Page 1

VeriCal™ In-Situ Calibration

Operation Manual

ST110, ST112, STP110, STP112

Thermal Mass Flow Meter

Fluid Components International LLC (FCI). All rights reserved.

Page 2

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components International LLC (FCI).

Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only (and does not include manufacture or

processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

© Copyright 2011 by Fluid Components International LLC. All rights reserved. FCI is a registered trademark of Fluid Components International LLC. Information subject to change without notice.

Notice of Proprietary Rights

Page 3

ST100 Series VeriCal Operation Manual

Introduction

This manual guides the user of the VeriCal instrumentation through an initial gathering of in-situ baseline data. This baseline line data will then be

compared to data gathered during similar future verification processes to determine if the system is operating within factory specifications.

Theory of Operation

The VeriCal system uses a sonic nozzle to consistently control the amount of compressed air (or nitrogen) injected onto the thermal flow transducer

located on the end of the probe assembly. It is critical to use the same gas for subsequent VeriCal runs to ensure repeatability.

The operating principle of the sonic nozzle requires the total or absolute pressure on the high side of the nozzle to be greater than 20.0 PSIA. The

pressure difference between the high side of the sonic nozzle and the process pressure (low-pressure side of the nozzle) must be greater than 2:1.

When these two requirements are met, a repeatable flow is injected onto the thermal flow transducer.

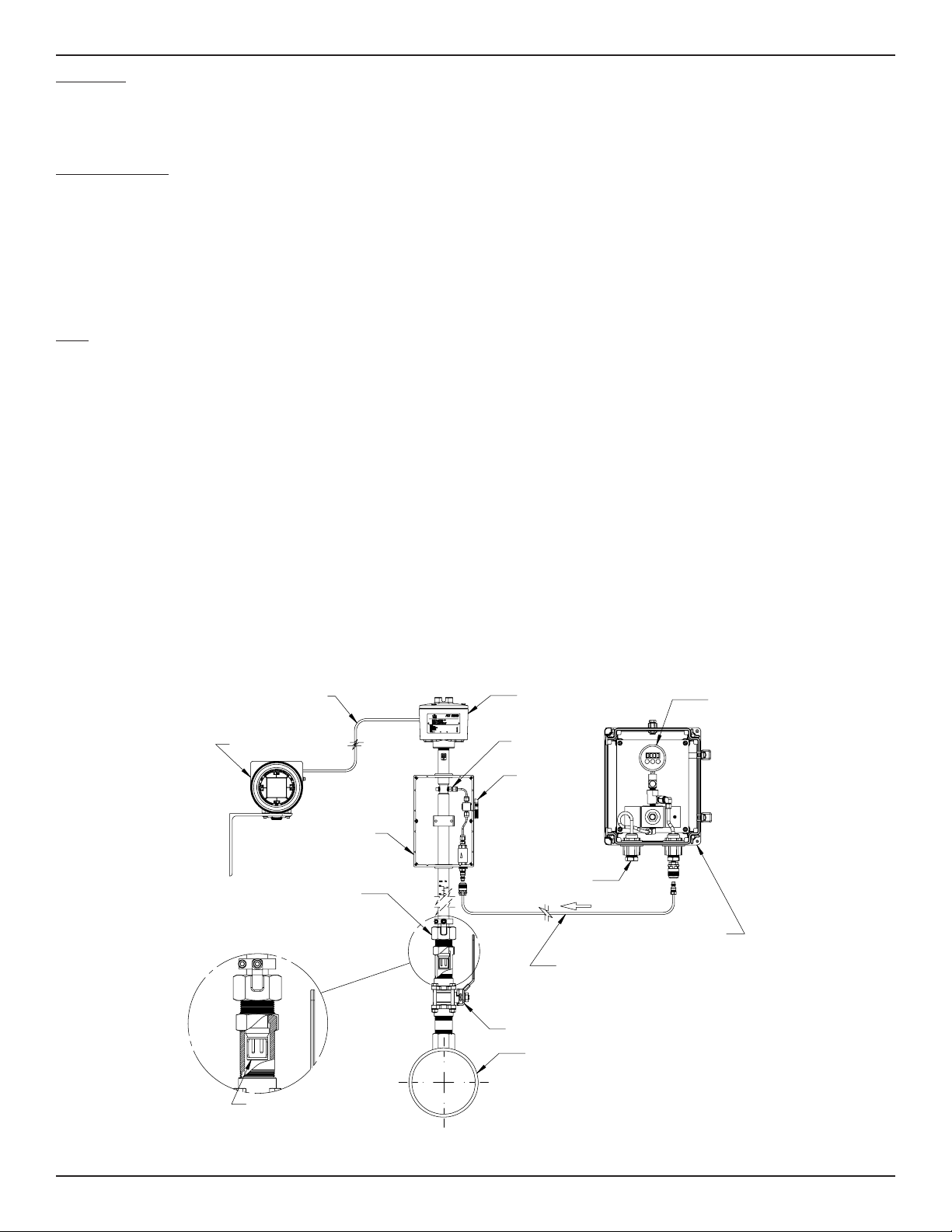

Setup

FCI Recommends that this procedure be run during the commissioning process of the instrument to determine an initial installed baseline calibration

and to document any installed offset from the factory VeriCal baseline.

