Page 1

Victoreen 07-494

Wide-Range Digital kVp Meter

Operators Manual

December 2006

Manual No. 168001 Rev. 4

©2006 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: General Information................................................................................... 1-1

1.1 Product Description ..................................................................................... 1-1

1.2 Specifications............................................................................................... 1-2

Section 2: Getting Started........................................................................................... 2-1

2.1 Receiving Inspection.................................................................................... 2-1

2.2 Storage........................................................................................................2-1

2.3 Routine Cleaning......................................................................................... 2-1

2.4 Indicators and Controls................................................................................ 2-2

Section 3: Theory and Applications........................................................................... 3-1

3.1 General........................................................................................................ 3-1

3.2 Filtration Effects........................................................................................... 3-1

3.3 Waveform Effects ........................................................................................ 3-2

3.4 Focus to Detector Distance (FDD)............................................................... 3-2

3.5 mAs Requirements...................................................................................... 3-2

3.6 Detector Positioning..................................................................................... 3-3

3.7 Low Battery.................................................................................................. 3-3

3.8 Applications ................................................................................................. 3-3

Section 4: Operation.................................................................................................... 4-1

4.1 Making a Measurement ............................................................................... 4-1

4.2 Interpreting Front Panel Warning Indications............................................... 4-2

4.3 Viewing the Waveform Output..................................................................... 4-3

Section 5: Calibration and Adjustments.................................................................... 5-1

5.1 Low Battery Threshold Adjustment.............................................................. 5-1

5.2 End of Shot Adjustment............................................................................... 5-3

5.3 50-90 kVp Calibration .................................................................................. 5-3

5.4 80-150 kVp Calibration ................................................................................ 5-3

Section 6: Maintenance and Troubleshooting........................................................... 6-1

6.1 Battery Replacement ................................................................................... 6-1

6.2 Accessing the Circuit Boards....................................................................... 6-1

6.3 Performance Verification (Calibration Constancy)....................................... 6-2

6.4 Verifying Supply Voltages............................................................................ 6-3

i

Page 4

(Blank page)

Page 5

General Information

Product Description

1

Section 1

General Information

1.1 Product Description

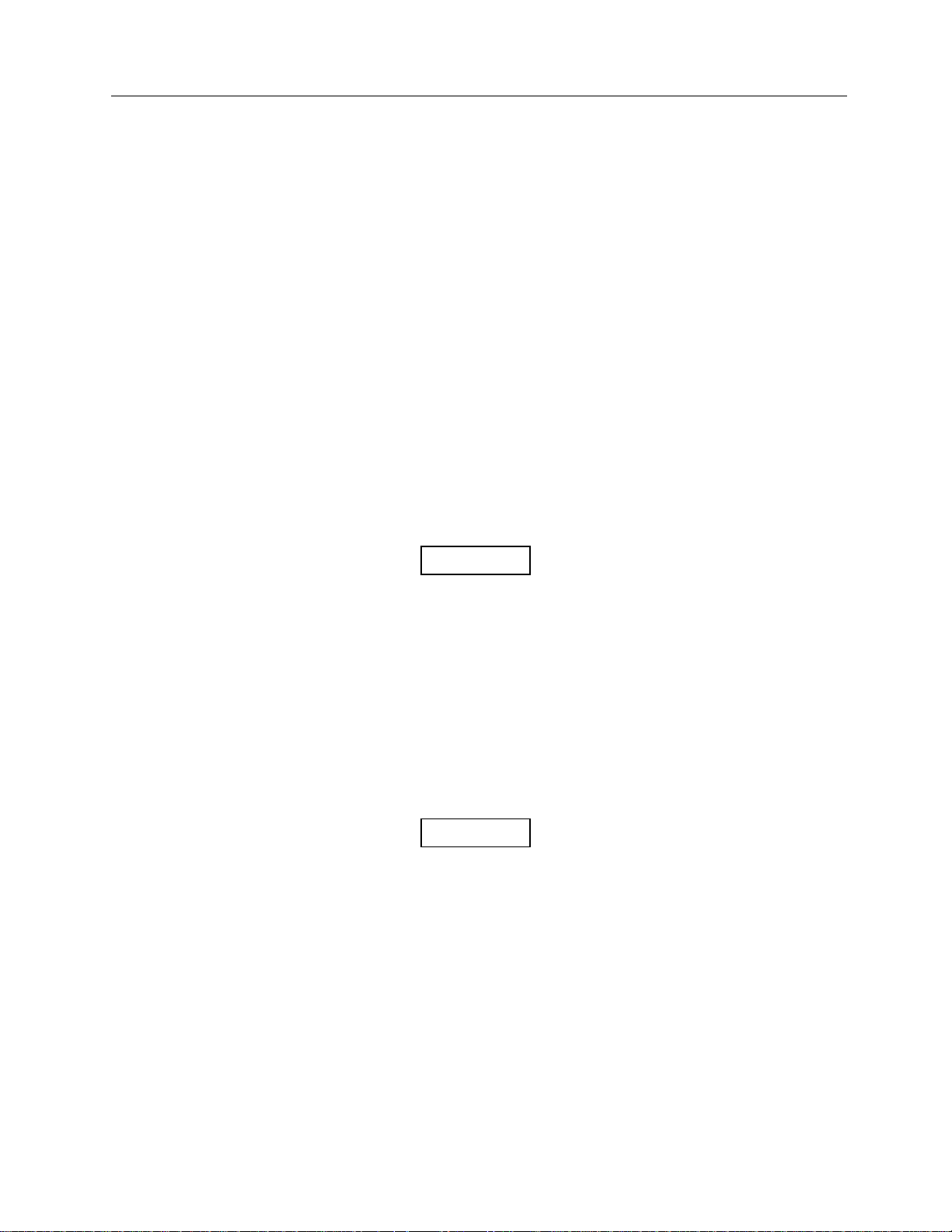

The Model 07-494 Wide-Range Digital kVp Meter (Figure 1-1) is a portable, battery operated unit which

non-invasively measures the effective peak potential applied to a tungsten target diagnostic x-ray tube. It

uses two differentially filtered x-ray detectors whose ratio of integrated outputs is calibrated over the

ranges of 50 to 90 kVp and 80 to 150 kVp. The desired range is selected using the range selector on the

top of the unit.

