Page 1

10100AT

TRIAD™ TnT Field Service Kit

August 2006

Manual No. 38651-1 Rev. 1

©2006 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Operators Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: General Information ...................................................................... 1-1

1.1 Introduction.................................................................................................. 1-1

1.2 Features....................................................................................................... 1-1

1.3 Manual Addenda.......................................................................................... 1-2

1.4 Before You Start – Safety Precautions ........................................................ 1-2

1.5 Safety Symbols and Terms.......................................................................... 1-2

1.6 Specifications............................................................................................... 1-3

1.7 Unpacking and Inspection............................................................................ 1-8

1.8 Getting Started............................................................................................. 1-9

Section 2: Operation..................................................................................... 2-1

2.1 Introduction.................................................................................................. 2-1

2.2 Front Panel Familiarization.......................................................................... 2-1

2.2.1 Control Buttons....................................................................................... 2-2

2.2.2 Display.................................................................................................... 2-3

2.3 Connector Familiarization............................................................................ 2-3

2.3.1 Ion Chamber Connector......................................................................... 2-4

2.3.2 kVp Divider Connectors.......................................................................... 2-4

2.4 Power-Up Self-Test and Display Messages................................................. 2-4

2.5 Using the Options Button............................................................................. 2-5

2.6 Basic Measurement Techniques.................................................................. 2-6

2.6.1 General Considerations.......................................................................... 2-6

2.6.2 Making Exposure Measurements........................................................... 2-9

2.6.3 Making Exposure Rate Measurements................................................... 2-9

2.6.4 Use of the Model 35050AT Dosimeter as a kVp Divider Readout........ 2-10

2.7 Simultaneous Measurement Mode............................................................ 2-13

2.7.1 Making Combined Exposure Rate and kVp Measurements ................. 2-13

2.7.2 Making Combined Exposure, kVp, and Time Measurements............... 2-13

2.7.2.1 Advanced Measurements Options .................................................. 2-14

2.7.2.2 Time Corrections............................................................................. 2-14

2.7.3 Making kVp and Time Measurements Without an Ion Chamber .......... 2-14

2.7.4 Making Exposure or Exposure Rate Measurements Without a Model

35080/80A/80B kVp Divider ................................................................. 2-15

2.7.4.1 Advanced Measurements Options .................................................. 2-15

2.8 Exclusive Measurement Mode................................................................... 2-16

2.9 Using the Ion Chamber Test Stand and Accessories ................................ 2-17

2.9.1 Using the Test Stand for Over-Table Tubes......................................... 2-18

2.9.2 Using the Test Stand for Under-Table Tubes....................................... 2-19

i

Page 4

2.9.3 Using the Test Stand for Horizontal X-ray Beams................................ 2-21

2.9.4 Using the Test Stand for Mammo kVp Measurements......................... 2-21

2.10 Using the Ion Chamber Cable Stem .......................................................... 2-22

2.11 Measurement Considerations.................................................................... 2-22

2.11.1 Using Other Ion Chambers................................................................... 2-22

2.11.2 Using Air Density Corrections............................................................... 2-22

2.11.3 Using Exposure/Frame Units................................................................ 2-23

2.11.4 Making Mammo kVp Measurements.................................................... 2-24

2.11.4.1 Cadmium k-edge Filter Pack Use.................................................... 2-24

2.11.4.2 Linear Filter Pack Use..................................................................... 2-25

Section 3: Theory of Operation ...................................................................... 3-1

3.1 Introduction.................................................................................................. 3-1

3.2 Overall Functional Description..................................................................... 3-1

3.3 Power Supply............................................................................................... 3-2

3.4 Front Panel Switches................................................................................... 3-3

3.5 Microcomputer............................................................................................. 3-3

3.6 Display......................................................................................................... 3-3

3.7 Serial Communications Port ........................................................................ 3-3

3.8 Multiplexer/A-D Converter............................................................................ 3-4

3.9 kVp Input Signal Buffer/Divider.................................................................... 3-4

3.10 Ion Chambers.............................................................................................. 3-4

3.10.1 Basic Theory .......................................................................................... 3-4

3.10.2 Air Density Corrections........................................................................... 3-5

3.11 Electrometer/HV Isolator/Ranging Amplifier................................................. 3-5

3.12 300 Volt Electronic Bias Supply................................................................... 3-6

3-13 Measurement Technique............................................................................. 3-6

3.13.1 High Sensitivity Dose.............................................................................. 3-6

3.13.2 High Sensitivity Rate .............................................................................. 3-7

3.13.2.1 Very Low Dose Rate ......................................................................... 3-7

3.13.3 kVp/Dose/Time....................................................................................... 3-7

3.13.4 kVp/Rate................................................................................................. 3-7

3.14 Temperature and Pressure Sensor.............................................................. 3-8

Section 4:

Maintenance................................................................................. 4-1

4.1 Introduction.................................................................................................. 4-1

4.2 Cleaning the Instrument............................................................................... 4-1

4.3 Battery Replacement ................................................................................... 4-1

4.4 Fuse Replacement....................................................................................... 4-2

4.5 Replaceable Parts Information..................................................................... 4-3

4.6 Temperature / Pressure Sensor Adjustment................................................ 4-3

4.7 Recalibration and Repair Information/Technical Assistance........................ 4-4

4.8 Warranty Information ................................................................................... 4-4

ii

Page 5

Appendix A: Model 35050AT Default Ion Chamber Selection Screens...................A-1

A.1 Introduction..................................................................................................A-1

A.2 Model 96020C (150 CC) Ion Chamber ........................................................A-1

A.3 Model 96035B (15 cc) Ion Chamber............................................................A-2

Appendix B: Model 96020C Ion Chamber Specifications......................................B-1

B.1 Introduction..................................................................................................B-1

B.2 Physical Specifications ................................................................................B-1

B.3 Electrical Specifications...............................................................................B-2

B.4 Radiological Specifications..........................................................................B-2

B.5 Calibration and Verification..........................................................................B-3

B.6 Energy Correction Factors...........................................................................B-5

B.6.1 Attenuated Beam (Behind the Phantom)................................................B-5

B.6.2 Unattenuated Beam (In Front of the Phantom).......................................B-7

Appendix C: Model 96035B Ion Chamber Specification .......................................C-1

C.1 Introduction..................................................................................................C-1

C.2 Physical Specifications ................................................................................C-1

C.3 Electrical Specifications...............................................................................C-2

C.4 Radiological Specifications..........................................................................C-2

C.5 Calibration and Verification..........................................................................C-4

C.6 Energy Correction Factors...........................................................................C-5

C.6.1 Diagnostic – Unattenuated Beam (In Front of the Phantom)..................C-5

C.6.2 Diagnostic – Attenuated Beam (Behind the Phantom)...........................C-7

C.6.3 Mammographic Beam Qualities .............................................................C-8

iii

Page 6

(Blank page)

Page 7

General Information

Introduction

1

Section 1

General Information

1.1 Introduction

The TRIAD Service Kit can be used for government compliance testing, troubleshooting, repair of

diagnostic x-ray equipment, installation and setup of new equipment, preventive maintenance,

radiographic quality assurance measurements, and measurements required for JCAHO accreditation.

The TRIAD Service Kit performs measurements on all modalities: mammographic, cine, dental,

radiographic, fluoroscopic, CT, and image intensifiers.

The Model 35050AT Dosimeter, as featured in the Model 10100AT TRIAD Field Service Kit, is both a

sensitive, full-function dosimeter and a digital display for the Models 35080/80A/80B Non-invasive kVp

Divider. It features a direct readout and simplified operator controls.

This manual contains all the information necessary for you to operate and service your Model 35050AT

Dosimeter/kVp/Time Readout and the Model 10100AT TRIAD Field Service Kit components. This

manual contains a description of usage of the Model 35080/80A/80B kVp Divider with the Model 35050AT

Dosimeter as its readout. The operator is referred to the Model 35080/80A/80B kVp Divider Instruction

Manual, though, for a complete coverage of specifications, general use, etc.

Some service kits may include a Model 35035 mA/mAs meter. The user is referred to its instruction

manual for details of operation, specifications, and servicing.