Frequency: Every 18 months minimum, every six months is recommended. After the process has been performed a couple times the customer should

determine the required verification frequency based upon the process conditions.

This procedure makes the assumption that the instrument has been installed and is completely functional in the normal operating condition and

orientation. The customer should also have access to the factory VeriCal calibration certificate.

Note: All standard safety procedures must be followed during the verification process. This procedure assumes the standard

packing gland process connection. Your process connections may vary. It is critical to establish a Field Baseline upon

receiving your ST100. This will ensure a greater likelihood of repeatability and establish a history of the VeriCal data.

• Apply the proper input power and allow for a 30-minute warmup. It is critical that the electronics and the sensor be fully warmed and stable

prior to the VeriCal process. Failure to allow the proper warmup time can impact repeatability.

• Loosen the packing nut on the packing gland assembly until the internal packing is lose enough to allow the probe assembly to be retracted out

of the process and is recessed completely into packing gland assembly. Retract the probe assembly completely.

INTERCONNECTING

REMOTE CABLE

REMOTE ENCLOSURE

(SYSTEM ELECTRONICS)

VERICAL BOX

(SHOWN WITHOUT COVER)

PACKING GLAND

ASSEMBLY

ASSEMBLY

WITH 1 1/4 " NPT

LOCAL ENLCOSURE

SONIC NOZZLE

PLUG VALVE

(SHOWN IN

OPEN POSITION)

1/8" FEMALE NPT,

AIR INLET

INTERCONNECTING,

AIR HOSE.

HIGH SIDE

PRESSURE

READING

REGULATOR

ASSEMBLY

BALL VALVE

PROCESS PIPING

RETRACTED

PROBE ASSY

C01061-1-1

Retracted VeriCal Mounting Configuration

Fluid Components International LLC 1

Page 4

ST100 Series VeriCal Operation Manual

• Level the orientation flat on the probe assembly using a standard bubble level and tighten the packing nut to secure the assembly. To optimize

the repeatability of the verification process, the position and orientation of the probe assembly should be identical every time the process is

performed.

• Attach the regulator assembly with the interconnecting hose to the inlet quick disconnect fitting on the probe assembly if it is not permanently

installed.

• Attach the calibration gas supply, typically compressed air (or Nitrogen), to the inlet side of the regulator assembly. Back out the pressure control regulator. Open the supply valve to the VeriCal pressure regulator box.

• Slowly apply 100 PSIG to the VeriCal setup and verify that the system is leak free using a liquid leak detection fluid on all junction points. This

should also ensure a steady flow across the sensors and remove any debris that might be on the thermowells or the outlet of the VeriCal tube.

Reduce the pressure on the system to 25.0 PSIG.