Figure 1-1. Model 07-494 Wide-Range Digital kVp Meter

1-1

Page 6

Victoreen 07-494

Operators Manual

1.2 Specifications

Range

Resolution

Accuracy

mAs Requirements

Reproducibility

Filtration Effects

Calibration Frequency

Battery

Display

LED Indicators

Controls

Low: 50 kVp to 90 kVp

High: 80 kVp to 150 kVp

0.1 kVp

± 3% or 3 kV, whichever is greater (tungsten target x-ray tube

with 4.5 mm Al total filtration)

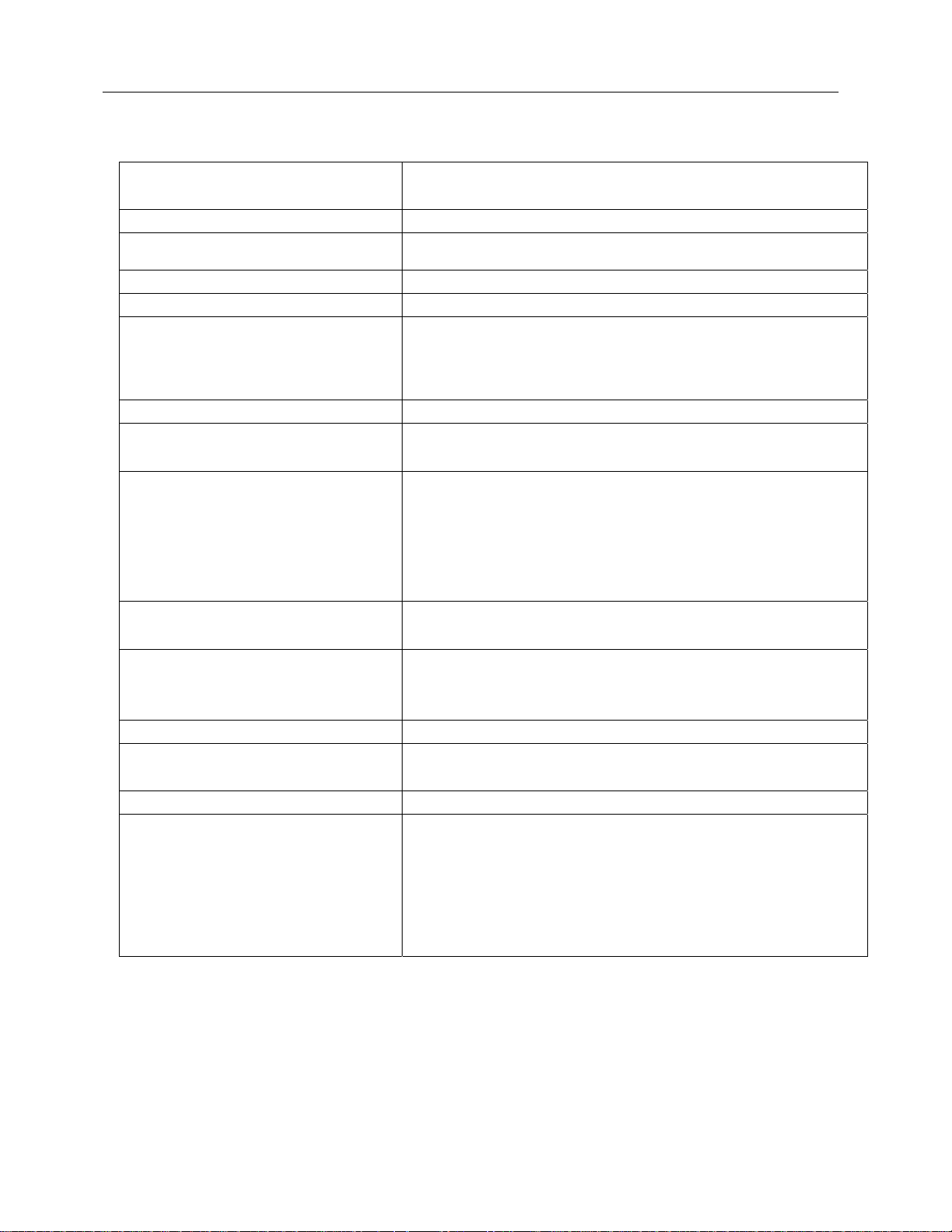

See Figure 1-2

± 1 kV or 1%, whichever is greater

50 kVp - 90 kVp range: less than 3.5% with 5.3 mm aluminum

added

80 kVp – 150 kVp range: less than 3% with 8 mm aluminum

added

One (1) year

Type: 9 V alkaline, NEDA 1604 (IEC 6F22) or alkaline equivalent

Life: 75 hr. typical

3 ½ digit, 0.5" high LCD with LO BAT indicator;

Below Range kVp: Flashing middle decimal point

Above Range kVp: Flashing left decimal point

Above Range mAs: Flashing right decimal point

Below Range mAs: Flashing right decimal point and 00.0

display

Auto Reset: New exposure detected, last kVp reading cleared

Range Fault: Range select sliding filter not properly engaged

Power Switch: ON/OFF

Phase Selection Switch: Single phase/3 phase

Filter Range Selection Switch: 50 to 90 kVp or 80 to 150 kVp

Connectors

Dimensions

(H x W x D)

Weight

Environmental Specifications Temperature:

1-2

BNC connector for waveform output

2.5 in. x 8 in. x 6 in.

(6.4 cm x 20.3 cm x 15.2 cm)

2.4 lbs. (1.1 kg)

Operating: 59 to 104° F (15 to 40° C)

Storage: - 0 to 122° F (-18 to +55° C)

Relative Humidity:

Operating: 0 to 90% non-condensing

Storage: 0 to 90% non-condensing

Page 7

Victoreen 07-494

Operators Manual

.

mA

Figure 1-2. mAs vs. kVp, Minimum Requirements (Typical Single Phase X-ray Unit)

kVp

1-2

Page 8

Victoreen 07-494

Operators Manual

(Blank page)

Page 9

Getting Started

Receiving Inspection

Section 2

Getting Started

2.1 Receiving Inspection

Upon receipt of the instrument:

1. Inspect the carton(s) and contents for damage. If damage is evident, file a claim with the carrier and

contact Fluke Biomedical, Radiation Management Services at 440.248.9300.

