Page 1

114, 115, 116, and 117

Digital Multimeters

Calibration Information

Introduction

XWWarning

To avoid electric shock or injury, do not perform the performance tests or

calibration adjustment procedures unless qualified to do so.

The information provided in this document is for the use of qualified personnel

only.

The 114, 115, 116, & 117 Calibration Information provides the information necessary to adjust and verify the

performance of the Fluke Models 114, 115, 115C, 116, 116C, 117, and 117C True RMS Multimeters (hereafter

known as the Meter). When specific models are noted in this manual, the “C” version is also included. For example,

when the listed model is 115, the instructions are applicable to the 115C as well.

®

The following information is included in this document:

• Safety Information and International Electrical Symbols (page 2)

• Specifications (page 3)

• Testing the Fuse (page 5)

• Replacing the Fuse and the Battery (page 6)

• Cleaning (page 7)

• Performance Tests (page 7)

• Calibration Adjustment (page 12)

• Replacement Parts and Accessories (page 17)

• Complete Warranty (page 19)

See the 114, 115, 117 Users Manual or the 115C, 117C Users Manual or the 116 Users Manuals or the 116C Users

Manual for complete operating instructions.

Service Information

To contact Fluke, call one of the following telephone numbers:

USA: 1-888-99-FLUKE (1-888-993-5853)

Canada: 1-800-36-FLUKE (1-800-363-5853)

Europe: +31 402-675-200

Japan: +81-3-3434-0181

Singapore: +65-738-5655

Anywhere in the world: +1-425-446-5500

Or, visit Fluke's Web site at www.fluke.com

To register your product, visit register.fluke.com

September 2006 ©2006 Fluke Corporation. All rights reserved. 1

.

Page 2

114, 115, 116, and 117

Calibration Information

Safety Information

"Warning" and "Caution" Statements

A “XW Warning" identifies hazardous conditions and actions that could cause bodily harm or death.

A "W Caution" identifies conditions and actions that could damage the Meter, the equipment under test, or cause

permanent loss of data.

XWWarnings and Precautions

To avoid possible electric shock or personal injury, follow these guidelines:

• Use the Meter only as specified in this manual or the protection provided by

the Meter might be impaired.

• Do not use the Meter or test leads if they appear damaged, or if the Meter is

not operating properly.

• Always use proper terminals, switch position, and range for measurements.

• Verify the Meter's operation by measuring a known voltage. If in doubt, have

the Meter serviced.

• Do not apply more than the rated voltage, as marked on Meter, between

terminals or between any terminal and earth ground.

• Use caution with voltages above 30 V ac rms, 42 V ac peak, or 60 V dc.

These voltages pose a shock hazard.

• Disconnect circuit power and discharge all high-voltage capacitors before

testing resistance, continuity, diodes, or capacitance.

• Do not use the Meter around explosive gas or vapor.

• When using test leads or probes, keep your fingers behind the finger

guards.

• Remove test leads from Meter before opening the battery door or Meter

case.

• Comply with local and national safety requirements when working in

hazardous locations.

• Use proper protective equipment, as required by local or national authorities

when working in hazardous areas.

• Avoid working alone.

• Use only the replacement fuse specified or the protection may be impaired.

• Check the test leads for continuity before use. Do not use if the readings are

high or noisy.

2

• Do not use the Auto-V LoZ function to measure voltages in circuits that

could be damaged by this function’s low input impedance (≈3 kΩ) (114, 116

and 117).

Page 3

Digital Multimeters

International Electrical Symbols

International Electrical Symbols

Table 1 lists the international symbols that appear in this document and on the Meter.

Table 1. Electrical Symbols

Symbol Description Symbol Description

B AC (Alternating Current) I Fuse

F DC (Direct Current) T Double Insulated

X Hazardous voltage W Important Information; Refer to manual

N Battery (Low battery when shown on the

display.)

J Earth ground

~ Do not dispose of this product as unsorted municipal waste. Contact Fluke or a qualified recycler for

disposal.

Specifications

Accuracy is specified for 1 year after calibration at operating temperatures of 18 °C to 28 °C, with relative humidity at 0 % to 90 %. Extended

specifcifications are available at www.fluke.com.

General Specifications

Maximum voltage between any

terminal and earth ground ................................... 600 V

Surge Protection................................................... 6 kV peak per IEC 61010-1 600V CAT III,

Pollution Degree 2

W Fuse for A input (115 & 117 only):.................. 11 A, 1000 V FAST 17 kA Fuse (Fluke PN 803293)

Display ................................................................... Digital: 6,000 counts, updates 4/sec

Bar Graph: 33 segments, updates 32/sec

Temperature .......................................................... Operating: -10 °C to +50 °C

Storage: -40 °C to +60 °C

Temperature Coefficient ...................................... 0.1 x (specified accuracy)/°C (<18 °C or >28 °C)

Operating Altitude ................................................ 2,000 meters

Battery ................................................................... 9 Volt Alkaline, NEDA 1604A / IEC 6LR61

Battery Life ............................................................ Alkaline: 400 hours typical, without backlight

Safety Compliances.............................................. Complies with ANSI/ISA 82.02.01 (61010-1) 2004, CAN/CSA-C22.2 No 61010-1-04, UL 6101B

(2003) and IEC/EN 61010-1 2nd Edition for measurement Category III, 600 V, Pollution

Degree 2, EMC EN61326-1

Certifications ......................................................... UL, P, CSA, TÜV, ; (N10140), VDE

IP Rating (dust and water protection) ................. IP42

3

Page 4

114, 115, 116, and 117

Calibration Information

Accuracy Specifications

Function Range Resolution

± ([% of Reading] + [Counts])

Accuracy

DC millivolts 600.0 mV 0.1 mV 0.5 % + 2 114, 115, 116, 117

DC Volts

6.000 V

60.00 V

600.0 V

0.001 V

0.01 V

0.1 V

0.5 % + 2 114, 115, 116, 117

DC, 45 to 500 Hz 500 Hz to 1 kHz

Auto-V LoZ

[2]

True-rms 600.0 V 0.1 V 2.0 % + 3 4.0 % + 3 114, 116, 117

45 to 500 Hz 500 Hz to 1 kHz

AC millivolts

AC Volts

Continuity 600 Ω 1 Ω

Ohms

[2]

True-rms 600.0 mV 0.1 mV 1.0 % + 3 2.0 % + 3 114, 115, 116, 117

[2]

True-rms

6.000 V

60.00 V

600.0 V

600.0 Ω

6.000 kΩ

60.00 kΩ

600.0 kΩ

6.000 MΩ

40.00 MΩ

0.001 V

0.01 V

0.1 V

0.1 Ω

0.001 kΩ

0.01 kΩ

0.1 kΩ

0.001 MΩ

0.01 MΩ

1.0 % + 3 2.0 % + 3 114, 115, 116, 117

Beeper on <20 Ω, off >250 Ω; detects opens

or shorts of 500 μs or longer.

