Page 1

ScopeMeter 190 Series II

Fluke 190-062, -102, -104, -202, - 204

Service Manual

PN 4822 872 05405

July 2011, Rev. 4, March 2013

© 2011, 2012, 2013, Fluke Corporation, All rights reserved. Printed in the Netherlands

All product names are trademarks of their respective companies.

Page 2

PLACING ORDERS AND GETTING ASSISTANCE

To locate an authorized service center, visit us on the World Wide Web:

http://www.fluke.com

or call Fluke using any of the phone numbers listed below:

+1-888-993-5853 in U.S.A. and Canada

+31-40-2675200 in Europe

+1-425-446-5500 from other countries

Page 3

Table of Contents

Chapter Title Page

1 Safety Instructions .............................................................................. 1-1

1.1 Introduction.................................................................................................. 1-3

1.2 Safety Precautions........................................................................................ 1-3

1.3 Caution and Warning Statements ................................................................ 1-3

1.4 Symbols ....................................................................................................... 1-3

1.5 Impaired Safety............................................................................................ 1-4

1.6 General Safety Information ......................................................................... 1-4

1.7 Safe Handling and Use of Li-ion battery pack ............................................ 1-4

2 Characteristics..................................................................................... 2-1

3 List of Replaceable Parts.................................................................... 3-1

3.1 Introduction.................................................................................................. 3-3

3.2 How to Obtain Parts..................................................................................... 3-3

3.3 Final Assembly Parts................................................................................... 3-4

3.5 Accessories .................................................................................................. 3-8

4 Performance Verification .................................................................... 4-1

4.1 Introduction.................................................................................................. 4-3

4.2 Equipment Required For Verification ......................................................... 4-3

4.3 General Instructions..................................................................................... 4-4

4.4 Operating Instructions.................................................................................. 4-4

4.4.1 Resetting the Test Tool......................................................................... 4-4

4.4.2 Navigating through menu’s.................................................................. 4-4

4.4.3 Creating a StandardTest Tool Setup, e.g. SCOPE1.............................. 4-5

4.5 Display and Backlight Test.......................................................................... 4-6

4.6 Scope Input A, B, C, D Tests....................................................................... 4-8

4.6.1 Input A, B, C, D Vertical Accuracy Test ............................................. 4-8

4.6.2 Input A, B, C, D DC Voltage Accuracy Test...................................... 4-10

4.6.3 Input A, B, C, D AC Voltage Accuracy Test (LF).............................. 4-13

4.6.4 Input A, B, C, D AC Coupled Lower Frequency Test ......................... 4-15

4.6.5 Input A, B, C, D Peak Measurements Test.......................................... 4-16

4.6.6 Input A, B, C, D Frequency Measurement Accuracy Test.................. 4-17

4.6.7 Input A&B / C&D Phase Measurements Test...................................... 4-18

4.6.8 Time Base Test..................................................................................... 4-19

4.6.9 Input A Trigger Sensitivity Test........................................................... 4-20

4.6.10 Input A AC Voltage Accuracy (HF) & Bandwidth Test.................... 4-22

4.6.11 Input B Trigger Sensitivity Test......................................................... 4-23

4.6.12 Input B AC Voltage Accuracy (HF) & Bandwidth Test.................... 4-24

4.6.13 Input C Trigger Sensitivity Test......................................................... 4-25

i

Page 4

ScopeMeter 190 Series II

Service Manual

4.6.14 Input C AC Voltage Accuracy (HF) & Bandwidth Test.................... 4-26

4.6.15 Input D Trigger Sensitivity Test......................................................... 4-27

4.6.16 Input D AC Voltage Accuracy (HF) & Bandwidth Test.................... 4-28

4.6.17 Video test using the Video Pattern Generator.................................... 4-29

4.6.18 Video test using SC600 Scope Calibration Option ............................ 4-32

4.7 External Trigger Level Test......................................................................... 4-35

4.8 Meter (DMM) Tests..................................................................................... 4-36

4.8.1 Meter DC Voltage Accuracy Test........................................................ 4-36

4.8.2 Meter AC Voltage Accuracy & Frequency Response Test................. 4-37

4.8.3 Continuity Function Test...................................................................... 4-38

4.8.4 Diode Test Function Test ..................................................................... 4-38

4.8.5 Ohms Measurements Test .................................................................... 4-39

4.9 Probe Calibration Generator Test ................................................................ 4-40

5 Calibration Adjustment....................................................................... 5-1

5.1 General......................................................................................................... 5-3

5.1.1 Introduction .......................................................................................... 5-3

5.1.2 Calibration number and date ................................................................ 5-3

5.1.3 General Instructions.............................................................................. 5-3

5.1.4 Equipment Required For Calibration ................................................... 5-4

5.2 Calibration Procedure Steps......................................................................... 5-4

5.3 Starting the Calibration................................................................................ 5-5

5.4 Contrast Calibration Adjustment ................................................................. 5-6

5.5 Warming Up & Pre-Calibration................................................................... 5-7

5.6 Final Calibration (Firmware: V09.00, V10.00 or V10.4x).......................... 5-9

5.6.1 Warm Up Final and ADC Timing........................................................ 5-9

5.6.2 Input A LF-HF Gain............................................................................. 5-10

5.6.3 Input B LF-HF Gain............................................................................. 5-11

5.6.4 Input C LF-HF Gain............................................................................. 5-13

5.6.5 Input D LF-HF Gain............................................................................. 5-14

5.6.6 Input ABCD (AB) LF-HF Gain ........................................................... 5-16

5.6.7 Input ABCD (AB) Position................................................................. 5-18

5.6.8 Input ABCD (AB) Volt Gain ............................................................... 5-18

5.6.9 Input ABCD (AB) Zero........................................................................ 5-20

5.6.10 Multimeter (DMM) Volt Gain............................................................ 5-20

5.6.11 Multimeter (DMM) Numeric Zero..................................................... 5-21

5.6.12 Multimeter (DMM) Ohm Gain........................................................... 5-22

5.7 Final Calibration (Firmware: V11.10)......................................................... 5-24

5.7.1 Warm Up Final and ADC Timing........................................................ 5-24

5.7.2 Input A LF-HF Gain............................................................................. 5-25

5.7.3 Input B LF-HF Gain............................................................................. 5-26

5.7.4 Input C LF-HF Gain............................................................................. 5-27

5.7.5 Input D LF-HF Gain............................................................................. 5-28

5.7.6 Input ABCD (AB) LF-HF Gain ........................................................... 5-30

5.7.7 Input ABCD (AB) Position................................................................. 5-31

5.7.8 Input ABCD (AB) Zero........................................................................ 5-31

5.7.9 Input ABCD (AB) Volt Gain ............................................................... 5-32

5.7.10 Multimeter (DMM) Numeric Zero..................................................... 5-33

5.7.11 Multimeter (DMM) Volt Gain............................................................ 5-34

5.7.12 Multimeter (DMM) Ohm Gain........................................................... 5-35

5.8 Save Calibration Data and Exit.................................................................... 5-36

5.9 Probe Calibration......................................................................................... 5-38

ii

Page 5

6 Disassembling the Test Tool.............................................................. 6-1

6.1. Introduction................................................................................................. 6-3

6.2. Disassembly & Reassembly Procedures..................................................... 6-3

6.2.1 Required Tools ..................................................................................... 6-3

6.2.2 Removing the Tilt Stand, Hang Strap, and Side Strap ......................... 6-3

6.2.3 Opening the Test Tool, Removing the Battery Pack............................ 6-4

6.2.4 Getting access to Top Side of PCA...................................................... 6-4

6.2.5 Getting access to Bottom Side of PCA................................................. 6-5

6.2.6 Getting access to LCD, Keypad Foil and Keypad................................ 6-5

6.2.7 Pictures Showing Disassembly Steps................................................... 6-6

Contents (continued)

iii

Page 6

ScopeMeter 190 Series II

Service Manual

iv

Page 7

Chapter 1

Safety Instructions

Title Page

1

1.1 Introduction..................................................................................................1-3

1.2 Safety Precautions........................................................................................1-3

1.3 Caution and Warning Statements ................................................................1-3

1.4 Symbols .......................................................................................................1-3

1.5 Impaired Safety............................................................................................1-4

1.6 General Safety Information .........................................................................1-4

1.7 Safe Handling and Use of Li-ion battery pack ............................................1-4

1-1

Page 8

Page 9

Safety Instructions

1.1 Introduction 1

1.1 Introduction

Read these pages carefully before beginning to install and use the Test Tool.

The following paragraphs contain information, cautions and warnings which must be

followed to ensure safe operation and to keep the Test Tool in a safe condition.

Warning

Servicing described in this manual is to be done only by

qualified service personnel. To avoid electrical shock, do not

service the Test Tool unless you are qualified to do so.

1.2 Safety Precautions

For the correct and safe use of this Test Tool it is essential that both operating and service

personnel follow generally accepted safety procedures in addition to the safety

precautions specified in this manual. Specific warning and caution statements, where

they apply, will be found throughout the manual. Where necessary, the warning and

caution statements and/or symbols are marked on the Test Tool.

1.3 Caution and Warning Statements

Caution

Used to indicate correct operating or maintenance procedures

to prevent damage to or destruction of the equipment or other

property.

Warning

Calls attention to a potential danger that requires correct

procedures or practices to prevent personal injury.

1.4 Symbols

The following symbols are used on the Test Tool, in the Users Manual, in this Service

Manual, or on spare parts for this Test Tool.

See explanation in Users Manual

Live voltage

Static sensitive components

(black/yellow).