2. Remove the contents from the packing material.

3. Verify that all items listed on the packing list have been received and are in good condition. The

following items are shipped with the Model 07-494 kVp Meter

a. Part No.168005, Model 07-494 kVp III.

b. Part No.16-29, 9 V Alkaline Battery

c. Part No.168001 Instruction Manual

d. Part No. 010023 Registration Card

If any of the listed items are missing or damaged,

notify Fluke Biomedical at 440.248.9300.

2

2.2 Storage

If necessary to store the kVp meter prior to use, pack it in the original container if possible. Be sure the

storage area is free of corrosive materials, vibrations, and fluctuations in temperature and humidity. Also

be sure the environmental specifications (refer to Section 1-2, Specifications) are not exceeded.

2.3 Routine Cleaning

Do not immerse the Model 07-494 Wide-Range

Digital kVp Meter. This unit is not waterproof. Liquid

could damage the circuits. The unit should be kept

clean and free of dirt and contamination. The unit

may be cleaned by wiping with a damp cloth using

any commercially available cleaning or

decontaminating agent.

2-1

Page 10

Victoreen 07-494

Operators Manual

2.4 Indicators and Controls

Top Panel

The top panel (Figure 2-1) includes brief operating instructions, beam center indication, display guide for

warning indicators A through D, and the range selector switch.

The range selector switch allows the operator to select the appropriate kVp range for the measurement.

When the range selector is set to 80 - 150 kVp, a second filter pair is positioned above the photodiodes

and a separate calibration is applied to the measurement circuit.

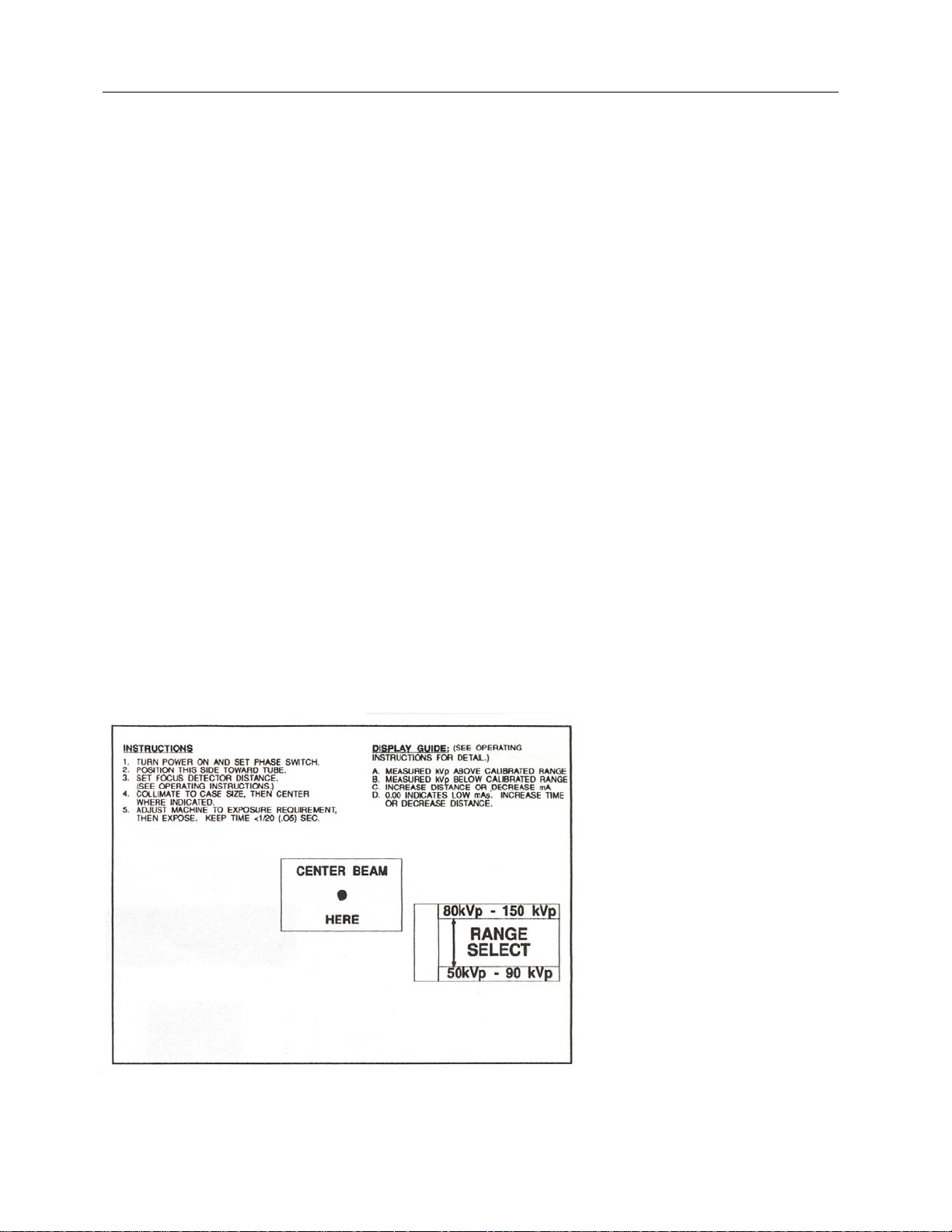

Front Panel

Refer to Figure 2-2 for front panel layout.

Numeric Readout: A 3-½ digit LCD display indicates the kVp value, provides warning status (flashing

decimal points), and indicates low battery voltage (LO BAT). Warning indications are listed on the top

panel and discussed further in Section 4, Operation.

Auto Reset LED: The auto reset LED is lit whenever the kVp Meter detects an x-radiation. The LED will

be on for 0.5 seconds or for the duration of the exposure, whichever is greater. The previous reading is

cleared when the LED turns on.

Range Fault LED: The range fault LED is lit whenever the range selector is between ranges or not

properly engaged.

Power Switch (ON/OFF): The power switch is an alternate action switch used to turn the instrument on or

off. The LCD readout is active when power is applied.

Phase Switch (1φ-3φ). The phase switch allows the operator to select either single phase (1φ) or three-

phase (3φ) operation. When the phase switch is in the 1φ position, the displayed value corresponds to a

single-phase waveform produced by a single-phase x-ray machine. When the phase switch is in the 3φ

position, the displayed value is the single phase calibrated output multiplied by a constant to compensate

for differences between 3 phase (or DC) and single phase waveforms.

