Fluid Components International ST50 User Manual

ST50 MASS FLOW METER

Installation and Operation Guide

Pre-Installation

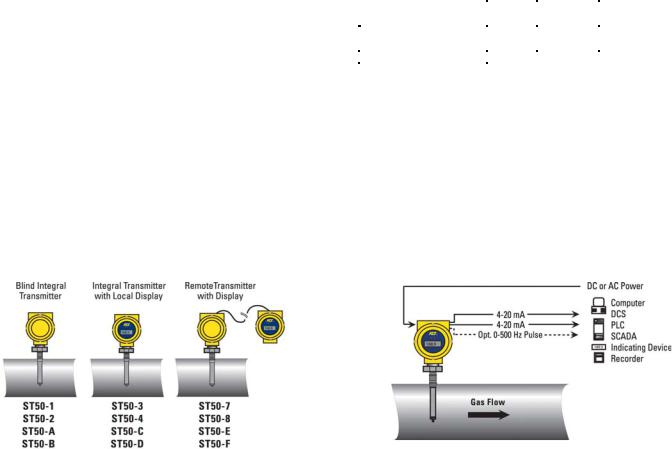

The ST50 can be specified with integral or remote electronics. The flow element has a serial number etched into the side of the extension pipe as shown on figure A. The transmitter circuit card has a serial number noted on the board as shown in figure B. The flow sensor and transmitter circuit have been calibrated as a matched set and should be paired together in service unless otherwise approved by a factory technician.

Flow Direction Alignment

All sensor elements have a flow arrow indicator marked on the element assembly at the reference flat. These flow elements have been calibrated in a particular direction and are designed to be used in service with the flow arrow facing in the same direction as flow in the pipe stream. See Appendix C for orientation and factory calibration details.

Flow Direction

FLOW

|

|

Serial Number |

|

|

Figure A |

Figure B |

|

|

|

||

Recommended Straight Run |

|

|

|

To optimize flow meter system performance, FCI recommends installation with a minimum of 20 pipe diameters upstream straight run and 10 pipe diameters of downstream straight run. Where straight run limitations significantly reduce the available pipe diameters, FCI utilizes Vortab flow conditioners to produce a transferable flow profile from the calibration installation to actual field installations. FCI’s proprietary AVAL software is available to make flow meter installation evaluations where straight run limitations are considered. See Fig C for recommended installation.

Figure C

FCI Flow Meters may be installed with less than the recommended straight run, but may have performance limitations. FCI offers Vortab flow conditioners for use in applications that have significant straight run limitations. FCI uses the AVAL application modeling software to predict meter performance in each installation. AVAL outputs are available to review prior to order placement and will indicate performance expectations both with and without Vortab Flow Conditioning.

This page is subject to proprietary rights statement on last page

FLUID COMPONENTS INTERNATIONAL LLC |

ST50 MASS FLOW |

Specifications

Instrument

Media Compatibility: Air, compressed air, and nitrogen

Pipe/Line Size Compatibility: 2” to 24” [51 mm to 610 mm]

Range: Air, compressed air, or nitrogen: 0.75 SFPS to 400 SFPS

[0.23 MPS to 122 MPS]

Accuracy: Standard: ± 2% of reading, ± 0.5% of full scale Optional: ± 1% of reading, ± 0.5% of full scale

Repeatability: ±0.5% of reading

Temperature Compensation:

Standard: 40°F to 100°F [4°C to 38°C] Optional: 0°F to 250°F [-18°C to 121°C]

Turndown Ratio: 3:1 to 100:1

Agency Approvals: 1

FM/CSA: Nonincendive for use in Class 1, Division 2, Groups A, B, C and D T4 Ta = 60°C Indoor Hazardous (Classified) Locations.

ATEX/IECEx: II 3 G EEx nA II T6; II 3 D T65°C (DC input power only)

CPA, CE Mark, PED

Warranty: One year

Flow Element (Standard or FPC Type) Installation: Insertion, variable length with 1/2” or 3/4” NPT(M) compression fitting.

