Page 1

SigmaPace 1000

External Pacemaker Analyzer

Operators Manual

PN 2243306

July 2007

© 2007 Fluke Corporation, All rights reserved. Printed in USA

All product names are trademarks of their respective companies.

Page 2

Warranty and Product Support

Fluke Biomedical warrants this instrument against defects in materials and

workmanship for one year from the date of original purchase. During the warranty period, we will repair or at our option replace, at no charge, a product

that proves to be defective, provided you return the product, shipping prepaid,

to Fluke Biomedical. This warranty covers the original purchaser only and is

not transferable. The warranty does not apply if the product has been damaged

by accident or misuse or has been serviced or modified by anyone other than

an authorized Fluke Biomedical service facility. NO OTHER WARRANTIES,

SUCH AS FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSED

OR IMPLIED. FLUKE SHALL NOT BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE

OR THEORY.

This warranty covers only serialized products and their accessory items that

bear a distinct serial number tag. Recalibration of instruments is not covered

under the warranty

This warranty gives you specific legal rights and you may also have other

rights that vary in different jurisdictions. Since some jurisdictions do not allow

the exclusion or limitation of an implied warranty or of incidental or consequential damages, this limitation of liability may not apply to you. If any provision of this warranty is held invalid or unenforceable by a court or other decision-maker of competent jurisdiction, such holding will not affect the validity

or enforceability of any other provision.

07/07

Page 3

Notices

All Rights Reserved

© Copyright 2007, Fluke Biomedical. No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language without the written

permission of Fluke Biomedical.

Copyright Release

Fluke Biomedical agrees to a limited copyright release that allows you to reproduce manuals and

other printed materials for use in service training programs and other technical publications. If

you would like other reproductions or distributions, submit a written request to Fluke Biomedical.

Unpacking and Inspection

Follow standard receiving practices upon receipt of the instrument. Check the shipping carton for

damage. If damage is found, stop unpacking the instrument. Notify the carrier and ask for an

agent to be present while the instrument is unpacked. There are no special unpacking instructions,

but be careful not to damage the instrument when unpacking it. Inspect the instrument for physical damage such as bent or broken parts, dents, or scratches.

Technical Support

For application support or answers to technical questions, either email techser-

vices@flukebiomedical.com or call 1-800- 648-7952 or 1-425-446-6945.

Claims

Our routine method of shipment is via common carrier, FOB origin. Upon delivery, if physical

damage is found, retain all packing materials in their original condition and contact the carrier

immediately to file a claim. If the instrument is delivered in good physical condition but does not

operate within specifications, or if there are any other problems not caused by shipping damage,

please contact Fluke Biomedical or your local sales representative.

Standard Terms and Conditions

Refunds and Credits

Please note that only serialized products and their accessory items (i.e., products and

items bearing a distinct serial number tag) are eligible for partial refund and/or credit.

Nonserialized parts and accessory items (e.g., cables, carrying cases, auxiliary modules,

etc.) are not eligible for return or refund. Only products returned within 90 days from the date

of original purchase are eligible for refund/credit. In order to receive a partial refund/credit of a

product purchase price on a serialized product, the product must not have been damaged by the

customer or by the carrier chosen by the customer to return the goods, and the product must be

returned complete (meaning with all manuals, cables, accessories, etc.) and in “as new” and resalable condition. Products not returned within 90 days of purchase, or products which are not in

“as new” and resalable condition, are not eligible for credit return and will be returned to the customer. The Return Procedure (see below) must be followed to assure prompt refund/credit.

Restocking Charges

Products returned within 30 days of original purchase are subject to a minimum restocking fee of

15 %. Products returned in excess of 30 days after purchase, but prior to 90 days, are subject to a

minimum restocking fee of 20 %. Additional charges for damage and/or missing parts and accessories will be applied to all returns.

Page 4

Return Procedure

All items being returned (including all warranty-claim shipments) must be sent freight-prepaid to

our factory location. When you return an instrument to Fluke Biomedical, we recommend using

United Parcel Service, Federal Express, or Air Parcel Post. We also recommend that you insure

your shipment for its actual replacement cost. Fluke Biomedical will not be responsible for lost

shipments or instruments that are received in damaged condition due to improper packaging or

handling.

Use the original carton and packaging material for shipment. If they are not available, we recommend the following guide for repackaging:

Use a double-walled carton of sufficient strength for the weight being shipped.

Use heavy paper or cardboard to protect all instrument surfaces. Use nonabrasive

material around all projecting parts.

Use at least four inches of tightly packed, industry-approved, shock-absorbent

Returns for partial refund/credit:

Every product returned for refund/credit must be accompanied by a Return Material Authorization (RMA) number, obtained from our Order Entry Group at 1-800-648-7952 or 1-425-446-

6945.

Repair and calibration:

To find the nearest service center, go to www.flukebiomedical.com/service

In the U.S.A.:

Cleveland Calibration Lab

Tel: 1-800-850-4606

Email: globalcal@flukebiomedical.com

Everett Calibration Lab

Tel: 1-888-99-FLUKE (1-888-993-5853)

Email: service.status@fluke.com

In Europe, Middle East, and Africa:

Eindhoven Calibration Lab

Tel: +31-402-675300

Email: ServiceDesk@fluke.com

In Asia:

Everett Calibration Lab

Tel: +425-446-6945

Email: service.international@fluke.com

material around the instrument.

, or

Certification

This instrument was thoroughly tested and inspected. It was found to meet Fluke Biomedical’s

manufacturing specifications when it was shipped from the factory. Calibration measurements

are traceable to the National Institute of Standards and Technology (NIST). Devices for which

there are no NIST calibration standards are measured against in-house performance standards using accepted test procedures.

WARNING

Unauthorized user modifications or application beyond the published specifications may

result in electrical shock hazards or improper operation. Fluke Biomedical will not be responsible for any injuries sustained due to unauthorized equipment modifications.

Page 5

Restrictions and Liabilities

Information in this document is subject to change and does not represent a commitment

by Fluke Biomedical. Changes made to the information in this document will be incorporated in new editions of the publication. No responsibility is assumed by Fluke Biomedical for the use or reliability of software or equipment that is not supplied by Fluke Biomedical, or by its affiliated dealers.

Manufacturing Location

The SigmaPace 1000 External Pacemaker Analyzer is manufactured in Everett, Washington by Fluke Biomedical, 6920 Seaway Blvd., Everett, WA, U.S.A.

Page 6

Page 7

Table of Contents

Chapter Title Page

1 Introduction and Specifications.............................................. 1-1

Introduction .......................................................................................... 1-3

Compatible Pacemaker Types........................................................... 1-3

Incompatible Pacemaker Types ........................................................ 1-3

General Safety Considerations.............................................................. 1-4

Symbols ............................................................................................ 1-4

Warnings and Cautions..................................................................... 1-4

Power Supply.................................................................................... 1-5

Defibrillators and Transcutaneous Pacemakers................................. 1-5

Applications.......................................................................................... 1-6

Features................................................................................................. 1-6

Unpacking and Inspection..................................................................... 1-7

Instrument Familiarization.................................................................... 1-8

Abbreviations........................................................................................ 1-10

General Specifications .......................................................................... 1-12

Instrument Specifications...................................................................... 1-12

Transcutaneous Pacemaker Tests...................................................... 1-13

Transvenous Pacemaker Tests .......................................................... 1-17

Accessories ........................................................................................... 1-28

2 Setup, Operation, and Maintenance ....................................... 2-1

Setting Up the Analyzer........................................................................ 2-3

Connecting External Transcutaneous Pacemakers............................ 2-3

Connecting External Transvenous Pacemakers ................................ 2-4

Load Test Cable Connector............................................................... 2-4

RS-232 Serial Port Connector........................................................... 2-5

High Level ECG Output Jack ........................................................... 2-5

Ventilation ........................................................................................ 2-5

Power Up Sequence.............................................................................. 2-5

Transcutaneous Pacemaker Testing...................................................... 2-7

Transvenous Pacemaker Testing........................................................... 2-7

Utility Functions ................................................................................... 2-7

Maintenance.......................................................................................... 2-8

Avoiding Damage............................................................................. 2-8