Information on customizing the Model 35050AT Dosimeter using the Customization Software is contained

in a separate manual (Model 35050A Customization Instruction Manual). Also, a separate Model 35050A

Programmer's Instruction Manual contains a description of the protocol and commands used to operate

the Model 35050AT Dosimeter via the RS-232 interface. The RS-232 interface also allows the user to

capture kV waveforms obtained during simultaneous use of the Model 35050AT Dosimeter and the Model

35080/80A/80B kVp Divider. Refer to these instruction manuals as needed.

1.2 Features

Simplified Controls – automatic or manual exposure reset, autoranging, automatic offset and drift

compensation, and automatic power down.

Battery or Line Current Operation - 6 AA alkaline batteries provide instrument power with an auto

power-down feature to extend battery life and a 300 V electronic ion chamber bias. An AC adapter is

provided which allows line current operation.

Direct Reading - readout in user-selected units: R, Gy, Sv, C/kg, A, C, /s, /min, /hr, /frame; pressure and

temperature corrected readings. Temperature and pressure corrections may be made automatically using

an internal temperature and pressure sensor or by manual entry.

Ion Chamber Flexibility - radiation units for any triaxial-BNC ion chamber with a known calibration factor,

including CT ion chambers.

High Sensitivity -image intensifier measurements at 0.1 mR and 5 mR/min resolutions.

kVp+Dose+Time - kVp, dose, and exposure time measurements when used with the Model

35080/80A/80B Non-Invasive kVp Divider. Exposure time may be displayed in seconds or pulses (for

single phase or pulsed outputs).

1-1

Page 8

10100AT

Operators Manual

RS-232 Interface - remote operation, waveform capture, digital calibration, custom display units,

customer specified ion chamber calibration factors, and Model 35080/80A/80B kVp Divider filter packs.

Self-Checking - the Model 35050AT Dosimeter and Model 35080/80A/80B kVp Divider battery voltage

level, bias voltage level, ion chamber/cable leakage, and hardware/software checks.

1.3 Manual Addenda

Any improvements or changes concerning the instrument or manual will be explained in an addenda

included with the manual. Be sure to note these changes and incorporate them into the manual.

1.4 Before You Start - Safety Precautions

This instrument is intended for use by qualified personnel who recognize radiation hazards associated

with use of x-ray equipment.

Always turn off unit prior to connecting or disconnecting ion chamber or triaxial cable. Failure to do so

could result in electrical shock or damage to the equipment.

Beyond the battery and fuse, this unit contains no operator serviceable parts. The operator should not

attempt to gain access beyond the battery access cover. High voltage is generated internally and may

remain on internal parts even after the batteries have been removed.

1.5 Safety Symbols and Terms

The following symbols and terms are found on the instrument and used in this manual.

The

located in the manual.

The

standard safety precautions to avoid personal contact with these voltages.

The heading used in this manual explains dangers that might result in personal injury or

death. Always read the associated information very carefully before performing the indicated procedure.

The heading used in this manual explains hazards that could damage the instrument.

Such damage may invalidate the warranty.

symbol on the instrument indicates that the user should refer to the operating instructions

symbol on the instrument shows that high voltage may be present on the terminal(s). Use

WARNING

CAUTION

1-2

Page 9

General Information

Specifications

1.6 Specifications

Exposure and Exposure Rate Accuracy

The basic accuracy of the Model 35050AT Dosimeter is ± 1% of reading ± 2 range resolution steps (see

Table 1-1) over the range of 18 to 28° C and ± 2% of reading ± 2 range resolution steps over the full

operating temperature range of 0 to 50° C. This accuracy is guaranteed for a period of 1 year and is

exclusive of all ion chamber effects. A 3% NIST traceable calibration is provided with each system and

includes the effects of the Model 35050AT Dosimeter, Model 96035B Ion Chamber, and Model 96020C

Ion Chamber.

Temperature and Pressure Accuracy

Temperature Accuracy: ± 2°C (3.6°F)

Pressure Accuracy: ± 5mm Hg

1

NOTE

The measured temperature is the internal

temperature of the Model 35050AT, TRIAD TnT

Dosimeter, which may not be the same

temperature as the Ion Chamber that is in use.

Adequate time must be allowed for the Dosimeter

and Ion Chamber to reach thermal equilibrium

before automatic temperature sensing is used.

At standard conditions of 22°C and 760mm Hg:

1°C ~ 0.36 % change in ADC

1 mm Hg ~ 0.13% change in ADC

1-3

Page 10

10100AT

Operators Manual

Electrometer Measurement Ranges

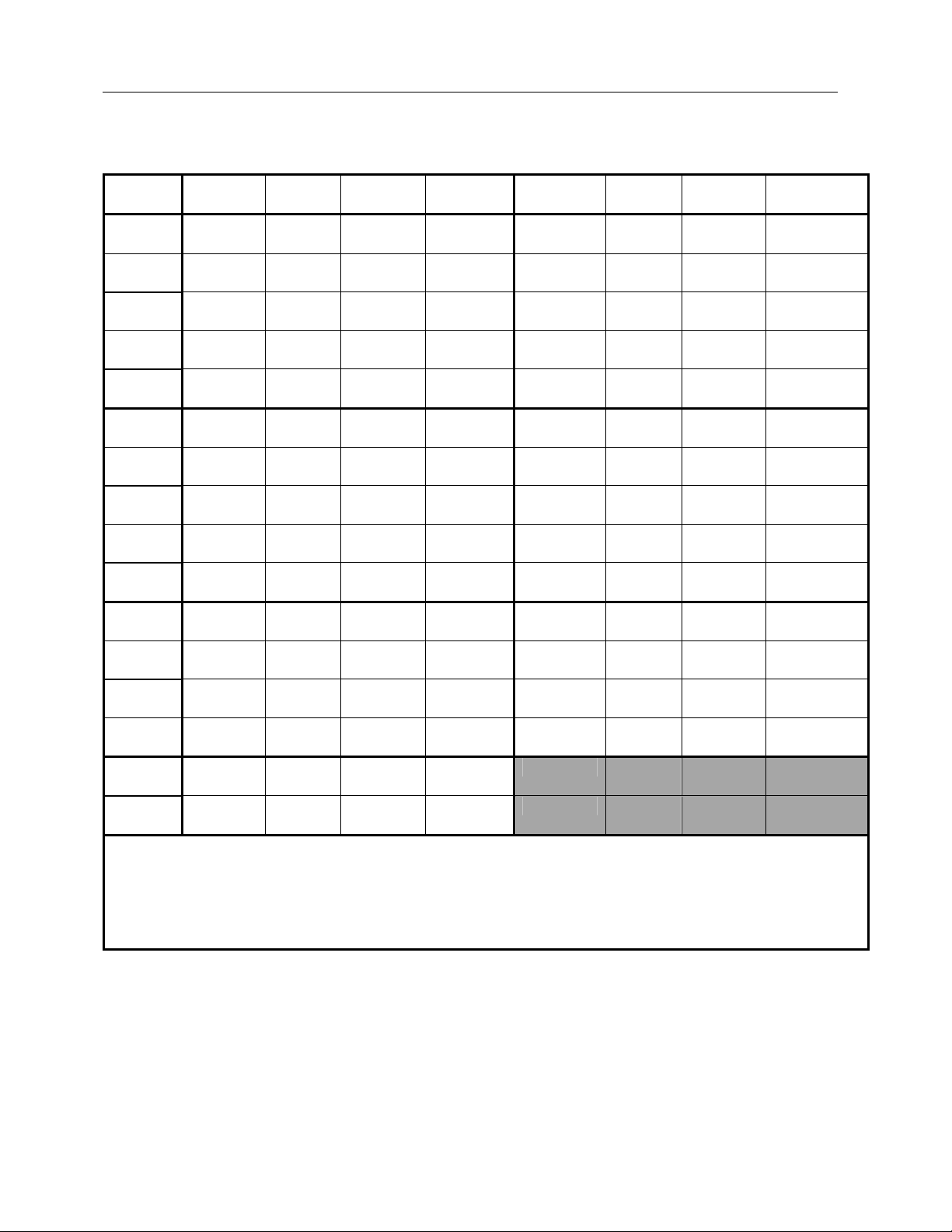

Table 1-1. Electrometer Measurement Ranges

Ion

Chamber

15 cc R 100 μ to

R/s 100 μ to

R/min 5 m to

R/hr 100 m to

R/frame** 2 μ to

150 cc R 10 μ to 2 6 μ 0.1 μ Gy 0.1 μ to

R/s 10 μ to 2 6 μ 0.1 μ Gy/s 0.1 μ to

R/min 0.5 m to

R/hr 10 m to

R/frame** 0.2 μ to

150 cc

VLDR

R/min 0.1 m to

R/hr 2 m to

R/frame** 0.04 μ to

Electrical

Units

A 1 p to

Values for ion chambers are calculated using nominal sensitivities:

