Page 1

®

2680A/2686A

Data Acquisition System/Data Logging System

June 2002, Rev. 1, 4/04

© 2002, 2004 Fluke Corporation. All rights reserved.

All product names are trademarks of t heir resp ective co mpani es.

Users Manual

Page 2

Limited Warranty and Limitation of Liability

Each Fluke product is warranted to be free from defects in material and workmanship under normal

use and service. The warranty period is one year and begins on the date of shipment. Parts, product

repairs and services are warranted for 90 days. This warranty extends only to the original buyer or

end-user customer of a Fluke authorized reseller, and doe s not appl y to fuses, di spo sab le batteries

or to any product which, in Fluke's opinion, has been misused, altered, neglected, contaminated, or

damaged by accident or abnormal condit ion s of operatio n or handling .

Fluke warrants that software will operate substantially in accordance with its functional specifications

for 90 days and that it has been properly recorded on non-defective media. Fluke does not warrant

that software will be error free or operate without interruption. The software is neither intended nor

warranted for use in medical or any other applications where human safety may be a concern.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user

customers only but have no authority to extend a greater or different warranty on behalf of Fluke.

Warranty support is available only if product is purchased through a Fluke authorized sales outlet or

Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for

importation costs of repair/replacement parts when product purchased in one country is submitted for

repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price, free of charge

repair, or replacement of a defective product which is returned to a Fluke authorized service center

within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain return

authorization information, then send the product to that service center, with a description of the

difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in

transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB

Destination). If Fluke determines that failure was caused by neglect, misuse, contamination,

alteration, accident or abnormal condition of operation or handling, including over vo ltage failures

caused by use outside the product’s specified rating, or normal wear and tear of mechanical

components, Fluke will provide an estimate of repair costs and obtain authorization before

commencing the work. Following repair, the product will be returned to the Buyer transportation

prepaid and the Buyer will be billed for the repair and return transportation charges (FOB Shipping

Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES AND/OR PROFITS, INCLUDING LOSS OF DATA,

ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion

or limitation of incidental or consequential damages, the limitations and exclusions of this warranty

may not apply to every buyer. If any provision of this Warranty is held invalid or unenforceable by a

court or other decision-maker of competent jurisdiction, such holding will not affect the validity or

enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

2/02

Page 3

XWCaution

This is an IEC safety Class 1 product. Before using, the

ground wire in the line cord or rear panel binding post

must be connect to an earth ground for safety.

Interference Information

This equipment generates and uses radio frequency energy and if not installed and used in strict

accordance with the manufacturer’s instructions, may cause interference to radio and television

reception. It has been type tested and found to comply with the limits for a Class B computing device

in accordance with the specifications of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference in a residential installation.

Operation is subject to the following two conditions:

• This device may not cause harmful interfere nce .

• This device must accept any interference received, including interference that may cause

undesired operation.

There is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one of more of the

following measures:

• Reorient the receiving antenna

• Relocate the equipment with respect to the receiver

• Move the equipment away from the receiver

• Plug the equipment into a different outlet so that the computer and receiver are on different

branch circuits

If necessary, the user should consult the dealer or an experienced radio/television technician for

additional suggestions. The user may find the following booklet prepared by the Federal

Communications Commission helpful: How to Identify and Resolve Radio-TV Interference Problems.

This booklet is available from the U.S. Government Printing Office, Washington, D.C. 20402. Stock

No. 004-000-00345-4.

Page 4

SAFETY TERMS IN THIS MANUAL

This device has been designed and tested to meet the requirements of EN61010-1

(Safety Requirements for Electrical Equipment for Measurement, Control and

Laboratory Use). It is an Installation Category II device intended for operation from

a normal single phase supply. The DIO relay controls are rated to 250 V ac CAT I

and should not be used in applications that exceed that rating.

contains information, warnings and cautions. Use of this equipment in a manner

not specified herein may impair the protection provided by the equipment.

Measurement category I is for measurements performed on circuits not directly

connected to MAINS. Examples are measurements on circuits not derived from

MAINS, and specially protected (internal) MAINS derived circuits.

Measurement category II is for measurements performed on circuits directly

connected to the low voltage installation. Examples are measurements on

household appliances, portable tools and similar equipment.

XWWARNING statements identify conditions or practices that could result in

personal injury or loss of life.

XWCAUTION statements identify conditions or practices that could result in

damage to equipment.

SYMBOLS MARKED ON EQUIPMENT:

This Users Manual

X WARNING Risk of electric shock.

J Ground (earth) terminal.

.

W

AC POWER SOURCE

The device is intended to operate from an ac power source that will not apply more

than 264 V ac rms between the supply conductors or between either supply

conductor and ground. A protective ground connection by way of the grounding

conductor in the power cord is required for safe operation.

Protective ground (earth) terminal. Must be connected to safety earth

ground when the power cord is used.

Attention. Refer to the manual. This symbol indicates that information

about usage of a feature is contained in the manual. This symbol

appears on the Universal Input Module and in the following two places

on the device rear panel:

1. Ground Binding Post (to the left of the line power connector).

2. Alarm/Trigger I/O and Digital I/O connectors.

Page 5

XWWARNING

Use the proper fuse. To avoid fire hazard, for fuse

replacement use only a 1/2 ampere, 250 V time delay line

fuse.

DC POWER SOURCE

The device may also be operated from a 9 V to 45 V dc power source when either

the rear panel ground binding post or the power cord grounding conductor is

connected properly. The input is protected by a 4 ampere fuse internal to the

device. This fuse should only be replaced by a qualified Fluke technician.

GROUNDING THE DEVICE

The device utilizes controlled overvoltage techniques that require the device to be

grounded whenever normal mode or common mode ac voltages or transient

voltages may occur. The enclosure must be grounded through the grounding

conductor of the power cord, or if operated on battery with the power cord

unplugged, through the rear panel ground binding post.

USE THE PROPER POWER CORD

Use only the power cord and connector appropriate for the voltage and plug

configuration in your country.

Use only a power cord that is in good condition.

Refer power cord and connector changes to qualified service personnel.

XWWARNING

To avoid possible electric shock or damage to the device:

• Read manual before operating.

• Do not position device so that air flow through side

vents is restricted.

• Do not use in a manner not specified in this manual or

safety protection may be impaired.

• Disconnect power cord and ALL other inputs before

replacing a fuse.

• Position the device where power cord can be

disconnected.

• Do not exceed maximum voltages.

Page 6

XWWARNING

• Do not operate in explosive atmospheres.

• To avoid personal injury or death, do not remove the

device cover without first removing the power source

connected to the rear panel. Do not operate the device

without the cover properly installed. There is no need

for the operator to remove the cover.

• Do not attempt to operate if protection may be

impaired.

• If the device appears damaged or operates abnormally,

protection may be impaired. Do not attempt to operate

the device under these conditions. Refer all question

of proper device operation to qualified service

personnel.

• Do not attempt to service unless you are a Fluke

qualified repair technician.

• To avoid personal injury or death, remove the AC

power cord and all analog and digital connector

modules before servicing the device.

Note

All signals must be removed from the analog and digital connector

wiring before opening the connector modules.

Page 7

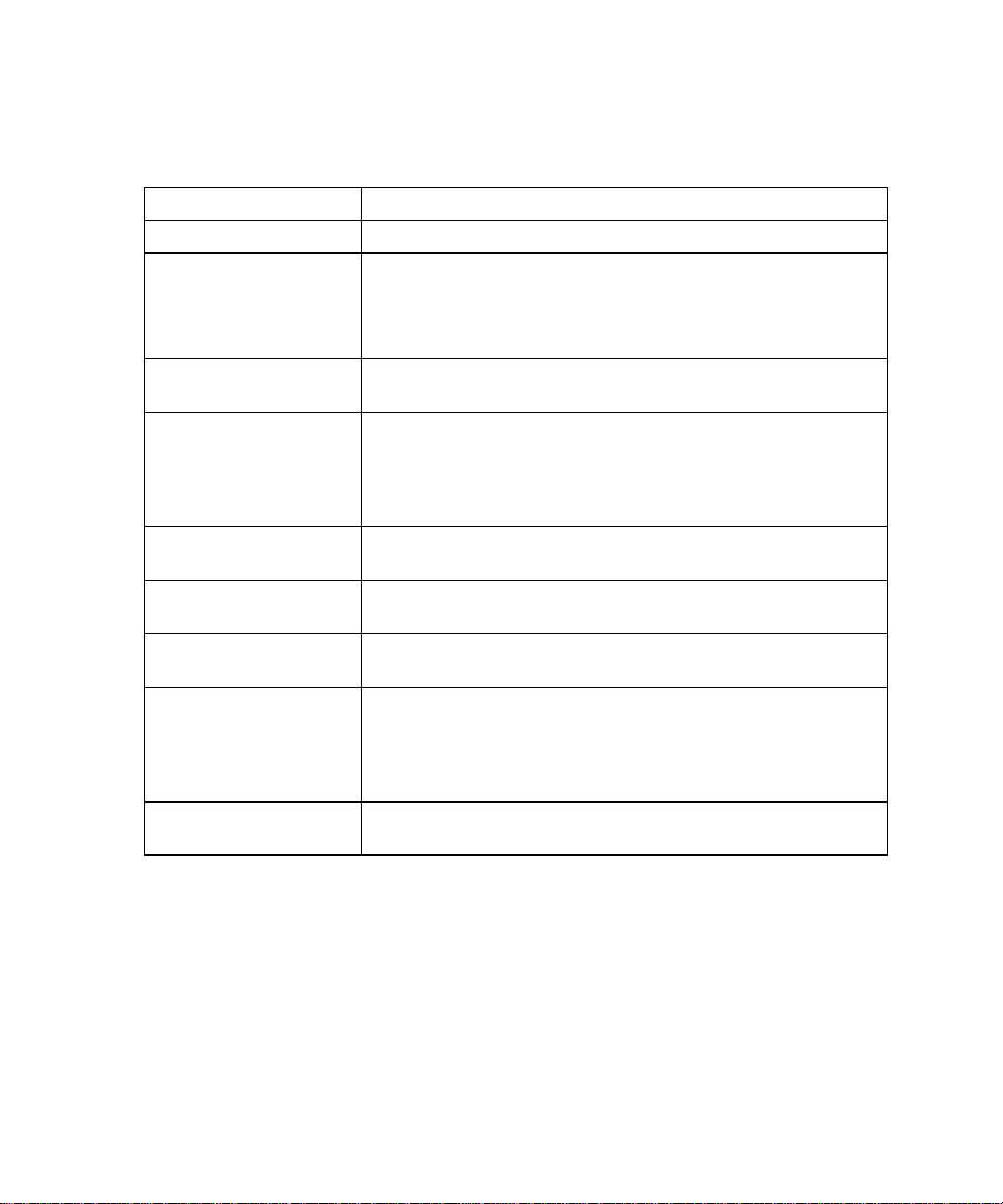

The following table provides additional safety information.