Type: Thermal dispersion

Material of Construction: 316 stainless steel body with Hastelloy C thermowell sensors, 316 stainless steel compression fitting with Teflon or stainless steel ferrule

Pressure (Maximum Operating without Damage):

Stainless steel ferrule: 500 psig [34 bar(g)] Teflon ferrule: 150 psig [10 bar(g)]

Temperature (Maximum Operation):

Stainless steel ferrule: 0°F to 250°F [-18°C to 121°C] Teflon ferrule: 0°F to 200°F [-18°C to 93°C]

Process Connection: 1/2” MNPT or 3/4” MNPT with stainless steel or teflon ferrule

Insertion Length: Field adjustable lengths: 1” to 6” [25 mm to 152 mm]; 1” to 12”[25 mm to 305 mm]; or 1” to 18” [25 mm to 457 mm]

Flow Transmitter

Enclosure: NEMA 4X [IP67], aluminum, dual conduit ports with either 1/2² NPT or M20x1.5 entries. Epoxy coated.

Analog Output Signals: Dual 4-20 mA, configurable to flow rate and/or temperature (500 ohm max impedance) and a pulse output for total flow.

Output Pulse Source: Totalized flow or alarm set point. 15VDC. Pulse width at 50% duty cycle for rates 0 to 500Hz, 0.5 second pulse width for pulse rates below 1Hz. 25mA maximum load pulsed, 10mA maximum load if state set to normally on.

Output Pulse Sink: Totalized flow or alarm set point. Pulse width at 50% duty cycle for rates 1 to 500Hz, 0.5 second pulse width for rates below 1Hz. Customer power source and load not to exceed 40VDC and 150mA.

Communication Port: RS232C. Wireless IR to PDA. 2

Input Power:

DC: 18Vdc to 36Vdc (6 Watt maximum)

AC: 85Vac to 265Vac (12 Watt maximum, 1.6 Amp fuse) (CE Mark Approval from 100Vac to 240Vac)

Power Filter Board |

A m p |

R a te d |

V o ltage |

|

|

|

C o de |

C u rren t |

R a tin g |

|

Littelf u se T R 5 S er ie s |

1 1 6 0 |

1 . 6 0 A |

2 5 0 V |

|

3 7 4 11 6 0 0 4 1 0 |

|||

|

|

|

|

|

|

B r eak in g C ap a city |

5 0 A /2 5 0 V A C 5 0 -6 0 H z co s φ = 1 . 0 |

||

Operating Temperature: For Indoor or Outdoor Use 0°F to 140°F [-18°C to 60 °C]

Maximum Relative Humidity: 100%

Maximum Altitude: 12,000 ft. (3,658m)

Digital Display: ±9999 Counts LCD, 0.45” H [11.4 mm] characters, user scalable to flow rate units or as 0-100%. 1

1 For applications in Div. 1 / Zone 1 environments and/or for dual-line digital display with built-in totalizer display, see FCI Model ST51

2 Requires user supplied PDA and FCI software P/N 019819-01

This page is subject to proprietary rights statement on last page |

2 |

Doc. No. 06EN003367 Rev. D |

ST50 MASS FLOW |

FLUID COMPONENTS INTERNATIONAL LLC |

Installing Flow Element

Insertion Depth

Warning: The element is shipped with a protective sleeve surrounding the flow element. After removing the sleeve, take care to prevent the element from sliding through the compression fitting and contacting the opposing wall with any force as it may cause damage to the element and potentially upset the calibration.

The ST50 is available with both Teflon compression fitting ferrules and metal ferrules. While the Teflon ferrule configuration can be readjusted, it is possible that over tightening may result in permanent positioning or damage to the extension pipe and will make future adjustment difficult. While Teflon provides for some adjustability, it has a lower process pressure rating and is not designed for continuous adjustments. The metal ferrule version can only be tightened down once and it becomes permanently positioned. The Ferrule type is indicated in the instrument part number displayed on the instrument tag. This can be cross referenced to the ordering information sheet.

All flow meters have been calibrated with the flow element located at the centerline of the pipe and flow stream as indicated in Figure D. Couplings and threadolets come in various dimensions. Proper installation requires that the element be measured with consideration to process connection dimensions and pipe centerline. FCI recommends that the element be first installed in the line with the compression fitting lightly tightened around the extension, then slowly move the pipe extension forward until the element is at centerline as shown.

Warning: On top mount installations, particularly, take care to prevent the element from sliding through the compression fitting and contacting the opposing wall with any force as it may cause damage to the element and potentially upset the calibration.

