Page 1

Power quality recording

and analysis: Techniques

and applications

Application Note

Hooking up a power quality recorder and taking

days’ worth of data can give you a rich picture

of your power. In this article we’ll talk about the

various recording techniques available in power

loggers and recorders—understanding the tools

and techniques you have available will be key to

your strategy. What should you be looking for?

And when does recording make sense?

Recording techniques

To really know your power, ideally,

you’d want to look at every line

cycle to see even the smallest

changes. However, since our power

swings through more than four

million cycles per day, it’s impractical to look at tiny changes—and

often unnecessary. Few loads even

notice occasional voltage dips of

one or two cycles.

How long you record depends

somewhat on the rhythm of your

building. If you are working on a

typical commercial or light industrial building, then a week is long

enough for a building to go through

its normal cycle. If you are working in a plant that runs special

equipment only periodically (say

a furnace that runs only monthly),

you’ll need to be sensitive to the

timing of these loads.

Different recording techniques

have been developed to look at

small changes over relatively long

time periods. Many instruments

combine several techniques to

improve their coverage. We’ll

describe the common techniques

and some of their pros and cons.

By understanding the different

techniques. you’ll be better able to

choose an appropriate tool for the

job at hand.

Setting up a Fluke 1735 Power Logger at the service entrance for a

30-day load study.

F r o m t h e F l u k e D i g i t a l L i b r a r y @ w w w . f l u k e . c o m / l i b r a r y

Page 2

Techniques for tracking

3

2

4

10 min.

10 min.

20 min.

20 min.

30 min.

30 min.

40 min.

40 min.

3

2

4

X

X

X

X

Actual variation over time

Plot using fixed 10 minute interval, extremes are lost

trends

Trending tracks power quality

parameters over hours or days.

Power loggers measure parameters like voltage, current, or

power and log them over time.

Trend recording is good for

tracking normal power, subtle

changes, and exceptional conditions but may have a limited

ability to catch fast events.

However, instrument makers

have come up with some creative

ways of showing faster events

while allowing recording lengths

of weeks or even months.

Fixed interval logging

This is the simplest form of

digital recording. To set it up, you

choose a time period, or interval,

between readings—usually in

seconds or minutes. The instrument calculates an average of the

rms values during each interval

and stores it in memory. This

technique is useful for tracking

changes longer than the logging

interval. Unfortunately, a very

short measurement interval will

catch fast events, but will also

use memory quickly. So even

though fixed interval logging is

easy to set up, it can’t capture

fast events over hours or days.