Cleaning............................................................................................ 2-9

i

Page 8

SigmaPace 1000

Operators Manual

Service and Calibration ........................................................................ 2-9

Packing Instructions ......................................................................... 2-10

Shipping ........................................................................................... 2-10

3 Transcutaneous Pacemaker Testing...................................... 3-1

Test Options ......................................................................................... 3-3

Output............................................................................................... 3-4

Demand Mode .................................................................................. 3-5

Asynchronous Mode......................................................................... 3-5

Amplitude Sensitivity....................................................................... 3-5

Line Frequency / Noise Immunity.................................................... 3-6

Refractory Period ............................................................................. 3-6

Paced Refractory Period (PRP) .................................................... 3-6

Sensed Refractory Period (SRP)................................................... 3-7

Long Term Test................................................................................ 3-8

Interactive Pacemaker / ECG Simulation......................................... 3-9

Simulated ECG Rate..................................................................... 3-9

Adjustable Threshold Level.......................................................... 3-9

Operational Modes ........................................................................... 3-9

Continuous ................................................................................... 3-9

Non-Capture ................................................................................. 3-9

Non-Function ............................................................................... 3-10

Setup and Testing................................................................................. 3-10

Output............................................................................................... 3-12

Demand Mode Pacemaker’s Interaction with ECG Signal............... 3-14

Continuous Mode Pacemaker’s Interaction with ECG Signal.......... 3-15

Demand Mode Pacemaker’s Ability to Sense ECG Activity............ 3-17

Amplitude of ECG Signal for Demand Mode Pacemaker ................ 3-20

Pacemaker’s Ability to Filter Line Noise......................................... 3-23

Purpose of the ECG Simulation Test................................................ 3-26

Long Term Tests .............................................................................. 3-27

4 Transvenous Pacemaker Testing........................................... 4-1

Test Options ......................................................................................... 4-3

Output............................................................................................... 4-4

Demand Mode .................................................................................. 4-4

Asynchronous Mode......................................................................... 4-4

Amplitude Sensitivity....................................................................... 4-5

Line Frequency / Noise Immunity.................................................... 4-5

Refractory Period ............................................................................. 4-5

Paced Refractory Period (PRP) .................................................... 4-5

Sensed Refractory Period (SRP)................................................... 4-5

Interactive Pacemaker/ ECG Simulation.......................................... 4-6

Simulated ECG Rate ........................................................................ 4-6

PR Interval ....................................................................................... 4-6

Adjustable Threshold Level.............................................................. 4-6

Operational Modes ........................................................................... 4-6

Continuous ................................................................................... 4-6

ii

Page 9

Contents

Non-Capture ................................................................................. 4-7

Non-Function................................................................................ 4-7

DC Leakage ...................................................................................... 4-7

Static Tests (Pacemaker Power OFF): .......................................... 4-8

Dynamic Tests (Pacemaker Power ON):....................................... 4-9

Current Drain Test ............................................................................ 4-9

Long Term Test ................................................................................ 4-11

Setup and Testing ................................................................................. 4-11

Output ............................................................................................... 4-13

Demand Mode and Dual-channel (AV) ECG Signal ........................ 4-16

Continuous Mode and Dual-channel (AV) ECG Signal ................... 4-18

Demand Mode Pacemaker’s Ability to Sense ECG Activity ............ 4-20

Amplitude of ECG Signal for a Demand Mode Pacemaker.............. 4-23

Pacemaker’s Ability to Filter Line Noise.......................................... 4-28

DC Leak Test................................................................................ 4-31

DC Load Test................................................................................ 4-34

ECG Simulation Test.................................................................... 4-36

Long Term Tests............................................................................... 4-38

5 Remote Operation .................................................................... 5-1

Introduction .......................................................................................... 5-3

Entering Remote Mode..................................................................... 5-3

Working in Remote Mode ................................................................ 5-3

Exiting Remote Mode....................................................................... 5-3

Command Syntax.............................................................................. 5-4

Responses to Commands .................................................................. 5-4

Remote Mode Analyzer Setup Commands ....................................... 5-4

Error Codes....................................................................................... 5-5

Transcutaneous Pacemaker Remote Setup and Testing........................ 5-6

Transvenous Pacemaker Remote Setup and Testing............................. 5-13

(continued)

iii

Page 10

SigmaPace 1000

Operators Manual

iv

Page 11

List of Tables

Table Title Page

1-1. Symbols ................................................................................................ 1-4

1-3. Standard Accessories ............................................................................ 1-28

1-4. Pacemaker Disposable Electrode Adapters........................................... 1-28

1-5. Serial Cables ......................................................................................... 1-29

1-6. Compatible Power Supply .................................................................... 1-29

1-7. Disposable Transcutaneous Pacemaker Adapters ................................. 1-29

1-8. High-Level Output Cables .................................................................... 1-30

5-1. SETMAKE Protocols by Manufacturer ................................................ 5-7

v

Page 12

SigmaPace 1000

Operators Manual

vi

Page 13

List of Figures

Figure Title Page

1-1. Analyzer Features and Controls ............................................................ 1-8

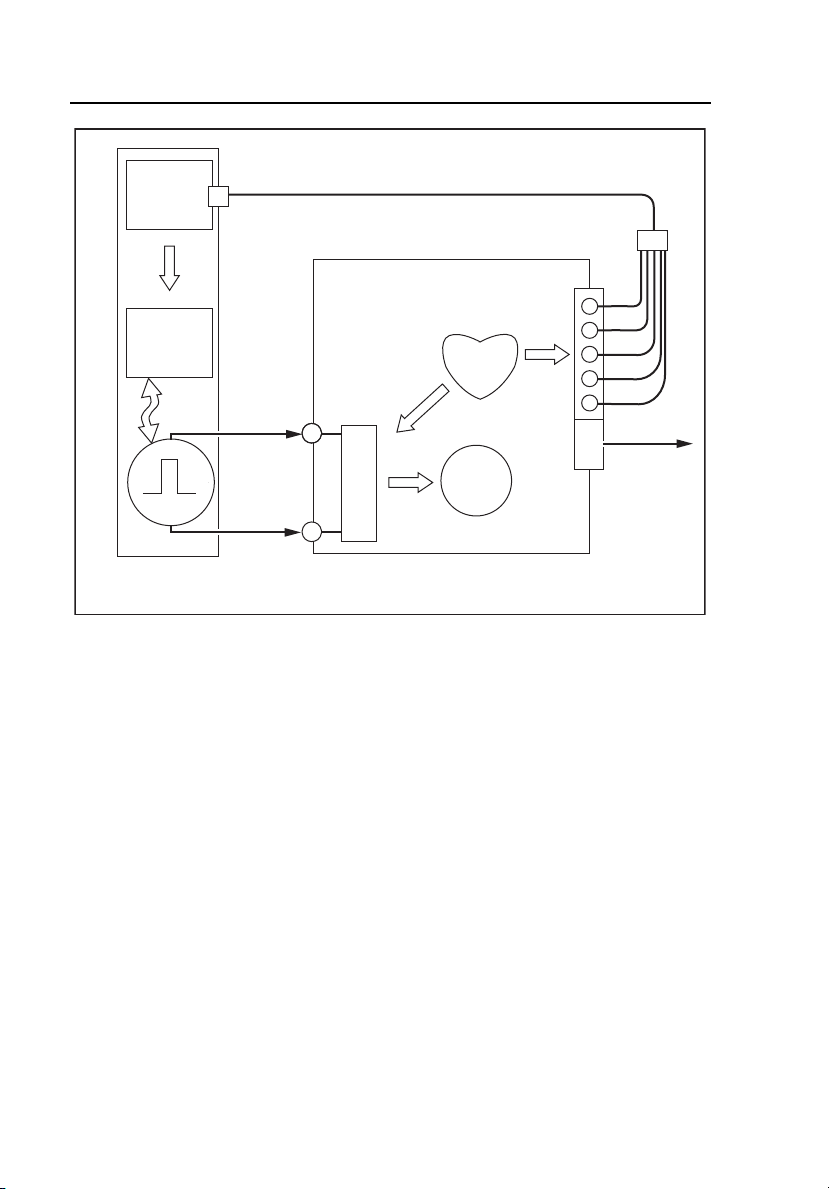

3-1. Scheme for Testing Transcutaneous Pacemakers ................................. 3-4

