Page 1

ST50 MASS FLOW METER

Installation and Operation Guide

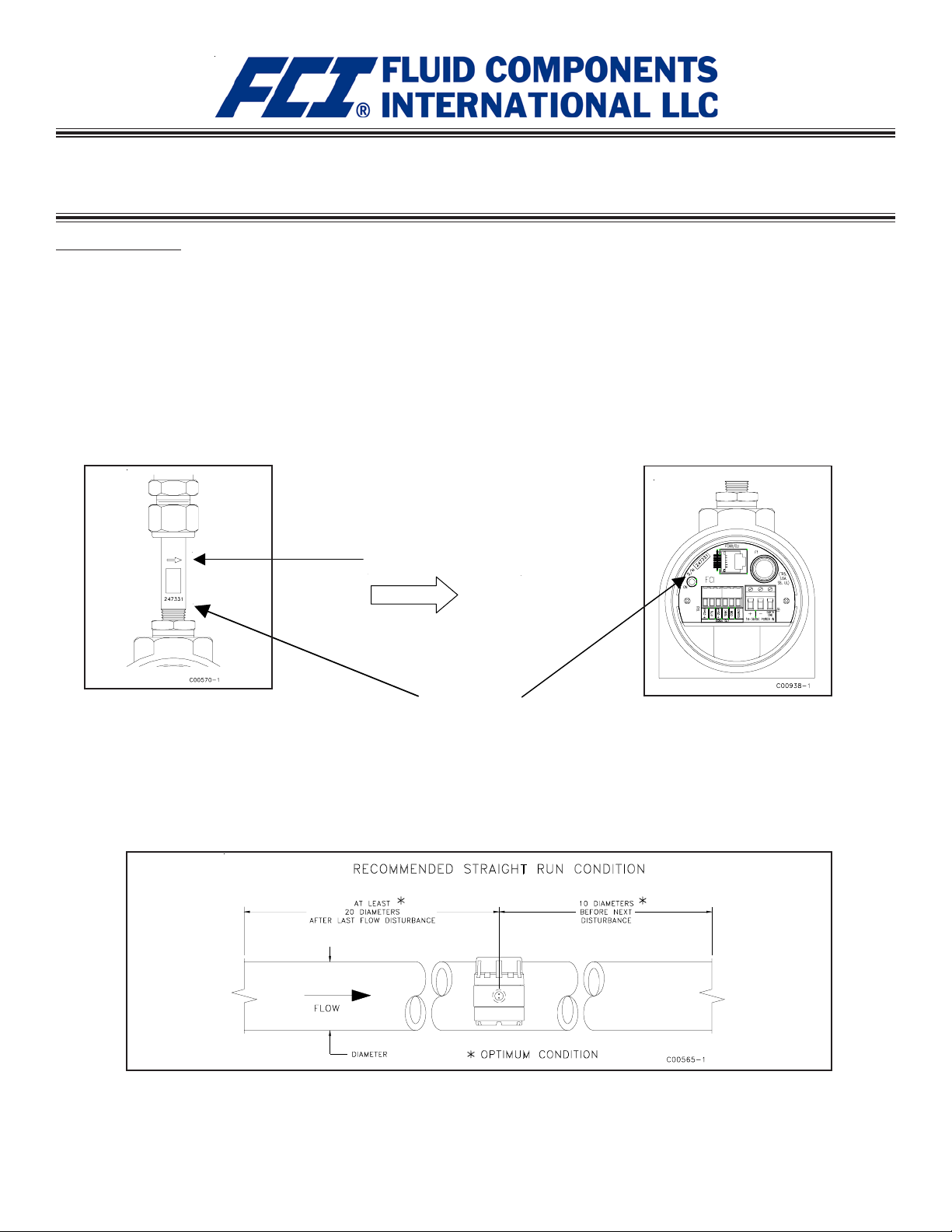

Pre-Installation

The ST50 can be specified with integral or remote electronics. The flow element has a serial number etched into the side of the

extension pipe as shown on figure A. The transmitter circuit card has a serial number noted on the board as shown in figure B. The

flow sensor and transmitter circuit have been calibrated as a matched set and should be paired together in service unless otherwise

approved by a factory technician.

Flow Direction Alignment

All sensor elements have a flow arrow indicator marked on the element assembly at the reference flat. These flow elements have

been calibrated in a particular direction and are designed to be used in service with the flow arrow facing in the same direction as

flow in the pipe stream. See Appendix C for orientation and factory calibration details.

Flow Direction

FLOW

Figure A

Serial Number

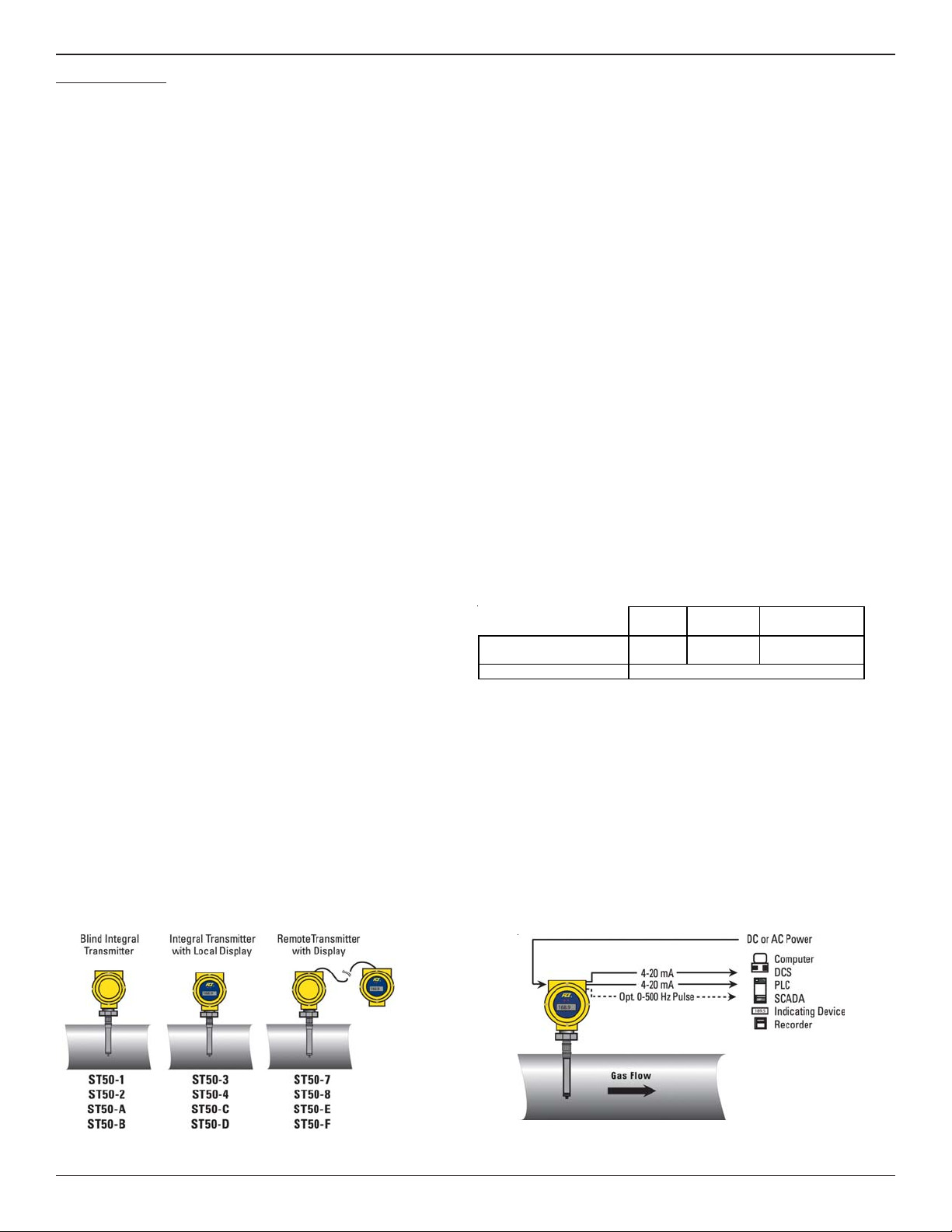

Recommended Straight Run

To optimize flow meter system performance, FCI recommends installation with a minimum of 20 pipe diameters upstream straight

run and 10 pipe diameters of downstream straight run. Where straight run limitations significantly reduce the available pipe diameters, FCI utilizes Vortab flow conditioners to produce a transferable flow profile from the calibration installation to actual field

installations. FCI’s proprietary AVAL software is available to make flow meter installation evaluations where straight run limitations

are considered. See Fig C for recommended installation.

Figure B

Figure C

FCI Flow Meters may be installed with less than the recommended straight run, but may have performance limitations. FCI offers

Vortab flow conditioners for use in applications that have significant straight run limitations. FCI uses the AVAL application

modeling software to predict meter performance in each installation. AVAL outputs are available to review prior to order placement

and will indicate performance expectations both with and without Vortab Flow Conditioning.

This page is subject to proprietary rights statement on last page

Page 2

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

Specifications

Instrument

Media Compatibility: Air, compressed air, and nitrogen

Pipe/Line Size Compatibility: 2” to 24” [51 mm to 610 mm]

Range: Air, compressed air, or nitrogen: 0.75 SFPS to 400

SFPS

[0.23 MPS to 122 MPS]

Accuracy: Standard: ± 2% of reading, ± 0.5% of full scale

Optional: ± 1% of reading, ± 0.5% of full scale

Repeatability: ±0.5% of reading

Temperature Compensation:

Standard: 40°F to 100°F [4°C to 38°C]

Optional: 0°F to 250°F [-18°C to 121°C]

Turndown Ratio: 3:1 to 100:1

Agency Approvals: 1

FM/CSA: Nonincendive for use in Class 1, Division 2,

Groups A, B, C and D T4 Ta = 60°C Indoor

Hazardous (Classified) Locations.

ATEX/IECEx: II 3 G EEx nA II T6; II 3 D T65°C

(DC input power only)

CPA, CE Mark, PED

Warranty: One year

Flow Element (Standard or FPC Type)

Installation:

3/4” NPT(M) compression fitting.

Type: Thermal dispersion

Material of Construction: 316 stainless steel body with

Hastelloy C thermowell sensors, 316 stainless steel

compression fitting with Teflon or stainless steel ferrule

Pressure (Maximum Operating without Damage):

Stainless steel ferrule: 500 psig [34 bar(g)]

Teflon ferrule: 150 psig [10 bar(g)]

Temperature (Maximum Operation):

Stainless steel ferrule: 0°F to 250°F [-18°C to 121°C]

Teflon ferrule: 0°F to 200°F [-18°C to 93°C]

Insertion, variable length with 1/2” or

Process Connection: 1/2” MNPT or 3/4” MNPT with

stainless steel or teflon ferrule

Insertion Length: Field adjustable lengths: 1” to 6”

[25 mm to 152 mm]; 1” to 12”[25 mm to 305 mm];

or 1” to 18” [25 mm to 457 mm]

Flow Transmitter

Enclosure: NEMA 4X [IP67], aluminum, dual conduit ports

with either 1/2² NPT or M20x1.5 entries. Epoxy coated.

Analog Output Signals:

rate and/or temperature (500 ohm max impedance) and a pulse

output for total flow.

