Page 1

Event recording (or logging)

with a Fluke 287/289

Digital Multimeter

One of the major features of the Fluke

280 Series digital multimeters (DMM) with

TrendCapture is their ability to record

measurement data or “do logging.” This

application note explains what kind of

logging these meters can perform, how

to use the recording feature, and what

information it can provide. This note also

discusses how to use FlukeView

PC software to increase the power of the

Recording feature.

For the balance of this note, we will

refer to the Fluke 289 DMM, although the

information is equally applicable to the

Fluke 287 DMM.

®

Forms

Application Note

Note: This article references features

included in a firmware upgrade to the 289

DMM released in August, 2008. To obtain

the latest firmware version, visit www.

fluke.com/software-downloads. For

a summary of the changes, reference the

end of this document.

Differences between

the Fluke 289 DMM and

a data logger

The Fluke 289 does not do data

logging in the traditional sense.

Typically, the goal of a data logger is to sample the input signal

at a rate sufficient to track activity that you might find in the

signal. This often means that it

is desirable to sample the input

as fast as possible so you don’t

miss anything. The problem

with this approach is you need

a large storage place for the fast

data sampling that is taking

place. You can also end up wading through a lot of redundant

data that is considered “normal”

to find the exceptional data (or

lack thereof).

The difference between the

Fluke 289 DMM and a traditional logger is that the DMM,

while sampling internally at a

sub-second rate, records only

significant changes in the readings. This technique, called

event recording, requires far

less memory. Still, it does an

effective job of monitoring and

logging data from an input signal, enabling you to detect if

and when the monitored system

is operating abnormally.

The other difference is that

the Fluke 289 DMM can graph

the data onscreen in TrendCapture mode, immediately after

the recording session is completed. TrendCapture is a major

enhancement in the 28X family

over the previous logging capability of the 189, which had to

upload each recording session to

software to graph and view the

results. The Fluke 289 uses similar graphing software (optional)

for detailed analysis, but its ability to graph even rough details

immediately, onscreen, can

be very powerful. In addition,

the 28X can now hold multiple

recording sessions in it’s memory allowing troubleshooters to

get multiple sets of data, possibly at different locations, without

having to download each session as in the past.

Introduction to event

recording

Event recording can be thought

of as an extension of the “Touch

Hold” feature of the original

Fluke 87 DMM. (Touch Hold is

now called “Auto Hold” on the

287/289.) When the Auto Hold

feature is activated, the meter

waits until a period of stability

From the Fluke Digital Library @ www.fluke.com/library

Page 2

Figure 1.

has been reached, then it beeps

and freezes (holds) a stable

reading on the display for the

user to see. If the input changes

to the point that it is no longer

stable, then becomes stable

again, the meter will beep a

second time and hold a new

reading on the display.

Event recording uses a similar

scheme. When the Fluke 289 is

recording, it is looking for periods of stability. For each stable

or unstable period the meter

logs a start time, the initial

reading, stop time, the maximum

reading, minimum reading (and

the times of their occurrence)

and average reading during

that period. The event recording

feature is designed to store only

enough information to describe

any changes; i.e., events, to the

input signal.