114, 115, 116, 117

0.9 % + 2

0.9 % + 1

0.9 % + 1

0.9 % + 1

114, 115, 116, 117

0.9 % + 1

1.5 % + 2

Diode test 2.000 V 0.001 V 0.9 % + 2 115, 116, 117

Capacitance 1000 nF

10.00 μF

100.0 μF

9999 μF

1 nF

0.01 μF

0.1 μF

1 μF

1.9 % + 2

1.9 % + 2

1.9 % + 2

100 μF - 1000 μF: 1.9 % + 2

115, 116, 117

>1000 μF: 5 % + 20

Lo-Z Capacitance (Powerup option)

AC Amps True-rms

[2]

(45 Hz to 500 Hz)

1 nF to 500 μF

6.000 A

[4]

10.00 A

20 A overload for 30

seconds maximum, 10

0.001 A

0.01 A

20% + 2

(10% +2 typical)

1.5 % + 3 115, 117

115, 116, 117

minutes rest minimum.

DC Amps

6.000 A

[4]

10.00 A

20 A overload for 30

0.001 A

0.01 A

1.0 % + 3 115, 117

seconds maximum, 10

minutes rest minimum.

Temperature (Type K

thermocouple)

AC μAmps True-rms

(45 Hz to 1 kHz)

-40 °C to 400 °C

-40 °F to 752 °F

[2]

600.0 μA 0.1 μA

0.1 °C

0.2°F

1.0 % + 10

1.0 % + 18

1.5 % + 3 (2.5 % + 3 > 500 Hz) 116

[5]

[5]

116

DC μAmps 600.0 μA 0.1 μA 1.0 % + 2 116

Model

[1]

4

Page 5

Digital Multimeters

Basic Maintenance

Accuracy Specifications (cont)

Function Range Resolution

99.99 Hz

Hz (V or A input)

Notes:

[1] Models listed in this column also refer to the “C” version of the model. For example, those rows containing model 115 are applicable to the 115C

as well.

[2] All ac ranges except Auto-V LoZ are specified from 1 % to 100% of range. Auto-V LoZ is specified from 0.0 V. Because inputs below 1 % of range

are not specified, it is normal for this and other true-rms meters to display non-zero readings when the test leads are disconnected from a circuit

or are shorted together. For volts, crest factor of ≤3 at 4000 counts, decreasing linearly to 1.5 at full scale. For amps, crest factor of ≤3. AC volts is

ac-coupled. Auto-V LoZ, AC mV, AC μamps, and AC amps are dc-coupled.

[3] AC Volts Hz is ac-coupled and specified from 5 Hz to 50 kHz. AC Amps Hz is dc-coupled and specified from 45 Hz to 5 kHz.

[4] >10 A unspecified.

[5] Temperature uncertainty (accuracy) does not include the error of the thermocouple probe.

[3]

999.9 Hz

9.999 kHz

50.00 kHz

0.01 Hz

0.1 Hz

0.001 kHz

0.01 kHz

± ([% of Reading] + [Counts])

Accuracy

0.1 % + 2 115, 116, 117

Model

[1]

Input Characteristics

Function Input Impedance (Nominal)

Volts AC >5 MΩ <100 pF >60 dB at dc, 50 or 60 Hz

Volts DC >10 MΩ <100 pF >100 dB at dc, 50 or 60 Hz >60 dB at 50 or 60 Hz

Auto-V LoZ ~3 kΩ <500 pF >60 dB at dc, 50 or 60 Hz

Ohms

Diode Test <2.7 V dc 2.000 V dc <1.2 mA

Open Circuit Test Voltage Full Scale Voltage Short Circuit Current

<2.7 V dc

Common Mode Rejection Ratio

(1 kΩ Unbalanced)