General Specifications

Specification Characteristic

Size 473 mm (18.6 in) x 432 mm (17 in) x 237 mm (9.3 in)

Weight 2680A/2686A (empty) 8.6 Kg (18.9 lb)

2680A – FAI 0.8 Kg (1.8 lb)

2680A – PAI 1.2 Kg (2.7 lb)

2680A – DIO 0.8 Kg (1.8 lb)

Power 100 – 240 V ac (no switching required), 50 to 60 Hz, 100 VA

maximum or optional 9 V d c to 45 V dc, 35 W maximum

EMC EN50082-2

EN55022-1

EN55011 class A

EN610000-4-2,3,4,6,8

EN61326

Safety EN61010-1, CAT II

CSA C22.2 No. 1010.1

Operating Temperature

-20 oC to 60 oC (-4 oF to +140 oF)

Range

Storage Temperature

-40 oC to 70 oC (-40 oF to +158 oF)

Range

Relative Humidity 90% maximum for -10 oC to 28 oC (14 oF to +82 oF)

75% maximum for 28

50% maximum for 35

o

C to 35 oC (82 oF to +95 oF)

o

C to 60 oC (95 oF to +140 oF)

(3 MΩ range, reduce humidity rating by 25% for 1 hour warm-up.

3 MΩ range meets full humidity ratings with 2 hour warm-up)

Altitude Operating: 2,000 m (6,562 ft) maximum

Non-operating: 12,200 m (40,000 ft) maximum

Page 8

Page 9

Table of Contents

Chapter Title Page

1 Overview........................................................................................... 1-1

Introduction...................................................................................................... 1-3

Contacting Fluke.............................................................................................. 1-3

Instrument Features and Capabilities............................................................... 1-5

Mainframe Features................................................................................... 1-8

Trigger Input......................................................................................... 1-8

Trigger Output ...................................................................................... 1-8

PC Card ATA Interface (2686A Only)................................................. 1-8

Master Alarm ........................................................................................ 1-9

Interval Trigger..................................................................................... 1-9

External Trigger.................................................................................... 1-9

Alarms................................................................................................... 1-9

Channel Monitoring.............................................................................. 1-10

Alarm Trigger ....................................................................................... 1-10

Channel Numbering .................................................................................. 1-10

Computed Channels .................................................................................. 1-11

Mx+B Scaling ........................................................................................... 1-11

Analog Channels ....................................................................................... 1-11

Digital I/O Module Option........................................................................ 1-12

Digital I/O............................................................................................. 1-12

Relay Output......................................................................................... 1-12

Totalizer................................................................................................ 1-12

User Interface................................................................................................... 1-13

Operating a 2680 Series Data Acquisition System.......................................... 1-14

Isolated Networks...................................................................................... 1-14

General Networks...................................................................................... 1-14

Ethernet Port.............................................................................................. 1-14

Group Operations...................................................................................... 1-15

Scanning and Logging............................................................................... 1-15

RS-232 Interface ....................................................................................... 1-17

i

Page 10

2680A/2686A

Users Manual

Host Computer Requirements......................................................................... 1-17

Options and Accessories ................................................................................. 1-18

2 Preparing for Operation................................................................... 2-1

Introduction..................................................................................................... 2-3

Instrument Preparation.................................................................................... 2-4

Unpacking and Inspecting the Instrument ................................................ 2-5

Positioning and Rack Mounting ............................................................... 2-5

Connecting to a Power Source and Grounding......................................... 2-5

Operating Using AC Power.................................................................. 2-6

Operating Using DC Power.................................................................. 2-7

Grounding and Common Mode Voltage.............................................. 2-7

Alarm/Trigger I/O Connection ................................................................. 2-7

Trigger Input......................................................................................... 2-8

Trigger Output...................................................................................... 2-9

Master Alarm........................................................................................ 2-10

External Trigger Wiring for a Group........................................................ 2-10

Universal Input Module Analog Connections (2620A-180)..................... 2-12

Shielded Wiring.................................................................................... 2-15

Crosstalk Considerations...................................................................... 2-15

Digital I/O Connector Module.................................................................. 2-15

Digital I/O............................................................................................. 2-16

Totalizer................................................................................................ 2-16

Totalizer Enable ................................................................................... 2-17

Relays ................................................................................................... 2-17

Controls and Indicators............................................................................. 2-17

Front Panel Controls............................................................................. 2-17

Front Panel Indicators .......................................................................... 2-19

Rear Panel Controls.............................................................................. 2-22

Rear Panel Indicators............................................................................ 2-23

Front Panel Operating Procedures ............................................................ 2-24

Power-On Options................................................................................ 2-24

Displaying a Monitor Channel ............................................................. 2-25

Displaying the Digital I/O Status ......................................................... 2-27

Displaying Relay Status ....................................................................... 2-28

Displaying the Totalizer Status ............................................................ 2-30

Reviewing and Setting the Base Channel Number............................... 2-31

Reviewing and Setting the Line Frequency.......................................... 2-33

Reviewing and Setting the Network Type............................................ 2-35

Reviewing and Setting the General Network Socket Port.................... 2-40

Reviewing and Setting the General Network IP Address..................... 2-41

Reviewing and Setting the Subnet Mask and Default Gateway........... 2-42

Viewing the Instrument Ethernet Address ........................................... 2-44

Reviewing and Setting PC Card Options ............................................. 2-46

ii

Page 11

Contents

(continued)

Host Computer and Network Preparation........................................................ 2-47

Installing Host Computer Ethernet Adapter.............................................. 2-47

Instrument and Host Computer Interconnection ....................................... 2-49

Host Computer/Instrument Direct Connection ..................................... 2-49

Interconnection Using 10/100BaseT (Twisted Pair) Ethernet Wiring.. 2-50

Set Up Windows Networking ................................................................... 2-52

Setting Host Computer Networking Parameters ....................................... 2-53

Installing Fluke DAQ Software................................................................. 2-53

Testing and Troubleshooting ........................................................................... 2-54

Installing and Testing the Installation ....................................................... 2-54

Troubleshooting Network Problems ......................................................... 2-58

3 Using Fluke DAQ Software .............................................................. 3-1

Introduction...................................................................................................... 3-3

Installing Fluke DAQ Software ....................................................................... 3-4

Understanding the User Interface .................................................................... 3-5

Fluke DAQ Main Window........................................................................ 3-5

Using the Toolbar...................................................................................... 3-6

Understanding the Workspace Area.......................................................... 3-8

Configuration Dialogs............................................................................... 3-9

Main Configuration Dialog................................................................... 3-9

Instrument Configuration Dialog.......................................................... 3-9

Module Configuration Dialog............................................................... 3-10

Analog Channel Configuration Dialog ................................................. 3-10

DIO Configuration Dialog.................................................................... 3-10

Computed Channel Configuration Dialog ............................................ 3-10

Communication Dialogs............................................................................ 3-11

Main Communication Dialog ............................................................... 3-11

Instrument Communication and Status Dialog..................................... 3-11

Module Communication Dialog ........................................................... 3-11

Digital I/O Points Dialog...................................................................... 3-11

Computed Channels Dialog.................................................................. 3-11

Communications Icons.......................................................................... 3-12

Security Dialogs........................................................................................ 3-12

Trend Dialog ............................................................................................. 3-13

Alarm Dialog............................................................................................. 3-13

Mail and Web Settings Dialogs................................................................. 3-13

Managing Your Network Using Fluke DAQ................................................... 3-14

Inserting and Configuring an Instrument .................................................. 3-14

Inserting and Configuring a Module ......................................................... 3-19

Inserting and Configuring a Channel ........................................................ 3-23

Configuring a Computed Channel............................................................. 3-26

Configuring Multiple Channels................................................................. 3-29

Using Equations with Computed Channels............................................... 3-30

iii

Page 12

2680A/2686A

Users Manual

Configuring Data Files.................................................................................... 3-46

Main Window Advanced Settings................................................................... 3-55

Using Fluke DAQ System Security Features.................................................. 3-56

Configuring Web and Alarm Mail Settings .................................................... 3-58

Starting a Scan .......................................................................................... 3-32

Starting a Configuration Scan .............................................................. 3-32