3-2. Paced Refractory Period ....................................................................... 3-7

3-3. Sensed Refractory Period...................................................................... 3-8

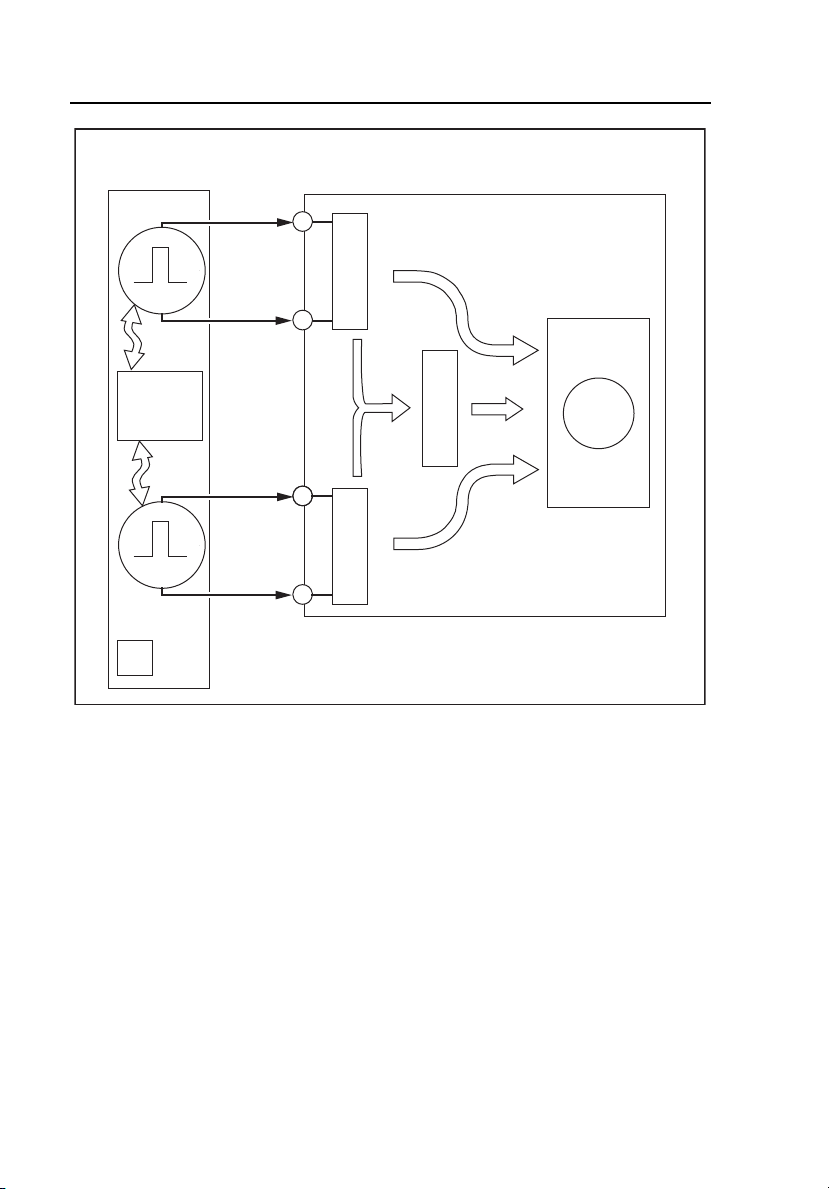

4-1. Scheme for Testing Transvenous Pacemakers...................................... 4-3

4-2. DC Leakage Testing ............................................................................. 4-8

4-3. Current Drain Test ................................................................................ 4-10

vii

Page 14

SigmaPace 1000

Operators Manual

viii

Page 15

Chapter 1

Introduction and Specifications

Contents Page

Introduction .................................................................................. 1-3

Compatible Pacemaker Types................................................... 1-3

Incompatible Pacemaker Types................................................ 1-3

General Safety Considerations ..................................................... 1-4

Symbols .................................................................................... 1-4

Warnings and Cautions............................................................. 1-4

Power Supply............................................................................ 1-5

Defibrillators and Transcutaneous Pacemakers........................ 1-5

Applications ................................................................................. 1-6

Features ........................................................................................ 1-6

Unpacking and Inspection ............................................................ 1-7

Instrument Familiarization ........................................................... 1-8

Abbreviations ............................................................................... 1-10

General Specifications.................................................................. 1-12

Instrument Specifications............................................................. 1-12

Transcutaneous Pacemaker Tests ............................................. 1-13

Transvenous Pacemaker Tests.................................................. 1-17

Accessories................................................................................... 1-28

1-1

Page 16

SigmaPace 1000

Operators Manual

1-2

Page 17

Introduction and Specifications

Introduction

1

Introduction

The SigmaPace™ 1000 External Pacemaker Analyzer, hereafter referred to as

the “Analyzer”, is the latest in external pacemaker analyzer technology. This

efficient, handheld Analyzer satisfies a wide range of external pacemaker

testing; with a comprehensive range of test suites, measurement algorithms,

and test loads.

Compatible Pacemaker Types

The Analyzer is designed to test temporary EXTERNAL pacemakers (pacers)

only. These devices are commonly referred to by the following nomenclature:

• External transcutaneous pacemaker

• External transthoracic pacemaker

• External transvenous pacemaker

• External temporary pacemaker

• External AV sequential pacemaker

• Dual-Chamber temporary pacemaker

• Non-Invasive pacemaker

Incompatible Pacemaker Types

The Analyzer is not designed to test internal pacemakers. Additionally, it is

not used to test any programmable implantable pacemakers, or any related

implanted cardiovascular catheters or lead wires. These devices are commonly

referred to using the following nomenclature:

• Internal pacemaker

• Implantable pacemaker

• Permanent pacemaker

Note

The Analyzer does not perform any clinical, diagnostic, therapeutic,

or monitoring functions and is not for use directly with patients.

1-3

Page 18

SigmaPace 1000

Operators Manual

General Safety Considerations

This instrument and related documentation must be reviewed for

familiarization with safety markings and instructions before you operate the

instrument.

Symbols

Table 1-1 describes the symbols used on the instrument and/or in this

document.

Table 1-1. Symbols

Symbol Description

W Important information; refer to manual.

X Hazardous voltage

~

Do not dispose of this product as unsorted municipal waste. Go

to Fluke’s website for recycling information.

; Conforms to relevant Australian EMC requirements

ΠConforms to relevant Canadian and US standards

P Conforms to European Union directives

IEC Measurement Category I – CAT I equipment designed to

CAT I

protect against transients in equipment on circuits not directly

connected to MAINS. Under no circumstances should the

terminals of the Analyzer be connected to any MAINS voltage.

Warnings and Cautions

A Warning identifies hazardous conditions and actions that could cause

bodily harm or death.

A Caution identifies conditions and actions that could damage the Analyzer,

the equipment under test, or cause permanent loss of data.

1-4

Page 19

Introduction and Specifications

General Safety Considerations

XW Warning

To avoid possible electrical shock or personal injury,

follow these guidelines:

• Use this Analyzer only in the manner specified by the

manufacturer, or the protection provided may be

impaired.

• Read the Operators Manual before operating the

Analyzer.

• Do not use the Analyzer if it operates abnormally.

• Do not use the Analyzer in wet locations, around

explosive gases or dust.

• Use extreme caution when working with voltages above

30 volts.

• Use the proper terminals, functions and ranges for the

test being performed.

• Do not connect the Analyzer to a patient or equipment

connected to a patient. The Analyzer is intended for

equipment evaluation only and should never be used in

diagnostics, treatment or in any other capacity where the

Analyzer would come in contact with a patient.

1

Power Supply

Make sure the external battery charger / power supply is rated and configured

for your voltage source, and compatible with the voltage and current ratings of

the Analyzer. Use only the specified power supply included with this

instrument. See Table 1-6.

Defibrillators and Transcutaneous Pacemakers

This instrument tests both external transcutaneous and transvenous

pacemakers. In most cases, transcutaneous pacemakers are built into cardiac

resuscitation equipment along with defibrillators. Defibrillators deliver highvoltage shocks to a patient in order to correct a life-threatening heart condition.