15 cc: 2.4 x 10

150 cc: 2.4 x 10

* Very Low Dose Rate effective range at 5% resolution steps

** At 60 frames/s (1 to 120 frames/ selectable).

*** IEC 61674 effective range at 1% resolution steps

Units Effective

Range***

20

20

1200

72 k

333 m

120

7.2 k

33 m

R/s 2 μ to 2* N/A 0.1 μ Gy/s 0.02 μ to

120*

7.2 k*

33 m*

C 1 p to

100 n

100 n

8

R/C

7

R/C

Threshold Resolution

Step Size

60 μ

60 μ 1 μ Gy/s 1 μ to 0.2

3.6 m 50 μ Gy/min 50 μ to

216 m 1 m Gy/hr 1 m to

1μ 0.02 μ Gy/frame** 0.02 μ to

0.36 m 5 μ Gy/min 5 μ to 1.2 3.15 μ 0.05 μ

21.6 m 0.1 m Gy/hr 0.1 m to

0.1μ 0.002 μ Gy/frame** 0.002 μ

N/A 5 μ Gy/min 1 μ to

N/A 0.1 m Gy/hr 0.02 m to

N/A 0.002 μ Gy/frame** 0.4 n

0.5 pC 0.01 p

250 fA 0.01 p

1 μ Gy 1 μ to 0.2

Units

Effective

Range***

12

720

3.33m

0.02

0.02

72

to 0.33 m

0.02*

1.2*

72*

0.33 m*

Threshold Resolution

Step Size

.52 μ

.52 μ

31.5 μ

1.89 m

.008 μ

.052 μ 0.001 μ

.052 μ 0.001 μ

.189 m 0.001 m

0.8 n 0.02 n

N/A 0.001 μ

N/A 0.05 μ

N/A 0.001 m

N/A 0.02 n

0.01 μ

0.01 μ

0.5 μ

0.01 m

0.2 n

1-4

Page 11

General Information

Specifications

1

Measurement Modes

Dosimeter Operation Only: In use when the Model 35080/80A/80B kVp Divider is not connected or

turned on.

Full-sensitivity Exposure: Automatic drift and offset compensation, and automatic post-exposure

display hold are performed in this mode. Measurement range covers a span from low-level image

intensifier inputs to unattenuated direct beams. Autoranging over five decades. Display updates at the

end of each exposure. When the Automatic Reset option is enabled, exposure start and end detection

are based on the exposure rate level crossing a 0.25 pA threshold. When the Automatic Reset option is

disabled, exposure start detection is based on the exposure rate level crossing a 0.25 pA threshold but

the exposure measurement is only reset by pressing the Reset/Measure key.

Full-sensitivity Exposure Rate: Automatic offset compensation and nonlinear digital filtering are

performed in this mode. Autoranging provides five decades of sensitivity ranges. The measurement

range covers a span from low-level image intensifier inputs to unattenuated direct beams. Display

updates once per second. Differentiation between exposure on and off condition based on 0.25 pA

threshold.

Very Low Dose Rate (VLDR): This mode is only for making very low dose rate measurements. Nonlinear

digital filtering and autoranging provide five decades of sensitivity ranges. Display updates once per

second. In this mode, automatic current offset and drift compensation is disabled. As a result, the system

leakage (includes dosimeter, cable and ion chamber) is displayed and must be compensated for. This

option should only be used with ion chambers suitable for very low dose rate measurements.

Dosimeter with kVp and Time Readout Operation: In use when the Model 35080/80A/80B kVp Divider

is connected and a filter pack is selected from the Model 35050AT Dosimeter's front panel.

Tri-measurement Exposure: A single shot, direct beam measurement of exposure, kVp, and time.

Autoranging across three-decade ranges and auto reset between exposures. Display updates following

each exposure. Exposure start and stop based on detection of voltage from the Model 35080/80A/80B

kVp Divider in excess of minimum kV for selected pack. A measurement delay of up to 999 ms may be

used to skip over unwanted portions of an exposure. To prevent measurement of spurious signals, the

35050AT Dosimeter can be set to ignore exposures of less than 5ms.

Dual-measurement Exposure Rate: A simultaneous measurement of kVp and exposure rate. The

display updates once per second. Autoranging across three-decade ranges provide adequate sensitivity

for direct beam measurements. Display updates approximately once each second.

Customization

A customization program, contained on a compact disk, is included as part of a Model 10100AT TRIAD

Field Service Kit.

The customization program runs on any IBM-PC or compatible computer. A cable and adapters are also

furnished with the kit and provide means of interconnecting the computer's and the Model 35050AT

Dosimeter's serial communications ports.

The program allows the user to modify the contents of the Model 35050AT Dosimeter's non-volatile

memory, and thus determine a number of important operating parameters for the Model 35050AT

Dosimeter. These are listed below:

1. All electrical calibration factors

2. All unit, ion chamber, and kV filter pack descriptions and conversion factors

3. Temperature and pressure unit types for use with air density corrections:

In degrees Fahrenheit, Celsius and Kelvin

In inches of Hg, mm of Hg, milliBars, hectoPascal, feet relative to sea level, and meters relative to

sea level

1-5

Page 12

10100AT

Operators Manual

4. Number of minutes to auto power-down, from 1 to 255

5. Optional Power-On and Test screen messages

Display

The display is a two-line, 20-character alphanumeric PLED (polymer light emitting diode) display with an

approximate character height of 0.5 cm. The display shows all ion chamber/kV filter pack identification

information, numerical measurement results, and other information such as battery level and calibration

date.

Bias Voltage Supply

An electronic bias supply is fixed at a nominal 310 V. The bias voltage is removed from the triaxial input

connector at instrument turnoff. Internal low and high bias voltage test limits are set at 300 and 325 V

respectively.

Power

Continuous operational life of approximately thirty hours is provided by six “AA” alkaline batteries. Auto

power-down feature turns off unit after user-selected period (1-255 min) of unattended operation.

An AC adapter allows line current operation. When the AC adapter is in use, no current is drawn from the

batteries. When the AC adapter is in use, the auto power down feature is disabled, providing continuous

operation. The AC adapter is an unregulated 9v, 200 mA adapter with a center negative, 2 .1 mm plug.

Note: before auto turnoff, unit stores selections of ion chamber, units, and kVp filter pack in nonvolatile

memory. Eliminates manual reselection at next power-up. The default factory setting for the automatic

power-down feature is 15 minutes.

Control Buttons

Power On/Off: initiates power-up and -down sequences

Detector Select: selection of ion chambers, kV filter packs

Units Select: selects measurement units, frame rates

Reset/Measure: starts measurement, provides manual reset (auto reset function is also available in the

Model 35050AT Dosimeter)

Air Density: sets ambient temperature and pressure

Options: selects measurement options and displays diagnostic information such as supply level, ion

chamber leakage, bias voltage, and other diagnostic information

Up, Down: scrolls through list of screen selections, increments / decrements numeric entries. Holding

down the up or down key increases scroll speed.

1-6

Page 13

General Information

Specifications

1

Connections

Model 35080/80A/80B kVp Divider Interface: A coaxial-BNC connector used for measurement of kVp and

exposure time.

Computer Interface: RS-232-C Serial Port offers full duplex communication with XON/XOFF handshaking.

Connector is RJ-45 (female) with DCE configuration. Data format is 8 bits, no parity, and one stop bit.

Data rate is fixed at 9,600 baud. Interface provides full instrument control, calibration, and automation.

Ion Chamber Input: A triaxial-BNC input connector: collector and guard positive-biased relative to ion

chamber body/dosimeter chassis.

Power: 2.1mm DC Power Jack, power input for an unregulated 9v, 200 mA adapter with a center

negative, 2.1 mm plug.

Models 96035B, 96020C Diagnostic Ion Chambers

Energy Range:

96035B: 25 kVp to 150 kVp

96020C: 30 kVp to 150 kVp

Calibration: pair of ion chambers with NIST-traceable calibration and 3% system calibration with Model

35050AT Dosimeter. Ion chambers are calibrated for use at 22°C and 760 mm Hg. Real time

measurement or front panel selection of ambient temperature and pressure allow for corrected readings

at other conditions.

