud rate.

5. Connect the computer COM port to the medTester COM1 port

(medTester to PC null modem serial cable).

6. Run the computer in DOS mode (command prompt).

2-5

Page 38

medTester 5000C

Operators Manual

Note

If running Windows 95 or 98, with the mouse you can click and

hold the Start button, then select Programs and MS-DOS Prompt.

If running Windows 2000 or XP, with the mouse click the Start

button, select Programs, Accessories, and Comnmand Prompt.

7. Insert the diskette into the computer's 3.5" floppy disk drive.

8. At the DOS prompt type this command:

A:\INSTALL port baud <Enter>

Where A is the floppy disk drive letter, A or B, and

port is the computer COM port, 1 through 4, and

baud is the selected baud rate: 300, 600, 1200, 2400, 4800, 9600,

or 19200.

Here’s an example of this command:

A:\INSTALL 1 9600<Enter>

9. The program will install (enable) the module in the medTester.

The computer should display MODULES SUCCESSFULLY

LOADED

.

Note: If you have problems or get a different message, you can

read the README file by typing A:README<Enter> for

suggestions.

Modules are customized for each instrument and can only be

installed on the instrument with that specific serial number. Some

modules need prerequisite modules to be installed first.

MODULE PREREQUISITE REQUIREMENTS

Module

2 RS232 / Printer None

3 100 Record Storage Module 2

4 Expanded Record Storage Modules 2 & 3

5 Waveforms / Extended Testing Modules 2 & 3

6 Data Transfer Modules 2 & 3

7 MedCheck Modules 2, 3, & 4

8 DEFIB Autosequences Modules 2,3, & 4

9 IVPUMP Autosequences Modules 2,3, & 4

10 Competitive CMMS Interface Modules 2,3,4,6 &

11 ESU Autosequences Modules 2,3, & 4

12 SPO2 Autosequences Modules 2,3, & 4

13 PACER Autosequences Modules 2,3, & 4

14 NIBP Autosequences Modules 2,3, & 4

Description Prerequisite

7

2-6

Page 39

Biomedical Test System

Installation

10.

To install more than one module, repeat steps seven (7) through

nine (9) for each module which has an installation disk. Install

them in numerical order.

11. If necessary, return to Windows from Command Prompt by

typing: EXIT<Enter> at the DOS prompt.

Confirming Module Installation

1. Turn the medTester 5000 power off to reset the microprocessor.

2. Turn the medTester 5000 power on. Check that the startup

message shows the correct instrument serial number and the

correct firmware version number.

3. Push F5 UTIL, then right arrow, then F3 MODULES. At this point,

each press of F5 NEXT will sequentially scroll through each

installed module allowing you to confirm the modules installed in

the medTester 5000.

2

2-7

Page 40

medTester 5000C

Operators Manual

2-8 3-1

Page 41

Chapter 3

Instrument Familiarity

This chapter familiarizes you with the medTester 5000C.

Know Your medTester 5000C

The medTester 5000C has two major control and interface sections—the top

panel and the rear panel. Below is a list of the controls, displays, and

connectors on these two panels. The numbers in the list refer to the locations

in Figure 3-1.

Top Panel Controls, Displays, and Connectors

1. ECG LEADS Binding Posts—There are ten binding posts used for

ECG leads whenever you test a device with patient leads. Connect

the patient leads to these posts. These posts accept snap

connectors, and you can unscrew the sleeves to expose a 4–

millimeter (mm) hole to which you attach diagnostic pin

electrodes or banana plugs.

2. TEST RECEPTACLE—Power receptacle for the equipment under

test (EUT).

3. DISPLAY—The LCD display contains two lines of 40 characters

each. See number nine (9) in this list.

4. DISPLAY ANNUNCIATORS—Eight LEDs, which when lit, indicate

coinciding test status conditions; that is CURRENT SOURCE, ISO

VOLTS

, OPEN GROUND, CLOSED GROUND, REV POLARITY (reversed

polarity), NORM POLARITY (normal polarity), OPEN NEUTRAL, and

CLOSED NEUTRAL.

5. ESCAPE KEY—Used to return to a previous menu or to abort an

operation.

