Page 1

Nuclear Associates 07-444

Little Genius Scanning Densitometer

March 2005

Manual No. 07-444-1 Rev. 2

©2004, 2005 Fluke Corporation, All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies

Operators Manual

Page 2

Fluke Biomedical

Radiation Management Services

6045 Cochran Road

Cleveland, Ohio 44139

440.498.2564

www.flukebiomedical.com/rms

Page 3

Table of Contents

Section 1: Introduction................................................................................................ 1-1

1.1 Product Description ..................................................................................... 1-1

1.2 Specifications............................................................................................... 1-1

1.3 Receiving Inspection.................................................................................... 1-2

1.4 Storage ........................................................................................................ 1-2

1.5 Routine Cleaning ......................................................................................... 1-2

1.6 Procedures, Warnings, and Cautions .......................................................... 1-2

Section 2: Getting Started........................................................................................... 2-1

2.1 Power........................................................................................................... 2-1

2.2 Controls ....................................................................................................... 2-1

2.3 Display ......................................................................................................... 2-1

2.4 RS-232 Interface.......................................................................................... 2-1

2.5 Operating Modes ......................................................................................... 2-2

Section 3: Functional Description .............................................................................. 3-1

3.1 Optical Density Measurement...................................................................... 3-1

3.2 Calculation Of Significant Values................................................................. 3-1

3.3 Displaying Data............................................................................................ 3-2

3.4 Data Logging ............................................................................................... 3-3

3.5 Data Retrieval .............................................................................................. 3-3

3.6 Data Reporting............................................................................................. 3-3

3.7 Setup Program Functions ............................................................................ 3-4

3.8 Calibration.................................................................................................... 3-4

Section 4: Setup........................................................................................................... 4-1

4.1 Entering a Facilities Title.............................................................................. 4-2

4.2 Clearing The Data Log................................................................................. 4-2

4.3 Setting Communication Parameters ............................................................ 4-3

4.4 Log Setup .................................................................................................... 4-5

4.5 Sending Data To The Output Port ............................................................... 4-8

4.6 Step Wedge Type ........................................................................................ 4-8

4.7 D Log E Setup ............................................................................................. 4-9

4.8 Step Wedge Type – Nuclear Associates.................................................... 4-14

4.9 Step Wedge Type - X-Rite ......................................................................... 4-14

4.10 Selecting the Appropriate Film Guide ........................................................ 4-17

4.11 Selecting The Step Wedge Type ............................................................... 4-17

4.12 X-Rite Scanning Technique ....................................................................... 4-17

i

Page 4

Section 5: Operation.................................................................................................... 5-1

5.1 Single Step Measurements.......................................................................... 5-1

5.2 Automatic 21-Step Measurements............................................................... 5-2

5.3 Displaying Logged Data............................................................................... 5-3

5.4 Reporting Logged Data................................................................................ 5-4

5.5 Printing A D Log E Curve............................................................................. 5-5

5.6 Printing Control Charts................................................................................. 5-5

Section 6: Calibration .................................................................................................. 6-1

Section 7: Maintenance and Troubleshooting........................................................... 7-1

7.1 General ........................................................................................................ 7-1

7.2 Photo Head Alignment................................................................................. 7-1

7.3 Displayed Error Messages........................................................................... 7-2

7.4 Battery Replacement ................................................................................... 7-3

7.5 Lamp Replacement...................................................................................... 7-3

7.6 Replacement Parts ...................................................................................... 7-3

ii

Page 5

Introduction

Product Description

1

Section 1

Introduction

1.1 Product Description

The Model 07-444 Little Genius scanning densitometer is designed to be used with a Nuclear Associates

sensitometer to monitor film-processing performance. Little Genius is a battery and/or line operated unit

capable of automatically scanning 21 Step films and making single point density measurements.

The Little Genius measures and displays the step densities of a 21-step film. It calculates and displays

base + fog, maximum density, speed index, average gradient, relative speed and contrast index of the

processed film.

Model 07-444 allows the user to label and store measurement data for up to 20 film processors. The

measurements can be downloaded to an IBM PC compatible computer or printer via the RS-232

interface, located on the back panel of the units.

The stand-alone or graphics mode with its control chart features provides a quick method for tracking

daily film processor performance. Control chart values for 31 daily measurements with up to 20

processors can be stored in the Little Genius. Control charts may be as either index or gradient values.

Control charts and D log E curves may be output directly to a printer via the RS-232 interface.

1.2 Specifications

Film Measures Model 07-417 or X-Rite Model 21-step sensitometer format in

scan mode.

Range (Density) 0 to 4.0 OD

Accuracy (Density) 0 to 3 OD ± 0.02 OD units; .3.0 OD to 4.0 OD ± 1%

Repeatability (Density) ± 0.02 OD units

Power Line: 110 VAC with AC power converter

Part 14-301 (USA, Japan)

Input: 117 VAC, 60 Hz, 12 W

Output: 9 VDC, 500 mA

Part 14-399 (Europe)

Input: 230 VAC, 50 Hz

Output: 9 VDC, 500 mA, 4.5 VA

Part 14-415 (UK)

Input: 230 VAC, 50 Hz, 12.6 VA

Output: 9 VDC, 680 mA

Part 14-415, Part 14-416 (Australia)

Battery Six (6) 1.5 V alkaline

Displayed Message “Low Battery” Battery is below threshold unit will not operate - Replace

Batteries

Spectral Response Centered at approximately 540 nm

1-1

Page 6

Nuclear Associates 07-444

Operators Manual

Aperture Size 1.0 and 2.0 mm

Operating Conditions 10°C to 40°C (50°F to 104°F)

Maximum humidity of 90% non-condensing

Dimensions (H x W x D) 2.75 in x 3.2 in x 7.1 in (7 cm x 8.1 cm x 18 cm)

1.3 Receiving Inspection

Upon receipt of the unit:

1. Check the shipping carton(s) and their contents for in-shipment damage. If damage is evident, file

a claim with the carrier and notify Fluke Biomedical at 440.248.9300.

2. Check that all items listed on the packing slip are present and in good condition. If any items are

missing or damaged, contact Fluke Biomedical at 440.248.9300.

1.4 Storage

If necessary to store the unit prior to use, pack it in the original container(s), if possible, and store in an

environment free of corrosive materials, fluctuations in temperature and humidity, and vibration and

shock.

1.5 Routine Cleaning

Do not immerse the Model 07-444 Miniscan Scanning Densitometer. The unit is not waterproof. Liquid

could damage the circuits. The unit should be kept clean and free from dirt and contamination. The unit

may be cleaned by wiping with a damp cloth using any commercially available cleaning or

decontaminating agent.

1.6 Procedures, Warnings, and Cautions

The equipment described in this manual should be used only by persons who have been trained in the

proper interpretation of its readings.

Although the equipment described in this manual is designed and manufactured in compliance with all

applicable safety standards, certain hazards are inherent in the use of electronic and radiometric

equipment.

WARNINGS and CAUTIONS are presented throughout this document to alert the user to potentially

hazardous situations. A WARNING is a precautionary message preceding an operation that has the

potential to cause personal injury or death. A CAUTION is a precautionary message preceding an

operation that has the potential to cause permanent damage to the equipment and/or loss of data.

Failure to comply with WARNINGS and CAUTIONS is at the user's own risk and is sufficient cause to

terminate the warranty agreement between Fluke Biomedical, Radiation Management Services and the

customer.

Adequate warnings are included in this manual and on the product itself to cover hazards that may be

encountered in normal use and servicing of this equipment. No other procedures are warranted by Fluke

Biomedical. It shall be the owner's or user's responsibility to see to it that the procedures described here

are meticulously followed, and especially that WARNINGS and CAUTIONS are heeded. Failure on the

part of the owner or user in any way to follow the prescribed procedures shall absolve Fluke Biomedical

and its agents from any resulting liability.

1-2

Page 7

Introduction

Procedures, Warnings, and Cautions

Indicated battery and other operational tests must be performed prior to each use to assure that the

instrument is functioning properly. If applicable, failure to conduct periodic performance tests in

accordance with ANSI N323-1978 (R1983) Radiation Protection Instrumentation Test and

Calibration, paragraphs 4.6 and 5.4, and to keep records thereof in accordance with paragraph 4.5 of the

same standard, could result in erroneous readings or potential danger. ANSI N323-1978 becomes, by

this reference, a part of this operating procedure.

1

1-3

Page 8

Nuclear Associates 07-444

Operators Manual

Page 9

Getting Started

Power

2

Section 2

Getting Started

2.1 Power

The Scanning Densitometers may be powered by batteries (with six 1.5 V alkaline batteries) or by AC line

power. An AC adapter is supplied with each unit. Connection for the adapter is located on the rear panel

of the unit.

2.2 Controls

The Little Genius Scanning Densitometer has four top panel controls:

1. An OFF/ON Power Switch.

2. A Push-button. (UP arrow)

3. A Push-button. (DOWN arrow)

4. An ENTER Push-button.

The Power Switch turns instrument power ON or OFF. When power is turned ON, the unit performs an

instrument self-check. When power is turned OFF, the unit saves all parameters and values entered

during the setup procedure.

