Page 1

VORTAB Flow Conditioner

Installation and Operation Guide

General

This document describes the procedures required to install, and maintain the Vortab Insertion Panel (VIP), Vortab Insertion Sleeve (VIS), Vortab Meter

Run (VMR), Vortab Short Run (VSR), Vortab Elbow (VEL) and Vortab Field Kit (VFK) Flow Conditioners.

In Industrial installations, process plants are designed to minimize floor space. Abbreviated floor space can result in inadequate short runs of straight

pipe required upstream from flow meters, pumps, compressors and other critical components used in the process industries. The resulting flow

disturbances increase flow meter error, and can induce cavitation and noise in pumps, which results in excessive wear and damage.

A flow conditioner isolates flow disturbances by providing a consistent outlet flow condition regardless of inlet conditions. Because of its unique tab

design, the Vortab flow conditioner is able to provide excellent flow meter isolation, yet it creates very little pressure loss and is virtually immune to

fouling.

Vortab flow conditioners come in six basic forms: Vortab Insertion Panel (VIP), Insertion Sleeve (VIS), Meter Run (VMR), Short Run (VSR), Elbow

configuration (VEL), or Field Kit (VFK). The VIP can be configured to slide into an existing process pipe or duct and welded in place, or offered as a

flange mount version to be captured between flange faces. The VIS is sized to slide into the existing process pipe or duct. It can be welded in place

or secured with optional capture flange between flanges faces. The VMR spool piece includes the Vortab flow conditioning internals as well as the

recommended settling distance for downstream flow meters. The VSR is a stand-alone pipe section 3 pipe diameters (3D) in length that includes only

the flow conditioning internals. The VEL elbow flow conditioner can be short or long radius with a vast array of process connections and downstream

metering connections. The VFK includes all the Vortab flow conditioning internals and fabrication instructions required for assembly in the field.

Theory of Operation

Vortab flow conditioners are passive mechanical devices, which effectively establish a repeatable, symmetric, and swirl free velocity profile regardless of the fluid’s inlet condition. These conditioners use vortex generating tabs to amplify and accelerate the boundary layer behavior of long pipe.

The basic principles involved are vorticity generation, force cancellation, and diffusion.