Figure 2-1. Top Panel

2-2

Page 11

Getting Started

Indicators and Controls

Figure 2-2. Front Panel

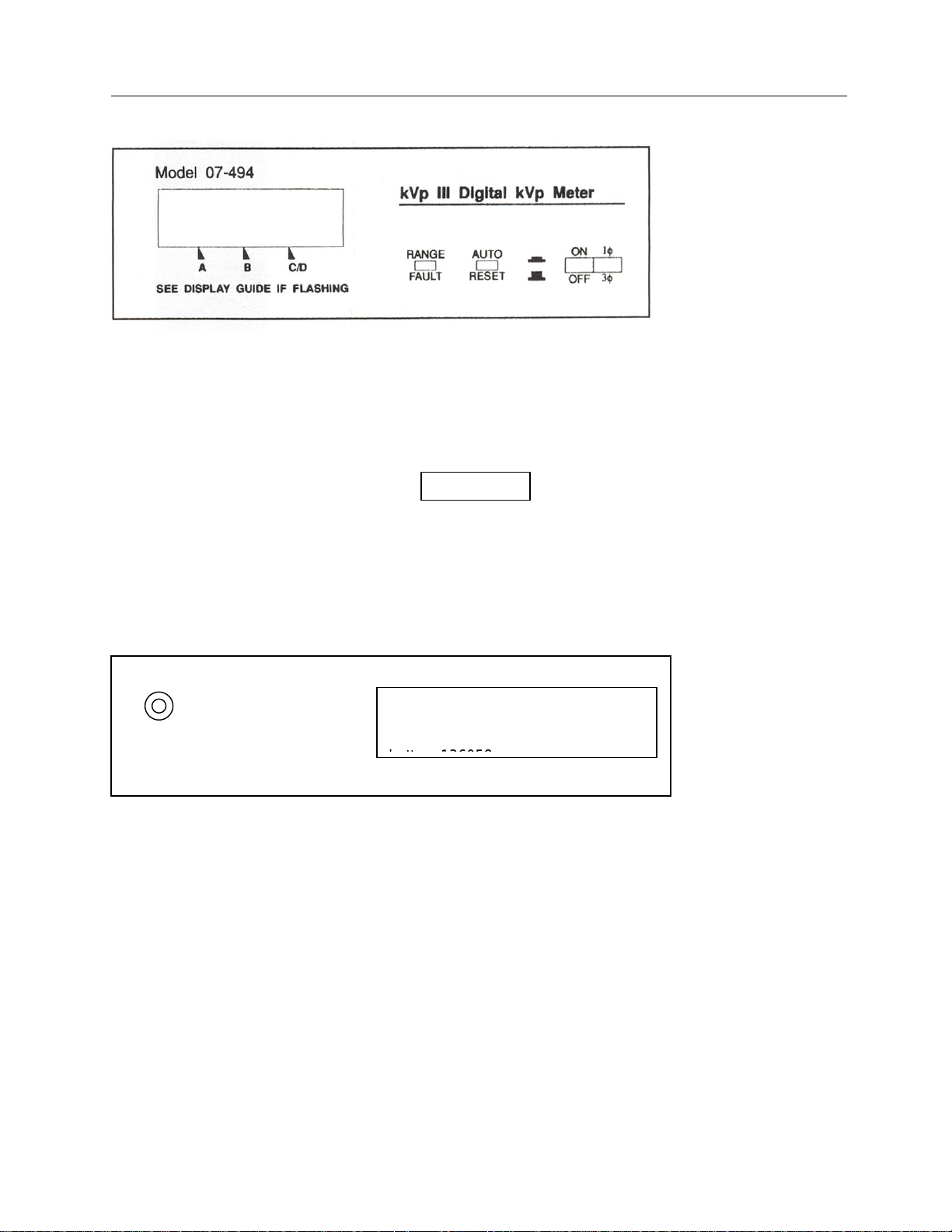

Rear Panel

Refer to Figure 2-3 for rear panel layout.

Battery Access Cover: The battery access cover is located on the rear panel. Refer to Section 5,

Maintenance for battery replacement procedures.

Be sure the unit is turned OFF before removing the

batteries.

BNC Connector: A BNC connector, located on the rear panel, provides a signal from the radiation

detection diodes. The signal can be observed on an oscilloscope during an exposure. However, the

signal lasts only as long as the exposure. Therefore, a storage scope or camera is required to view the

signal for extended periods of time.

2

Figure 2-3. Rear Panel

Scope

CAUTION: Turn off power switch

before replacing battery. Use

MN16404 or equivalent alkaline

2-3

Page 12

Victoreen 07-494

Operators Manual

(Blank page)

Page 13

Theory and Applications

General

3

Section 3

Theory and Applications

3.1 General

The kVp measurement is computed from a measurement of the linear absorption coefficient (µ) of the

hardened x-ray beam. As the kV increases, µ increases, as discussed in the following paragraphs.

An x-ray beam is composed primarily of two parts - the bremsstrahlung radiation and the characteristic

radiation. Bremsstrahlung radiation predominates below 70 kV. When the beam potential crosses the 70

kV threshold, an apparent beam hardening takes place due to the sudden increase in the emission of

higher energy x-rays. The linear absorption coefficient, µ, increases at continually faster rates until

approximately 90 kV. Above 90 kV, the characteristic radiation becomes less important and contributes

less hardening to the beam. The bremsstrahlung radiation again dominates, and μ increases at a slower

rate. Use of dual range filters above 90 kVp helps minimize this effect.

3.2 Filtration Effects

A slight change in the beam spectrum being measured results in a change in the µ as described above.

This change may be caused by filtration differences with respect to the calibration beam. With lower

filtration, the x-ray beam is as hard as the calibration beam and the results are lower. With more filtration,

the beam is harder than the calibration beam and the results are higher. Refer to Table 3-1.

Table 3-1. Filtration Effects

Selected Range kVp

50 – 90 kVp

80 – 150 kVp

The results in Table 3-1 were reduced from data taken with a single-phase machine with 4 mm Al

inherent filtration. The values in the display increase column represents the % change in displayed kV for

each added mm Al filtration. The correlation coefficient (r) was above 0.99 for all curves. The filtration

varied from 0 to 8 mm Al.

To correct the display for tube filtration above 4 mm Al, reduce the display by F% where:

F = (%/mm Al) x (Tube Filtration - 4 mm Al).

Use the %/mm Al value closest to the kVp results.