Refer to Section 4 - Setup for procedures for

entering setup values and parameters.

The Push-button scrolls down through menu selections. The Push-button scrolls up through menu

selections. The ENTER Push-button accepts the displayed selection, parameter, value, etc.

NOTE

2.3 Display

A single-line, 16-character LCD Display displays measurement data, calculated values, and user

instructions.

2.4 RS-232 Interface

Access to the RS-232 Interface is via a phone jack located on the backside of the case top of the

densitometer. The interface is compatible with an IBM-compatible personal computer or a serial printer.

Connection to a parallel printer requires the use of a serial to parallel converter. The RS-232 connector

pinouts are listed in Table 2-1. Communication Parameters are set through the Setup Program (refer to

Section 4 - Setup).

2-1

Page 10

Nuclear Associates 07-444

Operators Manual

2.5 Operating Modes

Setup Mode

The Setup Mode allows the user to:

• Make a single point measurement

• Enter a Facility Title

• Calibrate the unit with a step wedge

• Clear the data log

• Set RS-232 and other communication parameters

• Set Graphics mode and control chart parameters

• Enter information into the data log

• Send all logged data out the communication port

Section 4 - Setup contains detailed information about the Setup Mode and specific setup procedures.

Table 2-1. RS-232 Connector Pinouts (DB-9 Pin)

Pin Signal

2

3

8

6,4

5

Transmit Output

Receive Input

DTR (Data Terminal Ready) Output

DSR (Data Set Ready) Input

Ground Signal

Single Measurement Mode

The Single Measurement Mode allows the user to make single step density measurements. The

procedure for making a single step measurement is outlined in Section 5 - Operation.

Scan Mode

The Scan Mode is the normal mode of operation for the Little Genius densitometer. Using this mode,

measurements of sensitometry films can be made and the results calculated, displayed, and stored for

later reference. Specific procedures for performing the Scan Mode functions are outlined in Section 5 -

Operation.

Automatic Power down Mode

The densitometer automatically switches to a Power down Mode when there is no user interaction (i.e.,

pressing keys) for a period of ten (10) minutes. This is a power conserving function and does not affect

the data stored in memory.

To reactivate the densitometer, turn the unit OFF and then back ON.

NOTE

The Automatic Power down function is NOT

activated when the densitometer receives power

through the AC Power Converter.

2-2

Page 11

Functional Description

Optical Density Measurement

3

Section 3

Functional Description

This Section provides an overview of the functions performed by the Little Genius. Table 3-1 provides an

explanation of some of the terms used throughout this Instruction Manual.

3.1 Optical Density Measurement

The primary function of the Little Genius is to measure the optical density of test film that has been

exposed on a Nuclear Associates or X-Rite sensitometer. This consists of “21 step” measurements and a

base + fog measurement. The Densitometer is also capable of single-point measurements. In the single

measurement mode, the film is manually positioned with continuous display update.

3.2 Calculation of Significant Values

The Little Genius uses the readings taken during a measurement cycle to calculate/determine:

• Average Gradient

• Relative Speed

• Contrast Index

• Speed Index

• Maximum optical density

BF + AG

()

AG =

Average Gradient (AG) is defined as:

RL =

Relative Speed (RS) is defined as:

Calculating Average Gradient (AG) and Relative Speed (RS) is performed as follows:

1. Calculate (BF + AG Hi OD), (BF + AG Lo OD), and (BF + 1.0) where:

BF = Base Fog value.

AG Hi OD =

AG Lo OD =

2. Using interpolation if necessary, find the log relative exposure (LRE) corresponding to the each of

3. Determine AG and RL using the values calculated in Steps 1 and 2 in the appropriate equation.

LRE

()

BF+ 2.0

1

LRE

()

BF +10

the values calculated in Step 1.

HiOD

− BF + AG

()

− LRE

()

LoOD

BF +0.25

3-1

Page 12

Nuclear Associates 07-444

Operators Manual

The Contrast Index is defined as the density difference between the low contrast reference step and high

contrast reference step, a second point near the top of the straight-line portion of the curve. For most film

screen combinations, the High contrast reference point is step number 13 or 14, and the Low contrast

reference point is step 8.

The Speed Index density step is that step which produces a density closest to 1.0 above base + fog. For

most film screen combinations, the Speed Index is step number 10 or 11 and represents a density of

approximately 1.20. The same step is used for all measurements using the same film type.

The speed reference step and contrast reference steps for each file in the data log is set from the Setup

Program (refer to Section 4 - Setup).

3.3 Displaying Data

When operating the Little Genius in the stand-alone mode (i.e., Control Charts on), an automatic

comparison is made between the control chart items and the control chart limits defined in the chart file.

A value that exceeds its limit is flagged with either an "H" if the value is high or an "L" if the value is low.

When this condition is detected Chart Rng Error is displayed. See the Control Chart Setup on page 4-9

for further details.

On completion of a measurement cycle, the following values are available for display using the ∆ and ∆

front panel keys:

1. The Density Value at each of the 21 steps, displayed as:

∆

Step XX X.XX

2. The base + fog value, displayed as:

Base + Fog X.XX

.

∆

.

Table 3-1. Explanation of Terms

Term Explanation

Densitometer

Optical Density

Base + Fog (BF) Inherent density of a processed film plus additional density due to age or

Speed Index

Contrast Index Density difference between contrast reference point (generally Step 13 or 14) and

Sensitometer

Step Wedge Step tablet; wedge which provides varying optical densities, each marked with a

RS

LRE Log Relative Exposure; related to Step No. for Nuclear Associates step wedge

AG

D

max.

Instrument which measures optical density of exposed X-Ray film.

Diffuse transmission density; measure of light blocked by exposed film.

environmental conditions.

Density step with optical density closest to 1.00 + BF; generally Step 10 or 11.

speed index.

Instrument used with a step wedge to precisely expose X-Ray film.

step number; the density of each step increases with increasing step numbers.

The Nuclear Associates step tablet provides 21 steps with a step marker at the

mid-point of each step; Step No. relates to the log relative exposure as:

Log Relative Exposure =

Step No. X 0.15

Relative Speed.

as:

Log Relative Exposure =

Step No. X 0.15

Average Gradient.

Maximum Optical Density; largest optical density reading.

3-2

Page 13

Functional Description

Displaying Data

3. The contrast index value is displayed as:

Cnt Index X.XX.

4. The speed index value is displayed as:

Spd Index X.XX.

5. The maximum optical density value is displayed as:

Dmax X.XX

6. The average gradient is displayed as:

Ave Grad X.XX

7. The relative speed is displayed as:

Rel Speed X.XX

8. The temperature is displayed as:

Temp XXX.X.

3.4 Data Logging

The Model 07-444 Little Genius densitometer stores measurements and other related information for up

to 20 film processors. The information is stored in a buffer file and is accessible for display and/or

reporting. The data log is continuously battery backed-up and should be manually cleared prior to each

series of new readings.

3

The control chart mode provides additional storage of up to 31 daily values for the chart items and related

information for each of the 20 log files. The control chart files should be cleared prior to new baseline

measurements. These files are used to provide control chart printouts.

3.5 Data Retrieval

All logged measurement data and calculated values that have been logged are available for display.

Logged data can be scrolled through using the front panel keys.

3.6 Data Reporting

Data reporting can be setup as automatic or manual through the Setup Program (refer to Section 4 Setup).

1. In the automatic mode, data is automatically sent to the RS-232 port after the completion of each

measurement cycle. The Temperature Entry prompt, if active in the Setup Mode, is ignored in the

Automatic Mode (i.e., the user is not prompted to enter the Temperature prior to data transfer).

2. The user can initiate communication of selected data, either logged data or data for the last

measurement cycle, by selecting Send Data using the front panel keys (refer to Section 5 -

Operation for details).

3-3

Page 14

Nuclear Associates 07-444

Operators Manual

3.7 Setup Program Functions

Setup Mode Functions include:

• Making a single point measurement

• Entering a Facility Title

• Calibrating the optical density with a step wedge

• Clearing the data log

• Setting RS-232 and other communication parameters

• Entering information into the data log

• Setting the step wedge type

• Setting the graphics and control chart parameters

• Sending all logged data out the communication port

Detailed information and specific procedures available from the Setup Mode are outlined in Section 4 Setup.

3.8 Calibration

The calibration function, accessible through the Setup Program, allows the user to calibrate optical

density using a reference step wedge (supplied with each unit). The calibration value is entered from the

front panel and then read from the Reference Step Wedge. Refer to Section 6 - Calibration for more

information.

3-4

Page 15

Setup

Setup

Section 4

Setup

In the event of a static discharge induced lock-up of

the densitometer, it is necessary to reset the unit by

cycling the power (i.e. place the power switch to the

OFF position, then to the ON position). The unit

will power up in the normal operating mode.

The Little Genius densitometer uses a menu-driven Setup Program. The procedures outlined in this

Section start at the Setup Menu, step through the applicable procedure, and return to the Setup Menu.