Starting an Instrument Scan.................................................................. 3-33

Getting Scan Data................................................................................. 3-33

Viewing and Resetting the Totalizer .................................................... 3-34

PC Card Functions.................................................................................... 3-34

Getting PC Card Information ............................................................... 3-34

Formatting the PC Card........................................................................ 3-34

Getting PC Card Scan Data.................................................................. 3-35

Starting Spy .............................................................................................. 3-36

Viewing Module Measurement Data........................................................ 3-38

Using the Digital I/O Points Communication Dialog............................... 3-39

Using Trend to View Collected Data........................................................ 3-40

Changing the Trend Chart Display....................................................... 3-43

Viewing Alarms........................................................................................ 3-44

Selecting a Master for a Data Group......................................................... 3-47

Advanced Data File Configuration........................................................... 3-47

Real-time Data File Creation .................................................................... 3-53

4 Maintenance ..................................................................................... 4-1

Introduction..................................................................................................... 4-3

Self-Test Diagnostics and Error Codes ........................................................... 4-3

Cleaning .......................................................................................................... 4-6

AC Fuse Replacement..................................................................................... 4-7

DC Fuse Replacement..................................................................................... 4-9

Performance Test............................................................................................. 4-9

Configuring the Performance Test Setup.................................................. 4-9

Initializing the Performance Test Setup.................................................... 4-11

Accuracy Performance Tests........................................................................... 4-13

Master Alarm Output Tests....................................................................... 4-14

RS-232 Master Alarm Output Test....................................................... 4-14

Fluke DAQ Master Alarm Output Test................................................ 4-14

Trigger Input Tests ................................................................................... 4-15

RS-232 Trigger Input Test.................................................................... 4-15

Fluke DAQ Trigger Input Test............................................................. 4-15

Trigger Output Tests................................................................................. 4-15

RS-232 Trigger Output Test................................................................. 4-15

Fluke DAQ Trigger Output Test .......................................................... 4-16

Volts DC Accuracy Test (PAI Module).................................................... 4-16

Volts DC Accuracy Test (FAI Module).................................................... 4-17

iv

Page 13

Contents

(continued)

Volts AC Accuracy Test ........................................................................... 4-18

Frequency Accuracy Test.......................................................................... 4-19

Analog Channel Integrity Test .................................................................. 4-20

Open Thermocouple Response Test.......................................................... 4-20

2-Wire Resistance Accuracy Test (PAI) - Optional.................................. 4-21

2-Wire Resistance Accuracy Test (FAI Module) - Optional..................... 4-22

4-Wire Resistance Accuracy Test (PAI Module)...................................... 4-24

4-Wire Resistance Accuracy Test (FAI Module)...................................... 4-28

Digital Input/Output Tests......................................................................... 4-29

RS-232 Digital Input/Output Test......................................................... 4-29

Fluke DAQ Digital Input/Output Test .................................................. 4-30

DIO Relay/Fuse Tests ............................................................................... 4-30

RS-232 DIO Relay Fuse Test ............................................................... 4-30

Fluke DAQ DIO Relay Fuse Test......................................................... 4-30

Totalizer Tests........................................................................................... 4-31

RS-232 Totalizer Count Test ................................................................ 4-31

RS-232 Totalizer Count and Enable Test ............................................. 4-31

RS-232 Totalizer Count and Direction Test ......................................... 4-32

RS-232 Totalizer Count and Debounce Test ........................................ 4-32

Fluke DAQ Totalizer Count Test.......................................................... 4-33

Fluke DAQ Totalizer Count and Enable Test....................................... 4-33

Fluke DAQ Totalizer Count and Direction Test................................... 4-34

Fluke DAQ Totalizer Count and Debounce Test.................................. 4-34

Calibration ....................................................................................................... 4-35

Variations in the Display ................................................................................. 4-35

Service ............................................................................................................. 4-36

Replacement Parts ........................................................................................... 4-36

Appendices

A Specifications ............................................................................................ A-1

B Noise, Shielding, and Crosstalk Considerations ....................................... B-1

C True-RMS Measurements ......................................................................... C-1

D RTD Linearization..................................................................................... D-1

E Computed Channel Equations................................................................... E-1

F Data File Format........................................................................................ F-1

G Ethernet Cabling........................................................................................ G-1

H Network Considerations............................................................................ H-1

I Error Codes ............................................................................................... I-1

v

Page 14

2680A/2686A

Users Manual

vi

Page 15

List of Tables

Table Title Page

1-1. Channel Count vs Scan Rate............................................................................ 1-16

1-2. Models, Options and Accessories.................................................................... 1-18

2-1. Front Panel Key Descriptions.......................................................................... 2-18

2-2. Annunciator Display Descriptions................................................................... 2-20

2-3. Instrument Default Parameters ........................................................................ 2-24

2-4. Displaying a Monitor Channel......................................................................... 2-25

2-5. Displaying the Digital I/O Status..................................................................... 2-27

2-6. Displaying Relay Status................................................................................... 2-28

2-7. Displaying Totalizer Status.............................................................................. 2-30

2-8. Reviewing and Setting the Base Channel Number.......................................... 2-31

2-9. Reviewing and Setting the Line Frequency..................................................... 2-33

2-10. Reviewing and Setting the Network Type....................................................... 2-35

2-11. Reviewing and Setting the Network Type to General ..................................... 2-37

2-12. Reviewing and Setting the General Network Socket Port ............................... 2-40

2-13. Reviewing and Setting the General Network IP Address................................ 2-41

2-14. Reviewing and Setting the Subnet Mask and Default Gateway ...................... 2-43

2-15. Viewing the Instrument Ethernet Address....................................................... 2-44

2-16. Identifying Network Problems......................................................................... 2-58

2-17. Ethernet Indicators........................................................................................... 2-61

3-2. Configuration Control States ........................................................................... 3-29

3-3. File Renaming Example................................................................................... 3-51

3-4. File Size Control Criteria................................................................................. 3-52

4-1. Self-Test Codes................................................................................................ 4-4

4-2. Recommended Test Equipment....................................................................... 4-10

4-3. Replacement Parts ........................................................................................... 4-36

A-1. 2680 Series General Specifications ................................................................. A-2

A-2. 2680A/2686A Clock and Calendar.................................................................. A-3

A-3. Trigger In Specification................................................................................... A-4

A-4. Trigger Out Specification ................................................................................ A-4

A-5. Master Alarm Output Specification................................................................. A-5

A-6. 2686A - Active Channels and Number of Scans to Card Capacity................. A-5

vii

Page 16

2680A/2686A

Users Manual

A-7. PAI Module DC Voltage General Specifications............................................ A-6

A-8. PAI Module DC Voltage Range and Resolution Specifications..................... A-7

A-9. PAI Module DC Voltage Accuracy Specifications......................................... A-7

A-10. PAI Module AC Voltage General Specifications............................................ A-8

A-11. PAI Module AC Voltage Range and Resolution Specifications..................... A-9

A-12. PAI Module AC Voltage Accuracy Specifications......................................... A-10

A-13. PAI Module 4-Wire Resistance Temperature Coefficient .............................. A-11

A-14. PAI Module 4-Wire Resistance Range and Resolution Specifications........... A-11

A-15. PAI Module 4-Wire Resistance Accuracy Specifications............................... A-12

A-16. PAI Module 4-Wire RTD Temperature Coefficient ....................................... A-13

A-17. PAI Module 4-Wire RTD Specifications ........................................................ A-13

A-18. PAI Module Thermocouple General Specifications........................................ A-14

A-19. PAI Module Thermocouple Specifications ..................................................... A-15

A-20. PAI Module Frequency Accuracy Specifications ........................................... A-17

A-21. PAI Module Frequency Sensitivity Specifications.......................................... A-17

A-22. FAI Module DC Voltage General Specifications............................................ A-18

A-23. FAI Module DC Voltage Resolution and Repeatability Specifications.......... A-19

A-24. FAI Module DC Voltage Accuracy Specifications......................................... A-19

A-25. FAI Module AC Voltage General Specifications............................................ A-20

A-26. FAI Module AC Voltage Range and Resolution Specifications..................... A-20

A-27. FAI Module AC Voltage Accuracy Specifications......................................... A-21

A-28. FAI Module 4-Wire Resistance Temperature Coefficient .............................. A-22

A-29. FAI Module 4r-Wire Resistance Range and Resolution Specifications.......... A-22

A-30. FAI Module 4-Wire Resistance Accuracy Specifications............................... A-23

A-31. FAI Module 4-Wire RTD Temperature Coefficient ....................................... A-23

A-32. FAI Module 4-Wire RTD Specifications ........................................................ A-24

A-33. FAI Module Thermocouple General Specifications........................................ A-24

A-35. FAI Module Frequency Accuracy Specifications ........................................... A-27

A-36. FAI Module Frequency Sensitivity Specifications.......................................... A-27

A-37. DIGITAL I/O Specification ............................................................................ A-28

A-38. Totalizer Specification .................................................................................... A-29

A-39. DIGITAL I/O Relay Specification.................................................................. A-29

B-1. FAI Module Crosstalk Specifications. ............................................................ B-3

B-2. PAI Module Crosstalk Specifications ............................................................. B-4

I-1. Error Codes ..................................................................................................... I-1

viii

Page 17

List of Figures

Figure Title Page

1-1. 2680A/2686A Instrument ................................................................................ 1-4

1-2. 2680A/2686A Front Panel............................................................................... 1-5

1-3. Typical Front Panel Display During Scanning and Monitoring...................... 1-6

1-4. 2680A/2686A Rear Panel ................................................................................ 1-7