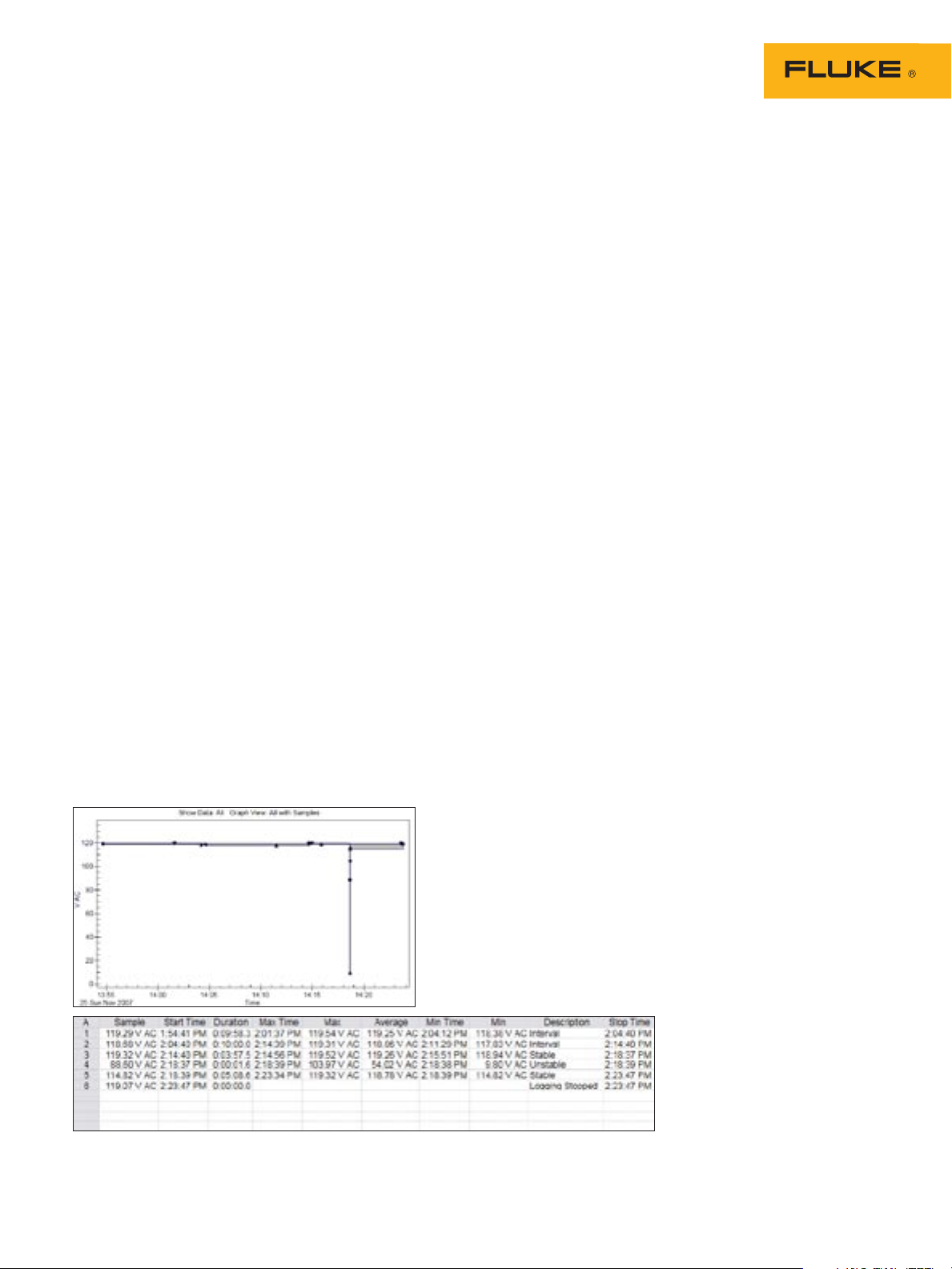

Event recording data

The Fluke 289 excels at recording transition events, but while

it has TrendCapture graphing

capability, it does not have the

kind of large graphical display

resolution needed to analyze all

of the event data. This is where

FlukeView Forms software takes

over, allowing you to view the

recorded data in table or graph

form on a PC. An example is

shown in the figure below.

Looking at this data, you can

see that the recording session

started at 1:54:41 PM and ended

at 2:23:47 PM with an elapsed

time of about 29 minutes. You

can also see that the signal

being measured was stable near

119 V for most of the logging

session.

However, there was one

unstable event detected by

the meter during a 1.6-second

period beginning at 2:18 PM.

The graph clearly shows the

switching event that happened

at that time. What is interesting about this example is that

the table of data shows only six

“events” needed to be stored

in the meter memory over the

entire 29 minutes of logging

to capture the essence of what

happened.

What this illustration shows is

that, with event recording, only

a very small amount of memory

is needed to store the information. To capture the same data

using traditional data logging

would require a one-second

sample rate over the entire 29

minutes which would have

produced 1,740 records of data,

yet that level of detail was not

required to detect the problem.

Recording—by the

numbers

Now that we know how the

Fluke 289 records data, let’s

go through the step-by-step

process for recording a desired

signal over time. In this case,

the test will record the signature

of the current drawn by a large

household refrigerator for more

than one day.

The following steps can be

generalized to any recording

situation.

Step 1

Make sure that the battery

indicator in the upper left hand

corner of the Fluke 289 display

shows at least two of the possible four bars, indicating enough

charge is left for a 24-hour operation. For any longer recording

period, or if in doubt, replace the

batteries with fresh new ones.