65

80

100

120

Display Increase

(%/mm AI)

0.34

0.40

0.40

0.45

Tube filtration effects below 4 mm Al have not been studied. It is suggested for the best accuracy in kVp

measurements that the tube filtration be increased to 4 mm Al if it is less than that. To test the filtration

present on the tube, measure the HVL of the beam with 80 kVp set on the tube. For 80 kVp and 4 mm Al

filtration, the HVL should be 3.5 mm Al. An HVL less than 3.5 mm Al indicates that the filtration is less

than 4 mm Al.

3-1

Page 14

Victoreen 07-494

Operators Manual

3.3 Waveform Effects

Beam spectrum changes also occur with different waveforms. Single-phase waveforms display different

readings than three phase waveforms, depending on the position of the range selector switch. Correction

for waveform effect is made by selecting the appropriate position (i.e., single phase or three phase) using

the front panel phase selection switch.

3.4 Focus to Detector Distance (FDD)

The Focus to Detector Distance (FDD) affects the mAs requirements as discussed in Section 3.5, mAs

Requirements. Table 3-2 lists FDD settings generally used to keep the mAs requirement between 20 and

100. The FDD does not affect the accuracy of the kV results.

Table 3-2. FDD Settings

Selected Range kVp FDD

50 – 90 kVp

80 – 150 kVp

50 to 70

70 to 90

80 to 100

100 to 150

18 in. (45 cm)

36 in. (30 cm)

18 in. (45 cm)

36 in. (30 cm)

3.5 mAs Requirements

The curves in Figure 1-2 (see Section 1-2, Specifications) are provided as guidelines for selecting the

mAs required for a particular kVp measurement. Any mAs beyond the required amount is not used in the

measurement.

To determine the mAs required:

1. Locate the kVp to be measured on the horizontal axis.

2. Read the mAs from the selected FDD. It may be necessary to interpolate between distances using

the inverse square law.

As examples:

For kVp = 70 and FDD = 18 in.,

the mAs = 20.

For kVp = 100 and FDD = 30 in.,

the mAs = (30 in. /36 in.) (30 in. /36 in.) 90 = 62.5

The curves in Figure 1-2 (see Section 1.2, Specifications) are derived from single-phase measurements.

Three phase machines generally require 70% of the mAs determined from the curves.

Specific mAs requirements depend on the following factors:

• Detector sensitivity

• Tube filtration

• Radiation waveform

• FDD

• mAs errors in the x-ray machine

3-2

Page 15

Theory and Applications

Detector Positioning

3

3.6 Detector Positioning

The kVp Meter should be positioned in the center of the beam. The measurement area of the meter is 2

square inches, and is located on the top panel of the unit. Measurements made on other parts of the

beam will result in inaccurate readings due to the fact that the beam spectrum is different for different

parts of the beam. The heel effect is an example of such a beam spectrum change. As an illustration of

the effect of detector positioning, place the kVp meter in a selected part of the beam, make an exposure,

and observe the displayed measurement. Then move the detector to another part of the beam, make

another exposure, and observe the displayed measurement. Notice that the two measurements are

significantly different.

3.7 Low Battery

A low battery indication is displayed when the battery voltage drops below a factory-preset value. The

preset value is high enough that there is not an immediate noticeable effect on the measurement results.

However, prolonged use of the Instrument in the low battery condition will result in decreased accuracy.

3.8 Applications

kVp Accuracy Determinations

With the Digital kVp Meter, it is possible to enter a diagnostic x-ray room and, within one minute,

determine kVp accuracy for several stations of the x-ray machine. As a result, a significant cause of poor

image quality can be immediately diagnosed without affecting patient throughput.

Calculating Generator Loading Effects

In an x-ray generator, when the load (mA) changes, the kV may also change. Often, the generator

circuitry has been designed to compensate for this effect so that there is not a change in kV as different

mA stations are selected. To test for this effect:

1. Determine the kV to be investigated and the maximum mA to be tested.

2. Determine the minimum mAs requirements for the kV from Figure 1-2 (see Section 1.2,

Specifications).

3. Set the distance (FDD) such that the high-test mA and 50 ms (1/20 sec.) correspond to the

minimum mAs requirements.

4. Make an exposure.

If a low mAs indication appears on the kVp meter,

set the timer to the next station.

5. Record the value displayed on the kVp meter.

6. Set the mA to the next lower position.

7. Increase the exposure time so that the mAs remains greater than or equal to the value determined

in Step 3.

8. Make an exposure.

9. Record the value displayed on the kVp meter.

10. Compare the values recorded in Step 5 and Step 9 to determine how well the generator

compensates for mA changes.

3-3

Page 16

Theory and Applications

Applications

To eliminate time as a variable, decrease the FDD and mA while holding time constant. Utilizing the

inverse square law:

3

FDD

NEW

= FDD

X SQRT (mA

MAX

NEW

/mA

MAX

):

where:

FDD

FDD

= FDD to be used with new mA,

NEW

= FDD used with the maximum mA, and

MAX

SQRT = Square root.

kVp vs. Time Studies

During an x-ray exposure, the kVp may vary as a function of time. This can be illustrated by keeping the

mA constant and changing the FDD to vary the measurement time.

The kVp Meter accumulates data until certain internal values are reached, and then it displays the result.

The measurement time is independent of the generator time. For example, if the minimum mAs

requirement for a particular kV position is 50, the mA is set to 500, and the exposure time is set to 1

second, the kVp meter will accumulate data only during the first 100 ms interval (=50 mAs). (Refer to the

discussion in Section 3.5, mAs Requirements.) Nine tenths of the shot is wasted and the displayed result

does not indicate what occurs during the tail end of the exposure. A greater portion of the total exposure

can be included by increasing the mAs requirement by increasing FDD. There is no limit on maximum

exposure time.

To implement this application:

1. Select the kV, the mA, and the longest exposure time to be studied. The product of the mA and

time should correspond to the minimum mAs requirements determined from Figure 1-2 (refer to

Section 1.2, Specification).

2. Set the FDD to correspond to the longest exposure time.

3. Make an exposure and record the results.

4. Decrease the FDD, which, in effect, decreases the exposure time according to the inverse square

law.

ISF = inverse square factor = SORT (TMAX)

where,

T= kVp measurement for the kVp, mA and distance values.

5. Make an exposure and record the results.

For a value of 65 kVp at a maximum FDD of 36 inches, using the low range filter set the minimum

required mAs is 150 (from Figure 1-2).