Nominal Sensitivity:

8

96035B: 2.35 x 10

radiography and mammography.

96020C: 2.1 x 10

measurements

Multiply values by 0.00876 to convert from R to Gy.

Construction:

96035B: Graphite-coated acrylic, parallel-plate, air-vented

96020C: Composite graphite-filled thermoplastic, parallel-plate, air-vented

Volumes:

96035B: --15 cc

96020C: --150 cc

R/C (2.06 x 106 Gy/C). Flat response is suitable for both conventional diagnostic

7

R/C (1.84 x 105 Gy/C), optimized for low-level image intensifier and cine

NOTE

See Appendix B and C in this instruction manual for

complete specifications on the Models 96020C and

96035B Ion Chambers.

Kit Accessories

Cable: (38208) 20 ft (6.1 m) Coax/Triax Cable

Test Stand: (37581) machined stainless steel upright rod with baseplate, ion chamber holder, Model

35080/80A/80B kVp Divider holder, and tray for HVL filters, which includes the ion chamber stem

(32147).

1-7

Page 14

10100AT

Operators Manual

Customization Kit: (37594) includes software on CD and a 6 ft (2 m) RS-232 interface cable with adapters

for PC- and AT-type computers.

Instruction Manuals: Model 10100AT TRIAD Field Service Kit Operator's Instruction Manual (38651).

HVL Filter Set: (37668) set of nine aluminum filters for half-value layer measurements: one -- 2 mm, two -

- 1 mm, two -- 0.5 mm, three -- 0.1 mm, and one -- 0.2 mm.

Kit Carrying Case: (37500D) high-density polyethylene (HDPE) plastic absorbs impact to protect contents.

Molded parallel ribs for strength. Corrosion-resistant hardware and locks. Custom-cut, high-quality foam

interiors surround and protect standard kit equipment and accessories. The case is gasketed to exclude

dust and moisture.

Environment

Operating: 0° to 50°C; relative humidity 20% - 80% non-condensing

Storage: -25° to 65°C

Kit Dimensions, Weight

Approximately 46 cm long x 33 cm wide x 15 cm deep (18 in x 13 in x 6 in); approximately 6.4 kg (14 lb).

kVp Measurement Accuracy and Method

The Model 35050AT Dosimeter will typically add an uncertainty of ± 2 mV to the voltage produced by the

Model 35080/80A/80B kVp Divider for a well behaved (quiet and constant) voltage waveform. The

accuracy of the peak detection method will be dependent upon both the shape of the kV waveform, and

the amount of noise present in the signal produced by the kVp divider. Based on sampling the output of

the kVp divider at a rate of 5 kHz, the peak voltage is determined by examining a 50 ms wide segment of

these samples. In selecting the data segment to be analyzed, a delay of one-tenth of the total exposure

time is inserted. When a measurement delay is used, this occurs after the measurement delay time

elapses or with the first rising edge after the delay time elapses. Before peak detection occurs, the signal

is passed through a digital filter with 1 ms time constant. The digital filter is not used with the Mobile filter

pack

Exposure Time Measurement Accuracy and Method

When seconds are selected as exposure time units, the exposure time accuracy is ± 0.1% of reading ±

0.2 ms. The measurement method is based on a kV threshold crossing. The threshold is set at 75% of

the kVp, or the minimum kVp for the filter pack in use, whichever is greater. The maximum exposure time

is six seconds and the measurement resolution is 0.2 ms.

When pulses are selected as exposure time units, the exposure time accuracy is ± 1 pulse. The

measurement method is based on a kV threshold crossing; pulses are counted by detecting each

passage through a threshold on the rising and falling edges each pulse in the output waveform.

When a negative measurement delay is specified, the TRIAD TnT Dosimeter does not include the delay

time in the measured exposure time. A negative measurement delay should be used in cases when x-ray

generator filament preheat pulses or other waveform anomalies should be excluded from kV and

exposure time measurements.

When the measurement delay is positive, the TRIAD TnT Dosimeter includes the delay time in its

measured exposure time. A positive measurement delay should be used in cases when the kV waveform

contains leading edge overshoot or other waveform anomalies that should be excluded from kV

measurements but included in the exposure time measurement.

* Specifications subject to change without notice.

1-8

Page 15

General Information

Unpacking and Inspection

1

1.7 Unpacking and Inspection

The Model 10100AT TRIAD Field Service Kit was carefully inspected before shipment. Upon receiving

the service kit, carefully unpack all items from the shipping carton and check for any obvious signs of

physical damage that might have occurred during shipment. Report any damage to the shipping agent at

once. Retain the original packing material in case reshipment becomes necessary. The following items

are included with every Model 10100AT Service Kit shipment.

Standard System Components

• Model 35050AT Dosimeter/kVp Readout

• Model 10100AT TRIAD Field Service Kit Operator's Instruction Manual (38651)

• System Carrying Case (37500D)

• 15 cc and 150 cc Ion Chambers (96035B and 96020C)

• Test Stand (37581)

• 6.1 m (20 ft) Coax/Triax Cable (38208)

• Ion Chamber Stem (32147)

• HVL Filter Kit (37668)

• Spare Battery Holder (87-3)

• Customization Software Kit includes a compact disk, 2 m (6 ft) RS-232 Interface Cable, and adapters

for PC- and AT-type computers (37594)

• AC Adapter

Optional Equipment

The Model 35080/80A/80B Non-invasive kVp Divider - is compatible with the Model 10100AT when

used with the appropriate filter packs:

• Wide Range Filter Pack (37617)

• CT Filter Pack (33551)

• Cadmium K-Edge Mammo Filter Pack (37355)

• Linear Mammo Filter Pack (37351)

• Mobile Filter Pack Plus (37946)

• Low Range Filter Pack (38237)

Model 35035 mA/mAs Meter - measures anode current (mA) and anode current and time product (mAs)

of x-ray generators.

TRIAD Toolkit for Excel (10500EXL) - is a complete software package for the TRIAD that includes an

Excel Add-In, called TRIAD Tool and Excel templates that may be used to evaluate the performance of

radiographic, mammographic, and fluoroscopic x-ray machines.

TRIAD QA Software (37978) - is a quality assurance software package for IBM-PC. It simplifies testing

of exposure reproducibility, linearity, kVp, timer accuracy, and HVL.

Cable and Reel Assembly (38209) - is used to keep the 6.1 m (20 ft) coax/triax cable tangle free.

1-9

Page 16

10100AT

G

Operators Manual

1.8 Getting Started

The Model 35050AT Dosimeter/kVp/Time Readout is a highly sophisticated instrument with many

capabilities. Although there are a number of complex aspects about the instrument, you can use the

following procedure to get your instrument up and running quickly. For more detailed information, you

should consult section 2 of this manual.

1. Carefully unpack your Service Kit as described in section 1.7.

a. Connect the supplied triaxial cable to the case side input jack. Connect an appropriate ion

chamber to the other end of the triaxial cable. Position the chamber where required.

To prevent electrical shock, the Model 35050AT

Dosimeter should always be turned off when

connecting or disconnecting an ion chamber or

triaxial cable.

2. a. If use of the Model 35080/80A/80B kVp Divider is intended, connect its output to input of the

Model 35050AT Dosimeter using the coaxial cable provided. Position the kVp divider in the

beam.

Make certain that the color of the cable boot

matches the color indicator around the connector of

the instrument.

2. b. If using the AC adapter, plug the adapter into a suitable power outlet and plug the 2.1mm plug

fully into the power jack on the side of the unit.

Only use the supplied AC adapter. Use of AC

adapters other than the one supplied with the unit

may damage the unit and void the warranty.

3. a. Depress the front panel POWER ON/OFF button for approximately one second to apply power

to the instrument. The instrument will power-up through a series of screens.

b. If a kVp divider is in use, set its switch to the RUN position and plug in desired filter pack.

4. a. At the Detector Select screen, make sure the ion chamber in use is indicated. If not, press the

UP or DOWN buttons until it is. If air density corrections are desired, find an ion chamber with

ADC in its description. If very low dose rate measurements are desired, find an ion chamber

with VLDR in its description.

b. If using a Model 35080/80A/80B kVp Divider, press the DETECTOR SELECT button and then

press the UP or DOWN buttons until the proper filter pack is selected.

c. If a kVp divider is not in use, press the DETECTOR SELECT button and then press the UP or

DOWN buttons until the filter pack selection displays “35080/80A Not Used”.

