Page 1

Clamp Meter ABCs

What is a clamp meter and what can it do? What measurements

can be made with a clamp meter? How do you get the most

out of a clamp meter? Which clamp meter is best suited to the

environment the meter will be used in? The answers to these

questions can be found in this application note.

With technological advances in

electrical equipment and circuits

come more challenges for electricians and technicians. These

advances not only require more

capability in today’s test equipment, but more skills on the part

of the people who use them.

An electrician who has a good

grounding in the fundamentals of

test equipment use will be better

prepared for today’s testing and

troubleshooting challenges. The

clamp meter is a important and

common tool found in the toolboxes of electricians and technicians alike.

A clamp meter is an electrical

tester that combines a voltmeter with a clamp-type current

meter. Like the multimeter, the

clamp meter has passed through

the analog period and into the

digital world of today. Originally

created primarily as a singlepurpose test tool for electricians,

today’s models have incorporated

more measurement functions,

more accuracy, and in some

instruments, some very special

measurement features. Today’s

clamp meters have most of the

basic functions of a digital multimeter (DMM), but with the added

feature of a current transformer

built into the product.

The transformer action

The ability of clamp meters to

measure large ac currents is

based on simple transformer

action. When you clamp the

instrument’s jaws or flexible

current probe around a conductor

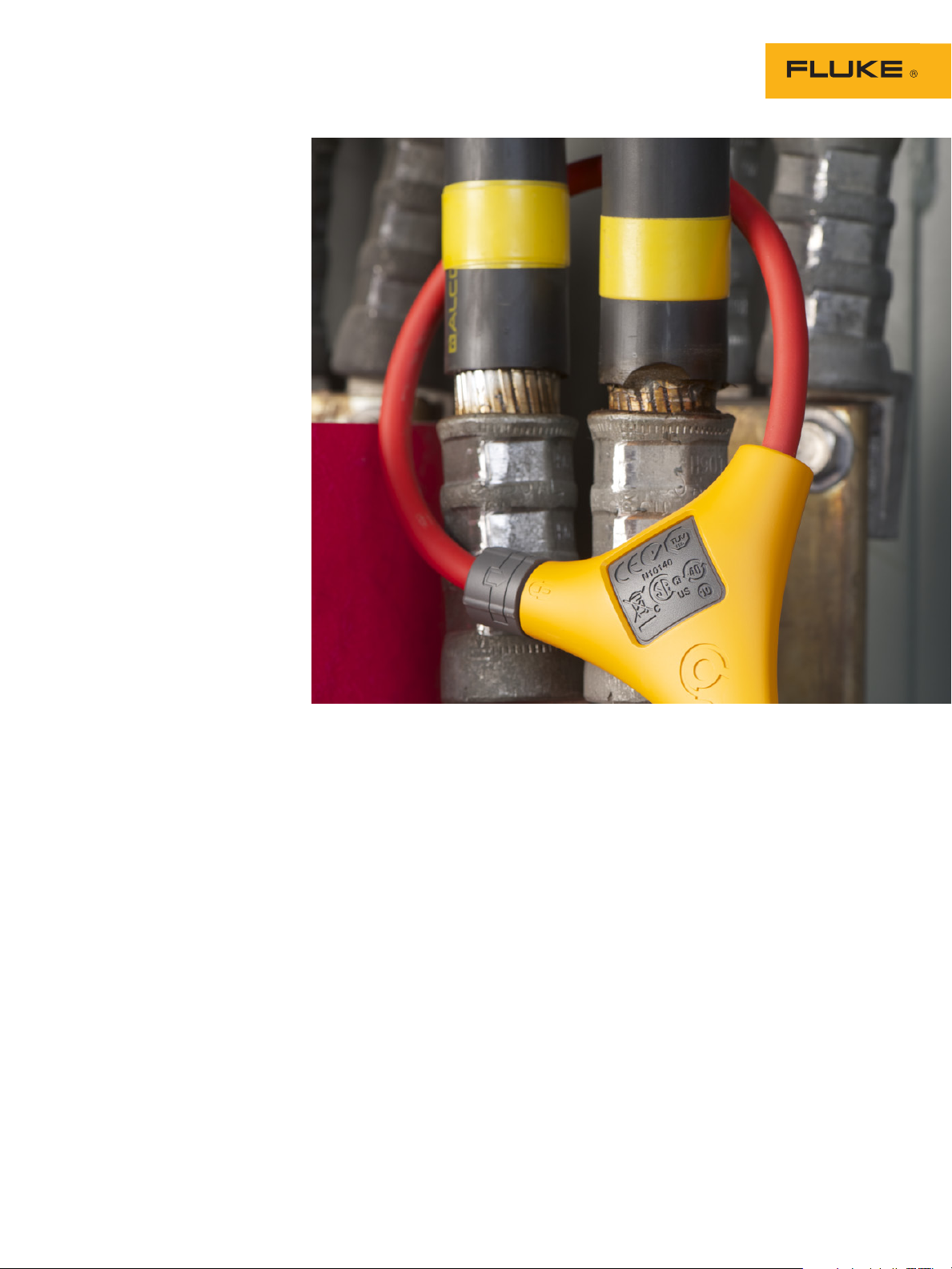

Choose a clamp meter rated to meet the electrical environment you’ll be working in, as well as the resolution and

accuracy of measurement you’ll need for your testing.

carrying ac current, that current

is coupled through the jaws,

similar to the iron core of a power

transformer, and into a secondary winding that is connected

across the shunt of the meter’s

input. A much smaller current

is delivered to the meter’s input

due to the ratio of the number

of secondary windings versus

the number of primary windings

wrapped around the core. Usually, the primary is represented

by the one conductor around

which the jaws or flexible current

probe is clamped. If the secondary has 1000 windings, then the

secondary current is 1/1000 the

current flowing in the primary, or

in this case the conductor being

measured. Thus, 1 amp of current

in the conductor being measured

Application Note

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

Page 2

would produce 0.001 amps or 1

milliamp of current at the input

of the meter. With this technique,

much larger currents can be

easily measured by increasing the

number of turns in the secondary.

Clamp meters measure any

combination of alternating and

direct current. This includes static

dc and charging dc as well as ac.

Clamp meters measure dc current

using Hall effect sensors. A Hall

effect sensor, basically a kind of

magnetometer, can sense the

strength of an applied magnetic

flux. Unlike a simple inductive

