Page 1

27

®

Multimeter

Service Manual

For IEC 61010 CAT III Meters Only

PN 690206

November 1998

© 1998 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Page 2

Page 3

Table of Contents

Chapter Title Page

1 Introduction and Specifications........................................................... 1-1

1-1. Using the Meter Safely .......................................................................... 1-3

1-2. Operating Instructions ............................................................................ 1-4

1-3. Specifications ......................................................................................... 1-5

2 Theory of Operation .............................................................................. 2-1

2-1. Introduction ........................................................................................... 2-3

2-2. Functional Description ........................................................................... 2-3

2-3. Block Diagram Description ................................................................... 2-4

2-4. Input Overload Protection ................................................................. 2-4

2-5. Function Switching Circuits .............................................................. 2-4

2-6. Signal Conditioning Circuits ............................................................. 2-4

2-7. Custom Analog IC (U1) .................................................................... 2-4

2-8. Peripherals to U1 ............................................................................... 2-6

2-9. Microcomputer Control ..................................................................... 2-6

2-10. Display .............................................................................................. 2-7

3 Maintenance........................................................................................... 3-1

3-1. Introduction ........................................................................................... 3-3

3-2. Service Information ............................................................................... 3-4

3-3. Operator Maintenance ............................................................................ 3-4

3-4. Battery Replacement ......................................................................... 3-5

3-5. Fuse Test ........................................................................................... 3-6

3-6. Fuse Replacement .............................................................................. 3-6

3-7. General Maintenance Information ......................................................... 3-7

3-8. Handling Precautions for Static-Sensitive Devices ........................... 3-7

3-9. Disassembly ....................................................................................... 3-7

3-10. Reassembly ........................................................................................ 3-10

3-11. Cleaning ............................................................................................ 3-12

3-12. Performance Tests ................................................................................. 3-12

3-13. Display Test ....................................................................................... 3-12

3-14. Voltage Functions Performance Verification .................................... 3-13

3-15. AC and DC Current Performance Verification .................................. 3-13

3-16. Ohms Function Performance Verification ......................................... 3-14

i

Page 4

27

Service Manual

3-17. Diode Test Performance Verification ................................................ 3-15

3-18. Calibration Adjustment .......................................................................... 3-15

3-19. Calibration Preparation ...................................................................... 3-15

3-20. DC Voltage Connection .................................................................... 3-16

3-21. AC Voltage Calibration ..................................................................... 3-16

3-22. Troubleshooting ..................................................................................... 3-17

3-23. Power-Up Self Test ........................................................................... 3-17

3-24. Overall System Check ....................................................................... 3-17

3-25. DC Voltage Signal Tracing ............................................................... 3-18

3-26. Fault Diagnosis Guide ....................................................................... 3-19

4 List of Replaceable Parts...................................................................... 4-1

4-1. Introduction ........................................................................................... 4-3

4-2. How to Obtain Parts ............................................................................... 4-3

4-3. Manual Status Information .................................................................... 4-3

4-4. Newer Instruments ................................................................................. 4-4

4-5. Service Centers ...................................................................................... 4-4

4-6. Parts Lists .............................................................................................. 4-5

5 Schematic Diagrams ............................................................................. 5-1

ii

Page 5

List of Tables

Table Title Page

1-1. Specifications.......................................................................................................... 1-5

3-1. Recommended Test Equipment .............................................................................. 3-3

3-2. Replacement Fuses.................................................................................................. 3-6

3-3. Ohm Function Performance Test ............................................................................ 3-15

3-4. Fault Diagnosis Guide............................................................................................. 3-19

4-1. Final Assembly ....................................................................................................... 4-6

4-2. A1 Main PCA ......................................................................................................... 4-8

4-3. A2 Digital PCA....................................................................................................... 4-11

iii

Page 6

27

Service Manual

iv

Page 7

List of Figures

Figure Title Page

3-1. Battery and Fuse Replacement................................................................................ 3-5

3-2. Disassembly............................................................................................................ 3-8

3-3. Calibration Adjustment Locations .......................................................................... 3-16

4-1. Final Assembly ....................................................................................................... 4-7

4-2. A1 Main PCA ......................................................................................................... 4-10

4-3. A2 Digital PCA....................................................................................................... 4-11

5-1. A1 Main PCA and A2 Digital PCA........................................................................ 5-3

v

Page 8

27

Service Manual

vi

Page 9

Chapter 1

Introduction and Specifications

Title Page

1-1. Using the Meter Safely........................................................................ 1-3

1-2. Operating Instructions.......................................................................... 1-4

1-3. Specifications....................................................................................... 1-5

1-1

Page 10

27

Service Manual

1-2

Page 11

1-1. Using the Meter Safely

Use the meter as described in this manual. Otherwise the safety features provided by the

meter might be impaired. A Warning identifies conditions and actions that pose hazards

to the user; a Caution identifies conditions and actions that might damage the meter.

Read First: Safety Information.

Read First: Safety Information

This meter complies with EN 61010-1:1993, ANSI/ISA S82.011994 and CAN/CSA C22.2 No. 1010.1-92 Overvoltage Category

III. Use the meter only as specified in the Users Manual,

otherwise the protection provided by the meter may be

impaired.

Warning

To avoid possible electric shock or personal injury:

• Do not use the meter if it is damaged. Before use, inspect the

case for cracks or missing plastic. Pay particular attention to the

insulation surrounding the connectors.

Introduction and Specifications

Using the Meter Safely

1

• Inspect the test leads for damaged insulation or exposed metal.

Check test lead continuity. Replace damaged leads.

• Do not use the meter if it operates abnormally. Protection may be

impaired. When in doubt, have the meter serviced.

• Do not operate the meter around explosive gas, vapor or dust.

• Do not apply more than the rated voltage, as marked on the meter,

between terminals or between any terminal and earth ground.

• Before each use, verify the meter’s operation by measuring a

known voltage.

• When servicing the meter, use only specified replacement parts.

• Use caution when working above 30 V ac rms, 42 V ac peak, or 60

V dc. Such voltages pose a shock hazard.

• Keep your fingers behind the finger guards on the probe when

making measurements.

• Connect the common test lead before connecting the live test

lead. Disconnect the live test lead first.

• Remove test leads from the meter before opening the battery

door.

• Make sure the battery door is closed and latched before operating

the meter.

• Use only a single 9 V battery, properly installed in the meter case,

to power the meter.

• Follow all equipment safety procedures.

1-3

Page 12

27

Service Manual

• Before measuring current, check the meter’s fuses (see “How to

Test the Fuse”).

• Never touch the probe to a voltage source when the test leads are

plugged into the 10 A or 40 mA input jacks.

• To avoid false readings, which could lead to possible electric

shock or personal injury, replace the meter’s battery as soon as

the low battery indicator (

• Avoid working alone.

To avoid possible damage to the meter or to equipment under

test:

• Disconnect the power to the circuit under test and

discharge all high voltage capacitors before testing

resistance, continuity or diodes.

• Use the proper function and range for your measurement

applications.

) appears.

Caution

• When measuring current, turn off circuit power before

connecting the meter in the circuit. Remember to place the

meter in series with the current.

This manual presents service information for the Fluke 27 Multimeters. Included are a

theory of operation, general maintenance procedures, performance tests, calibration

procedures, troubleshooting information, a list of replaceable parts, and a schematic

diagram.

1-2. Operating Instructions

For operating instructions, refer to the Users Manual provided with the instrument at time

of purchase.

1-4

Page 13

Introduction and Specifications

1-3. Specifications

Instrument specifications are presented in Table 1-1.

