Page 1

The costs of poor

power quality

Productivity is the key to survival in today’s globally competitive environment. When

you think about the basic inputs to production—time, labor, and materials—you can

see there isn’t much room for optimization. You have 24 hours per day, labor is costly,

and you don’t have much choice in materials. Thus, every company must use automation to gain more output from the same inputs, or perish.

So, we rely on automation, which in turn relies on clean power. Power quality

problems can cause processes and equipment to malfunction or shut down. And the

consequences can range from excessive energy costs to complete work stoppage.

Obviously, power quality is critical.

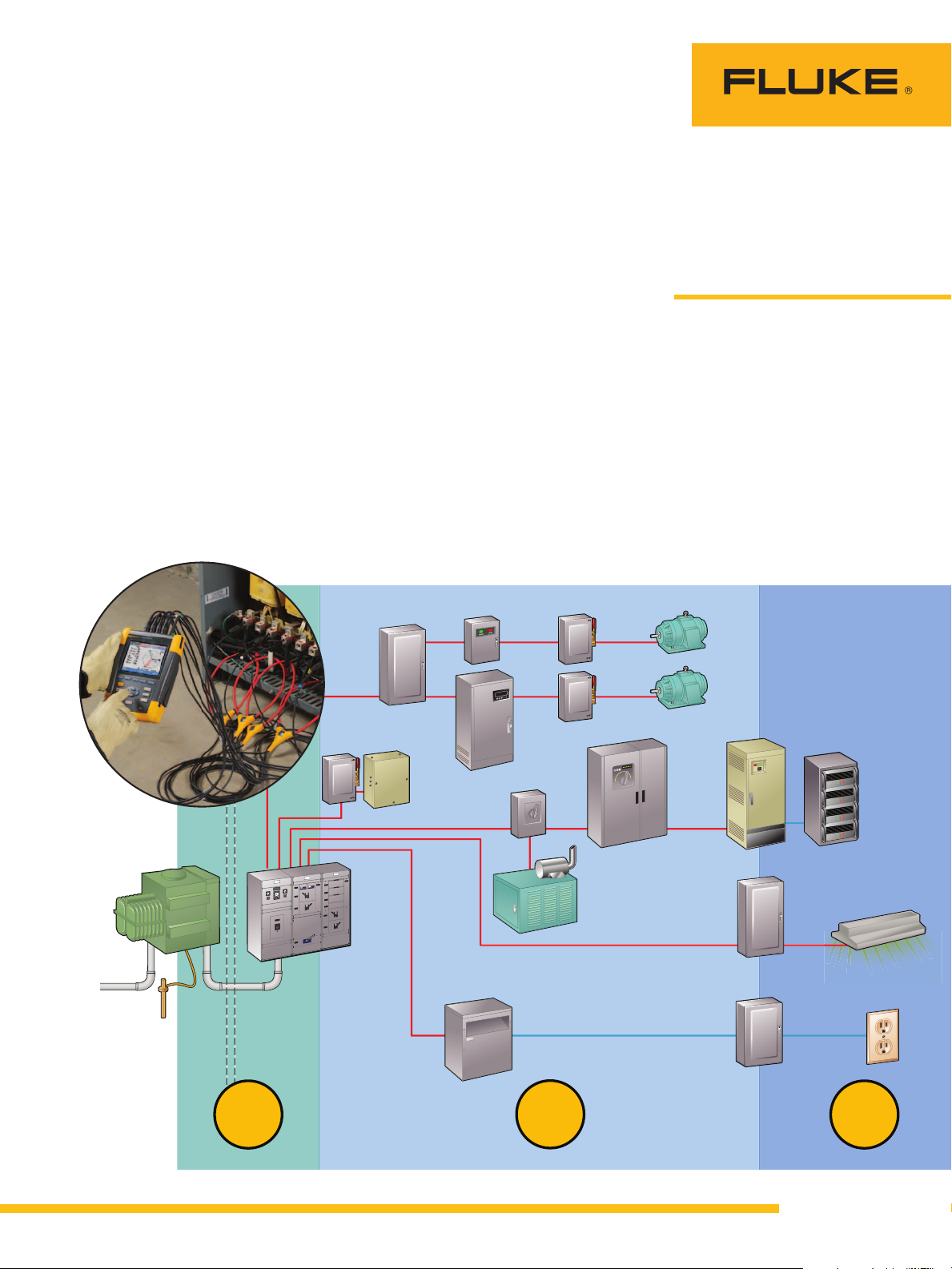

Starter Disconnect

480 V

panel

000124

Power

Disconnect

factor

correction

capacitors

Adjustable

speed motor

drive

Disconnect

Application Note

Motor

Motor

Transfer

Utility

power

Ground

system

480 V

CAT IV

600 V

Main switchgear

switch

Transformer

CAT III

1000 V

Emergency

generator

UPS

From the Fluke Digital Library @ www.fluke.com/library

PDU

480 V/

277 V

panel

120 V/

202 V

panel

Servers

Lighting

Receptacle

CAT II

300 V

Page 2

The interdependence of various

systems adds layers of complexity to power quality issues.

Your computers are fine, but the

network is down so nobody can

book a flight or file an expense

report. The process is operating correctly, but the HVAC has

shut down and production must

stop. Mission-critical systems

exist throughout the facility and

throughout the enterprise—power

quality problems can bring any

one of these to a grinding halt at

any time. And that will usually

be the worst possible time.

Where do power quality problems come from? Most originate

inside the facility. They may be

due to problems with:

• Installation—improper ground-

ing, improper routing, or

undersized distribution.

• Operation—equipment

operated outside of design

parameters.

• Mitigation—improper

shielding or lack of power

factor correction.

• Maintenance—deteriorated

cable insulation or grounding

connections.

Even perfectly installed and

maintained equipment in a

perfectly designed facility can

introduce power quality problems as it ages.

