Page 1

Troubleshooting made

simple with the Fluke

190 Series II ScopeMeter

®

Application Note

There’s probably not a service

engineer on the planet that

wouldn’t agree that intermittent electrical faults are the

most difficult and frustrating to

trace and solve. Although these

may seem like random disasters sent to test our patience,

invariably they have a sound

physical cause. The trick, of

course, is to discover what this

could be without spending

hours monitoring the offending

equipment until the elusive fault

finally chooses to show itself.

In this article, Henk ter Harmsel, Senior Product Specialist at

Fluke Industrial, The Netherlands, explains how the service

engineer’s life can be made

infinitely easier with the powerful troubleshooting features of

Fluke’s 190 Series II ScopeMeter.

Although usually highly

complex, modern electrical and

electronic equipment is also

incredibly robust, with masses

of protection circuitry to guard

against breakdown induced by,

for example, current and voltage

surges, mains harmonics, EMI…

you name it! This complexity, of

course, also has its down side

when it comes to maintenance.

Intermittent faults in particular,

always the curse of the service

engineer or technician, can

become a major headache to

trace in today’s ultra-sophisticated systems with their fast

and complex control signals.

Fortunately the situation is far

from hopeless since intermittent faults share one infuriating

characteristic—despite their

apparent randomness, they all

fall into several well-defined

categories. This offers an important clue to tracing and solving

them; a fact recognized by Fluke

when designing its 190 Series II

ScopeMeter.

Troubleshooting with

the Fluke 190 Series II

ScopeMeter

Any number of factors can lead

to spurious signals that may

cause equipment to suddenly

drop out for no apparent reason.

Some of these are equipment

related, for example, defective

circuitry, dry solder joints, dust

or corrosion, and overheating.

Others, such as mains fluctuations and voltage spikes due to

systems switching on, are

related to the mains supply.

Identifying the most likely cause

requires experience and intuition and, in many instances, a

lot of luck.

Now, however, with the Fluke

190 Series II ScopeMeter, luck

doesn’t have to enter the equation. This family of handheld

test tools combines the functions of digital multimeter with

a digital storage oscilloscope

in bandwidths up to 200 MHz

and with up to 2.5 GS/s realtime sampling per channel. The

series also offers highly innovative trouble-shooting features

found in the past only on very

expensive desktop oscilloscopes.

Available for the first time in a

portable instrument, these features make the job of a service

engineer much easier, enabling

him or her to trace and solve all

manners of intermittent faults.

Tracking down faulty

wiring

The scope continuously records

the last 100 screens in First-in/

First-out (FIFO) memory. As soon

as you spot an anomaly on the

scope or suspect something has

occurred that you might have

missed, the Replay button can

be pressed to freeze the last 100

screens and allow you to play

them over again. The feature,

in fact, allows two sets of 100

screens with individual time

stamps to be stored for later

recall or downloaded to a PC for

a more detailed analysis.

The last 100 screens are

available for scroll-through picture by picture, or replayed as a

“live” animation.

The last 100 screens are avai lable for scroll-through picture by

picture, or replayed as a “live” animation.