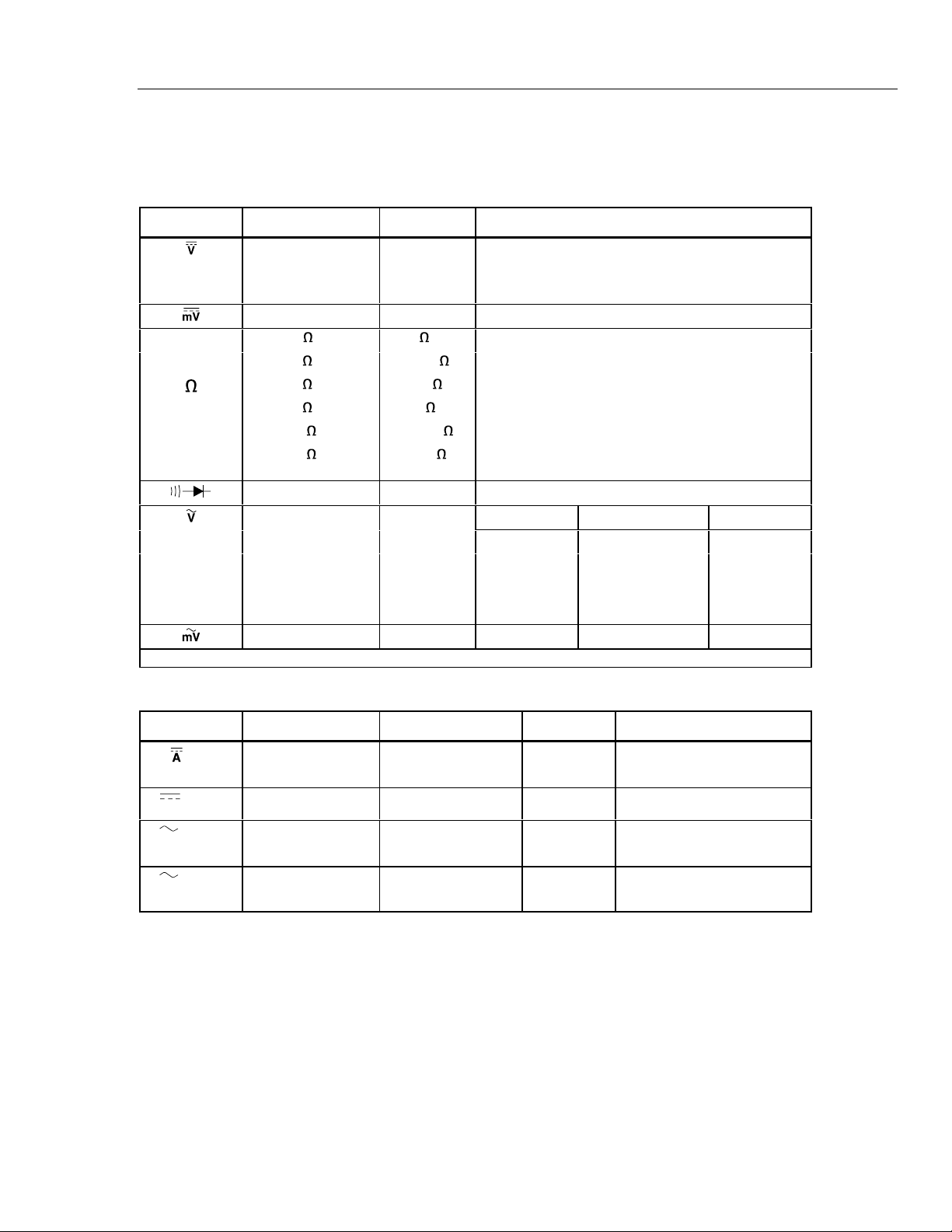

Table 1-1. Specifications

Function Range Resolution Accuracy

3.200 V

32.00 V

320.0 V

1000 V

320.0 mV 0.1 mV ±(0.1%+1)

320.00 0.1 ±(0.3%+3)*

3.200 k 0.001 k ±(0.2%+1)

32.00 k 0.01 k ±(0.2%+1)

(nS)

* When using the REL ∆ function to compensate for offsets.

320.0 k 0.1 k ±(0.2%+1)

3.200 M 0.001 M ±(0.2%+1)

32.00 M

32.00 nS

2.080 V 0.001 V ±(1%+1) typical

3.200 V 0.001 V ±(0.5%+3) ±(2%+3) ±(4%+ 10)

32.00 V 0.01 V ±(0.5%+3) ±(2%+3) ±(4%+ 10)

320.0 V 0.1 V ±(0.5%+3) ±(2%+3) ±(4%+ 10)

1000 V 1 V ±(1%+3) ±(3%+3) Not Specified

320.0 mV 0.1 mV ±(0.5% +3) ±(2%+3) ±(4%+10)

0.001 V

0.01 V

0.1 V

1 V

0.01 M

0.01 nS

40 Hz-2 kHz 2 kHz -10 kHz 10 kHz -30 kHz

±(0.1%+1)

±(0.1%+1)

±(0.1%+1)

±(0.1%+1)

±(1%+1)

±(0.2%+10)

Specifications

1

Function Range Resolution Accuracy Typical Burden Voltage

m /A

µA

mA/A

40-1000 Hz

µA

40-1000 Hz

32.00 mA

320.0 mA

10.00 A

320.0 µA

3200 µA

32.00 mA

320.0 mA

10.00 A

320.0 µA

3200 µA

0.01 mA

0.1 mA

0.01 A

0.1 µA

1 µA

0.01 mA

0.1 mA

0.01 A

0.1 µA

1 µA

±(0.75%+2)

±(0.75%+2)

±(0.75%+2)

±(0.75%+2)

±(0.75%+2)

±(1.5%+2)

±(1.5%+2)

±(1.5%+2)

±(1.5%+2)

±(1.5%+2)

5.6 mV/mA

5.6 mV/mA

50 mV/A

0.5 mV/µA

0.5 mV/µA

5.6 mV/mA

5.6 mV/mA

50 mV/A

0.5 mV/µA

0.5 mV/µA

1-5

Page 14

27

Service Manual

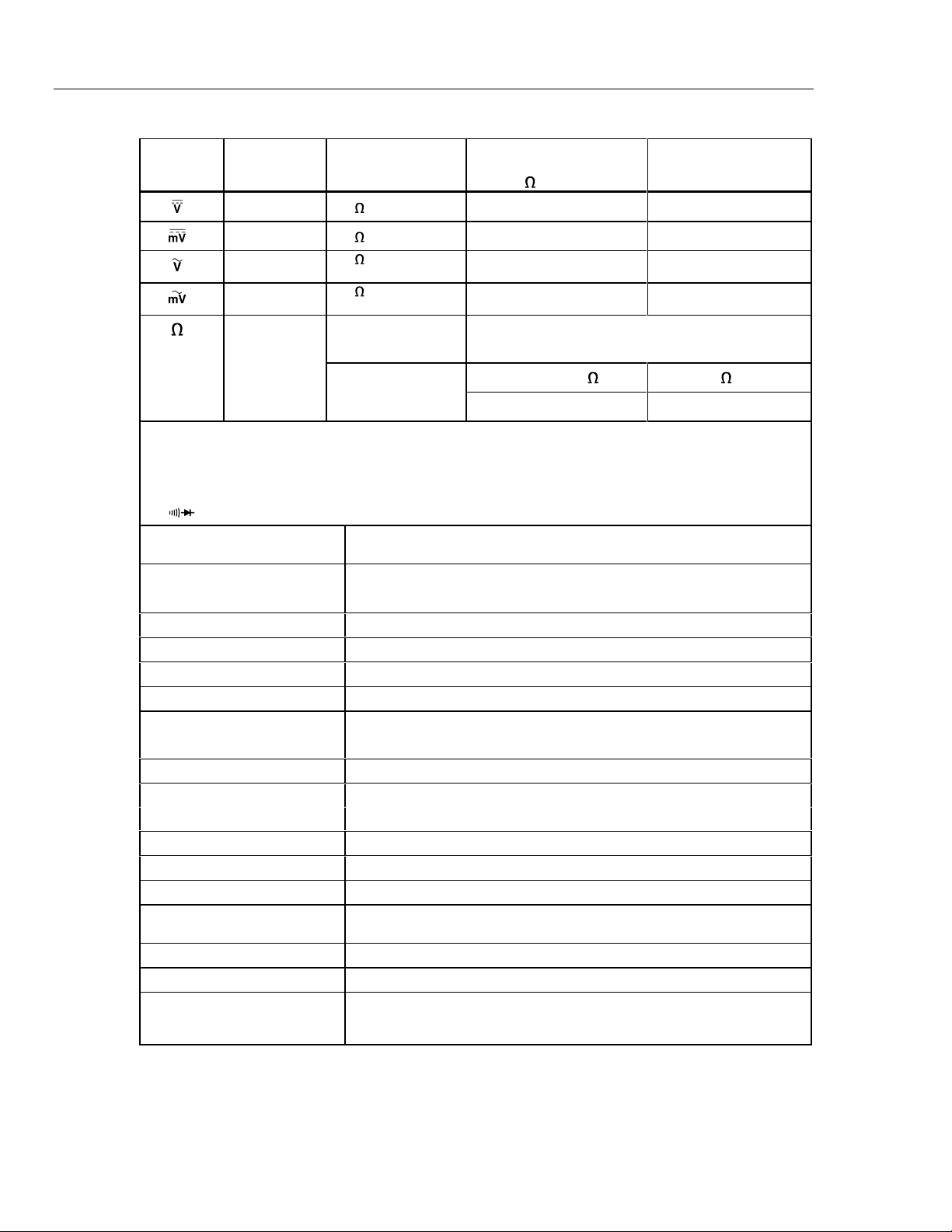

Table 1-1. Specifications (cont)

Function Overload

Protection**

1000 V rms 10 M in // with <100pF >120 dB at dc, 50 Hz, or 60 Hz >60 dB at 50 Hz or 60 Hz

1000 V rms 10 M in // with <100pF >120 dB at dc, 50 Hz, or 60 Hz >60 dB at 50 Hz or 60 Hz

1000 V rms

1000 V rms

1000 V rms Open Circuit Test

Input Impedance

(nominal)

10 M

in // with <100pF

(ac coupled)

10 M

in // with <100pF

(ac coupled)

Common Mode Rejection

Ratio

unbalance)

(1 k

>60 dB, dc to 60 Hz

>60 dB, dc to 60 Hz

Full Scale Voltage

Normal Mode

Rejection

Voltage

Up to 3.2 M 32 M or nS

<2.8 V dc <420 mV dc <1.3 V dc

** 107 V Hz Max

Basic electrical accuracy is specified from 18°C to 28°C with relative humidity up to 95%, for a period of one year after

calibration. All ac conversions are ac coupled, average responding, and calibrated to read the true rms value of a sine wave

input. Accuracy is specified as ±([% of reading] + [number of least significant digits]).