To 6.0 MΩ 40 MΩ

<0.7 V dc <0.9 V dc

Normal Mode Rejection

<350 μA

Basic Maintenance

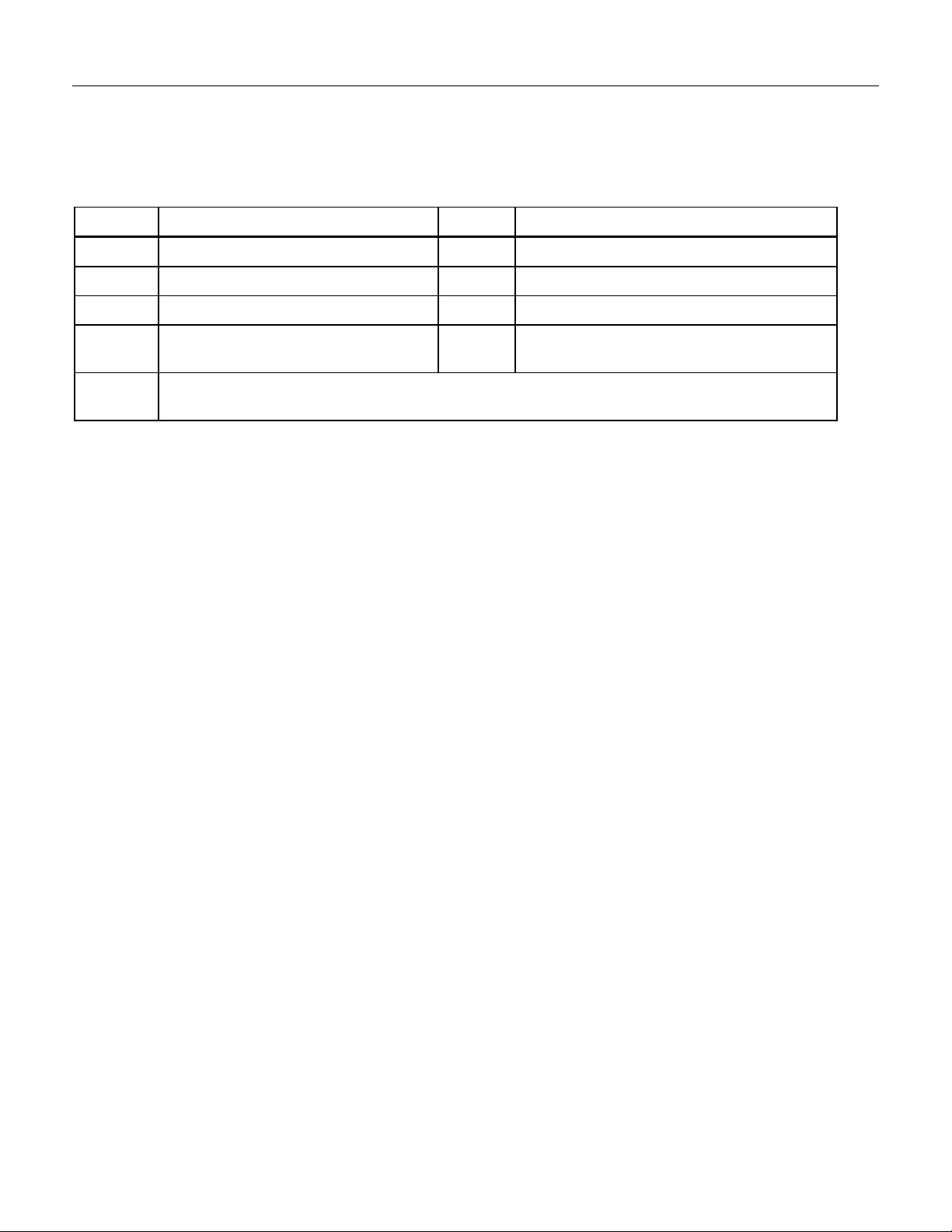

Testing the Fuse (115 & 117 only)

To test the fuse:

1. Set the rotary switch to

2. Plug a test lead into the v jack and touch the probe to the 10A jack, as shown in Figure 1.

If the display shows a resistance value in the range of that shown in Figure 1, the fuse is good.

If the display reads 0L, replace the fuse and test again.

If the display shows any other value, have the Meter serviced. See “Service Information” earlier in this document.

Ω.

5

Page 6

114, 115, 116, and 117

Calibration Information

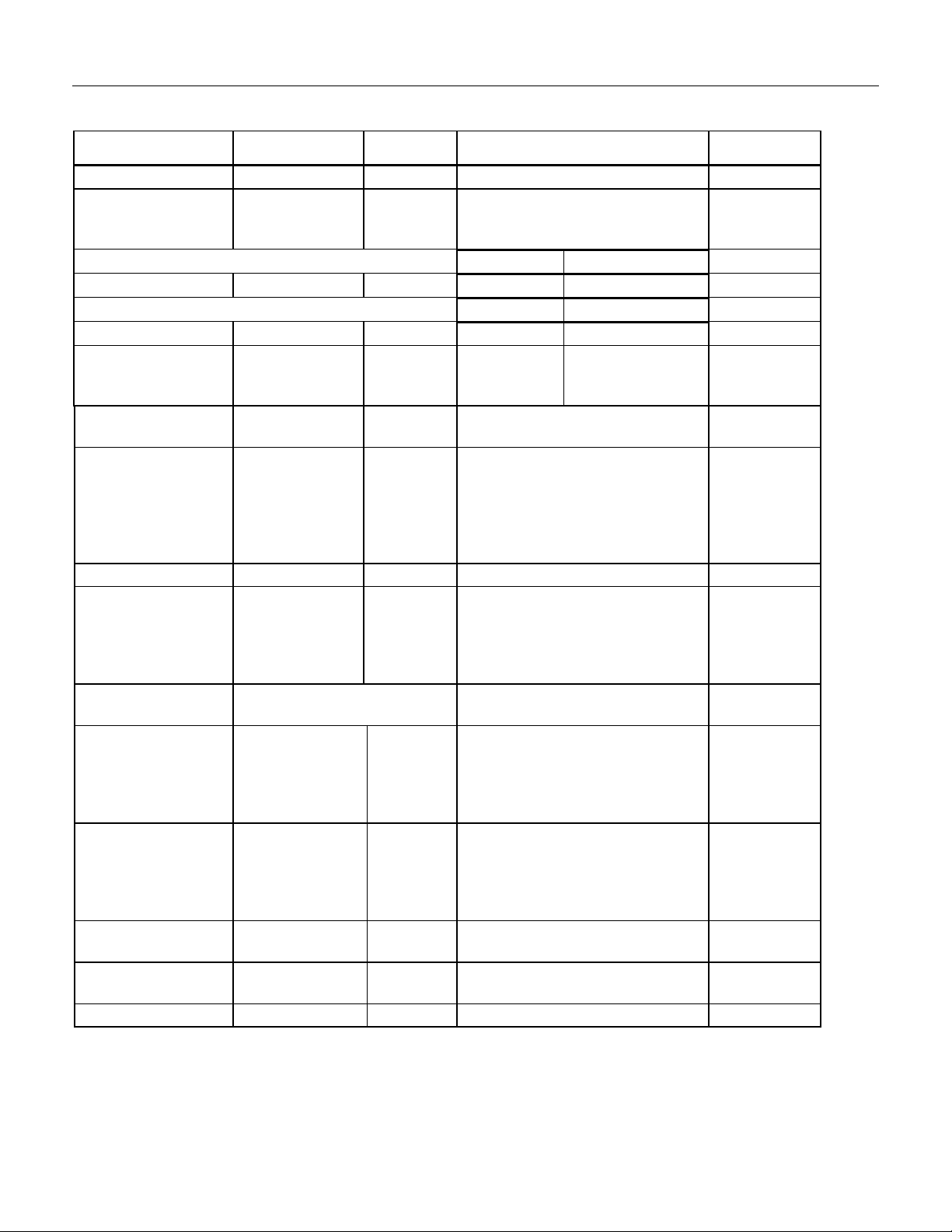

Replacing the Battery and Fuse

To avoid shock, injury, or damage to the Meter:

• Remove test leads from the Meter before opening the case or battery door.

• Use ONLY a fuse with the amperage, interrupt voltage, and speed ratings

specified.

VoltAler t

TRUE RMS MULTIMETER

117

<.5

Lo / H

HOLD MINMAX RANGE

Hz

AUTO-V

OFF

LoZ

V

V

mV

Volt

Alert

A

Hz

A

COMVA

10 A

FUSED

Figure 1. Fuse Testing

XWWarning

OK

OK

erc010f.emf

Battery

Fuse

Figure 2. Battery and Fuse Replacement

To remove the battery door for battery replacement, refer to Figure 2 while performing the following:

1. Remove the test leads from the Meter.

2. Remove the battery door screw.

3. Use the finger recess to lift the door slightly.

4. Lift the door straight up to separate it from the case.

5. The battery fits inside the battery door, which is then inserted into the case, bottom edge first, until it is

fully seated. Do not attempt to install the battery directly into the case.