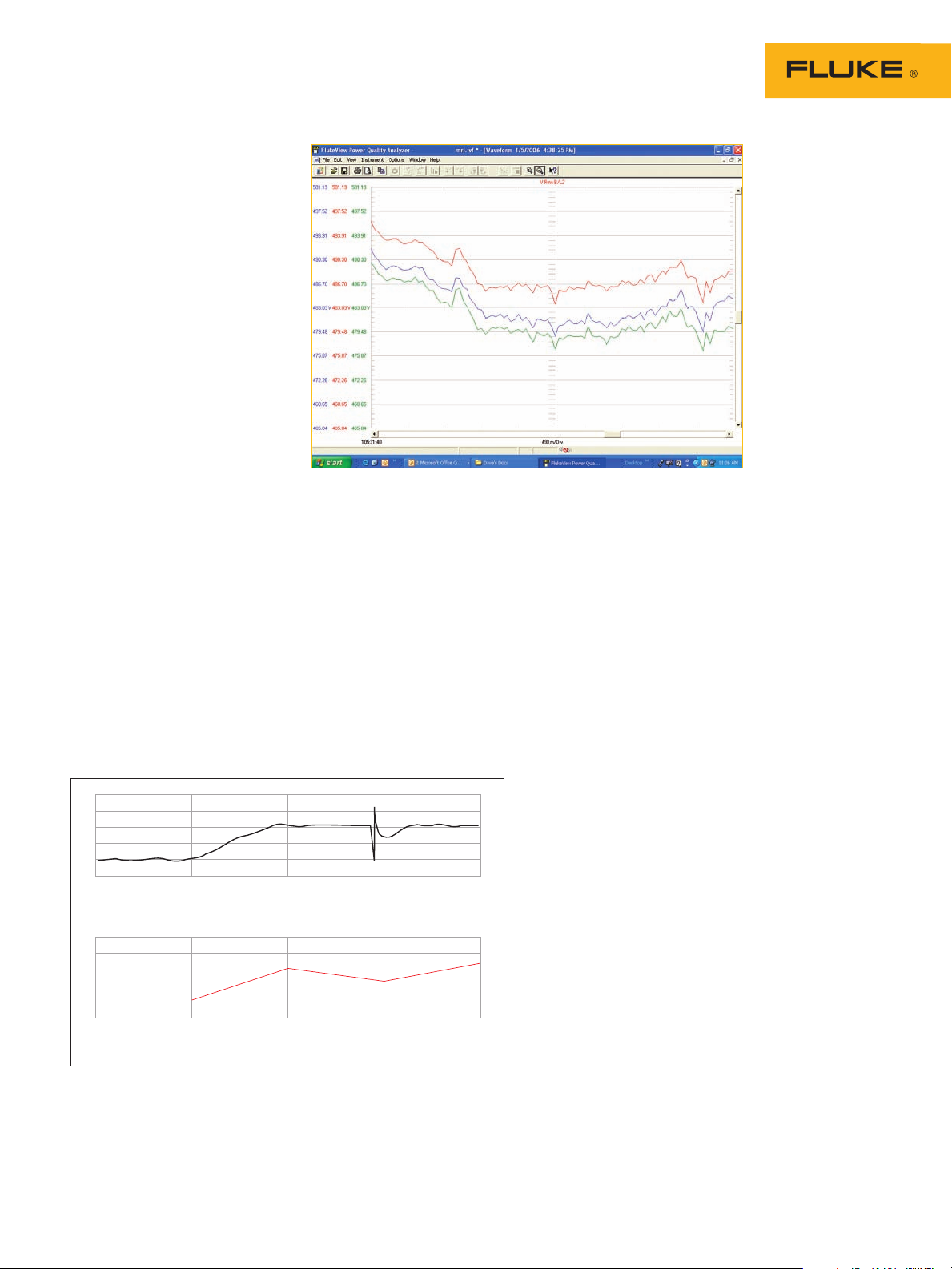

Figure 2. Min/Max/Avg trendplot.

Min/Max/Avg logging

This technique is similar to fixed

interval logging since it uses

a preset interval. But instead

of taking just one reading per

interval, the instrument takes

many high-speed measurements

over each interval. Processors

within the instrument crunch

through the measurements and

log three numbers for each

interval: a minimum, a maximum

and an average. The min and

max indicate the worst-case,

short-duration events, in some

instruments as short as a single

power cycle. The average tracks

the overall trend. Graphs from

these instruments will often plot

min, average and max on the

same graph.

Automatic time compression,

TrendPlot

TrendPlot is a logging technique

in some Fluke instruments. It is

a form of min/max/avg recording

in which the timescale automatically compresses whenever

the trend approaches the end

of memory. When the recorder

starts to run out of memory,

signal processors quickly go to

work. They combine adjacent

intervals into a new min, max,

and average. You still get to

see the worst-case measurements and the overall trend. And

because you choose when to stop

the measurement, you automatically get the best time resolution

with the available memory.

Figure 1. Fixed interval voltage trend.

2 Fluke Corporation Power quality recording and analysis: techniques and applications

Page 3

Event recording

#APTURED

7AVEFORM

4OLERANCE

%NVELOPE

6OLTAGE

7AVEFORM

Dips, swells, interruptions, and

transients are all voltage events.