Ranging is either automatic or manual in all functions with more than one range. Test resistance below approximately 270 J in

function produces a continuous audible tone.

the

Maximum voltage between any

terminal and earth ground

Fuse protection

mA or µA

A

Digital Display 3200 counts, updates 2/sec

Analog Display 31 segments, updates 25/sec

Operating Temperature -150°C to 55°C, to -40°C for 20 minutes when taken from 20°C

Storage Temperature -55°C to 85°C without battery, to 60°C with battery

Electromagnetic Compatibility

Temperature Coefficient 0.1 x (specified accuracy)/°C (18°C or >28°C)

Relative Humidity 0% to 95% (0°C to 35°C)

Altitude 2000 meters

Battery Type 9 V, NEDA 1604 or 6F22 or 006P

Battery Life 1000 hrs typical

Shock, Vibration and Water

Resistance

Size (HxWxL) 2.2 in x 3.75 in x 8 in (5.6 cm x 9.5 cm x 20.3 cm)

Weight 1.6 pounds (0.75 kg)

Safety Complies with ANSI/ISA S82.01-1994, CAN/CSA 22.2 NO. 1010.1:1992 to

1000 V

44/100 A 1000 V Fast

11 A 1000 V Fast

In an RF field of 2 V/m on all ranges and functions (except mVac),

total accuracy = specified accuracy + 1.0% or range. For mVac,

total accuracy = specified accuracy + 1.5% or range. EN 61326-1:1997.

0% to 70% (35°C to 55°C)

Per MIL-T-28800 for a Style A, Class 2 Instrument

1000 V Overvoltage Category III. UL License pending to UL3111-1. TUV

License pending to EN61010-1.

1-6

Page 15

Chapter 2

Theory of Operation

Title Page

2-1. Introduction ......................................................................................... 2-3

2-2. Functional Description......................................................................... 2-3

2-3. Block Diagram Description ................................................................. 2-4

2-4. Input Overload Protection ............................................................... 2-4

2-5. Function Switching Circuits ............................................................ 2-4

2-6. Signal Conditioning Circuits ........................................................... 2-4

2-7. Custom Analog IC (U1) .................................................................. 2-4

2-8. Peripherals to U1............................................................................. 2-6

2-9. Microcomputer Control................................................................... 2-6

2-10. Display ............................................................................................ 2-7

2-1

Page 16

27

Service Manual

2-2

Page 17

2-1. Introduction

This chapter describes how the Fluke 27 works. First, a functional description presents an

overview of operation. This is followed by a block diagram description, which describes

the major circuit functions in more detail. For reference, a detailed schematic diagram is

included in Chapter 5.

2-2. Functional Description

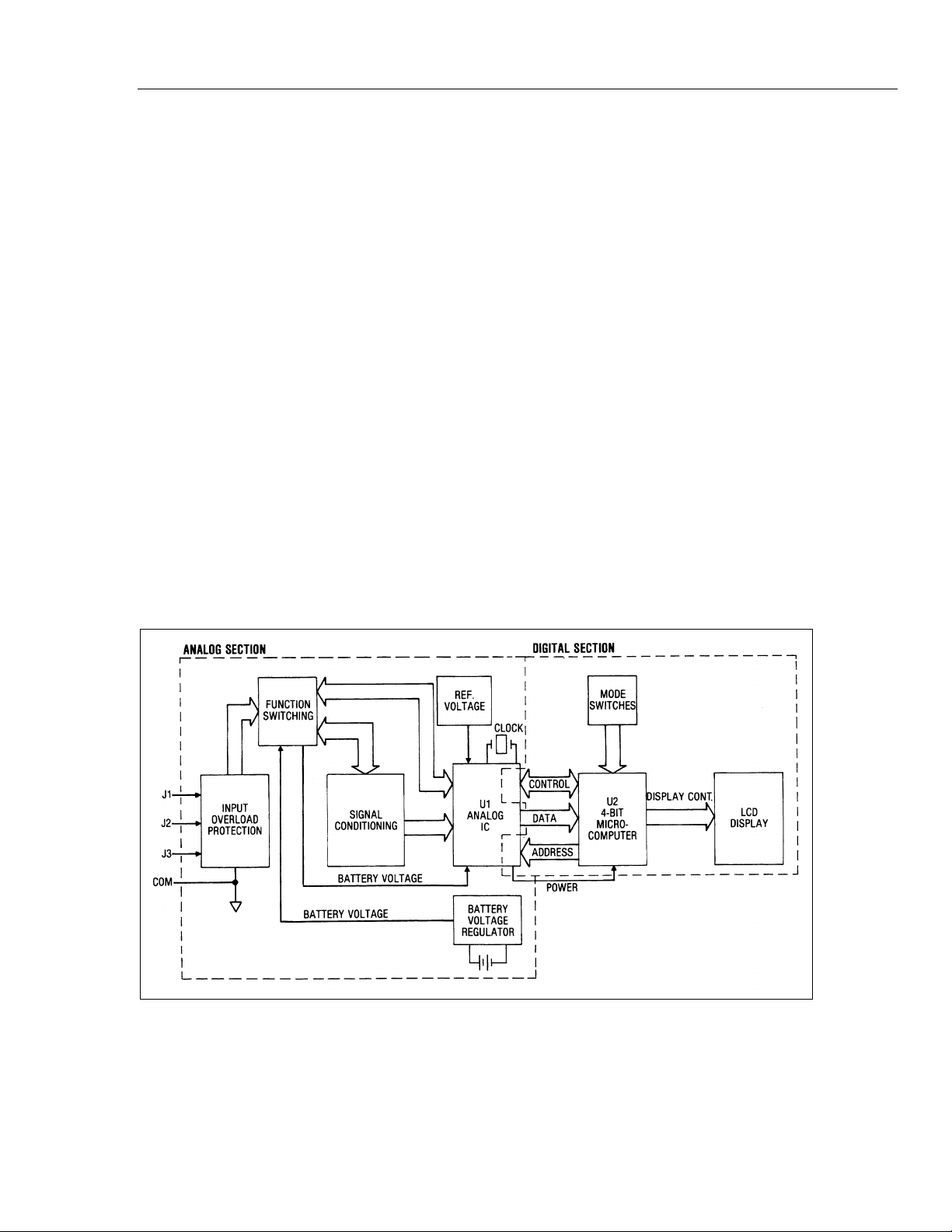

A block diagram of the Fluke 27 circuitry is shown in Figure 2-1. As this figure shows,

the instrument is composed of two major functional sections: the analog section and the

digital section. Each section contains one major active component and one or more

peripheral circuits. Most analog functions are performed by a custom analog IC (U 1) and

analog peripherals to U1. Digital functions are performed by a CMOS, 4-bit

microcomputer, U2.

The custom analog IC contains the A/D converter, signal conditioning circuits, and the

digital control circuitry required for communication with the microcomputer. Although

the custom IC is primarily analog, digital circuits provide state machine control for the

A/D converter, a read counter for A/D samples, decoding ROMs for analog switch drive,

and bus control for communication with the microcomputer.

Theory of Operation

Introduction

2

The microcomputer controls the A/D converter, initiates the range and function

switching, formats data for display, and drives the display. The mode push buttons supply

input to the microcomputer to initiate various modes. Output from the microcomputer is

displayed on the liquid crystal display (LCD).

Figure 2-1. Overall Functional Block Diagram

aac01s.tif

2-3

Page 18

27

Service Manual

2-3. Block Diagram Description

2-4. Input Overload Protection

Each of the blocks in the Figure 2-1 is discussed in the following paragraphs. In many

cases, circuit sections are described in greater detail than is shown in the Figure 2-1;

therefore, it may be helpful to refer to the schematic located near the back of this manual.

Overload protection for the volts/ohms/diode-test input (J1) is provided by a network of

five metal-oxide varistors (RV1 through RV5) a current-limiting resistor (R2) and a

thermistor (RT1).

A 44/100A, 1000 V fuse provides protection for the mA/µA input (J2) current shunts. An

11 A, 1000 V fuse provides protection for the 10 A input (J3) current shunt. In addition,

for the µA and mA ranges, a bridge rectifier (U7) and four diodes (CR1, CR2, CR3, CR4)

ensure that the fuses (instead of the shunts) open in very high current overload

conditions.

Transistors Q1, Q2, and Q1 provide additional overload protection for the millivolt and

ohms functions. If sufficient overload voltage is present, the transistors turn on and

connect that input to common through limiting resistors R2 and RT1, thereby protecting

the circuitry in U1. A clamp circuit (CR6 and Q15) connected to the volt/ohms/diode-test

input through Z1 and C3 provides similar protection for the volts/ohms/diode-test input.

2-5. Function Switching Circuits

Input signals are routed from the overload protection circuits to the function switch. The

function switch is a rotary switch with two double-sided wafers which provide the

necessary switching to select each of the various functions. In addition, battery voltage is

routed through the function switch from the battery voltage regulator to U1, and from U1

to U2.

2-6. Signal Conditioning Circuits

Each input signal is routed through signal conditioning circuitry before reaching U1.

Input signals received through the volts/ohms/diode-test input (J1) are routed through Z1,

a precision resistor network. The resistor network provides precise input scaling for the

various voltage ranges, and it provides precision reference resistors for the ohms

function. The capacitors in parallel with the various resistors in Z1 are used in the ac

voltage functions; the variable capacitors provide calibration adjustment for the high

frequency ac ranges.

