Page 1

1735

Power Logger

®

Users Manual

March 2006 Rev. 2, 3/10

© 2006-2010 Fluke Corporation, All rights reserved. Specifications are subject to change without notice. All product

names are trademarks of their respective companies.

Page 2

LIMITED WARRANTY AND LIMITATION OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship

under normal use and service. The warranty period is two years and begins on the date of

shipment. Parts, product repairs, and services are warranted for 90 days. This warranty

extends only to the original buyer or end-user customer of a Fluke authorized reseller,

and does not apply to fuses, disposable batteries, or to any product which, in Fluke's

opinion, has been misused, altered, neglected, contaminated, or damaged by accident or

abnormal conditions of operation or handling. Fluke warrants that software will operate

substantially in accordance with its functional specifications for 90 days and that it has

been properly recorded on non-defective media. Fluke does not warrant that software will

be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to enduser customers only but have no authority to extend a greater or different warranty on

behalf of Fluke. Warranty support is available only if product is purchased through a Fluke

authorized sales outlet or Buyer has paid the applicable international price. Fluke reserves the right to invoice Buyer for importation costs of repair/replacement parts when

product purchased in one country is submitted for repair in another country.

Fluke's warranty obligation is limited, at Fluke's option, to refund of the purchase price,

free of charge repair, or replacement of a defective product which is returned to a Fluke

authorized service center within the warranty period.

To obtain warranty service, contact your nearest Fluke authorized service center to obtain

return authorization information, then send the product to that service center, with a description of the difficulty, postage and insurance prepaid (FOB Destination). Fluke assumes no risk for damage in transit. Following warranty repair, the product will be returned to Buyer, transportation prepaid (FOB Destination). If Fluke determines that failure

was caused by neglect, misuse, contamination, alteration, accident, or abnormal condition

of operation or handling, including overvoltage failures caused by use outside the product’s specified rating, or normal wear and tear of mechanical components, Fluke will provide an estimate of repair costs and obtain authorization before commencing the work.

Following repair, the product will be returned to the Buyer transportation prepaid and the

Buyer will be billed for the repair and return transportation charges (FOB Shipping Point).

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS OF

DATA, ARISING FROM ANY CAUSE OR THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty,

or exclusion or limitation of incidental or consequential damages, the limitations and exclusions of this warranty may not apply to every buyer. If any provision of this Warranty is

held invalid or unenforceable by a court or other decision-maker of competent jurisdiction,

such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

11/99

Page 3

Table of Contents

Title Page

Introduction .......................................................................................... 1

Contacting Fluke................................................................................... 1

Symbols ................................................................................................ 2

Safety Instructions ................................................................................ 3

Standard and Optional Accessories....................................................... 5

Software and Information CD-ROM .................................................... 7

Instrument Familiarity .......................................................................... 7

Current Probes .................................................................................. 7

Control Elements, Display................................................................ 7

Display Symbols........................................................................... 8

Description of the Control Elements............................................. 9

Using the SAVE and CURSOR Keys........................................... 10

Connectors .................................................................................... 11

USB Interface ............................................................................... 11

Installing the USB Driver ............................................................. 11

Basic Adjustments (Menu)................................................................ 12

Menu Structuring .......................................................................... 12

Short Overview of the Menu......................................................... 13

Charging the Internal Battery................................................................ 14

Basic Operation .................................................................................... 14

Parameter Configuration................................................................... 15

Logging Menu............................................................................... 15

View/Delete Screenshots .............................................................. 17

View Auto Screenshots................................................................. 18

Instrument Setup............................................................................... 19

Current Probes .............................................................................. 19

Voltage Transformers ................................................................... 21

Phase Identification....................................................................... 21

Backlight....................................................................................... 21

Display Contrast ........................................................................... 21

Version & Calibration................................................................... 21

Power Network ................................................................................. 22

Date & Time ..................................................................................... 22

Language .......................................................................................... 22

Measuring Functions............................................................................. 23

i

Page 4

1735

Users Manual

Overview.......................................................................................... 23

Connecting the Power Logger to the Network ................................. 24

Volts / Amps / Hertz......................................................................... 32

Power ............................................................................................... 35

Events............................................................................................... 40

Harmonics ........................................................................................ 42

Scope................................................................................................ 45

Power Log PC Software....................................................................... 46

Installing Power Log Software......................................................... 46

Starting Power Log........................................................................... 46

Using Power Log.............................................................................. 47

Energy Recording with Fluke Power Log ........................................ 49

Recording Power (Demand) with 1735 Power Logger..................... 51

Inside the Logger.................................................................................. 52

Line Power or Battery Mode ............................................................ 52

Replacing the Battery Pack .............................................................. 52

Maintenance ......................................................................................... 54

Cleaning ........................................................................................... 54

Calibration........................................................................................ 54

Storage.............................................................................................. 54

Measurement Theory............................................................................ 55

Waveform......................................................................................... 55

Meter Volts / Amps / Hz .............................................................. 23

Scope............................................................................................ 23

Harmonics .................................................................................... 23

Power............................................................................................ 23

Events........................................................................................... 24

Color Coding Wire Clips.............................................................. 25

Single and Split Phase Connections ............................................. 26

Split Phase.................................................................................... 28

Measurement in a Three-Phase Power Network........................... 29

Logging ........................................................................................ 33

Measurement ................................................................................ 33

Save.............................................................................................. 34

Logging Function ......................................................................... 34

Measurement ................................................................................ 36

Three-Phase Power Theory .......................................................... 37

Save.............................................................................................. 38

Logging Function ......................................................................... 39

Logging ........................................................................................ 40

Save.............................................................................................. 41

Logged Events.............................................................................. 41

Measurement ................................................................................ 42

Logger Function ........................................................................... 43

Logging ........................................................................................ 44

Save.............................................................................................. 44

Measurement ................................................................................ 45

Save.............................................................................................. 46

ii

Page 5

Contents (continued)

Power Measurements........................................................................ 55

Total Harmonic Distortion................................................................ 57

Specifications........................................................................................ 57

General.............................................................................................. 57

Temperature Ranges ......................................................................... 57

EMC ................................................................................................. 58

Safety................................................................................................ 58

V-RMS Wye Measurement............................................................... 58

V-RMS Delta Measurement.............................................................. 59

A-RMS Measurement....................................................................... 59

Power Measurement (P, S, D)........................................................... 60

PF (Power Factor)............................................................................. 60

Frequency Measurement................................................................... 60

Harmonics......................................................................................... 61

Events ............................................................................................... 61

Unbalance ......................................................................................... 62

Recorded Values................................................................................... 63

iii

Page 6

1735

Users Manual

iv v

Page 7

List of Tables

Table Title Page

1. Symbols ................................................................................................ 2

2. Standard Equipment.............................................................................. 5

3. Optional Accessories ............................................................................ 6

4. Maximum Possible Measuring Periods................................................. 51

Page 8

1735

Users Manual

vi

Page 9

List of Figures

Figure Title Page

1. Display Symbols................................................................................... 8

2. Control Elements .................................................................................. 9

3. Power Logger Connectors..................................................................... 11

4. Menu Overview .................................................................................... 13

5. Using the Optional Mini Clamps .......................................................... 25

6. Single Phase Connections..................................................................... 27

7. Split Phase Connections........................................................................ 29

8. Three-Phase Wye Connections ............................................................. 30

9. Three-Phase Delta Δ Connections-Blondel (Aron, Two-Element

Delta) .................................................................................................... 31

10. Three-Phase Delta Δ Connections-Blondel (Aron, Three-Element

Delta) .................................................................................................... 32

11. Fluke Power Log Screen....................................................................... 47

12. Fluke Power Log Displaying Three Phases of Voltage

and Current ........................................................................................... 48

13. Replacing the Battery Pack................................................................... 53

vii

Page 10

1735

Users Manual

viii

Page 11

1735 Power Logger

Introduction

With this 1735 Power Logger (referred to throughout this manual as “Logger”)

you can conduct voltage, current and power studies for determining existing

loads. The Logger is also a general-purpose power quality investigative tool

that reveals the quality of voltage supply at any point in a distribution network.

The Logger was developed in particular for plant electricians and electrical

installers, who have an important role in investigating and solving disturbances

of the power distribution system.

Your 1735 Power Logger is equipped with Flash Technology. This enables

you to perform firmware updates. Please use the Windows Flash Update utility

to do this. You will find it on the supplied 1735 CD-ROM. If there is a

firmware update, it can be found on the Fluke website: www.fluke.com

Contacting Fluke

.

To contact Fluke, call one of the following telephone numbers:

• Technical Support USA: 1-800-44-FLUKE (1-800-443-5853)

• Calibration/Repair USA: 1-888-99-FLUKE (1-888-993-5853)

• Canada: 1-800-36-FLUKE (1-800-363-5853)

• Europe: +31 402-675-200

• Japan: +81-3-3434-0181

• Singapore: +65-738-5655

• Anywhere in the world: +1-425-446-5500

Or, visit Fluke's website at www.fluke.com

To register your product, visit http://register.fluke.com

To view, print, or download the latest manual supplement, visit

http://us.fluke.com/usen/support/manuals

1

.

.

.

Page 12

1735

Users Manual

Address correspondence to:

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090, P.O. Box 1186,

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

Symbols

Table 1 lists the symbols used on the instrument and/or in this manual.

Table 1. Symbols

Symbol Description

W Important information. See manual.

X Hazardous voltage.

J Earth ground.

T

Double insulation.

F DC (Direct Current).

P Conforms to requirements of European Union.

)

~

Canadian Standards Association is the certified body used

for testing compliance to safety standards.

Do not dispose of this product as unsorted municipal waste.

Go to Fluke’s website for recycling information.

; Conforms to relevant Australian Standards.

-

CAT III

2

Do not apply around or remove from HAZARDOUS LIVE

conductors.

IEC Overvoltage Category III

CAT III equipment is designed to protect against transients

in installations, such as distribution panels, feeders and

short branch circuits, and lighting systems in large buildings.

Page 13

Power Logger

Safety Instructions

Safety Instructions

Please read this section carefully. It will make you familiar with the most

important safety instructions for handling your Logger. In this manual, a

Warning identifies conditions and actions that pose hazard(s) to the user. A

Caution identifies conditions and actions that may damage the Calibrator or

the test instruments.

XW Warnings

To prevent possible electrical shock or personal injury,

follow these guidelines:

• The Logger must only be used and handled by

qualified personnel.

• Adhere to local and national safety codes.

Individual protective equipment must be used to

prevent shock injury where hazardous live

conductors are exposed.

• To avoid electrical shock, remove all test leads

from the Logger before you open the battery door.

Open the Logger only to replace the rechargeable

battery.

• Maintenance work must be done only by qualified

service personnel.

• Use only specified current probes. If you use

flexible current probes, wear suitable protective

gloves or work on de-energized conductors.

• Protect the Logger against dampness, wetness and

humidity.

• To prevent electrical shock, always connect

voltage and current test leads to the Logger before

connecting to the load.

