Page 1

Nuclear Associates 07-492

Mammographic Digital kVp Meter

March 2005

Manual No. 164001 Rev. 3

©2003, 2005 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Operators Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

120 Andrews Road

Hicksville, New York 11801

516.870.0100

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: General Information................................................................................... 1-1

1.1 Product Description ..................................................................................... 1-1

1.2 Specifications............................................................................................... 1-2

1.3 Receiving Inspection.................................................................................... 1-3

1.4 Storage ........................................................................................................ 1-3

1.5 Routing Cleaning ......................................................................................... 1-3

1.6 Procedures, Warnings and Cautions ........................................................... 1-3

1.7 Inspection and Material Return Instructions................................................. 1-4

Section 2: Indicators and Controls............................................................................. 2-1

2.1 Front Panels ................................................................................................ 2-1

2.2 Numeric Readout......................................................................................... 2-1

2.3 Switches ...................................................................................................... 2-2

2.4 Top Panel .................................................................................................... 2-2

2.5 Rear Panel................................................................................................... 2-2

Section 3: Battery Installation and Setup .................................................................. 3-1

3.1 Installing/Replacing the Battery ................................................................... 3-1

3.2 Setting the Phase Switch (Rear Panel)........................................................ 3-1

3.3 Detector Positioning..................................................................................... 3-1

3.4 Determining mAs Requirements .................................................................. 3-2

3.5 Initial and Periodic Operation Checks.......................................................... 3-3

3.6 Voltage Divider Method................................................................................ 3-3

3.7 Multiple X-Ray Machine Method .................................................................. 3-4

Section 4: Theory of Operation................................................................................... 4-1

4.1 General ........................................................................................................ 4-1

4.2 Filtration Effects ........................................................................................... 4-1

4.3 Waveform Effects ........................................................................................ 4-1

4.4 Low Battery.................................................................................................. 4-1

4.5 Positioning Error .......................................................................................... 4-1

Section 5: Calibration and Adjustment ...................................................................... 5-1

5.1 Lo Battery Threshold Adjustment................................................................. 5-1

5.2 kVp Calibration Adjustments........................................................................ 5-1

i

Page 4

(Blank page)

Page 5

General Information

Product Description

1

Section 1

General Information

Care must be taken to ensure radiation beam is off

prior to placing the unit into position.

To avoid erroneous results, the unit must be

positioned in the center of the beam. Failure to

position the unit in the center of the beam would

cause unexpected results do to the difference in the

beam spectrum at various locations of the beam.

This device is intended for use only by persons who

have been trained in the proper interpretation of its

readings and in the appropriate safety procedures

to be followed in the presence of radiation.

Use of instrument while "LO BAT" indicator is

displayed may result in erroneous measurements

due to the loss of an accurate voltage reference.

WARNING

CAUTION

1.1 Product Description

The Model 07-492 Mammography kVp Meter is designed to measure the effective peak potential applied

to mammographic x-ray tubes. The measurement is made without direct connection to the x-ray unit

being tested.

The kVp Meter is a battery powered, self-contained instrument designed for portable use. Two modes of

operation are available:

• Mo/Mo (Phase 1) - For use with single-phase x-ray machines using moly target (anode) and moly

filtration.

• Mo/Mo (Phase 3) - For use with three phase x-ray machines using moly target (anode) and moly

filtration.

1-1

Page 6

Nuclear Associates 07-492

Operators Manual

NOTE

Correction factors for different target/filter

combinations are provided in Section 5, Calibration

and Adjustment.

The kVp meter uses two differentially filtered detectors whose ratio of integrated outputs is calibrated over

the range of 24 to 40 kVp. Measurement results are presented on an easy to read 3½ digit Liquid

Crystal Display. Status is indicated by decimal point positioning on the readout. Low battery condition is

indicated by LO BAT displayed on the readout.

1.2 Specifications

Range Mo: 24 kVp to 40 kVp

Accuracy ± 1.5 kV

Reproducibility ± 0.5 kV

Resolution 0.1 kV

Distance Dependence Negligible for SSD of 20 cm or greater

Angle Dependence Negligible for 10 degrees or less

Position Dependence Negligible for misalignment of 5 cm or less at 30 cm.