Current inputs received through the mA/ µA input (J2) and the A input (J3) develop a

voltage across shunt resistors R14, R20, and R23 (320 µA, 32 mA, and 10 A

respectively). Resistors R9 and R10 comprise a 10:1 divider for the 3200-µA and 320mA current ranges.

2-7. Custom Analog IC (U1)

The analog-to-digital converter, autorange switching, and most of the remaining active

analog circuitry (including additional signal conditioning) are contained in U1, a custom

LSI package. Peripherals to U1 include the system clock, the reference voltage regulator

for the A/D converter, and some filtering and amplifier stabilization components. U1 also

contains digital circuitry for state machine control over the A/D decoding ROMs for

analog switch drive and read counter preset, and registers to store control outputs from

the microcomputer.

2-4

Page 19

Theory of Operation

Block Diagram Description

Analog-to-digital conversion is accomplished within U1 using a modified dual-slope A/D

converter circuit, as shown in Figure 2-2. The conversion method in the Fluke 27 can be

described as a charge-coupled, multiple-slope technique. A series of 10 minor

conversions occur every 40 ms (each at 1/10th the desired resolution) without taking time

for an autozero phase between the conversions. These minor conversions (or samples, as

they are called in the following discussion) occur at a rate of 25 per second, and are used

to provided the fast response bar-graph display and fast autoranging.

New samples are taken every 40 ms. Ten samples are summed to produce a fullresolution digital display, with full scale greater than 3200 counts. A 100 ms autozero

phase occurs every 10-sample sequence.

Basic A/D conversion elements and waveforms are illustrated in Figure 2-2. As this

figure shows, a residual charge is retained by the integrator capacitor due to the overshoot

past the true-zero base line. In the absence of an autozero phase, the residual charge

would normally produce a significant error in the sample next taken. However, a digital

algorithm eliminates the error and accounts for the residue as it propagates through all 10

samples.

2

Figure 2-2. A/D Conversion Elements and Waveform

aac02s.tif

2-5

Page 20

27

Service Manual

2-8. Peripherals to U1

Digital circuitry in U1 provides state machine control for the A/D converter, a read

counter for A/D samples, decoding ROMs for analog switch drive and for read counter

preset, and bi-directional bus control for storing control outputs from the microcomputer

and for transferring data to the microcomputer.

Basic timing for the A/D converter is defined as a series of 10 integrate/read cycles

(samples), followed by a 100 ms autozero phase. However, the diode test and continuity

function, the 32 M

autoranging, and the Touch-Hold

range, the battery test, the power-up self test, overload recovery,

®

mode all required variations from the basic timing.

The state machine, in combination with the ROM and preset read counter, plus an

autozero flag under computer control, establishes the timing variances necessary for the

various functions.

Circuitry peripheral to U1 provides regulated battery voltage to power U1, a regulated

reference voltage for the A/D converter, a system clock, signal conditioning, and

amplifier stabilization. The battery voltage regulator consists of AR1, Q12, and

associated components; the regulator circuit supplies consistent operating power to U1

and, through a second regulator circuit in U1, to the microcomputer (U2). Voltage

regulator VR1 (and associated components) supplies a regulated 1.000 V reference

voltage for the A/D converter. Potentiometer R19 provides for calibration adjustment of

the reference voltage.

Additional circuits are necessary for the active filter, integrator, and buffer in U1. the

active filter response is determined by R13, R16, C18, and C19. Integrator and buffer

signal characteristics are determined by C20, C21, and two resistors in Z1. Several

components external to U1 provide for ac-to-dc conversion; they are C41, C42, C43,

R35, R7, C16, R30, R31, and R32.

The system clock, with a frequency of 32.768 kHz, controls all timing synchronization

for the instrument. Y1 is a quartz crystal which determines the frequency of the clock

oscillator circuit.

2-9. Microcomputer Control

A CMOS, 4-bit microcomputer (U2) controls the various instrument functions and drives

the LCD display. The microcomputer reads and processes data samples from the A/D

converter, sends a code to U1 which represents the operator-selected function, performs

the Touch-Hold algorithm, selects the correct A/D mode for the function in used, controls

range, sets the autozero flag, and disables the analog filter during autoranging.

In reading and processing A/D samples, the computer accepts raw sample data, applies

necessary corrections as described in the preceding discussion of U1, and accumulates 10

samples which then become the full resolution conversion for digital display. Each minor

conversion is also processed for the bar-graph display. For the diode test and continuity

function, the microcomputer evaluates the data and determines whether or not the beeper

should be switched on.

Touch-Hold operation requires the microcomputer to perform a different algorithm. The

microcomputer does not allow a full-resolution conversion to be completed unless the

input signal is stable. When a stable reading occurs, the conversion is completed and the

microcomputer generates the corresponding display and freezes it. the microcomputer

then waits for a change in the signal to exceed a certain threshold, and then begins

watching for a stable reading again. There are two exceptions to this simple algorithm:

First, open test lead indication does not allow a full-resolution conversion to be

completed either; the microcomputer continues to wait for a stable signal which is outside

the open test lead region. (Open test leads in voltage or current function result in low

2-6

Page 21

readings; open test leads in resistance or diode test functions result in off-scale readings)

Second, if the Touch-Hold button is momentarily pressed at any time, then the fullresolution conversion is forced to complete in spite of input or test lead conditions.

The microcomputer also sets the required A/D converter mode. A single mode is used in

all voltage and current conversions, but there are three ohms function A/D converter

modes, a diode test mode, and two power-up test modes (battery test and self test). The

microcomputer sends the proper code to U1 to select the required A/D converter mode.

Following each group of 10 samples, in normal operation, the microcomputer sets the

autozero flag.

Both manual and autoranging are controlled by the microcomputer. The microcomputer

loads a range register in U1 in conjunction with a mode-dependent map. In autorange, the

analog filter is disabled to increase the autoranging speed.

Peripheral components Q13 and C12 force the microcomputer to reset when the function

switch is moved to OFF. A voltage-divider network (R3, R4, and C13) supplies a midlevel voltage to drive the multiplexed display.

2-10. Display

The liquid crystal display (LCD) operates under direct control of the microcomputer.

Characters are generated by the computer and displayed on the LCD. Both digital

readings and an analog bar-graph display are presented, in conjunction with annunciators

and decimal points. Refer to the Fluke 27 Users Manual for a more detailed description

of the display.

Theory of Operation

Block Diagram Description

2

2-7

Page 22

27

Service Manual

2-8

Page 23

Chapter 3

Maintenance

Title Page

3-1. Introduction ......................................................................................... 3-3

3-2. Service Information............................................................................. 3-4

3-3. Operator Maintenance.......................................................................... 3-4

3-4. Battery Replacement ....................................................................... 3-5

3-5. Fuse Test ......................................................................................... 3-6

3-6. Fuse Replacement............................................................................ 3-6

3-7. General Maintenance Information....................................................... 3-7

3-8. Handling Precautions for Static-Sensitive Devices ......................... 3-7

3-9. Disassembly..................................................................................... 3-7

3-10. Reassembly...................................................................................... 3-10

3-11. Cleaning .......................................................................................... 3-12

3-12. Performance Tests ............................................................................... 3-12

3-13. Display Test..................................................................................... 3-12

3-14. Voltage Functions Performance Verification .................................. 3-13

3-15. AC and DC Current Performance Verification................................ 3-13

3-16. Ohms Function Performance Verification....................................... 3-14

3-17. Diode Test Performance Verification.............................................. 3-15

3-18. Calibration Adjustment........................................................................ 3-15

3-19. Calibration Preparation.................................................................... 3-15

3-20. DC Voltage Connection .................................................................. 3-16

3-21. AC Voltage Calibration................................................................... 3-16

3-22. Troubleshooting................................................................................... 3-17

3-23. Power-Up Self Test ......................................................................... 3-17

3-24. Overall System Check..................................................................... 3-17

3-25. DC Voltage Signal Tracing ............................................................. 3-18

3-26. Fault Diagnosis Guide..................................................................... 3-19

3-1

Page 24

27

Service Manual

3-2

Page 25

Warning

To avoid electric shock or personal injury:

• Do not perform any servicing other than operator

maintenance unless you are qualified to do so. These

service instructions are for used by qualified personnel

only.

• Do not allow water to get inside case.

• Remove any input signals prior to removing test leads and

opening case.

• When servicing the meter, use only specified replacement

parts.

• Make sure the battery door is closed and latched before you

operate the meter.

• To prevent arc blast and resulting injury, install only

specified replacement fuses with the speed, amperage,

interrupt rating and voltage rating listed in Fuse

Replacement Maintenance section.

Maintenance

Introduction

3

3-1. Introduction

This chapter presents instructions for disassembly, performance tests, calibration

adjustment, and troubleshooting. The performance tests may be used as an acceptance

test when the instrument is first received, and can be used later as a preventive

maintenance tool.

A l-year calibration cycle is recommended to maintain the instrument’s specifications. In

addition, the seals should be replaced during servicing to maintain the environmental

specifications stated in that manual. A seal kit is available from the factory. The seal kit

(Model 8025A-740 1, part number 738112) contains a complete set of seals and four

replacement screws and washers for the bottom case.

