Page 1

It doesn’t take out

the garbage... yet

Introducing the Fluke 430 Series

Three-Phase Power Quality Analyzer

Application Note

It’s about time.

For the last several years, tool

users have told Fluke they

needed a three phase Power

Quality Analyzer to audit and

troubleshoot critical power applications in the facility, starting at

the service entrance.

No matter whether they were

a consultant or a facility technicians, the story was the same:

They needed to pinpoint power

quality problems quickly, and for

that, they needed detailed information. In particularly candid

moments, some admitted that if

the available monitoring devices

weren’t so hard to use, so expensive, or so heavy to lug around,

they would probably conduct

preventive maintenance more

.

often

Fluke’s answer is the 430

series handheld power quality

zer.

analy

Three-phases and four

•

channels

Rated for use at the service

•

entrance: CAT IV 600 V/

CAT III 1000 V

Sets up in less than one

•

minute

Simple, menu-driven interface

•

Automated recording and

•

analysis

Weighs just over three pounds

•

Includes analyzer, case, 4

•

dual-range clamps and 5

voltage clips and leads

Troubleshooting and

preventive maintenance

for all

Designed for power quality

specialists as well as electricians

and plant technicians working in

industrial, healthcare, business,

and public services settings,

the Fluke 430 Series is ideal for

troubleshooting and preventive

maintenance.

The Fluke 430 Series can

measure all phases, neutral and

ground on virtually every connection in a low voltage electrical

distribution system. The analyzer’s

measurement capabilities encompass all power system parameters

including true-rms voltage and

current, frequency, power, power

consumption (energy), unbalance

and flicker. They also automatically capture events like transients

(as fast as 5 microseconds and as

high as 6 kV), interruptions, rapid

voltage changes and dips and

swells.

Optimized for mobile

applications, these ruggedized

instruments operate up to seven

hours on a single battery charge

— no more searching for an

outlet! The large data memory

stores up to 50 screens and up to

10 measurements each comprising

32 parameters — including setups

and trend data — recorded for

more than a year, all of which

can be transferred to a PC via

FlukeView

or use in reports.

® software for analysis

From the Fluke Digital Library @ www.fluke.com/library

Page 2

Fluke 430 series features

The two most unique features are

AutoTrend, which records everything on the screen automatically

without setting a trigger, and

System-Monitor, a quick diagnosis of system performance against

user defined limits. Other features

include:

Viewing stored data while

•

continuing to record.

Switching back and forth from

•

digital display to trend without

interrupting the recording.

Optically isolated so you can

•

record while downloading

information to your PC.

High resolution, color LCD

•

for viewing multiple parameters and multiple phases

simultaneously.

Waveform capture lets you

•

test for interaction between

phases or between voltage

and current.

Triggering on envelope — or —

•

trigger on rms voltage or

current.

Screen cursors allow you to

•

pinpoint problems, quickly.

Capturing transients and

•

waveform disturbances with

5 µs resolution.

Toggling to phase or display at

•

any time for a quick check of

phase sequence.

Together these features help to

quickly diagnose problems and

enchmark

build b

maintenanc

study provides one such example.

s for predictive

e. The follow

ing case

Case study: Three-phase

motor failure

or three years in a row, a partic

F

ularly large three-phase motor

would fail twice a year. The facility maintenanc

in both the electrical contractor

and the motor manufacturer, who

pointed fingers at each other but

failed to resolve anything on site.

The facility was left in the mid-

ith no c

dle, w

cyclical motor repair costs, and

lost production from the repeated

ntimes

dow

e manager called

orrective action,

.

Tired of what was clearly a

pattern failure, the facility

manager hired an independent

consultant. The consultant told

the facility manager he would

perform a complete power quality

survey of the electrical distribution system feeding the motor,

determine its operating characteristics and work from there to

solve the problem.