Power quality events are characterized by the time and date

they occur, severity, and duration. User-defined thresholds or

triggers determine what qualifies

as an event. Event recording is

great for ensuring your voltage

stays within tolerances, say ± 10

%. Data is usually presented as

a list, making it easy to see all

of the extraordinary conditions

on the power system. Whether

or not an event causes problems

depends on both severity and

duration. For example, a 20 % dip

that lasts for 5 seconds is more

likely to cause problems than

a 20 % dip that lasts for 1 line

cycle. So event data is sometimes

compared to standard tolerance

curves, like the CBEMA curve,

that give limits for severity and

duration. The need to specify

multiple limits can make event

recording tricky to set up. If you

set the tolerances too tightly,

you’ll capture lots of events and if

you set the tolerance too loosely,

you may not see anything at all.

Transient waveform

capture

This technique records the

actual sine wave of the voltage

or current, allowing you to see

any event shorter than one line

cycle. The capture is initiated by

a trigger and uses a high speed

digitizer. Various triggers can

start the capture but most instruments use an “envelope trigger”.

Figure 3. This event table lists multiple small dips captured within seconds of each other.

An envelope trigger finds

deviations from a clean sine

wave. It builds an envelope

around the sinusoidal voltage

waveform, based on a userspecified tolerance. If the waveform goes outside the envelope

then the instrument captures and

These instruments can determine

event thresholds automatically and

adjust the threshold on the fly. This

eliminates the difficulty in setting

event thresholds. Full disclosure

recording is very useful for performing comprehensive studies over days,

weeks or even months.

stores. Some instruments, like the

Fluke 430 Series, can also take a

snapshot of the waveform based

on other criteria like rms events

or current increases.

Full disclosure recording

This technique combines min/

max/avg recording, transient,

and event capture all at the

same time. So you don’t have to

decide whether to look for dips or

transients—you can capture both.

Figure 4. Envelope trigger example.

3 Fluke Corporation Power quality recording and analysis: techniques and applications

Page 4

Recording applications

Power quality is recorded in

several general situations. This

section describes the most

common applications.

Troubleshooting with

long-term analysis

Troubleshooting intermittent

failures is challenging. When a

piece of equipment fails or resets

itself mysteriously, it’s tempting

to just swap gear out or reset a

circuit breaker and hope for the

best. For equipment with a high

cost of downtime, the risk of a

repeat failure is too great to rely

on a quick fix. Monitoring the

power after getting your equipment running again will reduce

the number of repeat failures

and rule out power problems if a

failure does recur.

The first decision you’ll have

to make is where to connect

the monitor or analyzer. In

general you should start with the

recorder close to the “victim load”

(the equipment that’s having

problems). This way the monitor

will “see” what the load “sees”. If

you have multiple tools available

it can help to record at different

points in the power system.

Before recording, start by

taking some spot measurements

to answer some basic questions.

Is the voltage level right? Is the

voltage waveform a clean sine

wave or is it noisy or distorted?

If the victim is a 3-phase load,

are the phases balanced? Is the

current being drawn by the load

too high?

The next question is: what

should I record? Unless you are

lucky enough to have a sophisticated power analyzer, you’re

probably going to have to decide

whether to start by tracking

trends or hunting for transients.

Trends will uncover more problems so try trend recording first

(use fixed interval logging or min/

max/avg). Recording rms voltage

trends on all relevant phases is

the most basic approach. This

will determine if the supply is

subject to voltage dips or outages

which can cause load dropouts

or resets. Recording voltage will

also uncover swells or unbalance

which can cause overheating.

Current trends can also help

in troubleshooting. Excessive

current draw will cause overheating. If the voltage is stable,

clean and balanced, high current

indicates a problem with the load

itself. By comparing the voltage

and current recordings you can

tell whether the voltage drop is

being caused by high current

being drawn by the victim load

or is being caused by some other

load upstream.