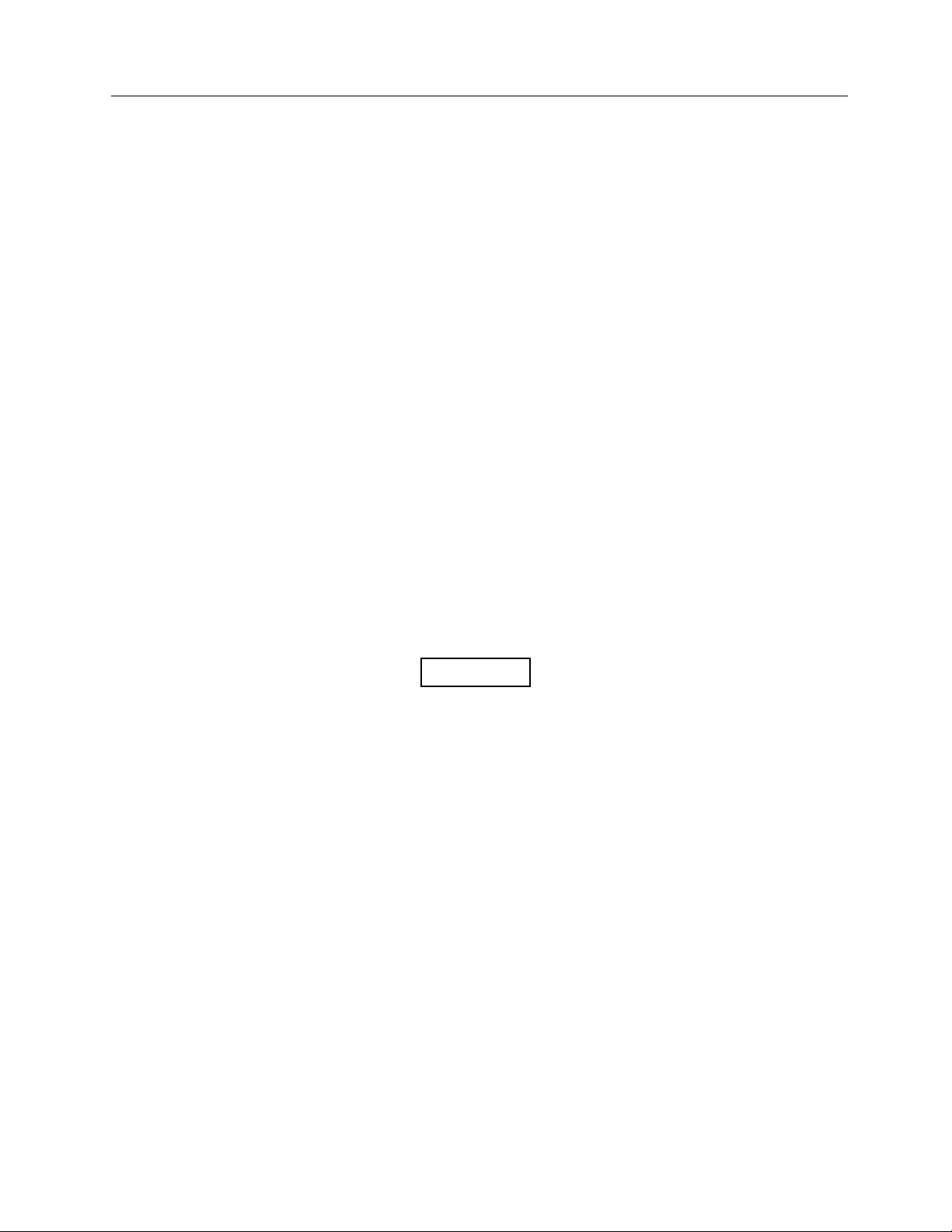

Figures 4-1, 4-2, and 4-3 illustrate screen flow within the Setup Program.

To use the Setup Program:

NOTE

4

1. Make sure the Power Switch is in the OFF position.

2. Press and hold the ENTER push-button while turning the Power Switch to the ON position. The

following message will be displayed:

Self testing...

3. When the unit has completed the self-test, the following Setup Menu label will be displayed:

Single

4. Press or to scroll through the Setup Menu labels.

5. Follow the procedures outlined in this section to edit the applicable setup parameters/values.

6. Exit the Setup Program as follows:

a. Press or to scroll through the Setup Menu labels until Exit Setup Menu is displayed.

b. Press ENTER. The unit will return to the Scan Mode.

Selecting Single from the Setup Menu allows the

user to make single step density measurements.

This procedure is outlined in Section 5 -

Operation. Selecting Calibrate from the Set-Up

Menu allows the user to calibrate the optical density

using a step wedge. This procedure is outlined in

Section 6 -Calibration.

NOTE

4-1

Page 16

Nuclear Associates 07-444

Operators Manual

4.1 Entering a Facility Title

This procedure allows the user to enter an alphanumeric string of characters for the Facility Title. The

entered title is printed each time data output is sent to a printer.

1. Press or to scroll through the Setup Menu labels until Facility Title is displayed.

Single

Enter Enter

Autozero

Screen

Enter

ENTER

to Read

Enter

Density =

x.xx

Enter

Exit Setup

Menu

Enter

Scanning

Mode

Enter

Facility

Title

Enter

Facility

Title Screen

Calibrating

Done.

Calibrating...

Calibrate

Enter

Enter

Density

Screen

Enter

Autozeroing...

Enter to

Read

Enter

Clear

Data

Log

Clearing

Data...

Comm.

Fig. 4-2

Enter

Log

Setup

Fig. 4-3

Step

Wedge

Type

Enter

NAD Step Wedge

XRITE Step Wedge

Enter

Graphics

Set-up

(fig. 4-4)

Send All

Data

Enter

Sending

Data

Figure 4-1. Setup Menu

2. Press ENTER. The current title, with a cursor under the first character, will be displayed. If no title

is stored, you will see [_________________________].

3. To Enter/edit the Facility Title the following steps are followed:

a. Press or to scroll through the available character set.

b. Press ENTER to select the displayed character; the cursor will move to the next

character.

c. Repeat Steps a and b as required to enter up to 20 characters, including spaces.

NOTE

After the 20th character is selected, by pressing

ENTER, the display will return to the Setup Menu

and Exit Setup Menu will be displayed.

4.2 Clearing the Data Log

This procedure clears the data log of all stored information.

1. Press or to scroll through the Setup Menu labels until Clear Data Log is displayed.

2. Press ENTER. The following message will be displayed:

Clearing Data...

3. After a few seconds, the display will return to the Setup Menu and Calibrate will be displayed.

4-2

Page 17

Setting Communication Parameters

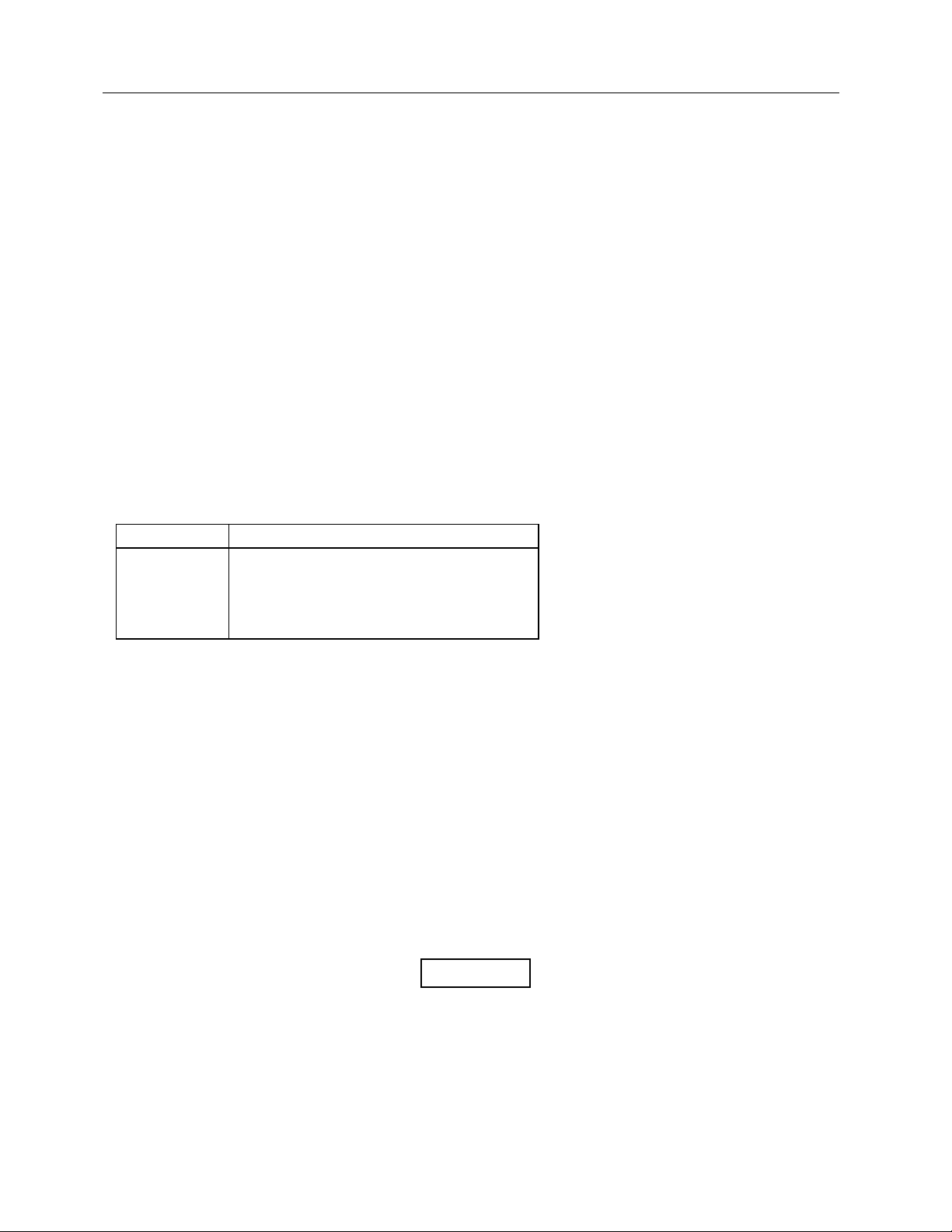

4.3 Setting Communication Parameters

From the Communications Menu, the user can set/edit the following parameters:

• Output Type (Factory Setting: Computer)

• Output Mode (Factory Setting: Manual)

• Baud Rate (Factory Setting: 9600)

• Parity (Factory Setting: None)

• Word Length (Factory Setting: 8 bits)

• Handshaking (Factory Setting: DSR Ignored)

Communications

Enter

Output

Type

Enter

Output

Mode

Enter

Enter

Printer/

Computer

Enter

Manual/

Automatic

Use the following procedure:

Baud Rate

Enter

Enter

9600, 1200,

2400, 4800

Parity

Enter

Enter

None/Space

Mark/Even/

Odd

Figure 4-2. Communications Menu

Clear

Data Log

Word

Length

Enter

Enter

7 Bits/

8 Bits

Enter

Exit

Comm.

Menu

Handshaking

Enter

Enter

DSR

Required/

DSR Ignored

Setup

4

1. Press or to scroll through the Setup Menu labels until Communications is displayed.

2. Press ENTER. The following message will be displayed:

Output Type.

3. Follow the procedures outlined below to edit applicable setup parameters/values.

4. Exit the Communications Menu as follows:

a. Press or to scroll through the Setup Menu labels until Exit Com. Menu is displayed.

b. Press ENTER. The display will return to the Setup Menu and Clear Data Log will be displayed.

Output Type

The selected output type tells the Densitometer whether the RS-232 port is connected to a computer or a

printer:

1. Press or to scroll through the Communications Menu until Output Type is displayed.

2. Press ENTER. The currently selected output type will be displayed.

3. Press or to scroll through the available output types (Printer or Computer).

4. When the output device you are using is displayed, press ENTER to make the selection. The

display will return to the Communications Menu and Output Mode will be displayed.

4-3

Page 18

Nuclear Associates 07-444

Operators Manual

Output Mode

In the Manual Mode, data is transmitted upon user command to send data; in the Automatic Mode, data is

transmitted upon completion of the measurement cycle.

1. Press or to scroll through the Communications Menu until Output Mode is displayed.

2. Press ENTER. The currently selected output mode will be displayed.

3. Press or to scroll through the available output modes (Automatic or Manual).

NOTE

When Automatic is the selected mode, user

temperature entry is not permitted, regardless of

whether it is enabled/disabled from the Log Setup

Menu.

4. Press ENTER to select the displayed output mode. The display will return to the Communications

Menu and Baud Rate will be displayed.

Baud Rate

1. Press or to scroll through the Communications Menu until Baud Rate is displayed.

2. Press ENTER. The currently selected baud rate will be displayed.

3. Press or to scroll through the available baud rates (9600, 1200, 2400, and 4800).

4. Press ENTER to select the displayed baud rate. The display will return to the Communications

Menu and Parity will be displayed.

Parity

1. Press or to scroll through the Communications Menu until Parity is displayed.

2. Press ENTER. The currently selected parity will be displayed.

3. Press or to scroll through the available choices (None, Space, Mark, Even, and Odd).

4. Press ENTER to select the displayed parity. The display will return to the Communications Menu

and Word Length will be displayed.

Word Length

1. Press or to scroll through the Communications Menu until Word Length is displayed.

2. Press ENTER. The currently selected word length will be displayed.

3. Press or to scroll through the available choices (7 bits or 8 Bits).

4. Press ENTER to select the displayed word length. The display will return to the Communications

Menu and Handshaking will be displayed.

Handshaking

1. Press or to scroll through the Communications Menu until Handshaking is displayed.

2. Press ENTER. The currently selected choice will be displayed.

3. Press or to scroll through the available choices (DSR Required or DSR Ignored).

4. Press ENTER to select the displayed choice. The display will return to the Communications Menu

and Exit Com. Menu will be displayed.

4-4

Page 19

Setup

Log Setup

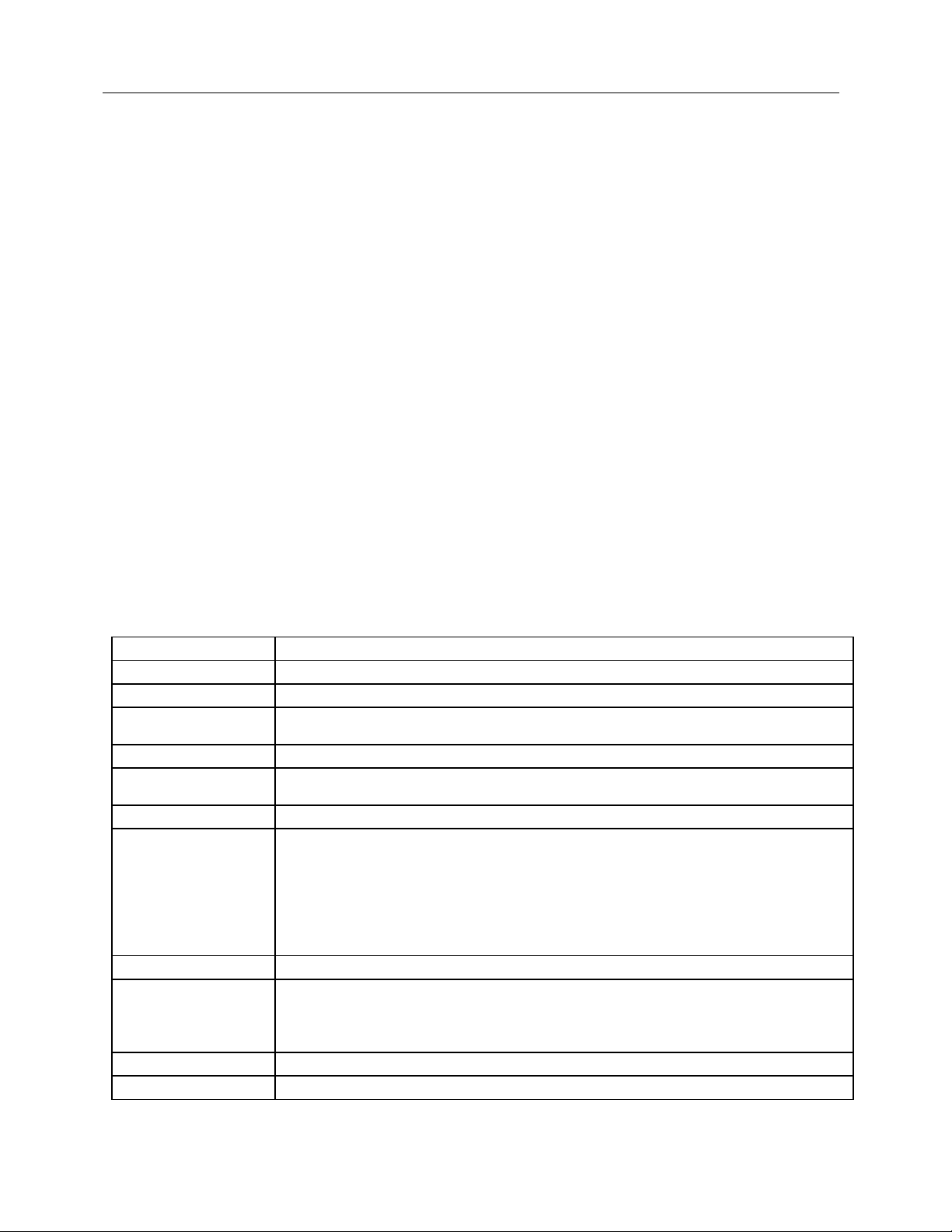

4.4 Log Setup

From the Log Setup Menu, the user can:

• Set/edit the File Name

• Set/edit the Contrast Reference Step

• Set/edit the Speed Reference Step

• Enable/disable the temperature entry function for each of 20 files

Use the following procedure:

1. Press or to scroll through the Setup Menu labels until Log Setup is displayed.

Communications

Enter

Exit

Log Setup

Change

Name

Enter Enter Enter Enter

Chg Spd

Ref Step

Chg Cnt

Ref Step

Enter Enter Enter Enter

Edit Name

Screen

Speed

Reference

Step Screen

Contrast

Reference

Step Screen

Figure 4-3. Log Setup Menu

2. Press ENTER. The Log Setup Menu will be displayed:

File 01 YYYY.

where YYYY is a 20 character or less name previously entered for the File 01.