6. Install and tighten battery door screw.

To open the case for fuse replacement, refer to Figure 2 while performing the following:

1. Remove the test leads from the Meter.

erc011f.emf

6

Page 7

Digital Multimeters

Performance Tests

2. Remove the Meter from its holster.

3. Remove two screws from the case bottom.

4. Separate the case bottom from the case top.

5. Remove the fuse from its holder and replace with an 11 A, 1000 V, FAST fuse having a minimum

interrupt rating of 17,000 A. Use only Fluke PN 803293.

6. To re-assemble the Meter, attach the case bottom to the case top and secure with the two screws. Insert

the Meter into its holster.

Cleaning the Meter

Wipe the case with a damp cloth and mild detergent. Do not use abrasives or solvents. Dirt or moisture in the

terminals can affect readings.

Performance Tests

XWWarning

To avoid electric shock, do not perform the performance test procedures unless

the Meter is fully assembled.

The following performance tests verify the complete operation of the Meter and check the accuracy of each Meter

function against its specifications. The recommended calibration interval is 12 months. If the Meter fails any part of

the test, calibration adjustment and/or repair is indicated.

In the performance tests, the Meter is referred to as the unit under test (UUT).

Required Equipment

Table 2 lists the equipment required to conduct a performance test on the Meter.

Table 2. Required Equipment

Recommended Equipment Measurement Function Accuracy

5500A Multi-product Calibrator (or

equivalent)

DC Volts 10 mV to 600 V

±0.125 %

DC Current (115, 116, and 117) 600 μA to 10 A

±0.25 %

AC Volts 6 mV to 600 V

±0.25 % @ 45 Hz to 1 kHz

AC Current (115, 116, and 117) 600 μA to 10 A

±0.375 % @ 45 Hz to 1 kHz

Resistance 0 to 5 MΩ

±0.225 %

10 to 30 MΩ

±0.375 %

Capacitance (115, 116, and 117) 9 to 900 μF

±0.475 %

Temperature (116) 0 °C to 400 °C ±0.25 %

7

Page 8

114, 115, 116, and 117

Calibration Information

Recommended Equipment Measurement Function Accuracy

Table 2. Required Equipment (cont)

5500A Multi-product Calibrator (or

equivalent)

Fluke 80 AK

K-type Thermocouple Adapter Accessory

K-type Thermocouple, mini-plug on both

ends

Double Banana plug VoltAlert (117)

Frequency (115, 116, and 117) 2 V, 50 kHz

±0.025 %

Temperature (116)

Temperature (116)

Testing the Display

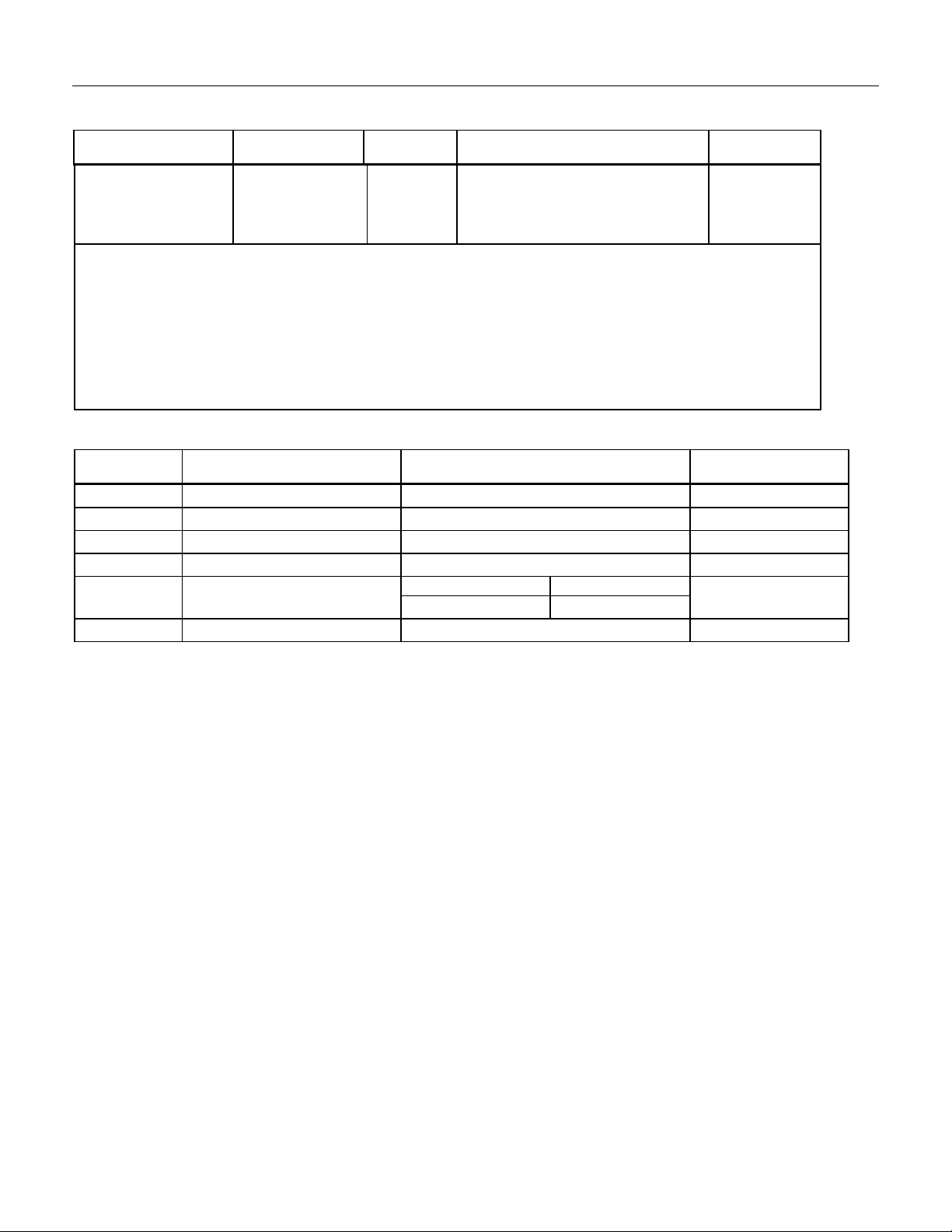

Push K and turn the rotary switch to the e position. Compare the display with the example in Figure 3.