Voltage distortion can also

cause overheating and should

be recorded if possible. The

most basic way to track voltage

distortion is by recording total

harmonic distortion (THD). Some

analyzers can also track individual harmonics which can help

point to the source of high THD.

If the victim load shows

evidence of arcing or blown

input circuitry transients may

be to blame, but don’t jump to

this conclusion too quickly. After

you’ve performed some trending, or if the evidence strongly

suggests transient damage, then

it’s time to try transient capture

and look at waveforms.

Checking data during recording with the wireless PDA feature of the

FLuke 1750 Power Recorder.

4 Fluke Corporation Power quality recording and analysis: techniques and applications

Page 5

Tools from Fluke

Fluke offers a number of power

recording tools for almost any

application. In some cases a

combination of tools is best. For

example, you could use the Fluke

434 for quick troubleshooting

and short term monitoring or for

longer term monitoring you might

select a Power Recorder.

Loggers Recorders

Fluke 434

Power

Quality

Analyzer

Applications

1-Phase / 3-Phase 3-Phase 3-Phase 1-Phase 3-Phase 3-Phase 3-Phase 3-Phase 3-Phase 3-Phase

Frontline troubleshooting

Predictive maintenance

Load study/PQ survey

Quality of service

compliance (EN50160)

Long-term analysis —

Recording capability

Typical recording period 1 week 1 month 1 month 1 month 3 months 3 months 3 months 1 month 3 months

Memory 8 Mb 16 Mb 32 kB 4 MB 4 MB 4 MB 8 MB 2 GB 1 GB

Min/Max/Avg logging

Event capture

Waveform capture

User defined logging —

Full-disclosure — — — — — — —

Powered off of measured

signals

Sample rate

High-speed capture rate 200 kHz 200 kHz

Peak voltage 6 kV 6 kV 2.5 kV

Features

Display Color

Voltage channels

Current channels 4 4 — 4 4 4 4 5 4 (0)

Included current probes 40 A/400 A

Dust/water resistance IP51 IP51 — IP 65 (not

Safety rating 600 V CAT IV 600 V CAT IV 300 V CAT III 600 V CAT III 600 V CAT III 600 V CAT III 600 V CAT III 600 V CAT IV 600 V CAT III

Software Fluke View Fluke Power

Battery Operation /UPS 7 hours 7 hours — 24 hours — — 5 hours 5 min UPS 40 min

Analysis capability

Statistical analysis

(including EN50160)

Report generator —

Root causeanalysis — — — —

Accuracy

IEC 61000-4-30 Class A

compliant

Volts rms 0.5 % Vnom 0.1 % Vnom ± 2 V

Amps rms 1 % +-5

• •

• •

• •

• •

• • • • • • • • •

• • • • • • • • •

• •

— — — —

10 kHz 10 kHz

Graphical

4 4 1 4 4 4 4 4

Clamps

• •

—

counts

Fluke 435

Logging

Power

Quality

Analyzer

Fluke VR101

Voltage

Event

Recorder

— — — — — — —

— — — — — — —

—

— —

Fluke 1735

Power

Logger

Fluke 1743

Power

Quality

Logger

Fluke 1744

Power

Quality

Logger

Fluke 1745

Power

Quality

Logger

Fluke 1750

Power

Recorder

• • • • • •

• • • • •

• • • • • • • •

— — — — —

•

— —

• • •

• •

—

•

— —

12.8 kHz and

15.36 kHz

5 MHz 0.5 or 10 MHz

6 kV 6 kV

PDA and

LEDs

400 A

Clamps

Analyze

—

• •

0.1 % Vnom 0.1 % Vnom

1 % with

flex CT

Color

Graphical

3000 A

Flexis

Log

•

•

0.5 % +-5

counts

• • •

1/2 cycle

integrated

10.24 kHz 10.24 kHz 10.24 kHz 10.24 kHz

• • • • •

• • • •

LED

— 15 A /150 A/

Fluke Event

View

—

—

Color

Graphical

3000 A Flexis

including

battery

housing)