Page 42

medTester 5000C

Operators Manual

11

10

8

12

9

1413 15 16 17 18 19

1

2

3

MED TESTER 5000

4

5

7

Figure 3-1. MedTester 5000C Top and Rear Panel Locator

6

3-2

Page 43

Biomedical Test System

Instrument Familiarity

6. ARROW KEYS—Control cursor movement when entering data into

the display from the keyboard and scroll through menus

horizontally. See Navigating the Menus later in this chapter.

7. KEYBOARD—Standard QWERTY-type keyboard with numeric

characters 0-9 and full alpha character list. The spacebar key is

positioned at the lower right-hand corner, and there is one shift

key and one control key. Special editing keys are located at the

SHF+KEY positions of numbers 1-4; for example, SHF+2 keys to

insert.

8. FUNCTION KEYS—Five function keys, F1 through F5. Used to

select menus, menu commands, and menu options. See Navigating

the Menus later in this chapter.

9. DISPLAY KEYS—Two keys, one white and one black. Pressing the

white key increases the display brightness. Pressing the black key

decreases the display brightness. Pressing these keys also changes

the viewing angle.

10. TEST POINTS—Four test points including a 100–µA test point,

two 0.5–ohm test points, and one ground stud.

3

11. EXTERNAL METER POSTS—Two pair of red and black binding

posts. One for external input (EXT INPUT) measurements. One for

a 100–mA CURRENT SOURCE used for resistance measurements.

Rear Panel Controls, Displays, and Connectors

12. BAR CODE PORT—For use with the optional bar code reader

wand.

13. PRINTER PORT—For use with printers compatible with personal

computers.

14. COM2 PORT—Receives input locally from the optional keyboard,

bar code scanning gun, or personal computer or terminal. Outputs

data to a personal computer or terminal. Also used by the

medTester 5000C for two-way communication with other Fluke

Biomedical test devices and for data output to personal computers

or a serial terminal. See Chapter 12, Remote Operation. With a

Wedge adapter, this port is expanded to eight ports on the Wedge.

15. HIGH-LEVEL ECG OUTPUT—A ¼" telephone jack with a Lead I

waveform at 1 V/mV of the low-level Lead I signal.

3-3

Page 44

medTester 5000C

Operators Manual

COM1 PORT—Receives input locally from the optional keyboard,

16.

bar code scanning gun, or personal computer or terminal. Outputs

data to a personal computer or terminal. With a Wedge adapter,

this port is used by the external PC keyboard interface.

17. FUSE—Twenty (20) ampere, slow-blow type, 250 V.

18. POWER SWITCH—Powers the medTester 5000C on or off.

19. POWER CORD and PLUG—The hardwired power plug is a 20A

configuration. For most testing leave the 20A to 15A adapter plug

on to plug into a 15A outlet.

Power Up

Locate the power switch on the rear panel, and power on the

medTester 5000C. The name and revision appear followed by the main menu.

To darken or lighten the display, use the DISPLAY keys to the left of the

display. The black-circled key darkens the display. The white-circled key

lightens the display.

Navigating the Menus

Operating the medTester 5000C is as easy as pressing the function key on the

top panel that corresponds to the desired menu item in the display. There are

five function keys marked F1 through F5 below the display (see the figure

below). The function keys select the menu functions that appear in the display

just above them. The medTester 5000C is operated through menu choices in

a tree-like structure. When you power on the medTester, the first menu you

see sits at the top of the tree. As you make menu choices, you move to lower

levels, or branches, of the tree. The menu you see below is the main menu.

3-4

00/00/00 MENU 1 00:00:00

AUTO

F1

MANUAL

F2

WAVES

F3

CHECK

F4

UTIL

F5

Note the right arrow located at the right edge of the menu. Whenever you see

a right arrow on a menu, it indicates that there are more menu items at the

same level. Access those items by pressing the right arrow key on the

keyboard. What you then see on the display is:

Page 45

Biomedical Test System

Instrument Familiarity

00/00/00 MENU 2 00:00:00

3

MEMORY

F1

TOOLBOX

F2

CUSTOM

F3

The display now shows menu two. Remember that menu two is an extension

of menu one. Menu-two menu items are at the same level as menu one items.

Menu two contains a left arrow which indicates that there are menu items

which you can scroll to by using the left arrow key. Pressing the left arrow

returns you to menu one.

3-5

Page 46

medTester 5000C

Operators Manual

3-6 4-1

Page 47

Chapter 4

Manual Tests

Learn to use the medTester 5000C to manually perform