1-5

Page 20

SigmaPace 1000

Operators Manual

W Caution

To avoid possible damage to the Analyzer, do not

discharge defibrillator pulses into the instrument.

The dual-channel pacemaker input jacks are electrically protected to prevent

damage if a defibrillator charge is applied. The instrument’s internal buzzer

activates to warn the user whenever a defibrillator pulse is sensed.

For transcutaneous pacemakers, both brand- and model-specific algorithms

and testload ranges can be selected for particular device manufacturers.

Applications

The Analyzer can be used to test external pacemakers in the Coronary Care

Unit (CCU) or Emergency Department (ED), to verify external pacemaker

performance following factory repair / upgrade, or troubleshooting pacemaker

operational problems.

The Analyzer is also a valuable clinical training and demonstration tool. In

addition to measuring the pacemaker’s basic output, amplitude sensitivity, and

refractory capabilities, you can also present the interactive pacemaker

operation using the standard ECG output with your bedside monitor, strip chart

recorder or oscilloscope. The Analyzer realistically mimics a patient’s cardiac

response to the attached pacemaker including threshold / capture, basic

asynchronous operation, and the four states of dual-channel transvenous

pacemaker operation.

Testing is made easier with the Analyzer because you no longer need to switch

test leads to conduct your desired atrial or ventricular channel test. All test

functions, with the required ECG waveforms, are instantly available to the user

via internal relay routing.

Features

• Tests both external transcutaneous and transvenous pacemakers.

• Large 21-character x 8-line alphanumeric LCD readout shows more

information than other external pacemaker Analyzers.

• Full range of selectable measurement algorithms and test loads for

external pacemakers.

1-6

Page 21

Introduction and Specifications

Unpacking and Inspection

• Dual-channel signal acquisition for capturing synchronous transvenous

AV-Sequential pacemaker pulse output data.

• Interactive pacemaker and ECG simulation with 5 Lead output.

• A Sleep mode conserves the charge of the internal lithium-ion battery

when not in use. Sleep mode is disabled when the external power supply

is plugged into a suitable voltage source.

• A “HOLD” function to “freeze” readings on the LCD.

• Test features for battery load current and dc leakage measurement.

1

Unpacking and Inspection

When unpacking the Analyzer, check for damage during shipment. If the

Analyzer has been damaged, call your Fluke Biomedical Service Center

immediately. If you must return the Analyzer to Fluke for service, follow the

procedure given under “Service and Calibration.”

1-7

Page 22

SigmaPace 1000

Operators Manual

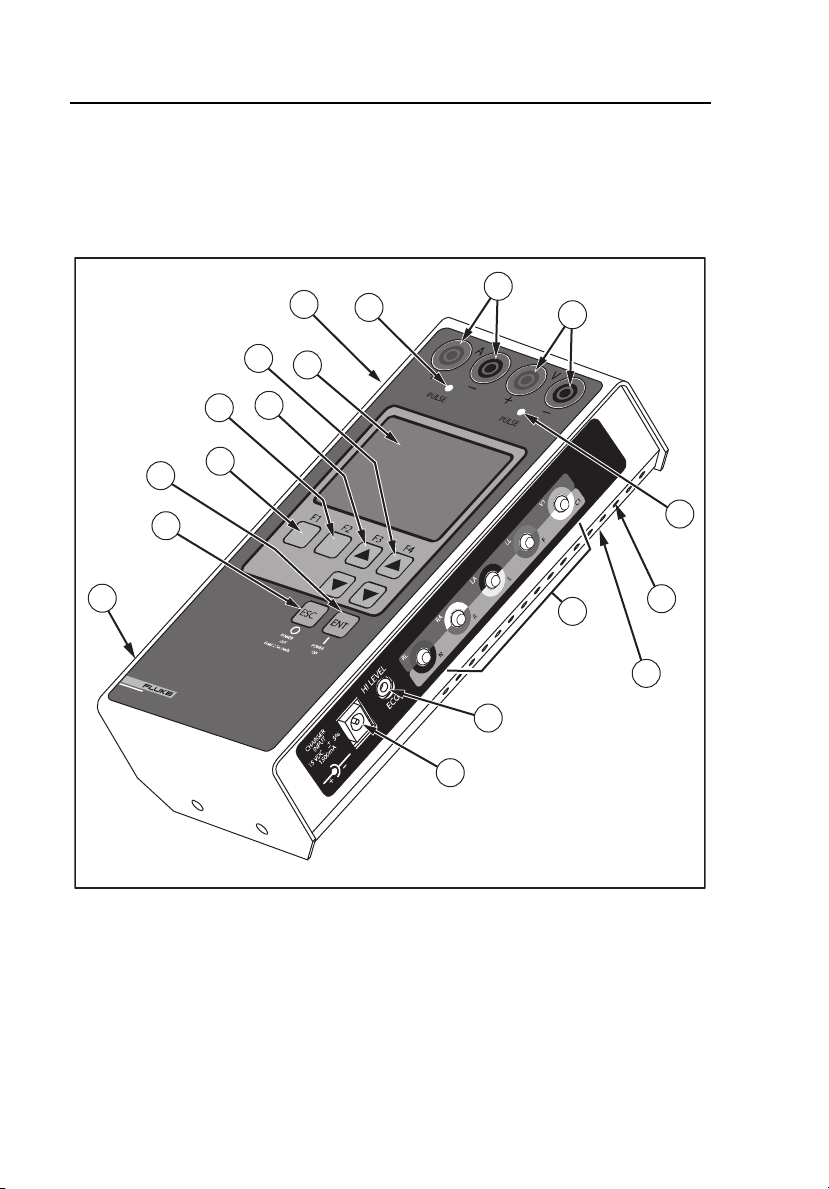

Instrument Familiarization

The Analyzer’s features and controls are shown in Figure 1-1 and described in

Table 1-2.

16

6

7

Biomedical

SIGMA PACE 1000

EXTERNALPACEMAKER ANALYZER

17

2

1

3

4

8

10

5

11

9

12

15

18

13

14

1-8

Figure 1-1. Analyzer Features and Controls

eyr056.eps

Page 23

Introduction and Specifications

Instrument Familiarization

Table 1-2. Analyzer Features and Controls

Number Description

Top Panel

LCD Readout (8 Lines X 21 Characters)

1

F4 / UP and DOWN Arrow Keys

2

F3 / UP and DOWN Arrow Keys

3

F2 Key

4

F1 Key

5

ENTER and POWER ON Key

6

ESCAPE and POWER OFF Key

7

Atrial Channel Sense Indicator (Yellow LED)

8

Atrial Channel Pacemaker Input Jacks (4 mm)

9

Red: Positive Black: Negative

Ventricular Channel Pacemaker Input Jacks (4 mm)

10

Red: Positive Black: Negative (Transvenous and

Transcutaneous)

1

Right Side Panel

11

12

13

14

15

16

17

18

Ventricular Channel Sense Indicator (Yellow LED)

Low Level ECG Output (Disposable Snap Compatible)

High Level ECG Output (Subminiature Phone Jack)

Charger / dc Power Supply Input Jack

Ventilation Slots

Left Side Panel

Load Current (Phantom Battery) Input Connector

RS-232 Serial Port

Bottom Panel

RESET Button

1-9

Page 24

SigmaPace 1000

Operators Manual

Abbreviations

The following list includes abbreviations used in this document.

A ampere

ANSI American National Standards Institute

AAMI

BLU blue (color)

BPM beats per minute

dB decibel

°C degrees Celsius (centigrade)

CQM Contact Quality Monitor

DMM digital multimeter

DUT device under test

EEPROM electrically erasable PROM

ECG electrocardiograph or electrocardiogram

ESU Electrosurgery Unit

EUT equipment under test

°F degrees Fahrenheit

GRA gray (color)

GRN green (color)

Hz hertz

Association for the Advancement of Medical

Instrumentation

in inch

J Joules

k kilo (10

kg kilogram

kHz kilohertz

3

)

1-10

Page 25

Introduction and Specifications

Abbreviations

kΩ kilohm

lb pound

LED light-emitting diode

LCD liquid crystal display

M meg(a) (106)

MHz megahertz

MΩ megohm

m meter

m milli (10

mA milliampere

mm millimeter

mV millivolt

p-p peak-to-peak

REM Return Electrode Monitor

-3

)

1

s second

YEL yellow (color)

µ micro (10-6)

µA microampere

µV microvolt

Ω ohm

1-11

Page 26

SigmaPace 1000

Operators Manual

General Specifications

Listed product specifications are subject to change.