FLOW ELEMENT INSTALLATION & “U” LENGTH ADJUSTMENT

FLUID COMPONENTS INTERNATIONAL LLC |

SCFM |

Figure D

Note: For proper performance, element shall be installed so that tip of probe is .25 inches [ 6mm] past pipe centerline. Instrument is specifically calibrated for centerline referenced installation. Critical for line sizes 4" [ 25mm] and smaller.

This page is subject to proprietary rights statement on last page |

3 |

Doc. No. 06EN003367 Rev. D |

FLUID COMPONENTS INTERNATIONAL LLC |

ST50 MASS FLOW |

To assist in final installation, FCI suggests making a readable mark on the extension pipe to indicate the final desired compression fitting position that will place the element at the centerline reference once the system is tightened down into place. With the compression fitting lightly tightened , hold the element assembly along the outside of the installation, or directly above, to visually verify the compression fitting location will ensure centerline installation. To calculate the actual “U” length dimension, take the inside diameter of the pipe or duct divide by 2 , then add 0.25", then add for the pipe wall thickness and the process fitting offset that allows the compression fitting to securely seat in the process port. See Figure D above.

Align the flat parellel to flow and adjust the instrument depth. Upon determination of the final compression fitting location on the extension pipe, apply the proper thread sealant to the NPT threads, firmly tighten the compression fitting into the mating process connection. Torque varies per application. Tighten the compression nut to the torque indicated with the corresponding ferrule material. Manufacturer recommends 1-1/4 turns from hand tight baseline.

Ferrule |

Torque |

Teflon |

65 in – lbs |

|

|

316 SST |

65 ft – lbs |

|

|

Instrument Wiring

Before the instrument is opened to connect power and signal, FCI recommends that the following ESD precautions be observed:

Use a wrist band or heel strap with a 1 megaohm resistor connected to ground. If the instrument is in the shop setting, there should be a static conductive mat on the work table or floor with a 1 megaohm resistor connected to ground. Connect the instrument to ground. Apply antistatic agents such as Static free made by Chemtronics (or equivalent) to hand tools to be used on the instrument. Keep high static producing items away from the instrument.

The above precautions are minimum requirements. The complete use of ESD precautions can be found in the U.S. Dept of defense handbook 263.

Warning: Only Qualified personnel are to wire or test this instrument. The operator assumes all responsibility for safe practices while wiring and trouble shooting.

FCI recommends installing and input power disconnect switch and fuse near the instrument to interrupt power during installation and maintenance. Operator must have power disconnected before wiring.

Safety instructions for the use of the ST50 series (18 to 36VDC version only) in Hazardous Areas. Approval, KEMA 06ATEX0207 X for Category 3 GD protection EEx nA T6 T65°. Special conditions for safe use:

1)Provision shall be made to prevent the rated Voltage from being exceeded by transient disturbances of more than 40%.

2)For applications in explosive atmospheres caused by air/dust mixtures, cables and conduit entries shall be provided a degree of protection of at least IP65 according to EN60529.

Input Power

The ST50 is available with both VDC and VAC input power configurations. Customers selecting VDC input power will have a VDC input board only. Similarly, the VAC power board is supplied only with VAC powered units. In addition, both boards are marked for either AC or DC power. Only connect the power specified on the wiring module as shown on Figures E and F respectively. Both VAC and VDC inputs require a Gnd wire to be connected. Input power terminal blocks are rated for 14-26 AWG.

To wire the instrument, ensure that the power is off. Pull the power and signal output wires through the port, using care not to damage wires. FCI recommends using crimp lugs on the output wires to ensure proper connection with the terminal strip. Connect the output wires as shown on figures E and F. Note that when the 4-20mA outputs are used simultaneously, a single return lead is used.

This page is subject to proprietary rights statement on last page |

4 |

Doc. No. 06EN003367 Rev. D |

ST50 MASS FLOW |

FLUID COMPONENTS INTERNATIONAL LLC |

VDC Power Connection |

VAC Power Connection |

RS 232 Connection |

RS 232 Connection |

|

Figure E

VDC Power

As Shown:

18-36VDC power connected with gnd

4-20mA connected for flow and temperature Pulse Out in source mode

Note: In source mode, 15VDC Output max, 50mA max.

Figure F

VAC Power

As Shown:

85-265 VAC power connected with gnd

4-20mA connected for flow and temperature Pulse Out in sink mode

Note: In sink mode, 40VDC max, 150mA max customer supplied power source.