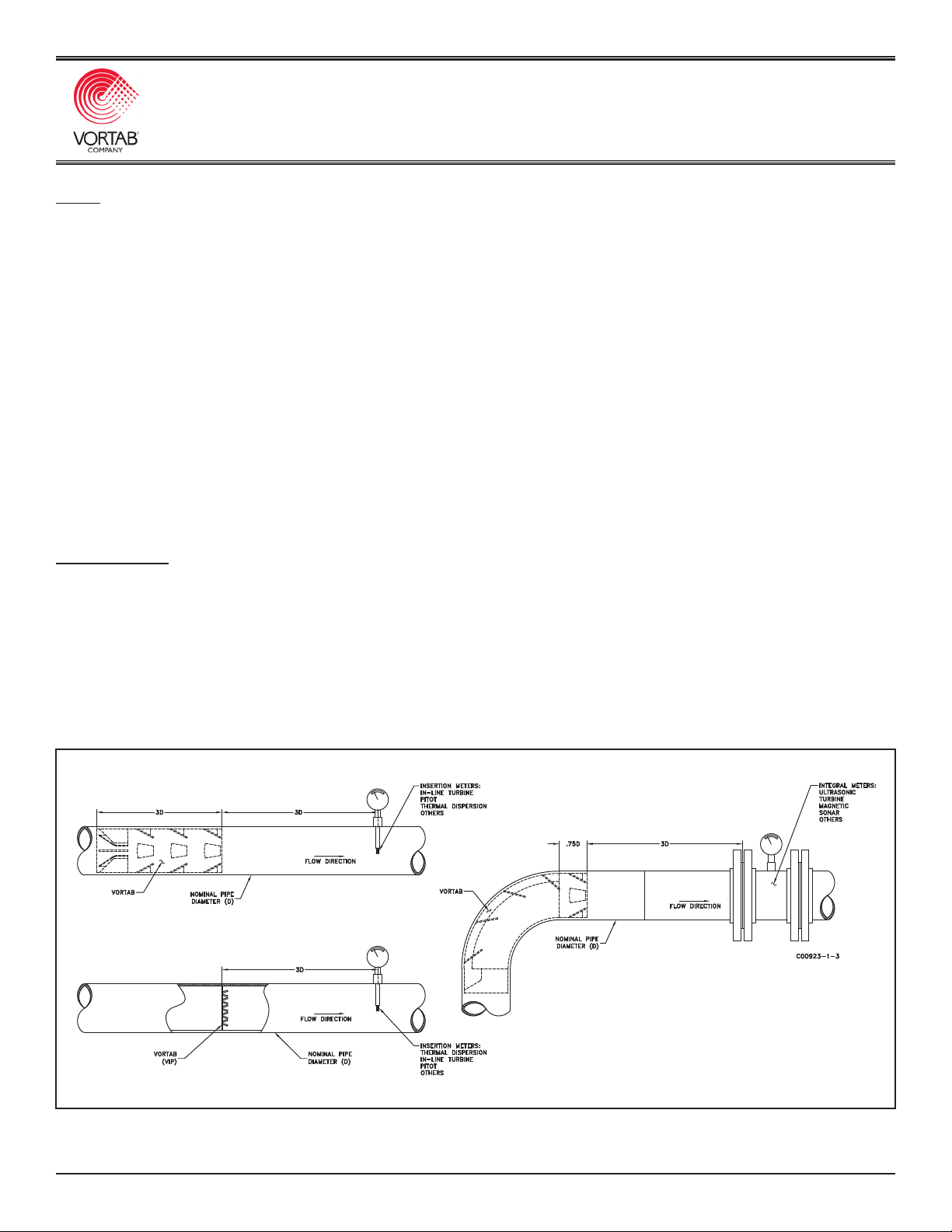

For flow meters, the Vortab flow conditioners are capable of producing uniform, non-swirling velocity profiles three pipe diameters (3D) downstream

from the Vortab. Depending on the severity of the downstream disturbance, one to five diameters (1D to 5D) of straight pipe are required after the

flow meter location. Figure 1-1 illustrates typical Vortab installations upstream from flow meters. For pumps, compressors, control valves and other

critical process equipment, the Vortab flow conditioners can be mounted directly to their downstream components. Figure 1-2 illustrates typical

installations upstream from pumps and compressors.

Figure 1-1. Typical Vortab Installation with Flowmeters

This page is subject to proprietary rights statement on last page

Page 2

VORTAB® Company VORTAB Flow Conditioner

Figure 1-2. Typical Vortab Installation with Pumps/Compressors

This page is subject to the proprietary rights statement on the last page 2 Doc. No. 06EN003269 Rev. D

Page 3

VORTAB Flow Conditioner VORTAB® Company

Technical Specication

Vortab Insertion Panel (VIP)

Process Pipe or Duct Inside Diameter

Available sizes: 2 inch to 40 inch

Available in larger sizes (special)

Material of construction

316L Stainless Steel

Length

Tabs extend into downstream flow conduit a distance of

.135 x conduit’s inner diameter.

Process Connection

Capture Flange mounted or Weld-In-Place inside duct or

pipe inner diameter.

Vortab Insertion Sleeve (VIS)

Process Pipe or Duct Inside Diameter

Customer specified inner diameter

Available in sizes: .87 inch and higher

Also available in ¼, ½, and ¾ sch 40 sizes

Material of construction

316L SST & Hastelloy C-276 for all sizes

Carbon steel for sizes 4.51 inch and higher

Length

Approximately 3 times the customer ID

Process Connection

Capture flange or welded to the pipe or

duct inside diameter

Vortab Meter Run (VMR)

Pipe size

Available in ¼, ½, and ¾ sch 40

1” (various schedules)

2” and above all pipe schedules

Material of construction

316L SST and Hastelloy C-276 throughout for all sizes

Carbon steel 8 inch and above

Also available with 316L SST body and carbon steel flanges for

all sizes

Length

7 nominal pipe diameters (7D)

Exception: Line sizes 2-inch and smaller, which may have

longer lengths than 7D. Consult factory for specific lengths.

Process Connection

Butt weld preparation, male NPT, flanged or customer specified

Flow Element Connection For Flowmeter Installation

Threaded ¾,1, or 1-1/4 inch female NPT, 1-1/4 inch NPT, 1-1/2 inch

flanged, or customer specified

Vortab Short Run (VSR)

Pipe size

Available in ¼, ½, and ¾ sch 40

1” (various schedules)

2” and above all pipe schedules

Material of construction

316L SST and Hastelloy C-276 throughout for all sizes

Carbon steel 8 inch and above

Also available with 316L SST body and carbon steel flanges for

all sizes

Length

3 nominal pipe diameters (3D)

Process Connection

Butt weld preparation, male NPT, flanged or customer specified

Vortab Elbow (VEL)

Pipe size

1” and higher

Smaller sizes available upon request

Material of construction

316L SST, Hastelloy C-276, and carbon steel for all sizes

Elbow Radius

Short and Long radius

Process Connection

Butt weld preparation, male NPT, flanged or customer specified

Flow Element Connection For Flowmeter Installation

Threaded ¾,1, or 1-1/4 inch female NPT, 1-1/4 inch NPT, 1-1/2 inch

flanged, or customer specified

Vortab Field Kit (VFK)

Material of construction

316L SST, Hastelloy C-276, and carbon steel

Other materials available upon request

Process Pipe or Duct Inner Diameter

Customer specified

Length

Approximately 3 times the customer ID

Attachment Method

Welded in the field. Fabrication and welding instructions provided

Doc. No. 06EN003269 Rev. D 3

This page is subject to the proprietary rights statement on the last page

Page 4

VORTAB® Company VORTAB Flow Conditioner

Installation - General

Receiving and Inspection

• Inspect for damage

• Packing List – verify correct configuration against purchase order. At a minimum, Vortab Company’s customer order number along with flow direc-

tion indicators will be etched on all products.

