Page 1

3561 FC

Vibration

Sensor

Vibration monitoring system

offering a frontline vibration

screening and remote

monitoring solution

Page 2

The Value of Vibration

Tiered Monitoring Strategy

Tiered data collectionTiered team Tiered assets

In-depth analysis for complex faults to

compare, trend, analyze, root cause,

and correct the fault

Diagnose fault, severity and severity

score and find repair recommendation

Automate data collection and recieve

warnings to screen the health of your

machinery based on alarms

Screening, diagnosing, and analyzing are all forms of vibration monitoring.

Vibration screening offers the greatest initial value by providing a simple scalable

solution to extend asset coverage, reduce routes and minimize labor costs.

ANALYZE

complex faults

and root cause

DIAGNOSE

common faults

and root cause

SCREEN

for potential

problems

PEOPLE Expert analyst

TOOLS Advanced analytical tools

ASSETS Analyzing critical assets

PEOPLE Experienced technicians

TOOLS Full-featured tools

ASSETS Evaluating critical assets

PEOPLE Entry-level technicians

TOOLS Simple screening tools

ASSETS Looking at all assets

3

2

1

ASSET CLASSES

NON-CRITICAL

SEMI-CRITICAL

CRITICAL

STAR ATHLETE

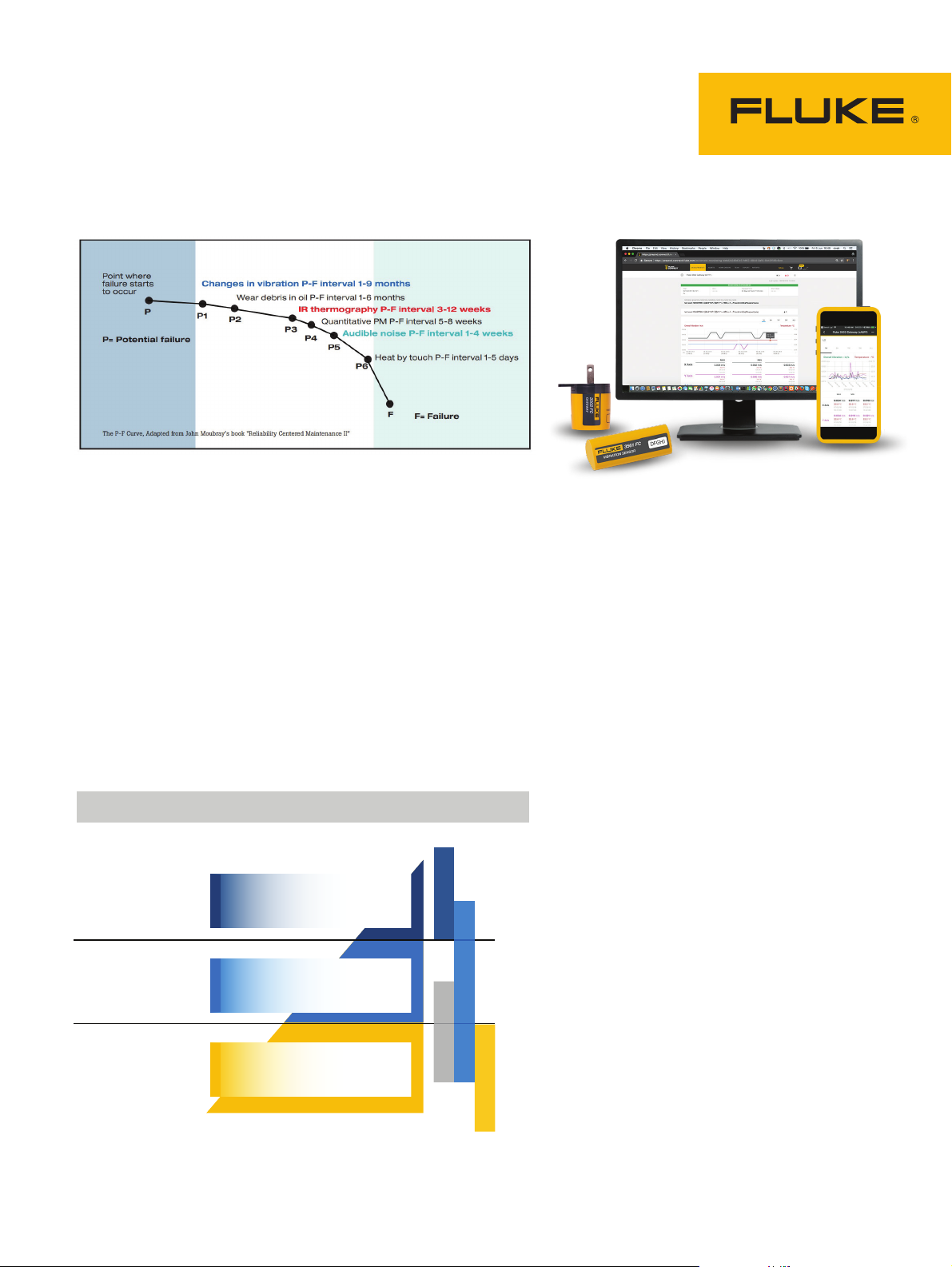

Vibration data informs maintenance teams of issues early enough for

them to decide how to respond to the issue before the equipment

is severely impacted – reducing capability, energy waste, and even

catastrophic failure.

Remote Vibration Monitoring

Screening for vibration in assets reduces the high cost of expert

analysis. Reserve third-party expertise for star athlete equipment and

use sensors to screen for potential problems on noncritical, semicritical and critical machinery.

Maintenance teams view real-time information and trend historical

data to predict a problem before it occurs. Users analyze triaxial vibration and temperature data over time to discern when assets need

repairs and when they don’t.

Team members automatically receive alarms when machinery experiences conditional changes.

Page 3

3561 FC Vibration Sensor

The Fluke 3561 FC Vibration Sensor is the ultimate

time-saver.

Maintenance teams can install the new vibration sensor in under an hour, allowing Fluke Connect™ Condition Monitoring (FCCM) software to grade asset health.

FCCM software includes vibration standards for 37

machine categories. Increase uptime by viewing trends

and receiving alarms on your smart device or computer

within seconds of an abnormality.

Sensors capture 24/7 vibration data, enabling your

team to avoid unnecessary or dangerous routes, decrease downtime and increase reliability.

Hardware

• Small size fits almost anywhere

• Leave in hard-to-reach and hazardous areas

• Frequency Range: 10 to 1,000 hertz

• Three-year battery life

Software

• View vibration and temperature data on graphs or

in time-boxed scaling

• Receive notification alarms on smart devices when

assets experience conditional changes, also viewable in computer web app

Page 4

Common use cases:

Remote Monitoring

Adding sensors to assets in distant locations saves time and money. Rather than

driving out to remote sites to take manual measurements, maintenance teams

can view data on a single screen from

anywhere, at any time.

Safety

Taking measurements during asset operation is dangerous. Installing sensors on

machinery allows teams to take measurements while equipment is running.

Reducing Routes

Maintenance teams miss taking measurements on assets because of the large

number of routes or other emergencies.

Place sensors on machines and capture

automatically aggregated data.

Loading...

Loading...