1-5. DIO Connector Module ................................................................................... 1-13

2-1. Instrument Preparation..................................................................................... 2-4

2-2. Connecting the Instrument to a Power Source................................................. 2-6

2-3. Alarm/Trigger I/O Connector.......................................................................... 2-9

2-4. External Trigger Wiring for a Group of Instruments....................................... 2-11

2-5. Universal Input Module Connections .............................................................. 2-13

2-6. 2-Wire and 4-Wire Connections..................................................................... 2-14

2-7. Digital I/O Connector ...................................................................................... 2-16

2-8. Front Panel Controls ........................................................................................ 2-17

2-9. Front Panel Indicators...................................................................................... 2-19

2-10. Rear Panel Controls ......................................................................................... 2-22

2-11. Displaying a Monitor Channel......................................................................... 2-26

2-12. Examples During Monitor ............................................................................... 2-26

2-13. Examples for Digital I/O, Relay, and Totalizer Status .................................... 2-29

2-13. Reviewing and Setting the Base Channel Number.......................................... 2-32

2-14. Examples for Reviewing and Setting the BCN................................................ 2-32

2-14. Reviewing and Setting the Line Frequency..................................................... 2-34

2-15. Examples for Reviewing and Setting the Line Frequency............................... 2-34

2-15. Reviewing and Setting the Isolated Network Type to Isolated........................ 2-36

2-16. Examples for Reviewing and Setting the Network Type................................. 2-36

2-17. Examples for Reviewing and Setting General Network Parameters ............... 2-38

2-17. Viewing the Instrument Ethernet Address....................................................... 2-45

2-18. Examples for Viewing the Ethernet Address................................................... 2-45

2-19. Preparing for Network Operation .................................................................... 2-48

2-20. Host Computer/Instrument Direct Connection ................................................ 2-49

2-21. Interconnection Using 10/100BaseT (Twisted Pair) Wiring ........................... 2-51

4-1. Replacing the Fuse........................................................................................... 4-8

ix

Page 18

2680A/2686A

Users Manual

4-2. Performance Test Setup .................................................................................. 4-11

4-3. 2-Wire Connections to 5700A......................................................................... 4-24

4-4. 4-Wire Connections to the Universal Input Module (Resistor)....................... 4-25

4-5. 4-Wire Connections to the Universal Input Module (5700A)......................... 4-26

A-1. 2680 Series Chassis......................................................................................... A-30

C-1. Comparison of Common Waveforms.............................................................. C-3

D-1. 385 RTD.......................................................................................................... D-2

D-2. 375 RTD.......................................................................................................... D-3

D-3. 391 RTD.......................................................................................................... D-4

D-4. 392 RTD.......................................................................................................... D-6

G-1. 10/100BaseT Ethernet Cables ......................................................................... G-2

x

Page 19

Chapter 1

Overview

Introduction 1-3

Contacting Fluke ............................................................................................. 1-3

Instrument Features and Capabilities .............................................................. 1-5

Mainframe Features.................................................................................. 1-8

Trigger Input......................................................................................... 1-8

Trigger Output...................................................................................... 1-8

PC Card ATA Interface (2686A Only)................................................. 1-8

Master Alarm........................................................................................ 1-9

Interval Trigger..................................................................................... 1-9

External Trigger.................................................................................... 1-9

Alarms .................................................................................................. 1-9

Channel Monitoring.............................................................................. 1-10

Alarm Trigger....................................................................................... 1-10

Channel Numbering.................................................................................. 1-10

Computed Channels.................................................................................. 1-11

Mx+B Scaling........................................................................................... 1-11

Analog Channels....................................................................................... 1-11

Digital I/O Module Option........................................................................ 1-12

Digital I/O............................................................................................. 1-12

Relay Output......................................................................................... 1-12

Totalizer................................................................................................ 1-12

User Interface .................................................................................................. 1-13

Operating a 2680 Series Data Acquisition System.......................................... 1-14

Isolated Networks ..................................................................................... 1-14

General Networks ..................................................................................... 1-14

Ethernet Port ............................................................................................. 1-14

Group Operations...................................................................................... 1-15

Scanning and Logging .............................................................................. 1-15

RS-232 Interface....................................................................................... 1-17

Host Computer Requirements ......................................................................... 1-17

Options and Accessories ................................................................................. 1-18

Contents Page

1-1

Page 20

2680A/2686A

Users Manual

1-2

Page 21

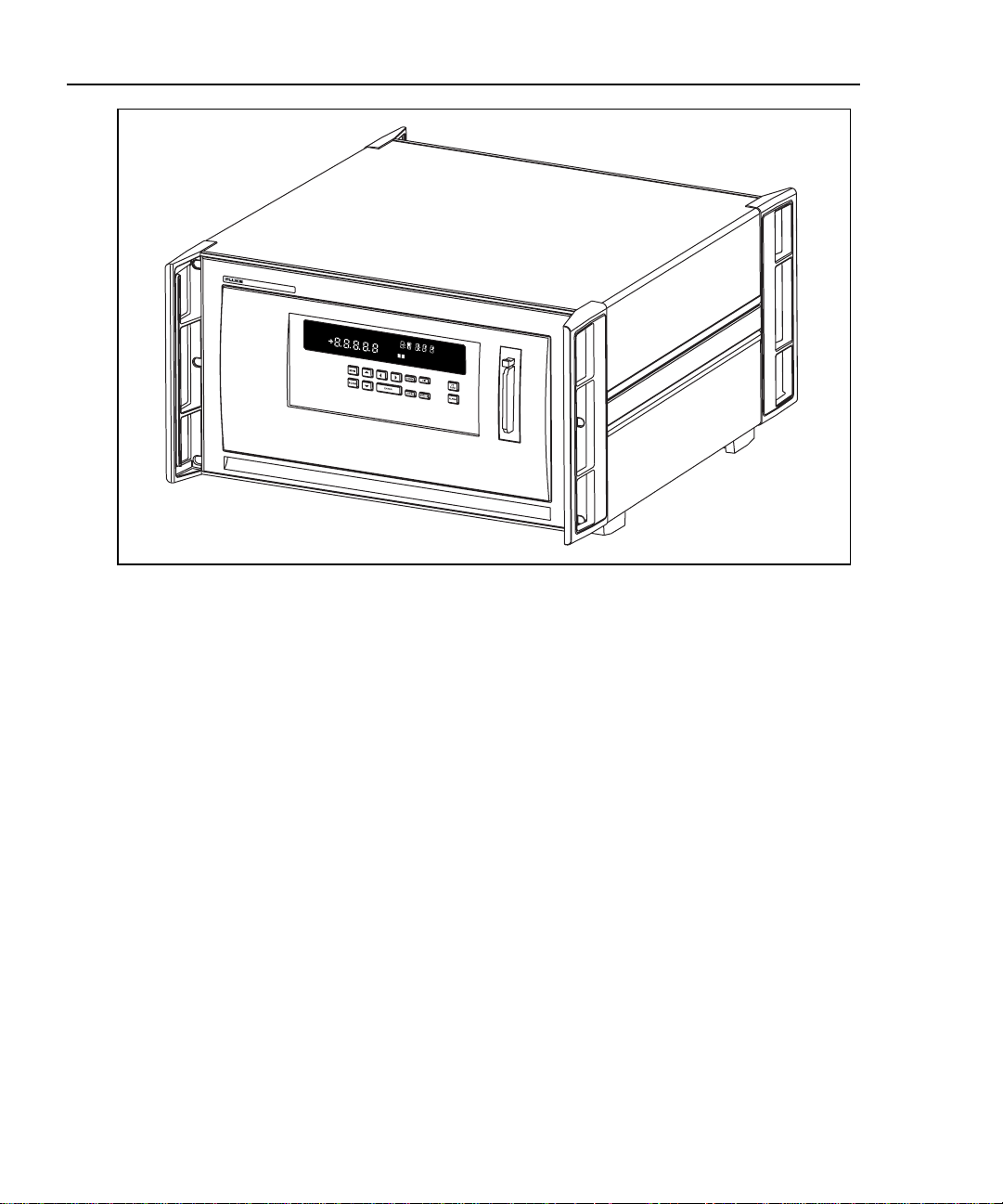

Introduction

The 2680A Data Acquisition System (DAS) and 2686A Data Logging System

(DLS) provide 20 to 120 channels that operate in conjunction with Fluke DAQ

software for Windows to form a data acquisition system.

The 2686A comes with a removable PC Card (PCMCIA) for stand-alone storage

operation. This socket accepts ATA memory cards up to 2 GB in size.

Each 2680 Series instrument can hold from 1 to 6 modules. These modules are the

Precision Analog module (PAI), Fast Analog module (FAI), and the Digital

IO/Relay and Totalizer module (DIO). These modules are all isolated from one

another. You can add the DIO module to the instrument in slot 6 only.

The analog modules measure dc volts, ac volts, ohms, temperature, frequency, and

dc current. Temperature measurements use thermocouples, thermistors or

resistance temperature detectors (RTDs). The instruments also have extensive

computed math capability. Besides using data collected from the analog modules

and digital totalizer, time can also be used in computed channel calculations.

The system scans 20 to 120 analog channels and calculates the values for up to 60

computed channels. Interval timers, alarm conditions, and/or an external signal

input can trigger scans. The Fluke DAQ software configures and controls up to 99

2680 Series instruments via an Ethernet connection. The software provides the

means to view scan data and log it into files. In addition, Fluke DAQ software

permits multiple master/slave groups to run simultaneously.