3

Page 14

1735

Users Manual

• The plug and socket connection for the voltage

lead set is designed for 600 V CAT III. The

maximum voltage between outer conductor and

earth potential must not exceed 600 V. With multiphase connections, phase-phase voltage may not

exceed 800 V.

• Use only the provided original or specified

accessories. This includes the ac power adapter.

Adequate qualifications are the following:

• Trained and authorized to switch on/off, ground (earth) and mark

power distribution circuits and devices in accordance with the safety

standards of electrical engineering.

• Training or instruction in accordance with the standards of the safety

engineering in maintenance and use of appropriate safety equipment.

• Training in first aid.

4

Page 15

Power Logger

Standard and Optional Accessories

Standard and Optional Accessories

The standard equipment for the Power Logger is listed in Table 2. Optional

accessories are listed in Table 3.

Table 2. Standard Equipment

Equipment Model or Part

Number

Power Logger Fluke-1735

Battery Charger, BC1735, 115V/230V 50/60 Hz 2584895

International AC Power Plug Set For Battery Charger 2441372

FS17XX, Shielded 4-Phase Flexi Set for Models 1735,

1743, 1744, 1745 (15A/150A/1500A)

VL1735/45,BANANA 4-PHASE VOLTAGE LEAD SET

FOR FLUKE-1735/45 3276205

Dolphin Clip, Black 2540726

WC17XX, COLOR CODE WIRE CLIPS 2637481

Rechargeable Battery,NiMH 7.2V 2625171

Soft Case 1642656

CD-ROM,FLUKE-1735 MANUAL AND SOFTWARE

Includes: manuals, PC application software, firmware

upgrade utility (English, French, German, Italian,

Spanish, Portuguese, Simplified Chinese, Czech,

Polish, Russian, Turkish, Swedish)

1735 Getting Started Manual 3611908

USB 2.0 Connection Cable, Mini USB B5 Male – USB

A Male 3671726

2637462

2583487

5

Page 16

1735

Users Manual

Table 3. Optional Accessories

Description

I1A/10A CLAMP PQ4, 4-PHASE 1A/10A MINI

CURRENT CLAMP SET FOR PQ

I5A/50A CLAMP PQ3, 3-PHASE 5A/50A MINI

CURRENT CLAMP SET FOR PQ

I5A/50A CLAMP PQ4, 4-PHASE 5A/50A MINI

CURRENT CLAMP SET FOR PQ

I20/200A CLAMP PQ3, 3-PHASE 20A/200A MINI

CURRENT CLAMP SET FOR PQ

I20/200A CLAMP PQ4, 4-PHASE 20A/200A MINI

CURRENT CLAMP SET FOR PQ

3000/6000A FLEX 4,3000A/6000A 36-INCH FLEXI

PROBE 4 PHASE

I1A/10A CLAMP PQ3, 3-PHASE 1A/10A MINI

CURRENT CLAMP SET FOR PQ

1-PHASE 1A/10A MINI CURRENT CLAMP SET FOR

PQ

1-PHASE 5A/50A MINI CURRENT CLAMP SET FOR

PQ

Model or Part

Number

3024424

3024436

3024449

3024451

3024460

3024472

3024413

3345753

3345766

SHIELDED 1-PHASE FLEXI SET FOR MODELS 1735,

1743, 1744, 1745

FS17XX IP65, IP65 RATED 4-PHASE FLEXI SET FOR

MODELS 1735, 1743, 1744, 1745

3000/6000A FLEX 4,3000A/6000A 36-INCH FLEXI

PROBE 4 PHASE

3345748

3474696

3024472

Inspect the contents of the shipping box for completeness and damage. If there

is any damage, report the damage to your shipper.

6

Page 17

Power Logger

Software and Information CD-ROM

Software and Information CD-ROM

The CD-ROM delivered with the Logger contains additional, important

information. This includes:

• International manuals

• Power Log PC application software

• 1735 Upgrade Utility for future Logger upgrades

• USB Drivers

Instrument Familiarity

Note

Please charge the battery before the first operation or use the

provided charging adapter at the beginning.

Current Probes

Fluke flexi-sets or current clamps are automatically detected by the Logger

when the Logger is turned on. If you change current probes, turn the Logger

off and on again so the Logger can recognize the new probe.

Control Elements, Display

This section familiarizes you with the display and the controls.

Turn the Logger on by turning the rotary switch in clockwise direction. The

display shows the selected measuring function.

7

Page 18

1735

Users Manual

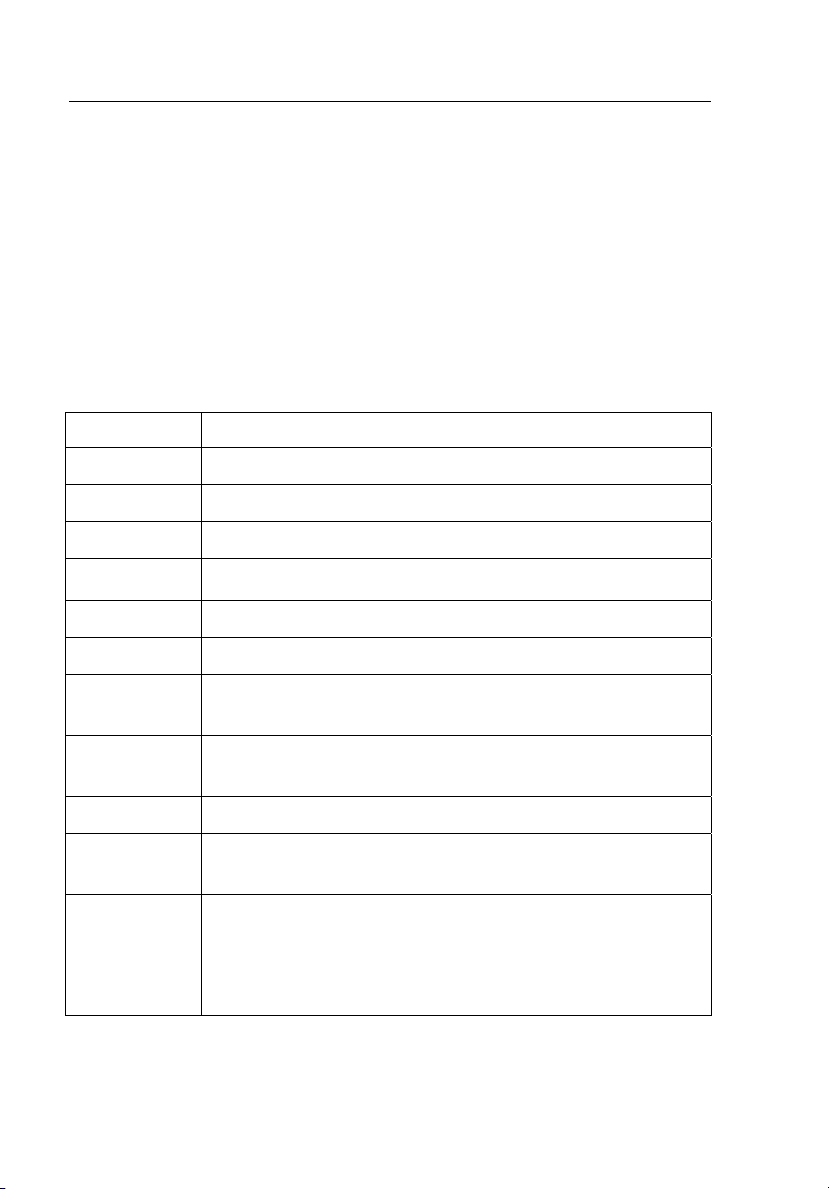

Display Symbols

Figure 1 shows the display symbols the Power Logger uses.

Status Display

Current Measuring

Function

Volts/Amps/Hertz

Measuring Mode

Memory Mode

Switch with:

Pause in Measuring Mode

Pause in Memory Mode

Activate with:

Menu

ON?OFF

Display Shared data

Record

Measure

Hold

Run

Menu

Esc

Figure 1. Display Symbols

Power Supply

Date/Time

2001-03-21, 20:50

Battery

Mains operation

edx004.eps

8

Page 19

Power Logger

Instrument Familiarity

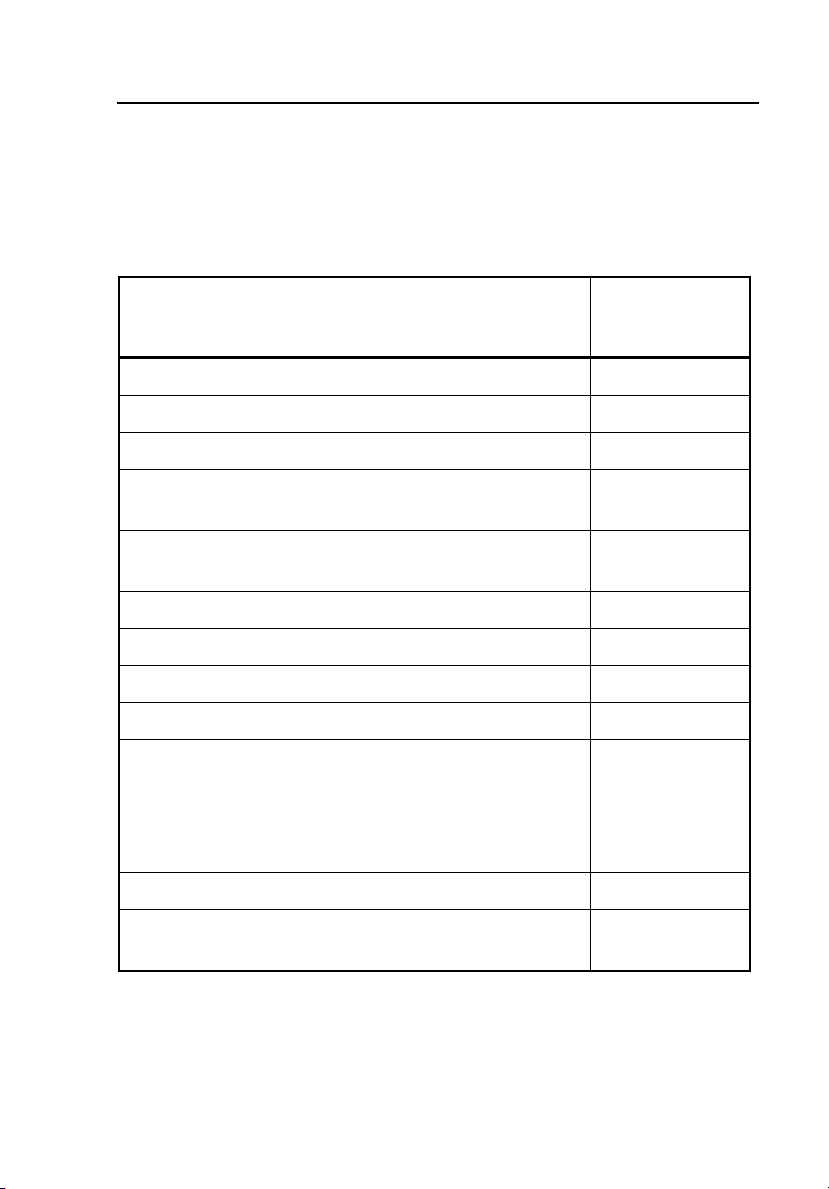

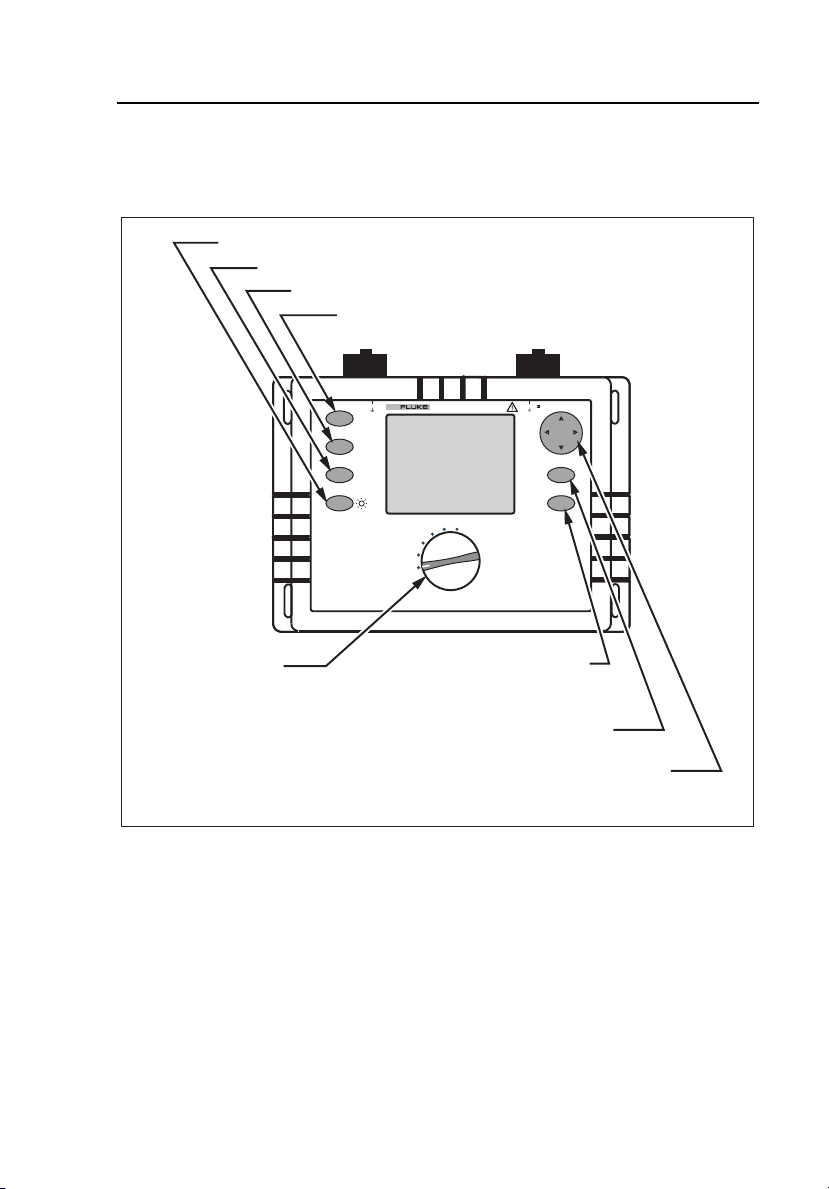

Description of the Control Elements

Figure 2 indicates the control elements of the Power Logger.

Activation - Adjustment of the background lighting

Activating the appropriate cursor function

Switching between measuring and recording function

Stopping and continuing the measurement

Rotary switch for

switching On and for

selecting different

MAX 30V

CURRENT INPUT

HOLD

RUN

RECORD

MEASURE

CURSOR

HARMONICS

SCOPE

METER

V A Hz

OFF

1735

POWER

POWER LOGGER

EVENTS

Call up the menu (at anytime)

or go back to a higher menu level

without saving changes

600V CAT

ENTER

SCREEN

SAVE

ESC

MENU

VOLTAGE INPUT

measuring functions

Save a screen shot or to acknowledge

changes of the menu

Cursor Control Key, Principal function and operation are

described below. For details see its functional description

Figure 2. Control Elements

Note

The symbols occurring in this operating instruction 21 and 4 5

correspond to the respective directions of the cursor control keys.

edx005.eps

9

Page 20

1735

Users Manual

Using the SAVE and CURSOR Keys

Pressing the ENTER/SAVE SCREEN key saves the current picture as a

screenshot.

Since it is a screenshot, a saved picture cannot be modified or edited with the

cursor.

The cursor control keys (4 5 2 1) are activated once you are in HOLD

mode. The CURSOR key activates HOLD mode and displays a cursor (vertical

line) for detailed analysis of measurement results.

Pressing the CURSOR key starts cursor mode. Press 4 and 5 to move the

cursor and read the current values on the display.

Pressing the CURSOR key in the view logged data mode sets a reference

cursor.

Screenshots can also be taken in cursor mode.

Pressing ESC exits cursor mode and returns to the hold mode. From HOLD

mode, different parameters may be selected and Cursor mode may be reentered by pressing CURSOR.

10

Page 21

Power Logger

Instrument Familiarity

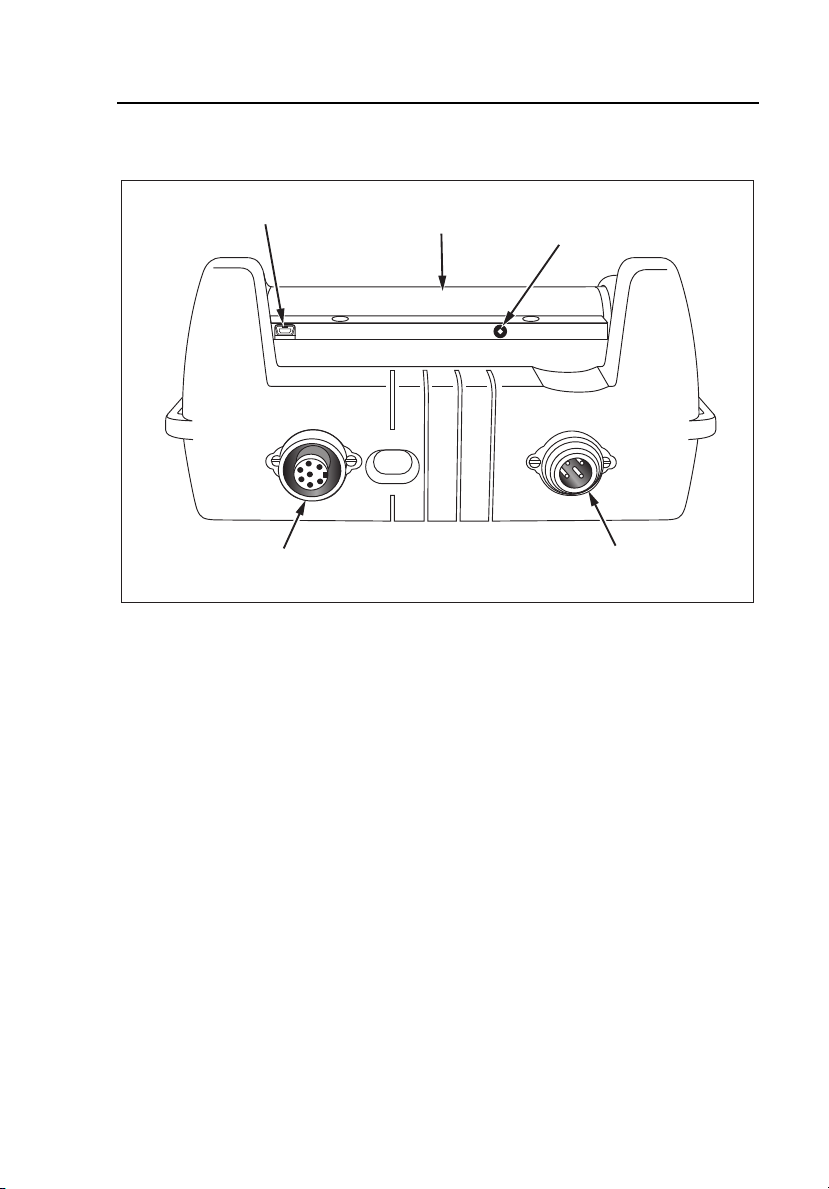

Connectors

USB Interface

Fluke flex inputs

Figure 3. Power Logger Connectors

Battery

compartment

AC - adapter

Voltage inputs for

L1, L2, L3, N

edx006.eps

USB Interface

The USB interface is used for communication with an external PC. Use Power

Log software (included) to download and analyze logged data. This interface is

also used for updating firmware using the 1735 Upgrade Utility. Refer to

“Installing the USB Driver”.

Installing the USB Driver

USB drivers are located on the CD-ROM that came with the instrument. Note

that some drivers will automatically load twice. See instrument manuals for

more details.

To load the USB driver:

1. Run the 1735 Product CD-ROM on a PC.

2. Click on USB Driver Installation.

11

Page 22

1735

Users Manual

3. Either select the default directory by clicking on Install, or click Change

Install Location… and change the file path to a different location.

4. Follow the on screen instructions.

5. The necessary files are copied to the PC.

6. Restart the PC to conclude driver installation.

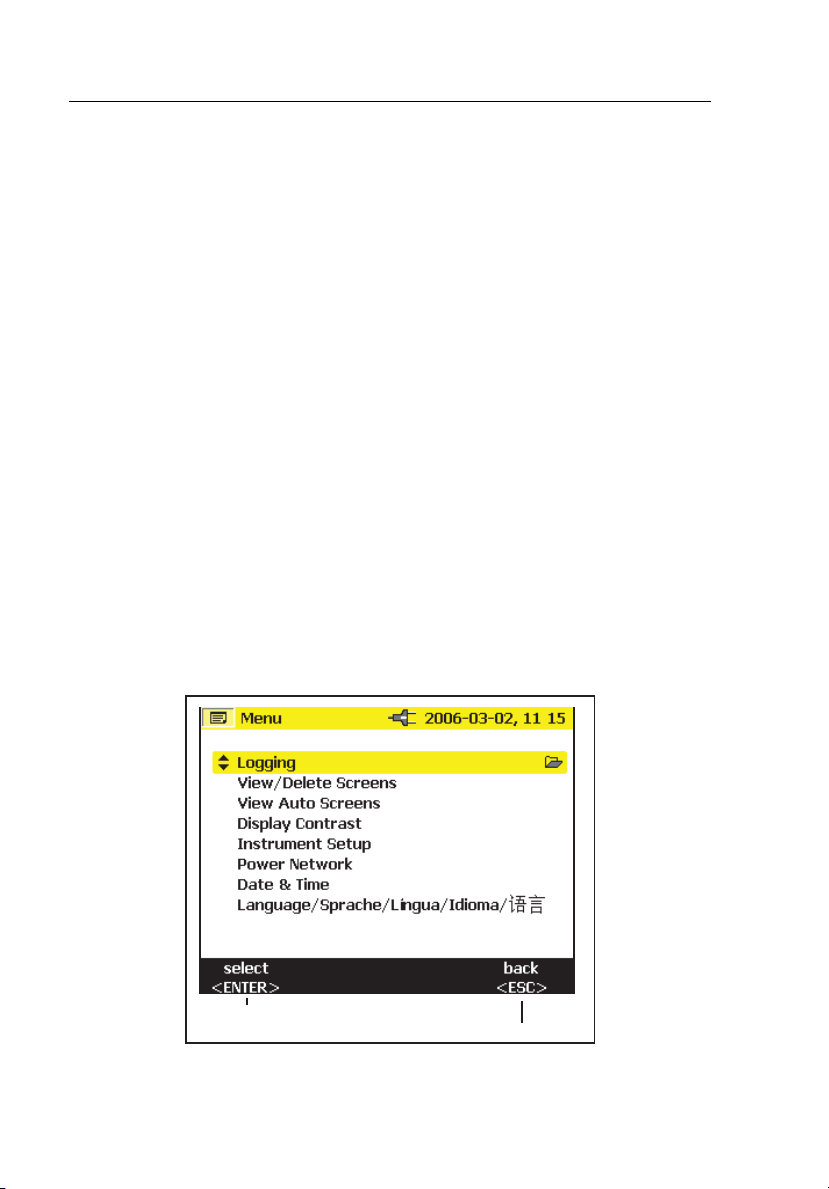

Basic Adjustments (Menu)

Menu Structuring

You make all basic adjustments of the Logger in the main menu. You can call

this at any time with the key M. If you push it again you return to the

previous display.