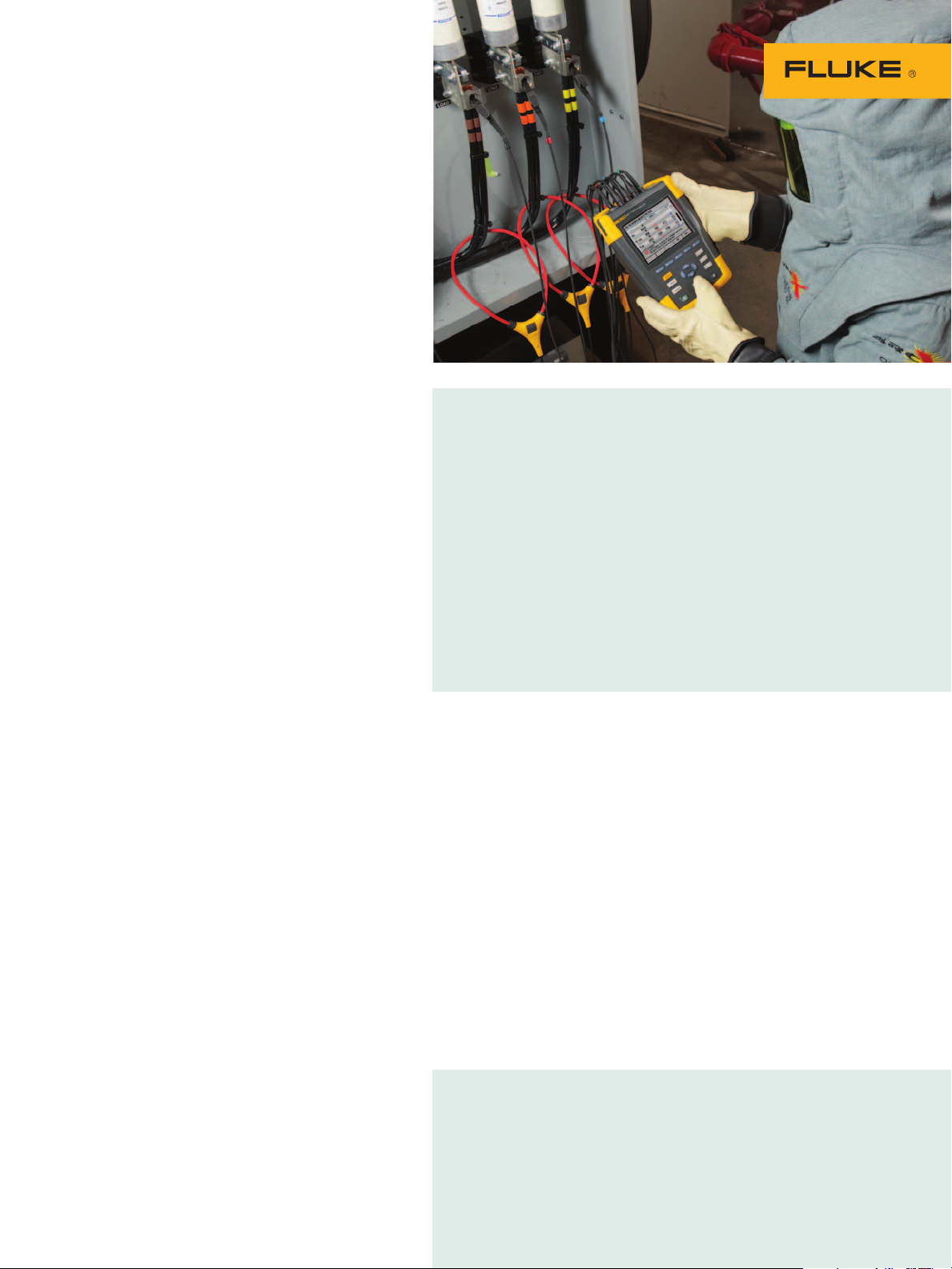

The direct measurement of

wastes due to poor power quality can be achieved with the

Fluke 430 Series II instruments,

which directly measure waste

due to harmonics and unbalance,

and quantify the cost of that

waste based on the unit cost of

power from the utility.

Power quality problems can

also originate from outside the

facility. We live with the threat

of unpredictable outages, voltage sags, and power surges.

Obviously, there’s a cost here.

How do you quantify it?

Let’s walk through an example. Your factory makes 1,000

widgets per hour, and each widget produces $9 of revenue. Thus,

your revenue per hour is $9,000. If your costs of production are

$3,000 per hour, your operating income is $6,000 per hour when

production is running. When production is down, you lose $6,000

per hour of income and you still have to pay your fixed costs

(e.g., overhead and wages). That’s what it costs to be down. But,

downtime has other costs associated with it:

• Scrap. How much raw material or work in process do you have

to throw away if a process goes down?

• Restart. How much does it cost to clean up and restart after an

unplanned shutdown?

• Additional labor. Do you need to pay overtime or outsource

work to respond to a downtime incident?

Downtime

To quantify system downtime

costs, you need to know two

things:

1. The revenue per hour your

system produces.

2. The costs of production.

Also, consider the business

process. Is it a continuous, fully

utilized process (e.g., a refinery)?

Must your product be consumed

when produced (e.g., a power

plant)? Can customers instantly

switch to an alternative if the

product is not available (e.g., a

