Page 1

Installation, Operation

& Maintenance Manual

Installation, Betrieb und Wartungshandbuch

Manual de Instalación, Operación y Mantenimento

安装、操作和维护手册

ST100 Series

Thermal Mass Flow Meter

Fluid Components International LLC (FCI). All rights reserved.

Page 2

ST100 Series Flow Meter

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components International LLC (FCI).

Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only (and does not include manufacture or

processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

© Copyright 2011 by Fluid Components International LLC. All rights reserved. FCI is a registered trademark of Fluid Components International LLC. Information subject to change without notice.

Notice of Proprietary Rights

Fluid Components International LLC

Page 3

ST100 Series Flow Meter 06EN003400 Rev. D

Table of Contents

1 GENERAL.....................................................................................................................................................................................................1

Product Description ..........................................................................................................................................................................................................1

Theory of Operation ..........................................................................................................................................................................................................1

Safety Instructions............................................................................................................................................................................................................1

Order Verification ..............................................................................................................................................................................................................1

Hardware - Model Descriptions ....................................................................................................................................................................................1

Documentation and Accessories...................................................................................................................................................................................2

Supplemental Manuals , optional .................................................................................................................................................................................2

Supplemental Software, optional .................................................................................................................................................................................2

Technical Specification .....................................................................................................................................................................................................3

2 INSTRUMENT INSTALLATION ................................................................................................................................................................5

Instrument Identification and Outline Dimensions...........................................................................................................................................................5

Insertion Sensor Installation ............................................................................................................................................................................................5

Flange Mount ....................................................................................................................................................................................................................7

NPT Pipe Thread Mount ..................................................................................................................................................................................................7

Adjustable/Retraceable Packing Gland Mounting ...........................................................................................................................................................8

STP100 and STP102A Flow Element Installation .............................................................................................................................................................8

Flow Element Wiring .....................................................................................................................................................................................................8

STP100/102A Electronics Description ..........................................................................................................................................................................8

Troubleshooting .............................................................................................................................................................................................................9

ST102A and STP102A Flow Element Installation ............................................................................................................................................................9

Installed Point Locations ..............................................................................................................................................................................................9

Flow Element Wiring ...................................................................................................................................................................................................10

ST/STP102A Electronics Description ..........................................................................................................................................................................10

Troubleshooting ...........................................................................................................................................................................................................11

In-Line Sensor Installation..............................................................................................................................................................................................11

Flow Transmitter Electronics Installation .......................................................................................................................................................................11

Integral Electronics .........................................................................................................................................................................................................11

Remote Electronics .........................................................................................................................................................................................................12

Remote Pipe Mounting ...................................................................................................................................................................................................13

Instrument Wiring...........................................................................................................................................................................................................13

Post Installation Check ...................................................................................................................................................................................................15

Basic Commissioning and Start-Up ................................................................................................................................................................................15

HMI Display Navigation .................................................................................................................................................................................................17

System Fault and Alarm Indication ............................................................................................................................................................................18

Functions .........................................................................................................................................................................................................................18

Real Time Clock Setup.................................................................................................................................................................................................18

Totalizer .......................................................................................................................................................................................................................20

Data Logging ...............................................................................................................................................................................................................22

Manual Start Logging Method ....................................................................................................................................................................................23

Log File Contents .........................................................................................................................................................................................................24

Fluid Components International LLC i

Page 4

06EN003400 Rev. D ST100 Series Flow Meter

APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS .........................................................................................................................27

APPENDIX B - WIRING DIAGRAMS .......................................................................................................................................................37

Figure B-1: Integral - AC Input Power, Analog and HART Output ...............................................................................................................................38

Figure B-2: Remote - AC Input Power, Analog and HART Output ..............................................................................................................................38

Figure B-3: Integral - DC Input Power, Analog and HART Output .............................................................................................................................39

Figure B-4: Remote - DC Input Power, Analog and HART Output .............................................................................................................................39

Figure B-5: Integral - AC Input Power, Foundation fieldbus Output ..............................................................................................................................40

Figure B-6: Remote - AC Input Power, Foundation fieldbus Output ..............................................................................................................................40

Figure B-7: Integral - DC Input Power, Foundation fieldbus Output .............................................................................................................................41

Figure B-8: Remote - DC Input Power, Foundation fieldbus Output .............................................................................................................................41

Figure B-9: Integral - AC Input Power, Modbus Output .............................................................................................................................................42

Figure B-10: Remote - AC Input Power, Modbus Output ............................................................................................................................................42

Figure B-11: Integral - DC Input Power, Modbus Output ...........................................................................................................................................43

Figure B-12: Remote - DC Input Power, Modbus Output ...........................................................................................................................................43

Figure B-13: Remote - 8 Conductor Interconnection Cable........................................................................................................................................44

Figure B-14: Source - Pulse/Fequency Output ............................................................................................................................................................44

Figure B-15: Sink - Pulse/Fequency Output................................................................................................................................................................45

Figure B-16: Flow Element Connection - Integral/Remote ........................................................................................................................................45

Figure B-17: Flow Element Connection - Remote ......................................................................................................................................................46

Figure B-18: Remote - 10 Conductor Interconnection Cable......................................................................................................................................46

APPENDIX C APPROVALS ........................................................................................................................................................................47

APPENDIX D CUSTOMER SERVICE .........................................................................................................................................................53

Customer Service/ Technical Support .........................................................................................................................................................................53

Warranty Repairs or Returns .......................................................................................................................................................................................53

Non-Warranty Repairs or Returns ...............................................................................................................................................................................53

Extended Warranty ......................................................................................................................................................................................................54

Return to Stock Equipment..........................................................................................................................................................................................54

Field Service Procedures .............................................................................................................................................................................................54

Field Service Rates ......................................................................................................................................................................................................54

Return Authorization Request ...................................................................................................................................................................................55

ii Fluid Components International LLC

Page 5

ST100 Series Flow Meter GENERAL

1 GENERAL

Product Description

The ST100 Series is a thermal dispersion, industrial process grade air/gas flow meter. It is suitable for all air and gas flow measurement applications

in line sizes from 1” to 100” [25 to 2500 mm] and larger. The instrument provides direct mass flow measuring and measures flow rate, totalized flow

and temperature, and the STP versions add pressure measurement.

The measurements are made available to the user by way of 4-20mA analog output channels with HART or pre-selected digital bus protocols. The

optional graphics display provides real-time process variable values along with flow range and process description information.

There are no moving parts to clean or maintain. It is offered in a wide selection of process connections to fit with any process piping and versions are

available for temperature service from -40°F [-40°C] to 850°F [454°C].

ST100’s electronics/transmitter can be integrally mounted with the flow sensor or remote mounted up to 1000’ [300m] from the sensor element.

Additional patented and/or FCI exclusive features include VeriCal® in-situ calibration verification, SpectraCalTM user selectable gas mixes, Dual

sensor/single transmitter models and a built-in data logger capable of storing more than 20M readings. All ST100’s are precision calibrated in FCI’s

world-class, NIST traceable calibration facility on one of our flow stands matched to your gas application and actual installation conditions.

Theory of Operation

The instrument functionally is based on the thermal dispersion operating principal. A low powered heater produces a temperature differential

between two resistance temperature detectors (RTDs) by heating one of the RTDs above process temperature. As the process mass flow rate

changes, the differential temperature between the RTDs changes. The differential temperature between the RTDs is proportional to the process

mass flow. The flow transmitter converts the RTD differential temperature signal into a scaled flow output signal. The signal from the unheated RTD

is used to provide the process temperature value.

Safety Instructions

• Warning – Explosion Hazard. Do not disconnect equipment when flammable or combustible atmosphere is present.

• Field wiring shall be in accordance with NEC (ANSI-NFPA 70) for Division 2 hazardous locations CEC (CSA C22.1) for division 2 locations as

applicable.

• The instrument must be installed, commissioned and maintained by qualified personnel trained in process automation and control

instrumentation. The installation personnel must ensure the instrument has been wired correctly according to the applicable wiring diagram.

• All location specific installation and wiring requirements must be met and maintained. FCI recommends an input power circuit breaker be

installed between the power source and the flow meter. This facilitates easy power disconnection during commissioning and maintenance

procedures. A switch or circuit breaker is required if installation is in a hazardous area.

• The flow meter contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling the circuit board

assemblies.

• Hazardous Areas: The instrument is designed for use in hazardous areas. The approved area classification is identified on the nameplate along

with the temperature and pressure limitations. The USB port and the Serial Communication port do not support the hazardous area requirements

and should only be used when the area is declassified.

• When mounting the flow element into the process pipe, it is important that a lubricant/sealant is applied to the mating threads. A lubricant/

sealant compatible with the process conditions should be used. All connections should be tightened firmly. To avoid leaks do not overtighten or

cross- thread connections.

Order Verication

• Verify the received hardware matches the purchased hardware and application requirements. Verify the Model number part number on the

instrument I.D. tag (i.e. ST100 – 10C0…) matches the purchased Model number part number.

• Review the Calibration requirements as specified on the Engineering Data Sheet in the documentation package. Verify the flow, temperature

and pressure limits meet the application requirements.

Hardware - Model Descriptions

ST100 – Single point insertion element with flow and temperature process output

ST100L – In Line element with flow and temperature process output

ST102 – Dual point insertion elements with flow and temperature process output

Fluid Components International LLC 1

Page 6

GENERAL ST100 Series Flow Meter

ST110 – Single point insertion element with flow and temperature process output, VeriCal option

ST112 – Dual point insertion elements with flow and temperature process output, VeriCal option

STP100 – Single point insertion element with flow, temperature and pressure process output

STP102 – Dual point insertion elements with flow, temperature and pressure process output

STP110 – Single point insertion element with flow and temperature process output, VeriCal option

STP112 – Dual point insertion elements with flow and temperature process output, VeriCal option

Documentation and Accessories

06EN003400 Installation and Operation Manual

06EN003403 ST100 Configuration Software Manual

Calibration Certification Documentation

PC Configuration Software and USB Cable

Supplemental Manuals , optional

06EN003404 HART Operation Manual

06EN003405 F

oundation™ fieldbus Manual

06EN003406 Modbus Operation Manual

06EN003407 PROFIBUS Operation Manual

06EN003408 VeriCal In-Situ Calibration Verification Operation Manual

Supplemental Software, optional

HART DD Files

Foundation fieldbus

PROFIBUS DD File

PDM/DTMs

2 Fluid Components International LLC

Page 7

ST100 Series Flow Meter GENERAL

Technical Specication

Instrument

Measuring Capability

ST1XX Models: Flow rate, total flow and temperature

STP1XX Models: Flow rate, total flow, temperature and pressure

Basic Style

ST100: Insertion, single-point

ST100L: In-line (spool piece), single-point

ST102: Insertion, dual-element system

ST110: Insertion, single-point with VeriCal™ capability

ST112: Insertion, dual-element system with VeriCal capability

STP100: Insertion, single-point with pressure measurement

STP102: Insertion, dual-element system with pressure measure-

ment

STP110: Insertion, single-point with pressure measurement and

VeriCal capability

STP112: Insertion, dual-element system with pressure measure-

ment and VeriCal capability

Flow Measurement Range

Insertion Style: 0.25 SFPS to 1000 SFPS [0,07 NMPS to 305 NMPS]

ST100L In-line: 0.0062 SCFM to 1850 SCFM

[0.01 Nm3/h to 3,140 Nm3/h]

– Air at standard conditions; 70 °F and 14.7 psia [0 °C and 1,01325

bar (a)]

Temperature Measurement Range

Up to 850 °F [454 °C] commensurate with element; see Operating

Temperature in Flow Element specification

Pressure Measurement Range (STP Models)

Available Ranges:

0 psig to 50 psig [0 bar (g) to 3,4 bar (g)]

0 psig to 160 psig [0 bar (g) to 11 bar (g)]

0 psig to 500 psig [0 bar (g) to 34 bar (g)