Check all segments for clarity and contrast.

Figure 3. Display Segments

Backlight Test

To Test the Backlight, press the Q button and verify that the backlight comes on.

Keypad Test

To test the keypad, turn the Meter to ACV and push each button separately. Each button push should cause the

Meter to beep and activate a display annunciator.

Reset the Meter by turning it Off and then back to an On position.

Preparing for the Performance Tests

XWWarning

To avoid possible electric shock or personal injury:

• Do not perform the following procedures unless qualified to do so. Some

procedures involve the use of high voltages.

• Before handling the test connections and in between tests, make sure

the calibrator is in standby mode (STBY).

erc022f.emf

To prepare for the performance test:

1. Make sure that you have the required equipment (refer to Table 2).

8

Page 9

Digital Multimeters

Performance Tests

2. Warm up the calibrator as required by its specifications.

3. Allow the temperature of the UUT to stabilize at room temperature (23 °C ± 5 °C [73 °F ± 9 °F] ).

4. Check the fuses and Battery, and replace them if necessary. Refer to “Testing the Fuses”, and

“Replacing the Battery and Fuse”.

To verify the accuracy of the DMM functions, do the following:

1. Connect the Calibrator to the VΩ and COM input terminals on the Meter.

2. Turn the rotary switch to the function listed in each step of Table 3.

3. Apply the input level for each step listed in Table 3.

4. Compare the reading on the Meter display with the Display Reading in Table 3.

5. If the display reading falls outside of the range shown in Table 3, the Meter requires calibration

adjustment or repair.

Testing Temperature (116 only)

Connect the K-type thermocouple to the temperature input of the Meter and temperature calibrator. To ensure an

accurate measurement, the Meter and the thermocouple connector must be at the same temperature. After connecting

the thermocouple to the Meter, allow the junctions to stabilize before recording the displayed reading. This can take

several minutes, depending on temperature gradients.

Table 3. DMM Performance Tests

Step Function Range Applied

1 600.0 0.0 Ω 0.0 to 0.2

2 600.0 500 Ω 495.3 to 504.7

3 6.000 k 5 kΩ 4.954 to 5.046

4 60.00 k 50 kΩ 49.54 to 50.46

5 600.0 k 500 kΩ 495.4 to 504.6

6 6.000 M 5 MΩ 4.954 to 5.046

7 40.00 M 10 MΩ 9.83 to 10.17

8

9 600 Ω 20 Ω Beeper On

10

11 6.000 V 5V, 45 Hz 4.947 to 5.053

12 6.000 V 5V, 1 kHz 4.897 to 5.103

13 60.00 V 50 V, 45 Hz 49.47 to 50.53

e

Ohms

R

Continuity

K

AC Volts

40.00 M 30 MΩ 29.53 to 30.4

600 Ω 250 Ω Beeper Off

[1]

114

115

Display Reading

[1]

116

7

[1]

117

[1]

14 60.00 V 50V, 1 kHz 48.97 to 51.03

15 600.0 V 600V, 45 Hz 593.7 to 606.3

16

17

e

AC Volts + Hz

600.0 V 600V, 1kHz 587.7 to 612.3

6.000V 2 v, 45 kHz

[1]

NA 49.93 to 50.07

9

Page 10

114, 115, 116, and 117

Calibration Information

Table 3. DMM Performance Tests (cont)

Step Function Range Applied

18 6.000V 0V -0.002 to 0.002

19 6.000V 5V 4.973 to 5.027

20 60.00V 50V 49.73 to 50.27

21 600.0V 600V 596.8 to 603.2

22

23 600.0 mV 6 mV, 45 Hz 5.6 to 6.4

24

25 600.0 mV 10 mV 9.7 to 10.3

26

27 G Diode 2.000 V 1.9V

28 1000 nF Open

29

30 LoZ

L

DC Volts

m

AC Millivolts

•

DC Millivolts

E

Capacitance

Capacitance

600.0V -600V -596.8 to -603.2

600.0 mV 600mV, 1 kHz 587.7 to 612.3

600.0 mV 600mV 596.8 to 603.2

9999 μF 900 μF N/A 881 to 919 881 to 919 881 to 919

10.00 μF 9 μF N/A 7.18 to 10.82

[1]

114

115

N/A 1.881 to 1.919

N/A 0 to 2 0 to 2 0 to 2

Display Reading

[1]

116

[1]

117

[1]

Set calibrator to standby, reconfigure leads, and program for amps output

31 A

DC Amps

32 ?

AC Amps

33 $

DC μamps

34 $

AC μamps

35 Open input N/A N/A 0PEn N/A

36 0.0 °C N/A N/A -1.0 to 1.0 N/A

37

38 0.5 V, 45 Hz 0.2 to 0.8,

39 0.5 V, 0 Hz 0.2 to 0.8,

40

y

Temperature

x

10.00 A 10A N/A

6.000 A 5.0A, 45 Hz N/A

600.0 μA 600 μADC N/A N/A

600.0 μA 600 μAAC, 45 Hz N/A N/A

500 V

400 °C N/A N/A

AC

Annunciator

On

DC

Annunciator

On

[2]

,

500 Hz

489.7 to

510.3

9.87 to

10.13

4.922 to

5.078

N/A

N/A

N/A

N/A

N/A

593.8 to

606.2

590.7 to

609.3

395.0 to

405.0

0.2 to 0.8,

AC

Annunciator

On

0.2 to 0.8,

DC

Annunciator

On

489.7 to

510.3

9.87 to

10.13

4.922 to

5.078

N/A

N/A

N/A

0.2 to 0.8,

AC

Annunciator

On

0.2 to 0.8,

DC

Annunciator

On

489.7 to

510.3

10

Page 11

Digital Multimeters

Performance Tests

Table 3. DMM Performance Tests (cont)

Step Function Range Applied

41 VoltAlert Hi

42 VoltAlert Lo

[1] If using a Fluke 9100 calibrator, the Calibrator Frequency mode must be used to obtain accurate frequency.

[2] To keep from tripping the calibrator to standby, ramp up the voltage in 50 V increments with a 5 second delay between

increments.