Fluke Power

Log

LEDs LEDs

15 A/150 A

/1500 A/

3000 A Flexis

IP65 IP65 IP50 IP50 IP50

Fluke PQ Log Fluke PQ Log Fluke PQ Log Fluke Power

15 A/150 A

/1500 A/

3000A Flexis

• • • • • •

• • • • • •

• • •

— — — — —

0 to 200 V

± 4 V

0 to 270 V

—

± (0.5 % +

10 counts)

± (1 % + 10

counts)

0.1 % of

range

2 % of range

with flex CT

0.1 % of

range

2 % of range

with flex CT

LCD and

LEDs

15 A/150 A

/1500A/

3000A Flexis

0.1 % of

range

2 % of range

with flex CT

Fluke 1760

Power

Quality

Recorder

•

—

10.24 kHz

LEDs

4 (8 without

current)

200 A/

1000 A

Flexis

Fluke PQ

Analyze

•

1 % with

flex CT

5 Fluke Corporation Power quality recording and analysis: techniques and applications

Page 6

Quality of service

In some cases, utilities agree to

provide power that complies with

predetermined specifications. The

specifications may be laid out in

contracts or may take the form

of regulations, like EN50160. In

these agreements, details of the

recording techniques, tolerances

and recording duration may be

spelled out. Standard EN50160,

for example, specifies tolerances

for a 1-week recording and references standard IEC 61000-4-30

for measurement and recording

Load studies, power

quality studies, and

commissioning

These types of recordings are

generally done to assess the

power prior to installation or

operation of equipment.

A load study is performed to

determine the existing loads on

a system, prior to adding more

loads. This may be required by

local authorities and local norms

or standards dictate the required

measurements, intervals and

durations. For example, the US

techniques. If you believe that

the power your utility is providing does not meet the agreed

upon specifications, test it.

Before you push the RECORD button

National Electrical Code specifies

current or power measurements

average over 15 minute intervals,

taken over 30 days. In addition to

satisfying the authorities, taking

recordings prior to significant

system modifications can help in

debugging the system later.

Power quality studies and

commissioning studies try to

answer the questions: “Is this

system healthy?” The strategy

in these applications is to cast a

wide net and record as much as

possible. Ideally we would record

voltage, current and power

trends, transients, and event logs.

Don’t jump right into record-

•

ing. Gather as much information as you can with spot

measurements of voltage level,

voltage waveform/distortion,

current, unbalance. These may

point you to the problem or

give you some insight as to

where to go next.

Check your connections. If

•

the instrument has a phasor

or scope display, use it to

verify that the connections are

correct.

To twist the old saying: set

•

twice, measure once. If you

are trending, double check

your recording interval. If you

are using event or transient

capture, recheck your limits.

6 Fluke Corporation Power quality recording and analysis: techniques and applications

Consider doing a short run of

•

an hour or so, before leaving

a monitor for a longer period.

This will help you work any

bugs out of your setup, and

you may get lucky and find

what you’re looking for!

Fluke. Keeping your world

up and running.

Fluke Corporation

PO Box 9090, Everett, WA USA 98206

Fluke Europe B.V.

PO Box 1186, 5602 BD

Eindhoven, The Netherlands

For more information call:

In the U.S.A. (800) 443-5853 or

Fax (425) 446-5116

In Europe/M-East/Africa +31 (0) 40 2675 200 or

Fax +31 (0) 40 2675 222

In Canada (800) 36-FLUKE or

Fax (905) 890-6866

From other countries +1 (425) 446-5500 or

Fax +1 (425) 446-5116

Web access: http://www.fluke.com

©2006 Fluke Corporation. All rights reserved.

Printed in U.S.A. 4/2006 2646555 A-EN-N Rev A

Loading...

Loading...