Page 1

Introduction

To prevent possible electrical shock, fire, or personal injury:

• Read all safety information before you use the Product.

• Do not do the performance tests or calibration adjustment

procedures unless qualified to do so.

• Carefully read all instructions.

The 28 II Ex Calibration Information contains adjustment and performance test

procedures for the Fluke Model 28 II Ex Digital Multimeter (the Product or Meter).

This document includes:

• Safety Information (page 2)

• International Electrical Symbols (page 4)

• Specifications (page 5)

• General Maintenance (page 9)

• Fuse Test (page 9)

• Performance Tests (page 12)

• Calibration Adjustment Procedure (page 16)

• Limited Lifetime Warranty (page 20)

28 II Ex

Digital Multimeter

Calibration Information

XWWarning

See the 28 II Ex Users Manual for instructions on Product operation.

How to Contact Fluke

To contact Fluke, call one of the following telephone numbers:

• Technical Support USA: 1-800-99-FLUKE (1-800-993-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-3434-0181

• Singapore: +65-6799-5566

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com.

To register your product, visit http://register.fluke.com.

To view, print, or download the latest manual supplement, visit

http://us.fluke.com/usen/support/manuals.

May 2012

© 2012 Fluke Corporation. All rights reserved. Specifications are subject to change without notice.

All product names are trademarks of their respective companies. 1

Page 2

28 II Ex

Calibration Information

Safety Information

A Warning identifies conditions and procedures that are dangerous to the user. A

Caution identifies conditions and procedures that can cause damage to the Product or the

equipment under test.

XWWarning

To prevent possible electrical shock, fire, or personal injury:

• Use the Product only as specified, or the protection

supplied by the Product can be compromised.

• The battery door must be closed and locked before you

operate the Product.

• Replace the batteries when the low battery indicator ()

shows to prevent incorrect measurements.

• Remove all probes, test leads, and accessories before the

battery door is opened.

• Do not use test leads if they are damaged. Examine the test

leads for damaged insulation, exposed metal, or if the wear

indicator shows. Check test lead continuity.

• Do not apply more than the rated voltage, between the

terminals or between each terminal and earth ground.

• Limit operation to the specified measurement category,

voltage, or amperage ratings.

• Do not operate the Product with covers removed or the

case open. Hazardous voltage exposure is possible.

• Do not touch voltages > 30 V ac rms, 42 V ac peak, or 60 V

dc.

• Use the correct terminals, function, and range for

measurements.

• Do not work alone.

• Measure a known voltage first to make sure that the

Product operates correctly.

• Use only cables with correct voltage ratings.

• Use only current probes, test leads, and adapters supplied

with the Product.

• Do not exceed the Measurement Category (CAT) rating of

the lowest rated individual component of a Product, probe,

or accessory.

• Connect the common test lead before the live test lead and

remove the live test lead before the common test lead.

2

Page 3

Digital Multimeter

Safety Information

• Examine the case before you use the Product. Look for

cracks or missing plastic. Carefully look at the insulation

around the terminals.

• Do not use and disable the Product if it is damaged.

• Do not use the Product if it operates incorrectly.

• Do not use the Product in damp or wet environments.

• Keep fingers behind the finger guards on the probes.

• Measure for hazardous voltage without the Low-Pass Filter.

WCaution

To prevent possible damage to the Meter or to the equipment

under test, follow these guidelines:

• Disconnect circuit power and discharge all high-voltage

capacitors before you do resistance, continuity, diodes, or

capacitance tests.

• Use the correct terminals, function, and range for all

measurements.

• Before you measure current, check the fuses of the Meter.

(See “Fuse Test”.)