Step 2

Connect the meter to the

circuit being measured.

In this example, the ac current

was measured by connecting

a current transformer probe to

the mA jacks of the Fluke 289.

That is because the probe output

is 1 mA/A. We then place the

jaws of the probe around the

circuit conductor in the distribution panel that is connected

to the breaker dedicated to the

refrigerator. If the DMM function

switch is in any position except

A/mA or μA, the meter will beep

to indicate that the switch must

be in one of these two positions to proceed, and the display

information screen will show

the details. In this case, we

want the A/mA function. The

meter will sense the presence

of the lead in the mA jack, and

select the proper circuit for the

recording.

Note: Although not required in this

case, if a signal normally varies a full

point, you might want to estimate a

maximum current or voltage that you

expect to encounter, and set manual

ranging to the higher range. This will

prevent recording multiple events due

to auto-ranging.

Step 3

Press the Save (F2) softkey

and highlight the Record option

using the navigation arrows.

Then, press the Record (F1)

softkey below the display.

At this point, the Recording

information screen appears.

Note that the bottom line of this

display indicates the battery

condition. If the battery is partially discharged, the Battery:

partly empty advisory appears.

See step 1 above.

2 Fluke Corporation Event recording (or logging) with a Fluke 287/289 Digital Multimeter

Page 3

16

12

8

4

0

00:0009:30 19:00 28:30 37:33

m

A

A

C

1.830 mA AC 01:57:42pm HH:MM

05/30/08 07:03:09pm

06/01/08

08:35 am

x1

16

12

8

4

0

14:36 16:36 18:36 22:3620:36

m

A

A

C

1.944 mAAC 02:21: 01pm HH:MM

05/30/08 07:03:09pm

06/01/08

08:35 am

x3

Important

These next steps (7 through 9) should be

performed immediately after the test is

ended, or when you return to retrieve you

meter, before you explore the data on screen.

This is to make sure you save the recorded

data in a known and easy to recall location.

3 Fluke Corporation Event recording (or logging) with a Fluke 287/289 Digital Multimeter

Step 4

Using the navigation arrows,

highlight Set Duration and

press Edit ( F1). Edit the duration

setting to 07 Days 00 Hrs 00

Min. (We can always manually

stop the recording procedure

earlier if we like.)

Note: Recording duration and sample

interval times may interact — setting

one variable may adjust the other to

fit the recording session within the

available memory.

Step 5

When Duration and Sample

Interval settings have been

changed to desired values, press

OK ( F1) to accept the changes.

Step 6

Press the Start (F2) softkey to

begin recording. You can now

leave the meter unattended.

The 289 will record the current

(amps) used by the refrigerator.

Note: While recording is active (1) the

power button LED will flash on and

off, (2) five minutes after any button

press, the display will turn off to conserve battery power. Press any button

to turn the display back on, and (3)

the display will show the start time,

the remaining time and number of

recorded interval samples and events.

Step 7

Recording is stopped in three

ways: (1) Automatically when

the recording duration time

has reached, (2) Automatically

when the battery level becomes

critically low or (3) Manually by

pressing the Stop (F4) softkey.

When recording is stopped,

the power button LED will stop

flashing on and off. Note that

once the recording session has

stopped, you cannot resume that

session.

Note: Returning to Stopped Screen

after meter auto powers off: When

recording ends automatically due to

duration time being reached, the display is turned on (if it had been off)

and the meter will power off according to the Auto Power Off setting in

Instrument Setup (never or N minutes).

If the recording ends due to the battery becoming critically low, the meter

will immediately power down. Turn

the meter back on. If the battery is

showing empty, turn the meter off and

replace the batteries. Turn the meter

back on. The meter will start showing

the display as if you were at the start

of Step 8.

Step 8

Press Save (F2) to bring up the

Save display.

Step 9

Press the +Name (F1) softkey

to select the recording session

name to be associated with this

saved data. In this case, since it

is a recording, you might choose

to highlight Recording and note

that a boxed number appears.

This number is automatically

incremented each time you do a

save using that save name. Note

this saved name (including its

number) so that you can easily

identify the source of the data

in memory after you upload it to

FlukeView Forms. That’s because

you could easily have ten or

more recordings in memory

before you return to a computer.