0 psig to 1000 psig 0 bar (g) to 70 bar (g)]

Media:

All gases that are compatible with the flow element material

Accuracy:

Flow:

Gas Specific Calibration: ± 0.75% reading, ± 0.5% full scale

SpectraCal Gas Equivalency: Typically ± 4% reading, ± 0.5% full

scale;

gas conditions specific to application will determine accuracy; utilize

FCI’s online tool, AVAL, to evaluate your application and provide

expected accuracy

Temperature: ± 2 °F [± 2 °C] (display only, flow rate must be greater

than 5 AFPS [1,5 m/sec])

Pressure (STP Models): ± 0.25% full scale pressure range

Temperature Coefficient

With optional temperature compensation; valid from 10% to 100%

of full scale calibration

Flow: Maximum ± 0.015% of reading / °F up to 850 °F

[± 0.03% of reading / °C up to 454 °C]

Repeatability

Flow: ± 0.5% reading

Temperature: ± 1 °F [± 1 °C] (flow rate must be greater than 5 AFPS

[1,5 NMPS])

Turndown Ratio

Normally factory set and field adjustable from 2:1 to 100:1

within calibrated flow range; up to 1000:1 possible with factory

evaluation of application

Temperature Compensation

Standard: ± 30 °F [± 16 °C]

Optional: ± 100 °F [± 55 °C]

Agency Approvals pending

FM, FMc: Class I, Division 1, Hazardous Locations;

Groups B,C,D,E,F,G

ATEX and IECEx: Zone 1, II 2 GD Ex d IIC T4

CPA, NEPSI

Calibration

Performed on NIST traceable flow stands and equipment

Flow Element

Material of Construction

All-welded 316L stainless steel; Hastelloy-C optional

Operating Pressure

Metal ferrule: 1000 psig [69 bar (g)]

Teflon ferrule: 150 psig [10 bar (g)] (200 °F [93 °C] maximum)

Fixed Connection NPT: 1000 psig [69 bar (g)]

Fixed Connection Flanged: per flange rating

Operating Temperature (Process)

ST100, ST102 Insertion Style

All Flow Elements (– FPC, – FP and – S):

-40 °F to 350 °F [-40 °C to 177 °C]

-40 °F to 500 °F [-40 °C to 260 °C]

-40 °F to 850 °F [-40 °C to 454 °C]

ST110, ST112 Insertion Style

– FP Style Flow Element:

-40 °F to 350 °F [-40 °C to 177 °C]

-40 °F to 500 °F [-40 °C to 260 °C]

STP Series Insertion Style

All Flow Elements (– FPC, – FP and – S):

-40 °F to 257 °F [-40 °C to 125 °C]

ST100L In-line Style

– FP and – S Style Flow Element:

-40 °F to 250 °F [-40 °C to 121 °C]

Process Connection

Compression Fittings: Models ST100 and ST102 only

3/4” or 1” male NPT, stainless steel with adjustable Teflon ferrule or

metal ferrule; or flanged tapped and threaded for 3/4″ fitting, ANSI or

DIN flanges

Compression fittings not available with 850 °F [454 °C] temperature

versions of ST100 or ST102

Retractable Packing Glands

Low pressure 50 psig [3,5 bar (g)] or medium pressure 500 psig

[34 bar (g)] with graphite or Teflon packing material; 1 1/4″ male NPT

or ANSI or DIN flange

Teflon packing required when process media is ozone, chlorine or

bromine

Fixed Fittings / All Welded

1” male NPT or ANSI or DIN flange

Insertion Length

Field adjustable lengths:

1” to 6” [25 mm to 152 mm]

1” to 12” [25 mm to 305 mm]

1” to 21” [25 mm to 533 mm]

Fluid Components International LLC 3

Page 8

GENERAL ST100 Series Flow Meter

1” to 36” [25 mm to 914 mm]

1” to 60” [25 mm to 1524 mm]

Fixed lengths from 2.6” to 60” [66 mm to 1524 mm]

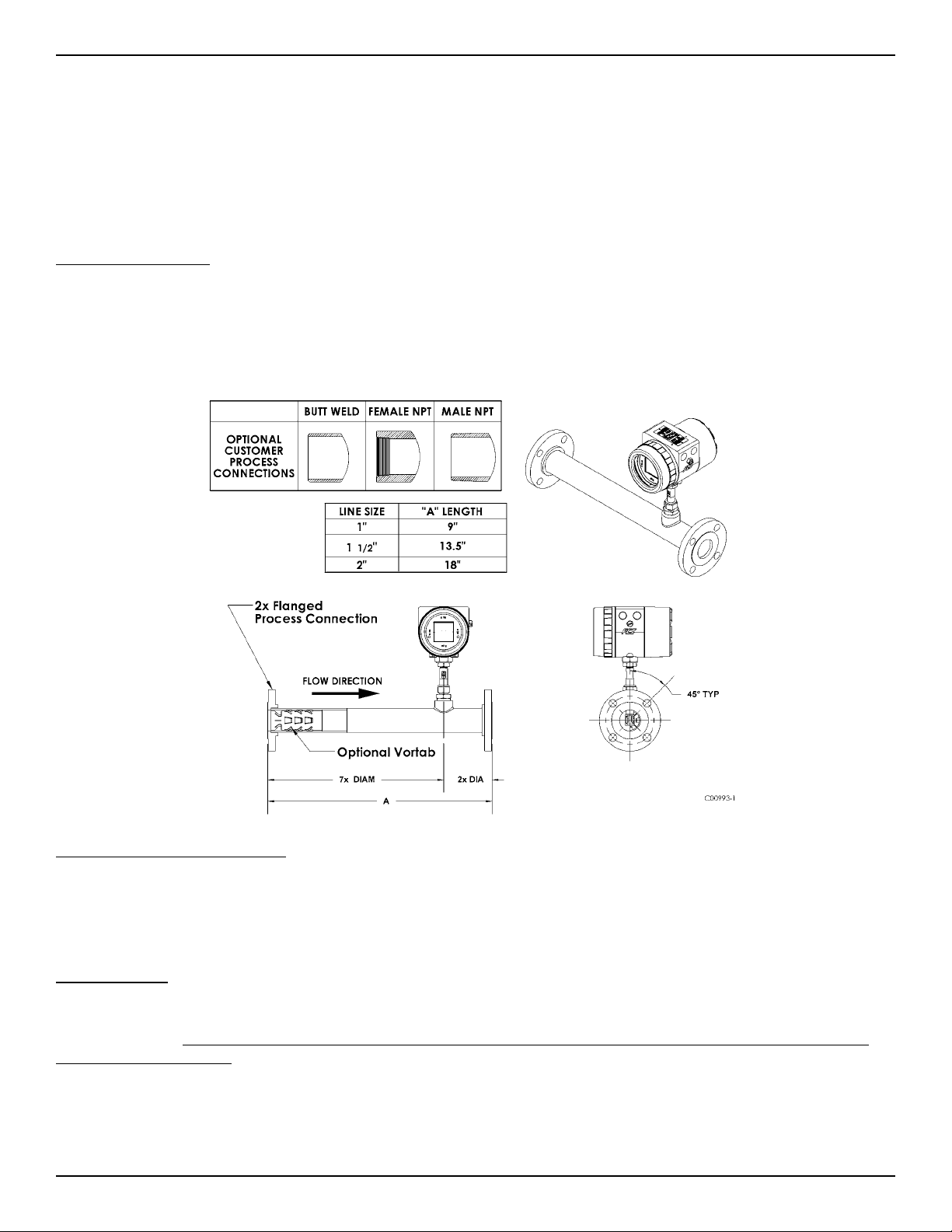

ST100L In-line Flow Tube

Flow element is threaded and keyed in an in-line flow tube, calibrated and supplied as a spool-piece; options include low flow injection

tubes and built-in Vortab flow conditioners for optimum low flow

rangeability and performance

Size: 1” diameter tubing; 1”, 1 1/2” or 2” schedule 40 pipe

Length: 9 nominal diameters

Process Connections: Female NPT, male NPT, ANSI or DIN

flanges, or butt weld prepared

Option: Flanges sized for flow tube

Remote Transmitter Configurations: Transmitter may be

mounted remotely from flow element using interconnecting cable

(up to 1000’ [300 m])

STP Models: Additional Specifications on Pressure Sensor

Calibrated at nominal 70 °F [21 °C]

Zero/Span Shift: 0.83% full scale/100 °F [1.5% full scale/100 °C]

Zero Tolerance: ± 0.5% of full scale

Span Tolerance: ± 0.5% of full scale

Long Term Stability: ± 0.2% full scale per year

Maximum over Pressure:

50 psi, 100 psi [3,4 bar, 7 bar] versions 3.0 x rated rate range

500 psi, 1000 psi [34 bar, 70 bar] versions 2.0 x rated rate range

Minimum burst Pressure (all):

50 psi, 100 psi [3,4 bar, 7 bar] versions 40 x rated rate range

500 psi, 1000 psi [34 bar, 70 bar] versions 20 x rated rate range

Wetted Materials:

17-4 PH stainless steel diaphragm (not recommended for hydrogen

service; contact FCI for Model STP for use in hydrogen)

304 stainless steel fittings

Flow Transmitter/Electronics

Operating Temperature: 0 °F to 140 °F [-18 ° to 60 °C]

Input Power

AC: 85 Vac to 265 Vac, 50 Hz to 60 Hz

DC: 24 Vdc ± 20%

Power Consumption

AC: 85 to 265V = 10W, 1 Flow Element

13.1W, 2 Flow Element

DC: 24V = 9.6W, 1 Flow Element

13.2W, 2 Flow Elements

Outputs

Analog

Standard: Three (3) 4-20 mA*, 0-1kHz, or 0-10 kHz pulse/frequency

4-20 mA outputs are user assignable to flow rate, temperature

and/or if so equipped, pressure; outputs are user programmable to

full flow range or subsets of full flow range; pulse/frequency output

is user selectable as pulse for external counter/flow totalizer, or as

0-1 kHz or 0-10 kHz frequency representing flow rate

* Outputs are isolated and have fault indication per NAMUR NE43

guidelines, user selectable for high (>21.0 mA) or low (<3.6 mA)

Optional: Standard output plus two (2) 2A SPDT relays

Relays independently user assignable to flow, temperature or

pressure; user programmable for hi/lo trip, hysteresis from 00.0 to

99.9 counts and time delay from 00.0 to 99.9 seconds

Digital

Standard: USB, Ethernet

Optional: HART (comes standard with analog outputs, V7 compliant

Foundation fieldbus H1, PROFIBUS PA or Modbus RS-485

Auxiliary Inputs

Two 4-20 mA input channels; used for FCI administered special

configurations to allow ST100 Series to accept inputs from external

devices such as gas analyzers, gas composition or pressure sensors

Enclosures

Main Transmitter / Electronics:

NEMA 4X, IP67; polyester powder coated aluminum; 4 conduit ports

threaded as 1/2” NPT or M20x1.5; 7.74” x 5.40” x 5.00” [196.6 mm x

137.2 mm x 127 mm]; stainless steel enclosure pending

Local Enclosure (Remote Configuration):

Model ST100L, Models ST100 and ST102 without packing gland

option:

NEMA 4X, IP67; polyester powder coated aluminum; 2 conduit ports

threaded as 1/2” NPT or M20x1.5; 3.75” x 4.00” x 3.24” [95 mm x

102 mm

x 82 mm]

Models ST100 and ST102 with medium pressure packing gland

option; ST110, ST112 and all STP Models:

NEMA 4X, IP67; polyester powder coated aluminum; 1 conduit port

threaded as 1” NPT or M20x1.5; 5.40” x 4.82” [137.2 mm x 122 mm]

Data Logger

User programmable for readings per time increment to a maximum

of 1 reading/second; removable, circuit board-mountable

2GB micro-SD (secure digital) memory card supplied; stores

approximately 21M readings in ASCII comma-separated format

Readout/Display and optical Touch buttons (optional):

• Large 2” x 2” [50 mm x 50 mm] LCD; digital plus bar graph and

engineering units

• Digital displays of flow rate, total flow, temperature and pressure

(with STP models); user selectable for engineering units

• Analog bar graph of flow rate

• Relay/alarm status indication

• User programmable 17 alphanumeric character field associated

with each calibration group

• Set-Up & Service mode displays text and service codes

• Four (4) optical touch buttons for user programming of instrument

set-up and service interrogation

• Optical touch button activation through front window – no need to

open enclosure to access or activate

• Display is electronically rotatable in 90° increments to optimize

viewing angle

Note: If readout/display not ordered, all user set-up and service interrogation must be done via computer link to bus comm and/or USB

port.