3

Page 4

28 II Ex

Calibration Information

Electrical Symbols

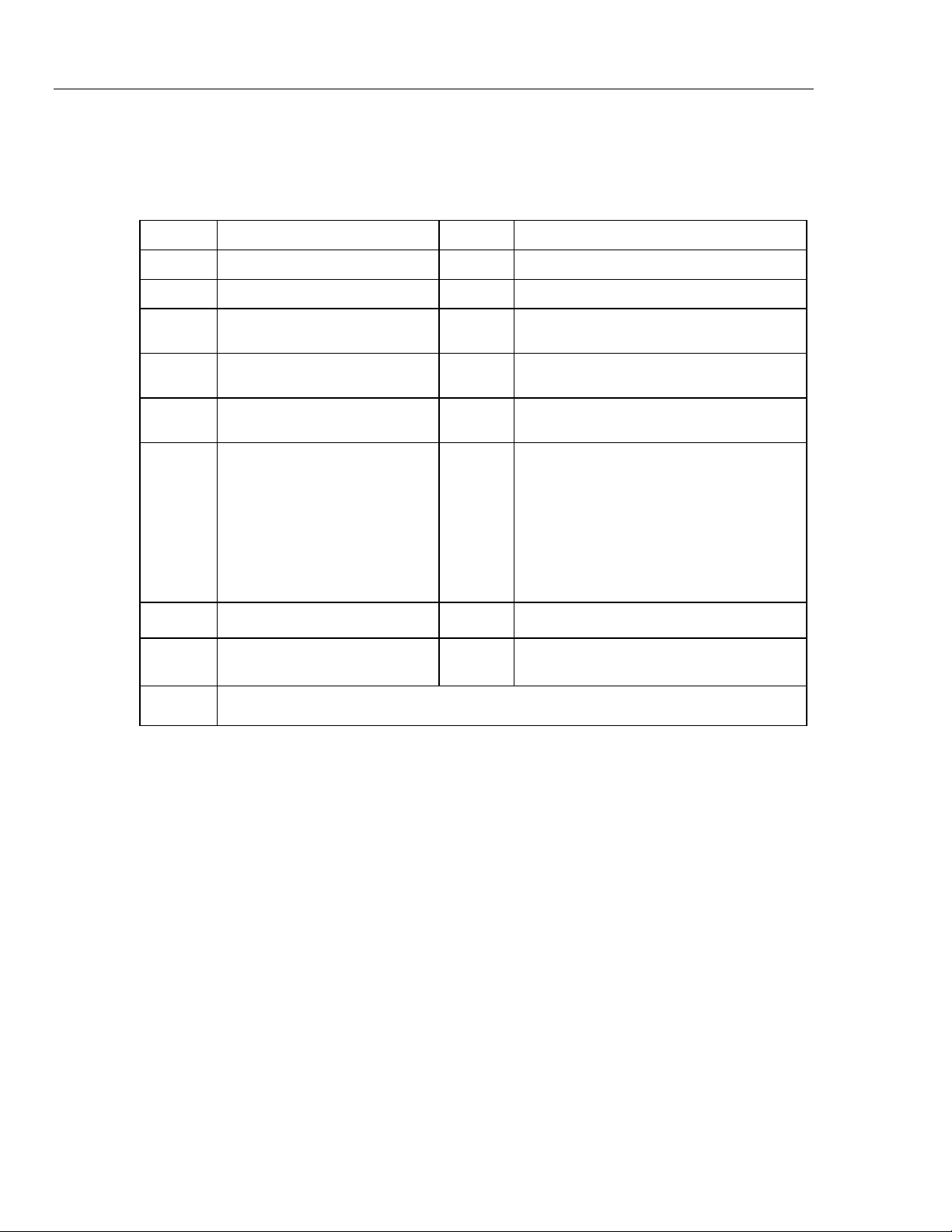

Table 1 is a list of electrical symbols that appear in this document and on the Meter.

Table 1. Symbols

X

W

R

CAT III

(

®

~

AC (Alternating Current)

DC (Direct Current)

Hazardous voltage

Risk of Danger. Important

information. See Manual.

Battery. Low battery when

displayed.

Continuity test or continuity

beeper tone.

IEC Overvoltage Category III

CAT III equipment is designed to

protect against transients in

equipment in fixed-equipment

installations, such as distribution

panels, feeders and short

branch circuits, and lighting

systems in large buildings.

Conforms to ATEX directive.

Inspected and licensed by TÜV

Product Services.

Do not dispose of this product as unsorted municipal waste. Go to Fluke’s website for

recycling information.

J

I

P

T

CAT IV

Æ

Earth ground

Fuse

Conforms to European Union directives.

Diode

Double insulated

Capacitance

IEC Overvoltage Category IV

CAT IV equipment is designed to protect

against transients from the primary supply

level, such as an electricity meter or an

overhead or underground utility service.

Conforms to relevant Australian standards.

Conforms to CAN/CSA-C22.2 No. 61010-1

nd

2

, + Amendment 1.

4

Page 5

Digital Multimeter

General Specifications

General Specifications

Maximum voltage between any

terminal and earth ground ........................................... 1000 V rms

W Fuse for mA inputs .................................................. 440 mA, 1000 V FAST Fuse

W Fuse for A inputs ..................................................... 11 A, 1000 V FAST Fuse

Display ........................................................................... 6000 counts, updates 4/sec (19,999 counts in high-resolution

Altitude

Operating .................................................................... 2,000 meters

Storage ....................................................................... 10,000 meters

Temperature

Operating .................................................................... -15 °C to 50 °C

Storage ....................................................................... -40 °C to +85 °C (without battery)

Temperature coefficient ............................................... 0.05 X (specified accuracy) / °C (<18 °C or >28 °C)

Electromagnetic Compatibility (EN 61326-1:2005) .... In an RF field of 3 V/M, accuracy = specified accuracy +20

Relative Humidity .......................................................... 0 % to 80 % (0 °C to 35 °C)

0 % to 70 % (35 °C to 50 °C)

Battery Type .................................................................. 3 AAA Alkaline batteries, NEDA 24A IEC LR03

Approved Batteries ....................................................... Duracell Procell MN2400 LR03

Battery Life .................................................................... 400 hrs typical without backlight (Alkaline)

Vibration ........................................................................ Per MIL-PRF-28800 for a Class 2 instrument

Shock ............................................................................. 1 Meter drop per IEC 61010 (3 Meter drop with holster)

Size (H x W x L) ............................................................. 4.57 cm x 10.0 cm x 21.33 cm (1.80 in x 3.95 in x 8.40 in)

Size with Holster ........................................................... 6.35 cm x 10.0 cm x 19.81 cm (2.50 in x 3.95 in x 7.80 in)

Weight ............................................................................ 567.8 g (1.25 lb)

Weight with Holster and Flex-Stand............................ 769.8 g (1.70 lb)

Safety Compliance ........................................................ Complies with ANSI/ISA S82.01-2004, CAN/CSA C22.2 61010-1-

Certifications ................................................................. CSA, TÜV, P,

IP Rating ........................................................................ 67 (Non-operating. Protected against dust and the effect of

mode).