12

Page 23

Power Logger

Instrument Familiarity

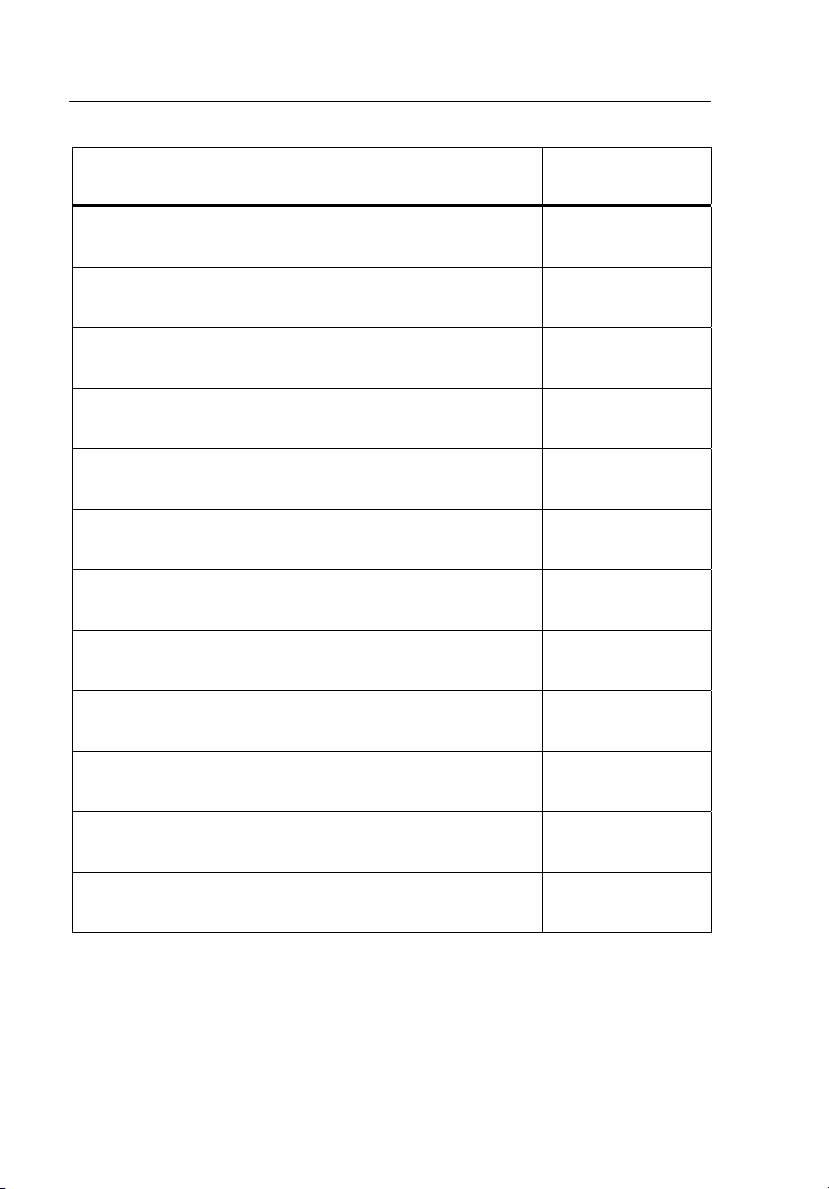

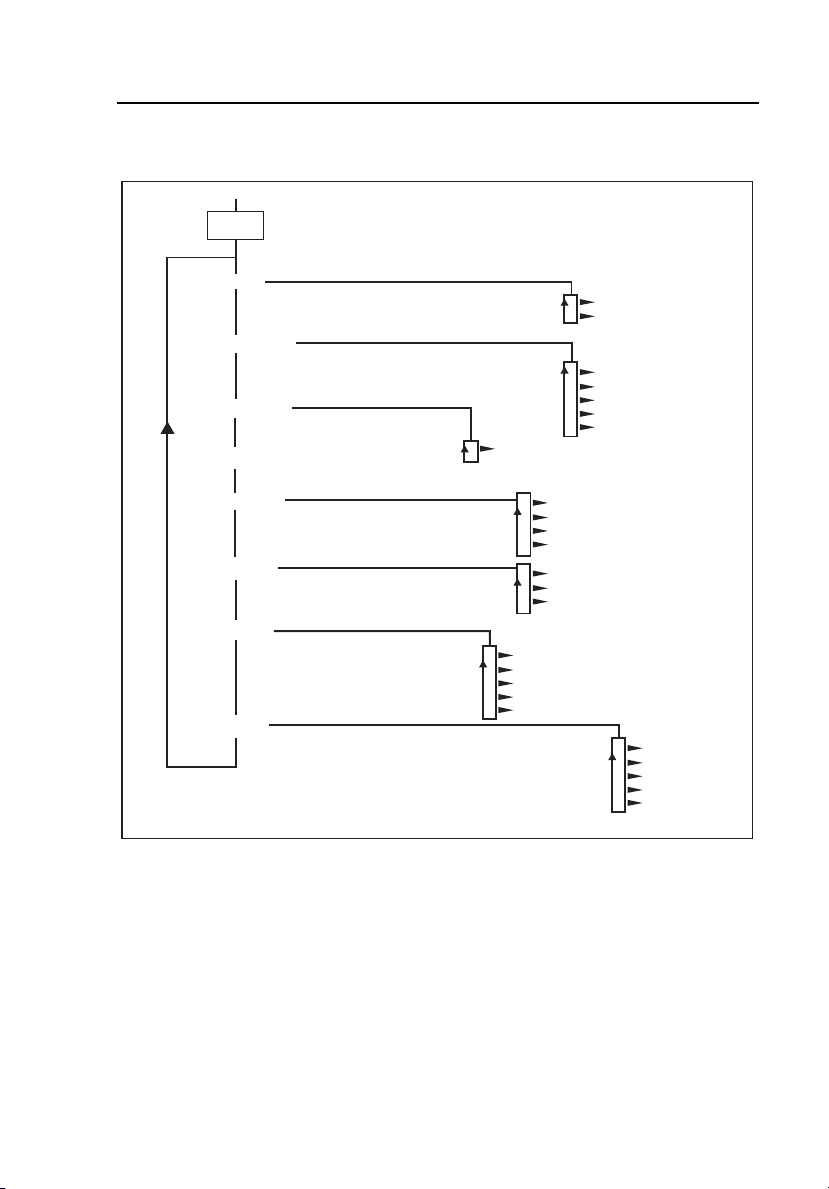

Short Overview of the Menu

MENU

Logging

Averaging Time

Event Thresholds

View/Delete Screens

Memory loc. 10.10

Memory loc. 11.20

View Auto Screens

Display Contrast

Memory loc. 01..06

Memory loc. 21.30

Memory loc. 31.40

Memory loc. 41.50

Instrument Setup

Power Network

Date / Time

Language

Ye a r

Month

Day

Hour

Minute

Figure 4. Menu Overview

Current Probes

Voltage Transformers

Backlight

Version & Calibration

Power Type

Nominal Voltage

Frequency

English

Deutsch

Français

Portuguese

Chinese

edx007.eps

13

Page 24

1735

Users Manual

Charging the Internal Battery

Before you use the Logger, charge the internal battery as follows:

1. Switch the 1735 Battery Charger to either 115V or 230V as

appropriate.

2. With the Logger power off, attach the BC1735 Battery Charger to a

power outlet and then to the Logger.

3. Charge the Logger for 5 hours before using it for the first time.

4. On subsequent use, turn the Logger power on before you connect the

BC1735 Battery Charger.

This helps ensure that the fast charge mode is activated. If the Logger

does not turn on due to a discharged battery, recharge the battery for 5

hours with the Logger power off as described in steps 2 and 3 above.

Basic Operation

The following examples show how to select parameters in the menu.

• Entering the main menu: M

• Selecting menu options with the cursor control keys: 2 1

<Enter>go to marked submenu

<ESC> back to the previous menu level

14

edx008.eps

Page 25

Power Logger

Basic Operation

Changing parameters:

• The displayed parameters can be modified with the cursor control

keys (in the available preset values).

• If values are not preset you can modify them by using the cursor

control keys. With 4 5 you can select the decimal place and with

2 1 you can modify the number.

Note

Selected parameters are stored in the memory with Enter. With ESC

the adjusted value can be rejected at any time.