4 Fluid Components International LLC

Page 9

ST100 Series Flow Meter INSTALLATION

2 INSTRUMENT INSTALLATION

• Warning – Consult the manufacturer if dimensional information on the flameproof joints is necessary.

• Warning – The ambient temperature range and applicable temperature class of the ST100 Series flow meter is based on the maximum process

temperature for the particular application as follows; T6 for - 40 °C ≤ Ta ≤ +65 °C; T1 for - 40 °C ≤ Ta ≤ + 65 °C.

• Warning – The painted surface of the ST100 Series flow meter may store electrostatic charge and become a source of ignition in applications

with a low relative humidity < 30% relative humidity where the painted surface is relatively free of surface contamination such as dirt, dust, or

oil. Cleaning of the painted surface should only be done with a damp cloth.

• Warning – Do not replace internal battery when an explosive gas atmosphere is present.

Instrument Identication and Outline Dimensions

Appendix A provides outline dimensions and mounting bracket dimensions for all integral and remote mounted electronic configurations. Verify all

dimensions meet the application requirements before beginning the installation process.

Insertion Sensor Installation

The proper flow meter location in the process piping configuration is critical to the instruments ability to measure the process variables accurately.

FCI recommends 20 nominal pipe diameters upstream and 10 pipe diameters downstream of the instrument installation point for most applications.

These distances can be significantly reduced when the flow meter is combined with FCI’s flow conditioning technology (Vortab).

Insertion flow elements can be mounted into the process using several available customer selectable configurations; compression fitting mounted,

threaded or flanged packing gland mounted, and threaded or flanged fixed “U” length mounted process connections. The specific sensor process connection is customer specified on the Order Information Sheet.

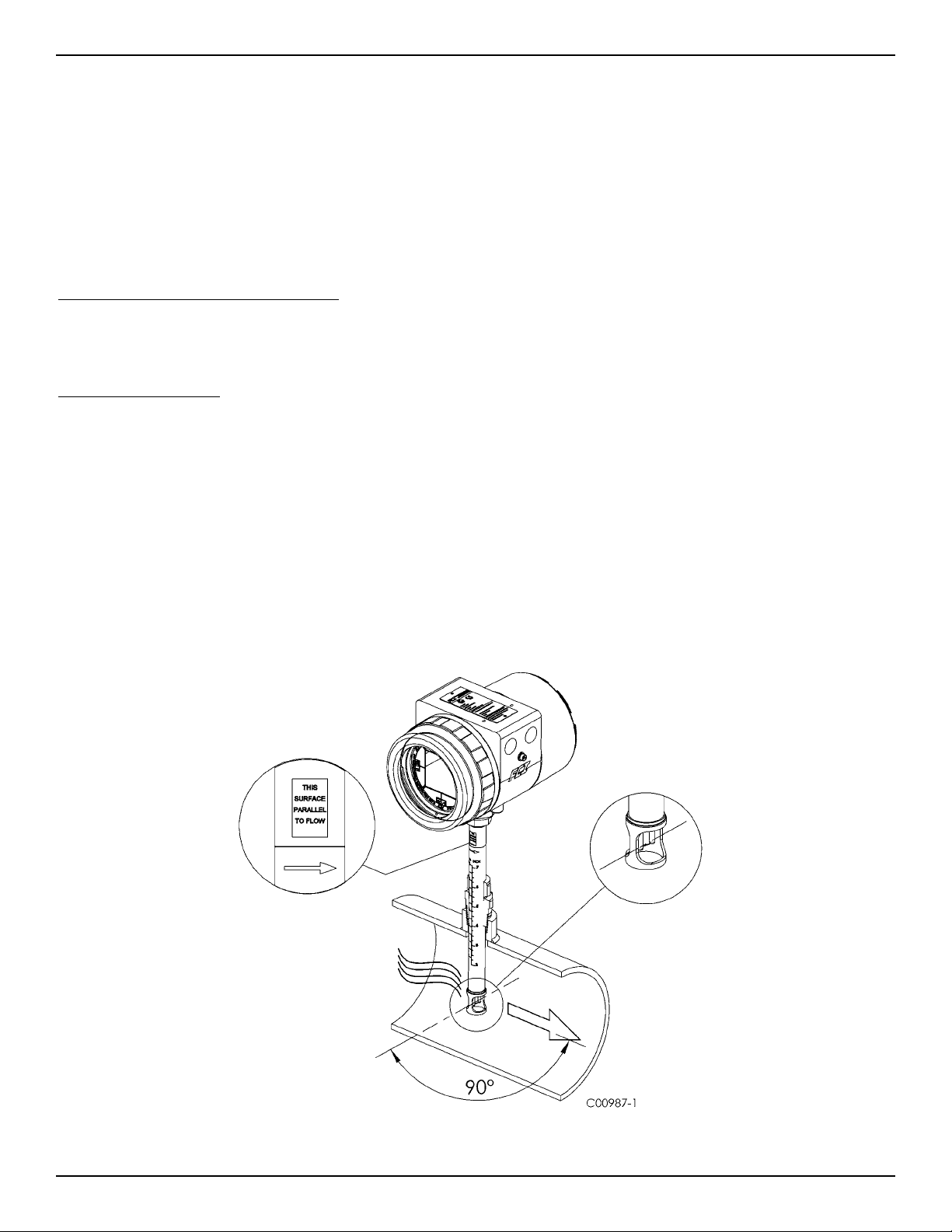

Mount the flow element to the process piping per the application piping requirements. The flow arrow etched on the element should always match

the direction of the process flow and the flat should be parallel to flow with-in +/- 3° of rotation. Flow elements with variable insertion lengths

should insert ½” inch past the centerline of the process pipe or tube and the flow direction arrow should be aligned and leveled correctly. After the

flow element has been located correctly and tightened into place, verify the process seal does not leak by slowly applying pressure until the maximum operation pressure is applied. Check for leaks at the process connection boundary using standard leak detection methods.

Figure 1. shows a properly mounted compression fitting process connection instrument.

Figure 1

Fluid Components International LLC 5

Page 10

INSTALLATION ST100 Series Flow Meter

Compression Fitting Mounting

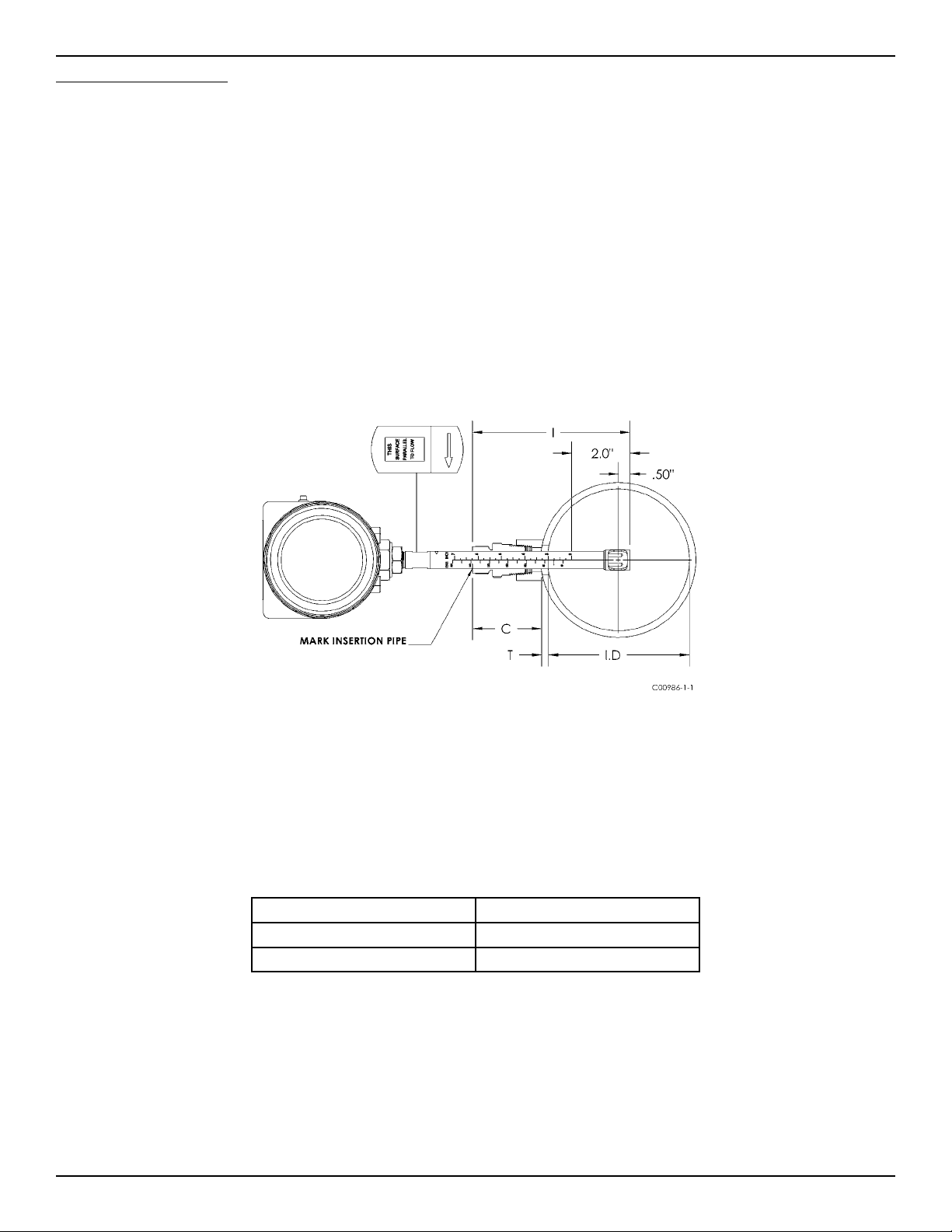

1. FCI single point insertion Flow Meters are calibrated at the centerline of the process pipe. The flow element is properly mounted when

the tip of the flow element is located 0.50 inches (13 mm) past the pipe centerline

2. I = Insertion depth

I.D. = Pipe inside diameter

T = Pipe wall thickness

C = Mounting coupling with and installed compression fitting length

Insertion Depth = I = 0.50 inches + (I.D. / 2) + T + C

3. The scale etched on the side of the insertion pipe indicates the length to the tip of the flow element.

4. Calculate the Insertion depth using the equation in step 2 above.

I = __________

5. Mark the insertion pipe at the calculated insertion depth.

Figure 2

6. Apply proper thread sealant to the tapered pipe thread on the compression fitting and secure into pipe mounting coupling.

7. Insert the flow element to the insertion depth mark and hand tighten the compression nut. Align the orientation flat parallel to the flow

direction.

8. Tighten the compression nut to the torque specified for the corresponding ferrule material. Compression fitting manufacture recommends

1-1/4 turns past hand tight.

Ferrule Material Torque

Teflon 6 FT-Lbs

316 SST 65 FT-Lbs *

Note: The metal ferrule configuration can only be tightened one time. Once tightened, the insertion length is no longer

adjustable.