The test equipment required for the performance tests and calibration adjustments is

listed in Table 3-1. Test equipment with equivalent specifications may be used if the

recommended models are unavailable.

Table 3-1. Recommended Test Equipment

Instrument Type Required Characteristics Recommended Model

Voltage Range: 0-1000 V ac, ±.05%

Frequency Range: 40 - 10,000 Hz, ±1%

DMM Calibrator Voltage Range: 0-1000 V dc

Accuracy: ±.05%

Current Range: 2 mA - 5 A

Accuracy: ±.2%

Fluke Model 5500A

Values: 100 ohm, 1 kilohm, 10 kilohm, 100

kilohm, 1 megohm, 10 megohm

Accuracy±.06%

3-3

Page 26

27

Service Manual

3-2. Service Information

The Fluke 27 has a lifetime warranty upon shipment of the instrument to the original

purchaser. Conditions of the warranty are described on the registration card.

Malfunctions that occur within the limits the warranty will be corrected at no cost to the

purchaser. For in-warranty service, ship the instrument post-paid to the Fluke Service

Center nearest you. A list of service centers is included at the back of this manual.

Fluke Service Centers are also available for calibration or repair. Upon request, a cost

estimate will be provided before work is performed on instruments.

If reshipment is necessary, please use the original shipping container. If the original

container is not available, be sure that adequate protection is provided to prevent damage

during shipment. It is recommended that the instrument be surrounded by at least 3

inches of shock absorbing material in the shipping container.

To contact Fluke, call one of the following telephone numbers:

USA and Canada: 1-888-99-FLUKE (1-888-993-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-356-5500

Or, visit Fluke’s Web site at www.fluke.com.

3-3. Operator Maintenance

The Fluke 27 Multimeter has been designed to meet the requirements of the

United States Department of Labor Mine Safety and Health Administration

for use in mines. If your instrument has MSHA approval, a decal stating so

will be present on the bottom of your instrument. The following Warning

applies only if the decal is present.

The Fluke 27 multimeter is approved (permissible) by the United

States Department of Labor Mine Safety and Health

Administration (MSHA) for use in mines (approval 2G-3665-0).

To maintain MSHA permissibility, repairs to these instruments

must be made using parts exactly like those furnished by Fluke

Corporation. Any changes in the intrinsically safe circuitry or

components may result in an unsafe condition.

The Fluke 27 multimeter was tested by the MSHA for intrinsic

safety in methane air mixtures only. The Fluke 27 multimeter is

approved with a 9 V NEDA 1604 (carbon zinc) battery only. Do

not use to check electrical blasting circuits. Do not connect to

an electrically energized circuit in a hazardous area.

Note

Warning

3-4

Page 27

3-4. Battery Replacement

To avoid false readings, which could lead to possible electric

shock or personal injury, replace the battery as soon as the

battery indicator (

The Fluke 27 is powered by a single 9 V battery (NEDA 1604, 6F22, or 006P). Referring

to Figure 3-1, use the following procedure to replace the battery:

1. Turn the rotary switch to OFF, and remove the test leads.

Warning

) appears.

Maintenance

Operator Maintenance

3

2. Lift the instrument stand on the back of the instrument, then remove the four #6 X

32, Pozidriv

screws from the battery cover.

3. Pull the battery cover straight out from the back of the instrument. (A coin-slot in the

side of the battery cover facilitates removal.)

Warning

To avoid electrical shock or personal injury, remove the test

leads and any input signals before replacing the battery or

fuses. Make sure the battery door is closed and latched before

you operate the meter.

4. Disconnect and remove the battery.

5. Snap the battery connector to the terminals on the new battery, then slide the battery

into the battery compartment.

6. Insert the battery spacer/cover into the instrument, then start the four screws removed

in step 2. Press firmly on the battery cover while tightening the screws in a diagonal

pattern.

Battery cover

Fuse cover

Battery

connector

Battery

F2

F1

ye1f.eps

Figure 3-1. Battery and Fuse Replacement

3-5

Page 28

27

Service Manual

3-5. Fuse Test

Warning

To avoid electrical shock or personal injury, remove the test

leads and any input signals before replacing the battery or

fuses. Make sure the battery door is closed and latched before

you operate the meter.

To prevent equipment damage or injury, install ONLY specified

replacement fuses with the amperage, voltage, interrupt, and

speed ratings listed in the Fuse Replacement Maintenance

section.

1. Turn the function selector switch to the

2. Connect a test lead from the volts/ohms/diode-test input terminal to the A input

terminal.

3. The display should indicate between 0.1

fast).

4. Move one end of the test lead from the A input terminal to the mA/µA input terminal.

5. The display should indicate between 5.3

(44/100 A, 1000 V) .

6. If either of the above display indications is OL (overload), replace the appropriate

fuse.

3-6. Fuse Replacement

Referring to Figure 3-1, use the following procedure to check or replace the Fluke 27

fuses:

1. Perform steps 1 through 4 of the battery replacement procedure.

2. Pull the fuse cover down, then out of the meter.

3. Remove the defective fuse (or check continuity) through the suspected fuse), and if

necessary install a new fuse of the same size and rating.

4. Snap the fuse cover back into place.

position.

and 0.3 . This tests F2 (11 A, 1000 V

and 6.0 . This tests F1

3-6

5. Reinstall the battery/cover as instructed in step 6 of the battery spacer replacement

procedure.

Table 3-2. Replacement Fuses

Item Description Fluke Part Number Quantity

F1 Fuse, F44/100 A, 1000 VAC/DC 943121 1

F2 Fuse, 11 A, 1000 VAC/DC 943118 1

To ensure safety, use exact replacement only

Page 29

3-7. General Maintenance Information

3-8. Handling Precautions for Static-Sensitive Devices

Caution

This unit contains CMOS components which can be damaged

by static discharge. Static-sensitive components include U1

(the custom analog IC), U2 (the microcomputer), and op amp

AR1. To prevent static discharge damage, take the following

precautions when servicing the instrument.

• Perform all work at a static-free work station.

• Do not handle components or pca (printed circuit assembly) by their connectors.

• Wear static ground straps.

• Use conductive foam to store components.

• Remove all plastic, vinyl, and Styrofoam from the work area.

• Use a grounded, temperature-regulated soldering iron.

Maintenance

General Maintenance Information

3

3-9. Disassembly

To avoid the possibility of electric shock, remove the test leads

prior to disassembly.

Opening the instrument case in damp, humid environments

followed by moving the instrument to a cooler environment

could cause condensation inside the case. Instrument

performance may be adversely affected by condensation.

To avoid contaminating the pcas with oil from the hands (or Oring lubricant), handle the pcas by the edges or wear gloves. If

a pca does become contaminated, refer to the cleaning

instructions given later in this chapter. Do not allow the LCD to

come in contact with moisture.

Disassembly requires a number 2 Pozidriv

screws and a number 1 Phillips-head screwdriver for all interior screws.

Reassembly requires silicone lubricant (Parker Super O-Lube is

recommended) and new seals. A Fluke seal kit (Model 8025 A-7401, Fluke

Part Number 738112) provides a complete set of seals and four

replacement screws and washers for the bottom case. A 2 oz tube of Parker

Super O-Lube can be obtained from the Fluke Corporation by ordering p/n

812230.

Warning

Caution

Caution

Note

®

screwdriver for all exterior

3-7

Page 30

27

Service Manual

MP2

MP19

U3

MP2 (2PL)

MP18

H2 (2PL)

Top Case/Digital

PCB Subsection

MP13

MP10

MP12

MP11

MP21

H1

MP4

MP7

MP1

MP5

MP6

S3

A2

H5 (4PL)

MP9

MP8

MP3

H4 (3PL)

Button-Up

Subsection

A1

Main Board

Subsection

MP17

H8 (2PL)

H9 (2PL)

F1

F2

H3 (4PL)

F1

F2

MP61

MP15

BT1

H7 (4PL)

MP16

MP14

H6

aac04f.eps

Figure 3-2. Disassembly

Most maintenance procedures require at least partial instrument disassembly. The

following procedure (illustrated in Figure 3-2) provides complete step-by-step

disassembly instructions to gain access to any assembly. Complete disassembly is not

required to gain access to most assemblies; the following procedure contains notes that

explain which maintenance procedures are possible at various levels of disassembly.

1. Turn the function switch to the upper OFF position.

2. Lift the tilt bail up about 1 inch up from the back of the instrument, then gently pull

out the ends of the tilt bail and remove it.

3. Remove the four Pozidriv

®

machine screws (H6) that hold the battery cover (MP14)

to the bottom case, then lift the battery cover and battery spacer out of the instrument.

4. Disconnect and remove the battery.

5. Unsnap the battery spacer from the battery cover.

3-8

Page 31

Maintenance

General Maintenance Information

6. Remove the old O-ring (MP15). Clean the O-ring surfaces of the battery cover and

the instrument case. Install the battery holder on the battery cover, then install the

new O-ring.

7. Remove the four Pozidriv

®

screws (H7) and rubber washers from the bottom case.

8. Lift the bottom case off the instrument, and remove the O-ring (MP13) between the

top and bottom cases. (Always install a new O-ring prior to reassembly.)

9. At this point, all calibration adjustments are accessible through the openings in the

side of the pca shield. Refer to the calibration adjustment procedure later in this

chapter to calibrate the instrument.