Step 10

Now, press Save ( F1) one more

time to complete the storage of

the test data in the DMM memory. The display screen will now

show the Start time, the Duration of the test, and the number

of Interval samples and Events

that were stored.

Congratulations!

You have successfully completed

a recording session and saved

the results in the meter. You can

now turn the meter off, or use

it for other purposes until you

choose to transfer your data to a

computer.

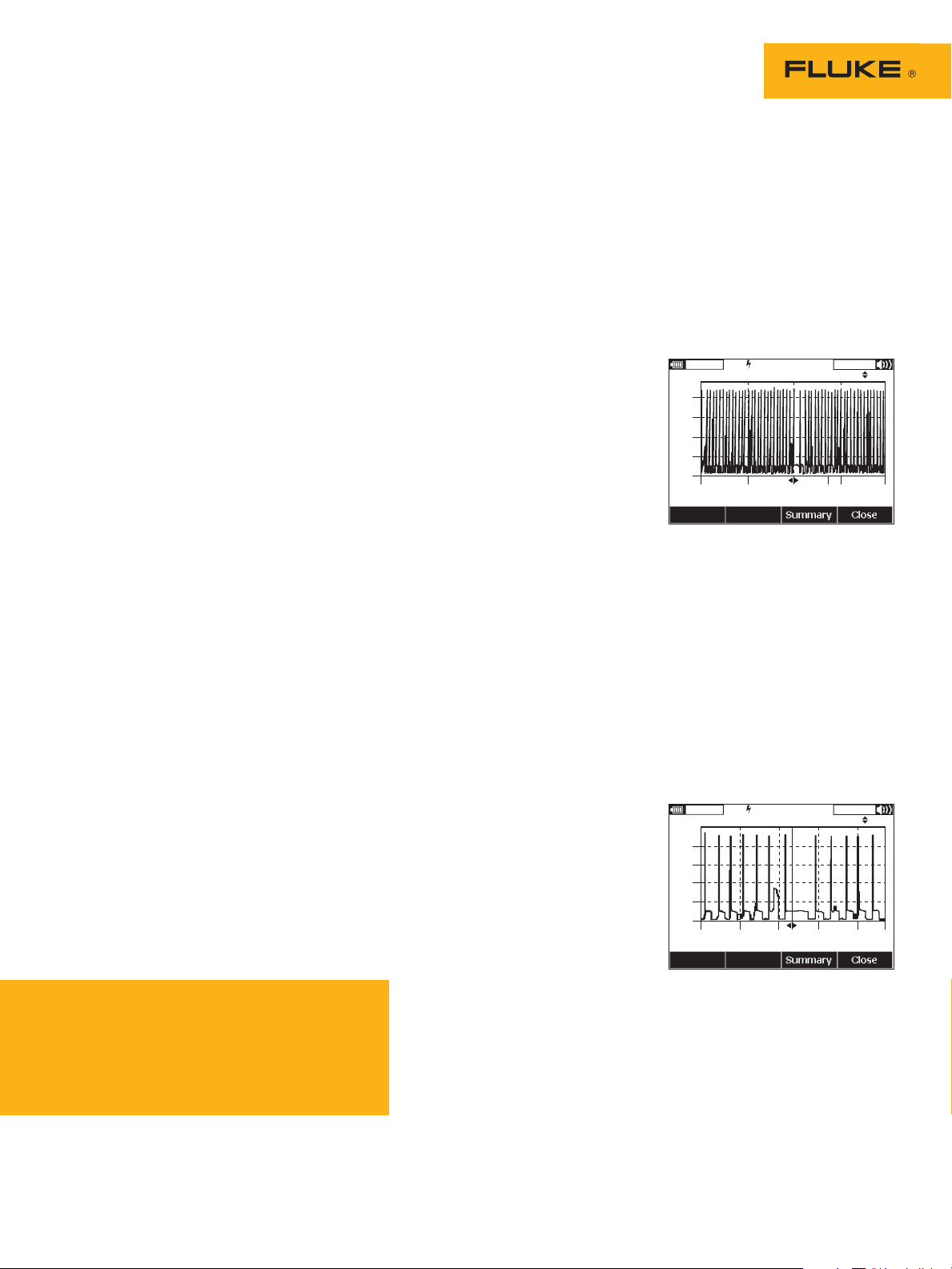

Using TrendCapture

You may now safely press the

Trend (F3) softkey to view

the stored results in graphical format. A vertical cursor

will appear in the center of the

TrendCapture display. Using the

navigation keys, you can move

this cursor over areas of interest

in the graph and the value and

time of recording for that value

will appear.