6 Fluid Components International LLC

Page 11

ST100 Series Flow Meter INSTALLATION

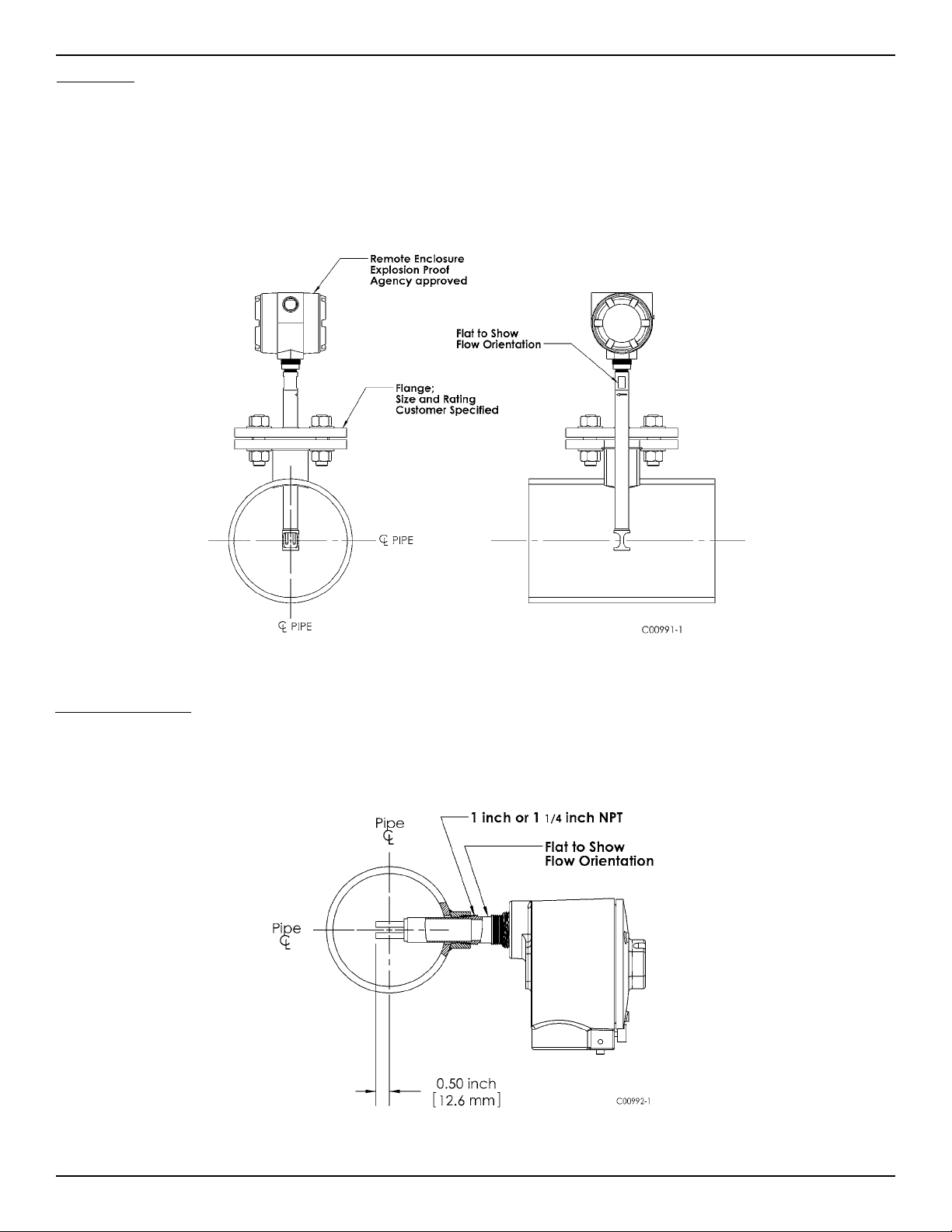

Flange Mount

The flange mount flow element in shown in Fig 3. Attach the process mating flange with care. The correct orientation of the flow element must be

maintained to ensure the calibrated accuracy.

• Verify the process media flow matches the flow direction arrow on the flow element.

• Apply appropriate gasket and or sealant to flange mount as required.

• Mate flow element flange to process flange keeping flat oriented properly.

• Secure flanges with appropriate mounting hardware.

Figure 3

NPT Pipe Thread Mount

The pipe thread configuration is shown in Fig 4. Apply sealant compatible with the process media to male threads. Carefully insert into process

mounting coupling. Tighten the flow element until snug and continue until flat and flow direction arrow are aligned with process flow.

Figure 4

Fluid Components International LLC 7

Page 12

INSTALLATION ST100 Series Flow Meter

Adjustable/Retraceable Packing Gland Mounting

Applications involving the use of packing glands should refer to drawings located in Appendix A for additional detail.

NPT and flange mounted gland are available. Isolation valves are typically used in packing gland applications.

• Follow the pipe thread or flange mount procedures as described in previous sections.

• Tighten the packing nut until the internal packing is tight enough to prevent excess process leakage but also allow the insertion pipe to be

inserted into place. Orient the flat and flow arrow properly.

• Proceed to insert the flow element into process media pipe. For the medium pressure packing gland, use the adjusting nuts on the all-thread to

pull the flow element into proper position. Tighten the opposing lock nuts.

• Tighten the packing nut another ½ to 1 turn until tight (approximately 65 – 85 ft-lbs)

• On low pressure packing glands, align the split ring collar with connecting strap on packing nut. Tighten the two ¼-28 cap screws on the split

ring locking collar.

STP100 and STP102A Flow Element Installation

The Model STP100 and STP102A add an additional pressure transducer measurement as a third process variable output. The process connections

available on the STP model include the standard connections available on the ST model except the compression fitting. The ST102 will have two

probe assemblies. Available process connections include:

• Retractable Packing Gland

• Fixed NPT

• Flanged

All flow element mounting and securing instructions for the selected process connections are identical to the ST100. These details are provided in

the previous process connection mounting sections.

The pressure limitation for the STP model will be determined by the selection of the pressure transducer. The available options include 50, 160, 500

and 1000 psig (3.44, 11.03, 34.47 and 69.95 bar) maximum pressure ranges.

The pressure transducer is offered in two different temperature service ranges:

• Standard: 32 to 176°F (0 to 80°C)

• Explosion Proof (Ex): -22 to 212°F (-300 to 100°C)

The pressure transducer is located inside the rectangular shaped enclosure attached to the flow element. The pressure tap is located in the center of

the two thermowells and extends through the center of the insertion pipe into the enclosure where the transducer is located. Because the pressure

transducer is located several feet away from the process media, at the end of a dead head tube assembly, the pressure transducer will be exposed to

the external ambient temperature of the flow element.

Flow Element Wiring

The STP100/102A can be configured with integral or remote electronics. Wiring diagrams for these configurations are located in Appendix B.

Remote configurations require a 10 conductor shielded cable as specified in the Instrument Wiring Table 1.

STP100/102A Electronics Description

The electronic transmitter for the instrument provides flow, temperature and pressure output on the display and the customer selected output

mode, analog or digital.

Analog 4-20mA output: factory default setup

•Output#1–FloworTwopointaverageFlow

•Output#2–temperatureorTwopointaverageTemperature

•Output#3–Pressure

8 Fluid Components International LLC

Page 13

ST100 Series Flow Meter INSTALLATION

HART output

•Command9–Slot0,2,4:FloworTwopointaverageFlow.

•Command9–Slot5:TemperatureorTwopointaverageTemperature

•Command9–Slot6:Pressure

Fieldbus output

•FlowAIBlock–TwopointaverageFlow

•TemperatureAIBlock–TwopointaverageProcessTemperature

•PressureAIBlock-Pressure

•ProcessTransducerblock–index13,PRIMARY_VALUE(AverageFLOW)

•ProcessTransducerblock–index15,SECONDARY_VALUE(AverageTEMPERATURE)

•ProcessTransducerblock–index19,Quaternary_VALUE(Pressure)

Modbus output

•Command3–TwopointaverageFlow

Two point average Temperature

Pressure, available on STP models

Totalizer

Troubleshooting

The “Service Mode” for both HART and Foundation Fieldbus provide access to the individual sensor output values.

The 102A electronics transmitter can recognize a disconnected flow element. If this condition is detected, the instrument will indicate a fault

condition and display process variables from the sensor that remains connected to the transmitter. The fault will self-correct when the sensor

is re-connected.

ST102A and STP102A Flow Element Installation

The Model ST/STP102A is a dual-element averaging system operating through a single transmitter. The ST/STP102A Flow Element offers the same

process connections that are available on the basic ST100. The ST/STP102A will have two probe assemblies. Available process connections include:

• Compression Fitting

• Retractable Packing Gland

• Fixed NPT

• Flanged

All flow element mounting and securing instructions for the selected process connections are identical to the ST100. These details are provided in

the previous process connection mounting sections. Each Flow element is identified with the instrument serial number followed by a -1 or -2.

For example:

Serial no: 409486-1 Description - flow element no.1

Serial no: 409486-2 Description - flow element no.2

Installed Point Locations

The flow element point locations for a two point averaging system are based from the US EPA – Method 1 Traverse Point recommendations.

This method is applicable to gas streams flowing in ducts, stacks, and flues with inside diameters greater than 12 inches. The recommended

point locations for a two point averaging system are shown in the diagram below.

Locate and secure the flow elements into position using (0.146 x Pipe I.D. + 0.50 inches) as the location dimension from the pipe I.D. to the

end of the flow element.

Fluid Components International LLC 9

Page 14

INSTALLATION ST100 Series Flow Meter

Flow Element Wiring

The ST/STP102A can be configured with one integral and one remote flow element or with two separate flow elements and remote electronics. Wiring diagrams for these configurations are located in Appendix B. Each of the flow elements on the ST102A/STP102A are connected to

the transmitter using an 8 conductor shielded cable as specified in the Instrument Wiring Table 1.

ST/STP102A Electronics Description

The electronic transmitter for the ST/STP102A type instruments provides a two point averaged flow and temperature output on the display

and the customer selected output mode, analog or digital.

Analog 4-20mA output: factory default setup

•Output#1–TwopointaverageFlow

•Output#2–TwopointaverageTemperature

•Output#3–Pressure,availableonSTPmodels

HART output

•Command9–Slot0,2,4:TwopointaverageFlow.

•Command9–Slot5:TwopointaverageTemperature

•Command9–Slot6:Pressure

Fieldbus output

•FlowAIBlock–TwopointaverageFlow

•TemperatureAIBlock–TwopointaverageProcessTemperature

•ProcessTransducerblock–index13,PRIMARY_VALUE(AverageFLOW)

•ProcessTransducerblock–index15,SECONDARY_VALUE(AvrageTEMPERATURE)

Modbus output

•Command3–TwopointaverageFlow

Two point average Temperature

Pressure, available on STP models

Totalizer

10 Fluid Components International LLC

Page 15

ST100 Series Flow Meter INSTALLATION

Troubleshooting

The “Service Mode” both HART and F

The ST/STP102A electronics transmitter can recognize a disconnected flow element. If this condition is detected, the instrument will indicate

a fault condition and display process variables from the sensor that remains connected to the transmitter. The fault will self-correct when the

sensor is re-connected.

oundation fieldbus provide access to the individual sensor output values.

In-Line Sensor Installation

The sensor can be threaded, flanged or butt weld mounted to the process piping. The specific sensor process connection is customer specified on the

Order Information Sheet.

Mount the sensor to the process piping per the application piping requirements. Verify the flow direction arrow is pointed in the correct direction.

After the sensor head has been located correctly and tightened into place, verify the process seal does not leak by slowly applying pressure until the

normal operation pressure is applied. Check for leaks at the process connection boundary.

Figure 5

Flow Transmitter Electronics Installation

The instrument electronic transmitter can be an integral part of the flow element or it can be mounted remotely using a shielded cable between the

flow element and the electronics.

Supply connection wiring must be rated at least 90 °C.