• If the above items are satisfactory then proceed with installation. If not, then STOP and contact the field representative or the factory personnel

for instructions.

There may be an additional sizing ring accompanying the Vortab Insertion Sleeve (VIS) in the shipping container. This is used to verify roundness and

diameter during fabrication. It may be needed to facilitate installation in the following sections. The sizing ring can be discarded upon completion of

the VIS installation.

Vortab Insertion Panel (VIP) Installation

Prepare the installation site or inspect the already prepared location to assure that the VIP will fit into the process pipe or duct.

• Verify that the VIP matches the geometry and dimensions of the intended process pipe mount.

• The VIP’s base plate, in which the tabs extend from, should be positioned at a distance of three nominal pipe diameters (3D) upstream from the

flow meter location. See Figure 2-1.

Figure 2-1. VIP Installation Recommendations

This page is subject to the proprietary rights statement on the last page 4 Doc. No. 06EN003269 Rev. D

Page 5

VORTAB Flow Conditioner VORTAB® Company

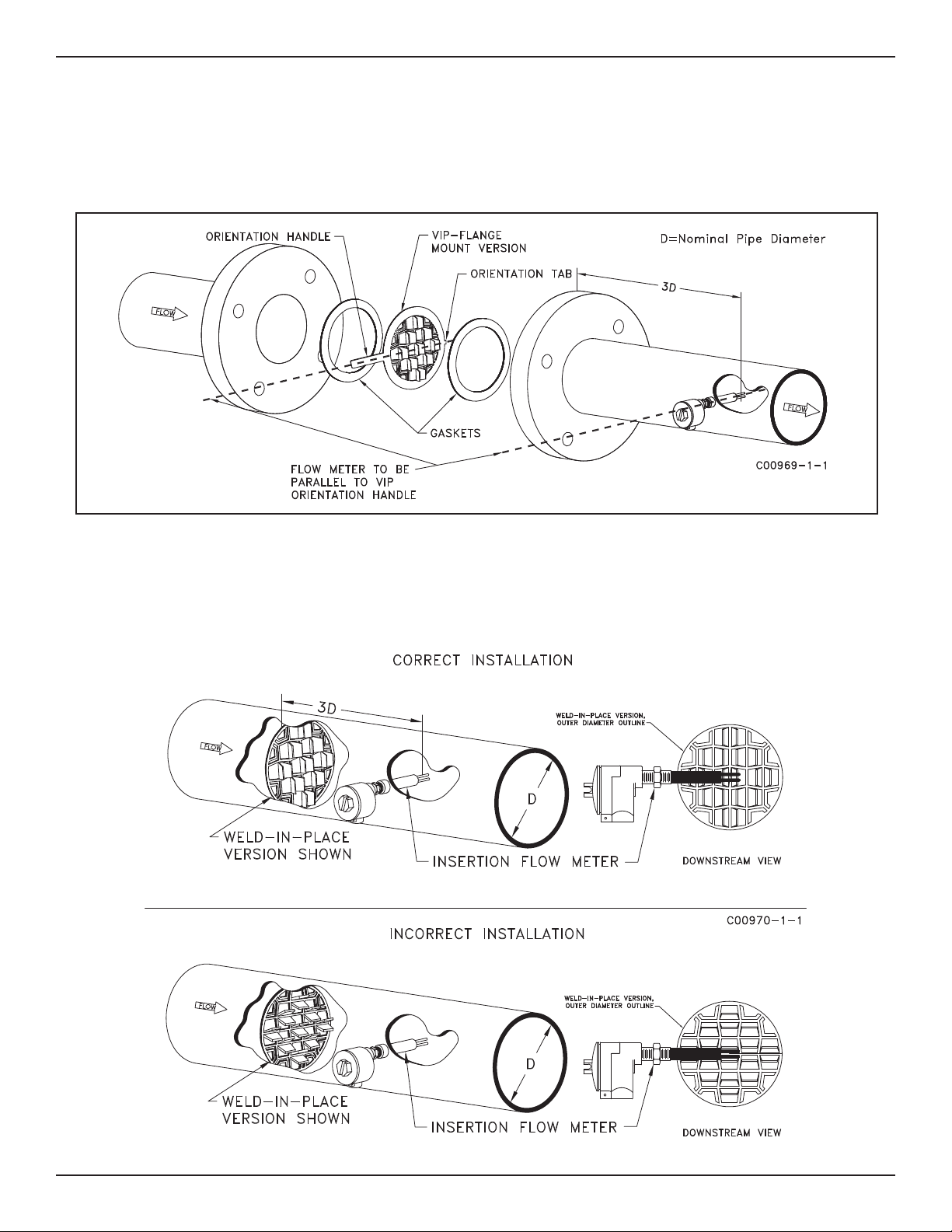

Flange Mount VIP

The flange-mounted VIP will appear one of two ways. Refer to Figure 2-2. For sizes below 24.40-inches (620 mm) there will be one orientation tab

and one orientation handle 180º offset from each other. For sizes 24.40” and above there will be two orientation tabs offset 180º from each other.