credit card)? If the answer to any

of these questions is yes, then

lost revenue is difficult or impossible to recover.

Are you an OEM producer? If

you can’t make timely deliveries,

your customer may switch to a

source that can.

Equipment problems

Exact costs are hard to quantify,

because you are dealing with

many variables. Did that motor

really fail from excess harmonics, or was there some other

cause? Is Line Three producing

scrap because variations in the

power supply are causing variations in machine performance?

To get the correct answers, you

need to do two things:

1. Troubleshoot to the root

cause.

2. Determine the actual costs.

Measuring power

quality costs

Power quality problems make

their effects felt in three general

areas: downtime, equipment

problems, and energy costs.

2 Fluke Corporation The costs of poor power quality

Here’s an example. Your factory is making plastic webbing that

must be of uniform thickness. Operators consistently report high

scrap rates in the late afternoon. You can directly trace machine

speed variances to low voltage caused by heavy HVAC loads. The

operations manager calculates the net scrap costs are $3,000 per

day. That’s the revenue cost of your low voltage. But, don’t forget

other costs, such as those we identified for downtime.

Page 3

Useful kilowatts (power available)

Reactive (unusable) power

Kilowatts made unusable

by unbalance issues

Kilowatts made unusable

by harmonics

Neutral current

Total cost of wasted kilowatt hours

Energy costs

To reduce your power bill, you

need to record consumption

patterns and adjust the system

and load timing to reduce one or

more of the following.