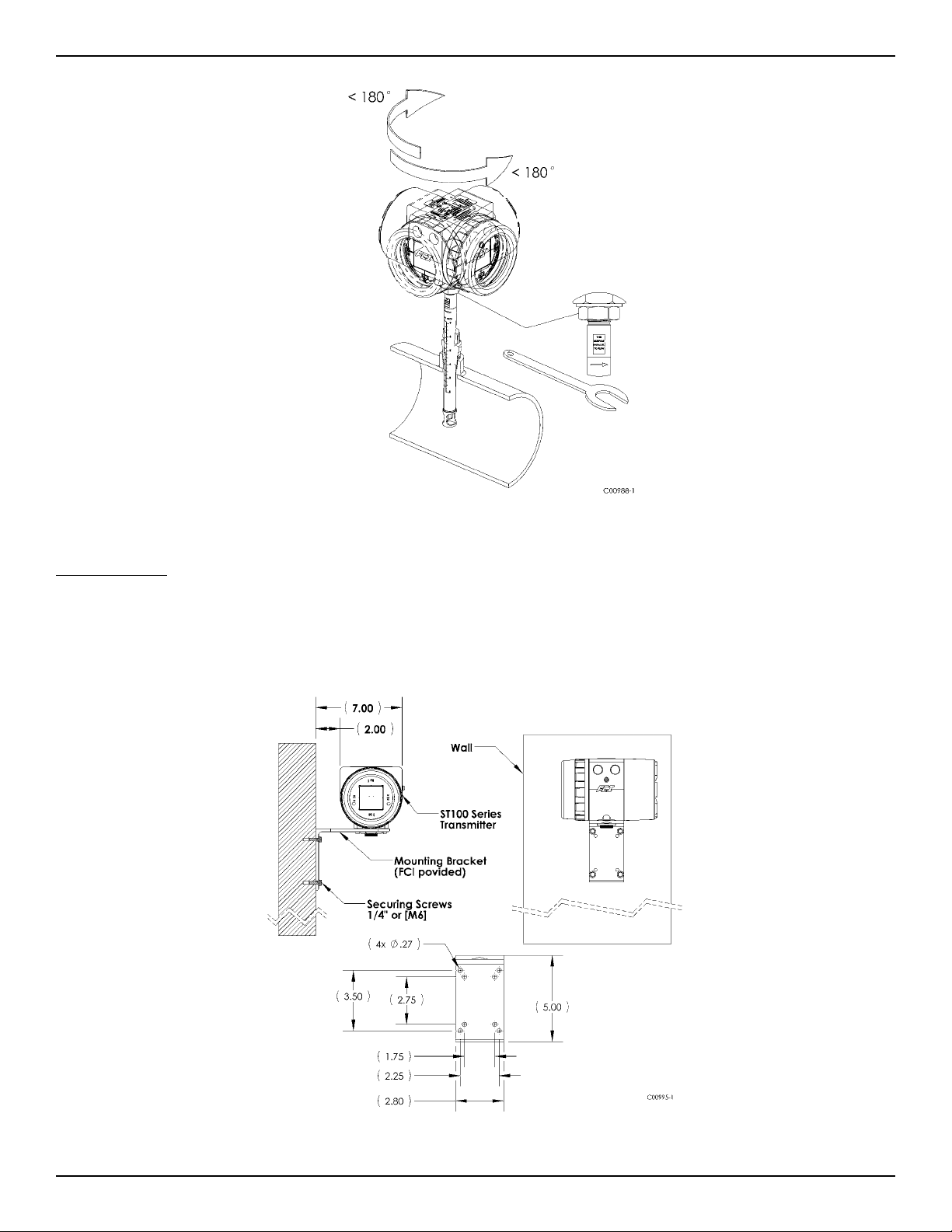

Integral Electronics

The integral electronics package is mounted during the flow element installation process. The integral electronics can be rotated +/- 180 degrees

on the top of the flow element insertion pipe. This is done by loosening the lock nut at the base of the enclosure and rotating the enclosure to the

preferred orientation. Do not rotate the electronics enclosure more than +/- 180 degrees, damage to internal wiring may result from

over rotating the enclosure!

Lock Nut Torque Specification: 30-35 ft-lbs (40-47 N-m)

The Integral electronics should be supported in applications where excessive vibration is present. A mounting bracket is available from FCI to support the electronics when additional support is required.

Fluid Components International LLC 11

Page 16

INSTALLATION ST100 Series Flow Meter

Figure 6

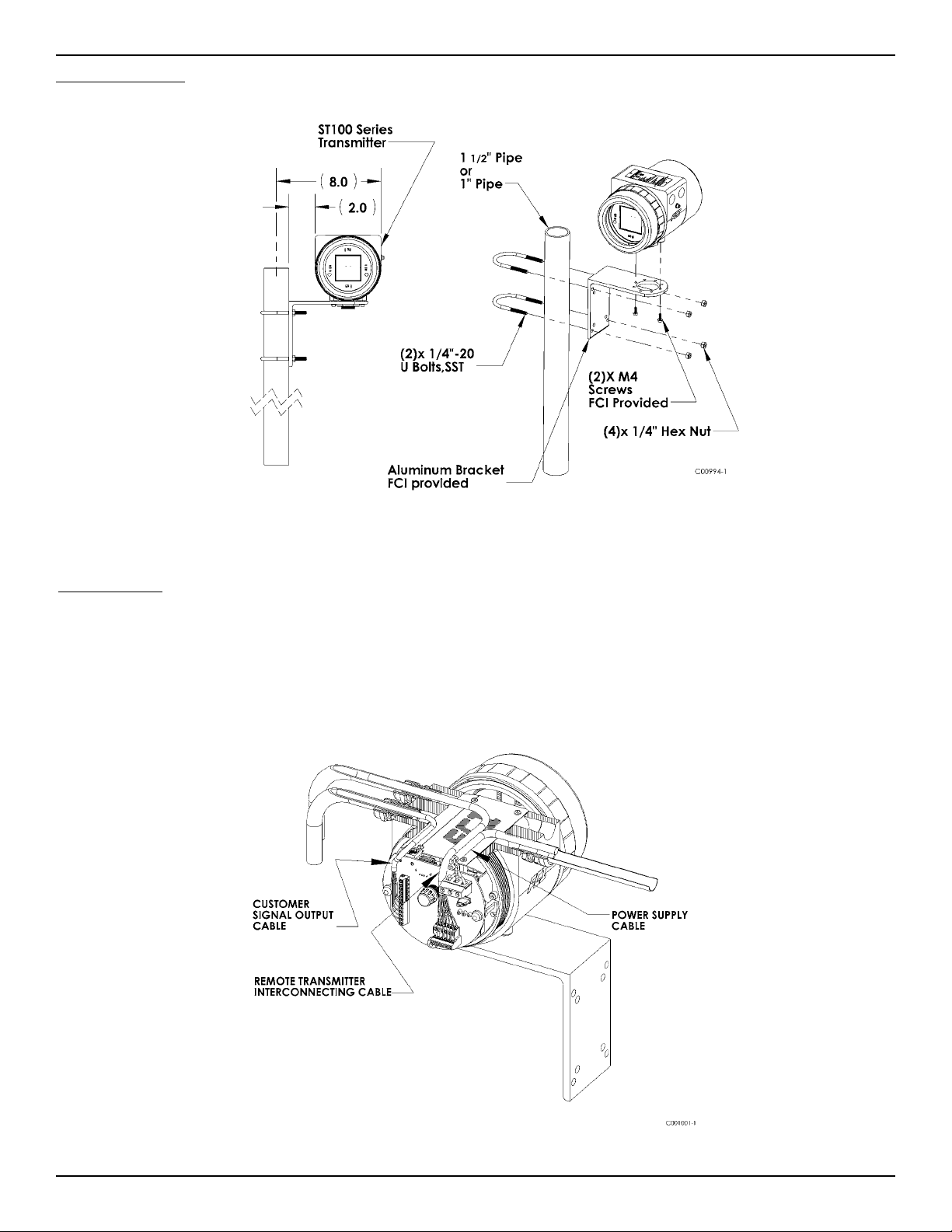

Remote Electronics

A mounting bracket is supplied when the Transmitter is ordered for remote mounting. The bracket mounting details are shown in Figure 7. below.

These details are also available on the Outline Installation Drawings located in appendix A. The electronics can be easily wall or pipe mounted.

The mount bracket is designed for .25 inch or M6 mounting hardware. The electronics should be securely mounted to cement or structural support

columns or beams. Mounting to plaster is not recommended and does not meet system approval requirements.

Figure 7

12 Fluid Components International LLC

Page 17

ST100 Series Flow Meter INSTALLATION

Remote Pipe Mounting

Figure 8

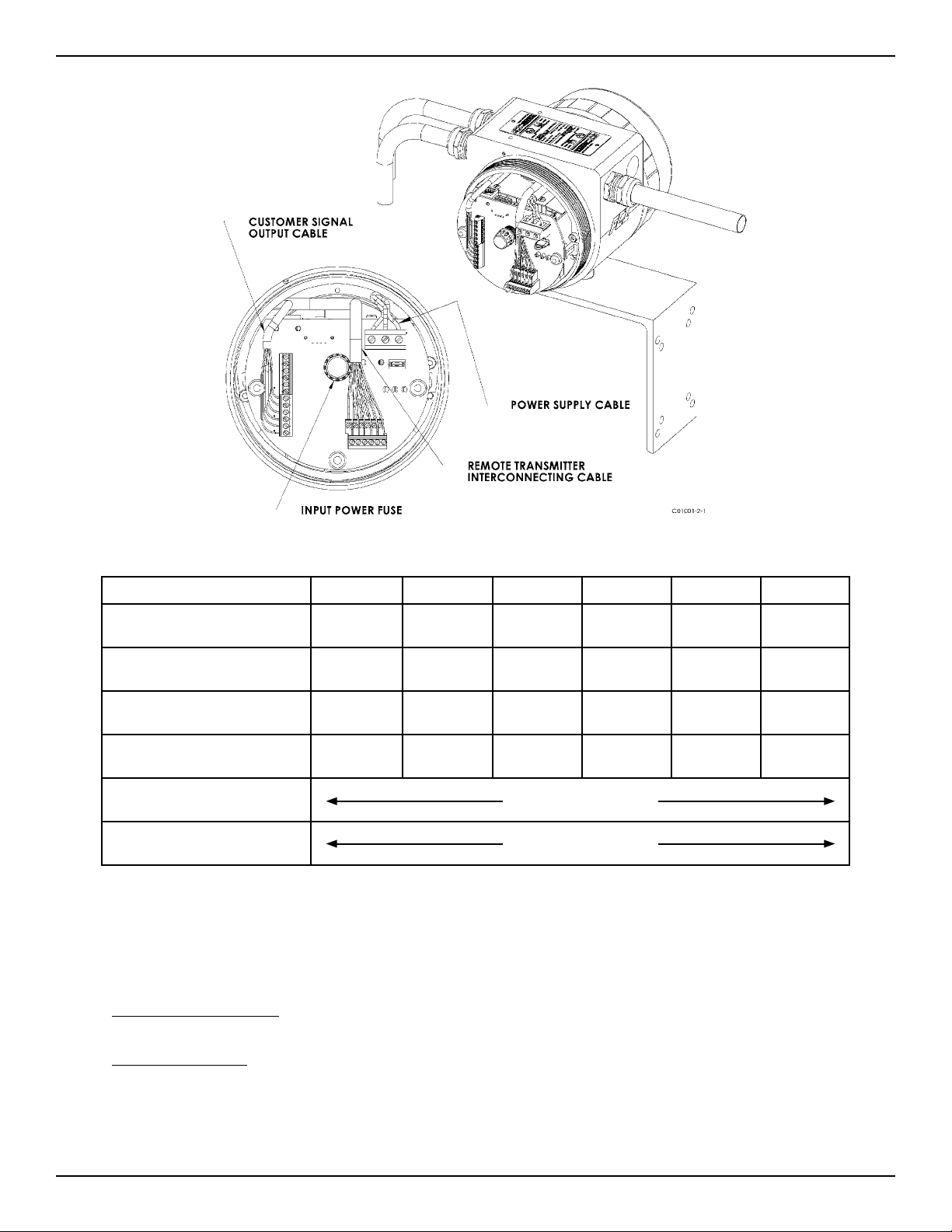

Instrument Wiring

The flow transmitter can be powered by 85 – 265 Vac or 24 Vdc as specified in the instrument specification. The electronics cannot be configured to

switch between AC and DC power. For 220/265 Vac installations, a neutral reference circuit must be used.