Figure 2-2. Upstream Views of Flange Mount VIP

Orientation of the VIP with respect to an insertion flow meter is important. Refer to Figure 2-3 for both correct and incorrect installations of the VIP

with respect to an insertion flow meter. An imaginary line passing through the two orientation tabs and/or orientation handle should be parallel to

the flow meter’s sensing element.

Figure 2-3. Orientation of Flange Mount VIP

Doc. No. 06EN003269 Rev. D 5

This page is subject to the proprietary rights statement on the last page

Page 6

VORTAB® Company VORTAB Flow Conditioner

When using the VIP upstream from flow meters other than FCI insert flow meters, whether it be in insert or flange mounted, such as turbine, annubar,

and ultrasonic flow meters, orientation is not critical but should mimic that which was calibrated. The VIP should be positioned upstream from the

flow meter in the orientation and distance in which it was calibrated.

The VIP is secured in place by way of sandwiching between flange faces. This will require two customer-supplied gaskets of which one will be

placed on each side of the VIP prior to installation. See Figure 2-4. The orientation tabs and/or orientation handle can be used to facilitate symmetric

installation of the VIP. Bolt flanges together to complete the installation.

Figure 2-4. Installation and Orientation of Flange Mount VIP

Weld-In-Place VIP

Orientation of the VIP with respect to an insertion flow meter is important. Refer to Figure 2-5 for both correct and incorrect installations of the weld

in place VIP with respect to an insertion flow meter.

Figure 2-5. Orientation of Weld-In-Place VIP

This page is subject to the proprietary rights statement on the last page 6 Doc. No. 06EN003269 Rev. D

Page 7

VORTAB Flow Conditioner VORTAB® Company

Refer to Figure 2-6 for installation recommendations. Welding the VIP into place may cause distortion and shrinkage to the receiving conduit’s wall

so it is suggested to weld the VIP away from any potential weld zones like that shown Step #1 of Figure 2-6. First identify the permanent location

of the VIP and determine the receiving conduit’s cut location (if required). It is recommended to position the VIP a quarter of a pipe diameter (.25D)

downstream from conduit re-weld zone. Before any welding is to take place, weld prep pipe ends if required per step #2. Position and correctly

orientate the VIP .25D downstream from conduit weld zone and provide full circumferential fillet weld to secure VIP in place per step #3. Complete

installation by welding conduit sections back together per step #4. Avoid welding the VIP flush with flange faces as warping or shrinkage of the

flange face may occur.

When using the VIP upstream from flow meters other than FCI insert flow meters, whether it be in insert or flange mounted, such as turbine, annubar,

and ultrasonic flow meters, orientation is not critical but should mimic that which was calibrated. The VIP should be positioned upstream from the

flow meter in the orientation and distance in which it was calibrated.

Figure 2-6. Weld-In-Place VIP Installation

Doc. No. 06EN003269 Rev. D 7

This page is subject to the proprietary rights statement on the last page

Page 8

VORTAB® Company VORTAB Flow Conditioner

Vortab Insertion Sleeve (VIS) Installation

Prepare the installation site or inspect the already prepared location to assure that the VIS will fit into the process pipe or duct.

• Verify that the VIS matches the geometry and dimensions of the intended process pipe mount.

• The outlet of the VIS must be located three nominal pipe diameters (3D) upstream from the customer meter. The process pipe must continue

straight for at least 1 pipe diameter (1D) past the customer meter. See Figure 2-7.

Figure 2-7. Orientation of VIS in Process Pipe or Duct

This page is subject to the proprietary rights statement on the last page 8 Doc. No. 06EN003269 Rev. D

Page 9

VORTAB Flow Conditioner VORTAB® Company

Tack Weld Mounting

Slide the VIS into the process pipe. Orientation of the tabs is not critical although symmetry with the downstream flow metering device is recommended. Weld Vortab into place; at least 1/2 of circumference should be securely welded. See Figure 2-8.

Note:

Depending on size, there may be an additional sizing ring enclosed in the shipping container. This is used for fabricating and

inspection purposes and can be discarded upon completion of installation.

If the VIS does not fit, use the sizing ring to determine where the flow conditioner is out-of-round. Carefully reshape the problem area and reinstall

the VIS.

Figure 2-8. Typical Welded Installation of a VIS

Retaining Wafer Mounting

Sandwiching the retaining wafer between flange faces secures the VIS in place. This will require two customer-supplied gaskets of which one will

be placed on each side of the retaining wafer prior to installation. Orientation of the tabs is not critical although symmetry with the downstream flow

metering device is recommended. Bolt flanges together to complete installation. See Figure 2-9.

Note:

Depending on size, there may be an additional sizing ring enclosed in the shipping container. This is used for fabricating and

inspection purposes and can be discarded upon completion of installation.