WARNIN

NOTE

NOTE

1-10

Page 17

General Information

Getting Started

5. Press the UNITS SELECT button if an integrated exposure is to be measured. Or, if exposure rate

is desired, these same units may be chosen with a timebase of seconds, minutes or hours.

Additionally, per frame and amperes are available. Select desired units of measurement by

pressing the UNITS SELECT button. Change the selection by pressing the UP or DOWN buttons.

If exposure/frame units are selected, the user must set the frame rate at this screen.

6. If an ion chamber using air density corrections is selected, press the AIR DENSITY button to

display the Air Density screen. If the temperature & pressure mode has been set to Automatic

Sense, the measured ambient temperature and pressure will be displayed. If the temperature &

pressure mode has been set to Manual Entry, the last used temperature and pressure will be

displayed. Set temperature and pressure to match ambient conditions.

NOTE

1

When air density corrections are in effect, a “ADC”

annunciator will appear on the Measurement

screen. In Automatic Sense mode the ambient

temperature and pressure are updated each time

RESET/MEASURE is pressed.

7. Press and release the RESET/MEASURE button to place the dosimeter in the measurement mode.

8. Make the exposure. Following an exposure, the display will be updated with measurement results

for the exposure. Additional exposures may be made at this point as the dosimeter will detect each

exposure and automatically update the display.

Complete detailed operation concerning the Model 35050AT Dosimeter front panel operation may be

found in section 2 of this manual, including the use of the Model 35080/80A/80B kVp Divider. If you wish

to control these functions over the RS-232 Interface Cable, consult the Model 35050A Programmer's

Instruction Manual.

1-11

Page 18

10100AT

Operators Manual

(Blank Page)

Page 19

Operation

Introduction

Section 2

Operation

2.1 Introduction

Operation of the Model 35050AT Dosimeter may be divided into two general categories: front panel

operation and RS-232 bus operation. This section contains information necessary to use the instrument

from the front panel. Note that many of these functions can also be programmed over the RS-232 bus,

as described in the Model 35050A Programmer's Instruction Manual.

The following paragraphs contain a complete description of the Model 35050AT Dosimeter front panel

operation. First a complete description of each front panel function is presented. Next the complete

procedure for each of the measuring functions is presented.

2.2 Front Panel Familiarization

2

The front panel of the Model 35050AT Dosimeter is shown in Figure 2-1. The front panel may be divided

into two sections: control buttons and display. The following paragraphs describe each of these items in

detail.

Figure 2-1. The Model 35050AT Dosimeter Front Panel

2-1

Page 20

10100AT

Operators Manual

2.2.1 Control Buttons

All front panel control buttons are momentary contact switches, but their functions are firmware latched

once depressed for even a short period of time. They are membrane type switches that provide a definite

tactile indication of operation.

Power On/Off

This button controls the power to the instrument. Depressing this button for approximately one second

turns the power on. Depressing and releasing the button a second time turns the power off.

When the power-up screens sequence is still in

progress, depressing any button will have no effect.

Similarly, depressing any button during the powerdown sequence will have no effect.

In the event of no button depression, no exposure, no operating kVp divider connected, or no RS-232

communication for a user-defined period; the instrument will automatically save its current settings and

turn its power off. Note that any measurement values displayed at power down will be lost. For

additional details on power-up screens, see section 2.4.

At next power-up, the unit will resume operation with these same selections. In addition, at power-up, the

unit will automatically advance through four basic status or self-test screens and then automatically

invoke the DETECTOR SELECT screen before returning control to the front panel buttons. This screen is

shown in Figure 2-1.

NOTE

Options

This button is used to select various measurement options and display of a series of test screens. For

additional details on test screens, see section 2.5. The complete wraparound list may be examined by

repeatedly pressing the Options button.

Air Density

This button causes display of the temperature and barometric pressure used for vented ion chamber

corrections. When the temperature & pressure mode is set to Automatic Sense, pressing the Air Density

button causes the ambient temperature and pressure to be displayed. When the temperature & pressure

mode is set to Manual Entry, the button has a toggle function: momentarily depressing it selects whether

temperature or barometric pressure may be adjusted. The current variable is indicated by the “greater

than” symbol (>) as first character in the display line; hereafter, this is referred to as the cursor. The

current variable may then be changed in value, if desired, by use of the UP and DOWN buttons. Air

density corrections to the exposure and exposure rate displays will be made only if 1) radiological units

(not A or C) have been selected, and 2) an ion chamber with air density corrections enabled has been

selected. When air density corrections are in effect, an “ADC” annunciator will be displayed on the

measurement screen. In the event that the temperature/pressure sensor becomes non functional, an

error message, “Temp & Press Error Use Manual Entry” is displayed and only the manual temperature

and pressure entry mode is available.

Units Select

This button causes display of the selected radiological or electrical units and cine frames per second.

This button also has the toggle function to cursor select the units or frame rate for changing. Changes

may then be made by means of the UP and DOWN buttons. The exposure and exposure rate displays

will be affected by the frame rate setting only if units of exposure per frame (R/frame, Sv/frame, etc.) have

been selected.

2-2

Page 21

Operation

Front Panel Familiarization

2

Detector Select

This button causes display of the identity of the ion chamber and kVp filter pack last used. This button

also has the toggle function to cursor select which chamber and/or filter pack is to be currently used. If

different, changes may then be made by means of the UP and DOWN buttons. The filter pack selection

is used only when a Model 35080/80A/80B kVp Divider is connected.

Reset/Measure

This button is used to both begin and reset the measurement process. When the Exposure Reset option

is set to Manual, indicated by

exposures to clear the display. When the Exposure Reset option is set to Automatic, this is not required

because of the automatic reset feature of the Model 35050AT Dosimeter. The manual reset feature is

only active in the Full-Sensitivity Exposure mode.

in the upper right corner, this button may be depressed between

2.2.2 Display

The display, located on the upper left-hand corner of the front panel, is a two line, twenty character per

line, alphanumeric PLED (polymer light emitting diode) display module. This module performs all visual

indications for the manual operator.

Annunciators

The battery/supply level and ion chamber bias potential are measured regularly by the instrument in a

background mode. Should either level go outside of preset limits, an annunciator is displayed. The

preset limits are given below.

Bias voltage limits 300 to 325 volts

Power battery limits 5.9 to 9.6 volts

The low battery limit of 5.9 V has been chosen to provide approximately two hours of useful battery life

following the initial display of the low battery annunciator.

NOTE

The battery voltage is measured at the input of the

5-volt regulator, after some drops in fuse, switch,

wiring, etc. There will be a discrepancy of several

tenths of a volt from the actual battery voltage.

2.3 Connector Familiarization

There are four external connectors provided on the Model 35050AT Dosimeter case sides. On the side

left of the front panel (front view) are the ion chamber and kVp divider connectors (marked by a yellow

ring). The following paragraphs detail the purpose and use of these connectors. On the side right of the

front panel are the DC power jack and the RS-232 connector. Information on RS-232 communication is

in the Model 35050A Programmer's Instruction Manual that is available upon request.

2-3

Page 22

10100AT

CAUTIO

Operators Manual

2.3.1 Ion Chamber Connector

Never connect a coaxial-BNC type cable to the

Model 35050AT Dosimeter's triaxial ion chamber

input connector. Doing so may damage the ion

chamber input connector.

WARNING

The central pin and inner shield shell of this

connector are operated at 300 volts above the

outer shell and instrument case. Although this

potential is energy and current limited, care should

be taken to avoid unnecessary and possibly

hazardous shocks. Mating and unmating to this

connector (or to the other end of a cable already

connected to it) should be done only when the

instrument is powered down. Within a few seconds

of turnoff, the high voltage is internally discharged

making such connections safe and convenient.

The connector is a triaxial-BNC female with dust cap and chain. It connects to the supplied coax/triax

cable or other low-noise triaxial-BNC male cables. And, by means of which, the Models 96020C Ion

Chamber, Model 96035B Ion Chamber, and other ion chambers can be operated with the Model

35050AT Dosimeter.

N

The connector is side-mounted to avoid contaminating spills and dust, but putting its dust cap in place

whenever a cable is not connected will help assure long service without leakage problems.