Disposal information

Table cont’d on next page:

Li-Ion

DOUBLE INSULATION (Protection

Class)

Earth Ground

Recycling information

Conformité Européenne

1-3

Page 10

Fluke 190-062, -102, -104, -202, - 204

Service Manual

Battery Safety Approval

Conforms to relevant Australian

standards

1.5 Impaired Safety

Whenever it is likely that safety has been impaired, the Test Tool must be turned off and

disconnected from line power. The matter should then be referred to qualified

technicians. Safety is likely to be impaired if, for example, the Test Tool fails to perform

the intended measurements or shows visible damage.

1.6 General Safety Information

Warning

Removing the Test Tool covers or removing parts, except those

to which access can be gained by hand, is likely to expose live

parts and accessible terminals which can be dangerous to life.

The Test Tool shall be disconnected from all voltage sources before it is opened.

Capacitors inside the Test Tool can hold their charge even if the Test Tool has been

separated from all voltage sources.

Safety Approval

RoHS China

When servicing the Test Tool, use only specified replacement parts.

1.7 Safe Handling and Use of Li-ion battery pack

The Test Tool uses a rechargeable Li-ion battery pack model BP290 (26 Wh) or BP291

(52 Wh).

For instructions how to safely handle and use this battery pack refer to Paragraph “Safety

Information” in the Users Manual of Fluke 190-062, 190-102, 190-104, 190-202, 190204, 190-502 (ScopeMeter 190 Series II).

The Users Manual can be downloaded from Fluke’s website.

1-4

Page 11

Chapter 2

Characteristics

For the specifications refer to the “Specifications” Chapter 8 in the Fluke

190-062, 190-102, 190-104, 190-202, 190-204, 190-502 (ScopeMeter 190

Series II) Users Manual.

The Users Manual can be downloaded from Fluke’s website.

2-1

Page 12

2-2

Page 13

Chapter 3

List of Replaceable Parts

Title Page

3.1 Introduction..................................................................................................3-3

3.2 How to Obtain Parts.....................................................................................3-3

3.3 Final Assembly Parts...................................................................................3-4

3.5 Accessories ..................................................................................................3-8

3-1

Page 14

Fluke 190-062, -102, -104, -202, - 204

Service Manual

3-2

Page 15

List of Replaceable Parts

3.1 Introduction 3

3.1 Introduction

This chapter contains an illustrated list of replaceable parts for the models Fluke 190

Series II ScopeMeter test tools. Parts are listed by assembly; alphabetized by item

number or reference designator. Each assembly is accompanied by an illustration

showing the location of each part and its item number or reference designator. The parts

list gives the following information:

• Item number or reference designator (for example, “R1201”)

• Description

• Ordering code

Caution

Electrical components and in particular active components

such as IC’s, transistors and diodes may be damaged by static

discharge.

Handling and servicing static sensitive components and

assemblies should be done only at a static free workstation by

qualified personnel.

3.2 How to Obtain Parts

To locate an authorized service center refer to the second page of this manual (back of the

title page).

In the event that the part ordered has been replaced by a new or improved part, the

replacement will be accompanied by an explanatory note and installation instructions, if

necessary.

To ensure prompt delivery of the correct part, include the following information when

you place an order:

• Instrument model (for example Fluke-190-104), 12 digit instrument code (9444 ...

....), and serial number (15500001). The items are printed on the type plate on the

bottom cover.

• Ordering code

• Item number - Reference designator

• Description

• Quantity

3-3

Page 16

Fluke 190-062, -102, -104, -202, - 204

Service Manual

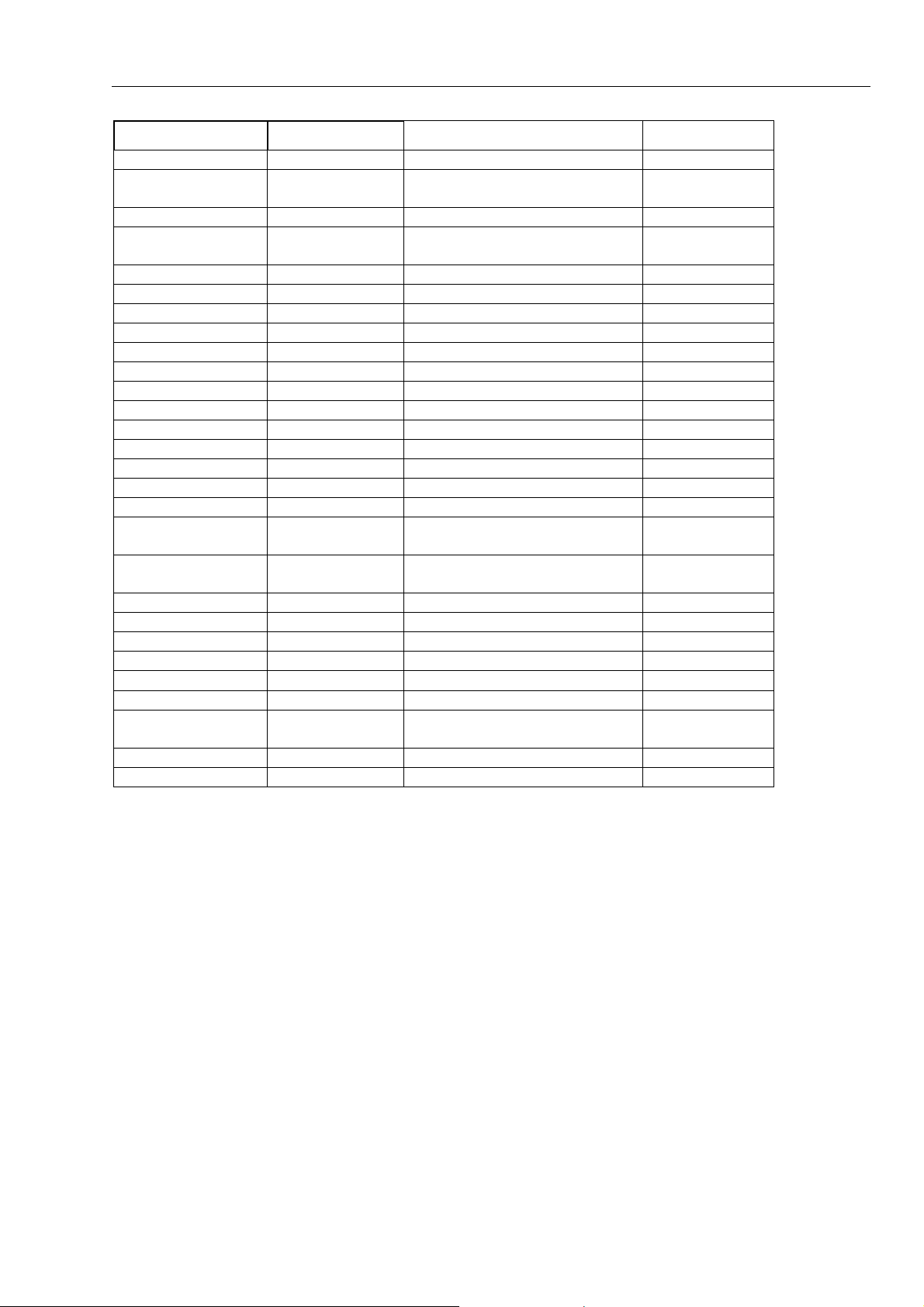

3.3 Final Assembly Parts

See Table 3-1 and Figure 3-1, 3-2 and 3-3 for the Final Assembly parts.

Part or Kit Ordering Code Consists of Following Parts Figure/Item nr

Case Set 4 channel 3981815

Dustseal long (2x) 3-3 / 3

Dustseal short (2x) 3-3 / 4

Case seal 3-3 / 13

Bottom case assy 3-1 / 3

Battery door 3-1 / 14

Quarter turn screw (2x) 3-1 / 15

Adhesive foam (for battery door) - Standup bracket 3-1 / 14

Case Set 2 channel 4035349

Dustseal long (2x) 3-3 / 3

Dustseal short (2x) 3-3 / 4

Case seal 3-3 / 13

Bottom case assy 3-1 / 3

Battery door 3-1 / 14

Quarter turn screw (2x) 3-1 / 15

Adhesive foam (for battery door) - Standup bracket 3-1 / 14

Quarter turn screw 948609 For battery door (1x) 3-1 / 15

Li-ion Battery Pack BP290 26 Wh, 10.8 V --Li-ion Battery Pack BP291 52 Wh, 10.8 V ---

Lens/decal 190-062 4035360 --- 3-3

Lens/decal 190-102 4035372 --- 3-3

Lens/decal 190-104 3981826 --- 3-3

Lens/decal 190-202 4035324 --- 3-3

Lens/decal 190-204 3981832 --- 3-3

Lens/decal 190-502 4035385 --- 3-3

LCD assy Flk-190-II 3981844 LCD module

Topholster (Input

Cover 2 ch. + meter)

Topholster (Input

Cover 4 channels)

Sealing strip (flexible)

around inputs

Mounting Material Set 3981859

Dowel (6x, to fix straps) 3-1 / 4

Steel Plate for Lock 3-1 / 5

Selftapping Screw 16.5 mm (4x, to

Screw M3x6 (2x, to fix bottom 3-1 / 8

4035397 --- 3-1 / 1

3945328 --- 3-1 / 1

3945319 --- 3-1 / 11

Table 3-1. Final Assembly Parts and Kits

Front case (Excl. lens/decal) 4

channel

Front case (Excl. lens/decal) 2

channel

LCD fixation foam

Flat cable

Selftapping Screw 10 mm (2x, to fix

input cover)

fix Rear Case)