1. Actual power (kWh) usage

2. Power factor penalties

3. A peak demand charge

structure

Until now, capturing the cost of

energy waste caused by power

quality issues was a task for the

most expert engineers. The cost

of waste could only be calculated

by serious number crunching,

a direct measurement of the

waste and monetization was

not possible. With the patented

algorithms used in the Fluke 430

Series II products, waste caused

by common power quality issues

such as harmonics and unbalance can be measured directly.

By inputting the cost of energy

in to the instrument the cost is

directly calculated.

You can reduce power usage by

eliminating inefficiencies in your

distribution system. Inefficiency

sources include:

• High neutral currents due to

unbalanced loads and triplen

harmonics.

• Heavily loaded transformers,

especially those serving

non-linear loads.

• Old motors, old drives, and

other motor-related issues.

• Highly distorted power, which

may cause excessive heating

in the power system.

You can avoid power factor penalties by correcting for

power factor. Generally this

involves installing correction

capacitors. But, first correct for

distortion on the system—capacitors can present low impedance

to harmonics and installing

inappropriate PF correction can

result in resonance or burned

out capacitors. Consult a power

quality engineer before correcting PF if harmonics are present.

You can reduce peak

demand charges by manag-

ing peak loading. Unfortunately,

many people overlook a major

component of this cost—the

underestimate their overpayments. To determine the real

costs of peak loading, you need

to know three things:

1. “Normal” power usage

2. “Clean power” power usage

3. Peak loading charge structure

By eliminating the power quality problems, you reduce the size

of the peak demands and the

base from which they start.

By using load management, you

control when specific equipment

operates and thus how the loads

“stack on top of each other.”

Now your building averages

515 kWh and your peak load

pegs at 650 kWh. But, you add

load management to move some

loads around and now fewer

loads stack on top of each other

at once —your new peak load

rarely goes beyond 595 kWh.

effect of poor power quality on

peak power usage—and thus

Let’s walk through an example. Your factory/office complex averages 570 kWh of consumption during the workday, but hits peaks

of 710 kWh most days. Your utility charges you for each 10 kWh

over 600 kWh for the whole month, any time you exceed 600kWh

during a 15-minute peak measurement window. If you were to

correct for power factor, mitigate harmonics, correct for sags, and

install a load management system, you would see a different

power usage picture—one you can calculate.

3 Fluke Corporation The costs of poor power quality

Page 4

Saving money with PQ

You’ve tallied up the costs of

poor power quality. Now, you

need to know how to eliminate

those costs. The following steps

will get you there.

• Examine design. Determine

how your system can best

support your processes and

what infrastructure you need

to prevent failure. Verify

circuit capacity before installing new equipment.

Re-check critical equipment

after configuration changes.

• Comply with standards.

For example, examine your

grounding system for compliance with IEEE-142. Examine

your power distribution

system for compliance with

IEEE-141.

• Examine power protection.

This includes lightning

protection, TVSS, and surge

suppression. Are these properly specified and installed?

• Get baseline test data on all

loads. This is the key to

predictive maintenance, and

it allows you to spot emerging

problems.

• Question mitigation.

Mitigating power quality problems includes correction (e.g.,

grounding repair) and coping

(e.g., K-rated transformers).

Consider power conditioning

and backup power.

• Review maintenance

practices. Are you testing,

then following up with

corrective actions? Conduct

periodic surveys at critical

points—for example, check

neutral to ground voltage and

ground current on feeders

and critical branch circuits.

Conduct infrared surveys

of distribution equipment.

Determine root causes of

failures, so you know how to

prevent recurrences.

• Use monitoring. Can you see

voltage distortions before they

overheat motors? Can you track

transients? If you don’t have

power monitoring installed, you

probably won’t see a problem

coming—but you will see the

downtime it causes.

At this point, you need to determine the costs of prevention and

remediation—and then compare

those to the costs of poor power

quality. This comparison will

allow you to justify the investment needed to fix the power

quality problems. Because this

should be an ongoing effort, use

the right tools so you can do

your own power quality testing

and monitoring rather than

outsourcing it. Today, it’s surprisingly affordable—and it will

always cost less than downtime.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2004-2012 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 6/2012 2391563C_EN

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

4 Fluke Corporation The costs of poor power quality

Loading...

Loading...