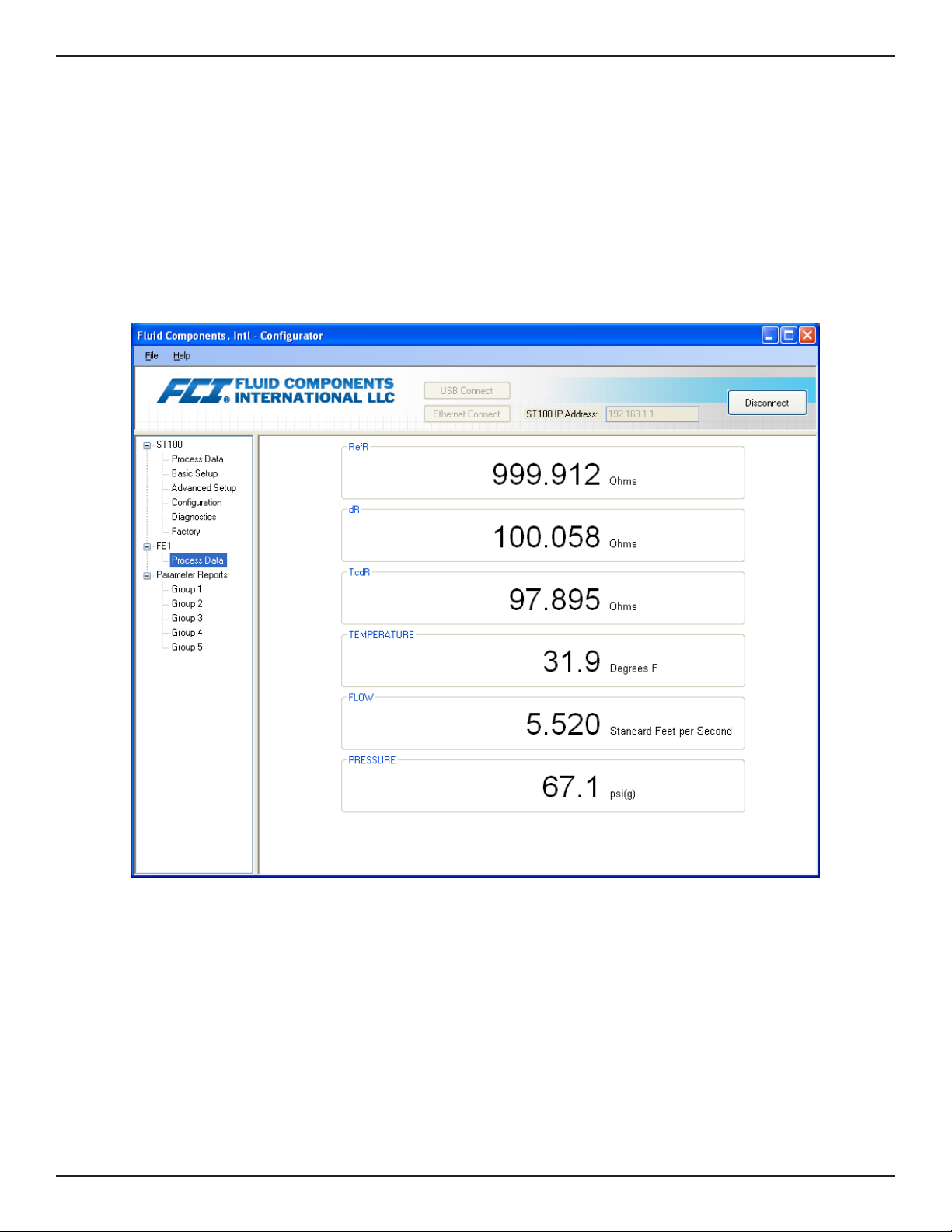

• Open the ST100 Configurator application via the USB connection to the ST100. Go to the Process Data tab for the appropriate FE (Flow Element).

Be ready to record this information on the In-Situ VeriCal Data Sheet.

Sample of the ST100 Configurator “Process Data”

• The instrument is now in the VeriCal configuration and ready to establish a set of “Field Baseline Data.”

2 Fluid Components International LLC

Page 5

ST100 Series VeriCal Operation Manual

Procedure

• Verify that the VeriCal pressure gauge indicates 25.0 PSIG (+/- 0.20 PSIG). Note: using the exact pressure levels allows one to compare the current findings to the FCI Factory findings and any subsequent findings.

• Allow the instrument to stabilize by sustaining the pressure for a minimum of 5 minutes. Observing the flow and temperature reading stability

on the ST100 Configurator to verify that the instrument has come to equilibrium.

• Record the VeriCal pressure as indicated on the regulator assembly pressure indicator and the ST100 data that is shown on the Configurator:

RefR, dR, TCdR, Temperature, Flowrate and optionally the output current across a precision 250Ω resistor.

• Repeat this process for 50, 75 and 100 PSIG pressures.

• The recorded values are the instrument’s in-situ baseline calibration readings. All future verification readings will be compared to these baseline

values and should be within 2-5% of the Field Baseline Data readings.

• It is advisable to complete one more round of “Field Check Data” to establish a pattern of repeatability for this specific combination.

Note: This step is not mandatory, but it will help to understand the VeriCal system and what can be expected for future verifications.

• The ST100 Configurator application can now be closed.

• Place probe assembly back into the correct location in the center of the process piping as indicated in the installation section of the operation

manual.