-40 °C to +60 °C (with battery)

counts, except 600 μA dc range total accuracy = specified

accuracy +60 counts. Temperature not specified

Duracell Plus MN2400 LR03

Varta Max Tech No. 4703

Varta Industrial Alcaline No. 4003 (min. operating temperature is 10 °C)

Eveready Energizer No. E92

Rayovac Alkaline AAA (U.S. Type)

Panasonic LR03XWA

04 to 600 V Measurement Category IV. Licensed by TÜV to

EN61010-1, Pollution degree 2

, ATEX, IECEx

immersion up to 1 m for 30 min.)

5

Page 6

28 II Ex

Calibration Information

Detailed Specifications

For all detailed specifications:

Accuracy is specified for 2 years after calibration, at operating temperatures of 18 °C to 28 °C, with relative humidity at

0 % to 80 %. Accuracy specifications take the form of ±([% of Reading] + [Number of least-significant digits]). In the 4

½-digit mode, multiply the number of least-significant digits (counts) by 10.

AC Voltage

AC conversions are ac-coupled and valid from 3 % to 100 % of range.

Range Resolution

600.0 mV 0.1 mV

6.000 V 0.001 V

60.00 V 0.01 V

600.0 V 0.1 V Unspecified

1000 V 1 V Unspecified Unspecified

Low-Pass Filter

[1] Below 10 % of range, add 12 counts.

[2] Frequency range: 1 kHz to 2.5 kHz

[3] Specification increases from -1 % to -6 % at 440 Hz when filter is used.

Accuracy

45 – 65 Hz 30 – 200 Hz 200 – 440 Hz 440 Hz – 1 kHz 1 – 5 kHz 5 – 20 kHz

±(0.7 % + 4)

±(1.0 % + 4)

±(2 % + 4)

±(2 % + 4)

[2]

±(2 % + 20)

Unspecified

±(0.7 % + 2)

+1.0 % + 4

±(1.0 % + 4)

[1]

-6.0 % - 4

Unspecified Unspecified Unspecified

[3]

[1]

DC Voltage, Conductance, and Resistance

Function Range Resolution Accuracy

mV dc 600.0 mV 0.1 mV

±(0.1 % + 1)

6.000 V 0.001 V

V dc

60.00 V 0.01 V

600.0 V 0.1 V

±(0.05 % + 1)

1000 V 1 V

600.0 Ω 0.1 Ω

6.000 kΩ 0.001 kΩ

Ω

60.00 kΩ 0.01 kΩ

600.0 kΩ 0.1 kΩ

6.000 MΩ 0.001 MΩ

50.00 MΩ 0.01 MΩ

nS

[1] Add 0.5 % of reading when measuring above 30 MΩ in the 50 MΩ range, and 20 counts below 33 nS in the 60 nS range.

[2] When using the rel function to compensate for offsets.

[3] >40 °C temperature coefficient is 0.1 x (specified accuracy)/°C.

60.00 nS 0.01 nS

±(0.2 % + 2)

±(0.2 % + 1)

±(0.6 % + 1)

±(1.0 % + 3)

±(1.0 % + 10)

[2]

[1,3]

[1,2,3]

Temperature

Range Resolution

-200 °C to +1090 °C

-328 °F to +1994 °F

[1] Does not include error of the thermocouple probe.

[2] Accuracy specification assumes ambient temperature stable to ± 1 °C. For ambient temperature changes of ± 5 °C, rated accuracy

applies after 2 hours.

0.1 °C

0.1 °F

Accuracy

±(1.0 % + 10)

±(1.0 % + 18)

[1,2]

6

Page 7

Digital Multimeter

Detailed Specifications

AC Current

Function Range Resolution Burden Voltage

μA ac

mA ac

A ac

[1] AC conversions are ac coupled, true rms responding, and valid from 3 % to 100 % of range, except 400 mA range. (5 % to 100 %

of range) and 10 A range (15 % to 100 % or range).

[2] 400 mA continuous. 600 mA for 18 hr maximum.

[3] W 10 A continuous up to 35 °C. <20 minutes on, 5 minutes off at 35 °C to 55 °C. >10 A to 20 A for 30 seconds maximum, 5 minutes

off.

[4] >10 A accuracy unspecified.

600.0 μA 0.1 μA 100 μV/μA

6000 μA 1 μA 100 μV/μA

60.00 mA 0.01 mA 1.8 mV/mA

400.0 mA

[2]

0.1 mA 1.8 mV/mA

6.000 A 0.001 A 0.03 V/A

10.00 A

[3,4]

0.01 A 0.03 V/A

Accuracy

(45 Hz – 2 kHz)

±(1.0 % + 2)

[1]

DC Current

Function Range Resolution Burden Voltage Accuracy

μA dc

mA dc

A dc

[1] 400 mA continuous; 600 mA for 18 hr maximum.

[2] W 10 A continuous up to 35 °C. <20 minutes on, 5 minutes off at 35 °C to 55 °C. >10 A to 20 A for 30 seconds maximum, 5 minutes

off.

[3] >10 A accuracy unspecified.

600.0 μA 0.1 μA 100 μV/μA ±(0.2 % + 4)

6000 μA 1 μA 100 μV/μA ±(0.2 % + 2)

60.00 mA 0.01 mA 1.8 mV/mA

400.0 mA

[1]

0.1 mA 1.8 mV/mA

6.000 A 0.001 A 0.03 V/A

10.00 A

[2,3]

0.01 A 0.03 V/A

±(0.2 % + 4)

±(0.2 % + 2)

±(0.2 % + 4)

±(0.2 % + 2)

Capacitance

Range Resolution Accuracy

10.00 nF 0.01 nF

100.0 nF 0.1 nF

±(1.0 % + 2)

1.000 μF 0.001 μF

10.00 μF 0.01 μF

100.0 μF 0.1 μF

±(1.0 % + 2)

9999 μF 1 μF

[1] With a film capacitor or better, using the rel mode to zero residual.