2.3.2 kVp Divider Connectors

The connector is a BNC jack marked with a yellow ring. It is the opposite gender of the usual panel

mounted BNC connector to prevent accidental connection of the triax cable to the BNC connector, and

vice versa. Such a cable connector mix up will damage some or all connectors involved. The male to

female BNC coaxial cable (as indicated by yellow boots) provides the connection between the Model

35080/80A/80B kVp Divider and the Model 35050AT Dosimeter / kVp Readout.

2.4 Power-Up Self-Test and Display Messages

When the instrument is powered up by pressing and releasing the POWER ON/OFF button on the front

panel, the following sequence of screens will be displayed:

1. Pixel test

2. Last calibration and software revision date (5 seconds)

3. Instrument power level in volts and HI, LO or OK advisory (5 seconds). If the unit is operating on

battery power, the displayed battery voltage will be between 5.9 and 9.6 volts. If the unit is powered

by its AC adapter, the displayed battery voltage will be between 10 and 13 volts.

2-4

Page 23

Operation

Power-Up Self-Test and Display Messages

NOTE

2

If the AC adapter is plugged into the instrument, but

is not plugged into an AC power source, the Supply

Level will be reduced by several tenths of a volt.

This is due to the additional components that are

switched into the power circuit when the AC

adapter is plugged into the unit. For best

performance on battery power, unplug the AC

adapter from the unit when not in use.

4. Optional power on screen displays user selected information (5 seconds):

This screen will be skipped if blank screen was specified using customization software.

During this opening screen sequence, pressing any front panel button will have no effect. The sequence

ends in DETECTOR SELECT. The last selected detector will be displayed on the screen. Other

functions or another detector may now be selected with the front panel buttons.

2.5 Using the Options Button

Pressing the OPTIONS button, when in any other function, will display one of the status/option screens.

Repeatedly pressing the OPTIONS button again will move the display through twelve status/option

screens as follows:

1. Last calibration and software revision dates

2. Optional test screen, can be skipped by customization

3. Supply Level in volts and HI, LO or OK advisory. When battery power is in use, the battery voltage

is displayed. When the AC adapter is in use, the AC adapter voltage is displayed.

4. System leakage current measuring mode without offset current subtraction. Enables operator to

directly see the ion chamber, cable, and dosimeter leakage current. See section 2.6.1 for more

information.

5. System bias level in volts and HI, LO or OK advisory

6. Ion chamber calibration factor in use: 4 digits plus exponent, dimensioned in either

Roentgens/Coulombs or Grays/Coulombs depending on option chosen during customization.

Factor also includes air density correction if applicable.

7. Voltage measured at Data Terminal Ready (DTR) line of RS-232 port

8. Temperature & Pressure Mode selection. Pressing the up or down button toggles between

Automatic Sensing of temperature and pressure or Manual Entry of temperature and pressure.

9. Short Exposure (< 5ms) selection. Pressing the up or down button toggles between Accept and

Ignore. Accept allows the 35050AT to measure exposures that are less than 5 milliseconds in

duration. When ignore is selected, the 35050AT ignores exposures that are less than 5 milliseconds

in duration. This is useful when spurious signals trigger unintended measurements. This feature is

only active when the 35050AT is in the Tri-measurement Exposure mode (when the 35080 is used).

10. kV Measurement Delay entry. Pressing the up or down buttons increments or decrements the

measurement delay. The measurement delay range is –999 to +999 milliseconds and can be set in

one-millisecond increments. The polarity of the measurement delay only affects how exposure time

measurements are performed. When a negative measurement delay is specified, the 35050AT

does not include the delay time in the measured exposure time. When the measurement delay is

positive, the 35050AT includes the delay time in its measured exposure time. This feature is only

active when the 35050AT is in the Tri-measurement Exposure mode (when the 35080 is used).

2-5

Page 24

10100AT

Operators Manual

11. Exposure Reset selection. Pressing the up or down button toggles between Automatic and Manual.

When the Exposure Reset option is set to Automatic, Model 35050AT Dosimeter automatically

resets between exposures; exposure start and end detection are based on the exposure rate level

crossing a 0.25 pA threshold. When the Exposure Reset option is set to Manual, this button may be

depressed between exposures to clear the display. A

the display when the Manual Reset option is active. Exposure start detection is based on the

exposure rate level crossing a 0.25 pA threshold but the exposure measurement is only reset by

pressing the Reset/Measure button. The manual reset feature is only active in the Full-sensitivity

Exposure mode.

12. Exposure Time Units selection. Pressing the up or down button toggles between Seconds and

Pulses. When Seconds are selected as exposure time units, exposure time is measured between

the first and last passage through the kV threshold. The displayed units are milliseconds (ms) or

seconds (s). The threshold is set at 75% of the kVp, or the minimum kVp for the filter pack in use,

whichever is greater. When Pulses are selected as exposure time units, exposure time is displayed

in pulses (P), and pulses are counted by detecting each passage through a threshold on the rising

and falling edges each pulse in the output waveform.

symbol appears in the upper right corner of

2.6 Basic Measurement Techniques

2.6.1 General Considerations

It will be helpful to the user to understand the presence of several automatic compensations being

performed during measurements and how they could affect the measurements under certain

circumstances.

Automatic Voltage Offset and Drift Compensation

The instrument automatically measures the voltage offset of the electrometer and subtracts the value

from the exposure and exposure rate measurement results.

Automatic Current Offset and Drift Compensation

In the usual situation, this feature is transparent and amounts to system leakage current being nulled from

the measurements. In order to do this, both a short-term history of the leakage current and the

establishment of a leakage/“real” current threshold must be made.

The threshold is set at 0.25 pA and only a few seconds are required for an accurate leakage level

assessment. In the typical case, system leakage current is on the order of 10 fA and reasonably steady.

It may be viewed at any time by going to the OPTIONS and scrolling to the System Leakage screen.

When it approaches the current threshold level and/or becomes highly erratic, the system may improperly

compensate the measurement value.

Another consideration of higher, but suppressed, leakage levels is that the automatic electrometer

integrator reset frequency is raised. This increases the small, but finite possibility, that a reset may occur

during an exposure and thereby lose some of its value. With low system leakage and manually resetting

just before the exposure, this possibility is precluded. In the case where the Model 35050AT Dosimeter

detects the start of an exposure immediately following an automatic reset, an error message will be

displayed advising the user to repeat the exposure.

For several reasons, then, it is good operator practice to regularly check for a low system leakage level.

Experience should serve as a guide to how often this needs to be done and in what circumstances.

Similarly, ten seconds or so should be allowed to elapse between the last triaxial cable or chamber

movement or other disturbances to the high impedance part of the system before commencing an

exposure--so that the “correct” history is applied to the measurement.

2-6

Page 25

Operation

Basic Measurement Techniques

Important implications of the 0.25 pA threshold for exposure rate measurements and the 0.5 pC threshold

for integrated exposure measurements in the case of integral exposure are the minimum radiological

quantities that can be measured.

2

Table 2-1. Threshold Minimum Roentgen readings

Ion Chamber Measurement Units Minimum Reading

15 cc R/s

R/min 3.6 m

R/hr .22

R/frame

R

150 cc R/s

R/min .36 m

R/hr 22 m

R/frame

R

To find minimum readings in other radiological units, use the following multipliers of the roentgen factors:

60 μ

1 μ

60 μ

6 μ

0.1 μ

6 μ

0.000258 for Coulombs/kg air

0.00876 for Grays (in air)

0.01 for Sieverts (in air)

Ion Chamber Selection

The primary purpose of the Model 35050AT Dosimeter is to measure the ionizing radiation outputs of

typical diagnostic x-ray machines. This will likely be done with either of the two ion chambers standard in

the Model 10100AT TRIAD Field Service Kit: Model 96020C Ion Chamber, 150 cc or Model 96035B Ion

Chamber, 15 cc. Typical units of use will be exposure, exposure rate or exposure per frame.

The choice of which ion chamber to use will depend upon the sensitivity required, the beam size, beam

accessing port dimensions or the performance of a special function (e.g. CT probe).