10. Remove the four Phillips-head screws (H3) at the bottom of the pca that connect the

pca to the input terminals molded into the top case.

11. Carefully lift the upper end of the main pca and shield assembly to disconnect the

assembly from the digital pca, then lift the main pca and shield assembly clear of the

case.

3

Figure 3-3. Switch Extension Shaft Installation

aac05s.tif

12. Note the position of the rotary switch extension shaft (MP17). With the rotary switch

in the OFF position, the single small pointer on the base of the extension shaft is

pointed toward the top of the instrument. Refer to Figure 3-3.

13. Lift the rotary switch extension shaft (MP17) off the rotary switch shaft (the shaft on

MP2).

14. Remove the E-ring retainer (MP6) and the detent spring (MP5) from the rotary

switch shaft.

15. Pull the rotary switch knob (MP2) out from the front of the top case (MP1). Take

care not to loose the Teflon bearing washer (H1) under the knob.

16. To replace the O-ring (MP4) on the rotary switch shaft, cut off the existing O-ring

without scratching the metal shaft. Clean the shaft thoroughly, and slide a new O-ring

over the shaft into the groove on the shaft.

3-9

Page 32

27

Service Manual

17. Remove the four lower Phillips-head screws (H5) that secure the digital pca to the

top case using a diagonal pattern (i.e., remove the upper-right screw, then the lowerleft, then the upper-left, and last the lower-right). Then remove the two Phillips-head

screws (H2) at the top of the digital pca, above the connector.

18. Carefully lift the digital pca straight up from the top case and remove it.

Caution

Do not touch the elastomeric LCD contact strips (MP20) or

contacts of the momentary switch (S3-S6) with bare hands.

Wear gloves or remove the contact strips using clean pliers or

tweezers. Avoid contaminating the contact strips.

19. Lift the momentary switch (S3-S6) from the top case. Remove the elastomeric LCD

contact strips (MP20) and LCD interconnect support (MP18), located on the back of

the LCD.

20. Remove the LCD (U3) and the LCD mask (MP19) from the case.

21. To disassemble the main pca/shield assembly, first remove the two Philllips-head

screws (H8) from the top shield (MP9). Take care not to lose the flat washers under

the screw heads.

22. Turn the assembly over and remove the three thread-forming, Phillips-head screws

(H4) that secure the bottom shield (MP3).

23. Lay the bottom shield aside, and separate the top shield from the pca.

24. At this point, all main pca components are accessible.

3-10. Reassembly

Reassembly requires a number 2 Pozidriv

screws, a number 1 Phillips-head screwdriver for all internal screws,

silicone lubricant (Parker Super-O-Lube is recommended), and new seals.

A Fluke seal kit (Model 8025A-7401, Fluke Part Number 738112) provides

a complete set of seals and four replacement screw and washers for the

bottom case. A 2-oz tub of Parker Super-O-Lube can be obtained from the

Fluke Corporation by ordering p/n 812230.

Reassembling the instrument is primarily a reversal of the disassembly procedure.

However, some precautions are necessary to ensure proper sealing and to maintain watertight integrity. Use the following procedure to reassemble the instrument:

Do not touch the elastomeric LCD contact strips (MP20) or

contacts of the momentary switch (S3-S6) with bare hands.

Wear gloves or remove the contact strips using clean pliers or

tweezers. Avoid contaminating the contact strips.

Note

Caution

®

screwdriver for all external

3-10

1. Position the LCD mask (MP19) in the top case (MP1), then place the LCD (U3) in

the LCD mask with the Fluke part number toward the top of the instrument, pressing

the LCD lightly to engage the spring action of the LCD mask. Place the LCD

interconnect support (MP18) over the LCD, then place the elastomeric connector

strips (MP20) at the top and bottom of the LCD interconnect support with the black

connection strip against the LCD.

Page 33

Maintenance

General Maintenance Information

2. Note the small bump at the center of tone edge of the momentary switch (S3-S6).

Place the momentary switch in the case with the bump toward the LCD display.

3. Place the digital pca in the top case with the connector toward the back of the

instrument and at the top of the case.

4. Install the four lower Phillips-head screws (H5) that secure the digital pca over the

momentary switch. Note that the momentary switch provides a seal between the case

and the digital pca. Install the screws using a diagonal sequence (i.e., upper-right,

then lower-left, then upper-left, then lower-right).

5. Install the two thread-forming, Phillips-head screws (H2) above the connector that

hold the top of the digital pca.

6. Install a new O-ring (MP4) on the rotary switch shaft (if not previously installed),

then place the Teflon washer (H1) on the rotary switch shaft, then install the rotary

switch knob in the front of the top case.

7. Lubricate the outer edges of the detent spring (MP5) with a very thin layer of silicon

lubricant, then install the detent spring over the rotary switch shaft. Detent spring

orientation is not critical.

8. Install the E-ring retainer (MP6) on the rotary switch shaft.

3

9. Rotate the rotary switch to the upper OFF position.

10. Place the rotary switch extension shaft (MP17) on the rotary switch shaft. Note the

small pointer on the base of the extension shaft. Place the pointer toward the center of

the display while the rotary switch knob is in the upper OFF position.

11. To reassemble the main pca/shield assembly, fit the top shield (MP9) over the

component side of the pca, taking care not to bend the connector pins. Make sure the

shield posts fit through the holes in the pca, and verify that the rotary switch is in the

upper OFF position.

12. Position the bottom shield (MP3) on the back of the pca with the stand-offs fitted

through the pca, then position the top shield on the top of the pca with the molded

stand-offs fitted through the pca.

13. Install the two Phillips-head machine screws (H8) and flat washers through the top

shield into the bottom shield. Install the three thread-forming Phillips-head screws

(H4) through the bottom shield into the top shield.

14. Carefully fit the main pca/shield assembly into the top case, taking care to ensure that

the connector pins on the main pca are lined up properly with the connector on the

digital pca, and the switch shaft extension aligns with the two rotary switch wafers in

the OFF position (do not use force). Engage the connector by pressing lightly on the

bottom shield at the case screw holes.

15. Install the four Phillips-head machine screws (H3) with lock washers that secure the

main pca/shield assembly to the back of the input terminals, again using a diagonal

pattern.

16. Install a new O-ring (MP13) on the bottom case (MP10), if it was not replaced during

disassembly, and position it at the beginning of the tapered area.

17. Place the bottom case on the top case, then start four new thread-forming screws

(H7) with rubber washers. (The new screws and washers are provided in the seal kit.)

Press the case halves firmly together, and using a number 2 Pozidriv

tighten the screws in a diagonal pattern (lower-right, upper-left, upper-right, lower

left), to ensure a proper seal.

®

screwdriver,

3-11

Page 34

27

Service Manual

18. If the battery compartment O-ring (MP15) was not replaced during disassembly, it

should be replaced before reassembly. Use the procedure given in step 5 of the

disassembly procedure.

19. Connect the battery to the battery terminal connector, then slide the battery into the

battery compartment.

20. Slide the battery spacer/cover assembly into the back of the instrument.

21. Start the four screws (H6) that secure the battery cover. Press firmly on the battery

cover while tightening the screws in a diagonal pattern using a number 2 Pozidriv

screwdriver.

22. Move the rotary switch knob from OFF to any function. All segments of the LCD

should illuminate briefly if the instrument has been properly assembled.

3-11. Cleaning

Do not use aromatic hydrocarbons or chlorinated solvents for

cleaning. These solutions will react with the plastic materials

used in the instrument.

Do not allow the LCD to come in contact with moisture.

Clean the exterior plastic parts using a mild solution of detergent and water on a soft

cloth. Clean dust from the pcas using clean, dry air at low pressure (less than 20 psi).

Clean contaminates from the pcas using isopropyl alcohol and a soft brush, followed by

demineralized water and a soft brush (remove the LCD before washing). Dry the pca at

50 to 60 degrees Celsius for 24 hours after washing (and before reassembly ) to assure

that no moisture is sealed in the instrument.

®

Caution

Caution

3-12

3-12. Performance Tests

The following procedures allow you to check the performance of the Fluke 27 against the

specifications given in the Fluke 27 Users Manual. The procedures are recommended for

incoming inspections, periodic calibration verification, and as an aid in troubleshooting.

If the instrument fails any test, calibration adjustment or repair is needed.

Prior to performing any of the sting procedures, allow the instrument to stabilize to room

temperature (18 to 28 degrees Celsius). Also, check the fuses and if the battery

annunciator is displayed, change the battery.

Note

In the following procedures, the Fluke 27 is referred to as the unit under

test, or UUT.

3-13. Display Test

When the function switch is moved from the OFF position to any other position, the

instrument performs a power-up self test. All LCD segments in the display are switched

on while the test is in progress, then the instrument commences normal operation. This

automatic self test verifies that the instrument is functional and that all LCD segments are

functioning.

Page 35

3-14. Voltage Functions Performance Verification

The following procedure may be used to verify proper operation and calibration of the ac

and dc voltage measurement functions. Required test equipment is listed in Table 3-1.

Caution

Connect the common terminal of the Digital Multimeter

Calibrator to the COM terminal on the UUT.

1. Verify that both the Digital Multimeter Calibrator (hereafter referred to as the DMM

Calibrator) and the UUT are off.

2. Connect the UUT, using the volts/ohms/diode-test input terminal, to the ac output

connections of the DMM Calibrator.