Temperature

Operating.............................................................18 - 40 °C

Storage................................................................0 - 50 °C

Relative Humidity, Operating ...............................90 % max (non-condensing)

Altitude ...................................................................2000 m

Serial Port

Connector Type...................................................DB-9 (Male)

Baud Rates..........................................................2400, 9600, and 19200

Service Manual ......................................................2243314

Power Requirement

External Battery Charger / Power Supply

Input ................................................................90-264 V, 50/60 Hz

Output..............................................................15 V +/-5 %, 1500mA 100 to 240 V ac

Auto power off / sleep mode

Sleep Modes

Reset ...................................................................Analyzer reset button accessed via

Physical

Size .....................................................................8” X 4” X 2” (approx.) (203 mm X 101

Weight .................................................................2 lb (0.90 kg) approximate

50 / 60 Hz operation

bottom panel.

Sleep mode conditions.

mm X 50 mm)

Instrument Specifications

Modes of Operation

Manual

Remote (via standard RS-232 serial port)

User Interface

Display

LCD Readout...................................................21 characters X 8 lines

Pushbuttons

Eight keys........................................................F-1, F-2, F-3 (UP Arrow), F-4 (UP

1-12

Brightness / viewing angle adjustment

Arrow), 2 Down Arrows, ESCAPE, and

ENTER

Page 27

Introduction and Specifications

Instrument Specifications

1

Transcutaneous Pacemaker Tests

Output Pulse Measurement

Test Type ............................................................... Quantitative

Measurement Ranges

Output ................................................................. 4.0 mA to 9.99 mA

Accuracy......................................................... ±2 % of reading or ±50 µA (whichever

Rate .................................................................... 5.0 PPM to 99.9 PPM

Accuracy......................................................... ±0.5 % of reading or 0.3 PPM

Width................................................................... 1.00 mS to 9.99 mS

Accuracy......................................................... ±0.5 % of reading or 14 µS (whichever

Energy ................................................................ 1µJ to 999 µJ

Accuracy......................................................... ±5 % of reading / computation

10.0 mA to 99.9 mA

100 mA to 250 mA

is greater)

100 PPM to 300 PPM

(whichever is greater)

10.0 mS to 99.9 mS

is greater)

1 mJ to 999 mJ

1.00 J to 1.99 J

Demand Mode Test

Test Type ............................................................... Qualitative

Physiological Simulation

Selection ............................................................. Normal Sinus Rhythm (NSR)

Amplitude............................................................ (V

Mode of Operation

Underdrive .......................................................... NSR @ 85 % of measured pulse

Overdrive ............................................................ NSR @ 115 % of measured pulse

Auxiliary Control................................................... The under / overdrive NSR simulations

1-13

generates the complete P-QRS-T

complex.

): 1.0 mV Lead I.

peak

interval / rate

interval / rate

can also be independently adjusted in

1 BPM increments.

Page 28

SigmaPace 1000

Operators Manual

Auxiliary Rate Range

Underdrive (minimum).........................................10 BPM

Overdrive (maximum)..........................................300 BPM

Active Outputs

Five lead ECG

Selected Ventricular Channel Test Load

High Level ECG Jack

This waveform is present on these three outputs.

Pacemaker Compatibility

Compatible Pulse Rates......................................30 to 200 PPM

Intended Type .....................................................External Transcutaneous VVI

(Ventricular Only Pace and Sense)

Asynchronous Mode Test

Test Type................................................................Qualitative

Physiological Simulation Selection

Selection..............................................................Normal Sinus Rhythm (NSR)

Amplitude (V

Rate (Interval)

Underdrive...........................................................NSR @ 85 % of measured pulse

Overdrive.............................................................NSR @ 115 % of measured pulse

Auxiliary Control ..................................................The under / overdrive NSR simulations

Auxiliary Rate Range

Underdrive (minimum).........................................10 BPM

Overdrive (maximum)..........................................300 BPM

Active Outputs

Five lead ECG

Selected Ventricular Channel Test Load

This waveform is present on both outputs.

Pacemaker Compatibility

Compatible Pulse Rates......................................30 to 200 PPM

Intended Type

External Transcutaneous

VOO (Asynchronous Ventricular Only Pace)

)..................................................1.0 mV Lead I

peak

generates the complete P-QRS-T

complex.

interval / rate

interval / rate

can be independently adjusted in 1

BPM increments.

1-14

Page 29

Introduction and Specifications

Instrument Specifications

1

Amplitude Sensitivity Test

Physiological Simulation

Selection ............................................................. +R-Wave, -S-Wave, and + T-Wave

Rate (Interval) ..................................................... Default: 120 BPM (500 mS)

Available Test Load

Selection(s)......................................................... (30) 50 Ω to 1550 Ω in 50 Ω steps

Waveform Selections.......................................... Square (SQU)

Amplitude

Range ................................................................. 0.05 mV

Accuracy ............................................................. ±5 % of setting

Resolution (Step Size)........................................ 0.05 mV steps from 0.05 mV

Width

Range ................................................................. 0.15 mS to 300 mS

Accuracy ............................................................. ±5 % of setting

Selection Count .................................................. 50

Resolution (Step Size)........................................ 0.05 mS steps from 0.15 mS to 0.95

Active Outputs

Five lead ECG

Selected Ventricular Channel Test Load

High Level ECG Jack

This waveform is present on these three outputs.

Pacemaker Compatibility

Compatible Pulse Rates ..................................... 30 to 200 PPM (Minimum)

Intended Pacemaker Type.................................. VVI (Ventricular Pace and Sense

Triangle (TRI)

Haversine (HSN)

SSQ

(50 V

peak

95 mV

mV

mS

1.0 mS steps from 1.0 mS to 19.0 mS

5.0 mS steps from 20 mS to 95.0 mS

25 mS steps from 100 mS to 300 mS

Only)

0.50 mV steps from 1.0

peak

to 5.0 mV

peak

) to 5.0 mV

peak

peak

peak

peak

to 0.

Noise Immunity Test

Waveform .............................................................. Sine Wave

Frequency.............................................................. 50 and 60 Hz

Accuracy................................................................ 0.5 Hz

1-15

Page 30

SigmaPace 1000

Operators Manual

Active Outputs

Selected Ventricular Channel Test load

Five lead ECG

Testload Amplitude Output

Ventricular Channel

Range..............................................................0.00 (OFF) to 10.0 mV

Accuracy..........................................................±5 % of setting

Resolution (Step Size).....................................0.50 mV

Pacer Load Range ..........................................(30) 50 Ω to 1550 Ω 1 %

Five Lead ECG Output

Range..................................................................0.00 (OFF) to 10.0 mV

Accuracy..............................................................±5 % of setting

Resolution (Step Size).........................................0.50 mV steps

Calibration Reference..........................................Lead I (RA to LA)

peak-to-peak

peak-to-peak

steps

peak-to-peak

Paced Refractory Period Test (PRP)

Range......................................................................20 mS to 500 mS

Accuracy..............................................................5 % of reading or 1 mS whichever is

Physiological Simulation

Selection..............................................................Triangle (TRI) Wave

Pulse Width .........................................................40 mS

Rate.....................................................................Single pulse: Interactive with applied

Amplitude...............................................................1.0 mV

Active Outputs .....................................................Five Lead ECG and selected

Pacemaker Compatibility

Compatible Pulse Rates......................................30 to 200 BPM

Intended Pacemaker Type ..................................VVI (Ventricular Pace and Sense

greater

pacemaker pulse activity in the

demand mode of operation.

Lead I

peak

ventricular channel test load This

waveform is present on both outputs.