Once a suitable ion chamber is selected, it is interconnected with the Model 35050AT Dosimeter by

means of the 6.1 m (20 ft) low-noise triaxial cable supplied and stably positioned at the measurement

point of interest by means of the test stand (see section 2.9) or ion chamber cable stem (see section

2.10) or other means. The dosimeter may be located where convenient and where both the dosimeter

and the operator are out of the radiation field. The dosimeter may now be turned on.

Verify Ion Chamber Selection

After the opening screen sequence, the instrument will go to the DETECTOR SELECT screen and await

a key press. If the ion chamber in use is not displayed, press the UP or DOWN buttons until it is.

Make sure that air density correction or no air density correction is what is desired--or required by the

nature of the detector, e.g., sealed chamber. If air density corrections are desired see section 2.2.1 and

2.11.2.

If very low dose rate measurements are desired, find an ion chamber with VLDR in its description. This

option should only be used with ion chambers suitable for very low dose rate measurements

Automatic Temperature & Pressure Sensing

The Model 35050AT Dosimeter contains an integrated temperature/pressure sensor. When using the

automatic temperature and pressure sensing feature, the measured temperature is the internal

2-7

Page 26

10100AT

Operators Manual

temperature of the Model 35050AT, TRIAD TnT Dosimeter. This temperature may not be the same

temperature as the Ion Chamber that is in use. In normal use, the internal operating temperature of the

35050AT may be 1 to 2°C above ambient temperature. This operating temperature is normally achieved

within 15 minutes of turn on.

Adequate time must be allowed for the Dosimeter and Ion Chamber to reach thermal equilibrium before

automatic temperature sensing is used. For a large temperature differential, the thermal equilibrium time

of the 35050AT may be up to 2 hours. If it is not possible to allow the instrument to reach thermal

equilibrium, manual entry of temperature and pressure is recommended. A 3°C change in temperature

results in approximately a 1% change in air density correction factor (ADC).

The housing of the Model 35050AT Dosimeter and its ion chambers are vented to atmospheric pressure;

as a result, there should be no difference between the atmospheric pressure measured by Model

35050AT Dosimeter and the actual atmospheric pressure of the ion chamber.

A 3°C change in temperature results in approximately a 1% change in air density correction factor (ADC);

an 8-mmHg change in barometric pressure results in approximately a 1% change in ADC.

In the event that the temperature/pressure sensor becomes non functional, an error message, “Temp &

Press Error Use Manual Entry” is displayed and only the manual temperature and pressure entry mode is

available.

kV Measurement Delay

A kV measurement delay may be used to postpone the start of data analysis in order to skip over

waveform anomalies (such as overshoots or filament preheat effects), which may occur at the beginning

of an exposure. This feature is only active in the Tri-measurement Exposure mode (when the 35080 is

used).

When a delay is used, the 35050AT waits for the specified delay time after the beginning of an exposure

before starting data analysis. If no radiation is detected after the delay time has elapsed, data analysis is

delayed for up to one second after the delay time has elapsed. If no radiation is detected within one

second after the delay time has elapsed, the 35050AT assumes that no exposure has occurred and

displays the "-delay" message.

The delay range is from -999 to +999 milliseconds, and the polarity of the measurement delay only affects

how exposure time measurements are performed.

When a negative measurement delay is specified, the 35050AT does not include the delay time in the

measured exposure time. A negative measurement delay should be used in cases when x-ray generator

filament preheat pulses or other waveform anomalies should be excluded from kV and exposure time

measurements.

When the measurement delay is positive, the 35050AT includes the delay time in its measured exposure

time. A positive measurement delay should be used in cases when the kV waveform contains leading

edge overshoot anomalies that should be excluded from kV measurements but included in the exposure

time measurement.

Exposure Time Units

When seconds are selected as exposure time units, the measurement method is based on a kV threshold

crossing. The threshold is set at 75% of the kVp, or the minimum kVp for the filter pack in use, whichever

is greater. The maximum exposure time is six seconds and the measurement resolution is 0.2 ms.

Exposure time is displayed in milliseconds (ms) or seconds (s).

When Pulses are selected as exposure time units, the 35050AT counts the number of x-ray pulses in a

pulsed or single-phase radiographic exposure. Pulses are counted by detecting each passage through a

threshold on the rising and falling edges each pulse in the output waveform. Exposure time is displayed in

pulses (P). This is primarily for use with single-phase full and half-wave rectified generators. Pulse

counting will not function properly on single-phase generators employing output filter capacitors to smooth

the generator's output because the generator's output does not drop to zero between pulses.

2-8

Page 27

Operation

Basic Measurement Techniques

2

2.6.2 Making Exposure Measurements

Select Exposure Unit

The following integral exposure units are available for selection:

Exposure: Roentgens or Coulombs/kg air

Absorbed Dose: Grays (in air)

Dose Equivalent: Sieverts (x, gamma, or electron source and N=1 for air)

Charge: Coulombs (for the unlisted ion chamber)

Press UNITS SELECT button and use UP or DOWN buttons until the cursor is on the desired unit.

Taking the Exposure

Press RESET/MEASURE just before the exposure. Make the exposure. The exposure value will be

displayed.

Automatic / Manual Reset & Hold

When the Exposure Reset option is set to Automatic Reset, the electrometer is reset once the instrument

senses the exposure is over. The final calculated value of the exposure is held on the display until either

another above threshold exposure occurs, in which case the old value is discarded and the new value is

displayed; or there is function change or power down. The instrument treats exposures separated by less

than two seconds as single exposures.

When the Exposure Reset option is set to Manual Reset, the electrometer is only reset when the

Reset/Measure button is depressed. The final calculated value of the exposure is held on the display until

Reset/Measure button is depressed, in which case the old value is discarded and the display is reset to

zero. When the Manual Reset option is active, the

display.

Resetting of the electrometer takes approximately 100 ms to complete. If an exposure starts while the

electrometer is being reset, the result is an erroneous measurement. Instead of displaying the erroneous

measurement, the display would read:

Simply repeat the exposure to clear the message and display a new measurement result.

symbol appears in the upper right corner of the

2.6.3 Making Exposure Rate Measurements

For selection of ion chamber, verification of ion chamber with the instrument, minimum radiological

quantities, and general considerations please refer to the discussions in section 2.6.1, as they apply here

equally well. In addition, there are some aspects that are unique to exposure rate measurements.

Nonlinear Filter

Incorporated in the instrument's firmware is a digital nonlinear filter that responds quickly to significant

changes in exposure rate, but possesses a much larger time constant for small changes, such as

measurement system noise.

Realtime Display

While operating in the exposure rate mode, the display is updated at an approximate rate of once per

second. Each new display value corresponds to the average exposure rate present since the previous

2-9

Page 28

10100AT

Operators Manual

display update. This differs from operation in the exposure mode where the display is updated and held

following each exposure.

Very Low Dose Rate Measurements

Very low dose rate measurements are selected by pressing Detector Select and selecting an ion chamber

with VLDR in its description. This option should only be used with Ion Chambers suitable for very low

dose rate measurements. To add this measurement option to an ion chamber, using the Customization

Software, add “VLDR” to the chamber’s description. This option is only active in the Exposure Rate mode

(35080 not used).

In order to display very low dose rates in the VLDR measurement mode, automatic current offset and drift

compensation is disabled. As a result, system leakage (dosimeter, cable and ion chamber) is displayed

and should be subtracted from the rate reading. For instance, if the displayed leakage rate is 0.2 uR/sec

(beam off) and the rate with the beam on is 6.9 uR/sec, the actual rate is 6.7 uR/sec.

Allow at least five minutes of settling time after connecting the ion chamber and cable to the dosimeter

before making very low dose rate measurements. Settling time must also be allowed after moving the ion

chamber, cable or dosimeter. When making very low dose rate measurements, the ion chamber, cable

and dosimeter must be stationary; any movement can induce currents.

2.6.4 Use of the Model 35050AT Dosimeter as a kVp Divider Readout

For a full discussion of the Model 35080/80A/80B kVp Divider, the reader is referenced to its instruction

manual. The information given here only concerns the combined operation of the two instruments.

There are some general considerations that apply to both the Exposure Rate/kVp mode and the

Exposure/Time/kVp mode.

Interconnection & Power-Up Sequence

Use the supplied coaxial-BNC cable to connect the Model 35080A kVp Divider to the Model 35050AT

Dosimeter. (Take note of the color-coding of BNC cable boots and respective connectors on the

instruments.)