NOTE

YYYY will be blank if the File 01 has not been

previously named.

3. Press or to scroll through the Log Setup Menu labels until the name of the file to be edited is

displayed:

File XX YYYY.

where XX is the File No. and YYYY is a 20 character or less name previously entered for the File.

Log Setup

Enter

File xx YYY

Exit File

Chg Temp

On/Off

Temp

On/Off

4

4-5

Page 20

Nuclear Associates 07-444

Operators Manual

NOTE

YYYY will be blank if the file has not been

previously named.

4. Press ENTER. The File Parameters Menu will be displayed:

Change Name.

5. Press or to scroll through the parameters available for editing.

6. Follow the procedures outlined in this section to edit applicable setup parameters/values.

7. Exit the File Parameters Menu as follows:

a. Press or to scroll through the File Parameters Menu labels until Exit File XX is displayed,

where XX is the number of the active file.

b. Press ENTER. The display will return to the Log Setup Menu and File XX will be displayed,

where XX is the number of the next file available for editing.

8. Exit the Log Setup File Menu as follows:

a. Press or to scroll through the Log Setup Menu labels until Exit Log Setup is displayed.

b. Press ENTER. The display will return to the Setup Menu and Communications will be

displayed.

Entering a File Name

1. Press or to scroll through the File Parameters Menu until Change Name is displayed.

2. Press ENTER. The current file number and name, with a cursor under the first character of the

name, will be displayed.

3. Enter/edit the file name as follows:

a. Press or to scroll through the available character set.

b. Press ENTER to select the displayed character; the cursor will move to the next character.

c. Repeat Steps a and b as required to enter 8 characters.

NOTE

When the 8th character is selected by pressing

ENTER, the display will return to the File

Parameters Menu and Chg. Spd Ref. Step will be

displayed.

Changing the Speed Reference Step

NOTE

The Speed Reference Step is factory set to Step

11.

1. Press or to scroll through the File Parameters Menu until Chg. Spd Ref. Step is displayed.

2. Press ENTER. The following will be displayed.

Spd Ref. Step: XX

where XX is the step currently set as the speed reference step.

3. Press or to increase/decrease the displayed Step No.

4-6

Page 21

Setup

Log Setup

4. Press ENTER to select the displayed Step No. The display will return to the File Parameters Menu

and Chg. Cnt Ref. Step will be displayed.

Changing the Contrast Reference Step

NOTE

The Contrast Reference Step is factory set to Step

13.

1. Press or to scroll through the File Parameters Menu until Chg. Cnt Ref. Step is displayed.

2. Press ENTER. The following will be displayed.

Cnt Ref. Step: XX

where XX is the step currently set as the contrast reference step.

3. Press or to increase/decrease the displayed Step No.

4. Press ENTER to select the displayed Step No. The display will return to the File Parameters Menu

and Exit File XX will be displayed, where XX is the active file.

Changing the Average Gradient O.D.

NOTE

The Average Gradient high and low O.D. s are

factory set as follows:

Grad OD Hi:2.00

Grad OD Lo:0.25

1. Press or to scroll through the File Parameters Menu until Chg. Avg Grad is displayed.

2. Press ENTER. The following will be displayed.

Grad OD Hi:2.00

3. Press or to increase/decrease the value of the cursor. Press ENTER to accept the current cursor

value and advance the cursor to the next digit. When the entry has been completed, the display will

advance to Grad OD Lo:0.25.

4. Press or to increase/decrease the value of the cursor. Press ENTER to accept the current cursor

value and advance the cursor to the next digit. When the entry has been completed, the display

will advance to the next chart item.

Changing the Relative Speed O.D.

NOTE

The Relative Speed O.D. is factory set as follows:

Speed O.D.:1.00

1. Press or to scroll through the File Parameters Menu until Change Rel Speed is displayed.

2. Press ENTER. The following will be displayed.

Speed O.D.:1.00

3. Press or to increase/decrease the value of the cursor. Press ENTER to accept the current cursor

value and advance the cursor to the next digit. When the entry has been completed, the display

will advance to the next chart item.

Enabling/Disabling Temperature Entry

4

4-7

Page 22

Nuclear Associates 07-444

Operators Manual

1. Press or to scroll through the Main Menu until Chg. Temp On/Off is displayed.

2. Press ENTER. The currently selected choice will be displayed: either Temperature On or

Temperature Off.

3. Press or to scroll through the available choices (Temperature On or Temperature Off).

4. Press ENTER to select the displayed choice. The display will return to the File Parameters Menu

and Exit File XX will be displayed, where XX is the active file.

NOTE

User temperature entry is only permitted when the

unit is in the Manual Mode. Therefore, if the unit is

in the Automatic Mode, the temperature entry

prompt will not be displayed after a film is scanned,

regardless of whether it has been enabled/disabled

in this procedure.

4.5 Sending Data to the Output Port

1. Press or to scroll through the Setup Menu until Send All Data is displayed.

2. Press ENTER. The message Sending Data... will be displayed, followed by transmission of all data

to the output port. The data will be sent to the selected output device (printer or computer running

Film-Pro software).

3. After completing the data transmission, the display will return to the Setup Menu and Log Setup will

be displayed.

4.6 Step Wedge Type

This procedure allows the user to select the type of step image that will be scanned. The type may be

changed by the user at any time without affecting previous readings. The selections are Nuclear

Associate Step Wedge and X-Rite Wedge. Scanning of step images produced by Model 07-417 Dual

Color Sensitometer or model 07-419 Dual Flash Sensitometer must be made with the NAD Step Wedge

selection.

1. Press or to scroll through the Main Menu labels until Step Wedge Type is displayed.

2. Press ENTER. The current selection will be displayed.

3. Press or to scroll through the available selections (NAD Step Wedge or X-Rite Wedge).

4. Press ENTER to select the displayed output mode. The display will return to the Setup Menu and

Log Setup will be displayed

GRAPHICS MODE SETUP

The Graphics Mode offers the user the opportunity to set the Little Genius for stand-alone operation. In

this mode both D log E curves and control charts may be selected, allowing direct output to a printer. The

control chart feature provides a quick method of tracking daily film processor performance over a 31-day

period. The control chart mode may be activated or de-activated by the user.

1. Press or to scroll through the Main Menu labels until Graphics Setup is displayed. Press

ENTER.

2. Press or to scroll through the available selections (D log E Setup, Ctrl Chart Setup, Exit Graph

Setup)

3. Press ENTER to make the selection.

4-8

Page 23

Setup

D log E Setup

4

4.7 D log E Setup

This procedure allows the user to select the units, either log relative exposure or step number, which

represent the X - axis (horizontal). The grid lines within the graph may be selected to be on or off. The

main menu selection Print D log E allows the user to print the curve for the active log file.

Grid Lines On Off

The grid lines that appear within the D log E graph may be turned on or off.

1. Press or to scroll through the Graphics Setup labels until D log E Setup is displayed.

2. Press ENTER.

3. Press or to scroll through the available selections until Grid Lines On Off is displayed.

4. Press ENTER. The current selection will be displayed.

5. Press or to scroll through the available selections (Grid Lines On, Grid Lines Off).

6. Press ENTER to select the displayed output mode. The display will return to the D log E Setup

Menu and Chg. LRE/Step Num. will be displayed.

Change LRE/STEP NUM.

The user to may select the units, either log relative exposure or step number, which represent the X - axis

(horizontal) on the printout.

1. Press or to scroll through the Graphics Setup labels until D log E Setup is displayed. Press

ENTER.

2. Press or to scroll through the available selections until Chg. LRE/Step Num. is displayed.

3. Press ENTER. The current selection will be displayed.

4. Press or to scroll through the available selections (Log Rel Exposure, Step Numbers).

5. Press ENTER to select the displayed output mode. The display will return to the D log E Setup

Menu and Exit D Log E will be displayed.

Control Chart Setup

The control chart feature provides a quick method of tracking daily film processor performance over a 31day period. The control chart mode may be activated or de-activated by the user. When the control chart

mode is activated, the user is prompted to enter the date upon power up. All control chart data is date

stamped. The user has complete control over the baseline and deviation values for each chart item.

Control charts for up to 20 processors (chart files) may be stored and maintained for subsequent printing.

Each chart file can be independently cleared. Once the control chart file is full, i.e. 31 - daily scans have

been saved, subsequent scans cause the oldest to be cleared, and the latest to be saved. This assures

that the previous 31 daily scans are always available for printing. See PRINTING CONTROL CHARTS,

Section 5.6 for further details.

1. Press or to scroll through the Main Menu labels until Graphics Setup is displayed. Press

ENTER.

2. Press or to scroll through the available selections until Ctrl Chart Setup is displayed. Press

ENTER.

3. Press or to scroll through the available selections (Chg. Chart On/Off, Pick Chart File, Cng. Chart

Display, Exit Chart Setup)

4. Press ENTER to make the selection.

4-9

Page 24

Nuclear Associates 07-444

Operators Manual

4-10

Figure 4-4. Control Chart Setup Menu

Page 25

Setup

D log E Setup

4

From After Last Scan

A

NOTE:

The items in the control chart are dependent upon

the "Change Chart Display" setting. Gradient

Chart Items are show in the flow chart.