If TMAX = 2 sec, tube current = (150 mAs/2 s) = 75 mA (Table 3-3). If TMAX = 0.5 sec, tube current =

(150 mAs/0.5 s) = 300 mA (Table 3-4).

Table 3-3. kVp vs. Time Study at 75 mA

mA T (sec) ISF X FDD

MAX

FDD (Inches) Measured kVp

75 2.000 36.0

75 1.000 0.707 25.5

75 0.500 0.500 18.0

75 0.250 0.354 12.7

75 0.1250 0.250 9.0

3-5

Page 17

Table 3-4. kVp vs. Time Study at 300 mA

Theory and Applications

Applications

3

mA T (sec) ISF X FDD

300 0.500 1.000 36.0

300 0.250 0.707 25.5

300 0.125 0.500 18.0

300 0.067 0.365 13.1

MAX

FDD (Inches) Measured kVp

mAs Reciprocity Corrections

A mAs reciprocity examination of an x-ray system involves variation of the mA or time or both

simultaneously. An ionization chamber (RAD-CHECK Plus, Model 06-526) is used to measure the output

of the machine and mR values are then calculated. The mR values should be proportional to the mAs

quantity. Normally the kV is held constant on the generator.

As discussed above, the kV may not be a constant function of mA and time if there is a malfunction in the

machine.

When mAs reciprocity is being tested, noted variations in the mR value may be due to kV fluctuations as

well as mA and timer nonlinearities. A simple correction for mAs reciprocity fluctuations due to kV

changes can be made if the kV fluctuations are known. If the percent change in kV is small, the mR

output will change as the square function of the kVp. That is, the percent change in mR output is double

the percent change in kV over a small percentage range (Table 3-5).

Table 3-5. mAs Reciprocity

Measured kVp mA Time mAs

80 100 0.1 s 10 160 16.0

82 300 0.1 s 30 525 17.5

In Table 3-5 there is a 9.4% increase in mR/mAs values. There is a 2.5% increase in kVp value which

would contribute to an approximate 5% increase in mR output. The 94% non-linearity in mAs reduces to

9.4% -5% = 4.4% which is acceptable.

mR mR/mAs

From this analysis, it is evident that the mA/kV compensation needs correction, whereas, without this

analysis, the mA or time looks suspect. If the changes in kV and mAs are in the opposite direction, the

mAs reciprocity results from the mR values may be very nearly linear and a simple reciprocity check

would indicate that the machine seems to be functioning properly. However, the use of the kVp Meter

would indicate the kV error and possibly an error in the mAs which was being cancelled out by the kV

error.

Waveform Diagnostics

If the mA is held strictly constant, and filtration does not change through the exposure, then variations in

the radiation waveform can be interpreted as variations in the kV waveform. It is difficult to reduce the kV

waveform from a single detector waveform even if the mA is held strictly constant. Relative judgments can

be made from the radiation waveform; however, absolute judgments should be avoided. For example,

the maximum observed point on a radiation waveform corresponds to the maximum kV point in the

waveform, but it may also be closely aligned to a maximum in the mA waveform.

The radiation waveform can exhibit symptoms of one or more type of malfunctions in an x-ray system as

listed in to Table 3-6.

Table 3-6. Waveform Diagnostics

3-5

Page 18

Theory and Applications

Problem Symptom

Preheat problems Waveform intensity continues to increase over

the first few cycles.

Arcing Waveform exhibits sharp rises and spikes with

a duration of 10 to 1000 microseconds.

Overshoot Problems Waveform exhibits overshoot on the first 2 or

3 pulses (3 phase machine).

Contactor Bounce Waveform peaks contain noise or smaller

peaks riding on major peaks.

Rectifier Imbalance Relative peak heights are different and

repeatable (i.e., one high and one low, or, in a

three phase machine, high-medium-low, highmedium-low, high-medium-low.)

Load Effects Waveform exhibits drooping during a long

exposure.

Applications

3

3-5

Page 19

Operation

Making a Measurement

Section 4

Operation

4.1 Making a Measurement

Use the following procedure to make a kVp measurement:

1. Turn the power switch to the ON position. The following should appear on the display:

00.0

If the low battery indication is displayed, or if the

display fails to respond, replace the battery. Refer

to Section 6, Maintenance for battery replacement

procedures.

2. Set the phase switch to the single-phase (1φ) or three-phase (3φ) position according to the type of

machine being measured.

If a fluoroscopic or constant potential is being

measured, set the switch to the three-phase (3φ)

position. (For an x-ray machine operated in the

fluoroscopic mode, the loading on the generator is

much lighter than normal and the radiation

spectrum more closely resembles that produced by

a three-phase, rather than single-phase,

generator.)

3. Set the range selector switch (located on the top panel) to the appropriate range for the kV to be

measured.

4. Set the desired Focus to Detector Distance (FDD), using the guidelines listed in Table 4-1.

4

Table 4-1. FDD Settings

Selected Range kVp FDD

50 – 90 kVp

80 – 150 kVp

5. Collimate the beam to the case size, using the light field.

6. Position the detector so that it is centered in the beam as indicated on the top panel.

7. Determine the mAs value using the guidelines discussed in mAs Requirements (refer to Section 3,

Theory and Applications).

8. Make an exposure and read the displayed kVp.

50 to 70

70 to 90

80 to 100

100 to 150

18 in. (45 cm)

36 in. (30 cm)

18 in. (45 cm)

36 in. (30 cm)

4-1

Page 20

Victoreen 07-494

Operators Manual

If a kVp value is not displayed, try doubling the

exposure time or decreasing the FDD by 30%.

9. Observe any displayed warnings, including flashing decimals or a low battery indication.

Warning indications are interpreted on the top

panel and in the following paragraphs.

The Digital kVp Meter has an auto reset feature. It senses when a new exposure takes place, resets the

display for a new reading and turns on the Auto Reset LED for 0.5 seconds or the duration of the

exposure, whichever is greater.

4.2 Interpreting Front Panel Warning Indications

Front panel warning indications are listed in Table 4-2.

A flashing decimal point above the A on the front panel indicates that the measured kVp is above the

calibrated range; that is, the kVp is above 150 kVp with the range selector in the 80 to 150 kVp setting or

above 90 kVp with the range selector in the 50 to 90 kVp setting.