3-3 / 5

3-3 / 5

3-3 / 1

3-3 / 2

3-3 / 7

3-1 / 2

3-1 / 6

3-4

Page 17

List of Replaceable Parts

Part or Kit Ordering Code Consists of Following Parts Figure/Item nr

holster)

Selftapping Screw (6x, 10.5 mm to

fix Main PCA Module to Front Case)

Side Strap 3945370 Can be fixed on Left or Right side ---

Hang Strap 946769 Can be fixed op Top Side of

Instrument

Bottom Holster Set 3981867 Bottomholster assy 3-1 / 7

Cover for USB 3-1 / 9

Cover for DC adapter power 3-1 / 10

Connector Set 3981871 Probe signal pin (J8010)

Probe ground pin (J8011)

USB-A connector (J8007)

USB-B mini connector (J8003)

Faston pin battery (5x, X9104-9108)

Cushion (Fits around Faston pin)

Sealing piece USB/Probe (black) 3-3 / 10

Sealing piece DC power (black) 3-3 / 11

Keypad 4 channels 3942805 --- 3-3/ 6

Keypad 2 ch. + meter 4035336 --- 3-3/ 6

Keypad Foil (all

models)

USB cable 3945381 USB-A to mini-USB-B (for PC

BNC Connector Red 3945031 X1100 ---

BNC Connector Blue 3945046 X1300 ---

BNC Connector Gray 3945054 X1400 ---

BNC Connector Green 3945068 X1200 ---

Banana Jack Black 4035403 X 1501 ---

Banana Jack Red 4035415 X 1500 ---

DC Power Input

Socket

3942810 (Incl. Flat Cable) 3-3 / 9

connection)

215785 X9100 ---

3.3 Final Assembly Parts 3

3-3 / 12

---

---

3-5

Page 18

Fluke 190-062, -102, -104, -202, - 204

Service Manual

Figure 3-1

3-6

Page 19

List of Replaceable Parts

3.3 Final Assembly Parts 3

Figure 3-2

Figure 3-3

Note

The test tool contains a Li-ion battery. Do not mix with the

Li-Ion

solid wastestream. Spent batteries should be disposed of by a

qualified recycler or hazardous materials handler.

3-7

Page 20

Fluke 190-062, -102, -104, -202, - 204

Service Manual

3.5 Accessories

For a list with accessories refer to the “Maintaining the Test Tool” Chapter in the Fluke

ScopeMeter 190 Series II Users Manual.

The Users Manual can be downloaded from Fluke’s website.

3-8

Page 21

Chapter 4

Performance Verification

Title Page

4.1 Introduction..................................................................................................4-3

4.2 Equipment Required For Verification .........................................................4-3

4.3 General Instructions.....................................................................................4-4

4.4 Operating Instructions..................................................................................4-4

4.4.1 Resetting the Test Tool.........................................................................4-4

4.4.2 Navigating through menu’s..................................................................4-4

4.4.3 Creating a StandardTest Tool Setup, e.g. SCOPE1..............................4-5

4.5 Display and Backlight Test..........................................................................4-6

4.6 Scope Input A, B, C, D Tests.......................................................................4-7

4.6.1 Input A, B, C, D Vertical Accuracy Test .............................................4-7

4.6.2 Input A, B, C, D DC Voltage Accuracy Test......................................4-10

4.6.3 Input A, B, C, D AC Voltage Accuracy Test (LF)..............................4-12

4.6.4 Input A, B, C, D AC Coupled Lower Frequency Test .........................4-13

4.6.5 Input A, B, C, D Peak Measurements Test..........................................4-14

4.6.6 Input A, B, C, D Frequency Measurement Accuracy Test..................4-16

4.6.7 Input A&B / C&D Phase Measurements Test......................................4-17

4.6.8 Time Base Test.....................................................................................4-18

4.6.9 Input A Trigger Sensitivity Test...........................................................4-19

4.6.10 Input A AC Voltage Accuracy (HF) & Bandwidth Test....................4-21

4.6.11 Input B Trigger Sensitivity Test.........................................................4-22

4.6.12 Input B AC Voltage Accuracy (HF) & Bandwidth Test....................4-23

4.6.13 Input C Trigger Sensitivity Test.........................................................4-24

4.6.14 Input C AC Voltage Accuracy (HF) & Bandwidth Test....................4-25

4.6.15 Input D Trigger Sensitivity Test.........................................................4-26

4.6.16 Input D AC Voltage Accuracy (HF) & Bandwidth Test....................4-27

4.6.17 Video test using the Video Pattern Generator....................................4-28

4.6.18 Video test using SC600 Scope Calibration Option ............................4-31

4.7 External Trigger Level Test.........................................................................4-34

4.8 Meter (DMM) Tests.....................................................................................4-35

4.8.1 Meter DC Voltage Accuracy Test........................................................4-35

4.8.2 Meter AC Voltage Accuracy & Frequency Response Test.................4-36

4.8.3 Continuity Function Test......................................................................4-37

4-1

Page 22

Fluke 190-062, -102, -104, -202, - 204

Service Manual

4.8.4 Diode Test Function Test .....................................................................4-37

4.8.5 Ohms Measurements Test ....................................................................4-38

4.9 Probe Calibration Generator Test................................................................4-39

4-2

Page 23

Performance Verification

4.1 Introduction 4

4.1 Introduction

Warning

Procedures in this chapter should be performed by qualified

service personnel only. To avoid electrical shock, do not

perform any servicing unless you are qualified to do so.

The Fluke 190 Series II ScopeMeter Test Tools family consists of following models:

Model Description of main features

190-062 Two 60 MHz Scope Inputs (BNC), one Meter Input (banana jacks).

190-102 Two 100 MHz Scope Inputs (BNC), one Meter Input (banana jacks).

190-104 Four 100 MHz Scope Inputs (BNC)

190-202 Two 200 MHz Scope Inputs (BNC), one Meter Input (banana jacks).

190-204 Four 200 MHz Scope Inputs (BNC).

190-502 Two 500 MHz Scope Inputs (BNC), one Meter Input (banana jacks).

This model has a separate Service Manual.

The Fluke 190 Series II ScopeMeter® Test Tool (referred to as Test Tool) should be

calibrated and in operating condition when you receive it.

The following performance tests are provided to ensure that the Test Tool is in a proper

operating condition. If the Test Tool fails any of the performance tests, calibration

adjustment (see Chapter 5) and/or repair (see Chapter 7) is necessary.

The Performance Verification Procedure is based on the specifications, listed in

Chapter 2 of this Service Manual. The values given here are valid for ambient

temperatures between 18 °C and 28 °C.

The Performance Verification Procedure is a quick way to check most of the Test Tool’s

specifications. Because of the highly integrated design of the Test Tool, it is not always

necessary to check all features separately.

4.2 Equipment Required For Verification

The primary source instrument used in the verification procedures is the Fluke 5500A. If

a 5500A is not available, you can substitute another calibrator as long as it meets the

minimum test requirements.

• Fluke 5500A Multi Product Calibrator, including SC300 or SC600 Oscilloscope

Calibration Option.

• Stackable test leads (4x) as supplied with the 5500A (required for Test Tools with a

meter section with banana jacks and 2 BNC oscilloscope inputs: 190-062, 190-102,

190-202).

• 50Ω Coax Cables (4x): use Fluke PM9091 (1.5m, 3 pcs.) and PM9092 (0.5m,

3 pcs.).

For Test Tools with with meter section with banana jacks and 2 BNC oscilloscope

inputs (190-062, 190-102, 190-202) 2 Coax Cables are sufficient.

• Male BNC to Dual Female BNC adapter (3x), Fluke PM9093/001.

For Test Tools with with meter section with banana jacks 1 adapter is sufficient.

• 50Ω feed through termination, use for example Fluke PM9585 or Fluke TRM50.

4-3

Page 24

Fluke 190-062, -102, -104, -202, - 204

Service Manual

• Dual Banana Plug to Female BNC Adapter (1x), Fluke PM9081/001.

• Dual Banana Jack to Male BNC Adapter (1x), Fluke PM9082/001.

• TV Signal Generator, Philips PM5418, NOT required if SC600 Oscilloscope

Calibration Option is used.

• 75Ω Coax cable (1x), Fluke PM9075.

• 75Ω Feed through termination (1x), ITT-Pomona model 4119-75.

• 10:1 Attenuator Probes as supplied with Test Tool.

4.3 General Instructions

Follow these general instructions for all tests:

• For all tests, power the Test Tool with the BC190 power adapter. The battery pack

must be installed.

• Allow the 5500A to satisfy its specified warm-up period.

• For each test point, wait for the 5500A to settle.

• Allow the Test Tool a minimum of 30 minutes to warm up.

• One division on the LCD consists of 25 pixels (1 pixel = 0.04 division).

• This procedure is setup for all models. Test steps that are not applicable to the Test

Tool to be verified can be skipped: e.g. the verification of the meter with banana

jacks can be skipped in instruments with four scope (BNC) inputs.

• The figures that show how to interconnect Signal Source and Test Tool show the

situation for 2 Scope Inputs + Meter Input and for 4 Scope Inputs.

4.4 Operating Instructions

4.4.1 Resetting the Test Tool

Proceed as follows to reset the Test Tool:

• Press

• Press and hold

• Press and release

• Wait until the Test Tool has beeped twice, and then release

has beeped twice, the RESET was successful.

4.4.2 Navigating through menu’s

During verification you must open menus, and to choose items from the menu.