Gradient Control Chart items: Average Gradient,

Relative Speed, Base + Fog, Max OD.

Index Control Chart items: Contrast Index, Speed

Index, Base + Fog, Max OD.

B

From Enter New Parameters

GRAD DEV: 0.XX

ENTER

SPEED DEV: 0.XX

ENTER

B + F DEV: 0.XX

ENTER

MAX OD DEV: 0.XX

ENTER

ENTER NEW

PARAMETERS

INCREMENT DECREMENT

ENTER VALUE

ENTER

INCREMENT DECREMENT

ENTER VALUE

ENTER

INCREMENT DECREMENT

ENTER VALUE

ENTER

INCREMENT DECREMENT

ENTER VALUE

ENTER

Previous

Menu

Level

GRAD BASE: X.XX

ENTER

GRAD DEV: 0.XX

ENTER

SPEED BASE: X.XX

ENTER

SEED DEV: 0.XX

ENTER

B + F BASE: X.XX

ENTER

B + F DEV: 0.XX

ENTER

MAX OD BASE: X.XX

ENTER

MAX OD DEV: 0.XX

ENTER

CLEAR CHART FILE

Figure 4-4. Control Chart Setup Menu (Continued)

NOTE:

Control chart items shown

represent "Gradient "

Display. When "Index"

display is selected, contrast

index and speed index

replace average gradient

and relative speed.

Previous

Menu

Level

4-11

Page 26

Nuclear Associates 07-444

Operators Manual

Control Chart Mode ON/OFF

The user may select the control chart mode on, which allows data to be stored and compared to baseline

measurements and enables all control chart features. The control chart off selection disables all control

chart features and prompts, however, previously stored chart data is not affected.

Follow the steps under control chart setup before proceeding.

1. Press or to scroll through the Graphics Setup labels until Ctrl Chart Setup is displayed. Press

ENTER.

2. Press or to scroll through the available selections until Chg. Chart On/Off is displayed. Press

ENTER.

3. The current selection will be displayed.

4. Press or to scroll through the available selections (Ctrl Charts On, Ctrl Charts Off).

5. Press ENTER to select the displayed output mode. When the control charts on selection is made,

Verify day/month/year (i.e. 1 Jan. 93) is displayed. The user is required to enter the date. Press

or to increment or decrement the day, press ENTER, repeat for month and year.

6. The display will return to the Control Chart Setup Menu and Pick Chart File will be displayed.

Change Chart Display

The Change Chart Display menu selection allows the user to choose between Gradient and Index Control

Charts. This setting affects the display of all chart files, as well as items contained in the output to the

printer.

The gradient control chart contains the following items:

• Average Gradient

• Relative Speed

• Base & Fog

• Max OD

The index control chart contains the following items:

• Contrast Index

• Relative Speed

• Base & Fog

• Max OD

Follow the steps outlined in control chart setup before proceeding.

1. Press or to scroll through the Graphics Setup labels until Ctrl Chart Setup is displayed. Press

ENTER.

2. Press or to scroll through the available selections until Chg Chart Display is displayed. Press

ENTER.

3. The current selection will be displayed.

4. Press or to scroll through the available selections (Index Display, Gradient Display).

5. Press ENTER to select the control chart method displayed.

6. The display will return to the control chart setup menu and Exit Chart Setup will be displayed.

Chart File Setup

4-12

Page 27

Setup

D log E Setup

This procedure allows the user to setup, maintain, and selectively clear the control chart files. The setup

of these files includes the automatic (Scan New Params) or manual (Enter New Params) entry of the

following parameters in Tables 4-1 and 4-2.

4

Table 4-1. Index Chart File

Chart Item Range

Contrast Index

Speed Index

Base + fog

Max. OD

Baseline

Deviation

Baseline

Deviation

Baseline

Deviation

Baseline

Deviation

0.00 - 4.00

0.02 - 3.98

(1)

0.00 - 4.00

0.02 - 3.98

(1)

0.00 - 4.00

0.02 - 3.98

(1)

0.00 - 4.00

0.02 - 3.98

(1)

Default

Setting

1.25

0.15

1.00

0.15

0.20

0.02

3.00

0.15

Table 4-2. Gradient Chart File

Chart Item Range

Average

Gradient

Relative speed

Base + fog

Max. OD

Baseline

Deviation

Baseline

Deviation

Baseline

Deviation

Baseline

Deviation

0.00 - 9.99

0.02 - 9.97

(1)

0.00 - 3.00

0.02 - 2.98

(1)

0.00 - 4.00

0.02 - 3.98

(1)

0.00 - 4.00

0.02 - 3.98

(1)

The deviation range is dependent on the baseline

value; the deviation must be less than half the

baseline value. This limit allows the control chart to

contain two deviation intervals above the baseline

and two below the baseline.

Default

Setting

2.00

0.15

1.00

0.15

0.20

0.02

3.00

0.15

NOTE

4-13

Page 28

Nuclear Associates 07-444

Operators Manual

Follow the steps under control chart setup before proceeding.

1. Press or to scroll through the Graphics Setup labels until Ctrl Chart Setup is displayed. Press

ENTER.

2. Press or to scroll through the available selections until Pick Chart File is displayed. Press

ENTER.

3. The first chart file, File 01, will be displayed.

4. Press or to scroll through the available selections (chart files 01 through 20, Exit Chart Files).

5. Press ENTER to select the displayed chart file.

6. Press or to scroll through the available selections (Scan New Params, Enter New Params, Exit

File 01).

Scan New Parameters

This procedure allows the user to automatically setup the parameters in a chart file by scanning films

processed under optimum processor conditions. In this mode the user may select from 1 - 9 sensitometer

films that are averaged to determine the baseline values for each chart item. Upon completion, the user

is prompted to enter the deviation or accept the default deviation for each item (refer to “SET-UP AND

USE WITH X-RITE STEP WEDGES” on page 4-16 for X-Rite info).

Follow the steps under chart file setup before proceeding.

1. Press or to scroll through the selected file setup functions until Scan New Params is displayed.

Press ENTER.

2. No. of scans: "X" will be displayed. Where "X" is the previously selected no. of scans (from 1 to 9),

the default is 5. Press the UA or DA to increment or decrement and press ENTER to select the

desired no. of scans and begin the process.

3. Ready for scan 1 will be displayed. Press ENTER, Auto zeroing... will be displayed. Upon

completion of the auto zero phase...

4. Scan the film(s) according to step wedge type selection as follows:

4.8 Step Wedge Type - Nuclear Associates

Swipe film now! Will be displayed.

Load the film from the top of the unit, oriented so that step 1 (lowest density measured first, and gently

swipe it toward the bottom of the unit. The display of an error message may indicate an erroneous scan,

repeat this step if necessary.

4.9 Step Wedge Type - X-Rite

ENTER when ready will be displayed.

Load the film from the top of the unit, oriented so that step 1 (lowest density) is measured first, slide the

film into position so that the measurement area is between the film edge and the first step in the base +

fog region. Press ENTER. Pull film now! will be displayed. Gently swipe it toward the bottom of the unit.

The display of an error message may indicate an erroneous scan, repeat this step if necessary.

The X-Rite wedge is read via pattern recognition

and therefore the user must be consistent and

careful in scanning the wedge.

NOTE

4-14

Page 29

Setup

Step Wedge Type-X-Rite

5. Analyzing data... will be displayed.

6. Ready for scan 2, 3, etc. will be displayed, repeat the scanning technique described above until the

previously selected number of scans has been completed.

7. The previous or default value will be displayed Grad Dev (or CIndx Dev): 0.XX. Edit the entry by

pressing or to increase or decrease the value at the cursor. Press Enter to accept the current

cursor value and advance the cursor to the next digit. When the entry has been completed the

display will advance to the next chart item.

8. The previous or default value will be displayed Speed Dev (or SIndx Dev): 0.XX. Edit the value as

previously described.

9. The previous or default value will be displayed B + F Dev: 0.XX. Edit the value as previously

described.

10. The previous or default value will be displayed Max OD Dev: 0.XX. Edit the value as previously

described. When the entry has been completed Enter New Params is displayed.

11. To exit file, press or to scroll through the available selections until Exit File XX is displayed.

Press ENTER.

12. To review the chart file values, press or to scroll through the available selections until Enter New

Params is displayed. Press ENTER. Continue to press ENTER to review each items baseline and

deviation. See section ENTER NEW PARAMETERS for further description.

Enter New Parameters

This procedure allows the user to manually setup the parameters in a chart file. User entry for each

baseline and deviation value may be entered. This mode may also be used at any time to review the

various values without changing them.

4

Follow the steps under chart file setup before proceeding.

1. Press or to scroll through the selected file setup functions until Enter New Params is displayed.

Press ENTER.

2. The previous or default value will be displayed Grad Base (or CIndx Base): X.XX. Edit the entry by

pressing or to increase or decrease the value at the cursor. Press Enter to accept the current

cursor value and advance the cursor to the next digit. When the entry has been completed the

display will advance to the next chart item.

3. The previous or default value will be displayed Grad Dev (or Cindx Dev): 0.XX. Edit the value as

previously described.