Calibration Period One year

Filtration Effects 1.5 kV per mmAl at 25 kVp

4.0 kV per mmAl at 35 kVp

Minimum Requirements 75 mA @ 24 kVp, 25 cm

Power Requirements 9V Alkaline Battery, MN1604A or equivalent

Display 3 ½ Digit LCD

Low Battery Indication: LO BAT

High kV Indication: Left Blinking Decimal

Low kV Indication: Middle blinking Decimal

High Intensity Indication: Right blinking decimal and non-zero display.

Low mAs Indication: Right blinking decimal and zero display.

LED Indicator Auto Reset, new exposure detected, and last reading cleared.

Controls Front Panel: Power switch.

Rear Panel: Phase selection switch

Output Connector BNC Connector on rear panel for waveform output.

Dimensions (H x W x D) 2.5 in. x 8 in. x 6 in. (6.4 cm x 20.3 cm x 15.2 cm)

Weight 2.1 lbs. (.95 kg)

Temperature Limits Operating: +18° to + 40° C (+64° to + 104° F)

Maximum 90% relative humidity, non-condensing

Storage: -18° to + 55° C (0° to + 132° F)

1-2

Page 7

General Information

Receiving Inspection

1.3 Receiving Inspection

1. Check the packaging and its contents for damage. If damage is evident, file a claim with the carrier

and contact Fluke Biomedical, Radiation Management Services at 440.248.9300 for further

instructions.

2. Remove the packaging and visually inspect the unit for damage.

3. Verify that the following items have been received and are in good condition:

• One Model 07-492 Mammography kVp Meter, Part No. 164005

• One MN1604A (or equivalent) 9V Alkaline Battery, Part No. 16-29

• One 07-492 Operator's Manual, Part No. 164001

NOTE

If items are missing or damaged, contact Fluke

Biomedical at 440.248.9300 for further instructions.

1.4 Storage

1

If necessary, the kVp meter may be stored in an area free of corrosive materials, temperature and

humidity fluctuations, vibration, and shock. In addition, the storage area should satisfy the environmental

specifications of the unit (refer to Section 2, Indicators and Controls).

1.5 Routine Cleaning

Do not immerse the Model 07-492 Mammography

Digital kVp Meter. The unit is not waterproof.

Liquid could damage the circuits. The unit should

be kept clean and free from dirt and contamination.

The unit may be cleaned by wiping with a damp

cloth using any commercially available cleaning or

decontaminating agent.

CAUTION

1.6 Procedures, Warnings, and Cautions

The equipment described in this manual is intended to be used for the detection and measurement of

ionizing radiation. It should be used only by persons who have been trained in the proper interpretation of

its readings and the appropriate safety procedures to be followed in the presence of radiation.

Although the equipment described in this manual is designed and manufactured in compliance with all

applicable safety standards, certain hazards are inherent in the use of electronic and radiometric

equipment.

WARNINGS and CAUTIONS are presented throughout this document to alert the user to potentially

hazardous situations. A WARNING is a precautionary message preceding an operation which has the

potential to cause personal injury or death. A CAUTION is a precautionary message preceding an

operation which has the potential to cause permanent damage to the equipment and/or loss of data.

Failure to comply with WARNINGS and CAUTIONS is at the user’s own risk and is sufficient cause to

1-3

Page 8

Nuclear Associates 07-492

Operators Manual

terminate the warranty agreement between Fluke Biomedical, Radiation Management Services and the

customer.

Adequate warnings are included in this manual and on the product itself to cover hazards that may be

encountered in normal use and servicing of this equipment. No other procedures are warranted by Fluke

Biomedical. It shall be the owner’s or user’s responsibility to see to it that the procedures described here

are meticulously followed, and especially that WARNINGS and CAUTIONS are heeded. Failure on the

part of the owner or user in any way to follow the prescribed procedures shall absolve Fluke Biomedical

and its agents from any resulting liability.