Output Pulse Source:

15VDC. Pulse width at 50% duty cycle for rates 0 to 500Hz,

0.5 second pulse width for pulse rates below 1Hz. 25mA

maximum load pulsed, 10mA maximum load if state set to

normally on.

Output Pulse Sink:

width at 50% duty cycle for rates 1 to 500Hz, 0.5 second pulse

width for rates below 1Hz. Customer power source and load

not to exceed 40VDC and 150mA.

Communication Port: RS232C. Wireless IR to PDA. 2

Input Power:

DC: 18Vdc to 36Vdc (6 Watt maximum)

AC: 85Vac to 265Vac (12 Watt maximum, 1.6 Amp fuse)

(CE Mark Approval from 100Vac to 240Vac)

Power Filter Board

Littelfuse TR5 Serie s

374 1160 0410

Breaking Capacity 50A/250V AC 50-60H z cos φ = 1.0

Amp

Operating Temperature: For Indoor or Outdoor Use

0°F to 140°F [-18°C to 60 °C]

Maximum Relative Humidity: 100%

Maximum Altitude: 12,000 ft. (3,658m)

Digital Display: ±9999 Counts LCD, 0.45” H [11.4 mm]

characters, user scalable to flow rate units or as 0-100%. 1

1 For applications in Div. 1 / Zone 1 environments and/or for

dual-line digital display with built-in totalizer display, see

FCI Model ST51

2 Requires user supplied PDA and FCI software P/N 019819-01

Dual 4-20 mA, configurable to flow

Totalized flow or alarm set point.

Totalized flow or alarm set point. Pulse

Code

1160 1.60A 250V

Rated

Current

Voltage

Rating

This page is subject to proprietary rights statement on last page

2 Doc. No. 06EN003367 Rev. D

Page 3

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

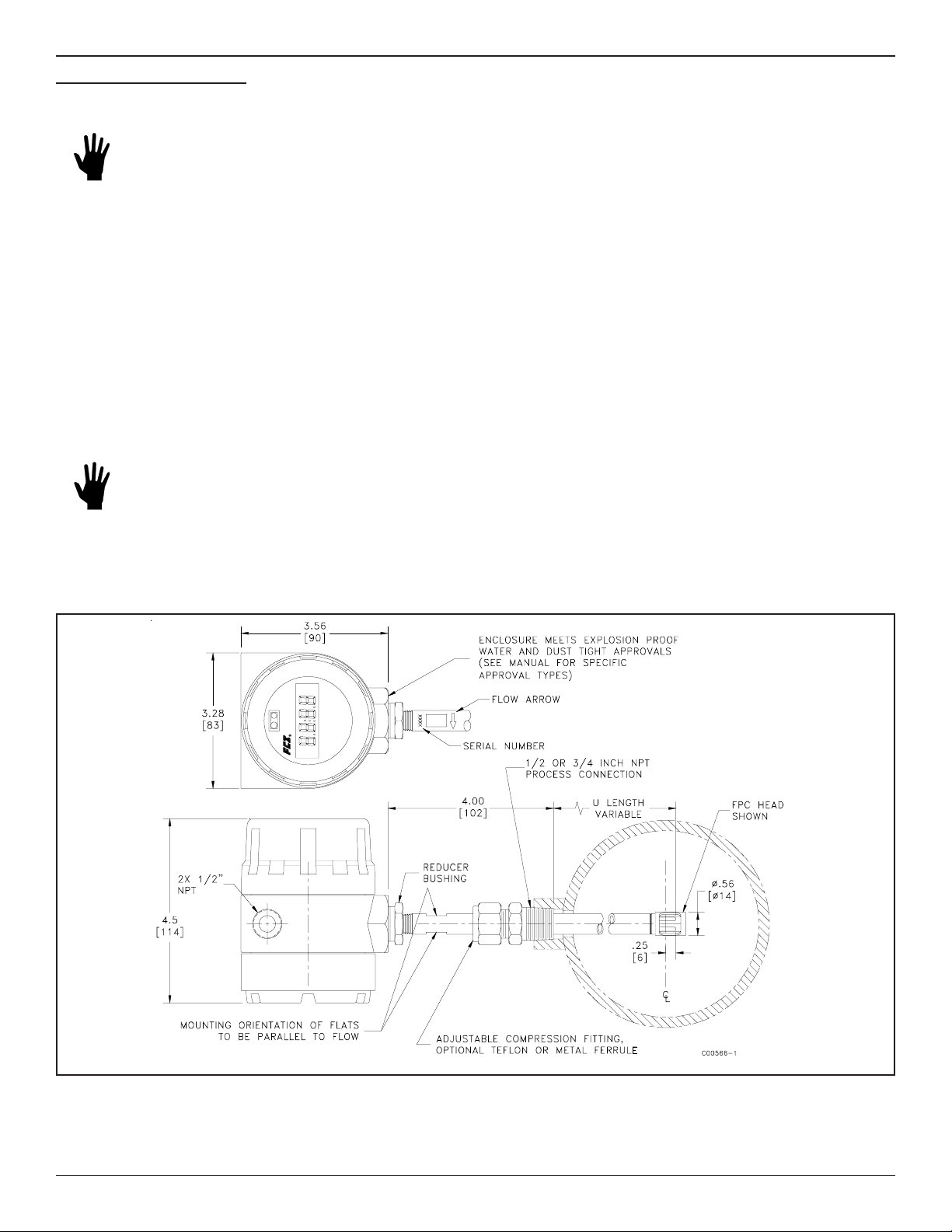

Installing Flow Element

Insertion Depth

Warning: The element is shipped with a protective sleeve surrounding the flow element. After removing the sleeve,

take care to prevent the element from sliding through the compression fitting and contacting the opposing wall with

any force as it may cause damage to the element and potentially upset the calibration.

The ST50 is available with both Teflon compression fitting ferrules and metal ferrules. While the Teflon ferrule configuration can

be readjusted, it is possible that over tightening may result in permanent positioning or damage to the extension pipe and will make

future adjustment difficult. While Teflon provides for some adjustability, it has a lower process pressure rating and is not designed

for continuous adjustments. The metal ferrule version can only be tightened down once and it becomes permanently positioned.

The Ferrule type is indicated in the instrument part number displayed on the instrument tag. This can be cross referenced to the

ordering information sheet.

All flow meters have been calibrated with the flow element located at the centerline of the pipe and flow stream as indicated in

Figure D. Couplings and threadolets come in various dimensions. Proper installation requires that the element be measured with

consideration to process connection dimensions and pipe centerline. FCI recommends that the element be first installed in the line

with the compression fitting lightly tightened around the extension, then slowly move the pipe extension forward until the element is

at centerline as shown.

Warning: On top mount installations, particularly, take care to prevent the element from sliding through the compression fitting and contacting the opposing wall with any force as it may cause damage to the element and potentially

upset the calibration.

FLOW ELEMENT INSTALLATION & “U” LENGTH ADJUSTMENT

FLUID COMPONENTS

INTERNATIONAL LLC

SCFM

Figure D

Note: For proper performance, element shall be installed so that tip of probe is .25 inches [ 6mm] past pipe centerline. Instrument is

specifically calibrated for centerline referenced installation. Critical for line sizes 4" [ 25mm] and smaller.

This page is subject to proprietary rights statement on last page

3 Doc. No. 06EN003367 Rev. D

Page 4

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

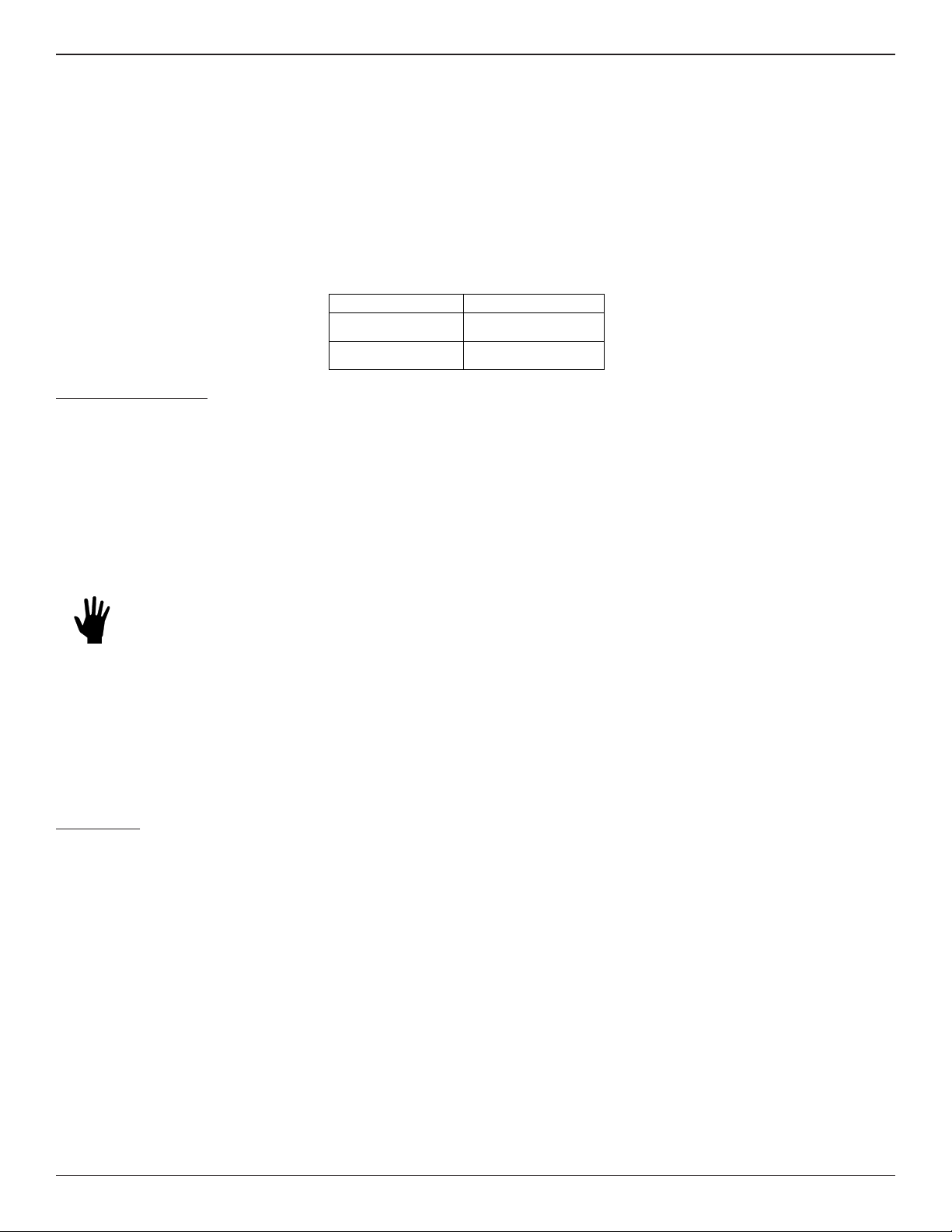

To assist in final installation, FCI suggests making a readable mark on the extension pipe to indicate the final desired compression

fitting position that will place the element at the centerline reference once the system is tightened down into place. With the compression fitting lightly tightened , hold the element assembly along the outside of the installation, or directly above, to visually verify

the compression fitting location will ensure centerline installation. To calculate the actual “U” length dimension, take the inside

diameter of the pipe or duct divide by 2 , then add 0.25", then add for the pipe wall thickness and the process fitting offset that

allows the compression fitting to securely seat in the process port. See Figure D above.