Power Disspation

AC Version

Power dissipation values under nominal conditions: Instrument (Electronics + Sensor): 11.6 Watts Sensor only: 0.25 Watts

Power dissipation values under maximum load conditions: Instrument (Electronics + Sensor): 12 Watts

Sensor only: 0.30 Watts

Analog Output

DC Version

Power dissipation values under nominal conditions: Instrument (Electronics + Sensor): 4.5 Watts Sensor only: 0.25 Watts

Power dissipation values under maximum load conditions: Instrument (Electronics + Sensor): 6 Watts

Sensor only: 0.30 Watts

4-20mA: The instrument is provided with a standard set up, of two 4-20mA outputs. Output 1 configured for flow and Output 2 configured for temperature. Terminal blocks rated for 14-28 AWG., 500 ohm max load per output.

VDC Input Power IO Board |

VAC Input Power IO board |

This page is subject to proprietary rights statement on last page |

5 |

Doc. No. 06EN003367 Rev. D |

FLUID COMPONENTS INTERNATIONAL LLC |

ST50 MASS FLOW |

The analog output configuration can be modified using three different methods:

1.The RS232 port, a FC88 hand held terminal and single letter commands as identified in Appendix A, table 5 of the Installation and Operation Guide. The “V” command specifically configures the instrument analog outputs.

2.The RS232 port, a computer and the CLI commands as identified in Appendix A, table 6 of the Installation and Operation Guide.

3.The PDA IR communication interface with version 1.11 software.

Pulse Output Activation

The ST50 provides a pulse output optional feature. Instruments ordered with this feature and volumetric or mass flow units will be factory set with totalizer and pulse output activated. The mode can be changed in the field. Wiring either sink or source mode is shown on page 7.

Source Mode: 15 VDC output, 50 mA max

Sink Mode: 40 VDC Max, 150 mA max. Customer supplied power source

Pulse Output Set up

The ST50 mass flow meter pulse output can be configured for either a pulse train (factory standard) for an external counter and/or flow rate indication or an alarm. The pulses are available in 2 modes, Source and Sink. The maximum frequency of the pulse output is 500Hz. The pulse output will only function after setup of the totalizer. After setup of the totalizer the pulse output needs to be setup. During the pulse setup, the mode needs to be selected as well as the pulse factor, sample period and the pulse state

Source mode: |

In this mode the flow meter electronics will supply the voltage and current |

||||||||

|

for the pulse. Maximum 15 Vdc and 50mA (depends on the connected load). |

||||||||

Sink mode: |

If the connected load requires >15 Vdc and 50mA, an external power supply is required. Maximum 40 Vdc and |

||||||||

|

150mA |

||||||||

Pulse factor: |

Number of pulses per selected engineering unit. Default =1 |

||||||||

|

Example in NCMH: |

||||||||

|

1 = 1 pulse per NCM |

||||||||

|

0.1 = 1 pulse per 0.1 NCM (10 pulses per 1 NCM) |

||||||||

|

10 = 1 pulse per 10 NCM |

||||||||

|

Range pulse factor 0.001 – 1000 |

||||||||

Sample time: |

time in seconds before calculating the next number of pulses. |

||||||||

Pulse state: |

can be set High to Low or Low to High. Meaning the pulse is normally high or low |

||||||||

|

+vdc |

|

|

|

|

|

|

|

|

|

High to Low |

|

|

|

|

|

|||

|

0vdc |

|

|

|

|

|

|||

|

|

|

|

|

|

||||

|

+vdc |

|

|

|

|

|

|

|

|

|

Low to High |

|

|

|

|

|

|

||

|

0vdc |

|

|

|

|

|

|

|

|

|

|

|

|

C00956-1 |

|||||

|

|

|

|

|

|

|

|

||

Pulse output functions: |

|||||||||

Alarm: |

can be set in Source and Sink mode. If this function is selected the state of the NPN open collector will change |

||||||||

|

from high to low or low to high, depending on the selected pulse state, at a set flow rate. (pulse factor and sample |

||||||||

|

time not required). |

||||||||

Counter: |

can be set in Source and Sink mode. The NPN open collector will output the calculated number of pulses* calcu- |

||||||||

|

lated based on the indicated flow. And external display will indicate the totalized flow. |

||||||||

Flow rate: |

can be set in Source and Sink mode. The NPN open collector will output the calculated number of pulses* calcu- |