Indicated battery and other operational tests must be performed prior to each use to assure that the

instrument is functioning properly. If applicable, failure to conduct periodic performance tests in

accordance with ANSI N323-1978 (R1983) Radiation Detection Instrumentation Test and Calibration,

paragraphs 4.6 and 5.4, and to keep records thereof in accordance with paragraph 4.5 of the same

standard, could result in erroneous readings or potential danger. ANSI N323-1978 becomes, by this

reference, a part of this operating procedure.

1.7 Inspection and Material Return Instructions

Instruments should be examined and tested as soon as received by the purchaser. Claims for damage, if

any, should be filed at once with the carrier. Any material returned for repair must be accompanied by a

valid customer purchaser order, identifying the work to be done. A Material Return Form is provided at

the back of this manual. Send the completed form with items returned for repair to enable our Sales

Personnel to process the order as quickly as possible.

Material valued at $200.00 or more and/or weighing more than twenty pounds should be shipped the best

way prepaid and fully insured.

Fluke Biomedical suggests that any instrument weighing over twenty pounds be wrapped in heavy Kraft

paper and packed in a double corrugated carton or wooden box. Protect the instrument on all sides with

at least three inches of excelsior or similar padding. Mark the case plainly with suitable caution warnings

to insure careful handling.

1-4

Page 9

Indicators and Controls

Front Panel

Section 2

Indicators and Controls

2.1 Front Panel

See Figure 2-1 for front panel control and indicator location.

2.2 Numeric Readout

The front panel 3 ½ numeric digit LCD readout displays the measurement data. Also indicated on the

display are low battery, overrange kVp, underrange kVp, high mAs, and low mAs conditions as listed in

Table 2-1.

Table 2-1. Displayed Indications

2

Condition Indication

Low Battery LO BAT in the upper left corner of the display.

Overrange kVp Flashing decimal point directly above A.

Underrange kVp Flashing decimal point directly above B.

High mAs Flashing decimal point directly above C/D and a non-zero numeric display.

Low mAs

Figure 1-1. Front Panel Indicators and Controls

An overrange kVp condition indicates that the measured kVp is above the calibrated range. An

underrange kVp condition indicates that the measured kVp is below the calibrated range.

Flashing decimal point directly above C/D and a display numerically equal to

zero.

A high mAs condition indicates that the beam intensity is too high and the measurement is completed with

less than 50 ms of the radiation waveform. The resulting measurements may be less accurate than those

obtained with longer sample times. This is especially true in the case of single-phase x-ray machines

where the radiation spectrum changes dramatically throughout the duration of a pulse. For example, if

the measured waveform contains less than six pulses of single-phase rectification, then a partial pulse

can have a significant contribution to the value of the average of the pulses. The effect is not as great for

three phase machines because the radiation spectrum remains relatively constant throughout the

2-1

Page 10

Nuclear Associates 07-492

Operators Manual

exposure. To improve accuracy, the user should either increase distance or decrease the mA, both of

which will reduce the beam intensity.

A low mAs condition indicates that the exposure is less than the required value to make a measurement.

The user should either increase time or mA or decrease distance for the particular kVp setting. Refer to

Section 3, Battery Installation and Setup, for a discussion of minimum mAs requirements.

The auto reset on the front panel will turn on whenever the kVp meter detects an x-ray exposure. The

LED will remain lit for 0.5 seconds or for the duration of the exposure, whichever is greater. The previous

reading is cleared when the LED lights.

2.3 Switches

The power switch is located on the front panel. The power switch is used to turn the unit on or off. A

phase switch is located on the rear panel which allows selection for single phase and three phase

applications.

2.4 Top Panel

The top panel of the kVp meter contains the following information:

• A brief set of operating instructions.

• An indication as to where to center the beam, referred to as the target.

• Display guide for A, B, C, and D decimal point indications as discussed above.