A flashing decimal point above the B on the front panel indicates that the measured kVp is below the

calibrated range; that is, that the kVp is below 80 kVp with the range selector in the 80 to 150 kVp setting

or below 50 kVp with the range selector in the 50 to 90 kVp setting.

Indication

A

B

C/D

(Display ≠ 00.00)

C/D

Display = 00.0

A flashing decimal point above the C/D on the front panel with a displayed value other than 00.0 indicates

that beam intensity is too high and the measurement is completed with less than 50 ms of radiation

waveform. Increase the FDD or decrease the mA to produce more accurate results. This is particularly

important for single-phase x-ray machines because the radiation spectrum changes dramatically

throughout e duration of 4 pulses. If the measured waveform contains less than 6 pulses of single-phase

rectification, a partial pulse has a significant contribution to the value of the average of the pulses. It is

less important for 3 phase machines because the radiation spectrum remains relatively constant

throughout the exposure.

Explanation

Measured kVp > calibrated range.

Measured kVp < calibrated range.

Beam intensity too high; measurement time too

short.

Beam intensity too low; measurement time too long.

4-2

Page 21

Operation

Interpreting Front Panel Warning Indications

4

For displayed values greater than 95 kVp a flashing

decimal point above the C/D on the front panel may

be impossible to avoid for any combination of mA

or distances. The sensitivity of the kVp Meter above

95 kVp increases such that the mAs requirements

become very low at short distances. More filtration

can be added to the X-ray beam with the sacrifice

of accuracy. Filtration effects are discussed in more

detail in Section 3, Theory and Applications.

A flashing decimal point the C/D on the front panel with a displayed value equal to 00.0 indicates that the

minimum mAs requirements have not been met. Increase either the time or the mA setting or decrease

distance to obtain the required results.

4.3 Viewing the Waveform Output

The BNC connector on the rear panel provides a signal from the unfiltered radiation detection diodes in

the kVp Meter. During the x-ray exposure, a voltage is present at the BNC connector and available for

display on an oscilloscope. Examination of the waveform will require photographing it on a conventional

oscilloscope or using a storage oscilloscope.

4-3

Page 22

Victoreen 07-494

Operators Manual

(Blank page)

Page 23

Calibration and Adjustment

Low Battery Threshold Adjustment

Section 5

Calibration and Adjustment

This instrument has been factory calibrated. Recalibration should be performed by the factory or a

qualified calibration facility every 12 months. Other than calibration, there are six potentiometers which

may require adjustment. The procedures are outlined in this Section. Refer to Figure 5-1 for

potentiometer location

5.1 Low Battery Threshold Adjustment

Potentiometer R25 adjusts the threshold for indicating LO BAT on the LCD display. Use the following

procedure:

1. Open the battery compartment on the rear panel.

2. Remove and disconnect the battery.

3. Connect a voltmeter between battery plus (TP3).

4. Connect a voltmeter between battery plus (TP3) and analog ground (TP4).

5. Turn on the power supply and adjust it for 9 V.

6. Turn on the kVp Meter. The voltmeter should read between 2.4 V and 3.2 V.

7. Slowly decrease the power supply voltage until the voltage at the test point starts to drop (between

6.5 V and 7.5 V).

8. Slowly increase the power supply until the voltage across the test points just returns to the value it

had prior to dropping off.

9. Turn R25 until LO BAT disappears from the display.

10. Turn R25 slowly in the opposite direction just until LO BAT reappears on the display.

11. Connect the voltmeter between analog ground and the power supply negative terminal.

12. Increase the power supply voltage until the voltmeter reads 4.5 V, being careful not to exceed 9 V

from the power supply. LO BAT should turn off at this point.

13. Replace the battery and close the battery compartment.

5

5-1

Page 24

Victoreen 07-494

Adj

Operators Manual

80 - 150 kVp

Calibration

Adjustments

TP1

R

R

TP3

TP2

Below

Batter

TP8

50 – 90 kVp

Calibration

ustments

R

RTP1

R33 TP7

Figure 5-1. Adjustment and Test Point Locations

R60

Three Phase

Adjustments

(R19 and R60)

R19

TP5

TP9

Low Battery

Threshold

Adjustment

TP1

TP4

5-2

Page 25

Calibration and Adjustment

End of Shot Adjustment

5.2 End of Shot Adjustment

R33 provides adjustment of the radiation detection diode sensitivity. Use the following procedure:

1. Connect the positive lead of a DVM to TP3.

2. Connect the negative lead of the DVM to TP4.

3. Record the DVM reading.

4. Connect the positive lead of the DVM to TP8.

5. Adjust R33 to obtain a reading on the DVM equal to 50% of the reading recorded in Step 3 (at

TP3).

The reading obtained in Step 5, after adjustment of

R33 should be between 1.2 and 1.5 V.

5.3 50 - 90 kVp Calibration

The adjustments for the 50 - 90 kVp range are R4 and R5. An independent accurate means of

measuring the kVp of the x-ray machine is necessary for proper calibration. The kVp meter must be

calibrated at 50 kVp and 85 kVp (+1%) to be within specification. Use the following procedure:

5

1. Set the front panel phase switch for single-phase or three-phase depending on the type of x-ray

machine used for calibration.

2. Set the range selector switch to the 50 - 90 kVp range.

3. Remove the cover from the meter.

4. Locate the meter at an FDD of 24 inches.

5. Set the x-ray machine to 50 kVp, 300 mA, and 1.5 seconds.

6. Make an exposure.

7. Adjust R5 until the display reads 50 kVp.

8. Set the x-ray machine to 85 kVp, 300 mA, and 0.3 seconds.

9. Make an exposure.

10. Adjust R4 until the display reads 85 kVp.

11. Repeat Steps 5 through 10 until the readings are accurate.

5.4 80 - 150 kVp Calibration

The two adjustments for the 80 kVp to 150 kVp range are R3 and R6. In this range the kVp meter must

be calibrated at 85 kVp and 140 kVp (±1%) to be within specification. Use the following procedure:

1. Set the front panel phase switch for single-phase or three-phase depending on the type of x-ray

machine used for calibration.