Parameter Configuration

Logging Menu

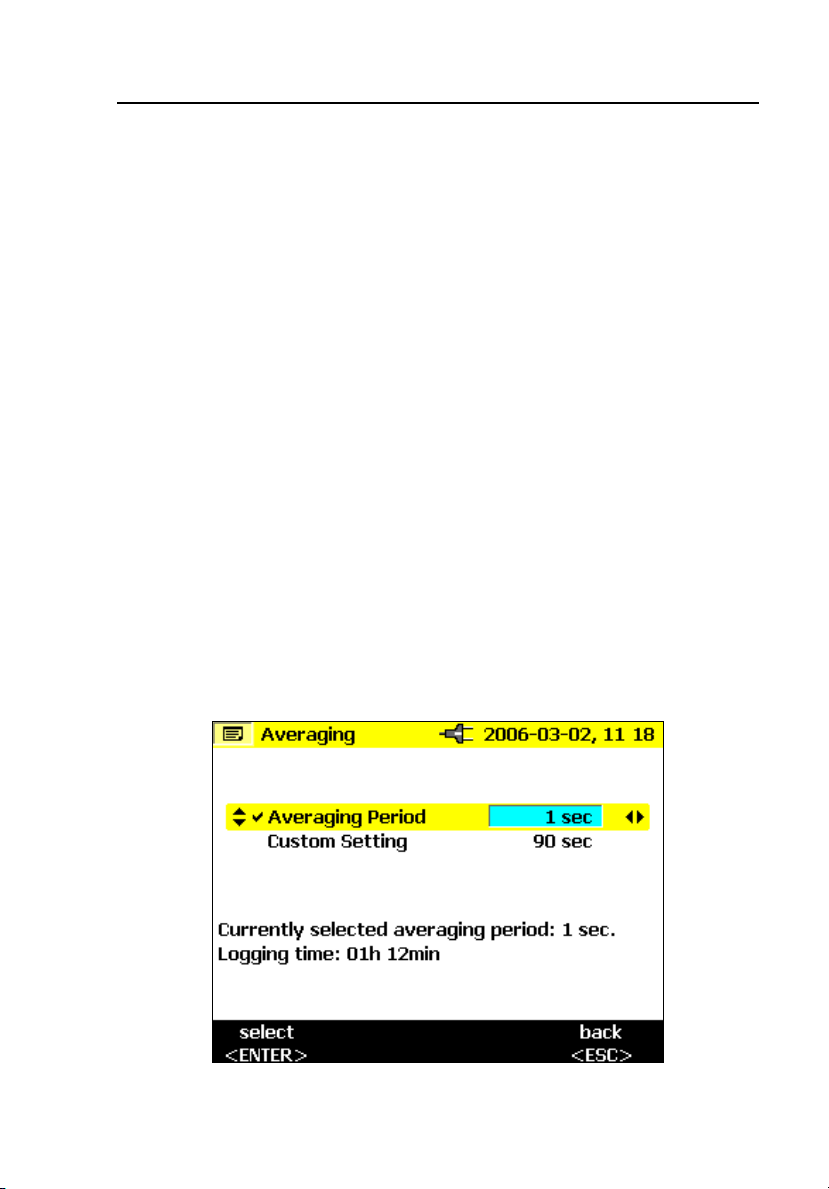

If you call the logging menu, then you can select between two further

submenus: Menu for adjusting the averaging time and for adjusting the event

threshold in recording adjustments.

In the menu Averaging you select the time over which the data are to be

averaged. You can also select these values from the predefined values for

averaging time. As you change the averaging time, you will see on the display

the resulting logging time available for each averaging interval.

edx009.bmp

15

Page 26

1735

Users Manual

With Custom Setting you can choose any averaging time value. Depending on

the selected averaging time, maximum available recording time is indicated in

the display at the same time. Up to 4,320 averaging intervals can be recorded

with the record function.

By selecting the menu Event Thresholds you can select the threshold voltage at

which the recording is to be started (see also “Harmonics”).

16

edx010.bmp

Page 27

Power Logger

Basic Operation

View/Delete Screenshots

Select one of the saved screenshots. Press ENTER to view it. All screenshots

include the date and time and the measuring mode, in which they were saved.

Each page lists 10 screens.

Use the 4 5 to change the page.

edx011.bmp

17

Page 28

1735

Users Manual

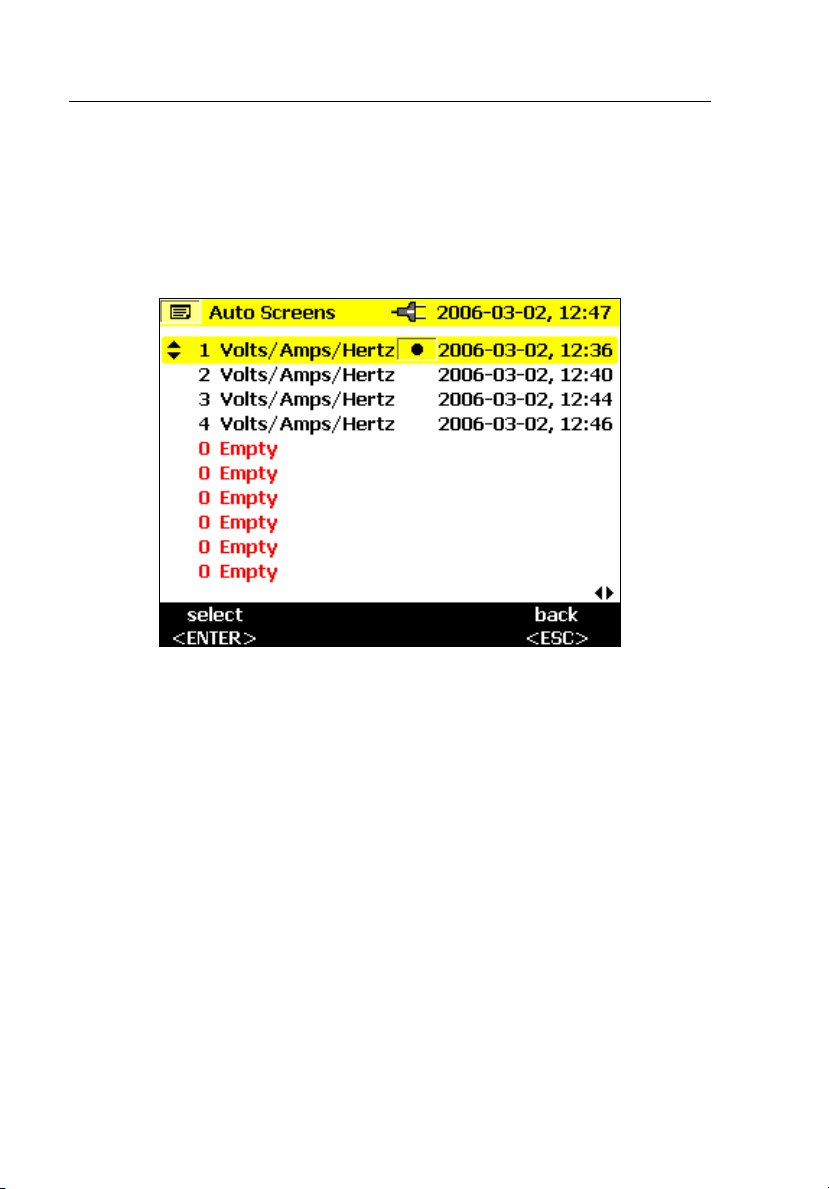

View Auto Screenshots

With this menu item, you can view the screenshots of a recording session,

which have been automatically saved in the Save mode. 6 screenshots are

available (01 to 06).

Select one of the pictures with the CURSOR key and press ENTER to view it.

edx012.bmp

Note

Saved Auto Screenshots always show the currently displayed

parameters.

Example: If you selected phase L2 in the Volt/Ampere/Hertz function and the

recording reaches the margin of the picture, a screenshot of the current picture,

i.e., phase L2, is saved.

18

Page 29

Power Logger

Basic Operation

Instrument Setup

In this menu option you can make adjustments in the submenu for:

• Current Probes

• Voltage Transformers

• Phase Identification

• Backlight

• Version and Calibration

These are described individually in the following:

Current Probes

When a Flexi set or Current Probe is connected to the instrument it is

automatically recognized, but only at power-up. Select the current measuring

range by pressing B. If the secondary of a current transformer is being

measured, it is possible to display the current in terms of the primary by

entering a CT ratio into the current probe setting. The Transformer ratio setting

is only available if one of the MINI clamps is attached. It is not available with

Flexi sets.

edx013.bmp

19

Page 30

1735

Users Manual

Use 21 to select transformer ratio

Use 4 5 to enter the ratio

Use 4 5 to select digit and 21 to adjust the value

edx014.bmp

edx015.bmp

The effect of the ratio is shown at the foot of the display with the primary of

the interposing transformer displayed above the secondary current (input to

probe).

Press ENTER to confirm changes.

20

Page 31

Power Logger

Basic Operation

Voltage Transformers

If you use voltage transformers, select transformation ratio with ENTER. Press

the 4 5 key and enter any transformation ratio with 21.

For transformation ratio details see information on the voltage transformer.

Phase Identification

Here you can choose whether the display shows “A, B, C” for phase

identification or “L1, L2, and L3.” In this manual, phases are called A, B, and

C, but this is equivalent to L1, L2, and L3.

Backlight

This selects whether the backlight deactivates automatically after 30 seconds

or whether you want to always deactivate it manually after you turn it on with

the C key.

Note

If the battery is in use, use the backlight only if necessary in order to

conserve battery life.

Display Contrast

Select the display contrast optimal for you with 21.

Version & Calibration

This menu serves for your information. No adjustments can be made. The

displayed data give information of type and version of the logger firmware.

21

Page 32

1735

Users Manual

Power Network

Select the Power Type (Single phase, split phase, wye, 2-element delta, 3element delta), here. This is also where you select the nominal phase voltage

and frequency.

edx016.bmp

Date & Time

Here you can enter the current date and the current time.

Language

Presents a menu of the provided languages for the Logger displays.

22

Page 33

Power Logger

Measuring Functions

Measuring Functions

Overview

The following information provides an overview of each rotary switch position.

Meter Volts / Amps / Hz

This function displays the voltage and current values at the same time, plus the

frequency and the neutral-conductor current. You can also use this measuring

function to get an overview of these values before you analyze the signal in

detail in the other functions.

Scope

Scope shows the voltages, currents and the ϕ (phase) angle in oscilloscope

representation as well as their instantaneous values at the cursor position. With

this function you get a clear picture of current and voltage waveforms and their

distortions.

Harmonics

Harmonics are sinusoidal voltages with a frequency that corresponds to an

integer multiple of the fundamental (line) frequency.

Every repetitive signal can be split into an infinite number of sine waves of

different frequency and amplitude. The contribution of each of these individual

sine waves is represented in a bar chart up to the 40

the harmonics are (starting from the 2

the better is the power network quality.

nd

harmonic, the 1st is the fundamental)

th

harmonic. The smaller

Power

This function indicates the values of the transferred power. At the same time

you can measure active power, reactive power, apparent power, distortion

power and the appropriate power factor. You can also view the active and

reactive power energy.

23

Page 34

1735

Users Manual

Note

Demand can be logged by setting the averaging period in the Setup

menu to either 10 or 15 minutes, which produces a record of

consecutive averages. This is called block demand.

Events

Events are voltage dips, swells and interruptions. This measuring mode

automatically records all events for later evaluation. The threshold values for

starting the recording are freely configurable in the menu.

Connecting the Power Logger to the Network

XWWarning

• To prevent the risk of electric shock, when

connecting current circuits, the corresponding test

leads must first be connected to the Logger and

then to the load.

• Adhere to local and national safety codes.

Individual protective equipment must be used to

prevent shock injury where hazardous live

conductors are exposed.

• Use only specified current probes. If flexible

current probes are used, wear suitable protective

gloves or work on de-energized conductors.

• To avoid shock or personal injury, keep fingers

behind the tactile barrier, see Figure 5.

Note

When using either flexi-probes or current clamp sets, make sure the

arrow on the current probe points towards the load.