2.5 Rear Panel

The battery access panel and a BNC connector are located on the rear panel. Refer to Section 3, Battery

Installation and Setup, for battery replacement procedures. The BNC connector allows the user to

connect an oscilloscope to the kVp meter to view the signal from the radiation detection diodes. The

signal can be observed on the oscilloscope for the duration of the exposure. A storage scope or camera

is necessary to view the signal for extended periods of time.

The phase selector switch is also located on the rear panel of the kVp meter. The switch has two

positions, one phase and three phase; position is determined by the type of x-ray machine being tested.

2-2

Page 11

Battery Installation and Setup

Installing/Replacing the Battery

3

Section 3

Battery Installation and Setup

3.1 Installing/Replacing the Battery

Use the following procedure to install/replace the 9 V Alkaline (P/N 16-29) battery used to power the kVp

meter:

1. Be sure the power switch located on the front panel is in the OFF position.

2. Open the battery cover door, located on the rear panel, by pulling on the access tab until it opens.

3. If applicable, remove the used battery. Connect the new battery to the terminal connector following

standard polarity conventions.

4. Place the battery into the battery compartment.

5. Close the battery compartment door.

3.2 Setting the Phase Switch (Rear Panel)

The Phase Switch position is determined by the type of x-ray machine to be tested as follows:

• The single-phase (1) position should be selected for testing single-phase x-ray machines.

• The three-phase (3) position should be selected for testing three phase x-ray machines.

3.3 Detector Positioning

The kVp meter should be positioned so that the red detector area on the top panel of the unit is centered

in the x-ray beam. The x-ray beam should cover at least the red portion of the case top to assure an

accurate measurement. Placement of the kVp meter relative to the x-ray tube is shown in Figure 3-1.