Proceed as follows to make choices in a menu:

• Reset the Test Tool

• Open a menu, for example press

A menu as showed in Figure 4-1 will be opened.

Active functions are marked by a yellow background or yellow characters.

If more than one menu groups are available, they will be separated by a vertical line.

The menu you opened indicates that

shows the result of a V rms measurement (

to turn the Test Tool off.

USER

.

to turn the Test Tool on.

USER

SCOPE

, then press

READING 1 (that is the upper left reading)

V ac+dc) on Input A (on A ).

F2

. When the Test Tool

(READING ...).

4-4

• Press

or to highlight the function to be selected.

Page 25

Performance Verification

B

C

D

A

4.4 Operating Instructions 4

• Press

ENTER

to confirm the selection.

The active function in the next menu group will be highlighted now. If the

confirmation was made in the last (most right) menu group, the menu will be closed.

Figure 4-1. Menu item selection

4.4.3 Creating a StandardTest Tool Setup, e.g. SCOPE1

Before starting the verification procedure you must define a standard Test Tool setup,

called for example SCOPE 1. During verification you will be asked to recall this setup.

This defines the initial Test Tool setup for each verification.

Note: the setup steps for channel C and D are only for the models 190-104, 190-204.

Proceed as follows to create a setup (for instance SCOPE1):

1. Reset the Test Tool. Input A is ON, other inputs are OFF now.

2. Press

actual settings.

3. Press

4. Select

5. Press

6. Press

7. Select

8. Press

9. Press

F3

Probe Type: Voltage | Attenuation: 1:1 .

F3

Probe Type: Voltage | Attenuation: 1:1 .

F3

: INPUT B ON. The black text with yellow background indicates the

to change the PROBE B setting.

: INPUT C ON.

to change the PROBE C setting.

: INPUT D ON .

to change the PROBE D setting.

10. Select

11. Press

12. Press

13. Select

4-5

Probe Type: Voltage | Attenuation: 1:1 .

. The inverse text indicates the actual settings.

F3

Probe Type: Voltage | Attenuation: 1:1 .

to change the PROBE A setting.

Page 26

Fluke 190-062, -102, -104, -202, - 204

A

Service Manual

14. Press

15. Press

16. Press

SCOPE

F1

F2

.

– READINGS ON.

– READING ... and select with

F1

– READINGS and with the

arrow keys:

Reading 1, on A, V dc,

Reading 2, on B, V dc,

Reading 3, on C, V dc,

Reading 4, on D, V dc.

17. Press

18. Press

19. Press

20. Press

21. Press

22. Using

23. Press

F4

WAVEFORM OPTIONS and select

Glitch: Off | Acquisition: Normal | Average: Off | Waveform: Normal .

MANUAL

AUTO

to select MANUAL ranging (MANUAL in upper right of screen) .

MOVE

MOVE

and

move the Input A ground level (indicated by

the zero icon

SAVE

.

F1

: Using

in the left margin) to the center grid line. Do this for all channels.

SAVE...

select SCREEN+SETUP.

ENTER

.

24. Using

select OK SAVE. Remember the name under which the settings are

saved (for instance SCOPE 1).

ENTER

25. Press

26. Press

to save the settings.

HOLD

RUN

to leave the Hold mode.

4.5 Display and Backlight Test

Proceed as follows to test the display and the backlight:

1. Press

2. Remove the BC190 power adapter, and verify that the backlight is dimmed.

3. Apply the BC190 power adapter and verify that the backlight brightness increases.

4. Press and hold

The Test Tool shows the calibration menu in the bottom of the display.

• Do not press

• Pressing

5. Press

The Test Tool shows

to turn the Test Tool on.

USER

(USER), then press and release

F3

at 4.

CLEAR

will toggle the menu on-off.

F1

PREVIOUS three times.

Contrast (CL 0100):

now! If you did, turn the Test Tool off and on, and start

CLEAR

(CLEAR MENU) .

4-6

6. Press

F3

CALIBRATE .The Test Tool shows a dark display; the test pattern as

shown in Figure 4-2 may be not visible or hardly visible.

Page 27

Performance Verification

4.6 Scope Input A, B, C, D Tests 4

Observe the display closely, and verify that the display shows no abnormalities, as

for example very light pixels or lines.

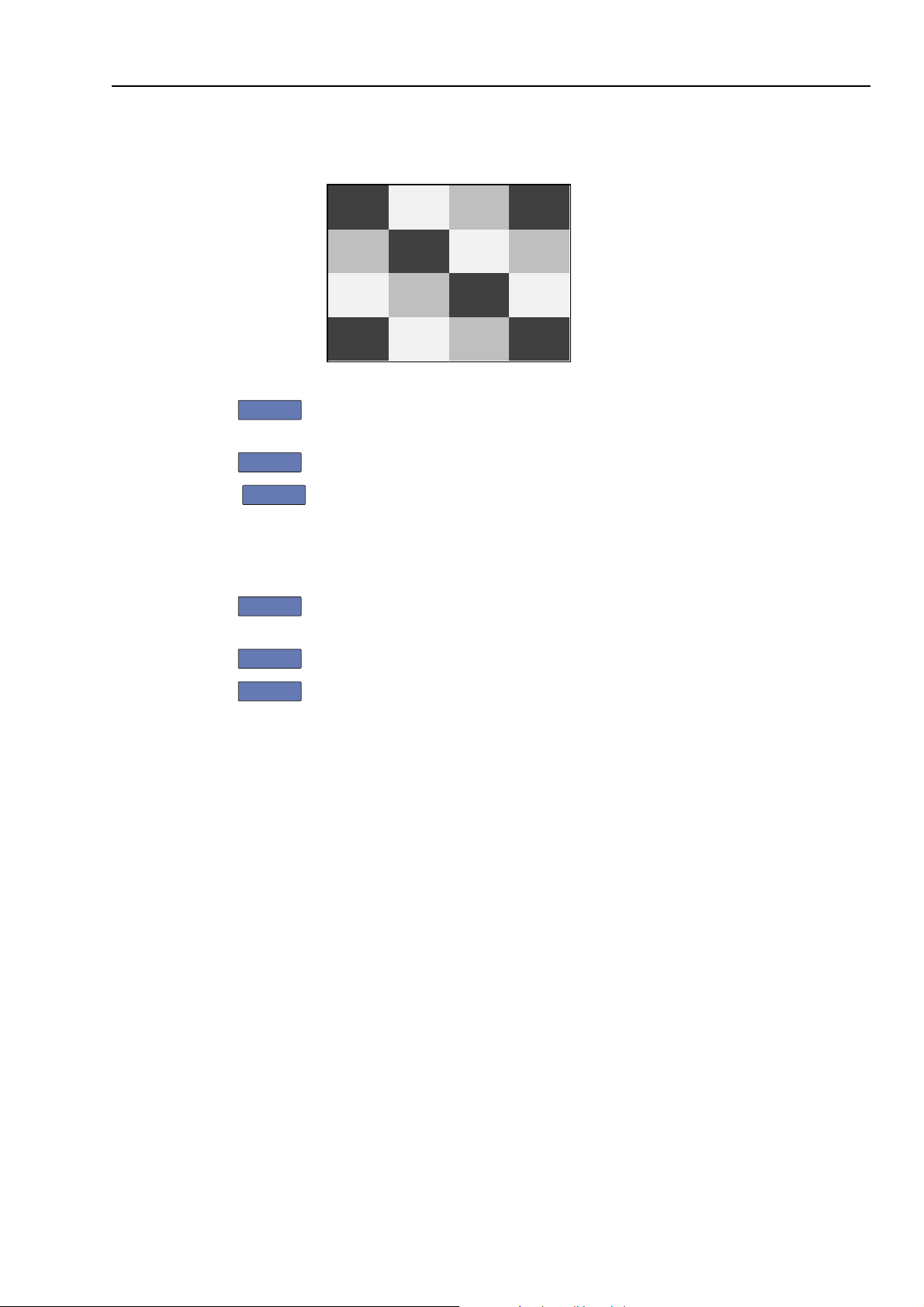

Figure 4-2. Display Test Pattern

7. Press

8. Press

9. Press

F2

.

The test pattern is removed; the Test Tool shows

F2

F3

again to do the next step Contrast (CL 0110):

CALIBRATE

Contrast (CL 0100):

The Test Tool shows the display test pattern shown in Figure 4-2, at default contrast.

Observe the display closely, and verify that the display shows no abnormalities.

Also verify that the contrast of the upper left and upper right square of the test pattern

is equal.

10. Press

F2

The test pattern is removed; the Test Tool shows

11. Press

12. Press

F2

F3

.

Contrast (CL 0110):

again to do the next step Contrast (CL 0120):

CALIBRATE

The Test Tool shows a light display; the test pattern as shown in Figure 4-2 may not

be visible or hardly visible.

Observe the display closely, and verify that the display shows no abnormalities.

13. Turn the Test Tool OFF and ON to exit the calibration menu and to return to the

normal operating mode.

If the maximum, minimum, or default display contrast is not OK, then you can adjust

these items without performing a complete calibration adjustment; refer to Section 5 for

detailed information.

4.6 Scope Input A, B, C, D Tests

4.6.1 Input A, B, C, D Vertical Accuracy Test

WARNING

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the Test Tool.

Note: the test steps for channel C and D are only for the models 190-104, 190-204.

4-7

Page 28

Fluke 190-062, -102, -104, -202, - 204

A

B

C

D

A

V

Service Manual

Proceed as follows:

1. Connect the Test Tool to the 5500A as shown in Figure 4-3. The vertical channels A,

B, C and D (A and B) are checked in succession so that there is one waveform on the

screen at a time to facilitate amplitude adjustment.