sensor, the Hall effect sensor will

work when the applied magnetic

flux is static, not changing. It will

work for alternating magnetic

fields as well. A clamp meter

contains a toroidal iron core that

clamps together with a Hall effect

chip in the gap between the

two halves, so that the induced

magnetic flux from the

current-carrying wire is

channeled through it.

Choosing your

clamp meter

Buying a clamp meter not

only requires looking at

specifications, but also looking

at features, functions, and the

overall value represented by a

meter’s design and the care taken

in its production.

Reliability, especially under

tough conditions, is more important than ever. Fluke’s design

engineers make a point of

building these test tools not only

electrically, but also mechanically,

robust. By the time Fluke clamp

meters are ready to be tossed into

toolcases, they’ve undergone a

rigorous testing and evaluation

program.

User safety should be a primary

consideration in choosing a

clamp meter—or any other piece

of electrical test equipment. Fluke

not only designs its clamp meters

to the latest electrical standards,

but each clamp meter is independently tested and then listed by

certified testing labs such as CSA,

TÜV, etc. Only with these certifications can you be assured an

electrical tester meets these new

safety standards.

Use a flexible current probe for situations like this, where large conductors make it difficult

to use the clamp meter jaws.

Using a clamp meter in

difficult situations

Electricians and technicians

often need to use clamp meters

in less-than-ideal situations.

The newest clamp meters use

the iFlex

to enable measuring where it’s

difficult to access—for example,

tight cabinets, bundled wires, or

awkward conductors.

remotely, a clamp meter with a

detachable display (such as the

Fluke 381) makes it possible to

see the display at a location other

than where the measurement

is being taken. This means one

person—not two—can take the

measurement.

™ flexible current probe

When it’s necessary to measure

Resolution, digits and

counts

Resolution refers to how fine a

measurement a meter can make.

By knowing the resolution of a

meter, you can determine if it’s

possible to see a small change

in the measured signal. For

example, if the clamp meter has

a resolution of 0.1 amp on a 600

amp range, it’s possible to see a

change of 0.1 amp while reading

100 amps.

You wouldn’t buy a ruler marked

in one-inch segments if you had

to measure down to one-quarter

inch. Similarly, you must choose a

meter that can display the

resolution you need to see in

your measurements.

2 Fluke Corporation Clamp Meter ABCs

Page 3

Accuracy

Accuracy is the largest allowable error that will occur under

specific operating conditions.

In other words, it is an indication of how close the meter’s

displayed measurement is to the

actual value of the signal being

measured.

Accuracy for a clamp meter is

usually expressed as a percent

of reading. An accuracy of 3

% of reading means that for a

displayed reading of 100 amps,

the actual value of the current

could be anywhere between 97.0

and 103.0 amps.