Figure 2. Single refrigeration cycle.

The first thing to note is that

the graph has been scaled to

20 mA. Here’s what’s happening.

The current level was mostly at

about the 2 mA level when the

compressor was running. The 18

mA “spikes” show the momentary motor starting current each

time the compressor ran.

The blank gap near the center

of the screen is interesting, so

now we’ll use the TrendCapture

Zoom feature, using the updown navigation keys, to look at

the detail.

Figure 3. Single cycle, zoomed.

While in Trend mode, the

F3 menu selection changes to

Summary. Press the softkey to

see the session summary data,

including the Start Time and

Duration of the recording and

the number of Interval Samples

and Events recorded. The main

display shows the last recorded

value in the session.

Note: Time scale for Figure 2 and 3 is

elapsed time.

Page 4

Use TrendCapture immediately after recording to do a

brief inspection of the recorded

data for any suspicious events

that might suggest further testing. You can also use it later, in

conjunction with the Summary

screen, to evaluate or identify

multiple saved files in the meter

if you didn’t note the saved

session name at the time of

recording.

Remember:

TrendCapture can only be used to review

recorded data—either the session just completed or

a saved data file—it cannot graph in real-time. If

you attempt to use TrendCapture during a recording session, you will terminate the recording.

Uploading recorded data

to FlukeView® Forms.

The next steps describe how to

transfer the recording results to

FlukeView Forms, where you can

complete reports that include

graphs, showing what happened to the refrigerator during

the time it was being recorded.

You can also program certain

functions of the meter from your

computer while it is connected.

Note: This process assumes you

already have FlukeView Forms

installed on your computer.

You should see a ‘connected’

icon with the port identified

in the lower right part of the

display. If there are port conflicts, you may see the Options

window appear, where you

will have to select an available

unused port. Press OK when you

see the ‘connected’ icon appear.

The next pop-up window to appear should be Get

Meter Data—Fluke 289/287.

It will ask you if you want

to Get meter data now? If

this window doesn’t appear

automatically, you may select

Meter on the menu bar and

then select Get meter data…

from the drop down list.

Step 3

Press OK to begin the upload

process. If the data you’re trying to upload is the last session

you recorded, then the data you

want will be displayed in the

FVF Virtual Meter “memory”

screen. You can verify this by

viewing the summary information at the bottom of the window

that appears. (Figure 4a.) Then

select Copy into Form on the

right side of the window. This

data will automatically copy to

the displayed Form (Figure 4b.)

Step 4

If the recording you want is

not the last one recorded, then

you must open the pull down

window in the upper left corner

of the window and select Data

Sessions. A table will appear

showing the Session Name,

Session Type, Start Time, and

Number of Readings for each

session saved in the meter. See

Figure 5.

Step 5

Select the desired Recording

and press Get Session Data.

When the upload is complete,

the selected recording will be

present and you can Copy into

Form.

In our example (Figure 6),

Recording 4 spanned nearly 42

hours of refrigerator operation.

What we see on the graph is the

repeated cycle of turn-on (the

18 amp narrow spike), compressor run (a few minutes at 2 to 3

amps), and off time (more than

15 minutes at 0.0 amps.)

A quick glance at the graph

shows an unusual event (highlighted by the dashed circle)

Step 1

Using the IR-USB cable, connect

the meter to your computer. It’s

best to have the meter in the

active measurement mode (not in

Figure 4a. Summary information

setup or any of the save/record/

view functions) while connected

to your computer. When connecting the IR connector to the

meter, verify that the Fluke logo

on the IR connector is visible

when viewing the display of the

Figure 5.

meter. Now, turn the meter on.

Note: The meter cannot upload data

while memory or TrendCapture information is being displayed.

Step 2

Start FlukeView Forms on the

computer. The ‘New Blank

Form’ window will appear. For

our refrigerator example, select

Sample Logging Form (short)

and then press OK.

4 Fluke Corporation Event recording (or logging) with a Fluke 287/289 Digital Multimeter

Figure 6.

Figure 4b.

Page 5

Figure 7.

near midnight on Thursday

morning. First, the running

current was near 5 amps, and

then the following cycle lasted

for much longer than normal.