Figure 2-9. Typical Retaining Wafer Mounting of a VIS

Doc. No. 06EN003269 Rev. D 9

This page is subject to the proprietary rights statement on the last page

Page 10

VORTAB® Company VORTAB Flow Conditioner

Vortab Meter Run (VMR), Vortab Short Run (VSR) & Vortab Elbow (VEL) Installation

Prepare the installation site or inspect the already prepared location to assure that the flow conditioner will fit into the process by verifying that the

flow conditioner matches the geometry and dimensions of the intended process pipe.

Butt Weld Mounting

VMR, VSR, and VEL Vortabs are supplied with weld prepped process connections to accommodate full penetration welds. Weld areas should be free

of moisture and contaminants prior to welding. Orientation of the tabs is not critical although symmetry with the downstream flow metering device is

recommended. See Figure 2-10.

Mount flow meter into Vortabs with optional flow element connection.

Figure 2-10. Typical Butt Weld VMR, VSR, and VEL

Flange Mounting

Standard flange bolt holes split the vertical axis, which is a common practice in piping community. See Figure 2-11. Customer supplied gaskets are

required between mating flanges. Bolt flanges together using customer supplied hardware.

Mount flow meter into Vortabs with optional flow element connection.

Figure 2-11. Typical Flanged VMR, VSR, and VEL

This page is subject to the proprietary rights statement on the last page 10 Doc. No. 06EN003269 Rev. D

Page 11

VORTAB Flow Conditioner VORTAB® Company

NPT Mounting

Threads per ANSI B1.20, American National Standard Taper Pipe Thread, NPT. Connection surfaces should be free of moisture and contaminants

(including storage compounds) prior to the application of thread compounds or Teflon tape. See Figure 2-12.

NPT Mounting with Pipe Dope Compounds

Apply a light, even coating of thread compound over the entire thread and seal areas, leaving the thread form clearly visible. The act of slapping a

“glob” of pipe dope on one side of the thread then relying on the pipe rotation during make-up to distribute is not sufficient. Teflon tape can be used

in conjunction with pipe dope, which would be wrapped around the applied pipe dope.

Thread Vortab into process connection and check for leaks. Mount flow meter into Vortabs with optional flow element connection.

NPT Mounting with Teflon Tape

Verify the Teflon tape being used is compatible with the media being isolated. There are approved Teflon tapes for gas service.

Although Teflon tape can inadvertently “seal” threads, it is actually intended to lubricate threads. The surfaces of threads are not smooth and as they

rub and pressure builds, they begin to gaul. This puts more material into the space between the mating threads, causing them to lock up prematurely.

Teflon tape eliminates gauling and promotes thread engagement, ensuring a tighter seal.

Wrap the male threads with Teflon tape. Wrap the threads in the same direction that the female end turns when attaching to pipe. Threads wrapped

in the wrong direction will unwind the tape when screwing mating threads together. A good rule of thumb is to wrap clockwise while looking into

the pipe from the threaded end.

Thread Vortab into process connection and check for leaks. Mount flow meter into Vortabs with optional flow element connection.

Figure 2-12. Typical Threaded VMR, VSR, and VEL

Doc. No. 06EN003269 Rev. D 11

This page is subject to the proprietary rights statement on the last page

Page 12

VORTAB® Company VORTAB Flow Conditioner

Vortab Field Kit (VFK) Installation

Process Pipe Preparation

The length of the flow conditioning section is three pipe diameters (3D). The inlet consists of eight symmetrically arranged anti-swirl tabs followed

by three sets of four symmetrically arranged profile tab/gusset assemblies. See Figure 2-13. Flow meters to be installed three pipe diameters (3D)

downstream from the exit of the flow conditioning section. The flow meter’s downstream requirements should adhere to the flow meter manufacturer’s installation recommendations. Orientation of the tabs is not critical although symmetry with the downstream flow metering device is recommended. Position the Vortab flow conditioning internals and respective flow meter per recommendations shown in Figure 2-13.

Figure 2-13. Tab Location

Weld Procedures

The easiest way to install the VFK is to have access to the VFK assembly location from both ends for welding. However, if only one end is accessible,

then start with the tabs the farthest from the access end. This could either be the anti-swirl tabs located at the flow conditioning inlet or it will be

the last set of downstream profile tab/gusset assemblies.

Welding surfaces should be free of moisture and contaminants.

It is highly recommended to mark the tab locations and then spray the inside of the process pipe with anti-spatter prior to any welding.

Before welding into process pipe, fabricate the profile tab/gusset assemblies by welding the twelve profile tabs to their respective gussets. Refer to

Figure 2-14.

Weld Vortab flow conditioning internals into process pipe. Thoroughly clean all weld spatter and slag from process pipe. Sandblast if possible.

Figure 2-14. Weld Detail

This page is subject to the proprietary rights statement on the last page 12 Doc. No. 06EN003269 Rev. D

Page 13

VORTAB Flow Conditioner VORTAB® Company

Maintenance

General

Without detailed knowledge of the environmental parameters of the application surroundings and process media, Vortab cannot make specific

recommendations for periodic inspection or cleaning procedures. However, some suggested general guidelines for maintenance steps are offered

below. Use operating experience to establish the frequency of each type of maintenance.