2. Set the range selector switch to the 80 - 150 kVp range.

3. Remove the cover from the meter.

4. Locate the meter at an FDD of 24 inches.

5. Set the x-ray machine to 85 kVp, 50 - 100 mA, and 0.3 seconds.

6. Make an exposure.

5-3

Page 26

Victoreen 07-494

Operators Manual

7. Adjust R6 until the display reads 85 kVp.

8. Set the x-ray machine to 140 kVp, 50 mA, and 0.3 seconds.

9. Make an exposure.

If the C/D decimal point is flashing, indicating that

the intensity of the exposure is too high, decrease

the mA or increase the FDD and repeat the

exposure.

10. Adjust R3 until the display reads 140 kVp.

11. Repeat Steps 5 through 10 until the readings are accurate.

5-4

Page 27

Maintenance and Troubleshooting

Battery Replacement

6

Section 6

Maintenance and Troubleshooting

6.1 Battery Replacement

When the internal battery no longer provides sufficient voltage for proper operation, a LOW BAT indicator

will appear in the upper left corner of the display. When this indication appears replace the battery as

follows:

1. Turn the power OFF.

2. Open the battery compartment on the rear panel.

3. Remove and disconnect the old battery.

4. Insert and connect a fresh 9 V NEDA type 1604 (or equivalent) battery.

5. Snap the battery compartment door closed.

6.2 Accessing the Circuit Boards

Use the following procedure to gain access to the circuit board components and test points:

Refer to Figure 5-1 (see Section 5, Calibration and

Adjustments) for adjustment and test point

locations.

1. Remove the two screws from the case bottom.

2. Carefully lift the top cover to expose the circuit board.

3. If necessary, remove the four screws which attach the slide filter to the circuit board to gain access

to the circuitry below the slider.

3. If required, remove the circuit board by removing the 4 nuts which hold it in the lower case.

To reassemble the unit:

1. Position the circuit board so that the mounting holes align with the screws in the lower case.

2. Position the standoff on the diode lead shield and attach the slide filter plate.

3. Carefully fit the top and bottom covers together.

4. Replace the two cover screws

6-1

Page 28

Victoreen 07-494

Operators Manual

6.3 Performance Verification (Calibration Constancy)

In this section, two methods are described for verifying the accuracy of the kVp meter. Both methods

require a careful collection of installation data and periodic re-measurement of that data. The voltage

divider method is more direct than the multiple x-ray machine method. However, if at least five x-ray

machines are used in the multiple machine test, the results are very positive.

Voltage Divider Method

If available, an x-ray voltage divider should be used concurrently during the initial testing of the kVp

Meter.

1. Choose two x-ray machines suited for the test. It is recommended that different types of machines

be used (e.g., use one three phase machine and one single phase machine).

2. Make comparative measurements of the voltage divider and the kVp Meter.

3. If an oscilloscope is used to measure the voltage divider, use an independent voltmeter to measure

the scope sensitivity each time.

Data with a kVp test cassette may be useful. Be

sure to note positioning error and film usage when

using the cassette.

4. Record all parameters of the measurement, including geometry, cable connections, tube ID,

generator ID, divider and kVp Meter waveform oscilloscope pictures, oscilloscope and voltmeter ID.

5. Periodically (every 6 months) or when a serious discrepancy occurs, repeat Steps 1 through 4 to

determine which piece of equipment is in error.

If two dissimilar x-ray machines are used, the

possibility of a systematic error is reduced. The kVp

Meter, divider, cassette results, and x-ray settings

should also be examined for constancy.

Multiple X-Ray Machine Method

If a voltage divider is not available, the following method may be used:

1. Choose several (if possible, at least five) x-ray machines suited for the test.

2. Make comparative measurements with each machine.

Data with a kVp test cassette may be useful. Be

sure to note positioning error and film usage when

using the cassette.

3. Record all parameters of the measurement, including geometry, cable connections, tube ID,

generator ID, and kVp Meter waveform oscilloscope pictures, oscilloscope, and voltmeter ID.

6-2

Page 29

Maintenance and Troubleshooting

Performance Verification (Calibration Constancy)

4. Periodically (every 6 months) or when a serious discrepancy occurs, repeat Steps I through 3 to

determine which piece of equipment is in error.

If the kVp meter suddenly produces different results

from previous tests on only one machine, then

there is a strong probability that the kVp Meter is

operating correctly. If all of the x-ray measurements

suddenly change, then the kVp Meter may not be

operating correctly.

6.4 Verifying Supply Voltages

Troubleshooting the kVp meter consists of verifying the supply voltages.

Equipment recommended for troubleshooting the kVp Meter includes:

1. A digital voltmeter (Fluke Model 77 or equivalent).

2. A storage oscilloscope (Tektronix Model 2430 or equivalent).

Use the following procedure:

6

1. Connect the DVM negative lead to TP4 (circuit ground).

All measurements will be made with reference to

TP4.

2. Apply power to the unit under test.

3. Test for the voltages listed in Table 7-1.

3. If any of the voltages cannot be verified, replace the faulty component (refer to the comments

column of Table 7-1).

The waveforms in Figures 6-2, 6-3, and 6-4 are provided for reference.

Table 6-1. Test Point Voltages

Test Point Voltage Comments

TP3 2.4 to 3.2 V Derived from U101 on VRM board.

TP5 -5.0 to 6.0 V Derived from U101 on VRM board.

TP10 1.2 to 1.6 V Derived from voltage divider R22, R23

6-3

Page 30

Victoreen 07-494

Operators Manual

CH1 = TP1

CH2 = TP8

Setup: Single phase x-ray machine

74.5 kVp @ 300 mA

28 “ SDD

CH1 1V

CH2 1V

CH1gnd

CH2gnd

Figure 6-2. Oscilloscope Waveform A

A 20ms -328mV CH1

CH1

CH2

6-4

Page 31

CH1 = TP1

CH2 = TP9

Setup: Single phase x-ray machine

74.2 kVp @ 300 mA

28 “ SDD

CH1 1V A 20ms 563mV CH1

CH2 1V

CH1gnd

CH2gnd

Figure 6-3. Oscilloscope Waveform B

Maintenance and Troubleshooting

Verifying Supply Voltages

CH1

CH2

6

6-5

Page 32

Victoreen 07-494

Operators Manual

CH1 = TP1

CH2 = TP2

Setup: Single phase x-ray machine

75.5 kVp @ 300 mA

28 “ SDD

CH1 1V A 20ms 563mV CH2

CH2 1V

CH1gnd

CH2gnd

Figure 6-4. Oscilloscope Waveform C

CH1

CH2

6-6

Page 33

(Blank Page)

Page 34

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Loading...

Loading...