What we have discovered is the

occasional defrost cycle that is

a feature of this refrigerator. The

5 amp portion is the operation

of the defrost heater, and the

longer next cycle is an extended

compressor run to remove the

excess heat.

Zoom choices as well as many

other options affecting the graph

(Figure 7.)

The highlighted Manual Zoom

allows you to precisely locate

the area of interest using the

time scale at the bottom of the

graph. In our example in Figure

8, we show the period from

10:00 PM on Wednesday to 2:15

AM Thursday morning—when

the defrost cycle occurred.

Here you can see a few normal cycles, then the defrost

cycle and recovery, and finally

the return to normal cycles.

There are three more features

in FlukeView Forms that you

should be aware of. The first

allows you to examine the detail

for a selected point on the graph.

This feature is revealed by moving your screen cursor to the

point of interest until the cursor

changes to a pointing finger. For

our example, we’ll choose the

beginning of the 6 amp reading. Then, left-click and hold

to see a pop-up window with

detailed information for the

selected sample. (Figure 9.)

This feature gives you instant

detail regarding a point of inter-

est in your recording. You’ll note

that reading 298 was an Interval

which only lasted 11+ minutes

rather than the normal 15 minutes. The likely reason was that

the interval was interrupted by

a sudden change in the meter

input.

Second, to look at the detailed

information recorded around

the event of interest, look to

the Logged Reading Table just

below the graph on your form.

(Figu r e 10.)

Scrolling to reading 298, we

see the interval in question in

detail. And, reading 299 was

an unstable event that shows

the time the defroster heater

turned off.

Figure 8.

A similar event might be the

operation of an ice dispenser as

it crushes ice, or the ice maker

as it refills and freezes new ice

cubes.

FlukeView Forms has a Zoom

feature that allows us to look

closely at an event of interest in

greater detail. You can click and

drag a box around the area of

interest, or you can right click

anywhere on the graph to see

a pop-up window with several

5 Fluke Corporation Event recording (or logging) with a Fluke 287/289 Digital Multimeter

Figure 9.

Tip:

To copy FVF information to

other documents, right-click

on the Logged Reading Table

and or other Fluke View

Forms graph and use the

“copy” option.

Third, notice the extensive

file naming and storing options

in the meter hinted at in the

Data Session selection window in Figure 4. Note that the

meter stores multiple sessions

with the user-selected Session Name, Session Type, Start

Time, and Number of Readings.

Page 6

Figure 10.

Session names are available in several categories and

use self-incrementing numbers

for each session in a selected

type. The meter can record four

session types: Measurement,

Min Max, Peak, and Recording. You can store sessions in

any one of the Name categories

you choose, although it’s generally a good idea to use the

Measurement name category

for individual measurement

saves and the Recording name

for long logging sessions, just

to keep things organized.

Wrapping it up

This is only a brief description

of Event Recording using the

Fluke 289, and the added power

provided by the companion PC

software, FlukeView Forms.

In our example, we used

only 405 readings to capture

the current used by a refrigerator over nearly 42 hours of

recording, yet, the meter was

able to detect 239 instances

of unusual events, down to

the second they occurred,

for our later inspection.

This step-by-step example

following one recording session from the meter recording

process into TrendCapture

and then FlukeView Forms is

intended as an introduction to

the power of Event Recording

in the Fluke 289. We recommend further exploring these

features at your leisure.

Selected recent updates to FlukeView Forms Software (v3.4)

Screen Shots from the meter

With the introduction of version 3.4 of FlukeView Forms, it

is now possible to save screen shots from a connected Fluke

287/289 digital multimeter.

The procedure for saving a screen shot is as follows:

1. On the meter, select the screen to be saved as the current

meter display.

2. In FlukeView Forms (connected) click the Meter icon.

3. In the upper left-hand corner of the 289/287 import window select Meter Display.

4. On the right hand side of the active display window,

select the Get Screen Shot button. The Fluke 289/287

Screen Shot save window will appear. Select the folder

and specify a file name for the file to be saved. The file

saved will be a zip file with an extension .bmp. The

screen shot can then be unzipped as a JPG or other file

format and placed on a FlukeView Forms Bitmap object in

your chosen form. It may also be used in other software

applications, or emailed if desired.

6 Fluke Corporation Event recording (or logging) with a Fluke 287/289 Digital Multimeter

Changing or adding data to the meter from

FlukeView Forms

There have been several additions to the ability to upload

information to the meter from FlukeView Forms.