Diode

Range Resolution Accuracy

2.000 V 0.001 V

±(2.0 % + 1)

Frequency

Range Resolution Accuracy

199.99 Hz 0.01 Hz

1999.9 Hz 0.1 Hz

19.999 kHz 0.001 kHz

±(0.005 % + 1)

199.99 kHz 0.01 kHz

>200 kHz 0.1 kHz Unspecified

[1] From 0.5 Hz to 200 kHz and for pulse widths > 2 μs.

[1]

[1]

7

Page 8

28 II Ex

Calibration Information

Frequency Counter Sensitivity and Trigger Levels

Input Range

600 mV dc 70 mV (to 400 Hz) 70 mV (to 400 Hz) 40 mV

600 mV ac 150 mV 150 mV 6 V 0.3 V 0.7 V 1.7 V

60 V 3 V

600 V 30 V

1000 V 100 V

Duty Cycle (Vdc and mVdc)

[1] 0.5 Hz to 200 kHz, pulse width >2 μs. Pulse width range is determined by the frequency by the frequency of the signal.

Input Characteristics

Function

L

K

Ω

Minimum Sensitivity (RMS Sine Wave)

5 Hz – 20 kHz 0.5 Hz – 200 kHz

7 V (≤140 kHz)

70 V (≤14.0 kHz)

200 V (≤1.4 kHz)

Range Accuracy

0.0 % to 99.9 %

Overload

Protection

1000 V rms

10 MΩ <100 pF

1000 V rms

1000 V rms

1000 V rms <7.0 V dc <1.7 V dc <1.9 V dc

10 MΩ < 100 pF

Open Circuit

Test Voltage

[1]

Input

Impedance

(nominal)

(ac-coupled)

Common Mode

Rejection Ratio

(1 kΩ unbalance)

> 120 dB at dc, 50 Hz

or 60 Hz

> 120 dB at dc, 50 Hz

or 60 Hz

> 60 dB, dc to 60 Hz

Full Scale Voltage Typical Short Circuit Current

To 6 MΩ

Within ± (0.2 % per kHz + 0.1 %) for rise times <1 μs.

5 MΩ or

60 nS

Approximate Trigger Level

(DC Voltage Function)

4 V

40 V

100 V

Normal Mode Rejection

> 60 dB at 50 Hz or 60 Hz

> 60 dB at 50 Hz or 60 Hz

600 Ω 6 kΩ 60 kΩ 600 kΩ 6 MΩ 50 MΩ

500 μA 100 μA 10 μA 1 μA 0.4 μA0.2 μA

G

1000 V rms <7.0 V dc 2.200 V dc 1.0 mA typical

MIN MAX Recording

Nominal Response Accuracy

100 ms to 80 %

(dc functions)

120 ms to 80 %

(ac functions)

250 μs (peak)

[1] For 6 V range: 1 ms

[1]

Specified accuracy ±12 counts for changes >200 ms in duration

Specified accuracy ±40 counts for changes >350 ms and inputs >25 % of range

Specified accuracy ±100 counts for changes >250 μs in duration

(add ±100 counts for readings over 6000 counts)

(add ±100 counts for readings in Low Pass mode)

8

Page 9

Digital Multimeter

Basic Maintenance

Basic Maintenance

XWWarning

To prevent possible electrical shock, fire, or personal injury:

• Have the Product repaired by ECOM Instruments GmbH or

an ECOM authorized service center to keep Product

certification.

• Do not operate the Product with covers removed or the case

open. Hazardous voltage exposure is possible.

General Maintenance

XWWarning

To prevent possible electrical shock, fire, or personal injury,

• Remove the input signals before you clean the Product.

• Use only specified replacement parts.

To clean the external surfaces of the Product, wipe the case with a damp cloth and mild

detergent. Do not use abrasives or solvents.

Dirt or moisture in the terminals can cause incorrect measurements and can falsely set off

the Input Alert feature. Clean the terminals as follows:

1. Turn off the Product and remove all test leads.

2. Shake out dirt that can be in the terminals.

3. Soak a clean swab with mild detergent and water. Move the swab around in each

It is recommended that the Product be calibrated by Fluke in 2 year intervals.

Fuse Test

As shown in Figure 1, with the Product in the

jack and place the probe tip on the other end of the test lead against the metal of the

current input jack. If LEAd appears in the display, the probe tip has been inserted too far

into the amps input jack. Lift the lead out a bit until the message no longer shows in the

display and 0L or a resistance measurement shows in the display. The resistance value

must be as shown in Figure 1. If the tests give measurements other than those shown,

have the Product serviced.

terminal. Dry each terminal with canned air to push the water and detergent out of the

terminals.

XWWarning

To prevent possible electrical shock or personal injury, use

only specified replacement fuses with the amperage, voltage,

and speed ratings shown in Table 3.

N function, put a test lead into the

9

Page 10

28 II Ex

Calibration Information

Good 0.44 A fuse: 0.995 kΩ to

1.005 kΩ

Replace fuse: OL

Touch top half

of input contacts

Good 11 A fuse: 0.0 Ω to

0.5 Ω

Replace fuse: OL

Battery Replacement

Replace the batteries with three AAA batteries (NEDA 24A IEC LR03).