Align the flat parellel to flow and adjust the instrument depth. Upon determination of the final compression fitting location on the

extension pipe, apply the proper thread sealant to the NPT threads, firmly tighten the compression fitting into the mating process

connection. Torque varies per application. Tighten the compression nut to the torque indicated with the corresponding ferrule

material. Manufacturer recommends 1-1/4 turns from hand tight baseline.

Ferrule Torque

Teflon 65 in – lbs

316 SST 65 ft – lbs

Instrument Wiring

Before the instrument is opened to connect power and signal, FCI recommends that the following ESD precautions be observed:

Use a wrist band or heel strap with a 1 megaohm resistor connected to ground. If the instrument is in the shop setting, there should

be a static conductive mat on the work table or floor with a 1 megaohm resistor connected to ground. Connect the instrument to

ground. Apply antistatic agents such as Static free made by Chemtronics (or equivalent) to hand tools to be used on the instrument.

Keep high static producing items away from the instrument.

The above precautions are minimum requirements. The complete use of ESD precautions can be found in the U.S. Dept of defense

handbook 263.

Warning: Only Qualified personnel are to wire or test this instrument. The operator assumes all responsibility for

safe practices while wiring and trouble shooting.

FCI recommends installing and input power disconnect switch and fuse near the instrument to interrupt power during

installation and maintenance. Operator must have power disconnected before wiring.

Safety instructions for the use of the ST50 series (18 to 36VDC version only) in Hazardous Areas. Approval, KEMA

06ATEX0207 X for Category 3 GD protection EEx nA T6 T65°. Special conditions for safe use:

1) Provision shall be made to prevent the rated Voltage from being exceeded by transient disturbances of more than

40%.

2) For applications in explosive atmospheres caused by air/dust mixtures, cables and conduit entries shall be provided

a degree of protection of at least IP65 according to EN60529.

Input Power

The ST50 is available with both VDC and VAC input power configurations. Customers selecting VDC input power will have a

VDC input board only. Similarly, the VAC power board is supplied only with VAC powered units. In addition, both boards are

marked for either AC or DC power. Only connect the power specified on the wiring module as shown on Figures E and F respectively. Both VAC and VDC inputs require a Gnd wire to be connected. Input power terminal blocks are rated for 14-26 AWG.

To wire the instrument, ensure that the power is off. Pull the power and signal output wires through the port, using care not to

damage wires. FCI recommends using crimp lugs on the output wires to ensure proper connection with the terminal strip. Connect

the output wires as shown on figures E and F. Note that when the 4-20mA outputs are used simultaneously, a single return lead is

used.

This page is subject to proprietary rights statement on last page

4 Doc. No. 06EN003367 Rev. D

Page 5

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

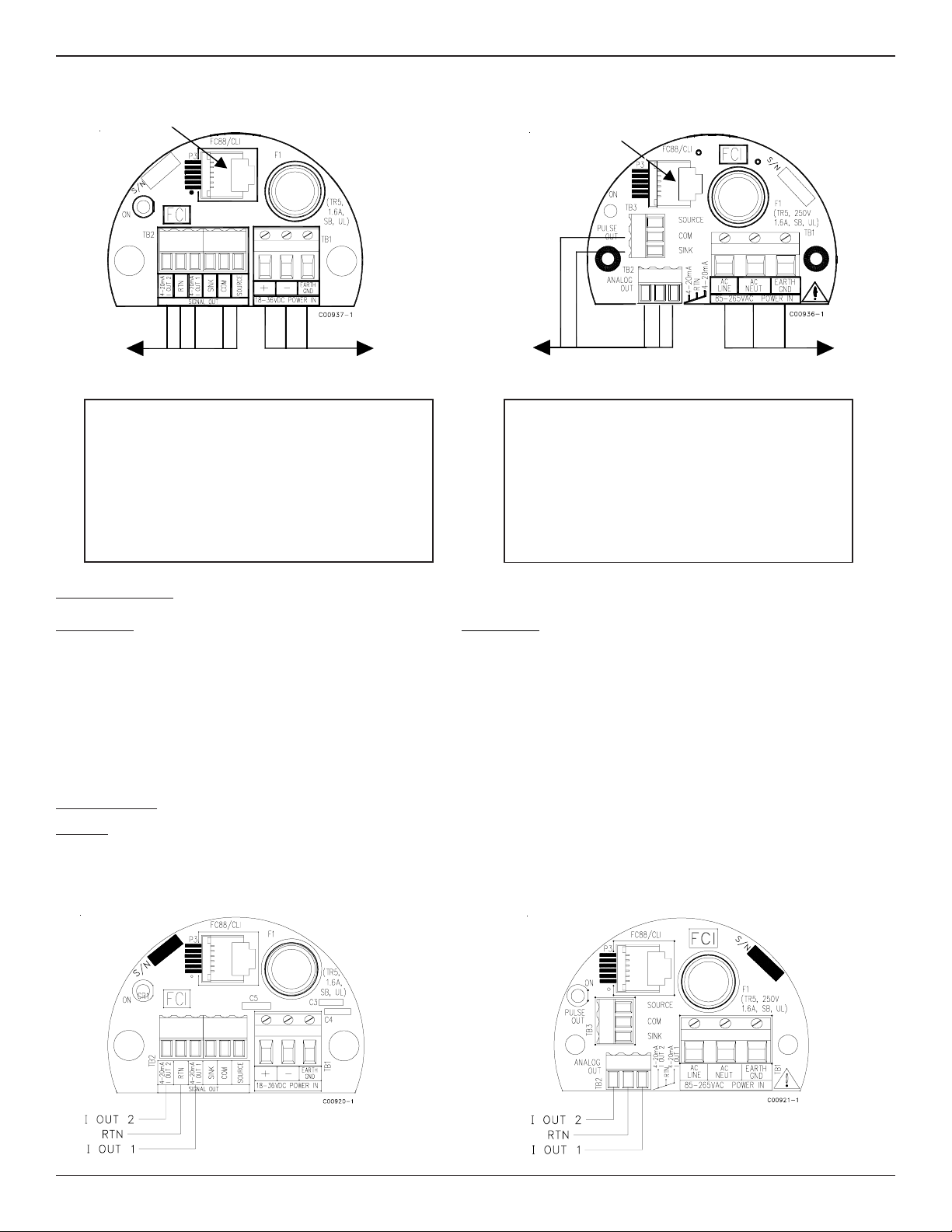

VDC Power Connection

RS 232 Connection

Figure E

VDC Power

As Shown:

18-36VDC power connected with gnd

4-20mA connected for flow and temperature

Pulse Out in source mode

Note: In source mode, 15VDC Output max, 50mA max.

VAC Power Connection

RS 232 Connection

Figure F

VAC Power

As Shown:

85-265 VAC power connected with gnd

4-20mA connected for flow and temperature

Pulse Out in sink mode

Note: In sink mode, 40VDC max, 150mA max customer

supplied power source.

Power Disspation

AC Version

Power dissipation values under nominal conditions:

Instrument (Electronics + Sensor): 11.6 Watts

Sensor only: 0.25 Watts

Power dissipation values under maximum load conditions:

Instrument (Electronics + Sensor): 12 Watts

Sensor only: 0.30 Watts

DC Version

Power dissipation values under nominal conditions:

Instrument (Electronics + Sensor): 4.5 Watts

Sensor only: 0.25 Watts

Power dissipation values under maximum load conditions:

Instrument (Electronics + Sensor): 6 Watts

Sensor only: 0.30 Watts

Analog Output

4-20mA: The instrument is provided with a standard set up, of two 4-20mA outputs. Output 1 configured for flow and Output 2

configured for temperature. Terminal blocks rated for 14-28 AWG., 500 ohm max load per output.

VDC Input Power IO Board

VAC Input Power IO board

This page is subject to proprietary rights statement on last page

5 Doc. No. 06EN003367 Rev. D

Page 6

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

The analog output configuration can be modified using three different methods:

1. The RS232 port, a FC88 hand held terminal and single letter commands as identified in Appendix A, table 5 of the Installation

and Operation Guide. The “V” command specifically configures the instrument analog outputs.

2. The RS232 port, a computer and the CLI commands as identified in Appendix A, table 6 of the Installation and Operation

Guide.

3. The PDA IR communication interface with version 1.11 software.

Pulse Output Activation

The ST50 provides a pulse output optional feature. Instruments ordered with this feature and volumetric or mass flow units will be

factory set with totalizer and pulse output activated. The mode can be changed in the field. Wiring either sink or source mode is

shown on page 7.

Source Mode: 15 VDC output, 50 mA max

Sink Mode: 40 VDC Max, 150 mA max. Customer supplied power source

Pulse Output Set up

The ST50 mass flow meter pulse output can be configured for either a pulse train (factory standard) for an external counter and/or

flow rate indication or an alarm. The pulses are available in 2 modes, Source and Sink. The maximum frequency of the pulse output

is 500Hz. The pulse output will only function after setup of the totalizer. After setup of the totalizer the pulse output needs to be

setup. During the pulse setup, the mode needs to be selected as well as the pulse factor, sample period and the pulse state

Source mode: In this mode the flow meter electronics will supply the voltage and current

for the pulse. Maximum 15 Vdc and 50mA (depends on the connected load).

Sink mode: If the connected load requires >15 Vdc and 50mA, an external power supply is required. Maximum 40 Vdc and

150mA

Pulse factor: Number of pulses per selected engineering unit. Default =1

Example in NCMH:

1 = 1 pulse per NCM

0.1 = 1 pulse per 0.1 NCM (10 pulses per 1 NCM)

10 = 1 pulse per 10 NCM

Range pulse factor 0.001 – 1000

Sample time: time in seconds before calculating the next number of pulses.