[1]

114

115

N/A N/A N/A

N/A N/A N/A

Display Reading

[1]

116

[1]

117

Refer to

steps 1 – 5

procedure

Refer to

steps 6 – 9

procedure

[1]

in the

below

in the

below

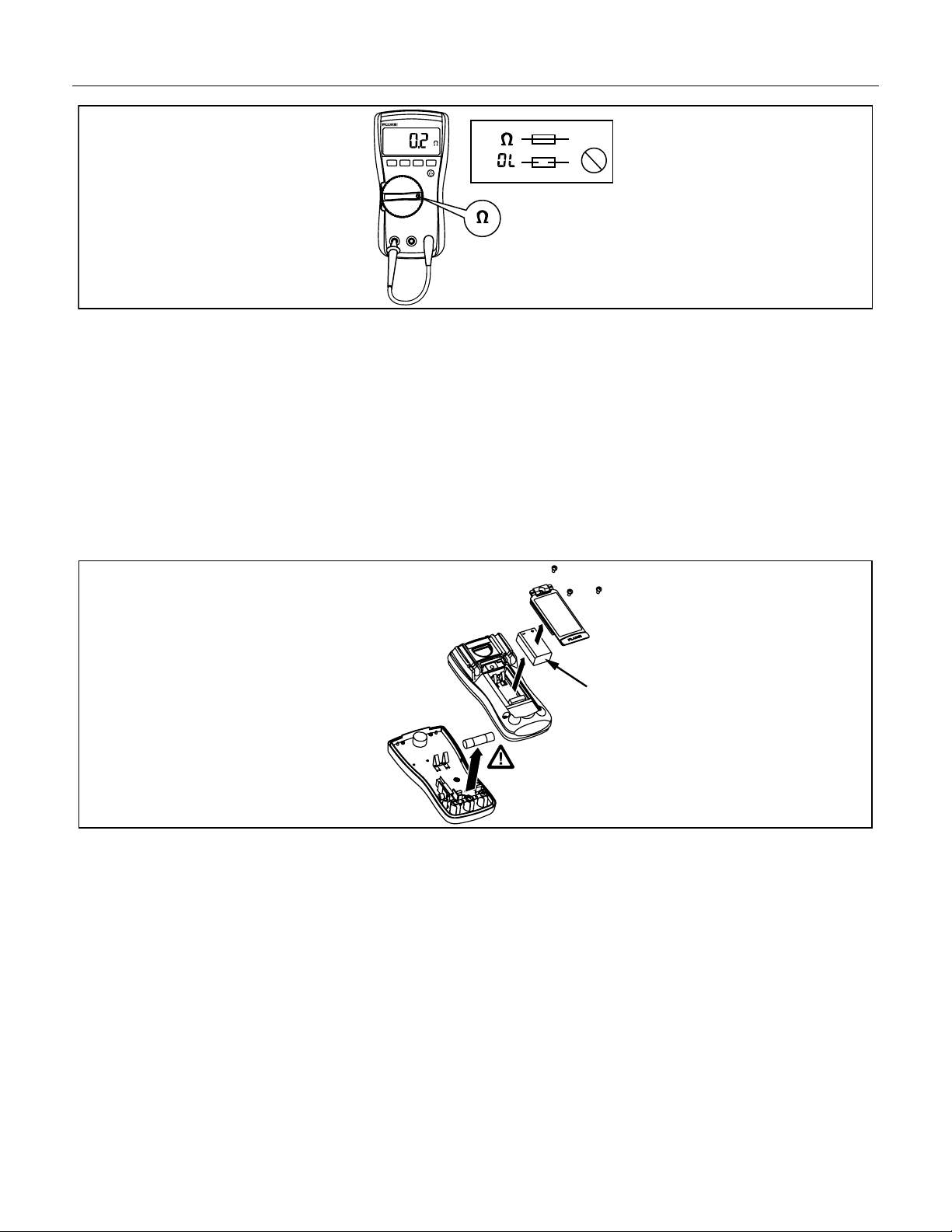

Testing the VoltAlert Function (117 only)

Use the following procedure to verify that VoltAlert functions properly.

Note

• Ensure the instrument is REMOVED from the holster prior to performing the test.

• Keep the meter away from electrical noise sources during the tests, i.e., florescent

lights, dimmable lights, motors, etc.. These sources can trigger VoltAlert and

invalidate the test.

• It may be necessary in steps 4 and 8 below to slightly adjust the Meter’s position for

maximum signal strength, in order to get the Meter’s beeper to sound continuously.

Refer to Figure 4 while performing the following steps.

1. Select the VoltAlert function, and verify that “Hi” is on the display. Verify that the beeper is silent and

the red LED is off.

2. Connect a double banana plug to the output voltage terminals of the calibrator (Fluke 5500A or

equivalent).

3. Set the calibrator output to 10 V at 60 Hz.

4. Hold the Meter so that the Meter’s top is vertically and horizontally centered and contacting the banana

plug’s Hi terminal. Verify that the Meter’s beeper is on continuously, and the red LED, at the top of the

display, lights up.

5. Place the calibrator in standby mode and verify that the beeper is now silent and the red LED is off.

6. Press the q(display should indicate ‘Lo’ range).

7. Set the calibrator’s output to 30 V at 60 Hz.

11

Page 12

114, 115, 116, and 117

Calibration Information

N

O

R

M

A

L

A

U

V

R

X

T

D

A

S

E

N

S

S

E

C

A

U

O

X

P

V

E

O

U

T

S

T

B

Y

T

R

I

G

7

8

4

5

.

2

+

/

0

.

1

V

1

o

7

l

t

A

T

l

e

R

r

U

t

E

R

M

S

M

U

L

T

I

M

E

T

E

R

Insert Double Banana

Center Meter top on Hi terminal.

Note that LED is RED

Figure 4. VoltAlert Testing

8. Hold the Meter so that the top is vertically and horizontal centered to the banana plug’s Hi terminal.

Verify that the Meter’s beeper is sounding continuously and the red LED at the top of the display lights.

9. Return the calibrator to standby mode and verify the Meter’s beeper is silent and the red LED is off.

Calibration Adjustment

The Meter features closed-case calibration adjustment using known reference sources. The Meter measures the

applied reference source, calculates correction factors, and stores the correction factors in nonvolatile memory.

The following sections present the features and Meter pushbutton functions available during the Calibration

Adjustment Procedure. Should the Meter fail any of the performance tests, perform the Calibration Adjustment

Procedure.

Use the following steps to view the Meter’s calibration counter.

1. While pressing K, turn the rotary switch from OFF to Ω function. The Meter should display

“ZCAL”.