4. The previous or default value will be displayed Speed Base (or SIndx Base): X.XX. Edit the value

as previously described.

5. The previous or default value will be displayed Speed Dev (or SIndx Dev): 0.XX. Edit the value as

previously described.

6. The previous or default value will be displayed B + F Base: X.XX. Edit the value as previously

described.

7. The previous or default value will be displayed B + F Dev: 0.XX. Edit the value as previously

described.

8. The previous or default value will be displayed max OD Base: X.XX. Edit the value as previously

described.

9. The previous or default value will be displayed Max OD Dev: 0.XX. Edit the value as previously

described. When the entry has been completed Clear Chart File is displayed.

10. To exit file, press or to scroll through the available selections until Exit File XX is displayed.

Press ENTER.

4-15

Page 30

Nuclear Associates 07-444

Operators Manual

11. To review the chart file values, press or to scroll through the available selections until Enter New

Params is displayed. Press ENTER. Continue to press ENTER to review each items baseline and

deviation.

Clear Chart Files

This procedure allows the user to selectively clear a particular chart file. This feature is useful when a

new baseline is established and the file contains outdated measurements.

Follow the steps under chart file setup before proceeding.

1. Press or to scroll through the selected file setup functions until Clear Chart File is displayed.

Press ENTER.

2. Hold ENTER to Clear... is displayed. Press and hold ENTER to clear the selected file. Press or

to abort the clear command.

3. Clearing Data... is displayed. Upon completion Data Cleared is displayed.

4. Exit File XX is displayed. Press ENTER to exit the chart file.

Set-Up And Use With X-Rite Step Wedges

Little Genius may be used to evaluate test films generated by X-Rite sensitometers. A specific technique

is required to properly scan these types of films. Little Genius can resolve images over a wide range of

exposures and scanning rates.

There are two types of X-Rite sensitometers that produce step wedges that can be read by the Little

Genius. Although the image produced by both units is nearly identical, the placement of the image on the

test film is different. One unit provides an image with the steps centered at approximately 7 mm from the

edge of the film, while the other unit places the image at 18 mm from the edge of the film. Two film

guides are supplied with Little Genius, one for the 7 mm type and another for the 18 mm type. The

standard film guide (18 mm type) is also used for the Nuclear Associates type step wedges (see Figure 4-

5).

Film Edge

Film Edge

7 mm

18 mm

ab

a ) X-Rite Model 334

b ) X-Rite Model 383 & 384 & Victoreen Sensitometers

Figure 4-5. Standard Film Guide

4-16

Page 31

Setup

Selecting The Appropriate Film Guide

4.10 Selecting The Appropriate Film Guide

Examine a sample film and determine the distance from the film edge to the center of the step wedge

image. Select either the 7 mm or the 18 mm film guide and install by pressing the guide into the light

table (see Figure 4-6).

7 mm Film Guide

Figure 4-6. Film Guide Selection

18 mm Film Guide

4.11 Selecting The Step Wedge Type

1. Place the Power Switch into the OFF position.

2. Press and hold the ENTER push-button while turning the Power Switch to the ON position. The

following message will be displayed: Self testing...

4

When the unit has completed the self-test, the following setup Menu label will be displayed: Single

3. Press the up arrow or down arrow to scroll through the Main Menu labels until Step Wedge Type is

displayed.

4. Press ENTER. The current selection will be displayed.

5. Press the up arrow or down arrow to scroll through the available selections (NAD Step Wedge or X-

Rite Wedge) until X-Rite Wedge is displayed.

6. Press ENTER to select X-Rite Wedge. The unit will operate in the X-Rite Wedge mode indefinitely,

until manually re-selected by the user.

4.12 X-Rite Scanning Technique

Use the following procedure to make automatic 21-step density measurements:

1. Turn the Power Switch to the ON position. The following message will displayed: Self testing...

2. After the self-check is complete, the active File No. will be displayed.

3. Press the up arrow or down arrow key to scroll the display to Scan Film.

4. Press ENTER. The unit will auto zero and display the following message: Auto zeroing...

The film must not be positioned in the densitometer

while the unit is auto zeroing.

Upon completion of the auto zeroing cycle, ENTER when ready will be displayed.

NOTE

4-17

Page 32

Nuclear Associates 07-444

Operators Manual

5. Within 5 seconds, load the film from the top of the unit, oriented so that step 1 (lowest density) is

measured first (see Figure 4-7).

NOTE

The unit will time-out after 5 seconds and the scan

cycle must start over from step 3.

ENTER when ready

Figure 4-7. Film Orientation

NOTE

User must leave sufficient space between Stop #1

and the edge of the film so that the Little Genius

can read B+F w/o reference (see figure on the

following page).

6. Slide the film into position so that the measurement area (aperture) on the densitometer is between

the film edge and step 1, in the base+fog region (see Figure 4-8).

Figure 4-8. Film Position

7. Press ENTER.

rate should be between 1 and 5 seconds. If the film is swiped too slowly, i.e. over 5 seconds, or too quickly,

under 1 second, the message

repeat the scanning process.

Pull film now!

will be displayed. Gently swipe the film toward the bottom of the unit. The scan

Couldn’t resolve

will be displayed. Adjust your swipe speed accordingly, and

NOTE

4-18

Page 33

Setup

X-Rite Scanning Technique

The unit will time-out after 5 seconds and the scan

cycle must start over from step 4.

NOTE

Position the film so that the lowest density steps

enter the Densitometer first, i.e., Step 1 - 21. Avoid

jerky movement of the film through the

Densitometer.

8. When 21-steps and base + fog measurements are complete, the unit will display the following

message:

Analyzing Data...

9. When data analysis is complete, if Chg. Temp On is selected in the Log Setup Menu, the following

will be displayed:

Temp = 000.0

10. Enter a value for the temperature as follows:

Press or to scroll through the available digits (0 - 9).

Press ENTER to select the displayed digit; the cursor will move to the next character.

Repeat Steps a and b as required to enter three digits.

11. When data analysis and temperature entry (if applicable) is complete, the File No. and name will be

displayed. If the automatic transmit mode is selected (see Section 4 - Setup), the data will be

automatically transmitted through the RS-232 port.

NOTE

The data, including the entered temperature, is

available for display using the or keys. (Refer to

Displaying Logged Data.)

12. Repeat Steps 3 through 12 as necessary to make additional measurements.

NOTE

After Auto Zeroing is complete, the measurement

must be made within approximately 5 seconds.

NOTE

Observe the display while swiping the film, if

analyzing data... is indicated on the display before

the step image passes completely over the

aperture the unit will not resolve the image.

Increase the swipe speed slightly to correct this

problem.

Maximum resolution is achieved by adjusting the

swipe speed so that the step image passes over

the aperture just before the message analyzing

data is shown on the display. A film swipe speed of

3 seconds permits the unit to acquire the maximum

number of samples, prior to analyzing the data.

4

4-19

Page 34

Nuclear Associates 07-444

Operators Manual

(Blank page)

Page 35

Operation

Single Step Measurements

Section 5

Operation

In the event of a static discharge induced lock-up of

the densitometer, it is necessary to reset the unit by

cycling the power (i.e. place the power switch to the

OFF position, then to the ON position). The unit

will power up in the normal operating mode.

This Section provides step-by-step procedures for the making single-step density measurements,

including:

• Making 21-step density measurements

• Displaying logged data

• Reporting logged data

Refer to Section 7 - Maintenance and

Troubleshooting for a description of Displayed Error

Messages.

NOTE

NOTE

5

5.1 Single Step Measurements

Use the following procedure to make single step density measurements:

1. Make sure the Power Switch is in the OFF position.

2. Press and hold the ENTER push-button while turning the Power Switch to the ON position. The

following message will be displayed:

Self testing...

3. When the unit has completed the self-test, the following setup Menu label will be displayed:

Single.

4. Press ENTER. The unit will auto zero and display the following message:

Auto zeroing...

5. After zeroing is complete, the density will be displayed:

Density = 0.00

6. Position the film or step wedge so that the area to be measured is over the aperture (Figure 5-1).

5-1

Page 36

Nuclear Associates 07-444

Operators Manual

Figure 5-1. Aperture Location

NOTE

After Auto Zeroing is completed, measurements

must be made within approximately 30 seconds.

7. Repeat step 6 as necessary to make additional measurements.

5.2 Automatic 21-Step Measurements

Use the following procedure to make automatic 21-step density measurements: (refer to “SETUP AND

USE WITH X-RITE STEP WEDGES” for X-Rite info)

1. From the power off state, turn the Power Switch to the ON position. The following message will be

displayed:

Self testing...

2. After the self-check is complete, the active File No. will be displayed.

3. Press or to scroll the display to Scan Film.

4. Press ENTER. The unit will auto zero and display the following message:

Auto zeroing...

Step Wedge Type - NAD

Swipe film now! will be displayed.

Load the film from the top of the unit, oriented so that step 1 (lowest density measured first, and gently

swipe it toward the bottom of the unit. The display of an error message may indicate an erroneous scan,

repeat this step if necessary.

Step Wedge Type - X-Rite

ENTER when ready will be displayed.