Overview

Introduction

1

The two analog modules that may be used with the 2680 Series are the FAI

module and the PAI module. The PAI modules emphasize precision with 5 ½

digits of resolution, .02% accuracy, and can withstand up to 150 V common mode

voltage (300 V on channels 1 and 11). The FAI modules emphasize increased

measurement speed with 4 ½ digits of resolution, 0.04% accuracy, and can

withstand up to 50 V common mode voltage. See Appendix A for instrument

specifications.

Contacting Fluke

To contact Fluke, call one of the following telephone numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com

1-3

.

Page 22

2680A/2686A

Users Manual

2680 SERIES DAQ SYSTEM

REVIEW

MAX

REM

LAST

SCAN

MIN

AUTO

SET

FUNC

MON

Mx+B

F

ALARM

C F RO

mV AC DC

LIMIT

x1Mk

HI

Hz

OFF

PRN

12

CH

LO

CAL

EXT

TR

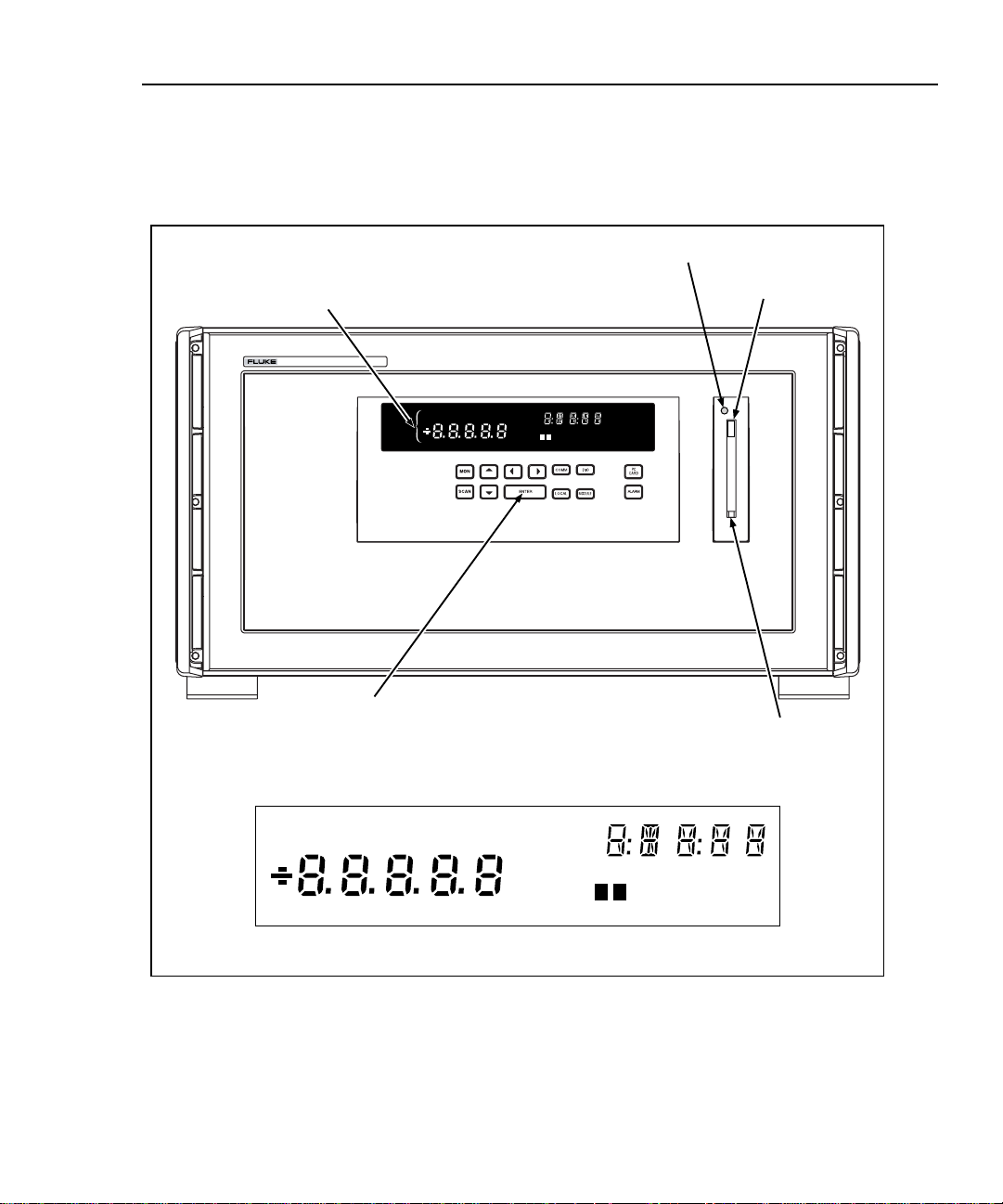

Figure 1-1. 2680A/2686A Instrument

alg46f.eps

1-4

Page 23

Instrument Features and Capabilities

Instrument Features and Ca pabilities

The following describes the front and rear panels of the instrument and its

capabilities (Figures 1-2 to 1-4).

Overview

1

Primary, Secondary, and Annunciator Displays.

Indicators and annunciators for operating mode,

configuration, display, and data measurements.

2686A DATA ACQUISITION SYSTEM

F

FUNC

SET

MAX

REM

SCAN

REVIEW

MIN

LAST

Function Keys. User keys for configuring

ALARM

Mx+B

AUTO

MON

C F RO

mV AC DC

LIMIT

Hz

x1Mk

12

operating parameters such as Base Channel

Number, and front panel displays such as

channel monitoring, digital I/O status, and

totalizer count.

Status Indicator (LED)

PRN

OFF

HI

EXTCHTR

CAL

LO

Eject Button

PC Card Slot

(Only available

on the 2686A)

Hz

F

LIMIT

12

HI

LO

OFF

CAL

PRN

EXTCHTR

REVIEW

LAST

MAX

MIN

REM

AUTO

SCAN

MON

SET

Mx+B

FUNC

ALARM

C F RO

mV AC DC

x1Mk

Display detail

alg47f.eps

Figure 1-2. 2680A/2686A Front Panel

1-5

Page 24

2680A/2686A

Users Manual

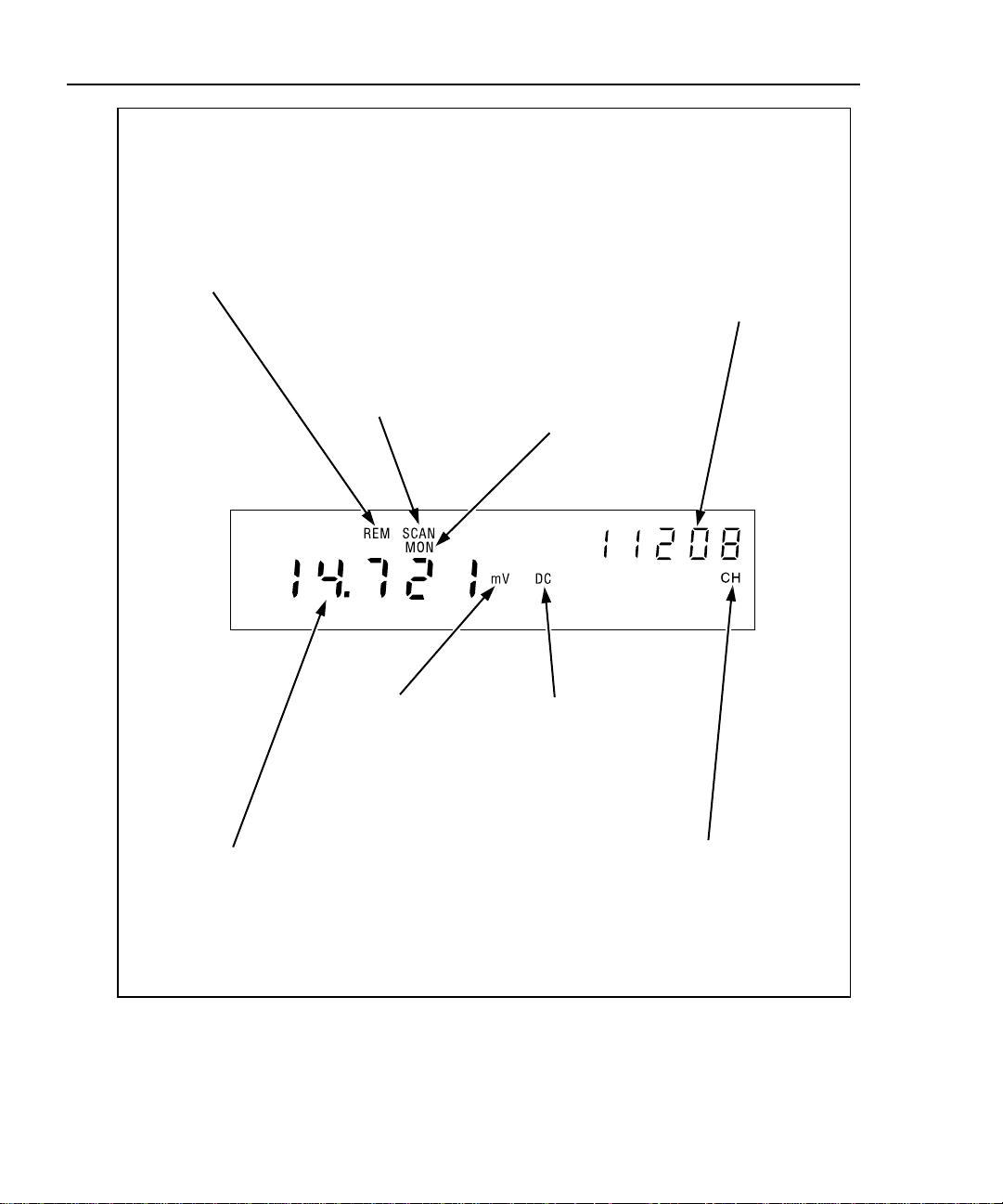

REM (Remote)

Annunciator.