PM9091

METER

AB

ADC

CONNECT TO CHANNEL A, B, C, D IN SUCCESSION

PM9091

B

50 OHM TERMINATIONNO

2 CHANN. + METER

Figure 4-3. Test Tool Inputs A, B, C, D (A, B) to 5500A Normal Output

4 CHANNELS

2. Select the following Test Tool setup:

• Recall the created setup (e.g. SCOPE 1, see section 4.4.3): press

RECALL , select SETUP, press

recall the setup.

• Press

Attenuator: Normal | Bandwidth:

• Press

Attenuator: Normal | Bandwidth: 20 kHz

• Press

Attenuator: Normal | Bandwidth: 20 kHz

• Press

Attenuator: Normal | Bandwidth: 20 kHz

• Press

CLEAR

, press

, press

, press

, press

to clear the softkey menu, and to see the full screen.

F4

F4

F4

F4

NORMAL SCOPE

PM9081

FLUKE 5500A CALIBRATOR

ENTER

, select SCOPE 1 and press

INPUT A OPTIONS... , and select

20 kHz

INPUT B OPTIONS... , and select

INPUT C OPTIONS... , and select

INPUT D OPTIONS... , and select

SAVE

F2

,

ENTER

to

4-8

Note:

The 20 kHz bandwidth limiter rejects calibrator noise. It does not affect the gain

accuracy at a 50 Hz input signal

3. Press

and using

mV

RANGE

and

RANGE

set the Input A sensitivity range to the first

test point in Table 4-1.

4. Set the 5500A to source the appropriate initial ac voltage.

5. Adjust the 5500A output voltage until the displayed Input A trace amplitude is 6

divisions.

6. Observe the 5500A output voltage and check to see if it is within the range shown

under the appropriate column.

7. Continue through the test points.

8. Next check channel B, C or D in succession:

Connect channel B, C or D input to 5500A,

Page 29

Performance Verification

4.6 Scope Input A, B, C, D Tests 4

Press

TRIGGER

and select B, C or D as trigger source with

F1

Press B, C or D to assign vertical range to channel B, C or D,

Observe the 5500A output voltage and check to see if it is within range.

9. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-1. Vertical Accuracy Verification Points

Range Initial 5500A Setting,

V ac, sine, 50 Hz

2 mV/div 4.243 mV 3.951 to 4.517

5 mV/div 10.606 mV 10.183 to 11.028

10 mV/div 21.213 mV 20.368 to 22.058

20 mV/div 42.426 mV 40.735 to 44.117

50 mV/div 106.06 mV 101.83 to 110.28

100 mV/div 212.13 mV 203.67 to 220.58

200 mV/div 424.26 mV 407.35 to 441.16

500 mV/div 1.0607 V 1.0184 to 1.1030

1 V/div 2.1213 V 2.0367 to 2.2058

Allowable 5500A output for trace amplitude of

6 divisions

,

2 V/div 4.2426 V 4.0735 to 4.4117

5 V/div 10.606 V 10.183 to 11.028

10 V/div 21.213 V 20.368 to 22.058

20 V/div 42.426 V 40.735 to 44.117

50 V/div 106.06 V 101.83 to 110.29

100 V/div 212.13 V 203.67 to 220.58

Note

The vertical accuracy test can also be done with dc voltage. This method is

advised for automatic verification using the Fluke Met/Cal Metrology

Software. For each sensitivity range you must proceed as follows:

1. Apply a +3 divisions voltage, and adjust the voltage until the trace is at

+3 divisions. Write down the applied voltage V1

2. Apply a -3 divisions voltage, and adjust the voltage until the trace is at

-3 divisions. Write down the applied voltage V2

3. Verify that V1-V2 = 6 x range

±

(2.1% + 0.04 x range).:

Example for range 10 mV/div. (range/div figure doubles because 2

measurements V1 and V2 are done for one accuracy check):

The allowed V1 - V2 = 60 mV

= 60 mV

±

(0.021 x 60 + 0.08 x 10)

±

(1.26 + 0.8) = 60 mV ± 2.06 mV

4-9

Page 30

Fluke 190-062, -102, -104, -202, - 204

A

B

C

A

V

Service Manual

4.6.2 Input A, B, C, D DC Voltage Accuracy Test

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the Test Tool.

Note: the test steps for channel C and D are only for the models 190-104, 190-204.

Proceed as follows to verify the automatic dc voltage scope measurement:

Connect the Test Tool to the 5500A as shown in see Figure 4-4.

PM9092

PM9093

METER

AB

ADC

WARNING

PM9092

PM9091

CONNECT TO CHANNEL A, B, C, D IN PARALLEL

50 OHM TERMINATIONNO

3

9

0

9

M

P

B

2 CHANN. + METER

Figure 4-4. Test Tool Inputs A, B, C, D (A, B) to 5500A Normal Output

4 CHANNELS

1. Select the following Test Tool setup:

• Recall the created setup (e.g. SCOPE 1, see section 4.4.3): press

RECALL , select SETUP, press

recall the setup .

• Press

• Select

• Press

• Select

• Press

• Select

• Press

• Select

• Press

2. Press

Attenuator: Normal | Bandwidth: 20 kHz.

Attenuator: Normal | Bandwidth: 20 kHz.

Attenuator: Normal | Bandwidth: 20 kHz.

Attenuator: Normal | Bandwidth: 20 kHz.

CLEAR

, then press

, then press

, then press

D

, then press

to clear the softkey menu, and to see the full 8 divisions screen.

and using

test point in Table 4-2. Do this also for channels B, C and D

mV

RANGE

PM9081

F4

F4

F4

F4

and

NORMAL SCOPE

FLUKE 5500A CALIBRATOR

SAVE

,

ENTER

, select SCOPE 1 and press

ENTER

INPUT A OPTIONS ...

INPUT B OPTIONS ...

INPUT C OPTIONS ...

INPUT D OPTIONS ...

RANGE

set the Input A sensitivity range to the first

F2

to

4-10

3. Set the 5500A to source the appropriate dc voltage.

4. Observe readings

A, B, C and D and check to see if they are within the range shown

under the appropriate column.

Due to calibrator noise, occasionally OL (overload) can be shown.

5. Continue through the test points.

Page 31

Performance Verification

4.6 Scope Input A, B, C, D Tests 4

6. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-2. Volts DC Measurement Verification Points

Range 5500A output V dc Input A, B, C, D (A, B) Reading

2 mV/div +6.0 mV +4.9 to +7.1

-6.0 mV -4.9 to -7.1

5 mV/div +15.0 mV +14.3 to +15.7

-15.0 mV -14.3 to -15.7

10 mV/div +30.0 mV +29.0 to +31.0

-30.0 mV -29.0 to -31.0

20 mV/div +60.0 mV +58.5 to +61.5

-60.0 mV -58.5 to -61.5

50 mV/div +150 mV +143 to +157

-150 mV -143 to -157

100 mV/div +300 mV +290 to +310

-300 mV -290 to -310

200 mV/div +600 mV +586 to +614

-600 mV -586 to -614

500 mV/div +1.50 V +1.43 to +1.57

-1.50 V -1.43 to -1.57

1 V/div +3.00 V +2.90 to +3.10

-3.00 V -2.90 to -3.10

2 V/div +6.00 V +5.86 to +6.14

-6.00 V -5.86 to -6.14

5 V/div +15.0 V +14.3 to +15.7

-15.0 V -14.3 to -15.7

10 V/div +30.0 V +29.0 to +31.0

-30.0 V -29.0 to -31.0

20 V/div +60.0 V +58.6 to +61.4

-60.0 V -58.6 to -61.4

50 V/div +150 V +143 to +157

-150 V -143 to -157

100 V/div +300 V +290 to +310

-300 V -290 to -310

4-11

Page 32

Fluke 190-062, -102, -104, -202, - 204

A

B

C

D

V

Service Manual

4.6.3 Input A, B, C, D AC Voltage Accuracy Test (LF)

This procedure tests the Volts ac accuracy with dc coupled inputs up to 50 kHz. The

high frequencies are tested in sections 4.6.10, 4.6.12, 4.6.14 and 4.6.16.

Note: the test steps for channel C and D are only for the models 190-104, 190-204.

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the Test Tool.

Proceed as follows to test the Input A, B, C and D automatic scope ac Voltage

measurement accuracy:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-4)

2. Select the following Test Tool setup.

• Recall the created setup (e.g. SCOPE 1, see section 4.4.3): press

RECALL , select SETUP, press

recall the setup .

• Press

• Select

| Bandwidth: 20 MHz (other ranges).

• Press

• Select

| Bandwidth: 20 MHz (other ranges).

• Press

• Select

| Bandwidth: 20 MHz (other ranges).

• Press

• Select

| Bandwidth: 20 MHz (other ranges).

• Press

3. Press

Attenuator: Normal | Bandwidth: 20 kHz (2 mV/d and 5 mV/d) or

Attenuator: Normal | Bandwidth: 20 kHz (2 mV/d and 5 mV/d) or

Attenuator: Normal | Bandwidth: 20 kHz (2 mV/d and 5 mV/d) or

Attenuator: Normal | Bandwidth: 20 kHz (2 mV/d and 5 mV/d) or

CLEAR

SCOPE

,

Warning

SAVE

F2

,

ENTER

, select SCOPE 1 and press

, then press

, then press

, then press

, then press

F4

F4

F4

F4

INPUT A OPTIONS ...