3-1

Page 12

Nuclear Associates 07-492

Operators Manual

Figure 3-1. Detector Positioning

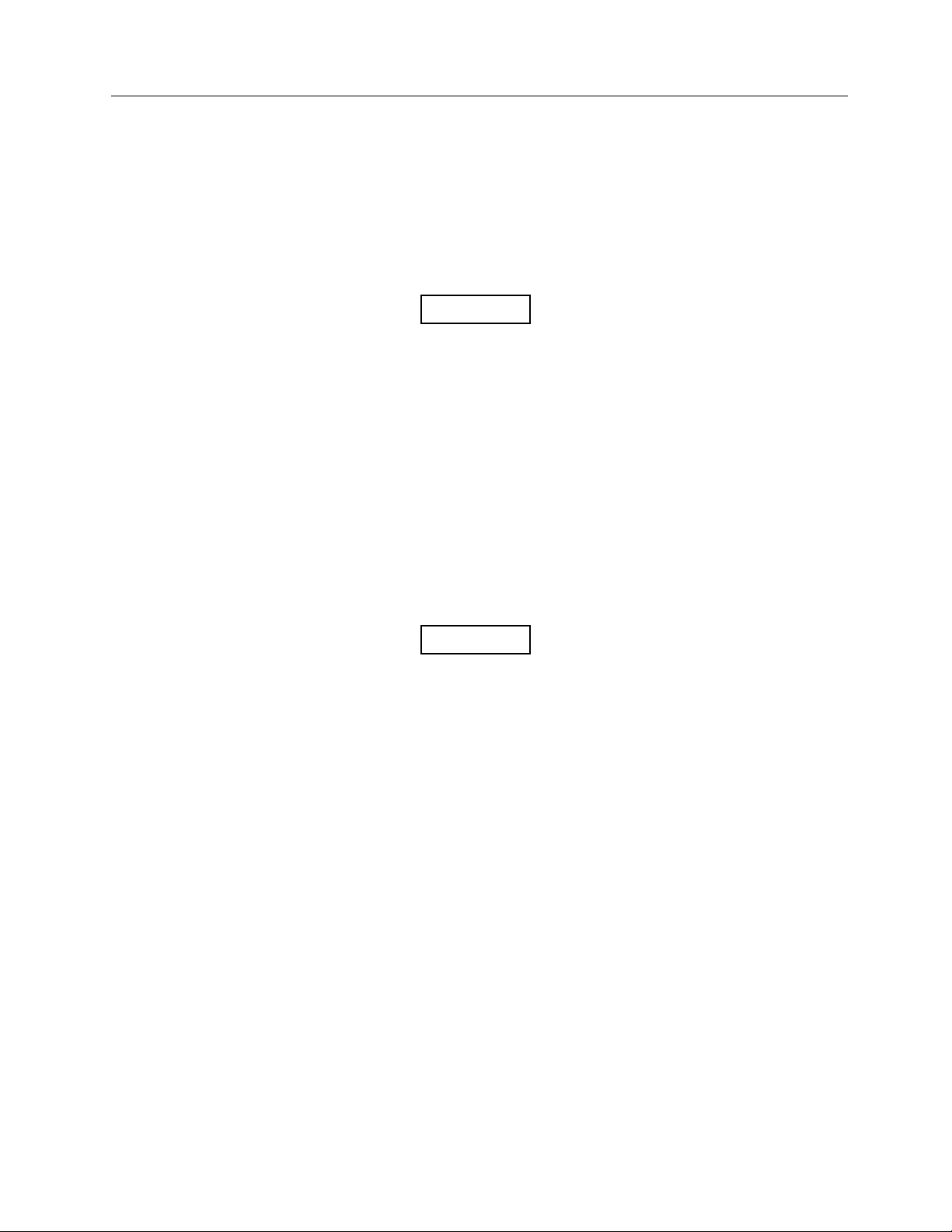

3.4 Determining mAs Requirements

The mAs minimum requirements as a function of distance and kVp are indicated in Figure 3-2. When the

mA has been determined from the chart as discussed in this section, the mAs should be calculated using

an exposure time of 50 ms (1/20 second) or greater.

The curves in Figure 3-2 are intended to guide the user in selecting the mAs required for a particular kVp

measurement. Any mAs beyond the user-designated amount will not be included in the measurement.

(Refer to Section 4, Theory of Operation, for a detailed discussion.)

Use the following guidelines to determine the required mAs from the graph in Figure 3-2:

1. Locate the kVp to be measured on the horizontal axis.

2. From the kVp point on the axis, move vertically to the selected FDD curve.

3. From the kVp position on the appropriate FDD curve, move horizontally to the vertical axis and the

read the required mAs.

4. If necessary, interpolate between distances using the inverse square law.

The curves in Figure 3-2 are derived from single-phase measurements. Three phase machines will

generally require 70% of the mAs determined from the curves.

mAs requirements may vary considerably depending on the following conditions:

1. Detector sensitivity

2. Tube filtration

3. Radiation waveform

4. FDD

5. mAs errors in the x-ray machine

If the determined kVp fails to produce a result, double the time (or decrease the FDD by 30%) and try

again.

3-2

Page 13

Battery Installation and Setup

Determining mAs Requirements

Typically, the largest apparent variation in mAs requirements will be due to a kVp error. If doubling the

mAs fails to produce a result, increase the kVp setting (or decrease the FDD) until a result is achieved.

1000

7

5

4

3

2

Digital kVp Meter:

Typical single phase mA Requirements

May vary on different machines

mA

100

10

7

5

4

3

2

7

5

4

3

2

FDD = 40 cm

80 cm

60 cm

1

22 24 26 28 30 32 34 36 38 40 42 44

kVp

Figure 3-2. Minimum Requirements (mA vs. kVp)

3

3.5 Initial and Periodic Operation Checks

Generally it is not easy to verify the accuracy of the kVp meter in normal field usage. If care is taken,

either of the methods outlined in the following sections can be used to verify performance of the meter.

Both methods discussed require a careful collection of installation data and periodic measurement of that

data.

3.6 Voltage Divider Method

Use the following procedure to perform initial and periodic operation checks of the kVp meter if an x-ray

voltage divider is available:

1. Choose two x-ray systems suited for the test, preferably two different systems, i.e. three phase vs.

one phase, falling load vs. not, etc. Choosing two dissimilar x-ray machines for the check reduces

the possibility of systematic errors.