||||||||

|

lated based on the indicated flow. External display set to calculate flow from incoming pulses. |

||||||||

This page is subject to proprietary rights statement on last page |

6 |

Doc. No. 06EN003367 Rev. D |

ST50 MASS FLOW |

|

|

|

FLUID COMPONENTS INTERNATIONAL LLC |

||||

|

|

Output and Pulse configuration setup command “V” |

|

|

||||

|

Analog out |

|

|

|

|

|

|

|

|

Select 1 |

Select |

2 |

Select 3 |

Select 4 |

|

||

|

4-20mA out1 |

|

Flow |

Flow |

|

Temp |

Temp |

|

|

4-20mA out 2 |

|

Temp |

Flow |

|

Flow |

Temp |

|

|

Pulse out |

|

|

|

|

|

||

|

Select 1 |

Select |

2 |

Select 3 |

Select 4 |

|

||

|

Source |

|

pulse |

pulse |

|

Alarm0 |

Alarm0 |

|

|

|

set |

Factor |

Factor |

|

Setpoint |

Setpoint |

|

|

|

|

Time |

Time |

|

sate |

state |

|

|

|

|

state |

state |

|

|

|

|

|

Sink |

|

Pulse |

Alarm1 |

Pulse |

Alarm1 |

|

|

|

|

|

Factor |

Setpoint |

Factor |

Setpoint |

|

|

|

|

|

Time |

sate |

|

Time |

sate |

|

|

|

|

state |

|

|

state |

|

|

*Each sample period the number of pulses are calculated and output by the open collector. Any remaining fractional pulse in the calculation will be added to the next sample. Example:

flow = 90 NCMM (= 1.5 NCMS), Pulse factor =1, sample time is 1.

after 1 second the number of calculated pulses is 1.5, pulse out is 1. Remainder = 0.5 after the next second the number of pulses is 2 (1.5+0.5), pulses out is 2. Remainder = 0

Pulse Output Wiring

15 vdc |

|

|

50mA max. |

|

|

FCI |

customer wiring |

|

egnd |

|

|

Neut |

jumper |

Counter input |

Line |

|

NPN |

source |

|

|

|

|

|

com |

|

10 |

sink |

|

K |

4-20 |

|

Ω |

RTN |

|

Com |

4-20 |

|

|

ST50 Pulse Output (Source)

FCI |

customer wiring |

|

|

egnd |

jumper |

External 24-40 vdc |

|

Neut |

|||

Line |

|

power Supply |

|

|

|

150mA maximum |

|

source |

|

- |

+ |

com |

10KΩ |

|

|

sink |

|

|

|

4-20 |

|

|

|

RTN |

|

|

|

4-20 |

|

Counter input |

|

|

|

NPN |

|

|

|

Com |

|

ST50 Pulse Output (Sink)

This page is subject to proprietary rights statement on last page |

7 |

Doc. No. 06EN003367 Rev. D |

FLUID COMPONENTS INTERNATIONAL LLC |

ST50 MASS FLOW |

Setup Interface

All parameters on this meter are set through the RS232 interface connection (P3 plug) or PDA IR interface. A jumper selection determines which communication mode is active. The factory default communication mode is set for the RS232 interface. This setting allows the instrument to be setup with either a FC88 hand held communicator or a computer. The FC88 is powered through the meter and comes with the serial interface cable. If a computer interface is used, an adapter (RJ to 9 pin Computer Serial Port) is required and may be obtained from FCI: Part No. 014108-02.

Using Windows Terminal (usually located in Accessories) execute the program by double-clicking on the Terminal Icon.

1.Go to Settings.

2.Click on Communication.

3.Set for COM1 or COM2, 9600 Baud, 8 Bit, and No Parity. Press OK

4.Press the ENTER key to see the Input Mode? prompt.

5.Enter any of the meters single letter commands to execute a function (reference complete function menu in Appendix B).

If the PDA IR interface is used for communication, then jumper JP5 needs to be moved to the alternate position, see Figure G and H. See PDA IR Communication Interface section for more details. Spare jumpers are provided in the documentation package.

An additional command line interface (CLI) is available through the RS232 port. This interface is accessed with the “Y” command using a computer or FC88. The command line password is “357”. See Appendix B - Table 6 for command line details.