Indicates the Host

Computer and the

Instrument are

communicating on the

network, i.e., the

instrument is being

operated remotely.

SCAN (Scanning)

Annunciator.

Indicates the

instrument is

scanning.

MON (Monitor)

Annunciator.

Indicates the

instrument is

monitoring a channel

(in this example,

analog channel 208).

You can monitor a

channel with or

without instrument

scanning.

11208 (Global

ChannelNumber).

Indicates the channel

being monitored is

11208. This number

consists of the

instrument Base

Channel Number (11),

Module Number (2)

and the selected

channel (08).

1-6

m Annunciator.

Indicates the multiplier

for the reading is .001

(milli). The other

multipliers are k (kilo,

1000), and M (mega,

1,000,000).

14.721 (Reading).

Indicates the reading

of the channel being

monitored has a value

of 14.721.

V DC (Volts DC)

Annunciator.

Indicates that the

number shown in the

primary display

(14.721) is the

function volts dc.

Figure 1-3. Typical Front Panel Display During Scanning and Monitoring

CH (Channel)

Annunciator.

Indicates the number

shown in the

secondary display

(11208) is the Global

Channel Number.

alg48f.eps

Page 25

Instrument Features and Capabilities

Overview

1

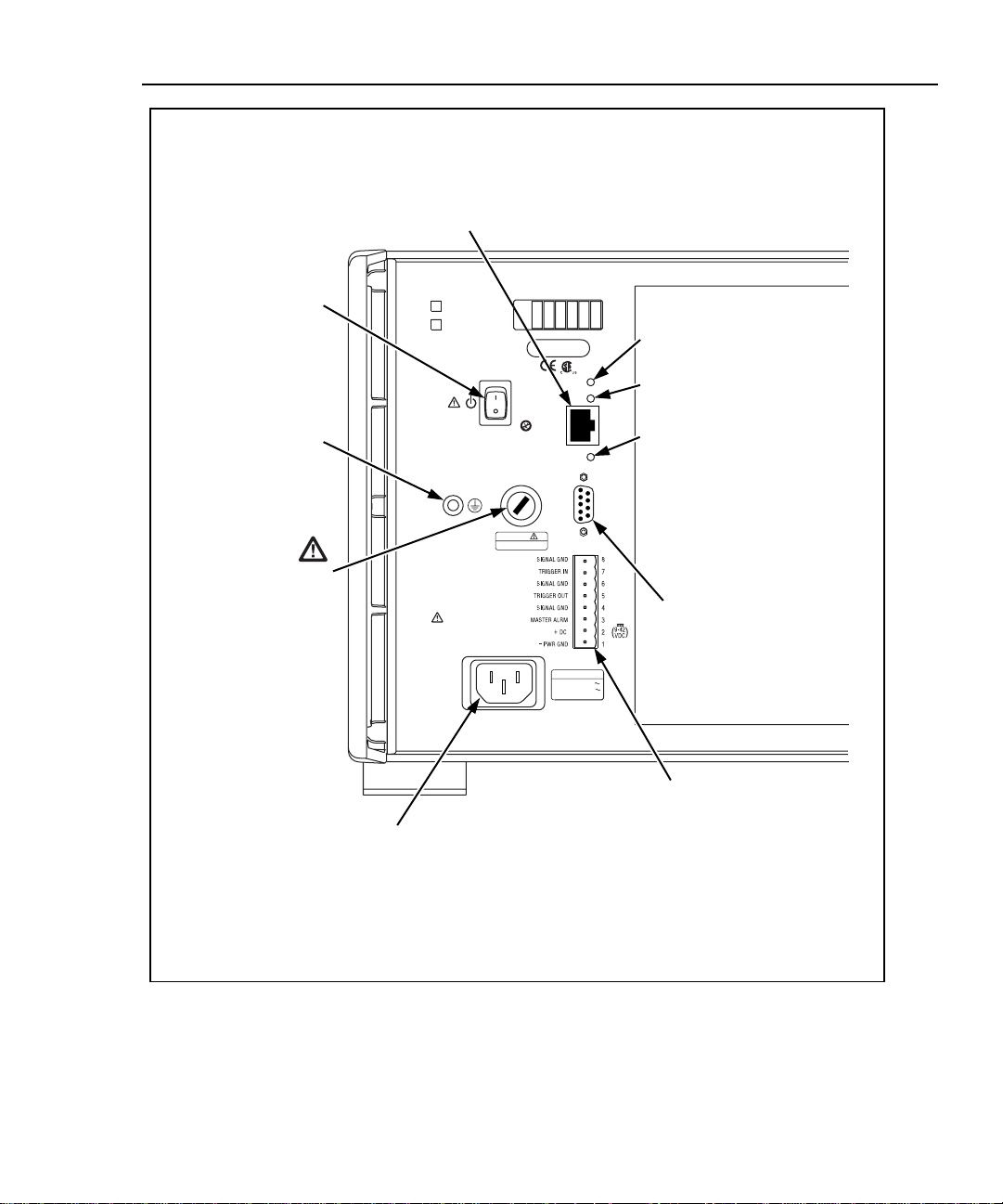

Ethernet 10/100BaseT Connector.

A RJ-45 connector that interfaces the

instrument with a 10/100BaseT

Twisted Pair Ethernet network. The

instrument automatically detects 10 or

100BaseT operation.

Power Switch.

Supplies power to the

instrument (ac or dc

operation).

Ground Terminal.

Connect to earth

ground when using

DC power.

Fuse Compartment

MODEL

2680A

2686A

FLUKE CORPORATION

MADE IN USA

www.fluke.com

PATENTS PENDING

STANDBY

CAUTION:

FOR FIRE PROTECTION

REPLACE ONLY WITH

A 250V FUSE OF

INDICATED RATING

CHASSIS

GROUND

FUSE

T1/2A 250V

WARNING:

TO AVOID

ELECTRIC SHOCK GROUNDING

CONNECTOR IN POWER CORD

MUST BE CONNECTED

NO INTERNAL USER SERVICEABLE PARTS.

REFER SERVICE TO QUALIFIED SERVICE PERSONNEL

AC Power Connector.

Connects to any line source

of 100 to 240 V ac (50/60 Hz).

SLOT CONFIGURATION

1

2

3456

SERIAL NUMBER

XMT

RCV

10/100 BASE T

ETHERNET

NOT FOR

CONNECTION

TO PUBLIC

TELEPHONE

SYSTEM

LINK

RS-232

SERIAL

PORT

(SB)

MAIN SUPPLY

100V- 240V

47Hz / 63Hz

100VA MAX

Ethernet Indicators.

XMT (transmit) blinks red for

instrument Ethernet transmissions.

RCV (receive) blinks red for any

Ethernet activity on the network.

LNK (link) lights red if 10BaseT is

operating, green if 100BaseT is

operating.

RS232

Serial Port

(for service use)

ALARM/TRIGGER I/O Connector.

Master Alarm output is logic low

when any channel is in alarm;

Trigger Out output is logic low for

nominal 125 ms start of any scan;

Trigger In input logic low triggers

scanning; DC PWR (dc volts input)

input is 9 to 45 V dc to power the

instrument.

alg60f.eps

Figure 1-4. 2680A/2686A Rear Panel

1-7

Page 26

2680A/2686A

Users Manual

Mainframe Features

Trigger Input

Trigger Input is an instrument connection used to trigger scans from an external

source. The connection uses the rear panel Trigger In and GND (Figure 1-4). A

logic low or contact closure between Trigger In and GND triggers an instrument

scan if External Trigger is enabled. While the trigger input line is held low, the

instrument continues to scan at Interval 2.

When there is no trigger input, an internal pull-up resistor holds the input at logic

high (nominal +5.0 V dc).

Trigger Output

Trigger Output is an output line that, when enabled, goes to logic low for 125 µs

every time a scan begins. The connection uses the rear panel Trigger Out and GND

(Figure 1-4). Use the Trigger Output to trigger other instruments by their Trigger

Input connection and to interface with external equipment. An internal pull-up

resistor holds the trigger output line at a logic high (nominal +5.0 V dc) when

there is no trigger output.

PC Card ATA Interface (2686A Only)

A PC ATA card interface provided in each 2686A system. It can be used to store

data when there is no network connection. The data produced is DOS compatible.

When scanned data is first recorded on the card, a copy of the configuration of the

instrument is also recorded. As a result, you can stop scanning, remove the card,

read results, reinstall the card in the same instrument, and restart scanning and

have only one file created. If you want to clear the existing memory card, the front

panel keys can be used to erase the card contents. You can use up to 2 GB ATA

compatible PC Card in a 2686A instrument. See Chapter 2 for additional

information.

1-8

An error will result if a card has partially been filled with data from a different

configuration. This can be fixed by using the front panel keys to erase the existing

data in the card.

XWCaution

Removing the PC card while the storage LED is on may

cause a loss of data. Before removing the card, stop the

instrument scanning. Loss of power while data is being

written to the card may also result in loss of data.

Page 27

Master Alarm

Master Alarm is an instrument output line that is logic low (nominal +0.8 V dc) for

as long as any channel is in alarm while scanning is active. The connection uses

the ALARM/TRIGGER I/O terminals Master Alarm and GND (Figure 1-4). This

TTL output interfaces with external equipment such as warning lights, alarms,

automatic shutdowns, and paging systems. When the alarm condition ends or

scanning stops, an internal pull-up resistor sets the output at logic high (nominal

+5.0 V dc).