All cable glands and conduit fittings must meet or exceed the area approval rating where the instrument is being installed.

The recommended instrument wiring routing is shown in figures 15 and 16.

Figure 15

Fluid Components International LLC 13

Page 18

INSTALLATION ST100 Series Flow Meter

Figure 16

Connection 10 FT 50 FT 100 FT 250 FT 500 FT 1000 FT

Power AC or DC 22 22 22 20 18 16

Flow Element

(8 Conductor Shielded)

STP Flow Element

(10 Conductor Shielded)

Analog Out (HART) 16-30 16-30 16-30 16-30 16-30 16-30

Digital Out

Foundation Fieldbus

Modbus RS485 (14-30 AWG)

Analog output maximum load: 600 ohms

Instrument Power Requirements: See Instrument Specifications, page 8.

Instrument Fuse rating and part no:

AC Input Power (85 - 265 Vac):

MFR - LITTLEFUSE, 2A TR5 SLO-BLO series 383 (2 Amp rating), part no. 38312000000; FCI part no. 022499-01.

DC Input Power (24 Vdc):

MFR - LITTLEFUSE, 2A TR5 SLO-BLO series 383 (2 Amp rating), part no. 38312000000; FCI part no. 022499-01.

The input power fuse is located on the customer interface board, see figure 16. Instrument power must be turned off when

replacing the fuse. To replace the fuse, unscrew the clear fuse cover and pull the fuse straight out of the holder. Replace the fuse

with the recommended fuse listed above by aligning the fuse pins with the receiving holes located in the fuse holder and pushing

securely into place until the fuse bottoms in the holder. Replace the fuse cover.

14 Fluid Components International LLC

24 24 24 22 22 18

22 22 22 22 22 18

FF-844 H1 (14-30 AWG)

Instrument Wiring Table 1 - Recommended AWG

Page 19

ST100 Series Flow Meter INSTALLATION

Reference the following wiring diagrams in Appendix B for specific integral and remote mounted electronics.

Figure B-1 : Integral - AC Input Power, Analog and HART Output

Figure B-2 : Remote - AC Input Power, Analog and HART Output

Figure B-3 : Integral - DC Input Power, Analog and HART Output

Figure B-4 : Remote - DC Input Power, Analog and HART Output

Figure B-5 : Integral - AC Input Power, Foundation fieldbus Output

Figure B-6 : Remote - AC Input Power, Foundation fieldbus Output

Figure B-7 : Integral - DC Input Power, Foundation fieldbus Output

Figure B-8 : Remote - DC Input Power, Foundation fieldbus Output

ST102/STP102

Figure B-16 : Flow Element Connection - Integral/Remote

Figure B-17 : Flow Element Connection - Remote

Figure B-9 : Integral - AC Input Power, Modbus Output

Figure B-10 : Remote - AC Input Power, Modbus Output

Figure B-11 : Integral - DC Input Power, Modbus Output

Figure B-12 : Remote - DC Input Power, Modbus Output

Figure B-13 : Remote - 8 Conductor Interconnection Cable

Figure B-14 : Source - Pulse/Fequency Output

Figure B-15 : Sink - Pulse/Fequency Output

STP100/STP102

Figure B-18 : Remote - 10 Conductor Interconnection Cable

Post Installation Check

Verify all wiring connections are secure and correct to the appropriate wiring diagram. Verify the flow direction arrow on the flow element is pointing

in the correct direction. Verify the mechanical process connection is secure and meets the system pressure requirements.

Basic Commissioning and Start-Up

When all wiring and process connections have been verified, apply power to the instrument. The instruments with the LCD will briefly show a

welcome screen indicating the software version followed by the normal operation process screen. The normal process screen indicates process flow

rate, total flow, temperature and pressure depending on the options ordered. The calibration group and group description are also displayed at the

bottom of the screen. Verify the process variable engineering units are correct.

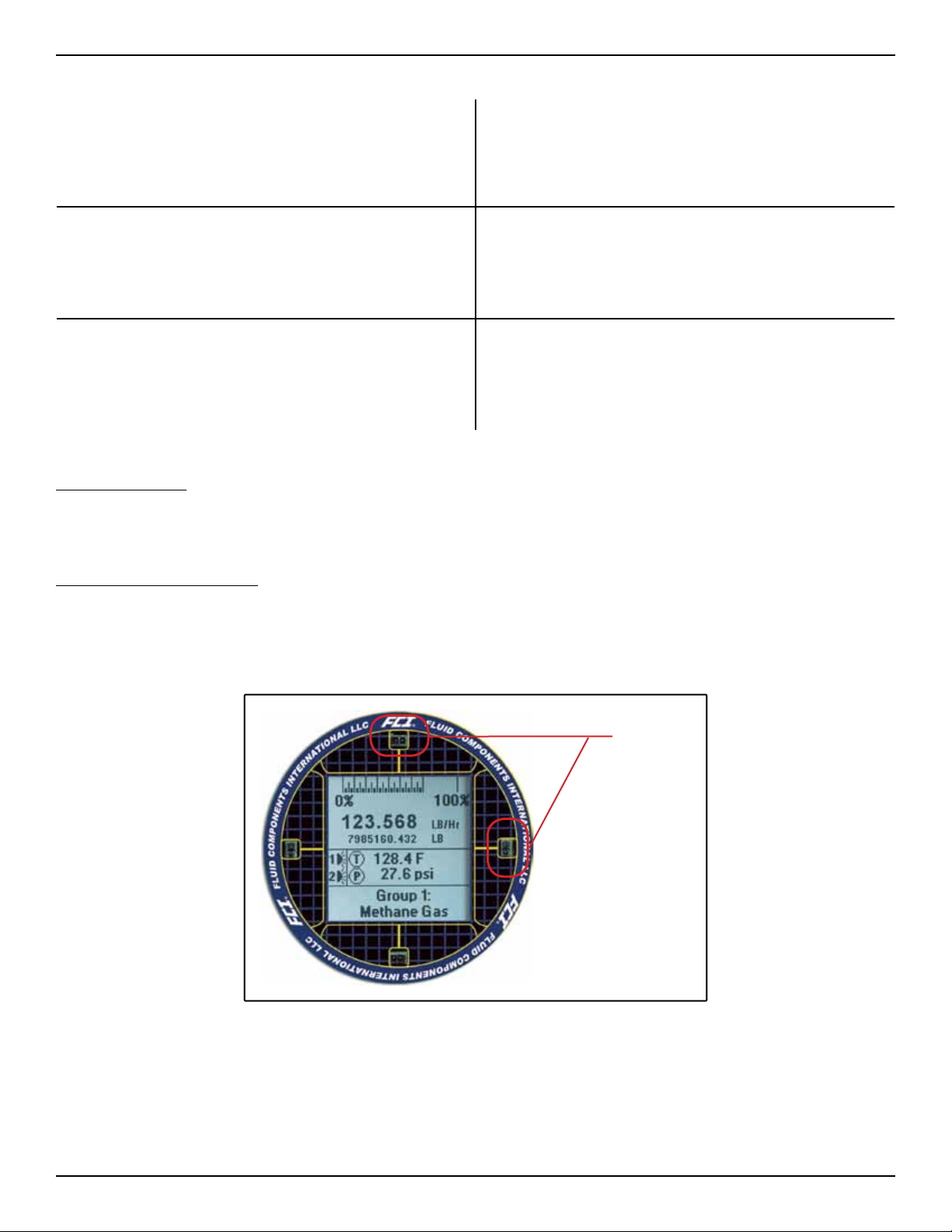

I.R. Sensors

(4 places)

Normal Operation Process Screen

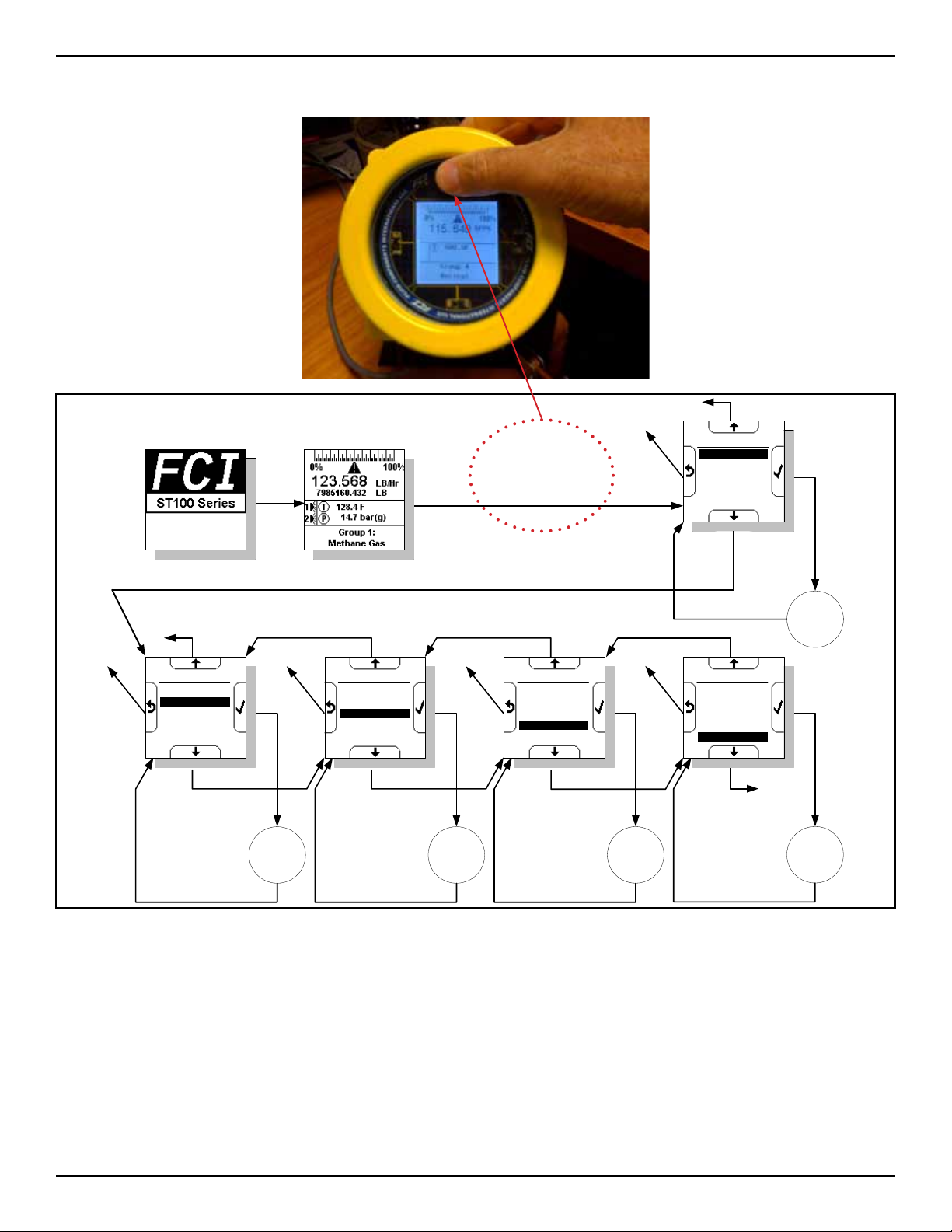

The instrument LCD display functions as a basic HMI setup tool. The four buttons (IR sensors) located at the 3, 6, 9 and 12 o’clock positions on the

display provide access to the basic setup parameters. The screen flow is shown in figure 18. The HMI setup menu can be accessed thru the window

without removing the electronics enclosure lids. This is done by holding your finger in front of the 12 o’clock sensor for 3 seconds. The LCD acknowledges the button selection by inverting the display characters and background while the button is held.