To prevent possible electrical shock, fire, or personal injury:

• Replace the batteries when the low battery indicator ()

shows to prevent incorrect measurements. If the display

shows “batt” the Product will not function until the

batteries are replaced.

• Use only three AAA 1.5 volt batteries, correctly installed to

power the Product. See the table on the subsequent page

for a list of approved batteries. All cells are to be replaced at

the same time with same part number cells in fresh air

locations only.

Replace the batteries as follows, refer to Figure 2:

1. Turn the rotary switch to OFF and remove the test leads from the terminals.

2. Remove the six Torx-head screws from the case bottom and remove the battery door

(item ).

Figure 1. Current Fuse Test

XWWarning

gaq105.eps

10

Note

When you lift the battery door, make sure the rubber gasket stays attached

to the battery compartment barrier.

3. Remove the three batteries and replace all three with AAA Alkaline batteries

(item ).

4. Make sure the battery compartment gasket (item ) is properly installed around the

Page 11

Digital Multimeter

Basic Maintenance

outside edge of the battery compartment barrier.

5. Align the battery compartment barrier with battery compartment while you replace

the battery door.

6. Attach the door with the six Torx-head screws.

Note

It is recommended the batteries be removed from the Product for long

periods of storage.

Table 2. Approved Batteries

Battery Description Manufacturer

Duracell Procell MN2400 LR03

Duracell Plus MN2400 LR03

Max Tech No. 4703

Industrial Alcaline No. 4003

Eveready Energizer No. E92 Eveready

Rayovac Alkaline AAA (U.S. Type) Rayovac

Panasonic LR03XWA Panasonic

[1] Minimum operating temperature is -10 °C.

1

2

Duracell

[1]

3

Varta

5

4

Figure 2. Battery and Fuse Replacement

gaq10.eps

11

Page 12

28 II Ex

Calibration Information

Fuse Replacement

XW Warning

To prevent possible electrical shock, fire, or personal injury,

use only specified replacement fuses.

Examine or replace the fuses in the Product as follows (See Figure 2):

1. Turn the rotary switch to OFF and remove the test leads from the terminals.

2. Refer to step 2 in the “How to Replace the Batteries” section to remove the battery

door.

3. Carefully lift out the fuse assembly (item ) from the fuse compartment.

4. Pry one end of the 11 A fuse loose, then lift the fuse out of its bracket (item ).

5. Install ONLY specified replacement fuses with the amperage, voltage, and speed

ratings shown in Table 3. The 440 mA fuse is attached to the fuse assembly. You

must use a new fuse assembly to replace the 440 mA fuse.

6. Install the fuse assembly into the fuse compartment.

7. Refer to steps 4 through 6 in the “How to Replace the Batteries” section above to

replace the battery door.

Table 3. Fuse Replacement

Description Qty. Fluke Part or Model Number

W Fuse, 11 A, 1000 V, FAST

28 II Ex Fuse Assembly 1

W To ensure safety, use exact replacement only.

Performance Tests

XWWarning

To prevent possible electrical shock, do not do the performance

test procedures unless the Product is fully assembled.

The performance tests verify the complete operation of the Meter and the accuracy of

each function against its specifications. Do the performance tests bi-annually to make

sure the Meter operates to it specifications. If one or more of the tests shows a

measurement that is not between the high and low limits, do the adjustment procedure.

See the “Calibration Adjustments” section.

Note

In the performance tests, the Meter is referred to as the Unit Under Test

(UUT).