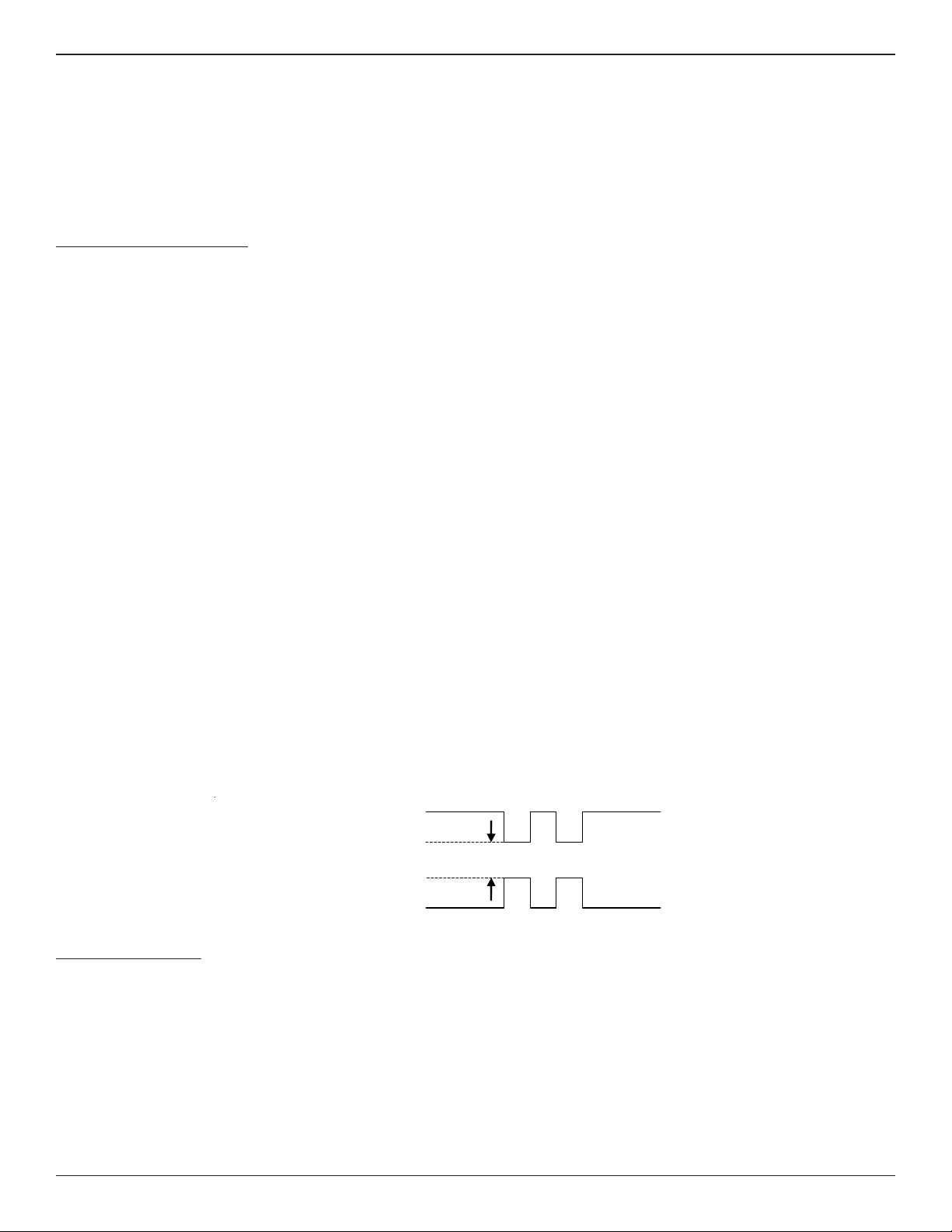

Pulse state: can be set High to Low or Low to High. Meaning the pulse is normally high or low

High to Low

Low to High

+vdc

0vdc

+vdc

0vdc

C00956-1

Pulse output functions:

Alarm: can be set in Source and Sink mode. If this function is selected the state of the NPN open collector will change

from high to low or low to high, depending on the selected pulse state, at a set flow rate. (pulse factor and sample

time not required).

Counter: can be set in Source and Sink mode. The NPN open collector will output the calculated number of pulses* calcu-

lated based on the indicated flow. And external display will indicate the totalized flow.

Flow rate: can be set in Source and Sink mode. The NPN open collector will output the calculated number of pulses* calcu-

lated based on the indicated flow. External display set to calculate flow from incoming pulses.

This page is subject to proprietary rights statement on last page

6 Doc. No. 06EN003367 Rev. D

Page 7

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

p

p

p

p

s

s

s

s

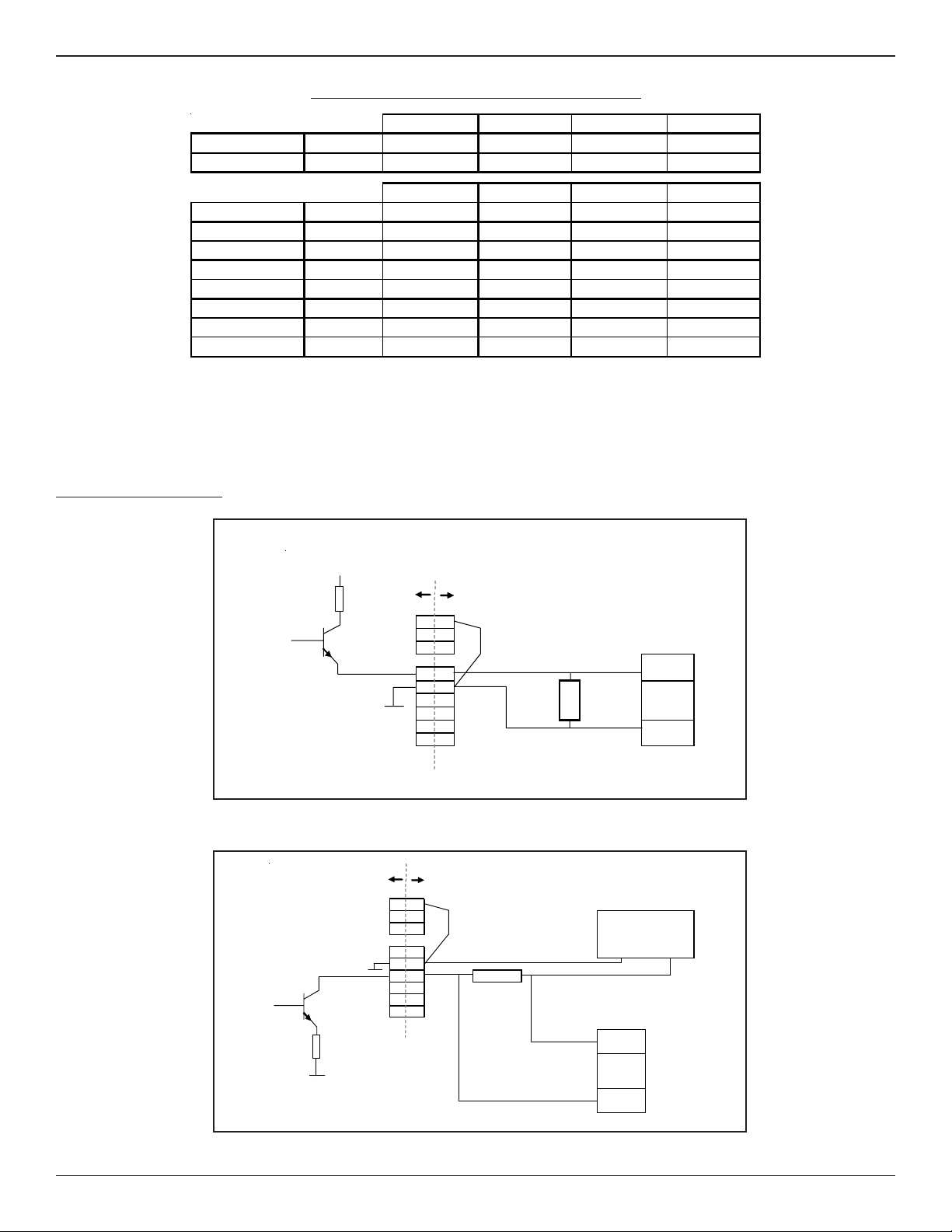

Output and Pulse configuration setup command “V”

Analog out

Select 1 Select 2 Select 3 Select 4

4-20mA out1 Flow Flow Temp Temp

4-20mA out 2 Tem

Pulse out

Source

Select 1 Select 2 Select 3 Select 4

ulse

Flow Flow Tem

ulse Alarm0 Alarm0

set Factor Factor Setpoint Setpoint

Time Time

ate

tate

state state

Sink Pulse Alarm1 Pulse Alarm1

Factor Setpoint Factor Setpoint

Time

ate Time

ate

state state

*Each sample period the number of pulses are calculated and output by the open collector. Any remaining fractional pulse in the calculation will be added

to the next sample. Example:

flow = 90 NCMM (= 1.5 NCMS), Pulse factor =1, sample time is 1.

after 1 second the number of calculated pulses is 1.5, pulse out is 1. Remainder = 0.5

after the next second the number of pulses is 2 (1.5+0.5), pulses out is 2. Remainder = 0

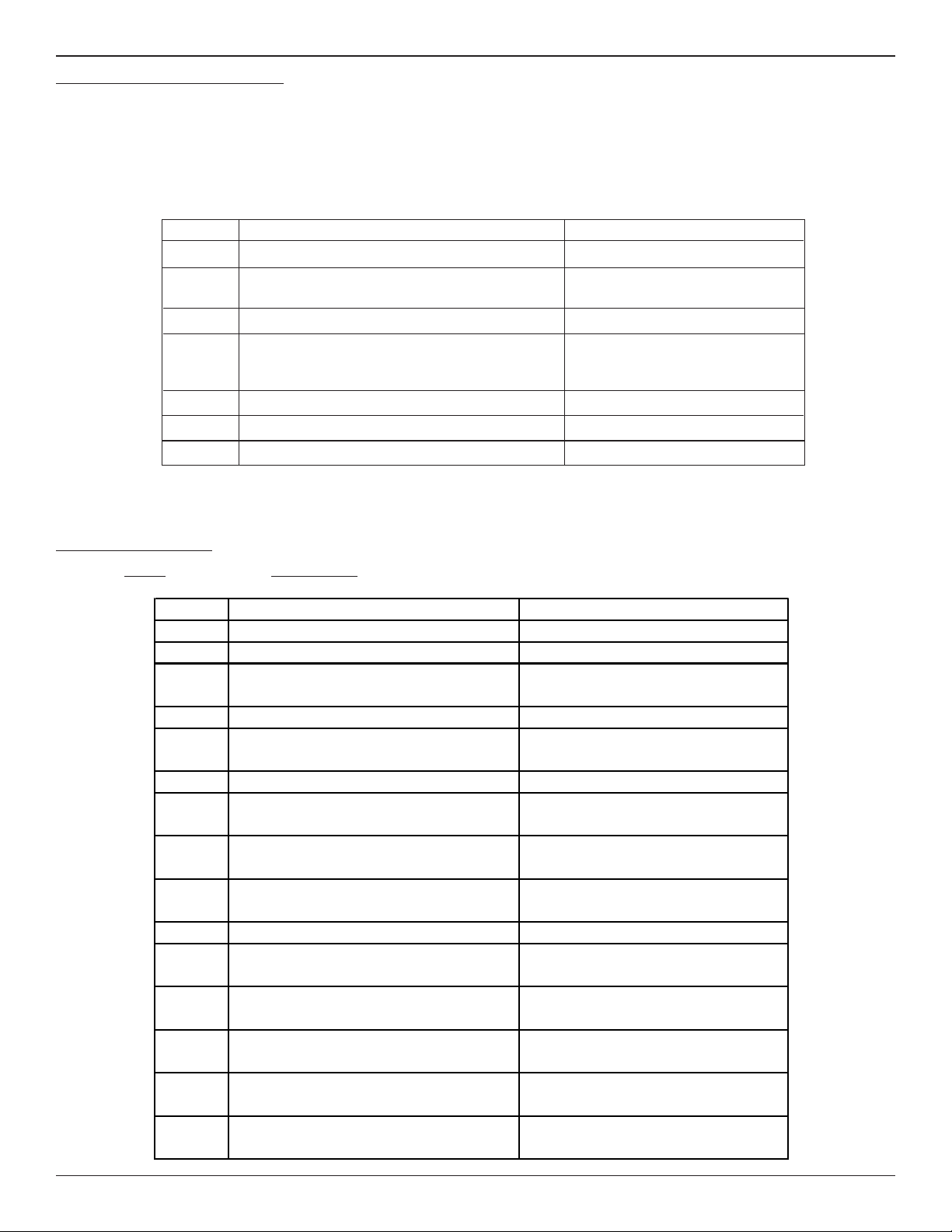

Pulse Output Wiring

15 vdc

50mA max.