2. Make comparative measurements of the x-ray systems using the voltage divider and the kVp meter.

3-3

Page 14

Nuclear Associates 07-492

Operators Manual

NOTE

If an oscilloscope is used to measure the voltage

divider, an independent voltmeter should be used

to measure scope sensitivity before each operation

check.

Data with a kVp test cassette would be useful. Note positioning error and film usage when applying the

cassette.

3. At installation, record all parameters of the measurement in a bound notebook. Also record

geometry, cable connections, tube I.D., generator I.D., divider and kVp meter oscilloscope

waveform pictures, oscilloscope and voltmeter I.D, and any other information that may prove useful

for periodic operation checks.

4. Periodically (every six months), or whenever a serious discrepancy in kVp operation is noted, the

above tests should be repeated to determine if the unit is operating properly. The kVp meter,

divider, cassette result, and x-ray settings should be examined for consistency.

3.7 Multiple X-Ray Machine Method

If a voltage divider is not available, use the following procedure to perform initial and periodic operation

checks of the kVp meter:

1. Choose several x-ray systems suited for the test. If possible, choose at least two different systems,

i.e. three phase vs. one phase, falling load vs. not, etc. Choosing dissimilar x-ray machines for the

check reduces the possibility of systematic errors.

2. Make comparative measurements of the x-ray systems using the kVp meter.

Data with a kVp test cassette would be useful. Note positioning error and film usage when applying the

cassette.

3. At installation, record all parameters of the measurement in a bound notebook. Also record

geometry, cable connections, tube I.D., generator I.D., kVp meter oscilloscope waveform pictures,

oscilloscope I.D, and any other information that may prove useful for later periodic operation

checks.

4. Periodically (every six months), or whenever a serious discrepancy in kVp operation is noted, the

above tests should be repeated to determine if the unit is operating properly. The kVp meter,

cassette result, and x-ray settings should be examined for consistency. If the kVp meter suddenly

produces different results from previous tests on a specific x-ray machine, then there is a strong

probability that the kVp meter is operating properly. However, if all of the x-ray measurements

suddenly change, then the kVp meter may be malfunctioning.

3-4

Page 15

Theory of Operation

General

Section 4

Theory of Operation

4.1 General

The kVp measurement is computed basically from a measurement of the linear absorption coefficient

(MU) of the hardened x-ray beam. As the kV increases, the linear absorption coefficient increases.

An x-ray beam is composed primarily of two parts, the bremsstrahlung radiation and the characteristic

radiation. For a sufficiently hardened beam, if a plot is made of the log of the kV vs. the ratio of the

bremsstrahlung part of the beam, a nearly straight line would result.

4.2 Filtration Effects

A slight change in the beam spectrum being measured will cause a change in the linear absorption

coefficient. Such a change can be caused by filtration differences with respect to the calibration beam.

With lower filtration, the x-ray beam will not be as hard as the calibration beam and the results will be

lower. With more filtration, the beam will be harder than the calibration beam and the results will be

higher.

4

4.3 Waveform Effects

Beam spectrum changes occur with different waveforms. A single-phase waveform, as opposed to a

three-phase waveform, displays an approximate 5% change in readings. Correction for this is made by

selecting the appropriate phase switch position. The Phase switch is located on the rear panel. If loading

on the generator causes the waveform to appear in the classic manner, the switch should be positioned in

the three-phase position. In some situations, the waveform may be somewhat between the single-phase

and the three-phase positions and the results may be compromised.

4.4 Low Battery

The low battery indication is displayed when the battery voltage drops below a predetermined value. This

value is selected such that there is not a noticeable effect on the measurement results. Use of the

instrument below this value (i.e. while the LO BAT indication is displayed) may result in erroneous

measurements due to the loss of an accurate voltage reference.

4.5 Positioning Error

The kVp meter should be positioned in the center of the beam. The measurement of the meter is two

square inches. If measurements are made in other parts of the beam, different results will occur since the

beam spectrum is different at different locations. The accuracy of the kVp meter will be compromised.