VIS, VMR, VSR VEL and VFK Maintenance

Periodically check the flow conditioner based on historical evidence of debris and foreign matter in the process pipe. The tapered design of Vortabs

make them self cleaning and inherently immune to fouling and clogging. The exception could be large items such as buckets, palm branches, hard

hats and other items that could become lodged if their size is larger than the through core diameter of the installed anti-swirl tabs. Due to the pressure differential between the upstream and downstream sides of the profile conditioning tabs, a vacuum effect constantly pulls media and debris

from the backsides of the tabs.

Build up of sticky substances such as paraffin (wax) could cause decreased effectiveness of the flow conditioner. Clean the flow conditioner according to process pipe cleaning schedules and procedures.

VIP Maintenance

Unlike the standard Vortab products, the Vortab Insertion Panel (model VIP) is not an open core flow conditioner and therefore, more likely susceptible to clogging from debris and foreign matter, which can lead to flow meter anomalies. Build up of sticky substances such as wax (paraffin) can

also contribute to flow meter discrepancies. Periodic checks are recommended especially after start up of new installations or when a flow meter’s

readings are questionable. Always re-install the VIP in the orientation in which it was removed, as they are orientation sensitive. Refer to VIP installation guidelines covered in previous sections.

Customer Service and Technical Support

Vortab provides full in-house technical support for our products 7 a.m. to 5 p.m. PST, Monday through Friday (except holidays and an annual plant

closure between Christmas and New Year’s day). Also, additional technical representation is provided by Vortab field representatives.

By Mail

Vortab

1755 La Costa Meadows Dr.

San Marcos, CA 92078-5115 USA

Attn: Customer Service Department

By Phone

Contact the area Vortab regional representative. If a field representative is unable to be contacted or if a situation is unable to be

resolved, contact the Vortab Customer Service Department toll free at 1 (800) 854-9959 or 1 (760) 736-6114.

By Fax

To describe problems in a graphical or pictorial manner, send a fax including a phone or fax n@umber to the regional representative.

Again, Vortab is available by facsimile if all possibilities have been exhausted with the authorized factory representative. Our Fax

number is 1 (760) 736-6250; it is available 7 days a week, 24 hours a day.

By E-Mail

Vortab Customer Service can be contacted by e-mail at: sales_technical_support@fluidcomponents.com. or donl@fluidcomponents.com.

Describe the problem in detail making sure a telephone number and best time to be contacted is stated in the e-mail.

International Support

For product information or product support outside the contiguous United States, Alaska, or Hawaii, contact your country’s Vortab

International Representative or the one nearest to you.

Doc. No. 06EN003269 Rev. D 13

This page is subject to the proprietary rights statement on the last page

Page 14

VORTAB® Company VORTAB Flow Conditioner

After Hours Support

For product information visit Vortab’s Worldwide Web at www.vortab.com. For product support call 1 (800) 854-9959 and follow the

prerecorded instructions. A person from the Technical Support Staff will be paged and promptly return the call.

Point of Contact

The point of contact for service, or return of items to Vortab is the authorized Vortab service representative.

Shipping and Handling Charges (All Shipping, Warranty/Nonwarranty Repairs or Returns)

The customer prepays all shipping, freight, duty/entry and handling charges from the customer site to the Vortab door. If the customer does

not prepay, Vortab will invoice the customer for the charges that appear on the freight bill. Address the return equipment to:

Warranty Repairs or Returns

Vortab prepays ground transportation charges for return of freight to the customer’s door. Vortab reserves the right to return equipment by

the carrier of our choice.

International freight, handling charges, duty/entry fees for return of equipment are paid by the customer.

Non-Warranty Repairs or Returns

Vortab returns repaired equipment to the customer either collect or prepaid and adds freight charges to the customer invoice.

Return to Stock Equipment

The customer is responsible for all shipping and freight charges for equipment that is returned to Vortab stock from the customer site. These

items will not be credited to customer’s account until either all freight charges are cleared or until the customer agrees to have any freight

costs incurred by Vortab deducted, along with applicable return to stock charges, from the credit invoice. Exceptions are made for duplicate

shipments made by Vortab.

If any repair or return equipment is received at Vortab, freight collect, without prior factory consent, Vortab bills the sender for these charges.

Field Service Procedures

Contact your Vortab field representative to request field service.

A field service technician is dispatched to the site from either the Vortab factory or one of the Vortab representative offices. After the work is

complete, the technician completes a preliminary field service report at the customer site and leaves a copy with the customer.

Following the service call, the technician completes a formal, detailed service report. The formal report is mailed to the customer within five

days of the technician’s return to the factory or office.

Field Service Rates

All field service calls are billed at the prevailing rates as listed in the Vortab Price Book unless specifically excepted by the Vortab Customer

Service Manager. Vortab reserves the right to bill for travel times at Vortab’s discretion.

Customers are charged for shipping costs related to the transfer of equipment to and from the job site. They are also invoiced for field

service work and travel expenses by Vortab’s Accounting Department.