Specifications may also include

a range of digits added to the

basic accuracy specification.

This indicates how many counts

the digit to the extreme right of

the display might vary. So the

preceding accuracy example

might be stated as ± (2 % + 2).

Therefore, for a displayed reading

of 100.0 amps, the actual current

could then be estimated to be

between 97.8 and 102.2 amps.

Crest factor

With the growth of electronic

power supplies, the current

drawn from today’s electrical

distribution system are no longer

pure 60 or 50 cycle sine waves.

These currents have become

fairly distorted, due to the

harmonic content these power

supplies generate.

However, electrical power

system components such as fuses,

bus bars, conductors, and thermal

elements of circuit breakers are

rated in rms current because

their main limitation has to do

with heat dissipation. If we want

to check an electrical circuit for

overloading, we need to measure

the rms current and compare the

measured value to the rated value

for the component in question.

Therefore, today’s test equipment must be able to accurately

measure the true-rms value of a

signal regardless of how distorted

the signal might be.

Crest factor is a simple ratio of

a signal’s peak value to its rms

value. For a pure ac sine wave,

the crest factor would be 1.414.

However, a signal that has a

very sharp pulse would cause

the ratio, or crest factor, to be

high. Depending on the width of

the pulse and its frequency, you

can see crest factors of 10:1 or

higher. In real power distribution

systems, crest factors of greater

than 3:1 are rarely seen. So as

you can see, crest factor is an

indication of a signal’s distortion.

A crest factor specification will

be found only in specifications for

meters that can make true-rms

measurements. It indicates how

much distortion a signal can have

and still be measured within

the meter’s accuracy specification. Most true-rms reading

clamp meters have crest factor

specifications of 2:1 or 3:1. That

rating will handle most electrical

applications.

Measuring current

One of the most basic measurements of a clamp meter is current.

Today’s clamp meters are capable

of measuring both ac and dc

current. Typical current measurements are taken on various

branch circuits of an electrical

distribution system. Determining

how much current is flowing in

various branch circuits is a fairly

common task for the electrician.

How to make current

measurements

1. Select Amps ac or Amps

dc .

2. Open the jaws of the clamp

meter and close the jaws

around a single conductor.

(If you are measuring ac

current, you can switch to

the iFlex setting and use a

flexible current probe.)

3. View the reading in the

display.

By taking current measurements

along the run of a branch circuit,

you can easily tell how much

each load along the branch

circuit is drawing from the

distribution system.When a circuit

breaker or transformer appears

to be overheating, it’s best to

take a current measurement on

the branch circuit to determine

the load current. However, make

sure you are using a true-rms

responding meter so you can get

an accurate measurement of the

signal heating up these components. The average responding

meter will not give a true reading

if the current and voltage are nonsinusoidal due to non-linear loads.

Measuring voltage

Another common function for a

clamp meter is measuring voltage.

Today’s clamp meters are capable

of measuring both ac and dc

voltage. AC voltage is usually

created by a generator and then

distributed through an electrical

distribution system. An electrician’s job is to be able to take

measurements throughout the

system to isolate and fix electrical problems. Another common

voltage measurement would be

testing battery voltage. In this

case, you would be measuring

direct current or dc voltage.

Testing for proper supply voltage

is usually the first thing measured

when troubleshooting a circuit. If

there is no voltage present, or if

it is too high or too low, the voltage problem should be corrected

before investigating further.

A clamp meter’s ability to

measure ac voltage can be

affected by the frequency of the

signal. Most clamp meters can

accurately measure ac voltages

with frequencies from 50 Hz to

500 Hz, but a digital multimeter’s

ac measurement bandwidth

might be 100 kHz or higher.

This is why the reading of the

same voltage by a clamp meter

and digital multimeter can have

very different results. The digital

multimeter allows more of the

high frequency voltage through to

the measurement circuitry, while

the clamp meter filters out some

of the voltage contained in the

signal above the bandwidth of

the meter.

When troubleshooting a variable frequency drive (VFD), the

input bandwidth of a meter can

become very important in getting

3 Fluke Corporation Clamp Meter ABCs

Page 4

a meaningful reading. Due to

the high harmonic content in the

signal coming out of a VFD to the

motor, a DMM would measure

most of the voltage content

(depending on its input bandwidth). Measuring the voltage

output of a VFD is now a common

measurement. A motor connected

to a VFD only responds to the

average value of the signal, and

to measure that power the input

bandwidth of the clamp meter

must be narrower than its DMM

counterpart. The Fluke 375, 376,

and 381 clamp meters have been

specifically designed for testing

and troubleshooting VFDs.