FCI customer wiring

egnd

Neut Coun te r input

Line

source

com 10

sink K

4-20 Ω

RTN Com

4-20

jumper

NPN

ST50 Pulse Output (Source)

FCI customer wiring

egnd

Neut

Line

source - +

com

sink

4-20

RTN

4-20 Coun ter input

jum per E xter nal 24 -40 vdc

10KΩ

pow er Supp ly

150m A ma ximu m

NPN

Com

ST50 Pulse Output (Sink)

This page is subject to proprietary rights statement on last page

7 Doc. No. 06EN003367 Rev. D

Page 8

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

Setup Interface

All parameters on this meter are set through the RS232 interface connection (P3 plug) or PDA IR interface. A jumper selection

determines which communication mode is active. The factory default communication mode is set for the RS232 interface. This

setting allows the instrument to be setup with either a FC88 hand held communicator or a computer. The FC88 is powered through

the meter and comes with the serial interface cable. If a computer interface is used, an adapter (RJ to 9 pin Computer Serial Port) is

required and may be obtained from FCI: Part No. 014108-02.

Using Windows Terminal (usually located in Accessories) execute the program by double-clicking on the Terminal Icon.

1. Go to Settings.

2. Click on Communication.

3. Set for COM1 or COM2, 9600 Baud, 8 Bit, and No Parity. Press OK

4. Press the ENTER key to see the Input Mode? prompt.

5. Enter any of the meters single letter commands to execute a function (reference complete function menu in Appendix B).

If the PDA IR interface is used for communication, then jumper JP5 needs to be moved to the alternate position, see Figure G and H.

See PDA IR Communication Interface section for more details. Spare jumpers are provided in the documentation package.

An additional command line interface (CLI) is available through the RS232 port. This interface is accessed with the “Y” command

using a computer or FC88. The command line password is “357”. See Appendix B - Table 6 for command line details.

JP5

Figure G

JP5 factory set for RS232 interface

Display and Transmitter Access

Figure H

JP5 set for PDA IR interface

Infra Red Communications

Window

Flow Rate Indicator

This page is subject to proprietary rights statement on last page

8 Doc. No. 06EN003367 Rev. D

Page 9

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Start up and Commissioning

1. Verify all Input power and output signal wiring is correct and ready for initial power start up.

2. Apply power to instrument. The instrument will initialize in the Normal Operation Mode. All outputs will be active and instruments with the display option will indicate flow with the factory set flow unit. Allow 10 minutes for the instrument to warm up

and come to the thermal equilibrium.

The following FC88 commands are typical commands that are used during start up and commissioning:

Command Name Description

T Normal Operation Mode All outputs are active

Z Flow Unit Set-Up Select Flow Units(4 English, 4

Metric)Pipe Dimensions

W Totalizer Enable/Disable

V Output Configuration Select one of 4 Configurations:

Pulse and/or AlarmPulse factor and/or

setpoint

F K-Factor (default=1) Flow factor

N Warm Re-set Re-initialize C/B

S Totalizer Menu Enables W menu (Option)

If the instrument is installed, and the process flow is zero, the instrument will now indicate 0.000. The engineering unit of flow is

indicated on the instrument bezel. If the flow units are modified, additional units indicators are provided with adhesive backing.

Flow Unit Modification

Example: SCFM Flow Units and 3 inch Sch 40 round pipe size set up:

Enter Display Description

Enter menu: > From Normal Operation Mode

Z E for English M for Metric > Flow Unit Set-Up menu

E

0=SFPS, 1=SCFM, 2=SCFH, 3=LB/H,

4=GPM #

1 R round duct or S rectangular> Select Standard Ft

R Select Round Duct

Dia.: 4.0260000

Change? (Y/N)>

YEnter value: #

3.068 3 inch Sch. 40 pipe I.D.

N

Y

area: 7.3926572 CMinflow: 0.0000000

Change? (Y/N)>

Maximum flow: 462.04

Enter to continue

Cmaxflow: 462.04

Change? (Y/N)>

Y#

462.04

N

N

N

CMintemp (F): -40.00000

Change? (Y/N)>

CMaxtemp (F): 250.00000

Change? (Y/N)>

Percent of Range is: OFF

Change to ON?>

LCD Mult Factor x1

Change? (Y/N)>

N 100.0 SCFM

English units

/Min (SCFM)

3

Instrument will end up in Normal

Operation Mode

This page is subject to proprietary rights statement on last page

9 Doc. No. 06EN003367 Rev. D

Page 10

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

RS232 / FC88

Menu Control and Organization

All user entries begin at the iput mode prompt “>”,except when the instrument is in the Main Function Mode. Most entries require at

least two key strokes; a Capital letter and the [ENTER] key, or one or more numbers and the [ENTER] key. If the unit is in the Main

Function Mode just press the desired function letter to make an entry.

Backspaces are made using the backspace [BKSP] key. Some entries are case sensitive between numbers and letters. Be sure the

SHIFT key is pressed to indicate the correct case. A square after the prompt caret indicates the FC88 is in lower case. A slightly

raised rectangle in the same spot indicates the FC88 is in the upper case.

It is recommended that the FC88 be plugged into the instrument before power is applied. If the FC88 is plugged in while the

instrument power is on and the FC88 does not respond, press [ENTER], if there is still no response Press [N] or cycle the power.

Note: The Zero and Span may be changed from the original calibration, provided the new values are within the original calibrated

range. i.e. If the original calibration was 1 to 100 SCFM (4-20mA), the new zero (4mA) must be equal to or greater than 1

SCFM, the new span (20mA) must be equal to or less than 100 SCFM.

Some entries require a Factory pass code. If this occurs contact FCI Field Service to continue programming the instrument. The

instrument will prompt the user when this is necessary. Do not change any parameters that require this code unless there is an

absolute understanding of the instrument's operation. The user can not exit some routines unless all entries are completed or the

power is recycled.

Caution: Always press “T” before unplugging the FC88. If a frozen meter display is observed, reconnect the FC88 and

wait 5 seconds for the meter to initialize. Disconnect the FC88 and confirm your meter display is varying.

The top level of the menu is shown in Appendix B - Table 5. Enter the large letter in the tables below to activate a command. The

user may exit a command at any time entering “Q” [ENTER] in the menus: D, K, V, W, or Z.

C Calibration Information

Display only: A/D, Delta-R, Ref-R data values

D Diagnostics

Display only: List of unit prameters.

K Factory Calibration Settings

Display only: Cal. parameters, i.e. linearization

and temperature compensation coefficients.

R Factory Reset

Replaces user data with factory calibration data

Table 1. Diagnostics and Factory Settings

Units

Select E=English M=Metric

Select 0= SFPS 5 = SMPS

or 1 = SCFM 6 = NCMH

or 2 = SCFH 7 = NCMM

or 3 = LBS/H 8 = KG/H

or 4 = GPM 9 = LPM

For Volumetric or Mass Flow

Select R = Round pipe or duct

or S = Square duct

Set Diameter or Wide X High (in inches or mm)

Set CMaxflow = Maximum flow rate (span)

Set CMinflow = Minimum flow rate (zero)

Note: Changing units requires rescaling the unit (set new zero and span).

Analog out

Select 1 2 3 4

4-20mA out 1 Flow Flow Temp Temp

4-20mA out 2 Temp Flow Flow Temp

Pulse out

Select 1 2 3 4

Source out Pulse Pulse Alarm0 Alarm0

Set Factor Factor Set pt.0 Set pt.0

Set Period Period State0 State0

Set State0 State0

Sink Pulse Alarm1 Pulse Alarm1

Set Set pt.1 Factor Set pt.1

Set State1 State1 Period State1

State1

Table 2. “Z” Flow Units Set-Up and Scaling

This page is subject to proprietary rights statement on last page

Table 3. “V” Output Configuration Set-Up

10 Doc. No. 06EN003367 Rev. D

Page 11

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

“V” Menu Output Configuration Set Up

NOTE: The display comes up to the last setting saved and stays for 2 seconds. If N or [ENTER] is entered, the menu

proceeds to the Pulse out. If Y is entered, the display moves to the selection options and/or asks for confirmation. If you

miss the option, select [Enter] repeatedly to loop around.

Analog out

Output Mode

Selected

4-20mA #1: Flow

4-20mA #2: Temp

Change? (Y/N)>

4-20mA #1: Flow

4-20mA #2: Temp

Enter 1 to make

the selection__

4-20mA #1:

4-20mA #2: Flow

Enter 2 to make

the selection__

4-20mA #1: Temp

4-20mA #2: Flow

Enter 3 to make

the selection__

4-20mA #1: Temp

4-20mA #2: Temp

Enter 4 to make

the selection__

Pulse out

Pulse Out

Selected

Source: Pulse

Sink: Pulse

Change? (Y/N)>

Source: Pulse

Sink: Pulse

Source: Pulse

Sink: Alarm1

Source: Alarm0

Sink: Pulse

Source: Alarm0

Sink: Alarm1

Enter 1 to make

the selection #__

Enter 2 to make

the selection #__

Enter 3 to make

the selection #__

Enter 4 to make

the selection #__

PFactor: 1.000

Change? (Y/N)>

if yes

Enter new factor: ____

Sample Period: 1 second

Change? (Y/N)>

if yes

Enter new Sample Period: ____

If alarm is a selected output

Set point1: 000 Set points are in the

Change? (Y/N)>

if yes

Enter new set point: ____

Resume normal operation

Source state:

High to Low

Change to Low to High?>

Example: COMMAND V (Reference Table 3)

Case: 4-20mA #1 = flow, 4-20mA #2 = Temperature, Source Out = Pulse, Sink = Alarm

Pressing [V] [ENTER] will display “Output Mode Selected” followed by:

“4-20mA #1 = Flow” “ 4-20mA #2 = Temp” followed by

“Change? (Y/N)”

Press [ENTER] (no change).

The last saved mode will display at this point. i.e.,

“Source: Pulse” “Sink: Pulse” followed by,

“Change? (Y/N)” Select Y [Enter]. The display reads,

“Source: Pulse” “Sink: Pulse” followed by,

“Enter 1 to make the selction #.” Select [ENTER]. The next display reads,

“Source: Pulse” “Sink: Alarm” followed by,

“Enter 2 to make the selction #.” Select 2 and [ENTER]. The next prompt reads,

“PFactor: 1.000” “Change? (Y/N)>” (this factor can be anywhere from 0.001 to 1000 - A

pulse factor of 1.000 will output 1 pulse per unit of

flow.)

If no change, select N and/or [ENTER] to continue.

The next prompt is, “Sample Period”

“Change? (Y/N)>” (this value may be set from 0.5 to 5 seconds)

If no change, select N and/or [ENTER] to continue.

The next prompt is, “Source state: ” “High to Low” Change to “Low to High?>” (this selection toggles the pulse

signal normally high or normally

low).

[ENTER] to read display.