Load the film from the top of the unit, oriented so that step 1 (lowest density) is measured first, slide the

film into position so that the measurement area is between the film edge and the first step in the base +

fog region. Press ENTER. Pull film now! will be displayed. Gently swipe it toward the bottom of the unit.

The display of an error message may indicate an erroneous scan, repeat this step if necessary.

5-2

Page 37

Operation

Automatic 21-Step Measurements

NOTE

Position the film so that the lowest density steps

enter the Densitometer first, i.e., Step 1 - 21. Avoid

jerky movement of the film through the

Densitometer.

5. When 21-steps and base + fog measurements are complete, the unit will display the following

message:

Analyzing Data...

6. When data analysis is complete, if Chg. Temp On is selected in the Log Setup Menu, the following

will be displayed:

Temp = 000.0

7. Enter a value for the temperature as follows:

Press or to scroll through the available digits (0 - 9).

Press ENTER to select the displayed digit; the cursor will move to the next character.

Repeat Steps a and b as required to enter three digits.

8. When data analysis and temperature entry (if applicable) is complete, the File No. and name,

selected in Step 7, will be displayed. If the automatic transmit mode is selected (see Section 4 -

Setup), the data will be automatically transmitted through the RS-232 port.

NOTE

The data, including the entered temperature, is

available for display using the or keys. (Refer to

Displaying Logged Data.)

9. Repeat Steps 3 through 12 as necessary to make additional measurements.

NOTE

After Auto Zeroing is complete, the measurement

must be made within approximately 5 seconds.

5

5.3 Displaying Logged Data

The Densitometer allows the user to view all stored data for the active file. In order to view data for a

specific file, the file must be selected as the active file.

1. Press or to scroll the display to Select Log Entry.

2. Press ENTER. A File No. and name will be displayed:

File XX YYYY

where XX is the currently active File No. and YYYY is the name of the currently active file as entered

in the Setup Program.

3. Press or to scroll the list of files.

4. Press ENTER to select the file to activate. The following message will be displayed:

Entry selected

The File No. and File Name will be re displayed.

5-3

Page 38

Nuclear Associates 07-444

Operators Manual

5. Press to scroll down through logged data as follows:

NOTE

Press — to scroll up through logged data.

a. Press . The following will be displayed:

base + fog X.XX D

b. Press . The following will be displayed:

Step 1 X.XX D

c. Repeat Step b as required to display density values to Step 21.

d. Press . The following will be displayed:

Temp XXX.X D

e. Press . The following will be displayed:

Rel. Speed X.XX

f. Press . The following will be displayed:

Ave Grad X.XX

g. Press . The following will be displayed:

Dmax X.XX D

h. Press . The following will be displayed:

Spd Index X.XX D

i. Press . The following will be displayed:

Cnt Index X.XX D

j. Press . The following will be displayed:

Send Data

k. Press . The following will be displayed:

Select Log Entry

l. Press . The following will be displayed:

Scan Film

m. Press . The File No. and Name will be re displayed.

6. Repeat Steps 1 through 5 as necessary to view additional files.

5.4 Reporting Logged Data

Use the following procedure to send all data logged in the currently active file to the output port:

1. Press or to scroll the display to Select Log Entry.

2. Press ENTER. A File No. and Name will be displayed:

File XX YYYY

where XX is the currently active File No. and YYYY is the name of the currently active file.

3. Press or to scroll the list of files.

4. Press ENTER to select the file to activate. The following message will be displayed:

Entry selected

The File No. and Name will be re displayed.

5. Press or to scroll the display to Send Data.

5-4

Page 39

Operation

Reporting Logged Data

6. Press ENTER. The following message will be displayed:

Sending Data...

7. When transmission is complete, the File No. and Name will be re displayed.

8. Repeat Steps 1 through 7 to output data from other files as necessary.

5.5 Printing a D Log E Curve

The Little Genius allows the user to output a D Log E curve directly to a printer. See the D log E Setup

section for further description.

1. Press or to scroll through the menu until Select Log Entry is displayed. Press ENTER.

2. The active file will be displayed as File XX or a previously entered user label. Press or to scroll

through the file list and press ENTER to select the displayed file.

3. Entry selected... will be displayed, followed by the currently active file. Press or to scroll through

the menu until Print D Log E is displayed. Press ENTER.

4. The message Sending data... will be displayed.

5.6 Printing Control Charts

5

The Little Genius allows the user to output the control charts directly to a printer. See the Control Chart

Setup section for further description.

1. Press or to scroll through the menu until Select Log Entry is displayed. Press ENTER.

2. The active file will be displayed as File XX or a previously entered user label. Press or to scroll

through the file list and press ENTER to select the displayed file.

3. Entry selected... will be displayed, followed by the currently active file. Press or to scroll through

the menu until Print Ctrl Chart is displayed. Press ENTER.

4. The message Sending data... will be displayed.

5-5

Page 40

Nuclear Associates 07-444

Operators Manual

(Blank page)

Page 41

Calibration

Calibration

Section 6

Calibration

The 5-Step Reference Step Wedge is used to calibrate the Densitometer. The calibration point is

generally Step 4.

The following procedure allows calibration of the optical density of the Scanning Densitometer:

1. Be sure the Power Switch is in the OFF position.

2. Press and hold the ENTER push-button while turning the Power Switch to the ON position. The

following message will be displayed:

Self testing...

3. When the unit has completed the self-test, the following Setup Menu label will be displayed:

Single.

4. Press or to scroll through the Setup Menu until Calibrate is displayed.

5. Press ENTER. The current calibration density is displayed with the cursor under the first digit of the

density value:

Density = X.XX

6. Edit the density value as follows:

a. Press or to increase/decrease the value at the cursor.

b. Press ENTER to select the displayed value; the cursor will move to the second digit.

c. Press or to increase/decrease the value at the cursor.

d. Press ENTER to select the displayed value; the cursor will move to the third digit.

e. Press or to increase/decrease the value at the cursor.

f. Press ENTER to select the displayed value; the unit will auto zero and display the following

message:

Auto zeroing...

7. After zeroing is complete, the following message will be displayed:

ENTER to read.

8. Position the step wedge so that the area to be measured is over the aperture, with the emulsion

side UP.

9. Press ENTER. The following message will be displayed:

Calibrating....

10. When calibration is complete, Calibrating done will be displayed briefly. The display will then return

to the Setup Program Menu and Facility Title will be displayed.

11. Scroll through the Setup Menu until the message SINGLE is displayed. Measure each step to

verify the correct calibration.

After Auto Zeroing is completed, the measurement

must be made within approximately 30 seconds.

NOTE

6

6-1

Page 42

Nuclear Associates 07-444

Operators Manual

(Blank page)

Page 43

Maintenance and Troubleshooting

General

Section 7

Maintenance and Troubleshooting

7.1 General

NOTE

This instrument contains CMOS integrated circuits.

Static charge normally present in a dry atmosphere

or leakage current in soldering irons or other nongrounded tools can instantly destroy CMOS

components. Do not attempt to remove or replace

ICs in this device without observing anti-static and

leakage current precautions. Service should be

performed only by a technician thoroughly familiar

with CMOS devices.

As with any precision instrument, certain precautions and periodic maintenance procedures are

necessary. Observe the following:

7

1. Keep the underside of the photo head clean, using alcohol and a soft cloth as required. DO NOT,

UNDER ANY CIRCUMSTANCES, USE ANY OTHER SOLVENT.

2. Periodically check the alignment of the aperture and the photo head. Misalignment may be due to:

a. Dropping the instrument.

b. Using excessive pressure to hold the instrument closed.

c. Letting the top section "slam" in the open position.

If the photo head and aperture are severely out of

alignment, return the unit to Fluke Biomedical for

service.

NOTE

7.2 Photo Head Alignment

Proper photo head alignment is critical. Adjustments can be made by slowly tightening or loosening the

four (4) adjustment screws, visible when holding the top section of the unit open.

Proper adjustment is achieved when the photo head is parallel to the surface of the light table and the

gap is just wide enough to allow the film to slide through with slight resistance. Always check the

calibration after making photo head adjustments.

7-1

Page 44

Nuclear Associates 07-444

Operators Manual

7.3 Displayed Error Messages

Refer to Table 7-1 for a description of error messages that may be displayed during operation or setup of

the Densitometer.

Table 7-1. Displayed Error Messages

Message Description Corrective Action

Low Battery Battery voltage is below threshold;

unit will not operate.

DSR Invalid DSR line (DTR from computer)

indicates that the computer is not

ready to accept data.

Scanning Halted Scanning process halted for one of

following reasons:

- Text on film edge.

- Jerky movement of film through

Densitometer.

- Improperly positioned step

wedge on test film.

- Very dim marks on the test film.

- Missing marks above steps on

test film.

Too Many Marks More than 21 step marks detected. Check that test film is properly marked.

Invalid Data One or more of 22 readings is

greater than 4:005.

B + F value = 0.00

The relative speed is not

calculated.

The average gradient is not

calculated.

Couldn't resolve 21 steps could not be identified for

one of the following reasons:

Jerky movement of film through

the densitometer.

Improperly positioned step

wedge on test film.

Timed Out Film not read within 20 seconds. Position film and take reading within 20

Replace batteries.

Check that DTR line from computer is