INPUT B OPTIONS ...

INPUT C OPTIONS ...

INPUT D OPTIONS ...

to clear the softkey menu, and to see the full 8 divisions screen.

ENTER

to

4-12

4. Press

F2

– READING ... and select with

F1

arrow keys:

Reading 1, on A, V ac,

Reading 2, on B, V ac,

Reading 3, on C, V ac,

Reading 4, on D, V ac.

5. Using

TIMEsns

change the time base to lock the time base on 20 μs/div for the

20 kHz signals, and on 10 ms/div for the 60 Hz signal.

6. Using

mV

RANGE

and

RANGE

select manual vertical ranging, and set the input A, B, C and D

sensitivity range to the first test point in Table 4-3.

The sensitivity ranges is indicated in the lower display edge.

– READINGS and with the

Page 33

Performance Verification

4.6 Scope Input A, B, C, D Tests 4

7. Set the 5500A to source the appropriate ac voltage.

8. Observe readings

A, B, C and D and check to see if they are within the range shown

under the appropriate column.

9. Continue through the test points.

10. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-3. Volts AC Measurement Verification Points

Range 5500A output Input A, B, C, D Reading

V ac Frequency

2 mV/div (Select 10 ms/div)

Set input A, B, C, D Bandwidth

20 kHz to prevent OL due to

calibrator noise: see step 2.

5 mV/div 10 mV 60 Hz 8.9 mV to 11.1 mV

10 mV/div (Select 20 μs/div).

Set input A, B, C, D Bandwidth to

20 MHz

20 mV/div 40 mV 20 kHz 37.5 mV to 42.5 mV

50 mV/div 100 mV 20 kHz 96.0 mV to 104.0 mV

4 mV 60 Hz 3.0 mV to 5.0 mV

20 mV 20 kHz 18.0 mV to 22.0 mV

100 mV/div 200 mV 20 kHz 180 mV to 220 mV

200 mV/div 400 mV 20 kHz 375 mV to 425 mV

500 mV/div (Select 10 ms/div) 900 mV 60 Hz 877 mV to 923 mV

500 mV/div (Select 20 μs/div) 900 mV 20 kHz 863 mV to 937 mV

1 V/div 2 V 20 kHz 1.80 V to 2.20 V

2 V/div 4 V 20 kHz 3.75 V to 4.25 V

5 V/div 9 V 20 kHz 8.63 V to 9.37 V

10 V/div 20 V 20 kHz 18.0 V to 22.0 V

20 V/div 40 V 20 kHz 37.5 V to 42.5 V

50 V/div 90 V 20 kHz 86.3 V to 93.7 V

100 V/div 200 V 20 kHz 180 V to 220 V

4.6.4 Input A, B, C, D AC Coupled Lower Frequency Test

Note: the test steps for channel C and D are only for the models 190-104, 190-204.

Proceed as follows to test the ac coupled input low frequency accuracy:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-4).

2. Select the following Test Tool setup:

4-13

Page 34

Fluke 190-062, -102, -104, -202, - 204

A

B

C

D

V

Service Manual

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL , select SETUP press

recall the setup.

• Press

• Press

SCOPE

F2

the arrow keys:

Reading 1, on A, V ac,

Reading 2, on B, V ac,

Reading 3, on C, V ac,

Reading 4, on D, V ac.

• Press

• Press

• Press

• Press

• Press

3. Using

4. Using

CLEAR

TIMEsns

mV

RANGE

and

SAVE

ENTER

, select SCOPE 1 and press

– READING ... and select with

, then using

, then using

, then using

, then using

F2

F2

F2

F2

select COUPLING AC.

select COUPLING AC.

select COUPLING AC.

select COUPLING AC.

F1

– READINGS and with

to clear the softkey menu, and to see the full screen.

change the time base to lock the time base on 40 ms/div.

RANGE

set the Input A, B, C and D sensitivity range to 500 mV.

,

ENTER

F2

to

5. Set the 5500A to source the appropriate ac voltage and frequency, according to

Table 4-4.

6. Observe the reading

A, B, C and D and check to see if they are within the range

shown under the appropriate column.

7. Continue through the test points.

8. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-4. Input A, B, C, D AC Input Coupling Verification Points

5500A output, V rms 5500A Frequency Reading A, B, C, D (A, B)

900 mV 60 Hz 873 mV to 927 mV

900 mV 5 Hz >630 mV

4.6.5 Input A, B, C, D Peak Measurements Test

WARNING

Dangerous voltages will be present on the calibration source

and connecting cables during the following steps. Ensure that

the calibrator is in standby mode before making any connection

between the calibrator and the Test Tool.

Note: the test steps for channel C and D are only for the models 190-104, 190-204.

Proceed as follows to test the Peak measurement accuracy:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-4).

2. Select the following Test Tool setup:

4-14

Page 35

Performance Verification

V

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL, select SETUP press

ENTER

, select SCOPE 1 and press

4.6 Scope Input A, B, C, D Tests 4

SAVE

F2

,

ENTER

to

recall the setup.

SCOPE

F2

– READING ... and select with

F1

– READINGS and with

• Press

• Press

the arrow keys:

Reading 1, on A, Peak ... and next Peak-Peak,

Reading 2, on B, Peak ... and next Peak-Peak,

Reading 3, on C, Peak ... and next Peak-Peak,

Reading 4, on D, Peak ... and next Peak-Peak.

CLEAR

• Press

3. Using

4. Using

mV

RANGE

to clear the softkey menu, and to see the full screen.

TIMEsns

change the time base and lock the time base on 1 ms/div.

RANGE

and

set the Input A, B, C and D sensitivity ranges to 100 mV.

5. Set the 5500A to source the appropriate ac voltage and frequency, according to

Table 4-5.

6. Observe readings

A, B, C and D and check to see if they are within the range shown

under the appropriate column.

7. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

Table 4-5. Volts Peak Measurement Verification Points

5500A output, Vrms (sine) 5500A Frequency Reading A, B, C, D

212.13 mV (0.6 V pp) 1 kHz 0.56 to 0.64

4-15

Page 36

Fluke 190-062, -102, -104, -202, - 204

V

Service Manual

4.6.6 Input A, B, C, D Frequency Measurement Accuracy Test

Note: the test steps for channel C and D are only for the models 190-104, 190-204.

Proceed as follows to test the frequency measurement accuracy:

1. Connect the Test Tool to the 5500A as shown in Figure 4-5. Do NOT use 50 Ω

terminations!

METER

PM9092

B

ADC

4 CHANNELS

PM9093

AB

2 CHANN. + METER

Figure 4-5. 5500A Scope Output to Test Tool Input A, B, C, D (A, B)

2. Select the following Test Tool setup:

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL , select SETUP press

recall the setup.

SCOPE

• Press

• Press

F2

– READING ... and select with

the arrow keys:

Reading 1, on A, Hz,

Reading 2, on B, Hz,

Reading 3, on C, Hz,

Reading 4, on D, Hz.

3. Using

mV

RANGE

and

RANGE

select range 100 mV/div for A, B, C and D.

3

9

0

9

M

P

PM9092

PM9091

CONNECT TO CHANNEL A, B, C, D IN PARALLEL

50 OHM TERMINATIONNO

NORMAL SCOPE

FLUKE 5500A CALIBRATOR

ENTER

, select SCOPE 1 and press

F1

– READINGS and with

SAVE

,

ENTER

F2

to

4. Using

TIMEsns

select the required time base setting.

5. Set the 5500A to source a sine wave according to the first test point in Table 4-6.

As no 50Ω termination is applied, the 5500 leveled sine wave output amplitude will

be twice the set value.

6. Observe reading

A, B, C and D and check to see if it is within the range shown under

the appropriate column.

7. Continue through the test points.

8. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

4-16

Page 37

Performance Verification

V

Table 4-6. Input A, B, C, D Frequency Measurement Accuracy Test

4.6 Scope Input A, B, C, D Tests 4

Model Time

base

all 20 ms/div wavegen, sine 600 mVpp 16 Hz 15.90 to 16.10

190-062 20 ns/div levsine 600 mVpp 60 MHz 59.68 to 60.32

190-104

190-102

190-204

190-202

20 ns/div levsine 600 mVpp 100 MHz 99.3 to 100.7

20 ns/div levsine 600 mVpp 200 MHz 198.8 to 201.2

5500A-SC... MODE Voltage Frequency Input A, B, C, D

Reading

Note

Duty Cycle and Pulse Width measurements are based on the same

principles as Frequency measurements. Therefore the Duty Cycle and

Pulse Width measurement function will not be verified separately.

4.6.7 Input A&B / C&D Phase Measurements Test

Note: the test steps for channel C and D are only for the models 190-104, 190-204.

Proceed as follows to test the phase measurement accuracy:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-5).

2. Select the following Test Tool setup:

SAVE

F2

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL, select SETUP press

ENTER

, select SCOPE 1 and press

,

ENTER

to

recall the setup.

SCOPE

F2

– READING ... and select with

F1

– READINGS and with

• Press

• Press

the arrow keys:

Reading 1, on A, Phase

Reading 2, on B, Phase

Reading 3, on C, Phase

Reading 4, on D, Phase

3. Using

4. Using

mV

RANGE

and

TIMEsns

RANGE

select range 100 mV/div for A, B, C and D.

select the required time base setting.

5. Set the 5500A to source a sine wave according to the first test point in Table 4-7.

As no 50Ω termination is applied, the 5500 leveled sine wave output amplitude will

be twice the set value.

6. Observe the readings

A, B, C and D and check to see if they are not outside the range

shown under the appropriate column.

