Fluke 113 Service Guide

Revenue meter

socket checks using

the new Fluke 113

Utility Multimeter

All utilities generally require that revenue

self-contained meter sockets be checked

and tested for proper wiring and no backfeed conditions. These checks happen

before setting a meter in place and supplying utility power to the facility. This is also

true when re-connecting a meter after a

service termination or disconnect.

This application note describes the

procedure for testing a meter socket with

the Fluke 113 Utility Multimeter before

setting or re-connecting a revenue meter

to utility power.

Application Note

About the Fluke 113 Utility Multimeter

Testing revenue meter sockets, for sets or

re-connects, became easier when Fluke released

the 113 Utility Multimeter. The Fluke 113 offers

several advantages for revenue socket tests over

standard high impedance multimeters or testers.

1. VCHEK

2. Low impedance input

3. Ease of Use

4. CAT IV 300 V/CAT III 600 V safety rating

VCHEK combines a continuity test and a volt-

age measurement on a single switch position. The

meter automatically determines and displays what

is being measured. This eliminates the guesswork

and allows the meter technician to quickly determine whether continuity or voltage is present

without changing switch positions or pressing any

buttons.

The Fluke 113 also incorporates a low impedance

input, which acts as a load for the socket tests,

in cases where ghost voltages may be present.

This combination makes ease of use a key factor

in selecting and using the Fluke 113 for all meter

socket checks.

™

Measurement function

Measuring load side to neutral.

From the Fluke Digital Library @ www.fluke.com/library

Meter socket test procedure

The sample test procedure in this application note

uses a self contained 120 V/240 V single phase

three wire socket. A similar test methodology

would be utilized for other commercial and industrial socket checks, with the only difference being

the line side voltage readings for the different

socket configurations.

Setup recommendations:

• Complete a thorough visual inspection of the

meter socket and its surroundings. Look for

improperly mounted enclosures, exposed weatherheads, frayed conductors, discolored socket

contacts, and so forth.

Do not begin meter socket tests until all

visible external defects are corrected.

• If the socket has a bypass handle, do not raise

the handle until the meter socket has been

completely checked out.

• Use appropriate PPE (Personal protective equip-

Line 1 Line 2

Load 1 Load 2

Neutral

Line side –

from transformer

Load side –

to customer

ment) for ALL checks. While your employer

or utility may have different guidelines, this

equipment generally consists of, but may not be

limited to, the following items:

• Hard hat

• Safety glasses

• Rubber gloves with approved protectors

(600 V)