Maintenance

Performance Tests

3

3. Turn the function switch on the UUT to the ac voltage position (

4. Switch on power to the DMM Calibrator, and program it for an output of 2.7 V ac, at

100 Hz.

5. Verify that the UUT indicates between 2.684 and 2.716 V ac.

6. Program the DMM Calibrator for an output of 27 V ac, at 10 kHz.

7. Verify that the UUT indicates between 26.43 and 27.57 V ac.

8. Program the DMM Calibrator output for 250 V ac, at 10 kHz.

9. Verify that the UUT indicates between 244.7 and 255.3 V ac.

10. Program the DMM Calibrator for an output of 1000 V ac, at 10 kHz.

11. Verify that the UUT indicates between 967 and 1033 V ac.

12. Program the DMM Calibrator for an output of zero volts.

13. Turn the UUT function switch to the dc voltage position (

14. Program the DMM Calibrator output for 2.7 V dc.

15. Verify that the UUT indicates between 2.696 and 2.704 V dc.

16. Program the DMM Calibrator for an output of 27 V dc.

17. Verify that the UUT indicates between 26.96 and 27.04 V dc.

18. Program the DMM Calibrator output to 250 V dc.

19. Verify that the UUT indicates between 249.6 and 250.4 V dc.

).

).

20. Program the DMM Calibrator for an output of 1000 V dc.

21. Verify that the UUT indicates between 998 and 1002 V dc.

22. Switch off the DMM Calibrator. Disconnect the Calibrator from the UUT.

3-15. AC and DC Current Performance Verification

The following procedure may be used to test the ac and dc current functions, and to

verify current measurement accuracy.

1. Turn the UUT function switch to the ac mA/A position (m

2. Connect the DMM Calibrator output to the UUT mA/µA input terminal.

3. Switch on power to the DMM Calibrator and program the DMM Calibrator output

for 27 mA at 50 Hz.

4. Verify that the UUT indicates between 26.58 and 27.42 mA.

5. Program the DMM Calibrator output for 200 mA at 50 Hz.

/A).

3-13

Page 36

27

Service Manual

6. Verify that the UUT indicates between 196.8 and 203.2 mA.

7. Program the DMM Calibrator output for zero amps.

8. Switch the UUT to the ac µ

output for 2000 µ

at 500 Hz.

function (µ ), then program the DMM Calibrator

9. Verify that the UUT indicates between 1968 and 2032 µA.

10. Program the DMM Calibrator to standby.

11. Connect the DMM Calibrator output to the UUT amp (A) and common (COM) input

terminals.

12. Switch the UUT to the AC mA/A function, then program the DMM Calibrator output

for 5 A at 1 kHz.

13. Verify that the UUT indicates between 4.91 and 5.09 A. Program the DMM

Calibrator to standby.

14. Set the UUT to the dc m

/A function(m /A).

15. Program the DMM Calibrator output for an output of 5.0 A dc.

16. Verify that the UUT indicates between 4.94 and 5.06 A.

17. Program the DMM Calibrator to standby.

18. Turn the function switch on the UUT to the dc m

/A position (m /A).

19. Connect the DMM Calibrator output to the UUT mA/µA input terminal, then

program the DMM Calibrator for an output of 27 mA dc.

20. Verify that the UUT indicates between 26.78 and 27.22 mA.

21. Program the DMM Calibrator output for 2700 µ

function (µ ).

22. Program the DMM Calibrator for 2.7 mA.

23. Verify that the UUT indicates between 2678 and 2722 µA.

3-16. Ohms Function Performance Verification

The following test may be used to verify correct ohms function operation and to verify

UUT accuracy in the various ohms ranges.

1. Connect the DMM Calibrator to the UUT using the volts/ohms/diode-test input

terminal and common.

2. Turn the function switch to the

position.

3. Switch on power to the DMM Calibrator. Program the DMM Calibrator to the

resistance values indicated in Table 3-2, and verify that the UUT indication is within

the tolerances given for each input value.

dc. Set the UUT to the dc µ

3-14

Page 37

Table 3-3. Ohm Function Performance Test

Step Resistance Indication

1 100 99.5 to 100.5

2 1.000 k .997 to 1.003 k

3 10.00 k 9.97 to 10.03 k

4 100.0 k 99.7 to 100.3 k

51 M .997 to 1.003 M

6 10 M 9.89 to 10.11 M

*7 open circuit -00.10 to .0010 nS

*Note: Conductance (nS) range must be entered using manual range selection.

3-17. Diode Test Performance Verification

The following procedure may be used to verify proper operation of the diode test

function. (This test can not be performed unless the source can sink 0.6 mA at 0.9 V.)

1. Turn the UUT function selection switch to the diode test function.

2. The UUT should display OL.

Maintenance

Calibration Adjustment

3

3. Connect the DMM Calibrator to the UUT volt/ ohms/ diode-test input terminal and

common, and switch on Calibrator power.

4. Program the DMM Calibrator output for 1.00 V, then push the Range Lock button on

the Calibrator to place the Calibrator in the 3.3V range.

5. Program the DMM Calibrator output for 0.090 V and verify that the UUT indicates

approximately 0.090 V and the beeper is sounding continuous tone.

6. Increase the DMM Calibrator output to 0.11 V. The beeper should turn off.

7. Increase the Calibrator output to 1.0V, then slowly decrease the Calibrator output to

0.6 V. Note that the UUT beeper produces a short beep as the voltage descends

through 0.7 V (typical silicon diode threshold).

8. Push the DMM Calibrator Range Lock button to return to Autorange operation.

3-18. Calibration Adjustment

Under normal operating conditions, the Fluke 27 should maintain its specifications for a

period of one year after calibration. If the instrument has been repaired, or if it has failed

any of the performance tests, the following calibration adjustment procedures must be

performed. Use a non-conductive tool for adjustments.

In the following procedures, the Fluke 27 is referred to as the unit under

test, or UUT.

Note

3-19. Calibration Preparation

Allow the UUT to stabilize at an ambient temperature of 21 to 25 degrees Celsius (70 to

77 degrees Fahrenheit) and at a relative humidity of less than 80% with the power off for

at least 30 minutes before beginning calibration. Calibration adjustments require removal

of the bottom cover. Complete steps 1 through 7 of the disassembly procedure given

earlier in this chapter, and then reconnect the battery to the UUT’s battery connector.

3-15

Page 38

27

Service Manual

3-20. DC Voltage Connection

The dc voltage function must be calibrated before calibrating the other functions. Use the

following procedure to calibrate the dc voltage function.

1. Connect the DMM Calibrator to the UUT volts/ohms/diode-test input terminal and

common. Refer to Figure 3-4 for calibration component locations.

2. Select the dc voltage function (

) on the UUT.

3. Switch on power to the DMM Calibrator, and program the Calibrator output for

2.700 V dc.

4. Adjust potentiometer R19 on the UUT for a display indication of 2.700 V on the 3 V

range.

5. Program the DMM Calibrator for zero output, and disconnect the Calibrator from the

UUT.

3-16

C4 (320 V AC Range)

C10 (1000 V AC Range)

Figure 3-3. Calibration Adjustment Locations

3-21. AC Voltage Calibration

There is a single ac-to-dc converter adjustment for basic ac voltage accuracy. However,

each ac voltage range must be calibrated independently for high frequency accuracy.

Variable capacitors provide these high frequency adjustments. There should be no

interaction between the various ranges when adjustments are made in the specified order.

Use the following procedure to calibrate the ac voltage ranges.

C6 (3.2 V AC Range at 10 kHz)

R19

R7

(3.2 V AC Range)

C8

(32 V AC Range)

(DC V olts)

aac06f.eps

Page 39

Warning

The following procedure requires that high voltages be

supplied to the UUT for calibration. Read the safety precautions

in the Fluke 27 Users Manual before performing the following

procedure.

Maintenance

Troubleshooting

3

1. Select the ac voltage function (

2. Connect the DMM Calibrator to the volts/ohms/diode-test input terminal on the

UUT.

3. Program the DMM Calibrator output for 2.7 V ac at 100 Hz.

4. Adjust R7 to obtain a display of 2.700 V ac ±0.001 V ac.

5. Program the DMM Calibrator output for 270 V ac at 10 kHz.

6. Adjust C4 to obtain a display of 270.0V ac ±0.1 V ac.

7. Program the DMM Calibrator output for 1000 V ac at 10 kHz.

8. Adjust C10 to obtain a display of 1000 V ac ±1 V ac.

9. Program the DMM Calibrator output for 27.00 V ac at 10 kHz.

10. Adjust C8 to obtain a display of 27.00 V±0.01 V ac.

11. Program the DMM Calibrator output for 2.700 V ac at 10 kHz.

12. Adjust C6 to obtain a display of 2.700 V ac ±0.001 V ac.

13. Program the DMM Calibrator output for 2.700 ac at 100 Hz.

14. Verify that the UUT display indicates 2.700 V ac ±0.017 V ac.

15. Switch off both the DMM Calibrator and the UUT. Disconnect the DMM Calibrator

from the UUT.

) on the UUT.

16. Refer to the instructions in paragraph 30-10 to reassemble the UUT after calibration.

3-22. Troubleshooting

Static discharge can damage CMOS components U1 and U2.