How to make voltage

measurements

1. Select Volts AC ( ) or Volts DC

(

), as desired.

2. Plug the black test probe into

the COM input jack. Plug the

red test probe into the V

input jack.

3. Touch the probe tips to the

circuit across a load or power

source (in parallel to the

circuit).

4. View the reading, being

sure to note the unit of

measurement.

5. (Optional) Press the HOLD

button to freeze the reading

in the display. Now you can

remove the meter from the

live circuit and then read the

display when you are safely

clear of the electrical hazard.

By taking a voltage measurement

at the circuit breaker and then

at the input of the load on that

breaker, you can determine the

voltage drop that occurs across

the wires connecting them. A

significant drop in voltage at the

load might affect how well the

load functions.

Measuring resistance

Resistance is measured in ohms

(Ω). Resistance values can vary

greatly, from a few milliohms

(mΩ) for contact resistance to

billions of ohms for insulators.

Most clamp meters measure down

to 0.1 Ω. When the measured

resistance is higher than the

upper limit of the meter, or the

circuit is open, “OL” appears in

the meter’s display.

Resistance measurements must

be made with the circuit power

off—otherwise, the meter or

circuit could be damaged. Some

clamp meters provide protection in the ohms mode in case of

accidental contact with voltages.

The level of protection may vary

greatly among different clamp

meter models.

How to make resistance

measurements

1. Turn off power to the

circuit.

2. Select resistance (W).

3. Plug the black test probe into

the COM input jack. Plug the

red test probe into the VW

input jack.

4. Connect the probe tips across

the component or portion of

the circuit for which you want

to determine resistance.

5. View the reading in the

meter’s display

Make sure the power is off

before making resistance

measurements.

Continuity

Continuity is a quick go/no-go

resistance test that distinguishes

between an open and a closed

circuit.

A clamp meter with a continuity

beeper allows you to complete

many continuity tests easily and

quickly. The meter beeps when

it detects a closed circuit, so you

don’t have to look at the meter as

you test. The level of resistance

required to trigger the beeper

varies from meter to meter. The

typical resistance setting to turn

on the beeper is a reading less

than between 20 ohms and

40 ohms.

Special functions

A fairly common measurement

function is reading the frequency

of an ac current waveform. With

the clamp meter’s jaws (or a

flexible current probe) wrapped

around a conductor carrying ac

current, switch on the Frequency

function and the meter’s display

will indicate the frequency of the

signal flowing in the conductor.

This is a very helpful measurement when tracking down

harmonic problems in an electrical distribution system.

Another feature that can be

found in some clamp meter

models is min, max, and average storage. When this feature is

activated, each reading the clamp

meter takes is compared against

any previously stored readings. If

the new reading is higher than

the reading in the high reading

memory, it replaces that reading

as the highest reading. The same

comparison is made against the

low reading memory, and the

new reading, if lower, replaces

the stored reading. The average

reading is updated accordingly.

As long as the min, max, and

average feature is active, all

readings are processed in this

way. Thus, after a period of time,

you can call up each of these

memory values to the display and

determine the highest, lowest,

and average reading over a

specific period of time.

In the past, not all clamp meters

could measure capacitance. The

Measuring current with a clamp meter.

4 Fluke Corporation Clamp Meter ABCs

Page 5

capacitance measurement function is now being incorporated

into the feature set of many new

clamp meters. This function is

useful for checking motor start

capacitors or measuring values of

electrolytic capacitors contained

in controllers, power supplies

or motor drives.For electricians

who deal with motors in their

work, the ability to capture the

amount of current drawn by a

motor during its start up can tell a

lot about a motor’s condition and

loading. The Fluke 374, 375, 376,

and 381 clamp meters incorporate inrush current measurement

as part of their feature sets. After

clamping the jaws (or the flexible

current probe) around one of

the motor’s input leads, activate

the inrush mode. Next, turn on

the motor. The clamp meter’s

display will indicate the maximum current drawn by the motor

over the first 100 milliseconds

of its start cycle. This proprietary

inrush measurement technology

filters out noise and captures

motor starting current exactly as

the circuit protection sees it.

Clamp meter safety

Making measurements safely

starts with choosing the proper

meter for the environment in

which the meter will be used.

Once the proper meter has been

chosen, you should use it by

following good measurement

procedures.