Measurements

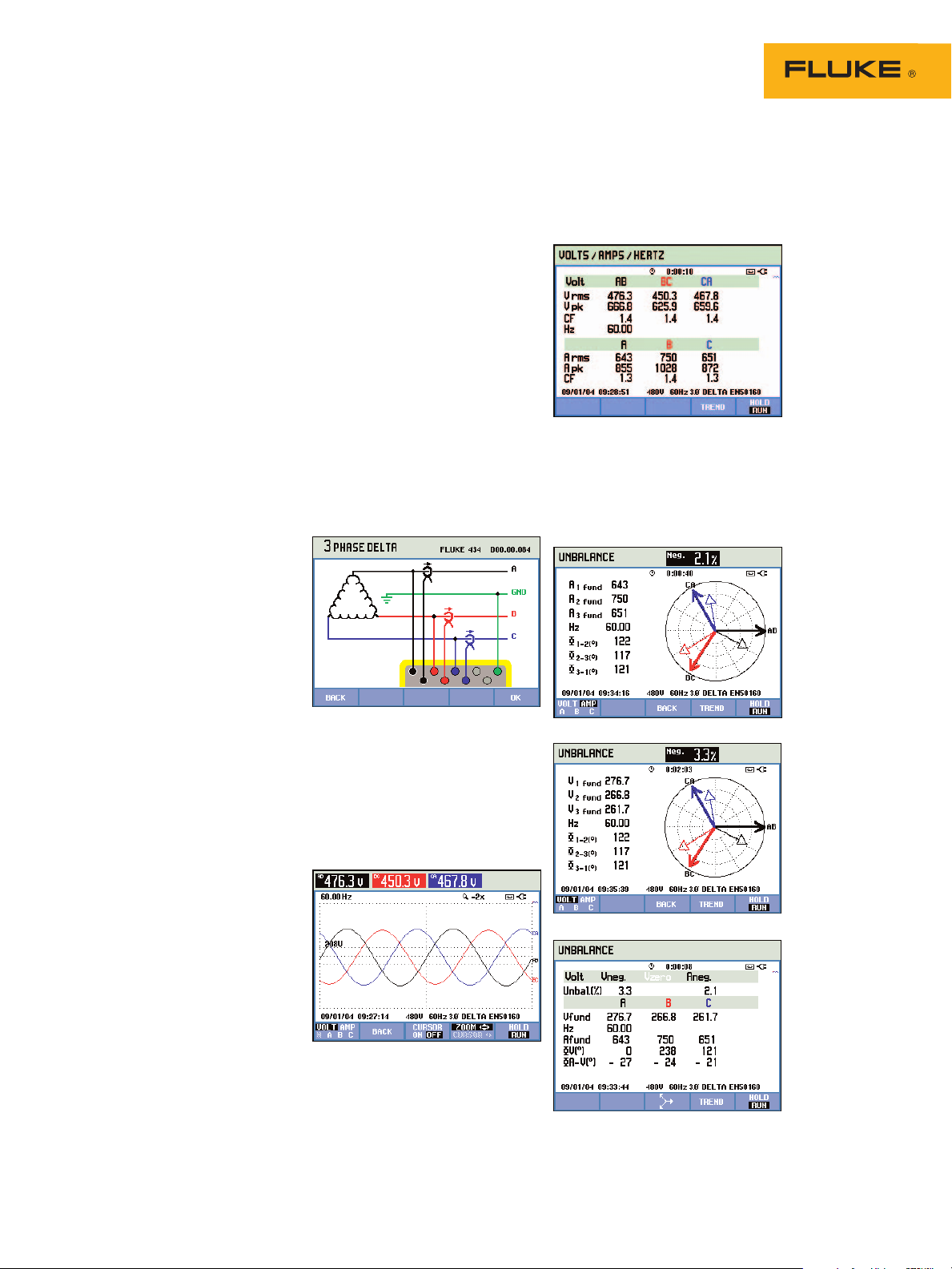

The consultant connected his

Fluke 434 Three-Phase Handheld

ower Quality Analyzer to the

P

ircuit supplying energy to the

c

motor and pushed the View

Config button

firmed that his connections were

proper and that the power type

was three-phase Delta.

From there, he pushed the

Scope button and looked at

waveforms and numeric values for

all three phases. Judging by the

differences between the magnitudes at the top of the screen,

there appeared to b

problem between the phases.

-

. The diagram con-

e a balanc

To gather more information, he

switched to the numeric readout

on the Voltz/Amps/Hertz screen.

The current reading there was

even higher and still unbalanced.

Switching to the Unbalance

screen, he checked the voltage

and current values as well as the

phase diagram, to see if the

motor was operating within

acceptable limits.

e

2 Fluke Corporation Logging and analyzing events with FlukeView® Forms Software

Page 3

Lastly, to cover his bases,

he selected Harmonics from the

menu to make sure frequencies

weren’t contributing to the

problem.

Analysis

From his unbalance measurements, he could see that an

unbalance was causing an

excessively large phase current

value. He checked the motor

specifications and confirmed that

phase current exceeded the

motor’s FLA (Full Load Amperage)

rating. Looking at the data for all

three phases, he traced the

current unbalance to excessive

loading on one voltage phase.

The consultant traced the

voltage unbalance to a set of

equipment installed three years

ago. It turned out that all of the

internal single-phase loads were

connected to the same phase.

That last new equipment installation caused such a significant

power system voltage unbalance

that it created a current unbalance at the motor, increasing

the operating temperature of the

conductors and motor windings

to beyond the limits.

Conclusion

To resolve the situation, the

consultant balanced the internal

single-phase loads between

the three phases, reducing the

overall voltage unbalance and

consequently, the current unbalance at the motor. This also

reduced the elevated phase

current value and operating

temperature at the motor.

He took new benchmark

measurements for future monitoring, transferred all of his saved

screens to his computer and

printed a before-and-after report

for the facility maintenance

manager.

While not a power quality

expert, the manager could see the

difference between the screens.

Now he understood why power

quality measurements needed to

be taken before and after new

equipment installation. All of the

motor repair and downtime costs

had been un-necessary. When the

consultant suggested setting up a

regular preventive maintenance

schedule, the manager agreed.

3 Fluke Corporation Logging and analyzing events with FlukeView® Forms Software

Fluke. Keeping your world

up and running

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The N

For more information call:

In the U.S.A. (800) 443-5853 or

ax (425) 446-5116

F

In Europe/M-East/Africa (31 40) 2 675 200 or

Fax (31 40) 2 675 222

In Canada (8

Fax (905) 890-6866

From other c

ax +1 (425) 446-5

F

Web access: http://www.fluke.com

©2004 Fluke Corporation. All rights reserved.

Printed in U

etherlands

LU

F

00) 36-

ountries +1 (425) 446-5500 or

6

1

1

. 9/2004 2394

.A

.S

.

E or

K

162 A-US-N Rev A

Loading...

Loading...