2. Press g once to view the calibration counter. For example, “n001”

erc013f.emf

3. Turn the rotary switch to OFF.

Calibration Adjustment Password

To start the Calibration Adjustment Procedure, the correct 4-digit password must be entered. The default password is

“1234”. The password can be changed or reset to the default as described in following paragraphs.

Changing the Password

Use the following steps to change the Meter’s password:

1. While pressing K, turn the rotary switch from OFF to Ω function. The Meter should display

“ZCAL”.

12

Page 13

Digital Multimeters

Calibration Adjustment

2. Press g once to see the calibration counter.

3. Press g again to start the password entry. The Meter displays “?>>>”

4. The Meter buttons indicated below represent the numbers 1 through 5 when entering or changing the

password:

K = 1 M = 2 q = 3 g = 4 Q = 5

5. Press 4 buttons to enter the current password. If changing the password for the first time, enter

K (1), M (2), q (3), and g (4).

6. Press qto change the password. The Meter displays “////” if the entered password is correct. If the

password is not correct, the Meter emits a double beep, displays “?>>>”, and the password must be

entered again. Repeat step 5.

7. Press the 4 buttons of the new password.

8. Press g to store the new password.

Restoring the Default Password

If the calibration password is forgotten, the default password (1234) can be manually restored using the following

steps:

XW Warning

To avoid electric shock or personal injury, remove the test leads and any input

signal before removing the Meter’s back case.

1. Remove the Meter’s back case. Leave the pca in the top case.

2. Apply 9.0V across the battery contacts (XBT1) + and (XBT2) – on the back of the PCA. See Figure 5.

3. Turn the rotary switch from OFF to any on position.

4. Short across the S7 CAL keypad on the back of the PCA. See Figure 5. The Meter should beep. The

default password is now restored.

5. Remove the 9.0V supply and replace the Meter’s back case.

Short S7 to reset to Default password XBT1

Figure 5. Calibration Password Reset

13

erc12f.emf

Page 14

114, 115, 116, and 117

Calibration Information

Meter Buttons Used in the Calibration Steps

When performing the Calibration Adjustment Procedure, the Meter buttons behave as follows. This may be of help

determining why a calibration step is not accepted and for determining the input value without referring to Table 4.

Press and hold K to show the measured value. The measured value is not calibrated so it may not match the

input value. This is normal.

Press and hold M to display the required input value.

Press g to store the calibration value and advance to the next step. This button is also used to exit calibration

mode after the calibration adjustment sequence is complete.

Press Q to toggle the backlight on and off.

Calibration Adjustment Procedure

To adjust the Meter’s calibration, use the following steps. If the Meter is turned off before completion of the

adjustment procedure, the calibration constants are not changed.

1. While holding down K, turn the rotary switch from OFF to Ω function. The Meter should display

“ZCAL”.

2. Press g once to see the calibration counter.

3. Press g again to start the password entry. The Meter displays “?>>>”.

4. Press the 4 button password.

5. Press g to go to the first calibration step. The Meter displays “C/01” if the password is correct. If the

password is not correct, the Meter emits a double beep, displays “?>>>” and the password must be

entered again. Repeat step 4.

6. Apply the input value listed for each calibration adjustment step. For each step, select the rotary switch

position and apply the input to the terminals as indicated in the Table 4.

Note

Some adjustment steps require additional wait time after the calibrator settles, as noted in

Table 4.

7. After each input value is applied, press g to accept the value and proceed to the next step (C/02 and

so forth).

Notes

After pressing g, wait until the step number advances before changing the calibrator

source or turning the Meter’s rotary knob. Some adjustment steps can take up to several

seconds to execute before moving to the next step.

If the knob is not in the correct position for a given step, the meter will flash the unit

annunciators until the knob is put in a valid position. The keys that show the reading and

required input values are not allowed until the knob is correct.

Likewise, if the rotary switch is not in the correct position or the measured value is not within

the anticipated range of the input value, the Meter will emit a double beep and will not

continue to the next step when g is pressed.

14

8. After the final step, the display shows “End” to indicate that the calibration adjustment is complete.

Press g to return to meter mode.

Page 15

Digital Multimeters

Calibration Adjustment

Notes

Set the calibrator to Standby prior to changing the function switch position and after

completing adjustment of each function.

If the calibration adjustment procedure is not properly completed, the Meter will not operate

correctly.

Table 4. Calibration Adjustment Steps

Position

e

Ohms

m

e

Ohms

Rotary

Switch

Calibration Steps

114 115

N/A C/01 C/01 C/01

C/01 C/02 C/02 C/02 VΩ/+ and COM 0 V, 0 Hz

C/02 C/03 C/03 C/03 VΩ/+ and COM 300 mV, 0 Hz

C/03 C/04 C/04 C/04 VΩ/+ and COM 100 mV, 0 Hz

C/04 C/05 C/05 C/05 VΩ/+ and COM -300 mV, 0 Hz

C/05 C/06 C/06 C/06 VΩ/+ and COM 60 mV, 0 Hz

C/06 C/07 C/07 C/07 VΩ/+ and COM 600 mV, 0 Hz

C/07 C/08 C/08 C/08 VΩ/+ and COM 600 mV, 60 Hz

C/08 C/09 C/09 C/09 VΩ/+ and COM 600 e, 2-wire comp

C/09 C/10 C/10 C/10 VΩ/+ and COM 6 ke

C/10 C/11 C/11 C/11 VΩ/+ and COM 60 ke

C/11 C/12 C/12 C/12 VΩ/+ and COM 600 ke

C/12 C/13 C/13 C/13 VΩ/+ and COM 6 Me

C/13 C/14 C/14 C/14 VΩ/+ and COM Short

C/14 C/15 C/15 C/15 VΩ/+ and COM 40 Me

[1]

116

[1]

117

[1,2]

[2]

No leads No leads

Input

Terminals

Calibrator

Source Value

[3]

[3]

[3]

K

? N/A C/22 N/A C/22 A and COM 6 A, 60 Hz

C/15 C/16 C/16 C/16 VΩ/+ and COM 6 V, 60 Hz

C/16 C/17 C/17 C/17 VΩ/+ and COM 60 V, 60 Hz

C/17 C/18 C/18 C/18 VΩ/+ and COM 600 V, 60 Hz

C/18 C/19 C/19 C/19 VΩ/+ and COM 6 V, 0 Hz

C/19 C/20 C/20 C/20 VΩ/+ and COM 60 V, 0 Hz

C/20 C/21 C/21 C/21 VΩ/+ and COM 600 V, 0 Hz

Set calibrator to standby, reconfigure leads, and program for amps output.