Fluid Components International LLC 15

Page 20

INSTALLATION ST100 Series Flow Meter

To enter HMI display menu, cover 12 o’clock button for 3 senconds.

...

T

Welcome Screen Process Screen

5 second

warmup

Aug 8, 2009

Version 1.0

Press and Hold

Press and Hold

Top Button for

Top

Button for 3 seconds

3 seconds

o

Pr

Sc

o

c

r

e

e

n

e

s

s

Options

Select Group

Alarm Ack

Diagnostics

Set-up

SD Card

...

Select

Group

...

Setup

T

o

Pr

Sc

o

c

r

e

e

n

e

s

s

Options

Select Group

Alarm Ack

Diagnostics

Set-up

SD Card

...

SD Card

T

o

Pr

Sc

o

c

r

e

e

n

e

s

s

Options

Select Group

Alarm Ack

Diagnostics

Set-up

SD Card

Alarm Ack

T

o

Pr

Sc

o

c

r

e

e

n

e

s

s

Options

Select Group

Alarm Ack

Diagnostics

Set-up

SD Card

Diagnostic

T

o

Pr

Sc

o

c

r

e

e

n

e

s

s

Options

Select Group

Alarm Ack

Diagnostics

Set-up

SD Card

Figure 18: LCD/HMI Basic Screen Flow

16 Fluid Components International LLC

Page 21

ST100 Series Flow Meter INSTALLATION

HMI Display Navigation

The four IR sensors are used to navigate the HMI menu structure. The top and bottom sensors are used to scroll thru the menu selections. The right

sensor button is used to select and the left sensor button is used to return to the previous menu.

Scroll Up

Go Back / Escape

Scroll Down

Enter/Select

The setup menu allows the user to modify all process variable engineering units and the pipe dimensions. The basic functions that that are accessible from the HMI menu are listed below:

1. Select Group (5 calibrations groups are available)

2. Acknowledge Alarms

3. Identify system faults

4. Set up:

Process variable engineering units

Pipe dimensions

Display orientation

Display contrast

5. SDcard remove and insert acknowledgment

HMIuserpassword:E#C

The HMI provides access to some of the basic instrument setup features. This allows the user to make configuration changes to the instrument without opening the enclosure lids. The ST100 PC interface configuration application provides an alternate method of configuring the

instrument. The PC configuration application is easy to use and is the recommended configuration tool when commissioning the instrument.

The ST100 configuration software instructions are provide in a supplement manual, FCI document number 06EN003403.

*ON display indicates PC Configuration Application is connected.

Fluid Components International LLC 17

Page 22

INSTALLATION ST100 Series Flow Meter

System Fault and Alarm Indication

The ST100 LCD Display indicates both alarm and fault conditions with a caution triangle icon directly above the flow rate indication on the

LCD.

Fault/Alarm Icon

When an alarm condition is met, the indicator will flash on and off. The flashing condition will continue until the alarm condition no longer

exists or the alarm is acknowledged using the HMI display menu. The alarm indicator can also be turned off by disabling the condition

through the configurator alarm Tab.

Instrument fault codes can be viewed by selecting the Diagnostics branch in the configurator tree or the HMI display menu.

Functions

Real Time Clock Setup

The ST100 clock reset function is accessed via the ST100 Configurator. Reference the ST100 Configuration supplemental manual for installation instructions, FCI document number 06EN003403. The Configuration program is installed on a PC or Laptop computer and can be connected via the USB or Ethernet. The USB is the primary mode of communication with the ST100.

Welcome Screen

To access the ST100 Clock Reset Function: 2

1. Connect a USB cable between the computer with the Configuration Application installed and the USB connection on the interface board.

2. Select the ST100 Configurator icon to open the application. The application will open to the welcome screen as shown above.

3. Select the USB Connect button at the top of the screen. The Configuration application will open to the Process Data screen as shown

below.

18 Fluid Components International LLC

Page 23

ST100 Series Flow Meter INSTALLATION

4. Select the Advanced Setup menu in the left menu tree.

Select the Date and Time Tab at the top of the page.

5.

Select the “Get from Device” button at the bottom of the page.

6.

7. Set the correct Date and Time.

Press the “Send to Device” button. (User password: 2772)

8. Verify the Date and Time have been set correctly by pressing the “Get from Device” button.

Fluid Components International LLC 19

Page 24

INSTALLATION ST100 Series Flow Meter

Totalizer

The Flow totalizer function accumulates the instrument total flow, very much like the odometer on an automobile. The engineering flow units

must be set in mass or volumetric units for this function to work. The total flow value is displayed directly below the real time flow value on

the instrument LCD display.

Total

Flow Value

Totalizer Setup

The ST100 totalizer function is accessed via the ST100 Configurator. Reference the ST100 Configuration supplemental manual for installation

instructions, FCI document number 06EN003403. The Configuration program is installed on a PC or Laptop computer and can be connected via

the USB or Ethernet. The USB is the primary mode of communication with the ST100.

To access the ST100 Totalizer Function:

1. Connect a USB cable between the computer with the Configuration Application installed and the USB connection on the interface board.

2. Select the ST100 Configurator icon to open the application. The application will open to the welcome screen as shown above.

3. Select the USB Connect button at the top of the screen. The Configuration application will open to the Process Data screen as shown

below.

Welcome Screen

20 Fluid Components International LLC

Page 25

ST100 Series Flow Meter INSTALLATION

4. Select the Basic Setup menu in the left menu tree

(User password: 2772)

Process Data Screen

5.

Select the Totalizer tab at the top of the page.

6. Select the “Totalizer Enabled” box.

7. Select the “Show Totalizer Value” box.

8. Select the “Send to Device” button.

Basic Setup Totalizer Tab Screen

The total flow value will now be displayed on the Instrument LCD display and the Process Data screen on the ST100 Configuration Application. The total flow value can be reset to zero using the “Reset Totalizer to Zero” button on the Basic Setup Totalizer screen.

Fluid Components International LLC 21

Page 26

INSTALLATION ST100 Series Flow Meter

Data Logging

The ST100 SD Card Logging features can be accessed via the ST100 Configurator Reference the ST100 Configuration supplemental manual for

installation instructions, FCI document number 06EN003403. The Configuration program is loaded on a PC or Laptop and can be connected via

the USB or Ethernet. The USB is the primary mode of communication with the ST100.

Welcome Screen

To access the ST100 Logging Function:

1. Connect a USB cable between the computer with the Configuration Application installed and the USB connection on the interface board.

2. Select the ST100 Configurator icon to open the application. The application will open to the welcome screen as shown above.

3. Select the USB Connect button at the top of the screen. The Configuration application will open to the Process Data screen as shown

below.

Process Data Screen

22 Fluid Components International LLC

Page 27

ST100 Series Flow Meter INSTALLATION

4. Select the Basic Setupinthemenulocatedintheleftmenu.ThenselecttheSDCardLoggingTab.YoushouldnowseetheLogging

setup menu as shown below.

Basic Setup, SD Card Logging Tab Screen

A logging session can be started by 2 different methods:

• Automatic when the SD card s present during an instrument power up.

• Manually using the ST100 Configuration Application.

Manual Start Logging Method

1. Begin with the Instrument power On and the Instrument connect to the Configuration Application thru

the USB port. Verify a memory card is inserted into the card slot on the back side of the interface

circuit board. The card should be inserted as shown with the contacts facing up. Inserting the

SD card upside down will cause damage to the socket. The card will click into position when

properly inserted.

2. Using the Logging Setup Menu in the ST100 Configuration Application:

• Press the “Remove Micro SD Card” button in the Logging setup Menu, this will close any logging

session that might be in progress.

(User Level Password = 2772)

• Select the Logging time interval.

• Press the “Send to Device” button.

• Press the “Insert Micro SD Card” button, the user may be prompted for a password, enter 2772 and press enter.

• The instrument begins logging Process Data.

• Press the “Remove Micro SD Card” button to close the logging file.

• Remove the SD Micro Card and open the log file as a .csv format. Each log file session creates a log file with a name format:

Logyymmddhhmmss.csv

Where:

yy is the 2 digit year

mm is the 2 digit month

dd is the 2 digit day

hh is the 2 digit hour

mm is the 2 digit minute

ss is the 2 digit second

Example File Name: Log110524134322

Note: The date and time information is retrieved from the real-time clock on the STAK CORE. If there is no battery installed, and/or if the date

and time have not been set prior to the initiation of the logging session, this could result in erroneous log file names.

Fluid Components International LLC 23

Page 28

INSTALLATION ST100 Series Flow Meter

Log File Contents

Log Entry Format

Each log entry consists of a single line (row) of data.

Each log entry is of a similar format:

<year>,<month>,<day>,<timestamp “hh:mm:ss”>,<tag>,<data 1>, <data 2>,…

Where:

<year> is the 4 digit year

<month> is the 2 digit month

<day> is the 2 digit day

<timestamp> is the time of day in hours (2 digit): minutes (2 digit) : seconds (2 digits)

<tag> is the 2 character entry type identifier

<data 1> <data 2> are the entry type specific data items

Log Entries

There are different types of log entries, and these are identified by the unique 2 character “tag” field. The data following the tag varies

depending on the type of log entry. A listing of the Tags and the associated description is shown below.

Tag Tag Description

PD Process Data

FL Fault

CF Core Fault

AL Alarm Activation

DR Automatic Delta-R test

Process Data – tag PD

Aprocessdataentryisaddedtotheloglebasedonthefrequencyofloggingspeciedviathe“0Q”CLIcommand.

Following the tag field, the data items are (in this order):

• Flow (in customer units)

• Temperature (in customer units)

• Pressure (in customer units)

• Totalizer (if present, in customer units. If totalizer not enabled, then “0.0”)

• CORE fault bitmap (8 character hexadecimal) for factory use

• FE0 fault bitmap (8 character hexadecimal) for factory use

• FE1 fault bitmap (8 character hexadecimal) for factory use

year month day time tag flow temp press Total fault code fault code fault code

2011 5 24 13:44:09 PD 0 85.87962 0 0x00100000 0x00000001 0x00000000

2011 5 24 13:44:39 PD 0 85.88636 0 0x00100000 0x00000001 0x00000000

2011 5 24 13:45:09 PD 0 85.88426 0 0x00100000 0x00000001 0x00000000

2011 5 24 13:45:39 PD 0 85.89391 0 0x00100000 0x00000001 0x00000000

Log File Entry Example: Instrument is in a no flow condition

24 Fluid Components International LLC

Page 29

ST100 Series Flow Meter INSTALLATION

Alarm Activation/Deactivation – tag AL

When an alarm condition either activates (alarm condition met) or deactivates (alarm condition no longer present), an alarm log entry will be

generated.

Following the tag field, the data items are:

• Alarm Id (1..6)

• Activated (1) or Deactivated (0)

• Alarm mode:

o Flow high: 1

o Flow low: 2

o Temperature high: 3

o Temperature low: 4

o Pressure high: 5

o Pressure low: 6

• Alarm process data value

o If Alarm mode 1 or 2, then flow (in customer units)

o If Alarm mode 3 or 4, then temperature (in customer units)

o If Alarm mode 5 or 6, then pressure (in customer units)

year month day time tag Alarm IDAct/

De-Act

2011 5 24 13:44:09 AL 1 1 2 0 0x00100000 0x00000001 0x00000000

2011 5 24 13:44:39 AL 2 1 3 86.63182 0x00100000 0x00000001 0x00000000

Log File Entry Example: Alarm 1 and 2 activated

FE Self Test: Delta-R – tag DR

When an automatic Delta-R test for an FE is executed, the results are logged with a Delta-R log entry.