JP5

Figure G |

Figure H |

JP5 factory set for RS232 interface |

JP5 set for PDA IR interface |

Infra Red Communications

Infra Red Communications

Window

Flow Rate Indicator

Display and Transmitter Access

This page is subject to proprietary rights statement on last page |

8 |

Doc. No. 06EN003367 Rev. D |

ST50 MASS FLOW |

FLUID COMPONENTS INTERNATIONAL LLC |

Start up and Commissioning

1.Verify all Input power and output signal wiring is correct and ready for initial power start up.

2.Apply power to instrument. The instrument will initialize in the Normal Operation Mode. All outputs will be active and instruments with the display option will indicate flow with the factory set flow unit. Allow 10 minutes for the instrument to warm up and come to the thermal equilibrium.

The following FC88 commands are typical commands that are used during start up and commissioning:

Command |

Name |

Description |

T |

Normal Operation Mode |

All outputs are active |

Z |

Flow Unit Set-Up |

Select Flow Units(4 English, 4 |

|

|

Metric)Pipe Dimensions |

W |

Totalizer |

Enable/Disable |

|

|

|

V |

Output Configuration |

Select one of 4 Configurations: |

|

|

Pulse and/or AlarmPulse factor and/or |

|

|

setpoint |

F |

K-Factor (default=1) |

Flow factor |

|

|

|

N |

Warm Re-set |

Re-initialize C/B |

|

|

|

S |

Totalizer Menu |

Enables W menu (Option) |

|

|

|

If the instrument is installed, and the process flow is zero, the instrument will now indicate 0.000. The engineering unit of flow is indicated on the instrument bezel. If the flow units are modified, additional units indicators are provided with adhesive backing.

Flow Unit Modification

Example: SCFM Flow Units and 3 inch Sch 40 round pipe size set up:

Enter |

Display |

Description |

|

Enter |

menu: > |

From Normal Operation Mode |

|

Z |

E for English M for Metric > |

Flow Unit Set-Up menu |

|

E |

0=SFPS, 1=SCFM, 2=SCFH, 3=LB/H, |

English units |

|

4=GPM # |

|||

|

|

||

1 |

R round duct or S rectangular> |

Select Standard Ft3/Min (SCFM) |

|

R |

Dia.: 4.0260000 |

Select Round Duct |

|

Change? (Y/N)> |

|||

|

|

||

Y |

Enter value: # |

|

|

3.068 |

area: 7.3926572 CMinflow: 0.0000000 |

3 inch Sch. 40 pipe I.D. |

|

Change? (Y/N)> |

|||

|

|

||

N |

Maximum flow: 462.04 |

|

|

Enter to continue |

|

||

|

|

||

Y |

Cmaxflow: 462.04 |

|

|

Change? (Y/N)> |

|

||

|

|

||

Y |

# |

|

|

462.04 |

CMintemp (F): -40.00000 |

|

|

Change? (Y/N)> |

|

||

|

|

||

N |

CMaxtemp (F): 250.00000 |

|

|

Change? (Y/N)> |

|

||

|

|

||

N |

Percent of Range is: OFF |

|

|

Change to ON?> |

|

||

|

|

||

N |

LCD Mult Factor x1 |

|

|

Change? (Y/N)> |

|

||

|

|

||

N |

100.0 SCFM |

Instrument will end up in Normal |

|

Operation Mode |

|||

|

|

This page is subject to proprietary rights statement on last page |

9 |

Doc. No. 06EN003367 Rev. D |

FLUID COMPONENTS INTERNATIONAL LLC |

ST50 MASS FLOW |

RS232 / FC88

Menu Control and Organization

All user entries begin at the iput mode prompt “>”,except when the instrument is in the Main Function Mode. Most entries require at least two key strokes; a Capital letter and the [ENTER] key, or one or more numbers and the [ENTER] key. If the unit is in the Main Function Mode just press the desired function letter to make an entry.

Backspaces are made using the backspace [BKSP] key. Some entries are case sensitive between numbers and letters. Be sure the SHIFT key is pressed to indicate the correct case. A square after the prompt caret indicates the FC88 is in lower case. A slightly raised rectangle in the same spot indicates the FC88 is in the upper case.

It is recommended that the FC88 be plugged into the instrument before power is applied. If the FC88 is plugged in while the instrument power is on and the FC88 does not respond, press [ENTER], if there is still no response Press [N] or cycle the power.