Interval Trigger

Interval Trigger is an internal software timer you can set using Fluke DAQ

software. It permits scanning at regular time intervals using Interval 1. Interval 1 is

in seconds, with a minimum of 0.000 (continuous scanning) and a maximum of

86400.000 (one scan every 24 hours). The time resolution is to the millisecond, for

example, 12.345 seconds.

External Trigger

External Trigger is started by an external event and triggers scanning when an

external logic low is applied to the instrument Trigger In line. As long as the

Trigger Input remains low, scans are triggered at regular time intervals using

Interval 2. Interval 2 is in seconds, with a minimum of 0.000 (continuous

scanning) and a maximum of 86400.000 (one scan every 24 hours). The time

resolution is to the millisecond, for example, 12.345 seconds. When scanning

starts, if the External Trigger is logic low, scanning begins at the Interval 2 rate. If

the External Trigger is logic high, no scans are triggered until the trigger line is set

to logic low.

Overview

Instrument Features and Capabilities

1

If one or more external trigger events occur while a scan is in progress, one

triggered scan follows the scan in progress.

Alarms

Two alarms, Alarm 1 and Alarm 2, can be applied to any configured channel. An

alarm condition occurs when a measurement falls below a low alarm value, rises

above a high alarm value, or is between the two alarm values. If you apply Mx+B

scaling as part of the channel configuration, the instrument bases the alarms on the

scaled values.

When any configured channel is in alarm, the Alarm annunciator is on dim, or

bright if a channel in alarm is being used as an Alarm Trigger. When a channel is

in alarm, the rear-panel Master Alarm output is asserted (logic low). You can use

alarms to trigger scanning (see Alarm Trigger later in this chapter) and to set a

Digital I/O line to a logic low (see Digital I/O Module later in this chapter) or

close a relay. The Fluke DAQ software displays and records alarm conditions.

1-9

Page 28

2680A/2686A

Users Manual

Channel Monitoring

Channel monitoring takes place at the front panel of the instrument. Use the front

panel MON key and arrow keys to select a channel for monitoring. The Fluke

DAQ software also allows the selection of a channel to monitor during scanning.

For an example of a front panel display of the instrument during monitoring, see

Figure 1-3. Monitor can also automatically scroll up or down through the channels

displaying each channel and then moving to the next. The channel monitoring

display nominally updates once per second.

Alarm Trigger

The alarm trigger triggers scanning when a channel designated as an alarm trigger

goes into alarm. As long as any such channel is in alarm, scans are triggered at

regular time intervals using Interval 2. Interval 2 is in seconds, with a minimum of

0.000 (continuous scanning) and a maximum of 86400.000 (one scan every 24

hours). The time resolution is to the millisecond, for example, 12.345 seconds.

The instrument performs background monitoring of channels designated as alarm

triggers to check for alarm conditions using Interval 3.

You can combine Alarm Trigger with External Trigger and Interval Trigger. For

example, set the Interval Trigger for 60 seconds (Interval 1) and the Alarm Trigger

for 10 seconds (Interval 2). Scanning is at 60 second intervals except when a

channel designated as an alarm trigger is in alarm, when scanning is at 10 second

intervals.

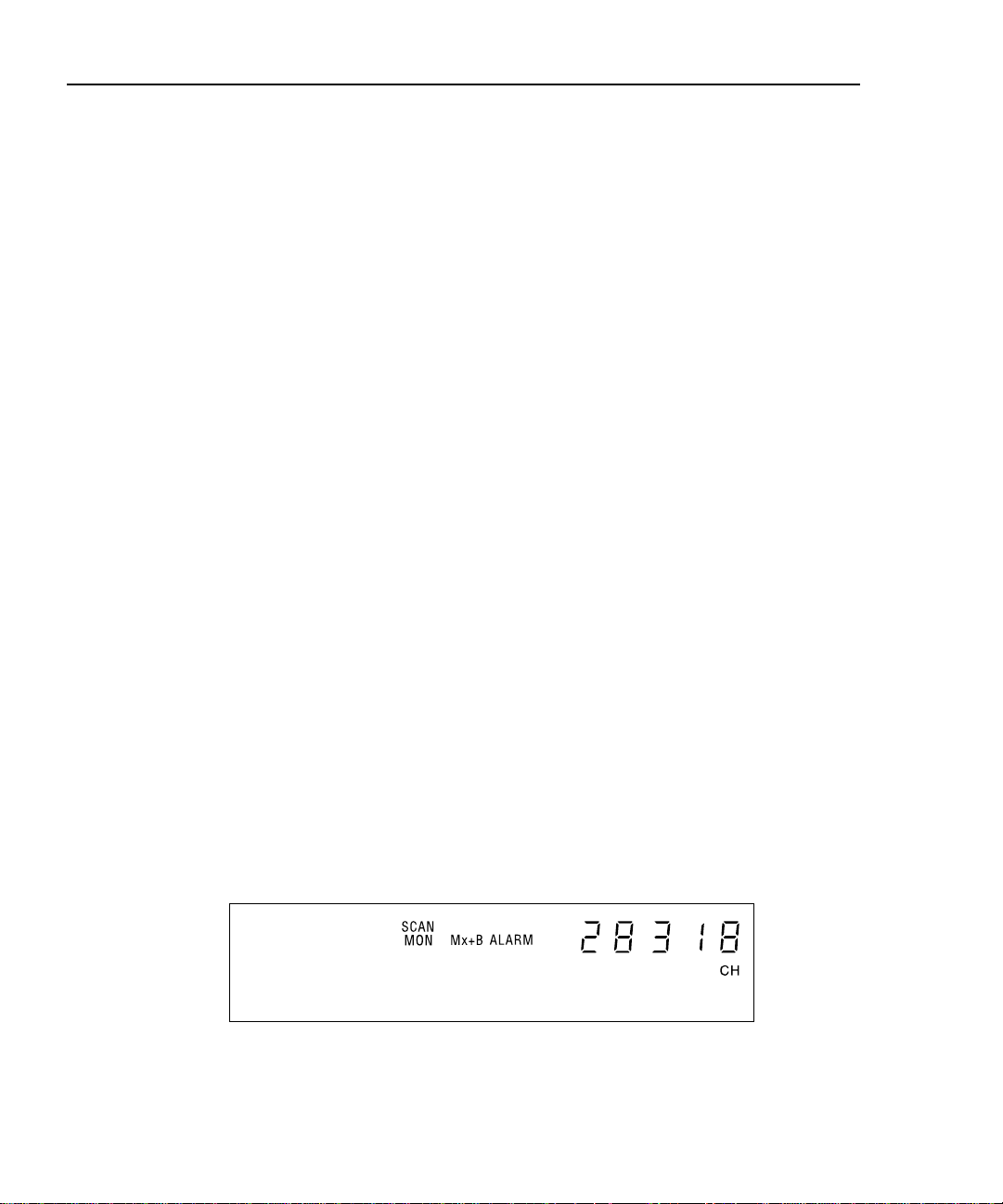

Channel Numbering

Each instrument channel, measured or computed, is identified by the Global

Channel Number (GCN). The first two digits of the GCN are the Base Channel

Number (01 to 99) that identifies the instrument. The third digit indicates the slot

or module number. The last two digits are the channel number. For example, GCN

28318 indicates instrument 28 , slot 3, and channel 18. When the instrument is in

the quiescent state, the channel number of the GCN shows dashes, for example,

45--- for instrument 45.

1-10

alg49f.eps

Page 29

Computed Channels

In addition to the analog channels, the instrument provides an additional 60

computed channels by processing analog channels and other computed channels.

The computed channels are numbered 901 to 960. The following calculations are

used:

• The average of a group of channels,

• The difference between any two channels,

• The difference between a channel and the average of a group of channels,

• A mathematical equation. Other channels, time and totalizer can be part of the

equation.

For computed channels, the functions use 24 bits and an exponent for calculations.

As a result, when the totalizer or time exceed 16,777,215 units, the number will be

rounded off to remain within the 24 bits. For example, one count more than

16,777,215 would be rounded to 16,777,220 in a computed channel.

Mx+B Scaling

Mx+B scaling multiplies a measurement by a multiplier M and then offsets it by

an offset B. For example, Mx+B scaling of 100x+50 applied to a measured or

computed channel value of 1.15 results in a reading of 100(1.15)+50=165. A

common use of Mx+B scaling is to scale a sensor or transducer to provide for

display and recording in engineering units. The Mx+B annunciator lights when a

monitored channel has scaling applied.

Overview

Instrument Features and Capabilities

1

Analog Channels

The analog channel measurement connections are made via the Universal Input

Modules. External signal conditioning for the analog inputs is not necessary for

most common electrical signals. The input channels are numbered 101 to 120, 201

to 220, 301 to 320, 401 to 420, 501 to 520, and 601 to 620. The host computer

configures all analog channels using the Fluke DAQ software.

There are two different analog modules available for the 2680 Series instruments

with up to 6 modules for any given instrument. Each module is isolated from every

other module to 300 V. One analog module is the fast analog module (FAI) and

has a maximum rate of 667 channel readings per second but a limited input voltage

of 50 V dc or 30 V rms. The other analog module is the precision analog module

(PAI). The PAI has a maximum of 300 V dc rms (on channel 1 and 11) and a

maximum rate of 133 channel readings per second. All other channels are 150 V

maximum for the PAI module. The Digital IO/Relay and Totalizer module can

monitor digital type (High or Low) signals.