“Switchpt1” “0.0000000” the current set point.

“Change? (Y/N)>” enter Y [ENTER] and enter #______ . Set Point Value , i.e. 50 (value is in same units as the flow and

must be within the calibrated range). [ENTER]. The next prompt is,

“Sink state: ” “High to Low” Change to “Low to High?>”. Set the output signal to be normally “High” or

normally “Low.” Pressing [Y] [ENTER] toggles the current setting. Pressing [ENTER] resumes normal operation.

same units as the flow

or temp.

This page is subject to proprietary rights statement on last page

11 Doc. No. 06EN003367 Rev. D

Page 12

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

PDA IR Communication Interface

The IR interface software is an optional accessory kit and can ordered using FCI part number 019819-01. The software is compatible with PALM OS 4.1 or greater. If the software was ordered with the instrument, a CD should be located with the instrument

documentation.

The factory has verified the following 3 PDA models. All commands meet their intended purpose and function properly.

1. Palm, Tungsten E, E2:Palm OS 5.2.1, 5.4.7

2. Palm, Zire 71, Palm OS 5.2.1

3. ecom instruments, m 515-EX, Intrinsically-safe. Palm OS 4.1

Procedure:

1. Down load the software into the target PDA. When complete, a yellow and blue FCI icon will be available.

2. Verify JP5 jumper is set in the PDA IR interface position, see Figure H.

3. Select FCI icon on PDA device.

4. The opening menu is displayed, select start.

5. Five menu groups are displayed.

Process: displays current process variables (Flow and Temperature)

ID-Unit: displays model, firmware version, serial no. …

Set-up: allows access to the following areas

Units K Factor

Line size Temp/Flow min/max

Totalizer Output Cal

LCD Output Config

Diagnostics: A/D values

Utilities: allows access to the following areas

Reset

Parameter memory

Calibration coefficients

Factory restore

Process and System Faults

6. After entering into specific menu areas, point the PDA IR port towards the Instrument display. Begin with the PDA device

within 5 feet of the instrument display. Select the “Get All” or “Get” button to retrieve information from the instrument. If a

value needs to be changed, the value must first be retrieved.

Example: reading standard process variable information

1. Verify instrument and PDA are functioning.

2. Select FCI icon on the PDA.

3. Select the start button on the opening screen.

4. Select the “Process” button.

5. Point the PDA at the instrument display, start with the PDA no futher that 5 feet from the instrument.

6. Select the “Get Data” button.

7. Flow and temperature Data will begin streaming to the PDA.

8. If the IR link is interrupted, a “Command response timed out” message will be displayed.

9. Repeat the process if the link is interrupted.

This page is subject to proprietary rights statement on last page

12 Doc. No. 06EN003367 Rev. D

Page 13

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Maintenance

The FCI instrument requires little maintenance. There are no moving parts or mechanical parts subject to wear in the instrument.

The sensor assembly which is exposed to the process media is composed of 316 SS and Hastelloy C.

Without detailed knowledge of the environmental parameters of the application surroundings and process media, FCI cannot make

specific recommendations for periodic inspection, cleaning, or testing procedures. However, some suggested general guidelines for

maintenance steps are offered below. Use operating experience to establish the frequency of each type of maintenance.

Calibration

Periodically verify the calibration of the output and recalibrate if necessary. FCI recommends every 18 months at a minimum.

Electrical Connections

Periodically inspect cable connections on terminal strips and terminal blocks. Verify that terminal connections are tight and

physically sound with no sign of corrosion.

Remote Enclosure

Verify that the moisture barriers and seals protecting the electronics in the local enclosure is adequate and that no moisture is entering

the enclosure.

Electrical Wiring

FCI recommends occasional inspection of the system’s interconnecting cable, power wiring and flow element wiring on a “common

sense” basis related to the application environment. Periodically the conductors should be inspected for corrosion and the cable

insulation checked for signs of deterioration.

Flow Element Connections

Verify that all seals are performing properly and that there is no leakage of the process media. Check for deterioration of the gaskets

and environmental seals used.

Insertion Type Flow Element Assembly

Periodically remove the flow element for inspection based on historical evidence of debris, foreign matter, or scale build-up and

appropriate plant shutdown schedules and procedures. Check for corrosion, stress cracking, and/or build-up of oxides, salts, or

foreign substances. The thermowells must be free of excessive contaminants and be physically intact. Any debris or residue build-up

could cause inaccurate flow indication. Clean the flow element, as necessary, with a soft brush and available solvents (compatible

with Stainless Steel).

This page is subject to proprietary rights statement on last page

13 Doc. No. 06EN003367 Rev. D

Page 14

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

INTENTIONALLY LEFT BLANK

This page is subject to proprietary rights statement on last page

14 Doc. No. 06EN003367 Rev. D

Page 15

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Troubleshooting

Application Verification

After verifying that the flow meter is functioning, review the application parameters as shown below to verify the calibration matches

the process media.

Equipment Needed

Flow Instrument Calibration Data

Process Parameters and Limits

Check Serial Numbers

Verify that the serial number of the flow element and the flow transmitter electronics are the same. The flow element and the flow

transmitter are a matched set and cannot be operated independently of each other.

Check the Instrument Installation

Verify correct mechanical and electrical installation. Verify the flow element is mounted at least 20 diameters downstream and 10

diameters upstream from any bends or interference in the process pipe or duct.

Check for Moisture

Check for moisture on the flow transmitter. Moisture may cause intermittent operation. Check for moisture on the flow element. If a

component of the process media is near its saturation temperature it may condense on the flow element. Place the flow element where

the process media is well above the saturation temperature of any of the process gases.

Check Application Design Requirements

Application design problems may occur with first time application instruments, although the design should also be checked on

instruments that have been in operation for some time. If the application design does not match field conditions, errors occur.

1. Review the application design with plant operation personnel and plant engineers.

2. Ensure that plant equipment such as pressure and temperature instruments conform to the actual conditions.

3. Verify operating temperature, operating pressure, line size, and gas medium.

Verify Standard Versus Actual Process Conditions

The flowmeter measures the mass flow rate. The mass flow rate is the mass of the gas flowing through a pipe per time. Other flow

meters, such as an orifice plate or a pitot tube, measure the volumetric flow rate. The volumetric flow rate is the volume of gas per

time. If the readings displayed do not agree with another instrument, some calculations may be necessary before comparing them. To

calculate the mass flow rate, the volumetric flow rate, and the pressure and temperature, the point of measurement must be known.

Use the following equation to calculate the mass flow rate (Standard Volumetric Flow rate) for the other instrument:

Equation:

QQ

=× ×

SA

Where: used for pressure and temperature.)

QA= Volumetric Flow QS= Standard Volumetric Flow

PA= Actual Pressure TA= Actual Temperature

PS= Standard Pressure TS=

PSIA and °R are used for pressure and temperature units.

P

T

A

A

T

S

P

S

Standard Temperature

(Metric: Where bar(a) and °K are

Example: (Metric: PS = 1.01325 bar(a)

QA= 1212.7 ACFM QS= 1485 SCFM TS = 21.1°C (294.1K))

PA= 19.7 PSIA TA= 120°F (580°R)

PS= 14.7 PSIA TS= 70°F (530°R)

1212.7 ACFM

(

This page is subject to proprietary rights statement on last page

1

)

(

19.7 PSIA

580° R

15 Doc. No. 06EN003367 Rev. D

)

(

530° R_

14.7 PSIA

)

=1485 SCFM

Page 16

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

Calibration Parameters Verification

The instrument uses a set of predetermined calibration parameters to process flow signals. Most of these parameters should not

change. A data package located with this manual contains the “ST50 Delta R Data Sheet”. This contains the calibration parameters

stored in the flow transmitter at the factory. To verify that these parameters have not changed, complete the following:

1. Identify the appropriate Delta R Data sheets by serial number of the instrument.

2. Press [D] [ENTER] to examine each of the parameters. The [ENTER] key allows scrolling one message at a time. Use

Table 4 to verify parameters with the Delta R Data sheet ST50 Parameters.

S/W Version: dR Min: T SpanIDAC 0:

Flow Factor: dR M ax: T ZeroIDAC 0:

Cmin Flow: Cal Re f: T SpanIDAC 1:

Cmax Flow: Tc s lp: T Z ero IDA C 1:

Eng Units: Tcslp 0: State 0:

Line Size 0: Tcslp 2: Switch Pt 0:

Line Size 1: Tot Menu: State 1:

Cmin Temp: Tot Flag: Switch Pt 1:

Cmax Temp: Totalizer: K factor 1:

Min Flow: Rollover Cnt: K factor 2:

Max Flow: Fix Pt Flag: K factor 3:

Density: Pulse Factor: K factor 4:

*C1 [1]: Puls e Out: I facto r:

*C1 [2]: Hours: Temp Flag:

*C1 [3]: Sample Period: Out Mode:

*C1 [4]: dR Slope: Boxcar Max:

*C1 [5]: dr Off Set: RTD-SLP-385:

Break Pt: Refr Slope: % of Range:

*C2 [1]: Refr Off Set: Us er Name:

*C2 [2]: SpanIDAC 0: Shop Order #:

*C2 [3]: ZeroIDA C 0: Serial No .:

*C2 [4]: SpanIDAC 1: Model#:

*C2 [5]: ZeroIDA C 1: LCD M u ltiplier

Table 4. Diagnostic Test Sequence on Display

If parameters that have an asterisk (*) have changed, this may indicate a problem. Customer Service should be contacted. If the

parameters have not changed, continue with the next section.

This page is subject to proprietary rights statement on last page

16 Doc. No. 06EN003367 Rev. D

Page 17

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Hardware Verification

Equipment Required:

Digital Multimeter

Screw Driver

The ST50 Flowmeter is comprised of 4 basic components:

1. Sensor element.

2. Customer interface circuit board

3. Control circuit assembly circuit board module.

4. Electronics enclosure.

Step 1

Verify fuse (F1) located on the customer interface circuit board is in normal working condition.

Remove power from the instrument. Open the electronics enclosure exposing the customer interface circuit board. This circuit

board is located under the shorter enclosure lid along with all of the power and input/output connections. Unscrew the clear cover

on the fuse and pull the fuse out of the fuse holder. Check the fuse for continuity. If fuse reads open, replace with equivalent

component (FCI part no. 019933-01), Wickmann Inc. series 374, amp code 1160, package 41.

Fuse (F1)

Ac power customer interface circuit board shown. Fuse (F1) on DC power customer interface circuit board located in similar

position.

Step 2

Verify interconnecting cable from the customer interface board and the control circuit board assembly module are correctly seated

into the appropriate header.

Remove power from the instrument. Open the electronics enclosure exposing the customer interface circuit board. This circuit

board is located under the shorter enclosure lid along with all of the power and input/output connections. Remove the 2 screws

securing the interface circuit board to the electronics enclosure. Carefully lift the interface face board exposing the interconnecting

cable between the interface board and the control circuit assembly. Verify cable is seated firmly at both ends of the cable header.

Interface Board

This page is subject to proprietary rights statement on last page

Control Circuit

Assembly

Cable Header

17 Doc. No. 06EN003367 Rev. D

Page 18

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

Step 3

Verify sensor element continuity and resistance.