Note: The Zero and Span may be changed from the original calibration, provided the new values are within the original calibrated range. i.e. If the original calibration was 1 to 100 SCFM (4-20mA), the new zero (4mA) must be equal to or greater than 1 SCFM, the new span (20mA) must be equal to or less than 100 SCFM.

Some entries require a Factory pass code. If this occurs contact FCI Field Service to continue programming the instrument. The instrument will prompt the user when this is necessary. Do not change any parameters that require this code unless there is an absolute understanding of the instrument's operation. The user can not exit some routines unless all entries are completed or the power is recycled.

Caution: Always press “T” before unplugging the FC88. If a frozen meter display is observed, reconnect the FC88 and wait 5 seconds for the meter to initialize. Disconnect the FC88 and confirm your meter display is varying.

The top level of the menu is shown in Appendix B - Table 5. Enter the large letter in the tables below to activate a command. The user may exit a command at any time entering “Q” [ENTER] in the menus: D, K, V, W, or Z.

CCalibration Information

Display only: A/D, Delta-R, Ref-R data values

DDiagnostics

Display only: List of unit prameters.

K Factory Calibration Settings

Display only: Cal. parameters, i.e. linearization and temperature compensation coefficients.

RFactory Reset

Replaces user data with factory calibration data

Table 1. Diagnostics and Factory Settings

|

Units |

|

|

Analog out |

1 |

2 |

3 |

4 |

Select |

E=English |

M=Metric |

|

Select |

||||

Select |

0= SFPS |

5 = SMPS |

|

4-20mA out 1 |

Flow |

Flow |

Temp |

Temp |

or |

1 = SCFM |

6 = NCMH |

|

4-20mA out 2 |

Temp |

Flow |

Flow |

Temp |

or |

2 = SCFH |

7 = NCMM |

|

|

|

|

|

|

or |

3 = LBS/H |

8 = KG/H |

|

Pulse out |

|

|

|

|

or |

4 = GPM |

9 = LPM |

|

Select |

1 |

2 |

3 |

4 |

|

For Volumetric or Mass Flow |

|

Source out |

Pulse |

Pulse |

Alarm0 |

Alarm0 |

|

Select |

|

Set |

Factor |

Factor |

Set pt.0 |

Set pt.0 |

||

R = Round pipe or duct |

|

|

||||||

|

|

Set |

Period |

Period |

State0 |

State0 |

||

or |

S = Square duct |

|

|

|||||

|

|

Set |

State0 |

State0 |

|

|

||

Set |

Diameter or Wide X High (in inches or mm) |

|

|

|

||||

|

|

|

|

|

|

|||

Set |

CMaxflow = Maximum flow rate (span) |

|

Sink |

Pulse |

Alarm1 |

Pulse |

Alarm1 |

|

|

Set |

|

Set pt.1 |

Factor |

Set pt.1 |

|||

Set |

CMinflow = Minimum flow rate (zero) |

|

|

|||||

|

Set |

State1 |

State1 |

Period |

State1 |

|||

|

|

|

|

|||||

Note: Changing units requires rescaling the unit (set new zero and span). |

|

|

|

|

State1 |

|

||

|

|

|

|

|||||

Table 2. “Z” Flow Units Set-Up and Scaling |

|

Table 3. “V” Output Configuration Set-Up |

|

|||||

This page is subject to proprietary rights statement on last page |

10 |

Doc. No. 06EN003367 Rev. D |

ST50 MASS FLOW |

FLUID COMPONENTS INTERNATIONAL LLC |

“V” Menu Output Configuration Set Up

NOTE: The display comes up to the last setting saved and stays for 2 seconds. If N or [ENTER] is entered, the menu proceeds to the Pulse out. If Y is entered, the display moves to the selection options and/or asks for confirmation. If you miss the option, select [Enter] repeatedly to loop around.