2-10

Page 29

Operation

Basic Measurement Techniques

2

CAUTION

Never connect a coaxial-BNC type cable to the

Model 35050AT Dosimeter's triaxial ion chamber

input connector. Doing so may damage the ion

chamber input connector.

Always power-up the Model 35050AT Dosimeter first and power it down last. Both instruments may now

be turned on.

kVp Divider Battery Check

With the Model 35050AT Dosimeter turned on, set the function selector of the Model 35080/80A/80B kVp

Divider to the BAT CHK position. The kVp divider battery measurement screen will be displayed by the

dosimeter. A battery voltage display between 7 and 9.6 volts will carry an advisory of OK with it. Below 7

volts, LO will be indicated. If a kVp value is displayed in the BAT CHK position, the battery is indeed

exhausted. Since the kVp divider is not under control of the readout, the operator must remember to

check battery voltage manually.

Filter Pack Selection & Verification

Select an appropriate kVp filter pack for the x-ray machine

involved and plug it into the Model 35080/80A/80B kVp Divider.

Position the kVp dividers long dimensional axis at right angles

to the x-ray tube axis, to avoid "heel" effect. The filter pack area

can be placed as close to the beam axis as the ion chamber

allows. Neither the ion chamber nor the kVp divider should

shadow the other.

X - R A Y

T U B E

Pushing DETECTOR SELECT should display the name of the

filter pack installed on the kVp divider. If it does not, scroll

through the filter packs until it does.

NOTE

Filter packs should not be exchanged between kVp

dividers. Each instrument and its filter pack(s) have

B E A M

T E S T

S T A N D

9 6 0 3 5 B

I O N

C H A M B E R

been carefully calibrated together as a unit. Always

check the calibration sheet serial numbers against the

actual combination. A mismatch can impact

measurement accuracy.

3 5 0 8 0 / 8 0 A / 8 0 B

L O N G

A X I S

O F

3 5 0 8 0

T O 3 5 0 5 0 A

T U B E

A X I S

Figure 2-3. The Model 35080/80A/80B kVp

Divider and Ion Chamber X-ray

Shot

2-11

Page 30

10100AT

Operators Manual

Internal Calibration Check

To use the cal check feature of the Model 35080/80A/80B kVp Divider, set the Model 35050AT Dosimeter

for exposure rate units (A, R/s, etc.). Set the function selector of the Model 35080/80A/80B kVp Divider

to the CAL position. After the Model 35050AT Dosimeter's RESET/MEASURE button is pressed the filter

pack cal level will be displayed in kVp. The Linear Mammo Filter Pack cannot show the calibration check

kVp, since it falls outside the specified kVp range.

Because the Model 35050AT Dosimeter automatically performs filter pack linearization corrections when

the Wide Range, CT, or Mobile Filter Pack is selected, the kVp level displayed by the Model 35050AT

Dosimeter will differ from the calibration kV level printed on the face of the filter pack. Table 2-2 gives the

Printed Calibration kV Level for each filter pack as well as the Corrected kVp Reading that should be

displayed by the Model 35050AT Dosimeter.

Table 2-2. Corrected kVp Readings for kV Filter Packs with Automatic Linearization Corrections

Filter Pack Type 37617C Wide Range 3351C CT 37946C Mobile

Printed Calibration kV Level 80 kV 124.4 kV 100.0 kV

Corrected kVp Reading 79.4 kVp 123.6 kVp 98.8 kVp

Nominal Calibration Voltage 0.400 V 0.644 V 0.600 V

The Nominal Calibration Voltage levels listed in Table 2-2 are also printed on the faces of the filter packs,

and may be read directly and without the effect of the Model 35050AT Dosimeter's automatic linearization

correction scheme by selecting the Test Pack from the Model 35050AT Dosimter's Detector Select

screen.

Dosimeter Range Reduction in kVp Modes

Because of the higher exposure rates associated with kVp determinations, the dosimeter is automatically

desensitized when in either kVp mode. This changes the minimum detectable quantities as follows

below.

An important implication of the 5-picoampere threshold in the case of kVp/Exposure Rate is that there are

minimum radiological quantities that can be read, depending on the ion chamber being used. Once

above the threshold, though, there will be good value resolution.

Table 2-3. Reduced Range, Minimum Roentgen Readings

Ion Chamber Measurement Units Minimum Reading

15 cc R/s 1.2 m

R/min 72 m

R/hr 4.3

R/frame*

150 cc R/s

R/min 7.2 m

R/hr .43

R/frame*

* at 60 frames/second

20 μ

120 μ

2 μ

2-12

Page 31

Operation

Basic Measurement Techniques

To find minimum readings in other radiological units, use the following multipliers to the roentgen factors

found above.

0.000258 for Coulombs/kg air

0.00876 for Grays (in air)

0.01 for Sieverts (in air)

2

kVp Out-of-Range Indications

If the peak kilovoltage during an exposure falls short of the filter pack's specified kVp range, the display

will indicate 0.0 kVp; if it exceeds, the display will indicate ---.- kVp.

2.7 Simultaneous Measurement Mode

The Model 35050AT Dosimeter can be configured to perform simultaneous exposure and kVp

measurements. The simultaneous measurement option can be enabled through the TRIAD

Customization Software. In this measurement mode, a delay of up to 999 ms may be used to skip over

unwanted portions of an exposure. To prevent measurement of spurious signals, the 35050AT Dosimeter

can be set to ignore exposures of less than 5ms.

2.7.1 Making Combined Exposure Rate and kVp Measurements

The Model 35050AT Dosimeter can be used with the Model 35080/80A/80B kVp Divider as its kVp

readout while at the same time measuring exposure rate. The operating instructions for measuring

exposure rate in this mode are the same as without a kVp divider with the exception that the Model

35080/80A/80B kVp Divider must be placed in the x-ray beam with the ion chamber see section 2.9.

When in this mode, a typical display might look like this:

Exposure rate measurements are entirely independent of the kVp measurements, even if the kVp

measures outside the specified range.

2.7.2 making Combined Exposure, kVp, and Time Measurements

If an exposure unit or coulombs is selected, and kVp filter pack is selected, this measurement mode is

entered. For general operating information, see section 2.6.4 and 2.7.1. The exposure measurement is

conducted the same as in section 2.6.2 with the following exception.

If the peak kilovoltage falls short of entering the filter pack's kVp range, a zero (0.00 R) exposure value

will be displayed. Under this condition, the displayed kVp value will be 0.0 kVp and the displayed time

value will be 0.2 ms.

For the case where the peak kilovoltage enters or exceeds the filter pack's kVp range, exposure and time

will be displayed correctly. If the range is exceeded, ---.- kVp will be displayed.

Waveform storage and the value of time is limited to six seconds. If an exposure is longer than six

seconds, the time overrange indication -.--- s, is displayed.

2-13

Page 32

10100AT

Operators Manual

After the exposure is over, which is defined as the waveform having dropped below the filter pack's kVp

range and not having returned to it in 100 ms, the instrument performs an analysis of the stored

waveforms to calculate the exposure time.

2.7.2.1 Advanced Measurement Options

When in the Combined Exposure, kVp, and Time Measurements mode, several measurement options are

available that enhance the usability of the 35050AT. These features are available via the options button.

Measurement Delay – Allows the user to specify a measurement delay to skip over unwanted portions of

an x-ray output waveform. The measurement delay range is from –999 to 999 milliseconds. When a

negative measurement delay is selected, the 35050AT does not include the delay time in the measured

exposure time. When a positive measurement delay is selected, the 35050AT includes the delay time in

its measured exposure time. If the selected delay time is longer than the exposure time, a “-delay”

message will be displayed.

When no measurement delay is used, time measurement starts either when the waveform first attains

75% of its peak value, or when the waveform first enters the kVp range, if 75% of its peak value lies

below the range. Time measurement ends when the waveform last attains this value.

Exposure Time Units – Allows the user to select exposure time units of seconds (milliseconds) or

pulses.

When seconds are selected as exposure time units, exposure time measurement method is based on a

kV threshold crossing. The threshold is set at 75% of the kVp, or the minimum kVp for the filter pack in

use, whichever is greater. Exposure time is measured between the first and last passage through this

threshold.

When Pulses are selected as exposure time units, the 35050AT counts the number of x-ray pulses in a

pulsed or single-phase radiographic exposure. Pulses are counted by detecting each passage through a

threshold on the rising and falling edges each pulse in the output waveform.