Use the original cables only for connecting the current probes and the voltages

to the Logger. If these are damaged do not use them. Before connecting to the

load, make sure that all plugs are connected correctly to the Logger and locked,

in order to prevent contact with live conductors.

24

Page 35

Power Logger

Single Insulated

Current Carrying

Conductor

Measuring Functions

AC CURRENT CLAMP

600V CAT III

SERIAL NUMBER

i5s

Release

Button

Load Direction

Arrow

Tactile Barrier

Figure 5. Using the Optional Mini Clamps

edx045f.eps

Color Coding Wire Clips

Your Logger includes a set of color clips that you can attach to the test leads.

These help you keep track of which current probe lead and voltage lead

belongs to which phase. The large clips are for the current probe leads and the

small clips are for the voltage leads. Use the plastic rod tool to help you attach

the clips.

25

Page 36

1735

Users Manual

Single and Split Phase Connections

For Single Phase + Neutral, refer to Figure 6 and connect the leads as follows:

Voltage:

Network Test Leads

Line A (L1)

Line (same) B (L2)

Line (same) C (L3)

N N

Current:

Network Test Leads

L1 A (L1)

Not connected B (L2)

Not connected C (L3)

N N

26

Page 37

Power Logger

L1

L1

L2 L3 N

L

N

N

L2

L3

Figure 6. Single Phase Connections

Measuring Functions

T

U

P

N

I

E

G

A

T

L

O

V

T

A

C

V

0

0

6

R

E

G

G

O

L

R

E

OW

P

5

3

7

1

R

E

T

N

E

E

AV

N

S

E

E

R

C

V

30

X

A

M

T

U

P

N

I

D

L

T

N

O

E

H

R

N

R

U

U

R

C

D

R

O

R

C

U

E

S

R

A

E

M

S

C

S

E

U

N

E

E

R

O

S

R

U

C

M

S

T

N

E

V

E

R

E

W

O

P

S

IC

N

O

M

R

A

E

H

P

O

C

S

R

E

T

z

H

E

M

A

V

F

F

O

edx040.eps

27

Page 38

1735

Users Manual

Split Phase

For Split Phase, the Neutral is center-tapped and there are two hot legs which

correspond to A and B test Leads. AB is the voltage from phase to phase,

which is twice that of each individual hot leg. Refer to Figure 7 and connect

the leads as follows:

Voltage:

Network Test Leads

Line 1 A (L1)

Line 2 B (L2)

Line 1 C (L3)

N N

Current:

Network Test Leads

A (L1) A (L1)

B (L2) Line 1 B (L2)

Not connected Neutral C(L3)

N N

28

Page 39

Power Logger

L1

L1

L2 L3 N

L1

L2

N

L2

N

L3

Figure 7. Split Phase Connections

Measuring Functions

T

U

P

N

I

E

G

A

T

L

O

V

T

A

C

0V

0

6

R

E

G

G

O

L

R

E

OW

P

5

3

7

1

R

E

T

N

E

E

V

N

SA

E

E

R

C

V

30

X

A

M

T

U

P

N

I

D

L

T

N

O

E

H

R

N

R

U

RU

C

D

R

O

R

C

U

E

S

R

A

E

M

S

C

S

E

U

N

E

E

R

O

S

R

U

C

M

S

T

N

E

V

E

R

E

W

O

P

S

C

I

N

O

M

R

A

E

H

P

O

C

S

R

E

T

z

H

E

M

A

V

F

F

O

edx041.eps

Measurement in a Three-Phase Power Network

In order to measure all phases in the three-phase power network with the

Logger you attach your Logger to the measuring power network according to

the following figures.

See ‘Power’ for further details.

29

Page 40

1735

Users Manual

Voltage:

Mains Line Test Leads

A (L1) A (L1)

B (L2) B (L2)

C (L3) C (L3)

N N

Current:

Mains Line Test Leads

A (L1) A (L1)

B (L2) B (L2)

C (L3) C (L3)

N N

30

L1

L2

L3

L1

L1

L2 L3 N

L2

L3

N

N

T

U

P

N

I

E

G

A

T

L

O

V

T

A

C

0V

0

6

R

E

G

G

O

L

R

E

OW

P

5

3

7

1

R

E

T

N

E

E

V

N

SA

E

E

R

C

V

30

X

A

M

T

U

P

N

I

D

L

T

N

O

E

H

R

N

R

U

U

R

C

D

R

O

C

U

E

S

R

A

E

M

S

C

S

E

U

N

E

E

R

R

O

S

R

U

C

M

S

T

N

E

V

E

R

E

W

O

P

S

C

I

N

O

M

R

A

E

H

P

O

C

S

R

E

T

z

H

E

M

A

V

F

F

O

edx042.eps

Figure 8. Three-Phase Wye Connections

Page 41

Power Logger

L1

L1

L2 L3 N

L1

Measuring Functions

L2

L3

L3

L2

T

U

P

N

I

E

G

A

T

L

O

V

T

A

C

0V

0

6

R

E

G

G

O

L

R

E

OW

P

5

3

7

1

R

E

T

N

E

E

V

N

SA

E

E

R

C

V

30

X

A

M

T

U

P

N

I

D

L

T

N

O

E

H

R

N

R

U

RU

C

D

R

O

R

C

U

E

S

R

A

E

N

M

S

C

S

E

U

N

E

E

R

O

S

R

U

C

M

S

T

N

E

V

E

R

E

W

O

P

S

C

I

N

O

M

R

A

E

H

P

O

C

S

R

E

T

z

H

E

M

A

V

F

F

O

edx043.eps

Figure 9. Three-Phase Delta Δ Connections-Blondel (Aron, Two-Element

Delta)

31

Page 42

1735

Users Manual

L1

L1

L2

L1

L2 L3 N

L2

L3

L3

WER LOGGER

O

P

1735

V

0

3

MAX

HOLD

UN

R

CURRENT INPUT

RECORD

N

MEASURE

CURSOR

Figure 10. Three-Phase Delta Δ Connections-Blondel (Aron, Three-

Element Delta)

Volts / Amps / Hertz

Select Meter with the rotary switch.

In this mode you can measure values for each phase (A, B, C) of

• Voltage (V)

GE INPUT

LTA

O

V

T

A

C

V

0

60

ENTER

VE

A

S

SCREEN

ESC

MENU

EVENTS

OWER

P

HARMONICS

SCOPE

Hz

METER

A

V

OFF

edx046f.eps

• Current (I)

• Frequency (F)

• Neutral-conductor current (In)

You can determine and store the values. It is also possible to log the values

with the logging function.

Measurement or calculation of the neutral-conductor current is optional.

32

Page 43

Power Logger

Measuring Functions

Logging

In Logging mode, the following values are recorded for every phase (A, B, C)

• Voltage (V) and

• Current (I) and the value of the

• Frequency (F)

These values can be recorded in the instrument, downloaded and evaluated

with the Fluke Power Log software package

Measurement

If you select this measuring mode you will see the following display:

edx024.bmp

21 Use this switch to get the following values:

- minimum of values

- maximum of values and

4 5 - frequency or neutral-conductor current

With Hold/Run the actual values “freeze” and the measurement is stopped or

started again.

33

Page 44

1735

Users Manual

Save

With Save/Enter you will get a screenshot and thus store the actual picture of

the display in the memory location subsequently shown.

Logging Function

With Record/Measure you can start the logging function or you can get back

into the measuring mode. Before the start, the maximum logging time is

indicated and you can change this value with Esc followed by entering using

the Cursor key.

Changes in the averaging time, cause corresponding changes in the logging

time of the measurement (double averaging time = double logging time).

When the logger graphics reach the screen margin during recording, a picture

of this screen is saved.

The display is then deleted and the recording is continued. Up to 6 auto screens

are saved in the course of a recording. The saved screenshots can be retrieved

via the View Auto Screenshots menu.

Note

Do not forget to operate the Logger with the AC adapter during

logging in order to prevent shutdown caused by low battery.

34

Page 45

Power Logger

Measuring Functions

edx025.bmp

21 Select between the individual phases

4 5

Select between the two representation modes:

- V and I (see fig.)

- V and F

- V and In

Analyzing the measured values of the recorder function:

These values can be recorded in the instrument, downloaded and evaluated

with Fluke Power Log software package.

Power

Select Power with the rotary switch.

In this measuring mode you can get the following values for each phase (A,

B, C):

• Power (P) in W (for each phase and its sum P

• Reactive power (Q) in var (for each phase and its sum Q

• Apparent power (S) in VA (for each phase and its sum S

• Distortion power (D) in VA (for each phase and its sum D

• Power factor (PF) and the average PF for the three phases.

• Cos ϕ and the average cosϕ for each of the three phases.

35

).

tot

).

tot

).

tot

).

tot

Page 46

1735

Users Manual

• Active energy (EP) in kWh.

• Reactive energy (EQ) in kVAR.

Note

When operating in DELTA connected modes, the Logger will only

display the Ptotal, Qtotal, and the related Power Factor.

Measurement

You can determine the instantaneous values and store them. You can also

record the values with the recorder function.

If you select this measurement mode you will get the following display:

edx026.bmp

21 Switch between the individual phases (detailed view: min- max- values

and distorted power and Energy values.

4 5 Switch between the representation modes:

- kW, kVA and PF

- kW, kVA and DPF

- kW, kVA and kVAR

36

Page 47

Power Logger

Measuring Functions

- kW, kVA and kWh

- kW, kVA and kVARh

On pressing 21 the accumulated energy function becomes active, this must

be acknowledged by pressing RUN to activate the accumulation timer.

edx027.bmp

The accumulation time is indicated at the top of the measurement display.

A further press of 21 gives a detail view of the individual phase values.

Capacitor or inductance symbols issue information about capacitive or

inductive reactive power.

With Hold/Run the values displayed at the moment “freeze” and the

measurement is stopped or started again.

Note

In the individual representation of A or B or C, the active and

reactive energy cannot be selected.

Three-Phase Power Theory

By switching the Power Network setting from wye to delta, the voltages and

currents I

When calculating the power, selecting the delta connection will use the twowattmeter method (Blondel or Aron) measuring circuit for the calculation.

, I L3, I

L1

are calculated, measured and displayed.

L2

37

Page 48

1735

Users Manual

The neutral conductor may be connected, however, it does not influence the

measurement even in open state. If no neutral conductor is connected, a

virtual ”metering neutral” is established in the Logger via symmetrization

resistors.

In the Blondel (or Aron) circuit, phase L2 becomes the return line for L1 and

L3 causing the current I

currents I

L1

I L3.

to be obtained as the sum of the two negative

L2

i2 (t) =-[i1(t)+ i3(t)]

In general, the instantaneous total power is:

• Ptot(t)=v1(t) i1(t)+ v2(t) i2(t)+ v3(t) i3(t)

• Ptot(t)= v1(t) i1(t)- v2 [i1(t)+ i3(t)]+ v3(t)i3(t)=

=[v1(t)- v2(t)] i1(t)+[ v3(t)-v2(t)]i3(t)

However, since the voltages between the lines of a poly-phase are measured in

the delta connection, the following formula results for the total power:

Ptot(t)= v12(t) i1(t)+v32 i3(t)

Integration via a period results in:

Ptot= V12 I1 cos (V12, I1) +V32 I3 cos (V32, I3)

Therefore, the total power corresponds to the total power of the Wye

connection. For control purposes, it can be derived from the sum of the powers

P

and P31.