[3]

A N/A C/23 N/A C/23 A and COM 6 A, 0 Hz

$

AC μamps

15

N/A N/A C/22 N/A + and COM 600 μA, 60 Hz

Page 16

114, 115, 116, and 117

Calibration Information

Table 4. Calibration Adjustment Steps (cont)

Rotary

Switch

Position

$

114 115

N/A N/A C/23 N/A + and COM 600 μA, 0 Hz

Calibration Steps

[1]

116

[1]

117

[1,2]

Input

Terminals

Source Value

DC μamps

[1] Models listed in this column also refer to the “C” version of the model. For example, model 115 steps are valid for the 115C.

[2] Do not calibrate the 117 or 117C with a line-frequency power source nearby (e.g. fluorescent light, power strip, etc.). These devices

can produce errors in the VoltAlert calibration.

[3] Wait an additional 5 seconds after calibrator has settled before pressing g.

Calibrator

16

Page 17

Digital Multimeters

Replacement Parts

Replacement Parts

Table 5 lists the Meter’s replacable parts identified in Figure 6.

6

5

8

12

9

10

7

23

16

17

2 PL

20

3

1

4

2

11

15 4 PL

13

19

14

18

21

22

erc14.emf

Figure 6. Exploded View of Meter

17

Page 18

114, 115, 116, and 117

Calibration Information

Table 5. Replacable Parts List

Item Description

1 LCD,FLUKE-11X,3.2V,TN,4-DIGIT,1/4-DUTY,1/3-BIAS,LEPTON 2509955 1

2 CONNECTOR,ELASTOMERIC,.010 IN CTR,.218 IN HIGH,.090 IN

THK,2.284 IN LONG,BULK 2534229

3

4 FLUKE-117-8005,DIFFUSER, BACKLIGHT 2535203 1

5

FLUKE-117-2006,BRACKET MASK, 117 2525608 1

FLUKE-117-2006-06,BRACKET MASK, 117 China 2631059 1

FLUKE-117-2006-01,BRACKET MASK, 114 2527431 1

FLUKE-117-2006-02,BRACKET MASK, 115 2527446 1

FLUKE-117-2006-04,BRACKET MASK, 115 China 2631032 1

FLUKE-117-2006-03,BRACKET MASK, 116 2527454 1

FLUKE-117-2006-05,BRACKET MASK, 116 China 2631044 1

FLUKE-117-2001,CASE TOP, 117 2525553 1

FLUKE-117-2001-01,CASE TOP, 114 2527405 1

FLUKE-117-2001-02,CASE TOP, 115 2527410 1

FLUKE-117-2001-03,CASE TOP, 116 2527422 1

Part

Number

Qty.

1

6 FLUKE-117-2008,KNOB 2525624 1

7 FLUKE-117-7602,RSOB HOUSING ASSEMBLY 2787083 1

8 FLUKE-117-8001,KEYPAD 2526276 1

9 FLUKE-117-2009,SPRING DETENT 2525636 1

10 FLUKE-117-8009,SHIELD, TOP 2571277 1

11 FLUKE-117-8010,IC SHIELD 2571292 1

12 O-RING,NITRILE,SHORE A 70,15.6MM OD,12.0MM ID ,1.8MM W 2535215 1

FLUKE-117-2002,CASE BOTTOM 2525566 1 13

FLUKE-117-2002,CASE BOTTOM, 11X China 2631098 1

FLUKE-117-2003,BATTERY DOOR 2525575 1 14

FLUKE-117-2003,BATTERY DOOR, 11X China 2631067 1

15 SCREW,2-28,.250,PAN,PHILLIPS,STEEL,ZINC-

CHROMATE,PLASTITE 48 THREAD FORMING 2516493

16

17 SCREW,5-14,.750,PAN,PHILLIPS,STEEL,BLACK

SCREW,M3,4MM,PAN,PHILLIPS,STEEL,ZINC-CHROMATE

CHROMATE,THD FORMING 832246

2032811

4

2 (114, 116)

3 (115, 117)

2

18 SCREW,M3X0.5,6MM,PAN,PHILLIPS,STEEL,ZINC-BLACK

CHROMATE 2032792

18

1

Page 19

Digital Multimeters

Warranty

Table 5. Replaceable Parts List

Item Description

19 BATTERY,PRIMARY,MNO2-

ZN,9V,505MAH,6LR61,ALKALINE, 17X26X48MM,BULK

20 FLUKE 12-8004,SHOCK ABSORBER 878983 1

FLUKE-117-2005,TILT STAND 2525594 1 21

FLUKE-117-2005,TILT STAND, 11X China 2631071 1

FLUKE-117-2010,HOLSTER 2525649 1 22

FLUKE-117-2010,HOLSTER, 11X China 2631080 1

23 FUSE,11A,1000V,FAST.406INX1.5IN,BULK 803293 1 (115, 117)

Not shown MANUAL,114/115/117 USERS MANUAL, EFSPAsia 2538674 1

Not shown MANUAL,114/115/117 USERS MANUAL, EFG(Eur) 2572573 1

Not shown MANUAL,115C/117C USERS MANUAL 2538695 1

Not shown MANUAL,116 USERS MANUAL, EFSPAsia 2538688 1

Not shown MANUAL,116 USERS MANUAL, EFG(Eur) 2572586 1

Not shown MANUAL,116C USERS MANUAL 2538707 1

614487

Part

Number

Qty.

1

Warranty

This Fluke product will be free from defects in material and workmanship for three years from the date of purchase. This warranty

does not cover fuses, disposable batteries, or damage from accident, neglect, misuse, alteration, contamination, or abnormal

conditions of operation or handling. Resellers are not authorized to extend any other warranty on Fluke’s behalf. To obtain service

during the warranty period, contact your nearest Fluke authorized service center to obtain return authorization information, then

send the product to that Service Center with a description of the problem.

THIS WARRANTY IS YOUR ONLY REMEDY. NO OTHER WARRANTIES, SUCH AS FITNESS FOR A PARTICULAR

PURPOSE, ARE EXPRESSED OR IMPLIED. FLUKE IS NOT LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OR LOSSES, ARISING FROM ANY CAUSE OR THEORY. Since some states or countries do

not allow the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of liability may

not apply to you.

Fluke Corporation

P.O. Box 9090

Everett, WA 98206-9090

U.S.A.

11/99

Fluke Europe B.V.

P.O. Box 1186

5602 BD Eindhoven

The Netherlands

19

Page 20

114, 115, 116, and 117

Calibration Information

20

Loading...

Loading...