This page is subject to the proprietary rights statement on the last page 14 Doc. No. 06EN003269 Rev. D

Page 15

VORTAB Flow Conditioner VORTAB® Company

1755 La Costa Meadows Drive, San Marcos, CA 92078-5115 USA

760-744-6950 / 800-854-1993 / Fax: 760-736-6250

Web Site: www.fluidcomponents.com

E-mail: techsupport@fluidcomponents.com

RA #______________

Return Authorization Request

1. Return Customer Information

Returning Company’s Name: _____________________________ Phone# __________________________________

Return Contact Name: __________________________________ Fax # ____________________________________

Email Address: ________________________________________________________________________________

2. Return Address

Bill To: _______________________________________ Ship To: _______________________________________

____________________________________________ ______________________________________________

____________________________________________ ______________________________________________

____________________________________________ ______________________________________________

3. Mandatory End User Information

Contact: ______________________ Company: _____________________________ Country: ________________

4. Return Product Information

Model No: ____________________________________ Customer No(s): _________________________________

Failure Symptoms

____________________________________________________________________________________________

What Correspondence Was Done Via Phone or Field Visit by VORTAB: _____________________________________

____________________________________________________________________________________________

VORTAB Factory Technical Service Contact: _________________________________________________________

5. Reason For Return Matching to Flow Meter for Calibration Damage to Flow Conditioning Internals

Fit Interference Built Incorrectly Credit Other

6. Payment Via

(Detailed Description Required)

: ____________________________________________________

Faxed Purchase Order

(Note: A priced quotation is provided for all Non-Warranty repairs after equipment has been evaluated. All Non-Warranty repairs

are subject to a minimum evaluation charge of $250.00)

Factory Return Shipping Address: VORTAB Company

1755 La Costa Meadows Drive

San Marcos, CA 92078-5115

Attn: Repair Department

RA #____________

Doc. No. 06EN003269 Rev. D 15

This page is subject to the proprietary rights statement on the last page

Page 16

VORTAB® Company VORTAB Flow Conditioner

The following Return Authorization Request form and Decontamination Statement

VORTAB before

must be included with the shipment

receipt of the signed forms.

Packing Procedures

1. Devices weighing more than 50 lbs., or extending more than four feet, should be secured in wooden crates. Retaining wafers

(model VIS) and flange faces are sealing mechanisms and therefore need special attention when preparing for shipment back

to the factory. Ensure adequate protection of these surfaces. Minor scratches on these surfaces can void their pressure sealing

capabilities.

2. VORTAB can supply crates for a nominal fee.

3. VORTAB will not be held liable for damage caused during shipping.

4. To ensure immediate processing mark the RA number on the outside of the box. Items without an RA number marked on the box

or crate may be delayed.

5. Freight must be “PrePaid” to VORTAB receiving door.

* Approriate dunnage as defined by UPS, will protect package contents from a drop of 3 feet.

a Return Authorization Number will be issued. The signed Decontamination Statement and applicable MSDS Sheets

. VORTAB will either fax, email or telephone you with the Return Authorization Number upon

MUST be completed, signed and faxed back to

*** Decontamination Statement *** This Section Must Be Completed ***

Exposure to hazardous materials is regulated by Federal, State, County and City laws and regulations. These laws provide VORTAB’s

employees with the “Right to Know” the hazardous or toxic materials or substances in which they may come in contact while handling returned products. Consequently, VORTAB’s employees must have access to data regarding the hazardous or toxic materials

or substances the equipment has been exposed to while in a customer’s possession. Prior to returning the instrument for evaluation/

repair, VORTAB requires thorough compliance with these instructions. The signer of the Certificate must be either a knowledgeable

Engineer, Safety Manager, Industrial Hygenist or of similar knowledge or training and responsible for the safe handling of the material

to which the unit has been exposed. Returns without a legitimate Certification of Decontamination, and/or MSDS when required,

are unacceptable and shall be returned at the customer’s expense and risk. Properly executed Certifications of Decontamination

must be provided before a repair authorization (RA) number will be issued.

Certification Of Decontamination

I certify that the returned item(s) has(have) been thoroughly and completely cleaned. If the returned item(s) has(have) been exposed to hazardous or toxic materials or substances, even though it (they) has (have) been thoroughly cleaned and decontaminated,

the undersigned attests that the attached Material Data Safety Sheet(s) (MSDS) covers said materials or substances completely.

Furthermore, I understand that this Certificate, and providing the MSDS, shall not waive our responsibility to provide a neutralized,

decontaminated, and clean product for evaluation/repair at VORTAB. Cleanliness of a returned item or acceptability of the MSDS

shall be at the sole discretion of VORTAB. Any item returned which does not comply with this certification shall be returned to your

location Freight Collect and at your risk.

This certification must be signed by knowledgeable personnel responsible for maintaining or managing the safety program at

your facility.