12

Since I

is only calculated as an auxiliary value and is not measured, P23 must

L2

be set to zero (as per definition), because it does not exist in the Aron circuit.

The power factor PF has no physical meaning in the Aron circuit, because one

would compare the current to the voltage between the lines of a poly-phase

system. Reactive and apparent power should be understood as pure computing

values and have no physical meaning.

Invalid measurements are suppressed from the display by the symbol ‘----‘.

The exact formulae for calculating the active power are given in the section

Measurement Theory.

Save

With Save/Enter you will get a screenshot and thus store the actual display in

the memory location shown subsequently.

38

Page 49

Power Logger

Measuring Functions

Logging Function

With Record/Measure you can start the logging (recorder) function or you can

get back into the measuring mode. Before the start, maximum recording time is

indicated and you can change this value with cursor.

Changes in the averaging time, cause corresponding changes in the recording

time of the measurement (double averaging time = double recording time).

When the recorder graphics reach the screen margin during recording, a picture

of this screen is saved.

The display is then deleted and the recording is continued. Up to 6 auto screens

are saved in the course of a recording. The saved screenshots can be retrieved

via the View Auto Screenshots menu.

Note

Do not forget to operate the Logger with the BC 1735 AC Power

Adapter during recording in order to prevent shutdown caused by low

battery.

Active and reactive energy are not shown in the recorder function.

edx028.bmp

21 Switch between the individual phases and

phase totals

4 5 Switch between the representation modes:

39

Page 50

1735

Users Manual

- kW and PF

- W and D (kVA)

- W and S (kVA)

- W and Q (kVAR)

- W and D

Logging

In the Logging (Record) mode, the following values are recorded for every

phase (L1, L2, L3)

• Active power (P)

• Apparent power (S)

• Reactive power (Q)

• Power factor (PF)

• Cos phi (cosϕ)

• Distortion power (D)

• Accumulated values (kWh, kVAh, kVARh)

These values can be recorded in the instrument, downloaded and evaluated

with Fluke Power Log software package.

Events

Select Events with the rotary switch.

This measuring mode records the voltage of every phase (L

of voltage dips, swells or interruptions (recorder function).

This function exclusively works with the recorder function.

Before you start the measurement, select the desired threshold value with

Menu/Esc (under recording adjustments). After the measurement has started

the following message appears on the display.

. . . waiting for events

The Logger is now in the trigger mode. If an event on one of the phases occurs,

the recording is started automatically and lasts for 4 minutes. The MIN and

40

, L2, L3) in cases

1

Page 51

Power Logger

Measuring Functions

MAX values of the half-cycle RMS values are shown as graphs. The

screenshots recorded by this method are saved as individual pictures and can

be viewed later, or the data can be displayed with the Power Log software. A

total of 999 events can be recorded. In the LC display the phase and the

number of recordings are displayed.

edx029.bmp

21 Switch between the individual events (if there is more than one).

This is also possible if the recording has been stopped and you want to

evaluate the stored events.

With Hold/Run you can stop/start the measurement or you can also start a new

measurement.

Save

With Save/Enter you will get a screenshot and thus store the actual display in

the memory location shown.

Logged Events

You can download logged events using Fluke Power Log software package.

The Fluke Power Log software presents the event data in a variety of formats:

• graphs similar to those displayed on the instrument

41

Page 52

1735

Users Manual

• statistical format with number of events, range of duration and range

of voltage

• spreadsheet format with date/time stamp, event type and duration

Harmonics

Select Harmonics with the rotary switch.

In this measuring mode you can determine the Harmonics H1 (fundamental

frequency) to H50 for all phases (L1, L2, L3) of:

• Voltage (V)

• Current (I)

Measurement

When selecting this measuring mode with the rotary switch the harmonics are

immediately and clearly represented on the LC display as follows:

edx030.bmp

21 Switch between the individual phases.

4 5 Switch between V and I.

With Hold/Run the values displayed at the moment “freeze” and the

measurement is stopped or started again. By pressing the CURSOR key, you

will go into Cursor mode, where you can read additional values of the

42

Page 53

Power Logger

Measuring Functions

individual harmonics. With 21 you can change the scale; use 4 5 to select

the individual harmonic from 100 %-50 % to 50 %-25 % or 10 %-5 %.

edx031.bmp

Logger Function

Record/Measure starts the logging function or toggles from logging to

measurement mode, respectively.

edx032.bmp

21 Switching between individual phases

43

Page 54

1735

Users Manual

4 5 Switching between V and I

When the recorder graphics reach the screen margin during recording, a picture

of this screen is saved.

The display is then deleted and the recording is continued. Up to 6 auto screens

are saved in the course of a recording. The saved screenshots can be retrieved

via the View Auto Screenshots menu.

You can exit a measurement with HOLD, however, the measurement cannot be

continued afterwards. In order to evaluate the measurement values of the

recorder function:

Use the Cursor key. Using the cursor control keys, select the respective time

and read the corresponding measurement value.

Logging

In Logging mode, the following values are recorded for every phase (L1, L2,

L3)

• Voltages (V) and

• Currents (I)

• THD V

• THD I

• Values of uneven harmonics from 1-25 for V and I shown as 25 bars,

for example fundamental + 24 harmonics, including even harmonics.

• Frequency

These values can be recorded in the instrument, downloaded and evaluated

with Power Log software package

Save

With Save/Enter you will get a screenshot and thus store the actual display in

the memory location shown subsequently.

44

Page 55

Power Logger

Measuring Functions

Scope

Select Scope with the rotary switch.

In this measuring mode you get a live picture of the waveforms of

• Voltage (V)

• Current (I)

• Angle (ϕ)

for all three phases (L1, L2, L3).

Measurement

If you select the measuring mode with the rotary switch the following figure

appears on the display. The three phase voltages and current values are plotted

for the time of one period.

edx033.bmp

21 Switch between the individual phases or total view of all phases.

4 5 While viewing the individual phases, the cursor can be shifted and the

value at this location is displayed.

In the individual view, the ϕ angle is also shown.

With Hold/Run the momentary values “freeze” and the measurement is

stopped or started again.

45

Page 56

1735

Users Manual

Save

With Save/Enter you will get a screenshot and thus store the actual display in

the memory location shown subsequently.

Note

In this mode the recorder function is not available. The angle (

describes the phase shift between first harmonic active power and

first harmonic reactive power. See formula in the Measurement

Theory section for more details.

ϕ

)

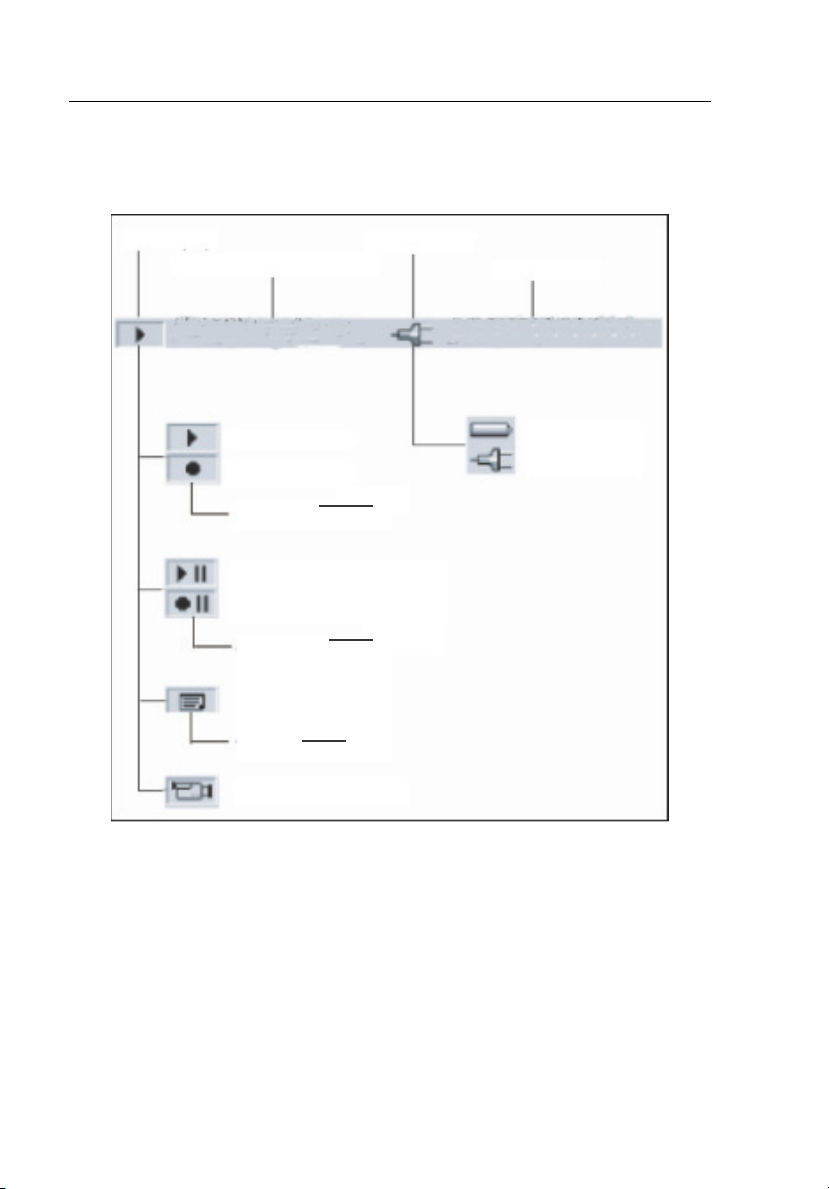

Power Log PC Software

Power Log provides data download, analysis and reporting in one simple to

use package.

Installing Power Log Software

Insert the supplied CD-ROM, the main menu starts automatically (if it doesn’t

double-click on “launch.exe” and execute the program). Please follow the

instructions appearing on the screen (menu):

Power Log is a simple but complete application designed to help the user get

the most from the 1735 Power Logger.

Check www.Fluke.com

for any available new releases.

Starting Power Log

1. Click the Start button.

2. From the start menu, point to programs, point to Fluke Power Log then

click Fluke Power Log.

For 3 seconds there is a screen that identifies the program:

Then your screen will look similar to this:

46

Page 57

Power Logger

Figure 11. Fluke Power Log Screen

Power Log PC Software

edx034.bmp

Fluke Power Log incorporates several toolbars which provide quick access to

commonly used functions. These functions are also accessible from the Menu

Bar. All toolbars can be re-arranged by dragging them, or make them ‘float’

over the application. It is also possible to hide them by clicking the ‘x’ button

when ‘floating’.

Using Power Log

Primary functions:

• The Download data button. A connection will be established with the

1735 Power Logger, and all Logger recordings will be downloaded.

• The Main Toolbar also comprises of 4 items, but only 1 is active at

start-up:

Open data from File: To retrieve previously saved data files from the

PC hard drive.