1-11

Page 30

2680A/2686A

Users Manual

Digital I/O Module Option

Digital I/O

20 general-purpose open collector digital outputs and Transistor Logic (TTL)

digital input lines are available in the Digital I/O module. A logic low can be

applied to an I/O line as an input; alternatively a logic low can be internally set by

the instrument if the channel is set as an output. If no logic low is set or applied

externally, the input is pulled up to logic high (+5 V) internally. An output logic

low condition takes precedence over an input logic high condition. When the I/O

lines are used as inputs, they signal an external condition that can be correlated to

the data measurements.

Fluke DAQ software records the status of the Digital I/O as the decimal equivalent

of the 20 binary bits. For example, 1111 1111 1111 1111 1111 (DIO19 to DIO0) is

represented by decimal 1,048,575; 0000 0000 0000 0000 1111 is represented by

decimal 15.

The instrument can display the Digital I/O status in binary format at the front panel

with updates each second.

Relay Output

There are also 8 relays capable of switching up to 1 A or 250 V rms. Fluke DAQ

software records the relay status as bits 24-31 of the DIO value. The selay status

can also be displayed on the instrument front panel.

1-12

Totalizer

The Digital I/O module also includes a totalizer with external enable. The totalizer

input counts contact closures or voltage transitions with a maximum count of

4,294,967,295. There is also an external totalizer enable that can be used to enable

the totalizer. The totalizer can be preset and count down to zero or count up from

zero.

The connections for the totalizer are the Σ and Σen input lines on the Digital I/O

connector (Figure 1-5). The instrument continuously detects the totalizer input on

the rear panel independently from instrument scanning and other activities. If the

Totalizer overflows (reaching the maximum count), the display briefly shows OL

(overload) and begins counting again.

Page 31

Overview

User Interface

1

A totalizer input from contact closures increments on the “open” portion of the

switch sequence close-open. To prevent switch contact “bounce” from triggering

false readings, select the Totalizer Debounce feature. A totalizer input from

voltage transitions increments during low-to-high voltage transitions with a

nominal threshold of +1.4 V. The maximum voltage input is +30 V dc, and the

minimum voltage input is -4.0 V dc. The maximum totalizer rate is 5,000

transitions per second without debounce and 500 transitions per second with

debounce.

The instrument reports totalizer status with scan data and can display it at the front

panel. You can initialize the totalizer count by cycling power to the instrument or

using Fluke DAQ software.

User Interface

Fluke DAQ is the operating software for the 2680 Series instruments. It lets you

configure and operate your system through a Windows-based environment. You

can install Fluke DAQ on either Windows XP, 2000 (Service Pack 3 required), or

NT (Service Pack 6.0 required). Chapter 3 of this manual provides detailed

information about using Fluke DAQ software.

K3A K3B

K6A K6B

RELAY

DIAGRAM

RELAYS DIGITAL I/O

K2A K2B K1A K1B

K5A K5B K4A K4B

K8BBK7A K7B

K8A

0

8

16

A

Kn

Figure 1-5. DIO Connector Module

DIO 0-7

DIO 8-15

DIO 16-19

-4V +30V

7

15

19

MAX

en

alg57f.eps

You can use Fluke DAQ software to easily perform the following:

• Configure your 2680 Series network and instrument settings.

• Download/upload configuration to the instruments.

• Send commands to the digital I/O.

1-13

Page 32

2680A/2686A

Users Manual

• Monitor the instruments on-line values and alarms.

• Plot trend charts, retrieve historical trends, acknowledge alarms, and export

data files in .csv format.

Note

Fluke DAQ supports the NetDAQ 2680 models (2640A and 2645A)

as well as the 2680A and 2686A.

Operating a 2680 Series Data Acquisition Sy stem

You can configure 2680 Series instruments to operate over either an isolated or

general network. An isolated network includes 2680 Series instruments and a host

computer only. A general network may also include servers, routers, gateways, or

other network devices. Both types of networks interconnect using Ethernet (i.e.,

using the IEEE 802.3 or ISO 8802-3 standards).

A unique 2 digit Base Channel Number (BCN) entered at the instrument front

panel identifies each 2680 Series instrument on the network. All subsequent

operations refer to the instrument by BCN. Fluke DAQ supports up to 99

instruments for operation. You cannot operate an instrument from more than one

host computer at a time.

Isolated Networks

An isolated network consists of only 2680 Series instruments and host computer.

The advantages include simplified setup, faster network operation, and freedom

from general network problems. Data throughput specifications are guaranteed

only for isolated networks. When you set Fluke DAQ software for an isolated

network, it automatically handles instrument IP addressing. You must configure

your host computer networking software to use a host computer IP address of

198.178.246.101 and subnet mask of 255.255.255.0. See Setting Host Computer

Network Parameters in Chapter 2 of this manual.

General Networks

A general network consists of host computers, 2680 Series instruments, and

servers, routers, gateways, or other network devices. Refer connectivity issues to

your network administrator and review Network Considerations in Appendix H for

more information. When you install the software for a general network, you must

enter the instrument IP addresses manually. For more information, see Reviewing

and Setting the Network Type in Chapter 2.

Ethernet Port

Each 2680 Series instrument has a 10/100BaseT twisted pair Ethernet network

port. The instrument automatically monitors the Ethernet port.

1-14

Page 33

Group Operations

Using Fluke DAQ, you can group scan data from multiple instrument modules and

sources. Fluke DAQ can record data from all sources in the group into a single .csv

data file.

When grouping data, one module or instrument is designated as the Master. The

Master determines the times of the scans in the .csv data file. Scan data can be

grouped while scanning, or after scanning has ended using the Export feature.

Scanning and Logging

When a scan is triggered, the instrument scans the 20-120 analog channels, scans

the Digital I/O channels and totalizer and calculates the 60 computed channels. It

stores the resulting time-stamped data in a scan record. Scans can be triggered

from several sources:

• Interval Trigger, where an elapsed interval timer triggers a scan.

• External Trigger, where an external input (ground or logic low) applied to the

instrument, the Trigger In signal triggers a scan.

• Alarm Trigger, where a channel going into alarm starts a scan.

Fluke DAQ software obtains scan records from the instruments and logs the data

into a history database and optionally into a .csv file. Each scan record consists of

a timestamp, values from all configured and recording analog channels and

computed channels, and the alarm states, plus the Digital I/O line status and the

count of the totalizer if the Digital I/O Relay module is in the instrument.

Overview

Operating a 2680 Series Data Acquisition System

1

A number of factors can affect the actual scan rate in the 2680A/2686A

instruments. These include:

• The number of active modules

• The number of active channels

• Use of the DIO for alarms or as a totalizer/counter

• Writing to a PC card

• Network data rates.

There is a 2.6 ms overhead associated with accessing each module in a instrument.

There is overhead associated with reading each channel. For an FAI module, it is

about 1.4 ms per channel. Consequently, including the module overhead, when

reading one FAI with 20 active channels, you can get the scanned data in 30 ms or

667 channels per second. If you read only one channel, it takes 4 ms for a rate of

only 250 channels per second. For high-speed measurements, it is faster to use

fewer channels on each module. However, when a single channel and minimum

scan interval are used on four or more FAIs, the internal program may not keep up

with the scan data rate and some data could be lost.

1-15

Page 34

2680A/2686A

Users Manual

The internal evaluation algorithm allows data from slower modules to be recorded

regardless of the scan speed of other modules. The measurements made by slower

PAIs well still be recorded even when running in a chassis of FAIs. Only the

fastest modules may experience some loss of data. If the user sets the interval time

of each module to 31 ms or greater, no data will be lost for any number of FAI

channels. In addition, if the total number of scans for all of the modules combined

is less than 1000 scans per second, there should be no problem with losing scans.

Below is a table showing the timing.

Using the DIO for alarms or the totalizer will slow system throughput because of

its 4 ms overhead. DIO data is provided with each module scan. Consequently,

having five modules scanning at the same speed will incur an additional 20 ms

delay if a DIO is active.

Writing to the PC card is more time consuming than writing to internal memory.

This is partly because the 2686A instrument uses a DOS compatible file storage

system that requires additional overhead. As a result, the maximum scan time

while storing data will be slowed.

Table 1-1. Channel Count vs Scan Rate

2680A/2686A Channel Rate With No Lost Data*

Channel Count Module Count Typical Total Time (ms) Typical Scan Rate (ch/s)

1 1 4 250

1 2 4 500

1 3 4 750

1 4 4 1,000

1 5 5 1,000

1 6 6 1,000

20 1 30 666

40 2 30.1 1,329

60 3 30.1 1,993

80 4 30.1 2,658

100 5 30.1 3,322

120 6 30.1 3,990

* Assumes no DIO, no PC card storage, no network communication, and only FAI modules in the

chassis.

1-16

Page 35

Network traffic can have a significant impact on instrument throughput. More

importantly, if the 2680 Series instruments cannot output the readings quickly

enough, the internal memory will eventually over flow. Depending on the setting

the user chose, the readings will either be written to the last location in memory or

start to write over the oldest data location (the default). In either case, data can be

lost.

The internal buffer memory can store up 30,000 scans. A scan can contain up to 20

channels from one module plus up to 60 computed channels. At the fastest

measurement rates, 6 FAI modules could fill up the internal memory in about 150

seconds. Once the internal memory is full, data will be lost.

RS-232 Interface

The instruments include an RS-232 port for calibration, servicing, and factory

procedures; the RS-232 port is not used for instrument control or scan data