From the Fluke Digital Library @ www.fluke.com/library

Page 2

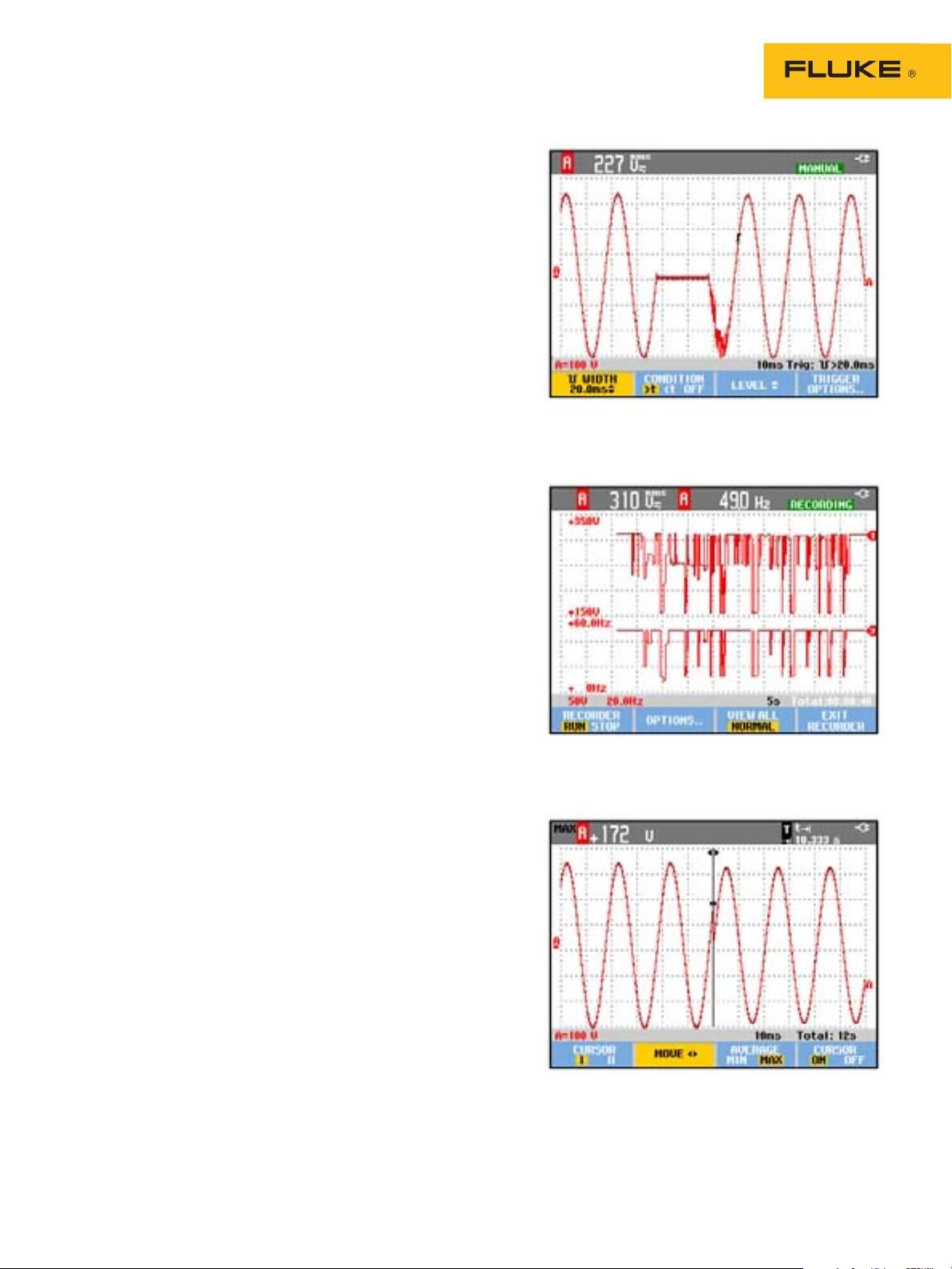

Catching signal

transients with capture

and replay

If you’re looking for a voltage

spike on the mains, for example,

the instrument should be set

to trigger on positive- or negative-going voltage pulses with

amplitude slightly larger than

mains voltage. This method can’t

be used, however, to capture

glitches that do not have voltage

levels higher than the signal

level. The solution then is to use

pulse-width triggering set to

capture, for example, negativegoing pulses with duration less

than a specified time. With the

200 MHz version (190 Series

II ScopeMeter), which has rise

and fall times of 1.7 ns, pulses

as narrow as 3 ns can easily

be captured using pulse-width

triggering. Setting the trigger to

capture negative-going pulses

that last longer than 20 ms can

also capture missing cycles on

the mains.

To see how often the event

occurs, just leave the ScopeMeter connected to the circuit for as

long as you like then press the

Replay key to see and analyze

the captured events.

Looking for sags and

swells with TrendPlot™

The 190 Series II ScopeMeter’s

TrendPlot feature is used specifically for occasions in which

relatively long-term monitoring is needed. Operating in the

ScopeMeter’s digital multimeter

mode, TrendPlot offers the ideal

way to locate causes of intermittent problems that occur perhaps

only once an hour or once a

week. Besides ambient temperature fluctuations, voltage sags or

swells on the mains or a failing

power supply are other intermittent problems that can be traced

with TrendPlot. In this mode,

the ScopeMeter acts in effect as

a paperless recorder, plotting for

more than 22 days the average,

minimum, and maximum values

of any selected scope or meter

measurement. Using this feature,

long-term irregularities can

easily be spotted. TrendPlot also

offers the important advantage

of accurate time stamping with

a resolution down to 0.2 seconds to show exactly when an

irregularity occurs. This can be

displayed as either time-of-day

or elapsed time, depending on

the nature of the change you’re

trying to monitor.

While TrendPlot is running,

the ScopeMeter operates unattended, continuously recording

the required data while

dynamically setting the vertical

ampli-tude scale to display the

maximum and minimum values,

and automatically compressing

the time scale to show the complete trend from the start.

Analyzing fast, complex

electrical processes

Here’s where the 190 Series II

ScopeRecord mode comes in

handy. This is a continuoussampling mode in which the

scope records points (consisting of minimum and maximum

values) at a rate of 125 MS/s.

With a 30,000-point deep

memory, the ScopeMeter can

record continuously in this

mode for up to 48 hours, capturing glitches as short as 15 ns.

What’s more, a 100x zoom function makes the smallest details

visible, such as the shape of an

individual power cycle.

The figure shows what happens when an UPS switches

over from the inverter to mains

supply. Although the switchover would not be visible with a

normal display of say 200 ms/

div, captured with ScopeRecord;

the switchover is clearly visible

using a 100x zoom factor. In this

case, the display clearly shows

that no interruption in supply

has occurred, with the mains

voltage connected and in phase

within just a few milliseconds.

Setting the ScopeMeter to trigger on negative-going pulses longer

than 20 ms will detect missing c ycles on the mains.

Plotting long-term irregularities with ScopeMeter’s TrendPlot

feature

ScopeRecord shows a voltage irregu larity when switching off a UPS

2 Fluke Corporation Troubleshooting made simple with Fluke’s 190 Series II ScopeMeter

®

Page 3

An ideal partner

With the modern trend toward

ever faster, more complex electronic control systems, the need

for sophisticated test tools can

only increase. While advanced

bench-top instruments may offer

an impressive array of troubleshooting features, their price

and lack of portability generally

preclude their use by mobile

service engineers. They need

an instrument that can be easily

carried around and, since they

never know what to expect on a

call-out, preferably one with the

widest range of troubleshooting

features. The Fluke 190 Series II

ScopeMeter fulfills these needs

perfectly. Combining portability with a range of advanced

features that are both powerful and intuitive to use, it’s the

ideal partner for today’s service

engineers and technicians who

work in the field.

3 Fluke Corporation Troubleshooting made simple with Fluke’s 190 Series II ScopeMeter

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA 98206 U.S.A.

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800)-36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2003-2011 Fluke Corporation.

Specifications subject to change without notice.

Printed in U.S.A. 4/2011 2127270B A-EN-N

Pub-ID 11790-eng

Modification of this document is not permitted

without written permission from Fluke Corporation.

®

®

Loading...

Loading...