47

Page 58

1735

Users Manual

• The other 3 buttons are active when the Fluke Power Log has data

stored in memory:

o Save data to File.

o Print Current Screen.

o Print report. This produces a printed report of the information on

screen. It is possible to adjust the report parameters to avoid the

printing of data not required and the generation of large reports.

Figure 12. Fluke Power Log Displaying Three Phases of Voltage and

edx035.bmp

Current

In the Power Log, every file has its own window within the main one. This

allows files to be open simultaneously for comparison. Each of these windows

has tab markers, which are used to select different viewing modes of the

recorded data.

48

Page 59

Power Logger

Power Log PC Software

Energy Recording with Fluke Power Log

The supplied software Fluke Power Log enables analysis of energy data in two

modes.

The first mode shows the energy as an incremental graph:

edx036.bmp

49

Page 60

1735

Users Manual

The second mode allows a time aggregation period to be set. The minimum

aggregation time is the same as the recorded average period. Values greater

than the recorded period may also be set.

50

edx037.bmp

Page 61

Power Logger

Power Log PC Software

Recording Power (Demand) with 1735 Power Logger

This section provides an example of using the logging function to record 15minute demand averages over 30 days. However, this is only one example of

the types of recordings that you can make.

The export of events is an exception, which is described separately in “Using

Power Log.”

• Connect Logger to the power network at switchgear, a junction box,

or breaker panel, or other convenient access point; set up for POWER.

• Start the measurement by pressing Record.

• In the POWER switch position,, Logger can record up to 4,320

intervals based on the preset interval time. The process can be

cancelled by pressing RECORD/MEASURE at any time.

Table 4. Maximum Possible Measuring Periods

Measurement

Function

V/A/Hz,

Harmonics,

Power

Average Interval Recording Time

½ sec

1 sec

2 sec

5 sec

10 sec

30 sec

1 min

5 min

10 min

15 min

20 min

36 minutes

1 hour, 12 minutes

2 hours, 24 minutes

6 hours

12 hours

1 day, 12 hours

3 days

15 days

30 days

45 days

60 days

51

Page 62

1735

Users Manual

Inside the Logger

Line Power or Battery Mode

You can operate the Logger continuously with the provided charging adapter

or for a few hours with the built-in battery. The battery is to ride through

power interruptions during logging sessions, and to provide operating power

during handheld troubleshooting and analysis of signals.

If you operate your Logger with the ac adapter, the battery is charged

automatically. On the display the symbol for “plugged-in” or battery is

displayed accordingly.

If the battery is completely discharged, it takes about 4 hours to charge it

completely. It is impossible to overcharge the battery as the Logger has an

automatic charging circuit.

When LO-BAT is indicated, attach the ac adapter to recharge the battery.

Replacing the Battery Pack

If the battery life is noticeably low (see technical specification), then it has to

be replaced. Replace the battery as follows, refer to Figure 13:

1. Turn off the Logger

2. Disconnect all measuring leads

3. Open the battery compartment (two cross-notched screws)

4. Unplug and replace the battery pack. Close the battery compartment

again.

52

Page 63

Power Logger

Inside the Logger

1

2 3

4

Battery Pack

Figure 13. Replacing the Battery Pack

Note

If you replace the battery please use original spare parts only – see

section “Standard and Optional Accessories”.

53

edx038.eps

Page 64

1735

Users Manual

Maintenance

If the Logger is used appropriately it does not require special maintenance or

repair. Maintenance work may be executed only by trained and qualified

personnel. This work may only be done at a company related service center

within the guarantee period. See www.fluke.com

information of Fluke Service Centers worldwide.

Cleaning

WCaution

To avoid damaging the Logger, do not use abrasives or

solvents on this instrument.

If the Logger gets dirty, wipe it off carefully with a damp cloth (without

cleaning agents). Mild soap may be used.

Calibration

As an additional service we offer the regular examination and calibration of

your Logger.

for locations and contact

Storage

If the Logger is stored for longer time or is not in use for longer time, you

should charge the battery at least once every six months.

54

Page 65

Power Logger

Measurement Theory

Measurement Theory

The following formulas are the basics of the measuring values:

Voltage and current measurement

1

= dtv

V

RMS

I

= RMS value of currents

RMS

N

Neutral is calculated when not measured, i.e., no 4-

Waveform

The angle given in the waveform function is based on the following formula.

2

RMS value of voltages

∫

T

2

1

dti

∫

T

IIII

++= RMS value of neutral-conductor current

321

phase Flexi set is connected.

⎤

1

⎥

Angle between

2

⎥

+

QP

1

⎦

reactive power of first harmonic

Q

1

P

active power of first harmonic

1

ϕ

=

arctan

⎡

P

⎢

2

⎢

1

⎣

Power Measurements

50

IVP

∑

=

1kk

1

=

P

M

55

××=

kk

M

→

P

active power over average interval

∑

iM

=

1

i

)cos(

ϕ

active power (200 ms average values)

V

, I

, ϕ

values of harmonics

k

k

k

Page 66

1735

Users Manual

tot

PPP

+= Total Active Power-Blondel (Aron)

2

12

=

50

∑

k

=

1kkk

M

1

=

∑

M

=

1

i

S

Q

tot

tot

Pi to single 200 ms values

M to number of values

PPPP

++= total active power

321

31

22

PSQ −= Total Reactive Power-Blondel (Aron)

tottottot

2

2

2

2

2

23

)(

III +−= Blondel (Aron) circuit

312

IVQ

1

31

3

ϕ

××=

IIIVVV

++⋅++

Total Apparent Power

3

2

)sin(

reactive power (200 ms average values)

Vk, Ik, ϕk values of harmonics

Q

reactive power over average time

i

IVS ×= apparent power

PF ==

P

λ

power factor

S

222

QPSD −−= distortion power

P

cos

ϕ

=

The distortion power is > zero if the waveform of current is different

from the voltage waveform.

56

1

cosine cosϕ

2

2

QP

+

1

1

Note

Page 67

Power Logger

Specifications

Total Harmonic Distortion

THD

50

∑

h

2

)(

V

h

2

=

1

V

%100

×=

Total Harmonic Distortion

V1 to RMS of the fundamental

Vh to RMS of the h-th harmonic

50

⎛

⎜

factork k-factor

=−

∑

⎜

1

h

=

⎝

I

I

2

⎞

I

h

I

RMS

2

⎟

⋅

h

⎟

⎠

… h-th harmonic (amps)

h

… RMS amps

RMS

h … harmonic order

Specifications

General

Display:

Quality:

Memory: 4 MB Flash memory, from this 3.5 MB for measuring data;

Interface: USB/RS232 USB with Mini USB B socket

Sample rate: 10.24 kHz

Line frequency:

¼ VGA Graphic Color transmissive displays 320 x 240 Pixel

with additional background lighting and adjustable contrast,

text and graphics in color.

Developed, designed and manufactured according to DIN ISO

9001

50 Hz or 60 Hz, user-selectable, with automatic

synchronization

Temperature Ranges

Working temperature

range:

Storage temperature

range:

Operating temperature

range:

57

-10 °C to +50 °C

-20 °C to +60 °C

0 °C to +40 °C

Page 68

1735

Users Manual

Note

The above terms are defined in European Standards.

To calculate the specification at any point in the

working temperature range, use the temperature

coefficient below.

Temperature coefficient:

Intrinsic error:

Operating error:

Climatic class:

Housing:

±0.1 % of the measured value per K.

Refers to reference temperature, max. deviation is

guaranteed for 2 years.

Refers to operating temperature range, max. deviation is

guaranteed for 2 years.

C1 (IEC 654-1) -5 °C to +45 °C, 5 % to 95 % RH, no dew

Cycoloy shock and scratch proof thermoplast V0-type (nonflammable) with rubber protection holster

EMC

Emission: IEC 61326-1:2006 class B

Immunity: IEC 61326-1:2006

Power supply: NiMH battery-pack, with ac adapter (15 V to 20 V/0.8 A)

Operation time with

battery:

Dimensions: 240 x 180 x 110 mm (6.1 x 4.6 x 2.8 in)

Weight: 1.7 kg (3.75 lb), including battery

Typical >8 h with bright backlight, >10 h with low backlight,

and 24 h without backlight

Safety

Safety:

Pollution Degree: 2

Protection:

RMS values are measured with a 20 ms resolution.

EN/IEC 61010-1:2001 (2

enforced insulation

IP65; EN60529 (refers only to the main housing without the

battery compartment)

V-RMS Wye Measurement

Measuring range:

Intrinsic error:

Operating error:

Resolution: 0.1 V

58

57 / 66 / 110 / 120 / 127 / 220 / 230/ 240 / 260 / 277 / 347 /

380 / 400 / 417 / 480 V AC

±(0.2 % of measured value. + 5 digits)

±(0.5 % of m. v. + 10 digit)

nd

ed.) 600 V CAT III, double or

Page 69

Power Logger

Specifications

V-RMS Delta Measurement

Measuring range:

Intrinsic error:

Operating error:

Resolution: 0.1 V

100 / 115 / 190 /208 / 220 / 380 / 400 / 415 / 450 / 480 / 600 /

660 / 690 / 720 / 830 V AC

±(0.2 % of m. v. + 5 digit)

±(0.5 % of m. v. + 10 digit)

A-RMS Measurement

Flexi Sets and current probes with voltage output are supported. All current probes must

correspond to 600 V / CAT III

Flexi set I ranges: 15 A / 150 A / 3000 A RMS (non-distorted sine wave)

Resolution: 0.01 A

For ranges 150 A/3000 A

Intrinsic error:

Operating error:

For range 15 A

Intrinsic error:

Operating error:

The errors of the current probes are not considered.

By using Flexi-Set:

Flexi Set measuring

error:

Position influence:

CF (typical): 2.83

±(0.5 % of m. v. + 10 digit)

±(1 % of m. v. + 10 digit)

±(0.5 % of m. v. + 20 digit)

±(1 % of m. v. + 20 digit)

±(2 % of m. v. + 10 digit)

±(3 % of m. v. + 10 digit)

Note

Error for current clamps is specified separately.

59

Page 70

1735

Users Manual

Power Measurement (P, S, D)

• Measuring range: see V RMS and A RMS measurement

• Power errors are calculated by adding the errors of voltage and current

• Additional error due to power factor PF

• Specified error x (1-IPFI)

• Maximum Range with Voltage range 830 V delta-connection and 3000 A

current range is 2.490 MW

Intrinsic error:

Resolution: 1 kW

Operating error:

Typical range with Voltage range 230 V Wye connection and 150 A Current range is

34.50 KW

Intrinsic error:

Resolution: 1 W to 10 W

Operating error:

The errors of the current sensors themselves have not been considered.

Energy Measurement (kWh, KVAh, kVARh)

Intrinsic error:

Resolution: 1 W to 10 W

Operating error:

* Frequency variation

error

±(0.7 % of m.v. +15 digit)

±(1.5 % of m.v. + 20 digit)

±(0.7 % of m.v. +15 digit)

±(1.5 % of m.v. + 20 digit)