• Flame retardant (FR) clothing

• 100 % natural fiber clothing

• Safety toe shoes

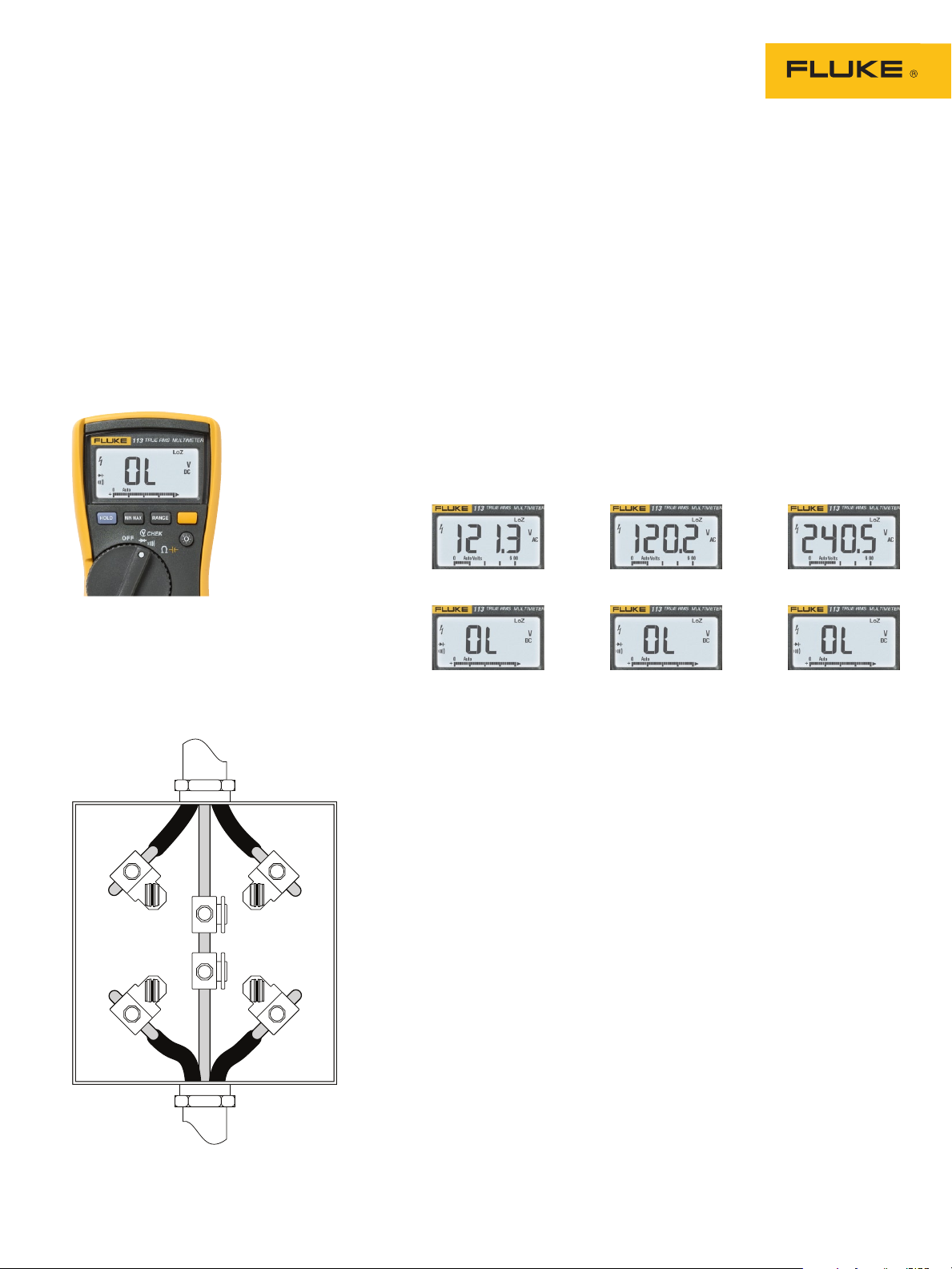

Before beginning the socket checks, switch the

Fluke 113 to the VCHEK position. The meter display

looks like this.

First and foremost: Work safe

To begin the tests, first insure that your test leads

and meter are in good working order.

Check the leads and probes for any physical or

visual damage. Do not use and replace if damage is

apparent or visible.

Short the test probes together. This checks and

tests for continuity of the leads. An audible tone

will also be heard if the leads are OK.

Measure a known live voltage source. In this

case, test #1 below accomplishes this.

Then, for this example and this type of installation, there are six tests to be performed.

Always make line side measurements first. This

insures utility power is present and connected and

that your test meter is working correctly before

doing the load side checks. Also make sure the load

side breaker is OFF.

Make the tests in the following order, and look for

results similar to those shown below:

The Fluke 113 is now ready to make either a

continuity test, diode check, or voltage measurement. All three tests are automatic. The meter will

determine the correct measurement.

Below is a diagram of a typical self-contained

120 V/240 V 3 wire meter socket.

1. Line 1 to Neutral.

4. Load 1 to Neutral.

2. Line 2 to Neutral.

5. Load 2 to Neutral.

3. Line 1 to Line 2.

6. Load 1 to Load 2.

Do not set or re-connect the meter if the load side

readings are not as indicated above.

The “OL” indication on the meter display indicates

no continuity or an open circuit condition when

checking the load side of the meter socket. This is

the expected result. Do not set the meter or operate

a bypass handle if there is a reading other than

“OL” indicated during steps 4 through 6. A reading

means:

1. There may be a short circuit or fault on the load

side of the meter socket or service equipment.

2. There could be a back feed voltage present from

another source connected to the load side.

3. There could be a line to neutral wiring error on

the load side of the system.

If a foreign voltage or unexpected reading is

found during the load side tests, many utilities

require their personnel to “blank and seal” or

“boot” the socket at this point. The meter cannot be

set or re-connected until the load side problem is

corrected by the customer.

2 Fluke Corporation Revenue meter socket checks using the new Fluke 113 Utility Multimeter

Loading...

Loading...