Process Flow Media _____________________________________________________________________________________

Product was or may have been exposed to the following substances: _______________________________________________

Print Name_____________________________________________________________________________________________

Authorized Signature ___________________________________________ Date _____________________________________

Company Title __________________________________________________________________________________________

This page is subject to the proprietary rights statement on the last page 16 Doc. No. 06EN003269 Rev. D

Page 17

VORTAB Flow Conditioner VORTAB® Company

WARRANTIES

Goods furnished by the Seller are to be within the limits and of the sizes published by the Seller and subject to the Seller’s

standard tolerances for variations. All items made by the Seller are inspected before shipment, and should any of said

items prove defective due to faults in manufacture or performance under Seller approved applications, or fail to meet

the written specifications accepted by the Seller, they will be replaced or repaired by Seller at no charge to Buyer provided return or notice of rejection of such material is made within a reasonable period but in no event longer than one (1)

year from date of shipment to Buyer, and provided further, that an examination by Seller discloses to Seller’s reasonable

satisfaction that the defect is covered by this warranty and that the Buyer has not returned the equipment in a damaged

condition due to Buyer’s or Buyer’s employees’, agents’, or representatives’ negligence and Buyer has not tampered,

modified, redesigned, misapplied, abused, or misused the goods as to cause the goods to fail. In addition, this warranty

shall not cover damage caused by Buyer’s exposure of the goods to corrosive or abrasive environments. Moreover, Seller shall in no event be responsible for (1) the cost or repair of any work done by Buyer on material furnished hereunder

(unless specifically authorized in writing in each instance by Seller), (2) the cost or repair of any modifications added by

a Distributor or a third party, (3) any consequential or incidental damages, losses, or expenses in connection with or by

reason of the use of or inability to use goods purchased for any purpose, and Seller’s liability shall be specifically limited

to free replacement, or refund of the purchase price, at Seller’s option, provided return or rejection of the goods is made

consistent with this paragraph, and the Seller shall in no event be liable for transportation, installation, adjustment, loss

of good will or profits, or other expenses which may arise in connection with such returned goods, or (4) the design of

products or their suitability for the purpose for which they are intended or used. Should the Buyer receive defective

goods as defined by this paragraph, the Buyer shall notify the Seller immediately, stating full particulars in support of

his claim, and should the Seller agree to a return of the goods, the Buyer shall follow Seller’s packaging and transportation directions explicitly. In no case are the goods to be returned without first obtaining a return authorization from the

Seller. Any repair or replacement shall be at Seller’s factory, unless otherwise directed, and shall be returned to Seller

transportation prepaid by Buyer. If the returned goods shall prove defective under this clause they will be replaced

or repaired by Seller at no charge to Buyer provided the return or rejection of such material is made within a reasonable period, but in no event longer than (1) year from the date of shipment of the returned goods. If the goods prove to

be defective under this paragraph, the Buyer shall remove the goods immediately from the process and prepare the

goods for shipment to Seller. Continued use or operation of defective goods is not warranted by Seller and damage

occurring due to continued use or operation shall be for Buyer’s account. Any description of the goods contained in

this offer is for the sole purpose of identifying them, and any such description is not part of the basis of the bargain, and

does not constitute a warranty that the goods will conform to that description. The use of any sample or model in connection with this offer is for illustrative purposes only, is not part of the basis of the bargain, and is not to be construed

as a warranty that the goods will conform to the sample or model. No affirmation of that fact or promise made by the

Seller, whether or not in this offer, will constitute a warranty that the goods will conform to the affirmation or promise.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES WITH RESPECT TO THE GOODS OR THEIR INSTALLATION, USE, OPERATION, REPLACEMENT OR REPAIR, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS OF PURPOSE; AND THE GOODS ARE BEING PURCHASED BY

BUYER “AS IS”. SELLER WILL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR OTHERWISE FOR ANY SPECIAL,

INCIDENTAL OR CONSEQUENTIAL LOSS OR DAMAGE RESULTING FROM THE USE OR LOSS OF USE OF THE GOODS.

Doc. No. 06EN003269 Rev. D 17

This page is subject to the proprietary rights statement on the last page

Page 18

VORTAB® Company VORTAB Flow Conditioner

NOTES

This page is subject to the proprietary rights statement on the last page 18 Doc. No. 06EN003269 Rev. D

Page 19

VORTAB Flow Conditioner VORTAB® Company

NOTES

Doc. No. 06EN003269 Rev. D 19

This page is subject to the proprietary rights statement on the last page

Page 20

VORTAB Flow Conditioner

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Vortab and protected by United States Patent Numbers 4,929,088 and 4,981,368. Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within

your company only (and does not include manufacture or processing uses). Any other use is strictly prohibited without the prior written consent of Vortab.

Visit VORTAB Company on the Worldwide Web: www.vortab.com

1755 La Costa Meadows Drive | San Marcos, California 92078 USA | Phone: 760-7366114 Toll Free (US): 800-854-9959 Fax: 760-736-6250

© Copyright 2014 by VORTAB Company | All rights reserved | Information subject to change without notice.

Notice of Proprietary Rights

VORTAB® Company 06EN003269 Rev. D

Loading...

Loading...