Following the tag field, the data items are:

• FE Id (0..15)

• Delta-R low measured flow value (in customer units)

• Delta-R low expected flow value (in customer units)

• Delta-R medium measured flow value (in customer units)

• Delta-R medium expected flow value (in customer units)

• Delta-R high measured flow value (in customer units)

• Delta-R high expected flow value (in customer units)

year month day time tag FE ID DR low m DR low e DR med m DR low e DR hi m DR hi e

2011 5 24 13:44:39 DR 0 60.48953 60.48953 100.48953 100.48953 150.48953 150.48953

Mode PD value fault code fault code fault code

Log File Entry Example: Automatic Delta R Calibration Check

Note: This log function is setup in the Diagnostic menu under the Scheduled Tests tab

Two other tag codes will be logged if the instrument identifies a system fault. These additional tags are FL and CF. If these fault tags are

identified in a log file, contact FCI customer service.

Fluid Components International LLC 25

Page 30

INSTALLATION ST100 Series Flow Meter

Intentionally Left Blank

26 Fluid Components International LLC

Page 31

ST100 Series Flow Meter APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS

APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS

Fluid Components International LLC 27

Page 32

APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS ST100 Series Flow Meter

28 Fluid Components International LLC

Page 33

ST100 Series Flow Meter APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS

Fluid Components International LLC 29

Page 34

APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS ST100 Series Flow Meter

D

APPROVED

1

DATE

REVISIONS

DESCRIPTION

REV

1.13

1 1/4 INCH NPT PROCESS CONNECTION,

LOW PRESSURE PACKING GLAND.

(TEFLON OR GRAPHITE PACKING MATERIAL)

6

4 3 2

29

"FP" STYLE HEAD

"S" STYLE HEAD

C

"U" LENGTH

159

6.25

GROUNDING SCREW

4X CONDUIT PORTS

1/2 INCH NPT OR M20

197

7.75

B

SPECIFICATIONS:

CUSTOMER:

PURCHASE ORDER NO:

CUSTOMER ORDER NO:

WETTED SURFACE MATERIAL:

108

83

TYP

.31

8

279

11.0

.25

127

5.0

6.35

A

FLUID COMPONENTS

INTERNATIONAL LLC

R

SAN MARCOS, CA 92078

HAZ LOC / TYPE 4X / IP67

REMOTE ELECTRONICS ASSEMBLY

TRANSMITTER, ST100, 1 1/4 INCH NPT PGL

TITLE

06/10/11

APPROVALS

MAX ELEMENT OPERATING TEMP:

PROCESS CONNECTION:

PACKING MATERIAL:

"U" LENGTH:

SERIAL NO.(S):

TAG NO.(S):

DRAWN

FOUAD.C

CHECK

ONLINE/INSTALLATION DRAWING

4.25

3.25

1.75

.75

44

19

2.25

57

APPROVALS

CONTRACT NO.

CONTRACT

±1/2°

ANGULAR

NOTED

TOLERANCES

DIMENSIONS ARE IN INCHES

.X ±.1

UNLESS OTHERWISE SPECIFIED

.XX ±.03

DECIMALS

.XXX ±.010

MATERIAL

USED ON

USED_ON-XX

APPLICATION

THIRD ANGLE PROJECTION

NEXT ASSY

NEXT_ASSY

-

REV

1 OF 1

1

SHEET

004852

NONE

SCALE

DWG NO.

64818

CAGE CODE

D

SIZE

ENGR

3 2

MFGQAQUAL

.030

MACH RAD:

PARTS TO BE FREE OF

BURRS & SHARP EDGES

DO NOT SCALE DRAWING

FINISH: 125 RMS

MACH SURFACE

4

MOUNTING ORIENTATION OF FLAT

TO BE PARALLEL TO FLOW

LOCKING COLLAR

7 6 5

4.68

NOTICE OF PROPRIETARY RIGHTS

8

LOCAL ENCLOSURE MEETS EXPLOSION

PROOF WATER AND DUST TIGHT APPROVALS.

you is expressly conditioned upon your assent that its use is limited to use within your company

without prior written consent of FCI.

This document contains confidential technical data, including trade secrets and proprietary

information which is the property of Fluid Components International (FCI). Disclosure of this data to

only (and does not include manufacture or processing uses). Any other use is strictly prohibited

119

(SEE MANUAL FOR SPECIFIC APPROVAL TYPES)

D

MAX

91

3.60

123

4.86

109

4.28

1 INCH NPT PORT

137

5.40

GLAND ASSEMBLY

FLOW ELEMENNT AND PACKING

C

178

7.00

127

5.00

REMOTE ENCLOSURE MEETS

STAINLESS STEEL TAG

3/4 INCH PLUG

DISPLAY

2X M4 SCREWS

EXPLOSION PROOF WATER

AND DUST TIGHT APPROVALS.

(SEE MANUAL FOR SPECIFIC

APPROVAL TYPES)

REMOTE ELECTRONICS ASSEMBLY

B

MOUNTING BRACKET,

ALUMINUM

C].

C].

F [454

F [260

7 6 5

8

PACKING GLAND SPECIFICATIONS:

- MAXIMUN OPERATING TEMPERATURE, TEFLON PACKING: 500

- MAXIMUM OPERATING PRESSURE: 50 PSIG [3.5 BAR(G)].

5. SEE INSTRUMENT MANUAL FOR ADDITIONAL INFORMATION

AND INSTRUCTION.

4. ALL ORIENTATIONS AND/OR MOUTING REFERENCES ARE INDICATED FROM TERMINAL

ENCLOSURE END OF SENSING ELEMENT.

6.

- MAXIMUM OPERATING TEMPERATURE, GRAPHITE PACKING: 850

3. FOR ELECTRICAL OPTIONS, CONNECTIONS AND TESTS, SEE APPLICABLE WIRING DIAGRAM.

NOTES: UNLESS OTHERWISE SPECIFIED

2. THIS DRAWING IS REFERENCE DOCUMENT ONLY.

1. DIMENSIONS IN BRACKET [ ] ARE IN MILLIMETERS.

A

30 Fluid Components International LLC

Page 35

ST100 Series Flow Meter APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS

1

4 3 2

APPROVED

DATE

REVISIONS

DESCRIPTION

REV

7

13.00

330

38

1.50

"U" LENGTH

MAX

165

6.50

MIN

2.25

57.15

MAX

D

1.13

29

1 1/4 INCH NPT PROCESS CONNECTION,

LOW PRESSURE PACKING GLAND.

(TEFLON OR GRAPHITE PACKING MATERIAL)

6

MOUNTING ORIENTATION OF FLAT

TO BE PARALLEL TO FLOW

C

"S" STYLE HEAD

"FP" STYLE HEAD

GROUNDING SCREW

4X CONDUIT PORTS

1/2 INCH NPT OR M20

197

7.75

2X ADJUSTING RODS

B

SPECIFICATIONS:

CUSTOMER:

PURCHASE ORDER NO:

CUSTOMER ORDER NO:

WETTED SURFACE MATERIAL:

108

83

TYP

.31

8

279

11.0

.25

127

5.0

6.35

A

FLUID COMPONENTS

INTERNATIONAL LLC

R

SAN MARCOS, CA 92078

HAZ LOC / TYPE 4X / IP67

REMOTE ELECTRONICS ASSEMBLY

TRANSMITTER, ST100, 1 1/4 INCH NPT PGM

TITLE

06/10/11

APPROVALS

MAX ELEMENT OPERATING TEMP:

PROCESS CONNECTION:

PACKING MATERIAL:

"U" LENGTH:

SERIAL NO.(S):

TAG NO.(S):

DRAWN

FOUAD.C

CHECK

ONLINE/INSTALLATION DRAWING

4.25

3.25

19

.75

44

1.75

57

2.25

MOUNTING BRACKET,

ALUMINUM

APPROVALS

CONTRACT NO.

CONTRACT

±1/2°

ANGULAR

NOTED

TOLERANCES

DIMENSIONS ARE IN INCHES

.X ±.1

UNLESS OTHERWISE SPECIFIED

.XX ±.03

DECIMALS

.XXX ±.010

MATERIAL

USED ON

USED_ON-XX

APPLICATION

THIRD ANGLE PROJECTION

NEXT ASSY

NEXT_ASSY

-

REV

1 OF 1

1

SHEET

004877

NONE

SCALE

DWG NO.

64818

CAGE CODE

D

SIZE

ENGR

3 2

MFGQAQUAL

.030

MACH RAD:

PARTS TO BE FREE OF

BURRS & SHARP EDGES

DO NOT SCALE DRAWING

FINISH: 125 RMS

MACH SURFACE

4

"U" LENGTH +

7 6 5

4.28

109

4.86

123

8.00

203

178

7.00

LOCKING COLLAR

5.00

127

REMOTE ENCLOSURE MEETS

EXPLOSION PROOF WATER

AND DUST TIGHT APPROVALS.

(SEE MANUAL FOR SPECIFIC

APPROVAL TYPES)

DISPLAY

2X M4 SCREWS

3/4 INCH PLUG

C].

C].

F [454

F [260

7 6 5

STAINLESS STEEL TAG

140

5.53

NOTICE OF PROPRIETARY RIGHTS

8

you is expressly conditioned upon your assent that its use is limited to use within your company

This document contains confidential technical data, including trade secrets and proprietary

information which is the property of Fluid Components International (FCI). Disclosure of this data to

only (and does not include manufacture or processing uses). Any other use is strictly prohibited

LOCAL ENCLOSURE MEETS EXPLOSION

PROOF WATER AND DUST TIGHT APPROVALS.

(SEE MANUAL FOR SPECIFIC APPROVAL TYPES)

without prior written consent of FCI.

D

1 INCH NPT PORT

GLAND ASSEMBLY

FLOW ELEMENNT AND PACKING

C

REMOTE ELECTRONICS ASSEMBLY

DEPICTS SUPPORT ROD AND ENCLOSURE POSITION WHEN FULLY INSERTED.

PACKING GLAND SPECIFICATIONS:

- MAXIMUN OPERATING TEMPERATURE, TEFLON PACKING: 500

7.

- MAXIMUM OPERATING PRESSURE: 250 PSIG [17 BAR(G)].

5. SEE INSTRUMENT MANUAL FOR ADDITIONAL INFORMATION

6.

- MAXIMUM OPERATING TEMPERATURE, GRAPHITE PACKING: 850

B

AND INSTRUCTION.

4. ALL ORIENTATIONS AND/OR MOUTING REFERENCES ARE INDICATED FROM TERMINAL

ENCLOSURE END OF SENSING ELEMENT.

3. FOR ELECTRICAL OPTIONS, CONNECTIONS AND TESTS, SEE APPLICABLE WIRING DIAGRAM.

2. THIS DRAWING IS REFERENCE DOCUMENT ONLY.

A

8

NOTES: UNLESS OTHERWISE SPECIFIED

1. DIMENSIONS IN BRACKET [ ] ARE IN MILLIMETERS.

Fluid Components International LLC 31

Page 36

APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS ST100 Series Flow Meter

32 Fluid Components International LLC

Page 37

ST100 Series Flow Meter APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS

Fluid Components International LLC 33

Page 38

APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS ST100 Series Flow Meter

34 Fluid Components International LLC

Page 39

ST100 Series Flow Meter APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS

Fluid Components International LLC 35

Page 40

APPENDIX A - OUTLINE DIMENSIONAL DRAWINGS ST100 Series Flow Meter

Intentionally Left Blank

36 Fluid Components International LLC

Page 41

ST100 Series Flow Meter APPENDIX B - WIRING DIAGRAMS

APPENDIX B - WIRING DIAGRAMS

Fluid Components International LLC 37

Page 42

APPENDIX B - WIRING DIAGRAMS ST100 Series Flow Meter

Figure B-1: Integral - AC Input Power, Analog and HART Output

Figure B-2: Remote - AC Input Power, Analog and HART Output

38 Fluid Components International LLC

Page 43

ST100 Series Flow Meter APPENDIX B - WIRING DIAGRAMS

Figure B-3: Integral - DC Input Power, Analog and HART Output