From the menu, select Meter-Change Meter Setup.

The window that appears shows everything that may be

changed in the meter. (To change a name in the meter’s

#Name list, click on the Edit Name List button at the bottom

of the window.)

Changing FlukeView Form items to accept

information

When you have uploaded Operator Name information from

FlukeView Forms to the meter (to be viewed on the meter

using Setup-Meter Info), the added Operator Name will be

appear in FlukeView Forms when you download data from

the meter. It will appear in the FlukeView Meter Infor-

mation form item. If you’re using one of the sample forms

delivered with the software, this item may be shown on

your form with the Serial No. label. Make sure you expand

this item on the form (using FlukeView Forms Designer) to

display this second line of information. You might also want

to change the label to something more appropriate, such as

“Meter Info”, since the field now displays more than just a

serial no.

Page 7

Firmware updates to Fluke 287/289 Digital Multimeters

The internal programs of these meters are stored

in flash memory. As a result, Fluke can now offer

product updates and improvements from time

to time.

This sidebar summarizes new additions to the

Fluke 289/287 firmware with version 1.1. Where

applicable, these feature changes have already

been incorporated into the main body of this

application note. The updated firmware may be

downloaded from the Fluke website at www.

fluke.com/software-downloads and installed

using the USB connecting cable furnished with

FlukeView Forms software. Any future firmware

updates for the Fluke 287/289 Digital Multimeters

will include these same features.

Page numbers () are indicated to help you

locate details of these features in the updated

user manual available online in pdf format at

www.fluke.com/289-manual.

Recording and display (TrendCapture)

1. Basic settings for a recording session have

been simplified and clarified. (53-54)

Recording setup is accessed using the Save-

Record soft-keys. In the Recording Menu, you

now select only Duration of recording and

Sample Interval. Percentage of available memory and battery condition are reported.

2. Event Threshold Value (%) for AutoHOLD and

Recording can now be set in the meter. (54)

Previously, it was necessary to make this set-

ting using FlukeView Forms software from a

connected computer. (Default values are 4 %

for both functions.) Threshold value setup is

accessed using the Setup-Recording soft-keys.

On the Recording Setup screen, you may now

select Event Threshold to adjust the AutoHOLD

threshold value and adjust using the cursor

keys for values between 1 % and 30 %. Event

Threshold for Recording may be turned off, if

only interval recording is desired, or set to one of

seven selected values between 1 % and 25 %.

3. The TrendCapture graphic display of events

recorded by the meter has been improved to

more clearly indicate the activity of a device

being recorded. No change in user operation is

required to make use of this improved display.

4. A new Zoom feature has been added to the

Trend Data display that expands the graph to

show more details of unusual events (51)

To use this new feature, first position the

vertical cursor bar over the point of interest

in the Trend Data display (using the left and

right arrows) and then press the up arrow to

magnify the display by two, centered on the

cursor position. You can do this repeatedly until

the desired resolution is achieved. Zoom back

out by using the down arrow. Date and time

are reported above the graph along with the

zoom level (full display is x1). The recorded

value at the cursor position and the time it was

recorded are reported under the graph.

Other features, additions, and updates

1. When switching to the current measurement

functions (A/mA or uA) the meter will ‘remember’ the last used selection for ac or dc. (39)

Once in this function, the same setting will

hold between A, mA and uA. This feature is

useful when the operator is using ac only or

ac+dc current clamp accessories, to minimize

repeat setup actions.

2. A Smoothing mode may be enabled for ac

measurements. (49)

This feature allows you to select a filter to

smooth noisy ac readings. Smoothing options

are accessed using the Setup-Instrument

soft-keys. Under Edit, you can then turn the

smoothing function on or off using up-down

arrow keys.

3. You can add your name, company name,

worksite, and contact information under

Setup-Meter Info (49)

This information can only be added using

FlukeView Forms software while the meter is

connected to your computer.

4. Changing file names.(49)

When saving a measurement, min/max, peak

min/max, or recording session, the meter

selects one of eight possible Save Names with

an auto incrementing number. The user can

now use Fluke View Forms to change the Save

Names to something more meaningful.

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2008 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 8/2008 3325448 A-EN-N Rev C

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

7 Fluke Corporation Event recording (or logging) with a Fluke 287/289 Digital Multimeter

Loading...

Loading...