1

803293

4016494

12

Page 13

Digital Multimeter

Performance Tests

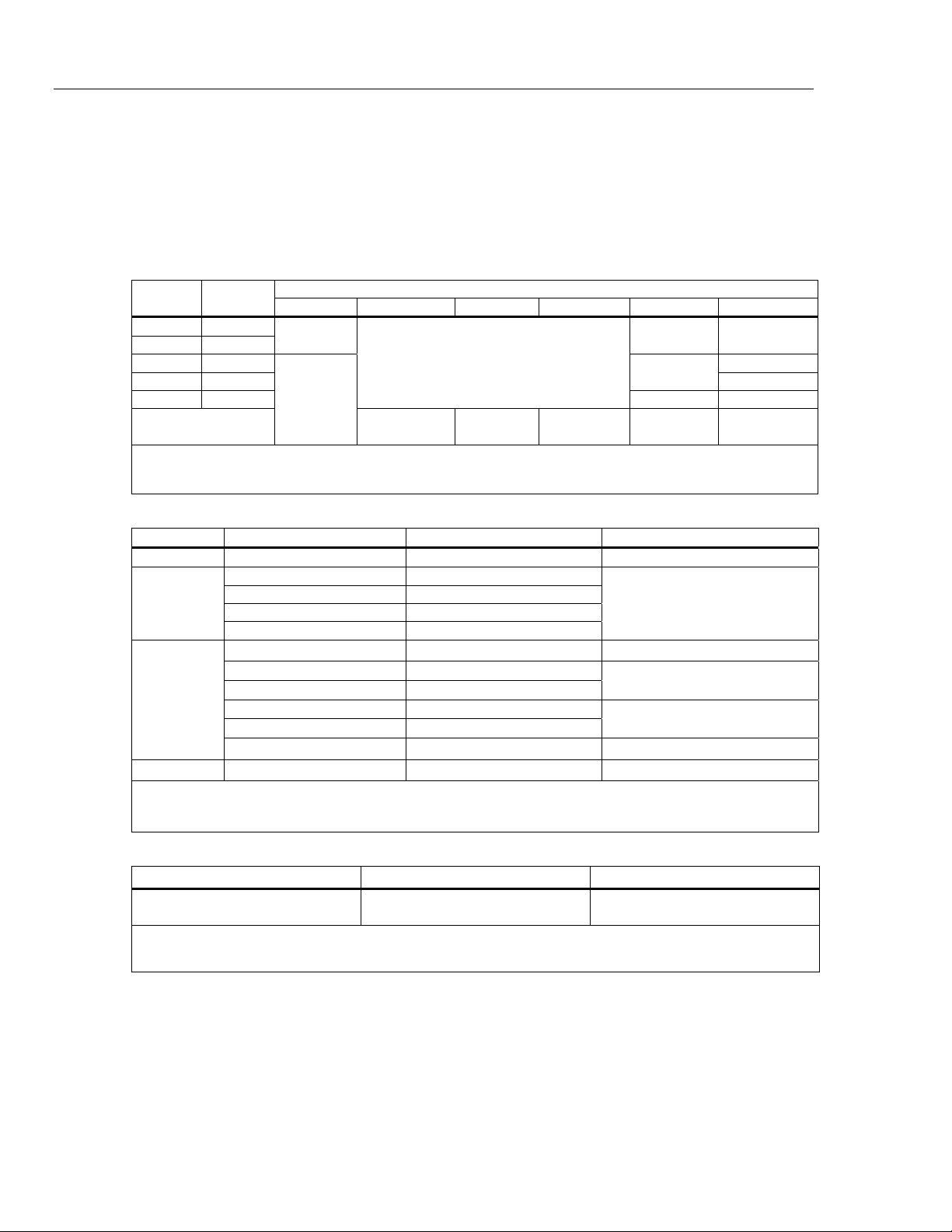

Required Equipment

Table 4 is a list of the equipment necessary to do performance tests on the Meter.

Table 4. Required Equipment

Recommended Equipment Measurement Function Accuracy

Calibrator

(Fluke 5520A or equivalent)

K-type Thermocouple, mini-plug

on both ends

DC Volts

DC Current

AC Volts

AC Current

Resistance

Capacitance

Frequency 19.999 kHz to 199.99 kHz,

Temperature

0 V to 1000 V ±0.012 %

350 μA to 2 A ±0.05 %

0 V to 1000 V ±0.15 %

@ 60 Hz to 20 kHz ±3 %

350 μA to 2 A ±0.39 %

@ 60 Hz to 1 kHz

1 Ω to 100 MΩ ±0.06 %

9 μF to 900 μF ±0.475 %

±0.0137 %

150 mV to 6 Vrms, ±5 %

Accuracy Test

To measure the accuracy of the Meter, set the Calibrator to the Calibrator output

parameters shown in Table 5. Make sure the UUT measurement is between the low and

high limit shown in the table.

Table 5. Accuracy Tests

Step

1

2 600 mV 330 mV, 60 Hz 327.3 mV 332.7 mV

Test

Function

AC Volts

Range Calibrator Output

600 mV 60 mV, 60 Hz 59.2 mV 60.8 mV

UUT Measurement

Low Limit High Limit

3 600 mV 600 mV, 13 kHz 586.0 mV 614.0 mV

4 6 V 675 mV, 60 Hz 0.666 mV 0.684 mV

5 6 V 3.3 V, 60 Hz 3.273 V 3.327 V

6 6 V 3.3 V, 20 kHz 3.214 V 3.386 V

7 60 V 6.75 v, 60 Hz 6.68 V 6.82 V

8 60 V 33 V, 60 Hz 32.75 V 33.25 V

9 600 V 67.5 V, 60 Hz 66.8 V 68.2 V

10 600 V 330 V, 60 Hz 327.5 V 332.5 V

11 600 V 330 V, 2.5 kHz 323.0 V 337.0 V

12 1000 V 100 V, 60 Hz 97 V 103 V

13 1000 V 1000 V, 1 kHz 986 V 1014 V

13

Page 14

28 II Ex

Calibration Information

Table 5. Accuracy Tests (cont.)