Only)

Sensed Refractory Period Test (SRP)

Range......................................................................15 mS to 500 mS

Accuracy..............................................................±5 % of reading or ±1 mS, whichever

Physiological Simulation

Selection..............................................................Triangle (TRI) Wave

1-16

is greater

Page 31

Introduction and Specifications

Instrument Specifications

Pulse Width......................................................... 40 mS

Rate .................................................................... Double pulse: interactive with applied

Amplitude .............................................................. 1.0 m V

Active Outputs ...................................................... Five Lead ECG and selected

Pacemaker Compatibility

Compatible Pulse Rates ..................................... 30 to 200 BPM

Intended Pacemaker Type.................................. VVI (Ventricular Pace and Sense

pacemaker pulse activity in the

demand mode of operation.

Lead I

peak

ventricular channel test load. This

waveform is present on both outputs.

Only)

1

Transvenous Pacemaker Tests

Output Pulse Measurement

Test Type ............................................................... Quantitative

Display Formats

Single.................................................................. Atrial or Ventricular only

Dual .................................................................... Atrial and ventricular Channels

Measurement Ranges

Current................................................................ 0.05 mA to .999 mA* (Single Channel

Accuracy......................................................... 2 % of reading or ±50 µA (whichever is

Polarity Indicator ................................................. + or -

Rate .................................................................... 10 PPM to 99.9 PPM

Accuracy......................................................... 0.5 % or 0.3 PPM (whichever is

Width................................................................... 0.02 mS to .999 mS

Accuracy......................................................... 0.5 % or ±14 µS (whichever is greater)

Resolution........................................................... ±1 LSD or ±4 µS (whichever is

Only)

1.00 mA to 9.99 mA

10.0 mA to 30.0 mA

greater)

100 PPM to 999 PPM

greater)

1.00 mS to 9.99 mS

10.0 mS to 99.99 mS

greater)

1-17

Page 32

SigmaPace 1000

Operators Manual

Voltage ................................................................ 0.050 V

1.00 V

10.0 V

peak

to 9.99 V

peak

to 30.0 V

peak

to .999 V

peak

peak

peak

Accuracy..........................................................2 % of reading or 0.05 V

(whichever is greater)

Polarity Indicator..................................................+ or -

Energy .................................................................1 nJ to 999 nJ

1 µJ to 999 µJ – add “J” range

Accuracy..........................................................5 % of reading / computation

Displayed Data

Single: Amplitude - Current

Amplitude ........................................................Volts

Rate

Width

Energy

Dual: Atrial and Ventricular

Amplitude ........................................................Current

Rate

Width

AV Interval

AV Interval (Delay Time)

Test Type................................................................Quantitative

Measurement Ranges

10.0 mS to 99.9 mS

100 mS to 999 mS

Start / Stop Points

Start.................................................................Leading edge of atrial pacemaker

Stop .................................................................Leading edge of ventricular

Accuracy..............................................................1 % of reading / computation

pulse

pacemaker pulse

peak

Demand Mode Test

Test Type................................................................Qualitative

Channels

Single ..................................................................Atrial or Ventricular Only

Dual .....................................................................A+V

1-18

Page 33

Introduction and Specifications

Instrument Specifications

Simulation

Waveform ........................................................... SSQ

Atrial Channel ..................................................... Simulated P-wave

Width............................................................... 30 mS

Amplitude........................................................ 2.0 mV

Ventricular Channel ............................................ Simulated R-wave

Width............................................................... 40 mS

Amplitude........................................................ 2.5 mV

PR Interval .......................................................... 90 mS

Interactive Simulated Rates

Default Settings

Underdrive ...................................................... NSR @ 85 % of measured pulse

interval / rate

Overdrive ........................................................ NSR @ 115 % of measured pulse

interval / rate

Manual Control ............................................... The under / overdrive NSR simulations

can also be independently adjusted in

1 BPM increments.

Manual Rate Limits

Underdrive (minimum) .................................... 10 BPM

Overdrive (maximum) ..................................... 300 BPM

Active Outputs (Synchronous)

Selected Ventricular Channel Test Load

Selected Atrial Channel Test Load

Pacemaker Compatibility

Pulse Rate Range............................................... 30 to 200 PPM

Intended Pacemaker Types

VVI (Ventricular Channel Only: Pace and Sense)

AAI (Atrial Channel Only: Pace and Sense)

DDD (Both Channels: Pace and Sense)

peak

peak

1

Asynchronous Mode Test

Test Type ............................................................... Qualitative

Channels

Single.................................................................. Atrial or Ventricular Only

Dual .................................................................... A+V

1-19

Page 34

SigmaPace 1000

Operators Manual

Amplitude Sensitivity Test

Test Type................................................................Qualitative

Channels

Single Channel Operation Only (Atrial or Ventricular)

Atrial Channel

Test Type................................................................Quantitative

Physiological Simulation

Selection..............................................................+P-Wave

Rate.....................................................................30 to 120 BPM, Waveform delayed by

Active Outputs

Atrial Channel (4mm Banana Jacks) Only Test Load(s)

Available Selection(s)..........................................(3) 200 Ω, 500 Ω, and 1000 Ω ±1 %

Default Setting.....................................................500 Ω

Waveform Selections ..........................................Square (SQU)

Default Setting .......................................................SSQ

Amplitude

Pacer Load Selection ..........................................500 Ω (default)

Range..............................................................0.05 mV

Accuracy..........................................................±5 % of setting

Resolution (Step Size).....................................0.05 mV

Pacer Load Selection ..........................................200 Ω

Range..............................................................0.05 mV

Accuracy..........................................................±5 % of setting

Resolution (Step Size).....................................0.05 mV

80 % of the pulse-to-pulse

interval or 400 mS (whichever is

shorter).

Triangle (TRI)

Haversine (HSN)

Sine Square (SSQ)

Asymmetrical Triangle (ISO)

(Fixed Width 2 mS rise time / 13 mS

fall time)

0.95 mV

0.50 mV

50.0 mV

0.95 mV

0.50 mV

20.0 mV

(50 V

peak

steps from 0.05 mV

peak

peak

steps from 1.0 mV

peak

peak

(50 V

peak

steps from 0.05 mV

peak

peak

steps from 1.0 mV

peak

peak

) to 50.0 mV

peak

) to 20.0 mV

peak

peak

peak

peak

peak

peak

to

peak

to

to

to

1-20

Page 35

Introduction and Specifications

Instrument Specifications

Pacer Load Selection.......................................... 1000 Ω

Range ............................................................. 0.05 mV

peak

Accuracy......................................................... ±5 % of setting

Resolution (Step Size).................................... 0.05 mV

0.95 mV

0.50 mV

49.5 mV

05.0 mV

100 mV

Default Setting

Amplitude............................................................ 2.0 mV

Width

Range ................................................................. 0.15 mS to 95.0 mS

Accuracy ............................................................. ±5 % of setting

Selection Count .................................................. 50

Resolution (Step Size)........................................ 0.05 mS steps from 0.15 mS to 0.95

mS

1.0 mS steps from 1.0 mS to 19.0 mS

5.0 mS steps from 20 mS to 95.0 mS

Intended Pacemaker Types

AAI (Atrial Pace and Sense Only)

Compatible Pulse Rates ..................................... 30 to 200 PPM

(50 V

peak

steps from 0.05 mV

peak

peak

steps from 1.0 mV

peak

peak

steps from 50 mV

peak

peak

peak

) to 100 mV

peak

peak

peak

peak-to-

peak

to

to

1

to

Ventricular Channel

Physiological Simulation

Selection ............................................................. +R-Wave, -S-Wave, and + T-Wave

Rate .................................................................... 30 to 120 BPM, Delayed from the

Active Outputs ...................................................... Selected ventricular test load (4 mm

Waveform Selections

Square (SQU)

Triangle (TRI)

Haversine (HSN)

Sine Square (SSQ)

Asymmetrical Triangle (ISO)

(Fixed Width........................................................ 2 mS rise time / 13 mS fall time)

Default Setting .................................................... Sine Square (SSQ)

Test Load(s)

1-21

ventricular demand pacemaker

pulse by 80 % of the pulse-to-pulse

interval or 400 mS (whichever is

shorter).

Banana Jacks) only.