Analog out |

|

|

Pulse out |

|

|

|

|

Output Mode |

|

|

Pulse Out |

|

|

PFactor: 1.000 |

|

Selected |

|

|

Selected |

|

|

Change? (Y/N)> |

|

4-20mA #1: |

Flow |

|

Source: |

Pulse |

if yes |

|

|

|

Enter new factor: ____ |

||||||

4-20mA #2: |

Temp |

|

Sink: |

Pulse |

Sample Period: 1 second |

||

Change? (Y/N)> |

|

Change? (Y/N)> |

Change? (Y/N)> |

||||

|

if yes |

|

|||||

|

|

|

Source: |

Pulse |

Enter new Sample Period: ____ |

||

4-20mA #1: |

Flow |

Sink: |

|

Pulse |

|

|

|

4-20mA #2: |

Temp |

|

|

Enter 1 to make |

If alarm is a selected output |

||

|

|

Enter 1 to make |

|

|

the selection #__ |

Set point1: 000 |

Set points are in the |

|

|

the selection__ |

Source: |

Pulse |

|

same units as the flow |

|

4-20mA #1: |

|

Sink: |

|

Alarm1 |

|

or temp. |

|

4-20mA #2: |

Flow |

|

|

Enter 2 to make |

Change? (Y/N)> |

|

|

|

|

Enter 2 to make |

|

|

the selection #__ |

if yes |

|

|

|

the selection__ |

Source: |

Alarm0 |

Enter new set point: ____ |

||

4-20mA #1: |

Temp |

Sink: |

|

Pulse |

Resume normal operation |

||

4-20mA #2: |

Flow |

|

|

Enter 3 to make |

|

|

|

|

|

Enter 3 to make |

|

|

the selection #__ |

Source state: |

|

|

|

the selection__ |

Source: |

Alarm0 |

High to Low |

|

|

4-20mA #1: |

Temp |

Sink: |

|

Alarm1 |

|

|

|

4-20mA #2: |

Temp |

|

|

Enter 4 to make |

Change to Low to High?> |

||

|

|

Enter 4 to make |

|

|

the selection #__ |

|

|

|

|

|

|

|

|

||

|

|

the selection__ |

|

|

|

|

|

Example: COMMAND V (Reference Table 3)

Case: 4-20mA #1 = flow, 4-20mA #2 = Temperature, |

Source Out = Pulse, |

Sink = Alarm |

||||

Pressing [V] [ENTER] will display |

|

“Output Mode Selected” |

followed by: |

|||

“4-20mA #1 = Flow” |

|

“ 4-20mA #2 = Temp” |

followed by |

|||

“Change? (Y/N)” |

|

|

|

|

|

|

Press [ENTER] (no change). |

|

|

|

|

|

|

The last saved mode will display at this point. i.e., |

|

|

|

|||

“Source: Pulse” |

|

|

“Sink: Pulse” |

followed by, |

||

“Change? (Y/N)” |

|

Select Y [Enter]. |

The display reads, |

|||

“Source: Pulse” |

|

|

“Sink: Pulse” |

followed by, |

||

“Enter 1 to make the selction #.” |

|

Select [ENTER]. |

The next display reads, |

|||

“Source: Pulse” |

|

|

“Sink: Alarm” |

followed by, |

||

“Enter 2 to make the selction #.” |

|

Select 2 and [ENTER]. |

The next prompt reads, |

|||

“PFactor: 1.000” |

|

“Change? (Y/N)>” |

(this factor can be anywhere from 0.001 to 1000 - A |

|||

|

|

|

|

|

pulse factor of 1.000 will output 1 pulse per unit of |

|

|

|

|

|

|

flow.) |

|

If no change, select N and/or [ENTER] to continue. |

|

|

|

|||

The next prompt is, “Sample Period” |

|

|

|

|

||

“Change? (Y/N)>” |

|

(this value may be set from 0.5 to 5 seconds) |

||||

If no change, select N and/or [ENTER] to continue. |

|

|

|

|||

The next prompt is, “Source state: ” |

“High to Low” Change to “Low to High?>” (this selection toggles the pulse |

|||||

|

|

|

|

|

|

signal normally high or normally |

|

|

|

|

|

|

low). |

[ENTER] to read display. |

|

|

|

|

|

|

“Switchpt1” |

“0.0000000” |

the current set point. |

|

|

||

“Change? (Y/N)>” enter Y [ENTER] and enter |

#______ . Set Point Value , i.e. 50 (value is in same units as the flow and |

|||||

must be within the calibrated range). [ENTER]. The next prompt is, |

|

|

||||

“Sink state: ” “High to Low” Change to “Low to High?>”. Set the output signal to be normally “High” or normally “Low.” Pressing [Y] [ENTER] toggles the current setting. Pressing [ENTER] resumes normal operation.

This page is subject to proprietary rights statement on last page |

11 |

Doc. No. 06EN003367 Rev. D |

Loading...

Loading...