LOCAL ENCLOSURE

REMOTE

ENCLOSURE

(SYSTEM ELECTRONICS)

INTERCONNECTING

REMOTE CABLE

VERICAL BOX

ASSEMBLY

PACKING GLAND

ASSEMBLY WITH

1 1/4" NPT

BALL VALVE

PROCESS PIPING

PLUG VALVE

(SHOWN IN CLOSE POSITION)

A

OPEN

A

VIEW A-A

.50

C01061-2-1

Normal Mounting Configuration

Fluid Components International LLC 3

Page 6

ST100 Series VeriCal Operation Manual

INTENTIONALLY LEFT BLANK

4 Fluid Components International LLC

Page 7

ST100 Series VeriCal Operation Manual

1755 La Costa Meadows Drive, San Marcos, CA 92078-5115

Phone: 760-744-6950 Toll Free (US): 800-854-1993 Fax: 760-736-6250

www.fluidcomponents.com

Order Number: Equipment Used: Due Date

Customer: DMM:

Date: Resistor Pack:

Serial Number: Other:

Tag Number:

Field Baseline Data Date: Gas Supply:

Pressure

PSIG

ST100

RefR

ST100

dR

ST100

TCdR

In-Situ VeriCal Data Sheet

ST100

Temp

ST100

Flow Rate

(at 250Ω)

Vdc

Field Check Data Date: Gas Supply:

Pressure

PSIG

Field Check Data Date: Gas Supply:

Pressure

PSIG

ST100

RefR

ST100

RefR

ST100

dR

ST100

dR

ST100

TCdR

ST100

TCdR

ST100

Temp

ST100

Temp

ST100

Flow Rate

ST100

Flow Rate

Vdc

(at 250Ω)

Vdc

(at 250Ω)

Fluid Components International LLC 5

Page 8

ST100 Series VeriCal Operation Manual

INTENTIONALLY LEFT BLANK

6 Fluid Components International LLC

Page 9

ST100 Series VeriCal Operation Manual

Customer Service / Technical Support

FCI provides full in-house technical support. Additional technical representation is also provided by FCI field representatives. Before

contacting a field or in-house representative, please perform the troubleshooting techniques outlined in this document.

By Mail

Fluid Components International LLC

1755 La Costa Meadows Dr.

San Marcos, CA 92078-5115 USA

Attn: Customer Service Department

By Phone

Contact the area FCI regional representative. If a field representative is unable to be contacted or if a situation is unable to be resolved,

contact the FCI Customer Service Department toll free at 1 (800) 854-1993.

By Fax

To describe problems in a graphical or pictorial manner, send a fax including a phone or fax number to the regional representative.

Again, FCI is available by facsimile if all possibilities have been exhausted with the authorized factory representative. Our Fax number is

1 (760) 736-6250; it is available 7 days a week, 24 hours a day.

By E-Mail

FCI Customer Service can be contacted by e-mail at: techsupport@fluidcomponents.com.

Describe the problem in detail making sure a telephone number and best time to be contacted is stated in the e-mail.

International Support

For product information or product support outside the contiguous United States, Alaska, or Hawaii, contact your country’s FCI

International Representative or the one nearest to you.

After Hours Support

For product information visit FCI at www.fluidcomponents.com. For product support call 1 (800) 854-1993 and follow the prerecorded

instructions.

Point of Contact

The point of contact for service, or return of equipment to FCI is your authorized FCI sales/service office. To locate the office nearest you,

please go to www.fluidcomponents.com.

Fluid Components International LLC 7

Page 10

ST100 Series VeriCal Operation Manual

NOTES

8 Fluid Components International LLC

Page 11

ST100 Series VeriCal Operation Manual

NOTES

Fluid Components International LLC 9

Page 12

06EN003408 Rev. A ST100 Series VeriCal Operation Manual

FCI’s Complete Customer Commitment. Worldwide

ISO 9001 and AS9100 Certified

Visit FCI on the Worldwide Web: www.fluidcomponents.com

FCI World Headquarters

1755 La Costa Meadows Drive | San Marcos, California 92078 USA | Phone: 760-744-6950 Toll Free (US): 800-854-1993 Fax: 760-736-6250

FCI Europe

Persephonestraat 3-01 | 5047 TT Tilburg, The Netherlands | Phone: 31-13-5159989 Fax: 31-13-5799036

FCI Measurement and Control Technology (Beijing) Co., LTD | www.fluidcomponents.cn

Room 107, Xianfeng Building II, No.7 Kaituo Road, Shangdi IT Industry Base, Haidian District | Beijing 100085, P. R. China

Phone: 86-10-82782381 Fax: 86-10-58851152

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid

Components International LLC (FCI). Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your

company only (and does not include manufacture or processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

Notice of Proprietary Rights

© Copyright 2011 by Fluid Components International LLC. All rights reserved. FCI is a registered trademark of Fluid Components International LLC. Information subject to change without notice.

Fluid Components International LLC

Loading...

Loading...