Page 36

SigmaPace 1000

Operators Manual

Available Selection(s)......................................(3) 200, 500 and 1000 Ω ±1 %

Default Setting.................................................500 Ω

Amplitude

Pacer Load Selection ..........................................500 Ω

Range..............................................................0.05 mV

Accuracy..........................................................±5 % of setting

Resolution .......................................................0.05 mV

0.95 mV

0.50 mV

50.0 mV

Pacer Load Selection ..........................................200 Ω

Range..............................................................0.05 mV

Accuracy..........................................................±5 % of setting

Resolution .......................................................0.05 mV

0.95 mV

0.50 mV

20.0 mV

Pacer Load Selection ..........................................1000 Ω

Range..............................................................0.05 mV

peak

Accuracy..........................................................±5 % of setting

Resolution .......................................................0.05 mV

0. 95 mV

0.50 mV

49.5 mV

05.0 mV

100 mV

Default Setting .......................................................2.5 mV

Width

Range..................................................................0.15 mS to 300 mS

Accuracy..............................................................±5 % of setting

Selection Count ...................................................58

Resolution (Step Size).........................................0.05 mS steps from 0.15 mS to 0.95

mS

1.0 mS steps from 1.0 mS to 19.0 mS

5.0 mS steps from 20 mS to 95.0 mS

25 mS steps from 100 mS to 300 mS

Intended Pacemaker Type(s)

VVI (Atrial Pace and Sense Only)

Compatible Pulse Rates......................................30 to 200 PPM

(50 V

peak

steps from 0.05 mV

peak

peak

steps from 1.0 mV

peak

peak

(50 V

peak

steps from 0.05 mV

peak

peak

steps from 1.0 mV

peak

peak

(50 V

peak

steps from 0.05 mV

peak

peak

steps from 1.0 mV

peak

peak

steps from 50 mV

peak

peak

peak

) to 50.0 mV

peak

) to 20.0 mV

peak

) to 100 mV

peak

peak

peak

peak

peak

peak

peak

to

peak

peak

to

peak-to-

peak

to

to

to

to

to

1-22

Page 37

Introduction and Specifications

Instrument Specifications

1

Noise Immunity Test

Test Type ............................................................... Qualitative

Channels

Single.................................................................. Atrial or Ventricular Only

Waveform .............................................................. Sine Wave

Frequency.............................................................. 50 and 60 Hz

Accuracy................................................................ 0.5 Hz

Active Output(s).................................................... Selected atrial and / or ventricular

Output Selections

Atrial Channel Only

Ventricular Channel Only

ECG Signal ............................................................ ECG Signal can be added to the

Amplitude

Pacer Load Selection.......................................... 500 Ω

Range ............................................................. 0.00 (OFF) to 100 mV

Accuracy......................................................... ±5 % of setting

Resolution....................................................... 5 mV

Pacer Load Selection.......................................... 200 Ω

Range ............................................................. 0.00 (OFF) to 40 mV

Accuracy......................................................... ±5 % of setting

Resolution....................................................... 5 mV

Pacer Load Selection.......................................... 1000 Ω

Range ............................................................. 0.00 (OFF) to 200 mV

Accuracy......................................................... ±5 % of setting

Resolution....................................................... 5 mV

channel test load

selected Channel

steps

peak-to-peak

steps

peak-to-peak

steps

peak-to-peak

peak-to-peak

peak-to-peak

peak-to-peak

Refractory Period Test (Atrial Channel)

Test Selections

Paced Refractory Period (PRP)

Sensed Refractory Period (SRP)

Period..................................................................... 20 to 500 mS

Accuracy................................................................ ±5 % of reading or ±1 mS whichever is

Resolution ............................................................. ±1 LSD

Display Format...................................................... 3 digits

1-23

greater

Page 38

SigmaPace 1000

Operators Manual

Physiological Simulation

Selection (Default)...............................................Single Channel Simulation (A)

Atrial Channel......................................................Simulated P-wave

Width ...................................................................1.0 mS

Amplitude ............................................................20.0 mV

Active Outputs .....................................................Atrial Channel (4 mm Banana Jacks)

Additional Waveform Selections

Square (SQU)

Triangle (TRI)

Haversine (HSN)

Sine Square (SSQ)

Asymmetrical Triangle (ISO) (Fixed Width 2 mS rise time / 13 mS fall time)

Amplitude

Range...................................................................05 mV

Accuracy..............................................................±5 % of setting

Resolution (Step Size).........................................0.05 mV

Width

Range..................................................................0.15 mS to 95.0 mS

Accuracy..............................................................±5 % of setting

Selection Count ...................................................50

Resolution (Step Size).........................................0.05 mS steps: 0.15 mS to 0.95 mS

Active Output.......................................................Atrial Channel (4 mm Banana Jacks)

Intended Pacemaker Types ................................AAI (Atrial Pace and Sense Only)

Compatible Pacemaker Rates.............................30 to 200 PPM

Available Test Load.............................................500 Ω ±1 %

Square Wave

peak

Only

mV

peak

0.50 mV

mV

peak

peak

(50 V

peak

peak

) to 50.0 mV

peak

steps: 0.05 mV

steps: 1.0 mV

peak

peak

to 49.5

1.0 mS steps: 1.0 mS to 19.0 mS

5.0 mS steps: 20 mS to 95.0 mS

Only

peak

to 0.95

Refractory Period Test (Ventricular Channel)

Test Selections

Paced Refractory Period (PRP)

Sensed Refractory Period (SRP)

Period .....................................................................20 to 500 mS

Accuracy ................................................................±5 % of reading or 1 mS whichever is

1-24

greater

Page 39

Introduction and Specifications

Instrument Specifications

Resolution ............................................................. ±1 LSD

Display Format...................................................... 3 digits

Physiological Simulation

Selection (Default) .............................................. Single Channel Simulation (V)

Ventricular Channel ............................................ Simulated R-wave

Width................................................................... 1.0 mS

Amplitude............................................................ 20 mV

Active Outputs .................................................... Ventricular Channel

Available Test Load(s)........................................ 500 Ω Only

Additional Waveform Selections

Square (SQU)

Triangle (TRI)

Haversine (HSN)

Sine Square (SSQ)

Asymmetrical Triangle (ISO) (Fixed Width2 mS rise time / 13 mS fall time)

Amplitude

Pacer Load Selection.......................................... 500 Ω

Range ............................................................. 0.05 mV

Accuracy......................................................... ±5 % of setting

Resolution (Step Size).................................... 0.05 mV

Default Setting ................................................ 20.0 mV

Width

Range ................................................................. 0.15 mS to 300 mS

Accuracy ............................................................. 5 % of setting

Selection Count .................................................. 58

Resolution (Step Size)........................................ 0.05 mS steps from 0.15 mS to

Default Setting (mS) ........................................... 30 mS

Intended Pacemaker Types................................ VVI (Ventricular Pace and Sense

Compatible Pacemaker Rates ............................ 20 to 200 PPM

Square Wave

peak

(4 mm Banana Jacks) Only

50.0 mV

0.95 mV

0.50 mV

50.0 mV

(50 V

peak

peak

steps from 0.05 mV

peak

peak

steps from 1.0 mV

peak

peak

peak

peak

) to

0.95 mS

1.0 mS steps from 1.0 mS to 19.0 mS

5.0 mS steps from 20 mS to 95.0 mS

25 mS steps from 100 mS to 300 mS

Only)

peak

peak

1

to

to

1-25

Page 40

SigmaPace 1000

Operators Manual

DC Leakage Current

Test Type................................................................Quantitative

Measurement Range .............................................00.1 µA to 99.9 µA

Input Polarity..........................................................Positive and Negative

Resolution ..............................................................1 LSD

Display Format.......................................................3 digits plus decimal point

Test Selections

Static ...................................................................Continuous measurement

Pacemaker Power ...............................................OFF

Input Configurations ............................................Atrial+ and Atrial-

Dynamic ..............................................................Gated measurement preceding the

Pacemaker Power ...............................................ON

Input Configurations ............................................Atrial+ and Atrial-

Ventricular+ and VentricularAtrial+ and Ventricular- (third internal

500 Ω test load)

delivered pacemaker pulse.