Step

14

15 600 mV 150 mV, 199.50 kHz 199.48 mV 199.52 mV

16

17 60 V 7 V, 99.95 kHz 99.93 V 99.97 V

18

19

20

21

22

23 1000 V 1000 V dc 998 V 1002 V

24

25 600 mV 330 mV dc 329.6 mV 330.4 mV

26

27 6 kΩ 3.3 kΩ (Use 2 wire Comp) 3.292 kΩ 3.308 kΩ

Test

Function

AC Volts

Frequency

Sensitivity

Trigger level

Duty Cycle

DC Volts

DC Volts

Ohms

Range 5520A Output

600 mV 150 mV, 99.95 kHz 99.93 mV 99.97 mV

6 V 0.7 V, 99.95 kHz 99.93 V 99.97 V

6 V 3.4 V, 1 kHz Sq. Wave 999.8 V 1000.2 V

6 V 5 V, 1 kHz, DC offset 2.5 V

Square Wave

6 V

60 V

600 V

600 mV 50 mV dc 49.8 mV 50.2 mV

600 Ω 330 Ω ( Use 2 wire Comp) 329.1 Ω 330.9 Ω

3.3 V dc 3.297 V 3.303 V

33 V dc 32.97 V 33.03 V

330 V dc 329.7 V 330.3 V

49.7 % 50.3 %

UUT Measurement

Low Limit High Limit

28 60 kΩ 33 kΩ 32.92 kΩ 33.08 kΩ

29 600 kΩ 330 kΩ 327.2 kΩ 332.1 kΩ

30 6 MΩ 3.3 MΩ 3.279 MΩ 3.321 MΩ

31 50 MΩ 30 MΩ 29.67 MΩ 30.33 MΩ

nS

32

Conductance

33

Diode

34

AC Amps

35

DC Amps

36

AC Milliamps

37 400 mA 330 mA, 60 Hz 326.5 mA 333.5 mA

38

DC Milliamp

39 400 mA 330 mA 329.1 mA 330.9 mA

40

60 nS 100 MΩ 9.60 nS 10.40 nS

6 V 2.0 V dc 1.959 V 2.041 V

6 A 3.0 A, 60 Hz 2.968 A 3.032 A

6 A 3.0 A 2.990 A 3.010 A

60 mA 33 mA, 60 Hz 32.65 mA 33.35 mA

60 mA 33 mA 32.89 mA 33.11 mA

600 μA 330 μA, 60 Hz 326.5 μA 333.5 μA

41 6000 μA 3300 μA, 60 Hz 3265 μA 3335 μA

AC Microamps

14

Page 15

Digital Multimeter

Calibration Adjustments

Table 5. Accuracy Tests (cont.)

Step

42

43 6000 μA 3300 μA 3291 μA 3309 μA

44

45 100 nf 5 nf

46 100 μf 9.5 μf 9.2 nf 9.8 nf

47

48 1000 V 400 V, 800 Hz

49 VDC Peak

50 mVdc

51

[1] Remove test leads from unit.

[2] Use REL to compensate for internal Meter and lead capacitance (must disconnect test leads from calibrator before pushing REL)

[3] The Meter accuracy is not specified at this input signal frequency with Low-pass filter selected. The display reading shown, checks

that the Low-pass filter is active and follows an expected roll-off curve.

[4] To ensure accurate measurement, the Meter and thermocouple adapter must be at the same temperature. After connecting the

thermocouple adapter to the Meter allow for reading to stabilize before recording display reading.

Test

Function

DC Microamps

Capacitance

Low Pass

Filter

Min/Max

Temperature

[4]

Range 5520A Output

600 μA 330 μA 328.9 μA 331.1 μA

10 nf Open input

1000 V 400 V, 400 Hz 372 V 408 V

6 V 8 Vpp, 500 Hz Sq. Wave,

DC offset 2 V

0 °C -1.0 °C 1.0 °C

100 °C 98.0 °C 102.0 °C

[1]

0.28 nf 0.48 nf

[2]

4.7 nf 5.3 nf

[3]

226 V 340 V

-1.898 V to -

2.102 V

UUT Measurement

Low Limit High Limit

5.896 V to

6.104 V

Backlight Functional Test

A backlight test is done to make sure the backlight comes on with the first push of H.

The second push causes the backlight to be brighter and a third push turns off the

backlight.

Calibration Adjustments

If one or more of the accuracy tests shows a measurement that is not between the high

and low limits, you can do adjustments. This adjustment procedure sets the Meter to

operate to its specifications.

If the adjustment routine is stopped before you complete the procedure, no

changes are made to the calibration constants in memory.

You must set the Meter to the CAL mode and type in a password to do calibration

adjustments.

Cal Mode Button Functions

For the CAL mode, some of the buttons on the Meter have alternative functions. Some

buttons function differently at different points in the calibration adjustment procedure.

Table 6 is a list of the Meter buttons and their function for the calibration adjustment

procedure.

Note

15

Page 16

28 II Ex

Calibration Information

Button CAL Function

Table 6. Button Functions for Calibration Adjustment

Password

Numeric

Value

(Yellow)

C Push at the point where you type in the password to make a new password. 3

D

H Use only as a password value. 5

E Use only as a password value. 6

F Use only as a password value. 7

G

Push and hold to show the measured value in the display. The measurement

is not calibrated, so it can be inaccurate.

Use to set the Meter to the CAL mode. In a calibration procedure, push and

hold to show the necessary input level in the Meter display.

Use as the “ENTER” key. Push to store the new calibration adjustment value

and move to the subsequent step. This button is also used to exit the

calibration adjustment mode after the calibration adjustment sequence is

complete.

Push and hold to show the necessary frequency of the input signal in the

Meter display.

Calibration Adjustment Procedure

Note

In the calibration adjustment procedure, some adjustment steps are longer

to do than others (10 seconds to 15 seconds). For some of the steps, the

Meter gives two beeps when the step is complete. Not all steps have this

feature.

1

2

4

8

16

1. Push and hold down while you turn the rotary switch from OFF to .

CAL in the display shows you have set the Meter into the CAL mode.

2. Push D once to see the number of calibrations that have been completed.

3. Push D again to show ???? in the display.

4. Use the eight Meter buttons to type in the current password and push D.

Note

The default factory password is 1234. See the “How to Change the

Password” section to change the password. If the password you typed in is

????

not correct, then the Meter will beep two times and show

in the

display.

5. C-01 in the display shows the CAL mode is set and the Meter is at the first

calibration adjustment step.

WCaution

To prevent damage to the Meter, make sure the calibrator is in

standby before you change its parameters, or change the

function on the Meter.

6. Set the calibrator to the parameters shown in the Input Value column of Table 7 for

the calibration step shown in the display.

Page 17

Digital Multimeter

Calibration Adjustments

Note

You can push to show the necessary input signal level and G to

show the necessary input signal frequency for the calibration step.