Remove sensor element cable from the bottom of the control circuit assembly. Note that 2 of the wires have a red stripe and are

located closest to the interconnecting cable header. Using an ohm meter verify that resistance between the 2 red striped wires is

approximately 1100 ohms +/- 20. This resistance is temperature dependant. The resistance at 70 degrees F should be 1082 ohms.

Verify the resistance between the 2 natural colored wires are approximately the same.

Sensor Element Cable

This page is subject to proprietary rights statement on last page

18 Doc. No. 06EN003367 Rev. D

Page 19

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Transmitter Circuit Calibration Check (Delta R Verification)

References

Delta ‘R’ Data Sheet

Equipment

FC88 Communicator or equivalent.©

DMV

Delta R Data Sheet-Match by serial numbers

2 Precision Decade Resistance boxes, 0.1% (Largest steps: 1K Ohm, smallest steps 0.01 Ohms)

Small flat Blade Screwdriver, 3/32 inches wide blade

FCI Normalization Cable, FCI part number 006407

Procedure

1. Verify all “D” mode calibration parameters are correct according to the meters Delta R Data Sheet, before starting verification.

2. Turn power off

3. Mark all sensor element wires connected to the circuit board, so they may be reconnected to the proper terminals. Disconnect

the wires.

4. Connect the resistance decade box to the electronics as per the appropriate diagram for the ST50.

NOTE: Interconnector wiring (resistance decade box to electronics) must be 24 AWG and 45 inches long, to avoid any

inaccuracies in the Delta R verification, caused by improper wire lengths or wire gauges.

5. Set both decade boxes for the nominal resistance value (1000 ohms) +/- .01%

6. Connect DVM to the meters output termination and monitor the meter output.

7. Turn the power ON and allow the instrument 5 mins. To stabilize

8. With the FC88 connected, Press [T] [Enter] to view the Normal Operating Mode.

9. Adjust the Active Decade Box (Reference decade box remains fixed @ 1000 ohms) to achieve the appropriated Delta R for the

displayed flow value and output, noted on the meters Delta R Data Sheet.

10. Note the [C] mode and verify the meters displayed TCDR and REFR values corresponding to the displayed flow rate as per the

meters Delta R Data Sheet.

11. Return to the [T] mode to continue the verification.

ACTIVE

1433-W DECADE RISISTOR GENERAL RADIO USA

ORANGE

ORANGE

BLACK

BLACK

NORMALIZATION CABLE

FCI P/N 006407

10K

H

0

1

2

3

L

4

5

X

6

9

7

8

G

1K STEPS

23mA MAX

REFERENCE

1433-W DECADE RISISTOR GENERAL RADIO USA

10K

H

0

1

2

3

L

4

5

X

6

9

7

8

G

1K STEPS

23mA MAX

0

1

2

3

4

5

6

100 STEPS

80mA MAX

1

2

3

4

5

6

100 STEPS

80mA MAX

1

2

3

4

5

X

6

9

7

8

0

1

2

3

4

5

X

6

9

7

8

This page is subject to proprietary rights statement on last page

19 Doc. No. 06EN003367 Rev. D

Page 20

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

INTENTIONALLY LEFT BLANK

This page is subject to proprietary rights statement on last page

20 Doc. No. 06EN003367 Rev. D

Page 21

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Appendix A - Approval Information

EC

Information

This page is subject to proprietary rights statement on last page

21 Doc. No. 06EN003367 Rev. D

Page 22

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

INTENTIONALLY LEFT BLANK

This page is subject to proprietary rights statement on last page

22 Doc. No. 06EN003367 Rev. D

Page 23

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Appendix B - List Commands

COMMAND

MNEMONIC

A R AvgDelta_r, AvgRef

B R Delta_r, Ref_r

C R Tcdelta_r, Ref_r

D R Diagnostics

F R/W Kfactors

G R/W

K R/W Cal Parameters

L R/W Output Cal

N W Warm Restart

R W Factory Restore

S R/W Totalizer Menu On/Off

T R Normal Mode

V R/W Output Config

W R/W Totalizer

Y W Command Line Interface

Z W

COMMAND

FUNCTION COMMAND DECRIPTION

Clear FlashEE, Boxcar Count,

ADC to Ohms Cal

Flow units, Pipe Size, and LCD

Scaling

Table 5. ST50 List of Single Letter Commands

COMMAND COMMAND

MNEMONIC FUNCTION

BK R/W Brea k Poin t Floa t

BM R/W Boxcar Filter Max Integer

CM R/W Cminflo w Flo at

CR R/W Calibration Ref Float

CX R/W Cmaxflow Flo at

C1[1-5] R/W Coefficien ts s et1 Float

C2[1-5] R/W Coefficien ts s et2 Float

DI R Diagnostics Null

DM R/W DeltaR Minimum Float

DN R/W Density Float

DR R Delta R Float

DX R/W DeltaR Maximum Float

DS R/W DeltaR Slope Float

DF R/W DeltaR Offset Float

EU R/W Engineering Units Integer

FF R/W Flow Factor Float

FP R/W Fix Point Flag Integer

F0 R/W Puls e Out State0 Integer

F1 R/W Puls e Out State1 Integer

HR R/W Tot Du mp Hou rs Cntr Int eger

IF R/W I Factor Float

COMMAND DESCRIPTION DATA TYPE

This page is subject to proprietary rights statement on last page

Table 6. ST50 List of CLI Commands

23 Doc. No. 06EN003367 Rev. D

Page 24

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

Table 6. ST50 List of CLI Commands, Cont.

COMMAND COMMAND

MNEMONIC FUNCTION

K[1-4] R/W K Factors Float

L0 R/W Lin e Size 0 Flo at

L1 R/W Lin e Size 1 Flo at

MN R/W Minflow Float

MX R/W Maxflow Float

OM R/W Outmode Integer

PF R/W Pu lse Factor Float

PL R/W Pulse Out Integer

PS R/W Pu lse Sample Period Float

PW R/W Pulse W idth Float

P0 R/W Switch Po int0 Integer

P1 R/W Switch Po int1 Integer

RO R/W RollOver Cntr Long

RR R Reference R Float

RS R/W RefR Slope Float

RF R/W RefR Offset Floa t

SF R SFPS Flow Float

SN R/W Serial Number String (16 chars max.)

SO R/W Shop Order Number String (16 chars max.)

S0 R/W SpanDAC0 for 4-20mA #1 Integer

S3 R/W SpanDAC1 for 4-20mA #2 Integer

S2 W Save FA CTORY N/A

TC R TCdeltar Float

TD R/W Tcslp Float

TF R/W Totalizer OFF/ON Flag Integer

TM R/W Cmintemp Float

TP R/W Totalizer Temperature Flag Integer

TT R/W Totalizer Value Float

TX R/W Cmaxtemp Float

TZ R Temperature Float

T0 R/ W T cs lp 0 Flo at

T2 R/ W T cs lp 2 Flo at

T3 R/W TSp anDA C0 for 4-20mA # 1 Integ er

T7 R/W TSp anDA C1 for 4-20mA # 2 Integ er

T5 R/W TZeroDA C0 fo r 4-20mA #1 In te g er

T8 R/W TZeroDA C1 fo r 4-20mA #2 In te g er

UF R Us er Flow Flo at

UK R User FlowK Float

UN R/W Us er Name String (16 chars max.)

VN R Version Number String (16 chars max.)

XX R/W Tes t Flow Rate (SFPS) Float

XY W Delete Test Flow Rate Float

Z0 R/W ZeroDA C0 fo r 4-20mA #1 Integer

Z2 R/W ZeroDA C1 fo r 4-20mA #2 Integer

Command Line Password: 357

COMMAND DESCRIPTION DATA TYPE

This page is subject to proprietary rights statement on last page

24 Doc. No. 06EN003367 Rev. D

Page 25

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

NOTE: When invoking a Write Function, there must be a space separating the Command characters and the data value. All Read

and Write Functions are completed with a <CR>. To exit CLI, press <CR> following the last Command <CR>.

Examples: RBK<CR> (Read Breakpoint)

WBK 2222<CR> (Write Breakpoint 2222)

RC11<CR> (Read Coefficient C1,1)

WC11 –234.567<CR> (Write Coefficient C1,1, -234.567)

<CR> (Leave Command Line Mode)

This page is subject to proprietary rights statement on last page

25 Doc. No. 06EN003367 Rev. D

Page 26

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

INTENTIONALLY LEFT BLANK

This page is subject to proprietary rights statement on last page

26 Doc. No. 06EN003367 Rev. D

Page 27

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Appendix C - Drawings

INTERNATIONAL LLC

FLUID COMP ONENTS

This page is subject to proprietary rights statement on last page

27 Doc. No. 06EN003367 Rev. D

Page 28

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

FLUID COMPONENTS

INTERNATIONAL LLC

SCFM

FLUID COMPON ENTS

INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

FLUID COMPO NENTS

INTERNATIONAL LLC

28 Doc. No. 06EN003367 Rev. D

Page 29

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

FLUID COMPONENTS

INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

FLUID COMPON ENTS

INTERNATIONAL LLC

29 Doc. No. 06EN003367 Rev. D

Page 30

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

FLUID COMPONENTS

INTERNATIONAL LLC

This page is subject to proprietary rights statement on last page

FLUID COMPONENTS

INTERNATIONAL LLC

30 Doc. No. 06EN003367 Rev. D

Page 31

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Appendix D - Customer Service

Customer

Service/

Technical

Support

FCI provides full in-house technical support. Additional technical representation is also provided by

FCI field representatives. Before contacting a field or in-house representative, please perform the

troubleshooting techniques outlined in this document.

By Mail

Fluid Components International LLC

1755 La Costa Meadows Dr.

San Marcos, CA 92078-5115 USA

Attn: Customer Service Department

By Phone

Contact the area FCI regional representative. If a field representative is unable to be contacted or if a

situation is unable to be resolved, contact the FCI Customer Service Department toll free at

1 (800) 854-1993.

By Fax

To describe problems in a graphical or pictorial manner, send a fax including a phone

or fax number to the regional representative. Again, FCI is available by facsimile if all possibilities

have been exhausted with the authorized factory representative. Our Fax number is 1 (760) 736-6250;

it is available 7 days a week, 24 hours a day.

By E-Mail

FCI Customer Service can be contacted by e-mail at: techsupport@fluidcomponents.com.

Describe the problem in detail making sure a telephone number and best time to be contacted is stated

in the e-mail.

International Support

For product information or product support outside the contiguous United States, Alaska, or Hawaii,

contact your country’s FCI International Representative or the one nearest to you.

After Hours Support

For product information visit FCI's Worldwide Web at www.fluidcomponents.com. For product

support call 1 (800) 854-1993 and follow the prerecorded instructions.

Point of Contact

The point of contact for service, or return of equipment to FCI is your authorized FCI sales/service

office. To locate the office nearest you, please go to www.fluidcomponents.com.

This page is subject to proprietary rights statement on last page

31 Doc. No. 06EN003367 Rev. D

Page 32

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

Warranty Repairs or Returns

FCI prepays ground transportation charges for return of freight to the customer’s door. FCI

reserves the right to return equipment by the carrier of our choice.

International freight, handling charges, duty/entry fees for return of equipment are paid by the

customer.

Non-Warranty Repairs or Returns

FCI returns repaired equipment to the customer either collect or prepaid and adds freight charges

to the customer invoice.