Ventricular+ and VentricularAtrial+ and Ventricular+ (third internal

500 Ω test load)

Current Drain Test

Test Type................................................................Quantitative

Measurement Ranges

DC Current ..........................................................0.100 mA to .999 mA

Polarity ................................................................Positive or Negative

Polarity Indicator..................................................+ or - symbol preceding the numeric

Resolution ...........................................................±1 LSD

Display Format ....................................................3 digits plus decimal point

Accuracy..............................................................±5 % of Reading 10 µA

Input DC Voltage

Nominal ...............................................................±9 Volts

Range..................................................................5.0 Volts to 10.5 Volts

Input Protection ...................................................Short-circuit protection

Protection Type ...................................................Internal in-line fast-acting fuse rated at

Selectable Testloads ...........................................200 Ω, 500 Ω, and 1000 Ω

1.00 mA to 9.99 mA

10.0 mA to 99.9 mA

value

½ Ampere.

1-26

Page 41

Introduction and Specifications

Instrument Specifications

1

Battery Test Fixture ............................................ Includes the 9 volt battery supply and

facilitates connection of Analyzer to

the recessed battery terminals within

the Medtronic 5388 and 5348

Temporary Pacemakers.

Long Term Test

Test Configuration................................................ Atrial Channel or Ventricular Channel

Pulse Count Range............................................... 999,999 (maximum)

Rate ........................................................................ 2 % to 20 % (10 % default)

Amplitude .............................................................. 2 % to 20 % (10 % default)

Test Time (max) .................................................... 999:59:59 (hhh:mm:ss)

Maximum error Count .......................................... 200

Test Termination................................................... Manual or when maximum error count

Testloads Selectable ............................................ 200 , 500 , or 1000

is sensed.

Interactive Pacer ECG Simulation

Simulates demand, continuous, non-capture, and non-function patient ECG

activity.

Additional user-selectable parameters

PR Interval .......................................................... 0.05 to 0.300 Seconds

Independent Capture / threshold ........................ 1 mA to 25 mA (1 mA steps) for each

pacemaker channel.

Available Testloads (500 Ω Default)

Atrial Channel

Selections ........................................................... 200 Ω, 500 Ω, or 1000 Ω

Accuracy ............................................................. ±1.0 % of selection

Power Rating ...................................................... 2 Watts

Ventricular Channel

Selections ........................................................... 200 Ω, 500 Ω, or 1000 Ω

Accuracy ............................................................. ±1.0 % of selection

Power Rating ...................................................... 2 Watts

Tracking .............................................................. Atrial and ventricular channel settings

1-27

are identical.

Page 42

SigmaPace 1000

Operators Manual

Accessories

Standard accessories and associated part numbers are listed in Table 1-3;

optional accessories and associated part numbers are listed in Tables 1-4

through 1-8.

Table 1-3. Standard Accessories

Description Part Number

Transvenous Test Lead Red (2 each) 2201166

Transvenous Test Lead Black (2 each) 2201153

9 V dc Load Test Cable 2392272

Operators Manual 2243306

PC Interface Cable Female DB-9 to Female DB-9 2392260

Nylon Carry Case 2392906

Universal-Input Battery Eliminator 2184298

Table 1-4. Pacemaker Disposable Electrode Adapters

Description

All Pacemaker Disposable Electrode Adapters

Physio-Control QUIK COMBO 2201095

Physio-Control QUIK PACE 2201088

Hewlett Packard CodeMaster 2201109

Marquette Medical Responder 2201111

MDE / MRL R2 / DAROX 2201127

Zoll NTP Series 2201130

Zoll PD and M-Series 2201148

Part Number

1-28

Page 43

Introduction and Specifications

Accessories

Table 1-5. Serial Cables

Description Part Number

1

PC Interface Cable

Female DB-9 to Female DB-9

medTester Serial Interface

Female DB-9 to Female DB-25

Table 1-6. Compatible Power Supply

Region of Operation Part Number

Universal Power Supply 15V (90 to 264 VAC) IEC320

C6 3-wire

USA / CAN Power Cord IEC320 C5 3-wire 2198724

United Kingdom (UK) Power Cord IEC320 C5 3-wire 2201428

European Power Cord IEC320 C5 3-wire (SCHUKO) 2201437

Australia Power Cord IEC320 C5 3-wire 2201443

Table 1-7. Disposable Transcutaneous Pacemaker Adapters

Device Manufacturer Model/Designation Part Number

Medtronic/Physio Control

QUIK COMBO

Medtronic/Physio Control

QUIK PACE

HP/Agilent Technologies

Codemaster/HeartStream XL Series

GE Medical/Marquette

Responder Series

MDE Medical Data Electronics

MRL Medical Research Laboratories R2/DAROX

Zoll Medical

NTP Series•

Zoll Medical

PD and M Series (Multi- Function)

2200962

2200102

2184298

2201095

2201088

2201109

2201111

2201127

2201130

2201148

1-29

Page 44

SigmaPace 1000

Operators Manual

Table 1-8. High-Level Output Cables

Description Part Number

Subminiature Phone Plug to BNC Cable

(Oscilloscope Application)

Subminiature Phone Plug to 3-Conductor

¼” Phone Plug Cable (AA-900)

2199932

2200116

1-30

Page 45

Chapter 2

Setup, Operation, and Maintenance

Contents Page

Setting Up the Analyzer............................................................... 2-3

Connecting External Transcutaneous Pacemakers................... 2-3

Connecting External Transvenous Pacemakers........................ 2-4

Load Test Cable Connector...................................................... 2-4

RS-232 Serial Port Connector .................................................. 2-5

High Level ECG Output Jack................................................... 2-5

Ventilation................................................................................ 2-5

Power Up Sequence ..................................................................... 2-5

Transcutaneous Pacemaker Testing ............................................. 2-7

Transvenous Pacemaker Testing.................................................. 2-7

Utility Functions .......................................................................... 2-7

Maintenance................................................................................. 2-8

Avoiding Damage..................................................................... 2-8

Cleaning ................................................................................... 2-9

Service and Calibration................................................................ 2-9

Packing Instructions ................................................................. 2-10

Shipping ................................................................................... 2-10

2-1

Page 46

SigmaPace 1000

Operators Manual

2-2

Page 47

Setup, Operation, and Maintenance

Setting Up the Analyzer

2

Setting Up the Analyzer

The Analyzer utilizes an external plug-in universal power supply. It

automatically operates with applied main voltages rated from 83 to 264 V ac or

from the internal battery. No transformer taps, jumpers, or programming tabs

are required for Analyzer operation. The Analyzer is shipped from the factory

with the power supply configured for the desired (or specified) country or

region.

If your Analyzer is equipped with an incompatible power supply configuration,

contact the Fluke Biomedical Service Center regarding replacement/order

adjustment. Compatible power supplies and associated part numbers are listed

in the chapter “Introduction and Specifications.”

Set up the Analyzer for initial operation by plugging in the power supply plug

into the CHARGER INPUT located on the right side panel of the Analyzer.

Connecting External Transcutaneous Pacemakers

To facilitate the safe and convenient connection of the transcutaneous

pacemaker to the Analyzer, optional disposable electrode adapters are

available from Fluke Biomedical and are compatible with most device

manufacturers. These adapters connect the external pacemaker to the 4 mm

safety banana receptacle/jacks located on the Analyzer top panel and are listed,

with their Fluke part numbers, in the chapter “Introduction and

Specifications.”

W X Warning

To avoid injury to a patient, do not connect the Analyzer to

a patient or equipment connected to a patient. The

Analyzer is intended for equipment evaluation only and

should never be used in diagnostics, treatment or in any

other capacity where the Analyzer would come in contact

with a patient.

Refer to the latest Fluke Biomedical price list for availability of optional

electrode adapters.

2-3

Page 48

SigmaPace 1000

Operators Manual

Note

If desired, you may fabricate your own adapter cables by using

comparable general-purpose test leads with 4 mm safety (male)

banana plugs terminated with the requisite brand/designated

electrode connector.

Connecting External Transvenous Pacemakers

Two identical pairs of transvenous pacemaker test leads are supplied as

standard accessories with the Analyzer. These test leads are color-coded RED

(Part Number 2201166) and BLACK (Part Number 2201153) for connection

to the 4 mm safety banana receptacle/jacks located on the Analyzer top panel.

To securely connect the external transvenous pacemaker to the Analyzer, these