The heel effect is an example of such a beam spectrum change. To view the effects of beam positioning

on the measurement, the user may want to position the meter in various parts of the beam for illustration

purposes.

4-1

Page 16

Nuclear Associates 07-492

Operators Manual

(Blank page)

Page 17

Calibration and Adjustment

Lo Battery Threshold Adjustment

Section 5

Calibration and Adjustment

The Model 07-492 kVp Meter has been factory calibrated. Any calibration should be done by the factory

or a qualified calibration facility. The unit should be calibrated once a year by adjusting the five variable

resistors as discussed in the following sections.

5.1 Lo Battery Threshold Adjustment

Resistor R25 adjusts the threshold for the LO BAT indication on the LCD Display. Use the following

procedure to adjust R25:

1. Remove the battery.

2. Connect a variable DC power supply to the instrument at the battery connector cable.

3. Connect a voltmeter between battery plus (TP3) and analog ground (TP4).

4. Turn on the power supply and adjust it to 9 Volts.

5. Turn on the kVp meter. The voltmeter should read between 2.4 and 3.2 V.

6. Slowly decrease the power supply until the voltage across the test points just returns to the value it

had prior to dropping off.

7. Turn R25 until LO BAT disappears from the display.

8. Turn R25 slowly in the opposite direction just until LO BAT reappears on the display.

9. Connect the voltmeter between analog ground and the power supply negative terminal.

10. Increase the power supply voltage until the voltmeter reads 4.5 V while being careful not to exceed

9V from the power supply. LO BAT should be off at this point.

5

5.2 kVp Calibration Adjustments

The following are some guidelines to ensure proper calibration of the kVp meter:

1. An independent accurate means of measuring the x-ray machine is necessary.

2. The kVp meter must be calibrated at 26 kVp, 30 kVp, and 40 kVp (± 1 kVp) if it is to be within

specification over its entire range.

3. The potentiometers must be adjusted interactively as detailed below.

4. Be sure to set the phase switch, located the rear panel of the unit, appropriately.

5. Be sure to follow the procedure outlined below in the order listed.

Use the following procedure for kVp calibration:

1. Set a calibrated Moly Anode/Moly Filter x-ray machine to 26 kVp, with sufficient mAs to obtain a

reading.

2. Locate the Model 07-492 kVp meter in the center of the beam with the cover removed from the

meter.

5-1

Page 18

Nuclear Associates 07-492

Operators Manual

NOTE

Be sure the phase switch on the rear panel of the

kVp meter is in the appropriate position.

3. Make an exposure.

4. Adjust R106 (offset adjustment) until the kVp meter reads 26 kVp.

5. Set the x-ray machine to 30 kVp.

6. Make an exposure.

7. Adjust R105 (slope adjustment) until the kVp reads 30 kVp.

8. Repeat Steps 1 through 7 until the readings are accurate.

9. Set the x-ray machine to 40 kVp.

10. Make an exposure.

11. Adjust R104 (high end compensation adjustment) until the kVp reads 40 kVp.

12. Repeat Steps 5 through 11 until the readings are accurate.

13. Repeat Steps 1 through 11 until the readings are accurate.

After the Model 07-492 kVp Meter has been calibrated using the moly/moly filter combination, the

following correction table can be used when operating with different filter combinations.

Target/Filter Energy in kVp Correction Factor

Rh/Rh 25.0 0.903

30.0 0.993

35.0 1.057

39.9 1.097

44.9 1.126

48.9 1.144

Rh/AI 25.0 0.856

30.0 0.912

35.0 0.951

39.9 0.988

44.9 1.027

48.9 1.055

Mo/Rh 23.0 0.911

25.0 0.943

30.0 1.007

35.0 1.039

40.0 1.047

Mo/AI 24.0 0.888

27.1 0.890

30.0 0.902

35.0 0.926

40.0 0.955

45.0 0.981

49.0 1.004

5-2

Page 19

(Blank page)

Page 20

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

120 Andrews Road

Hicksville, New York 11801

516.870.0100

www.flukebiomedical.com/rms

Loading...

Loading...