Return to Stock Equipment

The customer is responsible for all shipping and freight charges for equipment that is returned to

FCI stock from the customer site. These items will not be credited to customer’s account until

either all freight charges are cleared or until the customer agrees to have any freight costs incurred

by FCI deducted, along with applicable return to stock charges, from the credit invoice.

(Exceptions are made for duplicate shipments made by FCI.)

If any repair or return equipment is received at FCI, freight collect, without prior factory consent,

FCI bills the sender for these charges.

Field Service Procedures

Contact an FCI field representative to request field service.

A field service technician is dispatched to the site from either the FCI factory or one of the FCI

representative offices. After the work is complete, the technician completes a preliminary field

service report at the customer site and leaves a copy with the customer.

Following the service call, the technician completes a formal, detailed service report. The formal

report is mailed to the customer within five days of the technician’s return to the factory or office.

Field Service Rates

All field service calls are billed at the prevailing rates as listed in the FCI Price Book unless

specifically excepted by the FCI Customer Service Manager. FCI reserves the right to bill for

travel times at FCI’s discretion.

Customers are charged for shipping costs related to the transfer of equipment to and from the job

site. They are also invoiced for field service work and travel expenses by FCI’s Accounting

Department.

This page is subject to proprietary rights statement on last page

32 Doc. No. 06EN003367 Rev. D

Page 33

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

RA #___________

1755 La Costa Meadows Drive, San Marcos, CA 92078-5115 USA

760-744-6950 / 800-854-1993 / Fax: 760-736-6250

Web Site: www.fluidcomponents.com

E-mail: techsupport@fluidcomponents.com

Return Authorization Request

1. Return Customer Information

Returning Company’s Name:__________________________________ Phone# _______________

Return Contact Name: ______________________________________ Fax # _________________

Email Address: ____________________________________________________________________

2. Return Address

Bill To: _________________________________ Ship To: __________________________________

_______________________________________ _________________________________________

_______________________________________ _________________________________________

_______________________________________ _________________________________________

3. Mandatory End User Information

Contact: __________________ Company: ________________________ Country: _____________

4. Return Product Information

Model No: ______________________________ Serial No(s): ______________________________

Failure Symptoms (Detailed Description Required): ________________________________________

___________________________________________________________________________________

What Trouble Shooting Was Done Via Phone or Field Visit by FCI: ___________________________

___________________________________________________________________________________

FCI Factory Technical Service Contact: __________________________________________________

5. Reason For Return Sensor Element Electronics As Found Testing Credit

Recalibrate (New Data) Recalibrate (Most Recent Data) Other

(Note: A new Application Data Sheet (ADS) must be submitted for all recalibrations and re-certifications)

6. Payment Via Faxed Purchase Order

(Note: A priced quotation is provided for all Non-Warranty repairs after equipment has been evaluated. All

Non-Warranty repairs are subject to a minimum evaluation charge of $250.00)

Factory Return Shipping Address: Fluid Components International LLC

1755 La Costa Meadows Drive

San Marcos, CA 92078-5115

Attn: Repair Department,

RA #____________

Visit FCI on the Worldwide Web: w ww.fluidcomponents.com

1755 La Costa Meadows Drive, San Marcos, California 92078 USA ‡ Phone: 760-744-6950 ‡ 800-854-1993 ‡ Fax: 760-736-6250

FCI Document No. 05CS000004C

This page is subject to proprietary rights statement on last page

33 Doc. No. 06EN003367 Rev. D

Page 34

FLUID COMPONENTS INTERNATIONAL LLC ST50 MASS FLOW

The following Return Authorization Request form and Decontamination Statement MUST be completed, signed and faxed back to

FCI before a Return Authorization Number will be issued. The signed Decontamination Statement and applicable MSDS Sheets must

be included with the shipment. FCI will either fax, email or telephone you with the Return Authorization Number upon receipt of the

signed forms.

Packing Procedures

1. Electronics should be wrapped in an anti-static or static-resistant bag, then wrapped in protective bubble wrap and sur-

rounded with appropriate dunnage* in a box. Instruments weighing more than 50 lbs., or extending more than four feet,

should be secured in wooden crates by bolting the assemblies in place.

2. The sensor head must be protected with pvc tubing, or retracted the full length of the probe, locked and secured into the

Packing Gland Assembly (cap screws tightened down).

3. FCI can supply crates for a nominal fee.

4. No more than four (4) small units packaged in each carton.

5. FCI will not be held liable for damage caused during shipping.

6. To ensure immediate processing mark the RA number on the outside of the box. Items without an RA number marked on the box

or crate may be delayed.

7. Freight must be “PrePaid” to FCI receiving door.

* Approriate dunnage as defined by UPS, will protect package contents from a drop of 3 feet.

*** Decontamination Statement *** This Section Must Be Completed ***

Exposure to hazardous materials is regulated by Federal, State, County and City laws and regulations. These laws

provide FCI’s employees with the “Right to Know” the hazardous or toxic materials or substances in which they may

come in contact while handling returned products. Consequently, FCI’s employees must have access to data regarding the hazardous or toxic materials or substances the equipment has been exposed to while in a customer’s possession. Prior to returning the instrument for evaluation/repair, FCI requires thorough compliance with these instructions. The signer of the Certificate must be either a knowledgeable Engineer, Safety Manager, Industrial Hygenist or

of similar knowledge or training and responsible for the safe handling of the material to which the unit has been

exposed. Returns without a legitimate Certification of Decontamination, and/or MSDS when required, are

unacceptable and shall be returned at the customer’s expense and risk. Properly executed Certifications of

Decontamination must be provided before a repair authorization (RA) number will be issued.

Certification Of Decontamination

I certify that the returned item(s) has(have) been thoroughly and completely cleaned. If the returned item(s)

has(have) been exposed to hazardous or toxic materials or substances, even though it (they) has (have) been

thoroughly cleaned and decontaminated, the undersigned attests that the attached Material Data Safety Sheet(s)

(MSDS) covers said materials or substances completely. Furthermore, I understand that this Certificate, and providing the MSDS, shall not waive our responsibility to provide a neutralized, decontaminated, and clean product for

evaluation/repair at FCI. Cleanliness of a returned item or acceptability of the MSDS shall be at the sole discretion of

FCI. Any item returned which does not comply with this certification shall be returned to your location

Freight Collect and at your risk.

This certification must be signed by knowledgeable personnel responsible for maintaining or managing the safety program at your facility.

Process Flow Media ________________________________________________________________________

Product was or may have been exposed to the following substances: _______________________________

_________________________________________________________________________________________

Print Name ________________________________________________________________________________

Authorized Signature _________________________________________________ Date _________________

Company Title _____________________________________________________________________________

FCI Document No. 05CS000004C

This page is subject to proprietary rights statement on last page

34 Doc. No. 06EN003367 Rev. D

Page 35

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

Instrument Warranty

Goods furnished by the Seller are to be within the limits and of the sizes published by the Seller and subject to the Seller’s

standard tolerances for variations. All items made by the Seller are inspected before shipment, and should any of said

items prove defective due to faults in manufacture or performance under Seller approved applications, or fail to meet the

written specifications accepted by the Seller, they will be replaced or repaired by Seller at no charge to Buyer provided

return or notice of rejection of such material is made within a reasonable period but in no event longer than one (1) year

for non-calibration defects and one (1) year for calibration defects from date of shipment to Buyer, and provided further,

that an examination by Seller discloses to Seller’s reasonable satisfaction that the defect is covered by this warranty and

that the Buyer has not returned the equipment in a damaged condition due to Buyer’s or Buyer’s employees’, agents’, or

representatives’ negligence and Buyer has not tampered, modified, redesigned, misapplied, abused, or misused the

goods as to cause the goods to fail. In addition, this warranty shall not cover damage caused by Buyer’s exposure of the

goods to corrosive or abrasive environments. Moreover, Seller shall in no event be responsible for (1) the cost or repair of

any work done by Buyer on material furnished hereunder (unless specifically authorized in writing in each instance by

Seller), (2) the cost or repair of any modifications added by a Distributor or a third party, (3) any consequential or

incidental damages, losses, or expenses in connection with or by reason of the use of or inability to use goods purchased

for any purpose, and Seller’s liability shall be specifically limited to free replacement, or refund of the purchase price, at

Seller’s option, provided return or rejection of the goods is made consistent with this paragraph, and the Seller shall in no

event be liable for transportation, installation, adjustment, loss of good will or profits, or other expenses which may arise in

connection with such returned goods, or (4) the design of products or their suitability for the purpose for which they are

intended or used. Should the Buyer receive defective goods as defined by this paragraph, the Buyer shall notify the

Seller immediately, stating full particulars in support of his claim, and should the Seller agree to a return of the goods, the

Buyer shall follow Seller’s packaging and transportation directions explicitly. In no case are the goods to be returned

without first obtaining a return authorization from the Seller. Any repair or replacement shall be at Seller’s factory, unless

otherwise directed, and shall be returned to Seller transportation prepaid by Buyer. If the returned goods shall prove

defective under this clause they will be replaced or repaired by Seller at no charge to Buyer provided the return or

rejection of such material is made within a reasonable period, but in no event longer than (1) year from the date of

shipment of the returned goods or the unexpired terms of the original warranty period whichever is later. If the goods

prove to be defective under this paragraph, the Buyer shall remove the goods immediately from the process and prepare

the goods for shipment to Seller. Continued use or operation of defective goods is not warranted by Seller and damage

occurring due to continued use or operation shall be for Buyer’s account. Any description of the goods contained in this

offer is for the sole purpose of identifying them, and any such description is not part of the basis of the bargain, and does

not constitute a warranty that the goods will conform to that description. The use of any sample or model in connection

with this offer is for illustrative purposes only, is not part of the basis of the bargain, and is not to be construed as a

warranty that the goods will conform to the sample or model. No affirmation of that fact or promise made by the Seller,

whether or not in this offer, will constitute a warranty that the goods will conform to the affirmation or promise. THIS

WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES WITH

RESPECT TO THE GOODS OR THEIR INSTALLATION, USE, OPERATION, REPLACEMENT OR REPAIR,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS OF PURPOSE; AND THE GOODS ARE

BEING PURCHASED BY BUYER “AS IS”. SELLER WILL NOT BE LIABLE BY VIRTUE OF THIS WARRANTY OR

OTHERWISE FOR ANY SPECIAL, INCIDENTAL OR CONSEQUENTIAL LOSS OR DAMAGE RESULTING FROM THE

USE OR LOSS OF USE OF THE GOODS.

This page is subject to proprietary rights statement on last page

35 Doc. No. 06EN003367 Rev. D

Page 36

ST50 MASS FLOW FLUID COMPONENTS INTERNATIONAL LLC

FCI’s Complete Customer Commitment. Worldwide

ISO 9001:2000 and AS9100 Certified

Notice of Proprietary Rights

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components

International LLC (FCI). Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only

(and does not include manufacture or processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

Visit FCI on the Worldwide Web: www.fluidcomponents.com

1755 La Costa Meadows Drive, San Marcos, California 92078 USA - 760-744-6950 - 800-854-1993 - Fax 760-736-6250

Doc. No. 06EN003367 Rev. DFluid Components International LLC (FCI) All Rights Reserved

Loading...

Loading...