7. Continue through the test points.

8. When you are finished, set the 5500A to 0 (zero) Volt, and to Standby.

4-17

Page 38

Fluke 190-062, -102, -104, -202, - 204

V

Service Manual

Table 4-7. Phase Measurement Verification Points

Time base 5500A-SC... MODE Frequency Voltage Input A, B, C, D Reading

20 ms/div wavegen, sine, 1 MΩ 10 Hz 600 mVpp -2 to +2

200 ns/div levsine 1 MHz 300 mVpp -2 to +2

20 ns/div levsine 10 MHz 300 mVpp -3 to +3

4.6.8 Time Base Test

Proceed as follows to test the time base accuracy:

1. Connect the Test Tool to the 5500A as shown in Figure 4-6.

... Deg

PM9091

50 OHM e.g. PM9585 or

TRM50

For 190-502 use only

TRM50!

METER

AB

2 CHANN. + METER 4 CHANNELS

50 OHM e.g. PM9585 or

TRM50

B

ADC

PM9091

USE 50 OHM

TERMINATION

NORMAL

FLUKE 5500A CALIBRATOR

SCOPE

Figure 4-6. 5500A Scope Output to Test Tool Input A

2. Set the 5500A to source a 8 ms time marker (MODE marker).

3. Select the following Test Tool setup:

• Reset the Test Tool

• Using

mV

RANGE

and

RANGE

select manual vertical ranging, and set the Input A

sensitivity range to 5 V/div (10:1 probe) or 500 mV/div (probe A factor is 1:1)

• Using

TIMEsns

change the time base to select manual time base ranging, and

lock the time base on 10 ms/div).

• Using

MOVE

move the trace to the left. Once the trigger point is shifted

across the left hand border of the screen, going off screen, the trigger delay time

with respect to the first vertical grid line will be indicated in the lower right of

the display, as can be seen in the left-hand screen in figure 4-7.

Adjust the trigger delay time to 8.000 ms (

• Using

TIMEsns

set the time base on 10 μs/div.

A →| 8.00 ms ).

4-18

Page 39

Performance Verification

V

4.6 Scope Input A, B, C, D Tests 4

4. Using

MOVE

move the trace to the right until the indicated trigger delay is

7.940 ms.

5. Examine the rising edge of the time marker pulse at the height of the trigger level

indicator top. Verify that the rising edge is at the center grid line. The allowed

deviation is ±3 pixels: see Figure 4-7.

Figure 4-7. Time Base Verification.

190c-tb3.bmp

4.6.9 Input A Trigger Sensitivity Test

Proceed as follows to test the Input A trigger sensitivity:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-6).

2. Select the following Test Tool setup:

• Reset the Test Tool

mV

• Using

RANGE

ranging, and lock the Input A sensitivity range on 2 V/div.

3. Using

TIMEsns

Table 4-8.

4. Set the 5500A to source the leveled sine wave for the appropriate Test Tool model.

5. Adjust the 5500A output voltage until the displayed trace has the trigger amplitude

indicated under the last column of Table 4-8.

6. Verify that the signal is well triggered.

If it is not, press

manual Trigger Level adjustment. Adjust the trigger level and verify that the signal

will be triggered now. The trigger level is indicated by the trigger icon (

RANGE

and

change the sensitivity range to select manual sensitivity

select the time base indicated under the second column of

TRIGGER

, then using

F3

enable the up/down arrow keys for

).

7. Continue through the test points.

8. When you are finished, set the 5500A to Standby.

4-19

Page 40

Fluke 190-062, -102, -104, -202, - 204

Service Manual

UUT UUT 5500A SC... MODE levsin UUT

Model Time base Initial Input Voltage Frequency Trigger Amplitude

ALL 200 ns/div 100 mV pp 5 MHz 0.5 div

190-062 10 ns/div 400 mV pp 60 MHz 1 div

10 ns/div 800 mV pp 100 MHz 2 div

190-104, -102 10 ns/div 400 mV pp 100 MHz 1 div

10 ns/div 800 mV pp 150 MHz 2 div

190-204, -202 10 ns/div 400 mV pp 200 MHz 1 div

10 ns/div 800 mV pp 250 MHz 2 div

Table 4-8. Input A Trigger Sensitivity Test Points

4-20

Page 41

Performance Verification

V

4.6 Scope Input A, B, C, D Tests 4

4.6.10 Input A AC Voltage Accuracy (HF) & Bandwidth Test

Proceed as follows to test the Input A high frequency automatic scope ac voltage

measurement accuracy, and the bandwidth:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-6).

2. Select the following Test Tool setup:

SAVE

F2

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL , select SETUP press

ENTER

, select SCOPE 1 and press

recall the setup.

• Press

on A | V ac

• Press

• Using

SCOPE

, then press

.

MANUAL

AUTO

to select autoranging (AUTO in upper right LCD edge)

mV

RANGE

RANGE

and

F2

- READING…, and select READINGS 1 (F1)

change the sensitivity range to select manual sensitivity

ranging, and lock the Input A sensitivity range on 500 mV/div. (

right LCD edge becomes

½ AUTO)

,

ENTER

to

AUTO in upper

• Using

MOVE

move the Input A trace zero to the center grid line

3. Set the 5500A to source a sine wave, to the first test point in Table 4-9.

4. Observe the Input A reading and check to see if it is within the range shown under

the appropriate column.

5. Continue through the test points.

6. When you are finished, set the 5500A to Standby.

Table 4-9. HF AC Voltage Verification Points

UUT 5500A SC... MODE levsine UUT

Model Voltage Frequency Reading A

all 2.545 Vpp 1 MHz 835 mV to 965 mV

all 2.545 Vpp 25 MHz 790 mV to 1.010 V

190-062 2.545 Vpp 60 MHz >630 mV

190-104, -102 2.545 Vpp 100 MHz >630 mV

190-204, -202 2.545 Vpp 200 MHz >630 mV

4-21

Page 42

Fluke 190-062, -102, -104, -202, - 204

B

V

Service Manual

4.6.11 Input B Trigger Sensitivity Test

Proceed as follows to test the Input B trigger sensitivity:

1. Connect the Test Tool to the 5500A as shown in Figure 4-8.

PM9091

50 OHM e.g. PM9585 or

TRM50

For 190-502 use only

TRM50!

METER

AB

2 CHANN. + METER

ADC

50 OHM e.g. PM9585 or

TRM50

B

4 CHANNELS

Figure 4-8. 5500A Scope Output to Test Tool Input B

2. Select the following Test Tool setup:

• Reset the test tool

• Press

• Press

• Using

TRIGGER

mV

RANGE

to turn Input B on.

and use

RANGE

and

ranging, and lock the Input B sensitivity range on 2 V/div.

3. Using

TIMEsns

select the time base indicated under the first column of Table 4-10.

PM9091

USE 50 OHM

TERMINATION

NORMAL

FLUKE 5500A CALIBRATOR

F1

SCOPE

to select Input B as trigger source.

change the sensitivity range to select manual sensitivity

4-22

4. Set the 5500A to source the leveled sine wave given in the first row of Table 4-10.

5. Adjust the 5500A output voltage until the displayed trace has the amplitude indicated

under the appropriate column of Table 4-10.

6. Verify that the signal is well triggered.

If it is not, press

TRIGGER

, then using

F3

enable the up/down arrow keys for

manual Trigger Level adjustment. Adjust the trigger level and verify that the signal

will be triggered now. The trigger level is indicated by the trigger icon (

).

7. Continue through the test points.

8. When you are finished, set the 5500A to Standby.

Page 43

Performance Verification

V

Table 4-10. Input B Trigger Sensitivity Test Points

UUT UUT 5500A SC... MODE levsin UUT

Model Time base Initial Input Voltage Frequency Trigger Amplitude

ALL 200 ns/div 100 mV pp 5 MHz 0.5 div

190-062 10 ns/div 400 mV pp 60 MHz 1 div

10 ns/div 800 mV pp 100 MHz 2 div

190-104, -102 10 ns/div 400 mV pp 100 MHz 1 div

10 ns/div 800 mV pp 150 MHz 2 div

190-204, -202 10 ns/div 400 mV pp 200 MHz 1 div

10 ns/div 800 mV pp 250 MHz 2 div

4.6 Scope Input A, B, C, D Tests 4

4.6.12 Input B AC Voltage Accuracy (HF) & Bandwidth Test

Proceed as follows to test the Input B high frequency automatic scope ac voltage

measurement accuracy, and the bandwidth:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-8).

2. Select the following Test Tool setup:

SAVE

F2

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL , select SETUP press

ENTER

, select SCOPE 1 and press

,

ENTER

to

recall the setup.

• Press

select

• Press

• Using

SCOPE

, then press

on B | V ac.

MANUAL

AUTO

to select autoranging (AUTO in upper right LCD edge)

mV

RANGE

RANGE

and

F2

READING… , select READINGS 2 (F1) and

change the sensitivity range to select manual sensitivity

ranging, and lock the Input B sensitivity range on 500 mV/div.

• Press

TRIGGER

and use

F1

to select Input B as trigger source.

3. Set the 5500A to source a sine wave, to the first test point in Table 4-11.

4. Observe the Input B reading and check to see if it is within the range shown under

the appropriate column of table 4-11.