Follow the handling precautions for static sensitive

components given previously. Never remove or install

components without first disconnecting all inputs to the

instrument and turning the function selector switch to OFF.

Refer to Table 3-4 and to the schematics in Chapter 5 of this manual as necessary during

the following troubleshooting procedures.

3-23. Power-Up Self Test

When the function switch is moved to any position from the OFF position, the instrument

performs a power-on self test. All LCD segments are switched on while the test is being

performed (about 1 second), then the unit commences normal operation.

3-24. Overall System Check

If the LCD display segments do not light, or if other malfunction indications occur during

power-up or operation, perform the following overall system check.. All measurements

are taken with respect to common. The overall system check is helpful in isolating a

Caution

3-17

Page 40

27

Service Manual

malfunction to the component area, and Table 3-4 provides further fault isolation within

the component area. Refer to the disassembly and reassembly procedures as necessary

(paragraphs 3-9 and 3-10).

1. Set up the instrument as follows:

a. Perform steps 1 through 10 of the disassembly procedure to remove the battery

cover, bottom case, and main pca/shield assembly from the instrument.

b. Perform steps 21 through 23 of the disassembly procedure to remove the top and

bottom shields from the main pca.

c. Perform step 14 of the reassembly procedure to install the main pca in the top

case.

d. Perform step 15 of the reassembly procedure to secure the main pca to the input

terminals.

2. Select the dc voltage function (

3. Use a Digital Voltmeter (DVM) to check the battery voltage at the battery connector

(battery voltage must be above 6.3 V). If battery voltage is less than 7.5 V, battery

replacement is advised. Normal current drain is less than 600 µA.

4. Connect either an oscilloscope or frequency counter, using a low-capacitance probe,

to pin 54 of U1 or to the junction of C17 and Y1 (the crystal). A 32.768 kHz sine

wave with an amplitude of approximately 600 mV peak-to-peak should be present at

the junction of C17 and Y1 (3 V peak-to-peak at U1 pin 54). Note that U2 and the

display will not operate if the clock signal is not present. If the clock signal is not

present, the most likely causes are U1, Y1 or C17.

5. Use a DVM to check for a reference voltage of 1.00V dc (adjustable through R l 9) at

pin 13 of U1 or at the junction of R15 and R18. If the reference voltage is not

present, the most likely causes are VR1, R12, R15, R18, R19, R37, or U1.

6. Use a DVM to check for Vm (voltage middle) at pin 55 of U2, pin 16 of J8, or at the

junction of R3 and R4. Vm should be 1.6 V dc ±0.1 V. If Vm is not present, the most

likely causes are R3, R4, or C13.

3-25. DC Voltage Signal Tracing

The following procedure is a step-by-step method of tracing a dc voltage input through the

instrument’s circuits to the output of the active filter. Faulty components in the input signal

path can be identified using this procedure. All measurements are taken with respect to

common.

).

3-18

1. Select the dc voltage function (

volts/ohms/diode-test input terminal.

2. Using a DVM, measure the 2 V input at the input terminal (Jl).

3. Check pin l of the input divider (Z l ) for 2 V dc. If 2 V dc is not present, R2, Sl, RV1,

RV2, RV3, RV4, or RV5 may be defective.

), then apply a 2 V dc input through the

4. Check pin 3 of Z1 for approximately 200 mV dc. If 200 mV is not present, either Z1

or U1 may be defective. (Measurement may be approximately 10% low if a

10 M

input impedance DVM is being used for signal tracing.)

5. Check the active filter input (pin 28 of U1) for approximately 200 mV dc. If 200 mV

is not present, U1 may be defective. (Measurement may be affected by loading.)

Page 41

Maintenance

Troubleshooting

6. Check the active filter output (pin 29 of U1) for approximately 200 mV dc. If 200

mV is not present, R13, R16, C18, or C19 may be defective. (Measurement may be

affected by loading.)

3-26. Fault Diagnosis Guide

Table 3-3 presents a fault diagnosis guide for the Fluke 27. The left column lists various

malfunction. The left column lists various malfunction symptoms. The center column

recommends actions to determine the exact problem. The right column lists the

components most likely to be defective.

Table 3-4. Fault Diagnosis Guide

Symptom Recommended Action Possible Component

Blank display Do system check given in paragraph 3-24. BT1, U1,U2,Y1,C13

Display reads zero in volt dc Do do signal tracing in paragraph 3-25. RT1,Z1,U1,S1

Display hangs up in self-test mode Do system check given in paragraph 3-24. R15, R18, R19, R12, R37, VR1, Z1,

Display reads OL or 0 in 320 mA

range

Display reads 0 in 320 mA or 10A

ranges

AC volts is inaccurate Check calibration R31, R32, R29, R30

320 mV range reads OL Q11, U1

AC volts measurement noisy at

50-60 Hz

Wrong annunciator displayed S1R, U1

Volts inaccurate Check calibration RV2-RV5

Ohms inaccurate Z1, U1

Intermittent display Clean connectors and connector strips on

LCD and pca

Display reads constant offset in

volts

Ohms reads low or will not read OL Q1,Q2 shorted or leaky

Ohms reads random or alternates

between

U1, C20, C21

R9, R10, U1

F1, F2, R9, R20, R14

R13, R16, C18,C19

Display Assembly

C18, C19, C20 shorted

R2, RT1

3

3-19

Page 42

27

Service Manual

3-20

Page 43

Chapter 4

List of Replaceable Parts

Title Page

4-1. Introduction ......................................................................................... 4-3

4-2. How to Obtain Parts............................................................................. 4-3

4-3. Manual Status Information .................................................................. 4-3

4-4. Newer Instruments ............................................................................... 4-4

4-5. Service Centers.................................................................................... 4-4

4-6. Parts Lists ............................................................................................ 4-5

4-1

Page 44

27

Service Manual

4-2

Page 45

4-1. Introduction

This chapter contains an illustrated list of replaceable parts for the Fluke 27 Multimeters.

Parts are listed by assembly; alphabetized by reference designator. Each assembly is accompanied by an illustration showing the location of each part and its reference

designator. The parts lists give the following information:

• Reference designator

• An indication if the part is subject to damage by static.

• Description

• Fluke stock number

• Total quantity

• Any special notes (i.e., factory-selected part)

A * symbol indicates a device that may be damaged by static

discharge.

Caution

List of Replaceable Parts

Introduction

4

4-2. How to Obtain Parts

Electrical components may be ordered directly from the manufacturer by using the

manufacturers part number, or from the Fluke Corporation and its authorized

representatives by using the part number under the heading FLUKE STOCK NO. In the

U.S., order directly from the Fluke Parts Dept. by calling 1-800-526-4731. Parts price

information is available from the Fluke Corporation or its representatives. Prices are also

available in a Fluke Replacement Parts Catalog which is available on request.

In the event that the part ordered has been replaced by a new or improved part, the

replacement will be accompanied by an explanatory note and installation instructions, if

necessary.

To ensure prompt delivery of the correct part, include the following information when

you place an order:

• Instrument model and serial number

• Part number and revision level of the pca containing the part.

• Reference designator

• Fluke stock number

• Description (as given under the DESCRIPTION heading)

• Quantity

4-3. Manual Status Information

The Manual Status Information table that precedes the parts list defines the assembly

revision levels that are documented in the manual. Revision levels are printed on the

component side of each pca.

4-3

Page 46

27

Service Manual

4-4. Newer Instruments

4-5. Service Centers

Changes and improvements made to the instrument are identified by incrementing the

revision letter marked on the affected pca. These changes are documented on a manual

supplement which, when applicable, is included with the manual.

To contact Fluke, call one of the following telephone numbers:

USA and Canada: 1-888-99-FLUKE (1-888-993-5853)

Europe: +31 402-678-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-356-5500

Or, visit Fluke’s Web site at www.fluke.com.

Note

The Fluke 27 Multimeter has been designed to meet the requirements of the

United States Department of Labor Mine Safety and Health Administration

for use in mines. If your instrument has MSHA approval, a decal stating so

will be present on the bottom of your instrument. The following Warning

applies only if the decal is present:

Warning

The Fluke 27 multimeters are approved (permissible) by the

United States Department of Labor Mine Safety and Health

Administration (MSHA) for use in mines (approval 2G-3665-0).

To maintain MSHA permissibility, repairs to this instrument

must be made using parts exactly like those furnished by the

Fluke Corporation. Any changes in the intrinsically safe

circuitry or components may result in an unsafe condition. The

Fluke 27 multimeter was tested by MSHA for intrinsic safety in

methane air mixtures only. The Fluke 27 multimeter is MSHA

approved with a 9 V NEDA 1604 (carbonzinc) battery only. Do

not use to check electrical blasting circuits. Do not connect to

an electrically energized circuit in a hazardous area.

Warning

When servicing, use only specified parts.

Warning

To ensure safety, use exact replacement parts where specified.

4-4

Page 47

List of Replaceable Parts

4-6. Parts Lists

The following tables list the replaceable parts for the 45 Multimeter. Parts are listed by

assembly; alphabetized by reference designator. Each assembly is accompanied by an

illustration showing the location of each part and its reference designator. The parts lists

give the following information:

• Reference designator

• An indication if the part is subject to damage by static discharge

• Description

• Fluke stock number

• Total quantity

• Any special notes (i.e., factory-selected part)