The International Electrotechnical Commission established new

safety standards for working on

electrical systems. Make sure you

are using a meter that meets the

IEC category and voltage rating

approved for the environment

where the measurement is to be

made. For instance, if a voltage

measurement needs to be made

in an electrical panel with 480V,

then a meter rated Category

III—600 V or higher should be

used. This means the input

circuitry of the meter has been

designed to withstand voltage

transients commonly found in this

environment without harming

the user.

this rating, which also has a CSA

or TÜV certification, means the

meter not only has been designed

to IEC standards, but has been

independently tested and meets

those standards. (See independent testing sidebar).

now carry a Cat IV safety rating,

which means they can be

used in outdoor or underground

settings where lightning strikes

or transients can occur more

frequently and at higher levels.

1

Choosing a meter with

Many new clamp meters

Safety checklist

✓ Use a meter that meets

accepted safety standards for

the environment in which it

will be used.

✓ Inspect test leads or flexible

current probe for physical

damage before making a

measurement.

✓ Use the meter to check

continuity of the test leads or

flexible current probe.

✓ Use only test leads that have

shrouded connectors and

finger guards.

✓ Use only meters with recessed

input jacks.

✓ Be sure the meter is in good

operating order.

✓ Always disconnect the “hot”

(red) test lead first.

✓ Don’t work alone.

✓ Use a meter that has overload

protection on the ohms function.

1

See the ABCs of Multimeter Safety (literature

code 1263690) to learn more about IEC-1010

and how it applies to multimeter use.

Special features

The following special features

and functions may make it easier

to use your clamp meter.

• Annunciators (display icons)

show at a glance what is being

measured (volts, ohms, etc.)

• Data Hold allows you to freeze

the reading in the display.

• One-switch operation makes

it easy to select measurement

functions.

• Overload protection prevents

damage to both the meter and

the circuit, and protects the

user.

• Autoranging automatically

selects proper measurement

range. Manual ranging lets you

lock into a specific range for

repetitive measurements.

• Low battery indicator warns

you when the battery needs

changing.

• Display with backlight, easyto-read characters, and wide

viewing angle makes readings easier to see in all sorts

of conditions. The backlight

display automatically sets the

correct measurement range so

you do not need to change the

switch positions while taking

a measurement.

• Integrated low pass filter and

state of the art signal processing allows for use in noisy

electrical environments while

providing stable readings.

5 Fluke Corporation Clamp Meter ABCs

Page 6

Glossary

N10140

Fluke

Accuracy. How close the

displayed measurement is to

the actual value of the signal

being measured. Expressed as a

percentage of reading or a as a

percentage of full scale.

Analog Meter. An instrument

that uses a needle movement to

display the value of a measured

signal. The user judges the reading based in the position of the

needle on a scale.

Annuciator. A symbol or icon that

identifies a selected range or a

function

Average Responding Meter.

A meter that accurately measures

sinusoidal waveforms, while

measuring non-sinusoidal waveforms with less accuracy.

Non-Sinudoidal Waveform.

A distorted waveform such as

a pulse train, square waves,

triangular waves, sawtooth waves

and spikes.

Resolution. The degree to which

small changes in a measurement

can be displayed.

RMS. The equivalent dc value of

an ac waveform.

Sinusoidal Waveform. A pure

sine wave without distortion.

True-rms Meter. A meter that

can accurately measure both

sinusoidal and non-sinusoidal

waveforms.

Independent testing is the

key to safety compliance

How can you tell if you’re getting a genuine

CAT III or CAT II meter? Unfortunately it’s not

always that easy. It is possible for a manufacturer to self-certify its meters as CAT II or

CAT III without any independent verification.

Beware of wording such as “Designed to meet

specification...” Designer’s plans are never a

substitute for an actual independent test. The

IEC (International Electrotechnical Commission) develops and proposes standards, but it

is not responsible for enforcing the standards.

Look for the symbol and listing number of

an independent testing lab such as UL, CSA,

TÜV or other recognized approval agency.

That symbol can only be used if the product

successfully completed testing to the agency’s

standard, which is based on national/international standards. UL 3111, for example,

is based on IEC 1010-1 2nd Edition. In an

imperfect world, that is the closest you can

come to ensuring that the multimeter you

choose was actually tested for safety.

R

LISTED

950 Z

N10140

6 Fluke Corporation Clamp Meter ABCs

Meter ratings and capabilities vary

by manufacturer. Before working with

a new meter, be sure to familiarize

yourself with all operating and safety

procedures for that meter contained in

the users manual.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2005-2010 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 10/2010 2562791C A-EN-N

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

Loading...

Loading...