5. Continue through the test points.

6. When you are finished, set the 5500A to Standby.

4-23

Page 44

Fluke 190-062, -102, -104, -202, - 204

C

C

V

Service Manual

UUT 5500A SC... MODE levsine UUT

Model Voltage Frequency Reading A

all 2.545 Vpp 1 MHz 835 mV to 965 mV

all 2.545 Vpp 25 MHz 790 mV to 1.010 V

190-062 2.545 Vpp 60 MHz >630 mV

190-104, -102 2.545 Vpp 100 MHz >630 mV

190-204, -202 2.545 Vpp 200 MHz >630 mV

4.6.13 Input C Trigger Sensitivity Test

Note: the test steps for channel C are only for the models 190-104, 190-204.

Proceed as follows to test the Input C trigger sensitivity:

1. Connect the Test Tool to the 5500A as shown in Figure 4-9.

Table 4-11. HF AC Voltage Verification Points

PM9091

B

ADC

4 CHANNELS

PM9585 - 50 OHM

USE 50 OHM

TERMINATION

NORMAL

FLUKE 5500A CALIBRATOR

SCOPE

Figure 4-9. 5500A Scope Output to Test Tool Input C

2. Select the following Test Tool setup:

• Reset the test tool.

• Press

• Press

• Press

• Using

TRIGGER

mV

RANGE

to turn Input C on.

: using

and use

and

MOVE

F1

RANGE

change the sensitivity range to select manual sensitivity

move the Input C trace zero to the center grid line.

ranging, and lock the Input C sensitivity range on 2 V/div.

3. Using

TIMEsns

select the time base indicated under the first column of Table 4-12.

to select Input C as trigger source.

4. Set the 5500A to source the leveled sine wave given in the first row of Table 4-12.

5. Adjust the 5500A output voltage until the displayed trace has the amplitude indicated

under the appropriate column of Table 4-12.

4-24

Page 45

Performance Verification

V

4.6 Scope Input A, B, C, D Tests 4

6. Verify that the signal is well triggered.

If it is not, press

TRIGGER

, then using

F3

enable the up/down arrow keys for

manual Trigger Level adjustment. Adjust the trigger level and verify that the signal

will be triggered now. The trigger level is indicated by the trigger icon (

).

7. Continue through the test points.

8. When you are finished, set the 5500A to Standby.

Table 4-12. Input C Trigger Sensitivity Test Points

UUT UUT 5500A SC... MODE levsin UUT

Model Time base Initial Input Voltage Frequency Trigger Amplitude

ALL 200 ns/div 100 mV pp 5 MHz 0.5 div

190-104 10 ns/div 400 mV pp 100 MHz 1 div

10 ns/div 800 mV pp 150 MHz 2 div

190-204 10 ns/div 400 mV pp 200 MHz 1 div

10 ns/div 800 mV pp 250 MHz 2 div

4.6.14 Input C AC Voltage Accuracy (HF) & Bandwidth Test

Note: the test steps for channel C are only for the models 190-104, 190-204.

Proceed as follows to test the Input C high frequency automatic scope ac voltage

measurement accuracy, and the bandwidth:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-9).

2. Select the following Test Tool setup:

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL , select SETUP press

recall the setup.

• Press

.

V ac

• Press

• Using

SCOPE

, then press

MANUAL

AUTO

to select autoranging (AUTO in upper right LCD edge)

mV

RANGE

RANGE

and

F2

change the sensitivity range to select manual sensitivity

ranging, and lock the Input C sensitivity range on 500 mV/div.

MOVE

• using

• Press

move the Input C trace zero to the center grid line

TRIGGER

and use

F1

3. Set the 5500A to source a sine wave, to the first test point in Table 4-13.

ENTER

, select SCOPE 1 and press

READING… , and select READINGS 3 on C |

to select Input C as trigger source.

SAVE

,

ENTER

F2

to

4. Observe the Input C reading and check to see if it is within the range shown under

the appropriate column of table 4-13.

5. Continue through the test points.

6. When you are finished, set the 5500A to Standby.

4-25

Page 46

Fluke 190-062, -102, -104, -202, - 204

D

V

Service Manual

UUT 5500A SC... MODE levsine UUT

Model Voltage Frequency Reading A

all 2.545 Vpp 1 MHz 835 mV to 965 mV

all 2.545 Vpp 25 MHz 790 mV to 1.010 V

190-104 2.545 Vpp 100 MHz >630 mV

190-204 2.545 Vpp 200 MHz >630 mV

4.6.15 Input D Trigger Sensitivity Test

Note: the test steps for channel D are only for the models 190-104, 190-204.

Proceed as follows to test the Input D trigger sensitivity:

1. Connect the Test Tool to the 5500A as shown in Figure 4-10.

Table 4-13. HF AC Voltage Verification Points

PM9091

B

ADC

4 CHANNELS

PM9585 - 50 OHM

USE 50 OHM

TERMINATION

NORMAL

FLUKE 5500A CALIBRATOR

SCOPE

Figure 4-10. 5500A Scope Output to Test Tool Input D

2. Select the following Test Tool setup:

• Reset the test tool

• Press

• Using

• Press

• Using

MOVE

TRIGGER

mV

RANGE

to turn Input D on.

move the Input D trace zero to the center grid line.

and use

RANGE

and

F1

change the sensitivity range to select manual sensitivity

ranging, and lock the Input D sensitivity range on 2 V/div.

3. Using

TIMEsns

select the time base indicated under the first column of Table 4-14.

to select Input D as trigger source.

4. Set the 5500A to source the leveled sine wave given in the first row of Table 4-14.

5. Adjust the 5500A output voltage until the displayed trace has the amplitude indicated

under the appropriate column of Table 4-14.

4-26

Page 47

Performance Verification

V

4.6 Scope Input A, B, C, D Tests 4

6. Verify that the signal is well triggered.

If it is not, press

TRIGGER

, then using

F3

enable the up/down arrow keys for

manual Trigger Level adjustment. Adjust the trigger level and verify that the signal

will be triggered now. The trigger level is indicated by the trigger icon (

).

7. Continue through the test points.

8. When you are finished, set the 5500A to Standby.

Table 4-14. Input D Trigger Sensitivity Test Points

UUT UUT 5500A SC... MODE levsin UUT

Model Time base Initial Input Voltage Frequency Trigger Amplitude

ALL 200 ns/div 100 mV pp 5 MHz 0.5 div

190-104 10 ns/div 400 mV pp 100 MHz 1 div

10 ns/div 800 mV pp 150 MHz 2 div

190-204 10 ns/div 400 mV pp 200 MHz 1 div

10 ns/div 800 mV pp 250 MHz 2 div

4.6.16 Input D AC Voltage Accuracy (HF) & Bandwidth Test

Note: the test steps for channel C are only for the models 190-104, 190-204.

Proceed as follows to test the Input D high frequency automatic scope ac voltage

measurement accuracy, and the bandwidth:

1. Connect the Test Tool to the 5500A as for the previous test (see Figure 4-10).

2. Select the following Test Tool setup:

• Recall the created setup (e.g. SETUP 1, see section 4.4.3): press

RECALL , select SETUP press

recall the setup.

• Press

.

V ac

• Press

• Using

SCOPE

, then press

MANUAL

AUTO

to select autoranging (AUTO in upper right LCD edge)

mV

RANGE

RANGE

and

F2

change the sensitivity range to select manual sensitivity

ranging, and lock the Input D sensitivity range on 500 mV/div.

MOVE

• using

• Press

move the Input D trace zero to the center grid line

TRIGGER

and use

F1

3. Set the 5500A to source a sine wave, to the first test point in Table 4-15.

ENTER

, select SCOPE 1 and press

READING… , and select READINGS 4 on D |

to select Input D as trigger source

SAVE

,

ENTER

F2

to

4. Observe the Input D reading and check to see if it is within the range shown under

the appropriate column of table 4-15.

5. Continue through the test points.

6. When you are finished, set the 5500A to Standby.

4-27

Page 48

Fluke 190-062, -102, -104, -202, - 204

Service Manual

UUT 5500A SC... MODE levsine UUT

Model Voltage Frequency Reading A

all 2.545 Vpp 1 MHz 835 mV to 965 mV

all 2.545 Vpp 25 MHz 790 mV to 1.010 V

190-104 2.545 Vpp 100 MHz >630 mV

190-204 2.545 Vpp 200 MHz >630 mV

4.6.17 Video test using the Video Pattern Generator

Note: you can skip this test if you do the test 4.6.17 Video test using the SC600 Scope

Calibration option

Only one of the systems NTSC, PAL, PALplus, or SECAM has to be verified.

Proceed as follows:

Table 4-15. HF AC Voltage Verification Points

1. Connect the Test Tool to the TV Signal Generator as shown in Figure 4-11.

PM9075

4119-75

75 OHM

A

4 CHANNELS /

2 CHANN. + METER

Figure 4-11. Test Tool Input A to TV Signal Generator

USE 75 OHM TERMINATION

USE 75 OHM COAX CABLE

PM5418

2. Select the following Test Tool setup:

• Reset the Test Tool

• Press

• Choose

Polarity: POSITIVE | PAL ( or NTSC or PALplus or SECAM )

• Press

• Press

TRIGGER

VIDEO on A... , then from the shown opened menu choose

F2

F3

• Using

, then press

to select ALL LINES

to enable the arrow keys for selecting the video line number.

select line number:

F4

to open the Trigger Options menu.

4-28

Page 49

Performance Verification

A

V

4.6 Scope Input A, B, C, D Tests 4

⇒ 622 for PAL, PALplus, or SECAM

⇒ 525 for NTSC.

• Press

, then

F3

and set Attenuation: to 1:1

• Using

• Using

• Using

MOVE

move the Input A trace zero to the center grid line

mV

RANGE

RANGE

and

TIMEsns