Page 1

CHAPTER 1 - GENERAL INFORMATION FLUID COMPONENTS INTL

1. General Information

Description

This document explains the operating principle of the Model RF83 Flow Switch. The following pages also present

the recommended procedures for the installation, operation, maintenance, and troubleshooting of the Model RF83.

The Model RF83 is an instrument that is capable of detecting bi-directional liquid or gaseous flow environments.

The instrument has field adjustable alarm set points for control of the media.

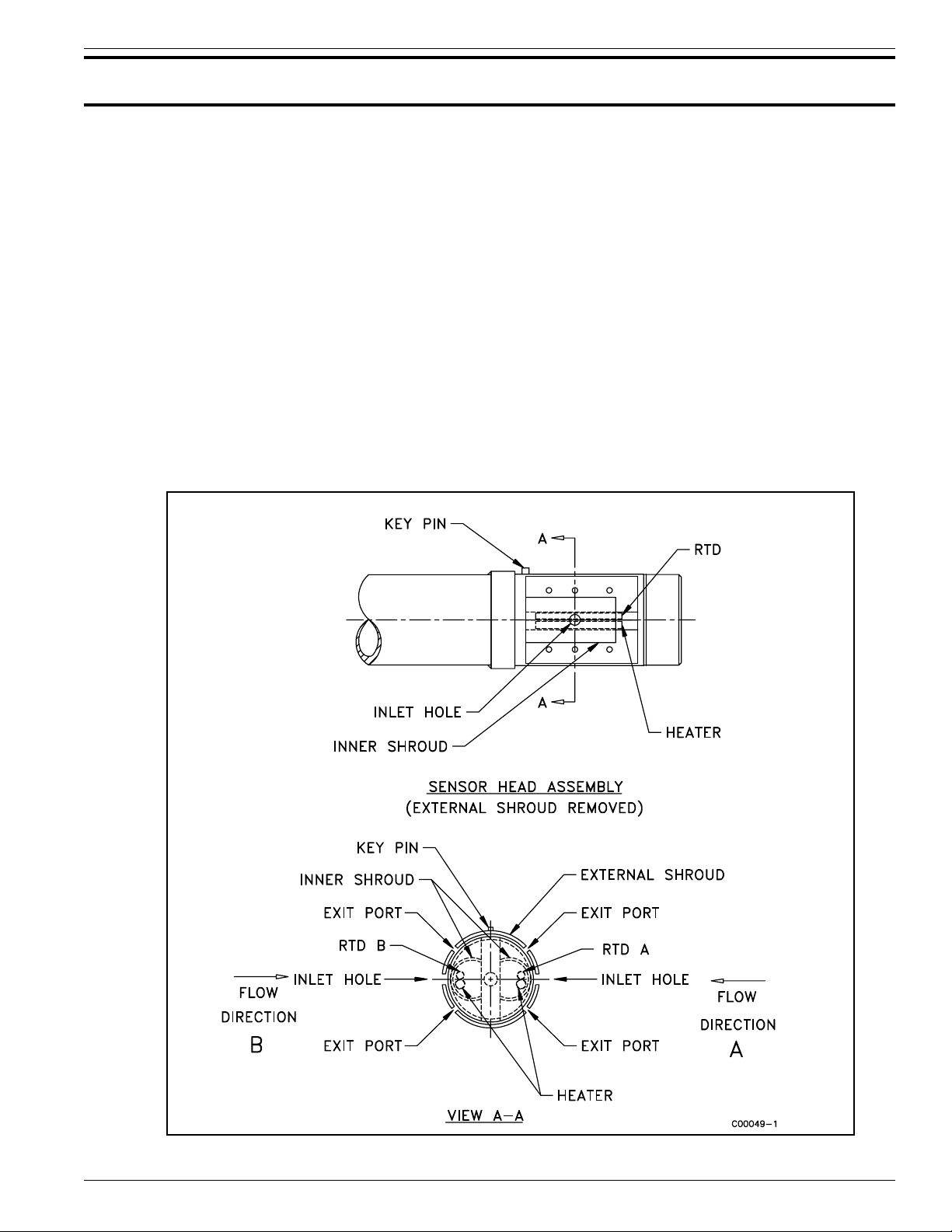

Flow Element

The operational parts of the flow element are the sensing points. The sensing points consist of four thermowells

(hollow tubes). There is two pair of thermowells welded together. The thermowell pairs have a heater in one

thermowell and a Resistance Temperature Detector (RTD) in the other thermowell. The thermowell pairs (sensing

points) are placed on opposite sides of a flow media barrier. There is a baffle placed around the sensing points to

direct the flow across the up-stream sensing point. As the flow media flows from sensing point B to sensing point A

(as shown in Figure 1-1) the flow media removes heat from the up-stream, heated RTD. There is no effect on the

heated RTD A. A delta R (DR) exists between the two RTD's that the electronics measures. If the flow reverses

RTD A looses heat and not RTD B.

Doc. No. 003147 Rev. B

Figure 1-1. Process Installation Showing the Sensing Point

1 - 1

Model RF83 Flow Switch

Page 2

FLUID COMPONENTS INTL CHAPTER 1 - GENERAL INFORMATION

Control Circuit

The basic functions of the control circuit are to provide power to the flow element, measure the DR between the two

RTDs, condition the sensing point signals, and provide relay alarm contacts for customer uses.

Single pole double throw (SPDT) or double pole double throw (DPDT) relays are available in the instrument for

connections to the customer alarm systems. The relay outputs can be set for either open or closed contacts when

there is either flow or no flow of the process media.

The place where the relays change state will vary depending on the type of media as well as air or liquid turbulence.

Therefore the instrument has field adjustable alarm set points.

Specifications

• Process Connections:

1 inch male NPT, 1-1/4 inch male NPT, or larger

flanged connections.

• Insertion Length:

2 inch (50mm) U-length, standard. Customer

specified U-length optional.

• Material of Construction:

All wetted surfaces are 316 series stainless steel with

nickel braze per process specifications AMS 4777.

Optional wetted surface material customer specified.

• Alarm Set Points:

Setable to any value within the indicated flow range.

5mV hysteresis. All units are preset with set-points

at mid-range in water. Factory certified alarm set

points available.

• Time Response:

5 to 150 seconds.

• Flow Rate:

From: 1 - 40 f/s (.3 - 12m/s) in air

To: .05 - .5 fps (.15 - 150 mm/s) in water.

• Electrical Connection:

• Relay Rating:

SPDT contacts rated at 6A at 115 Vac or 24 Vdc

resistive, relay coil de-energized at no-flow (standard

option). Optionalcontact and/or coil arrangements

are customer specified.

• Power Input:

100-132 Vac, 50/60 Hz, 6 watts maximum (standard

option). 24 Vac. 24 Vdc or 230 Vac are customer

specified.

• Electrical Enclosure:

Electrical components mounted in a NEMA 7 BCD

electrical enclosure. NEMA 4 and NEMA 4X

enclosures customer specified.

• Operating Temperatures:

Flow element: -100° to +350°F (-73° to +177°C).

Control circuit: -40° to +140°F (-40° to +60°C).

• Operating Pressure:

To 4000 psig (276 bar).

• Options:

Retractable probe and packing gland assemblies.

• Approvals:

1 inch female NPT

Model RF83 Flow Switch

1 - 2

FM, CSA, CENELEC, JIS and SAA for hazardous

locations.

Doc. No. 003147 Rev. B

Loading...

Loading...