8. Turn on the output signal on the calibrator.

9. Push D to complete the step and move to the subsequent step.

If the step shown in the display moves to the subsequent step, the adjustment was

successful. If the Meter gives two beeps and does not move to the subsequent step,

then the adjustment was not successful. Make sure the calibrator is set correctly and

push D again. If the calibrator output is correct, then it is necessary to repair the

Meter.

Note

If the calibration adjustment is not completed correctly, the Meter will not

operate correctly.

10. Put the calibrator in standby.

11. Do steps 6 through 10 for each calibration step in Table 7.

12. After you complete the last adjustment step, End shows in the display. Push D to

complete the calibration adjustment procedure and store the calibration constants in

the Meter.

Function

(Switch Position)

(AC Volts)

(DC Volts)

(DC Millivolts)

(Ohms)

(Diode Test)

Table 7. Calibration Adjustment Steps

Adjustment Step Input Value

C-01 600.0 mV, 60 Hz

C-02 600.0 mV, 20 kHz

C-03 6.000 V, 60 Hz

C-04 6.000 V, 20 kHz

C-05 60.00 V, 60 Hz

C-06 60.00 V, 20 kHz

C-07 600.0 V, 60 Hz

C-08 600.0 V, 10 kHz

C-09 6.000 V

C-10 60.00 V

C-11 600.0 V

C-12 600.0 mV

C-13 60.00 mV

C-14 600.0 Ω

C-15 6.000 kΩ

C-16 60.00 kΩ

C-17 600.0 kΩ

C-18 6.000 MΩ

C-19 0.000 Ω

C-20 50.0 MΩ

C-21 3.000 V

17

Page 18

28 II Ex

Calibration Information

Table 7. Calibration Adjustment Steps (cont.)

Function

(Switch Position)

(Amps)

(Amps)

(Microamps)

Change the Password

1. Push and hold down while you turn the rotary switch from OFF to . The

Meter shows Y CALin the display.

2. Push D two times to show ???? in the display.

3. Use the eight Meter buttons to type in the current password, but do not push D.

4. Push C to show "_ _ _ _" in the display.

5. Use the eight Meter buttons to type in a new password.

Adjustment Step Input Value

C-22 6.000 A, 60 Hz

C-23 6.000 A dc

C-24 60.00 mA, 60 Hz

C-25 400.0 mA, 60 Hz

C-26 60.00 mA dc

C-27 400.0 mA dc

C-28 600.0 μA, 60 Hz

C-29 6000 μA, 60 Hz

C-30 600.0 μA dc

C-31 6000 μA dc

6. Push D to save the new password.

Set the Password to its Default Value

If the password was forgotten, it can be set to its default value (1234). See Figure 3.

1. Turn the rotary switch of the Meter to OFF.

2. Remove the bottom case and bottom shield of the Meter.

3. Apply a dc voltage between 3.5 V and 5 V at the test points marked “+” and “-” at

the edge of the board. (See Figure 3, item 1).

18

Page 19

Digital Multimeter

S11

Calibration Adjustments

3

2X-2- 3001 REV 011

S11

1

2

3.5 - 5 V

grt102.eps

Figure 3. Reset the Password

4. Push and hold while you turn the rotary switch from OFF to J (See

Figure 3, item 2). The Meter shows Y CALin the display.

5. Short across keypad button S11 on the PCB (See Figure 3, item 3). The Meter will

beep.

6. Turn the rotary switch one position counterclockwise to the OFF position.

The password is set to the default value of 1234.

7. Replace the bottom shield and bottom case of the Meter before you do adjustments or

tests.

19

Page 20

28 II Ex

Calibration Information

Lifetime Limited Warranty

Each Fluke 20, 70, 80, 170, 180 and 280 Series DMM will be free from defects in material and workmanship

for its lifetime. As used herein, “lifetime” is defined as seven years after Fluke discontinues manufacturing

the product, but the warranty period shall be at least ten years from the date of purchase. This warranty

does not cover fuses, disposable batteries, damage from neglect, misuse, contamination, alteration,

accident or abnormal conditions of operation or handling, including failures caused by use outside of the

product’s specifications, or normal wear and tear of mechanical components. This warranty covers the

original purchaser only and is not transferable. For ten years from the date of purchase, this warranty also

covers the LCD. Thereafter, for the lifetime of the DMM, Fluke will replace the LCD for a fee based on then

current component acquisition costs.

To establish original ownership and prove date of purchase, please complete and return the registration card

accompanying the product, or register your product on

no charge, replace or refund the purchase price of a defective product purchased through a Fluke

authorized sales outlet and at the applicable international price. Fluke reserves the right to charge for

importation costs of repair/replacement parts if the product purchased in one country is sent for repair

elsewhere.

If the product is defective, contact your nearest Fluke authorized service center to obtain return authorization

information, then send the product to that service center, with a description of the difficulty, postage and

insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Fluke will pay return

transportation for product repaired or replaced in-warranty. Before making any non-warranty repair, Fluke

will estimate cost and obtain authorization, then invoice you for repair and return transportation.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A

PARTICULAR PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY

SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS

OF DATA, ARISING FROM ANY CAUSE OR THEORY. AUTHORIZED RESELLERS ARE NOT

AUTHORIZED TO EXTEND ANY DIFFERENT WARRANTY ON FLUKE’S BEHALF. Since some states do

not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this

limitation of liability may not apply to you. If any provision of this warranty is held invalid or unenforceable by

a court or other decision-maker of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

http://www.fluke.com. Fluke will, at its option, repair at

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

20

5/07

Loading...

Loading...