Page 1

DOCUMENT NUMBER

Uncontrolled Copy

This document is current on the FCI Website or the FCI intranet Quality Document Control program.

li

ic

SUBJECT

Quality Manual

PREPARED BY:

allp7

CAGE CODE

64818

1

1

1

01

7

LTI

DATE

10-8-2012

QUALITY MANUAL

SECTION

.11

07QA070003

PAGE

CURRENT

REVISION

L

Burt Tanaka

Quality Assurance Manager

Ronald E. Ogle

Director of Administr n & Quality

APPROVED BY:

Signature on File

President

Page 2

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

ii

CURRENT

REVISION

L

COMMITMENT TO QUALITY

FLUID COMPONENTS INTERNATIONAL LLC will hire experienced personnel, continually

train them, and clearly define their responsibilities in order to provide the highest level of quality

products and services to the wide variety of markets and industries that we support. All

employees will be responsible for quality and are expected to participate in continuous quality

improvement functions so that industry standards will be met or exceeded. Employees will also

be expected to take initiative in continuously improving processes and in their own selfdevelopment skills. Employees will be provided the tools, instructions, and authority to act in

the best interest of the company with regard to the quality of our products and or service. The

Quality Assurance and Quality Control organizations will function as a catalyst to establish

informational quality needs, compliance standards, mutual improvement targets, process

changes, and overall quality focus. These organizations will demonstrate continuous

communications and collaboration with all operational departments.

The Quality Assurance organization is chartered with defining and enforcing the standards that

are specific to the various industries that we service. Quality Assurance shall either integrate or

isolate those requirements so that we efficiently meet all industry specific quality expectations.

The Quality Manual that follows shall be used as an internal baseline for quality processes. The

Manual will serve as a standard for which we will compare our performance. The Manual will

be a living document and will be regularly updated with improvements and changes that are

necessary to meet the evolving business environment. The Manual will additionally reflect our

commitment of quality to our customer base and will be readily available for review and

recommendations.

The President

Page 3

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

iii

CURRENT

REVISION

L

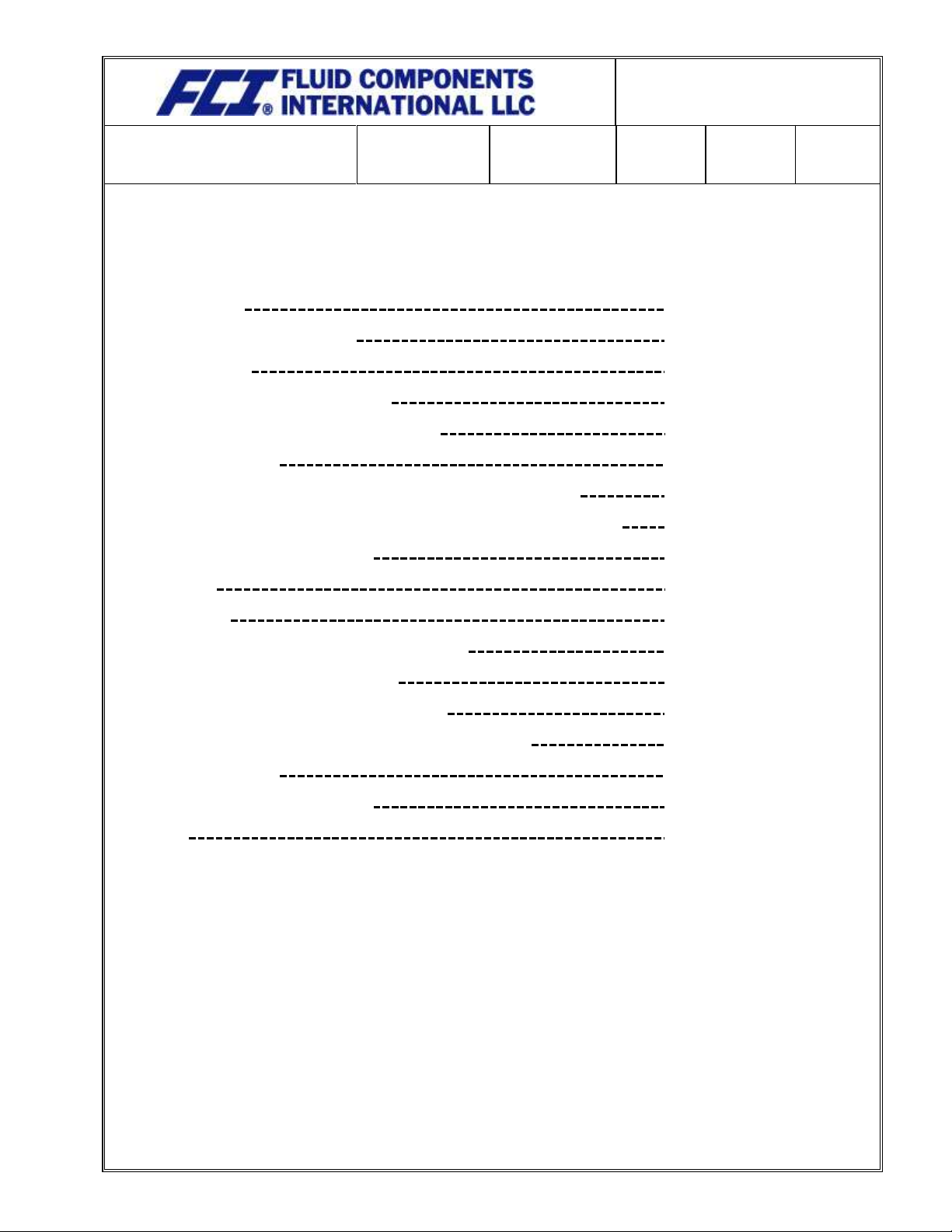

TABLE OF CONTENTS

DESCRIPTION

SECTION

PAGE

Title Page

-

i

Commitment to Quality Statement

-

ii

Table of Contents

-

iii

Revision Page

-

iv, v,

Quality Management System

-

vi-viii

Appendix A

-

ix

Appendix B

-

x-xii

Appendix C

-

xiii

Appendix D

-

xiv-xviii

Section One

1

1 – 19

Section Two

2

1 – 32

Section Three

3

1 -- 21

Page 4

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

iv

CURRENT

REVISION

L

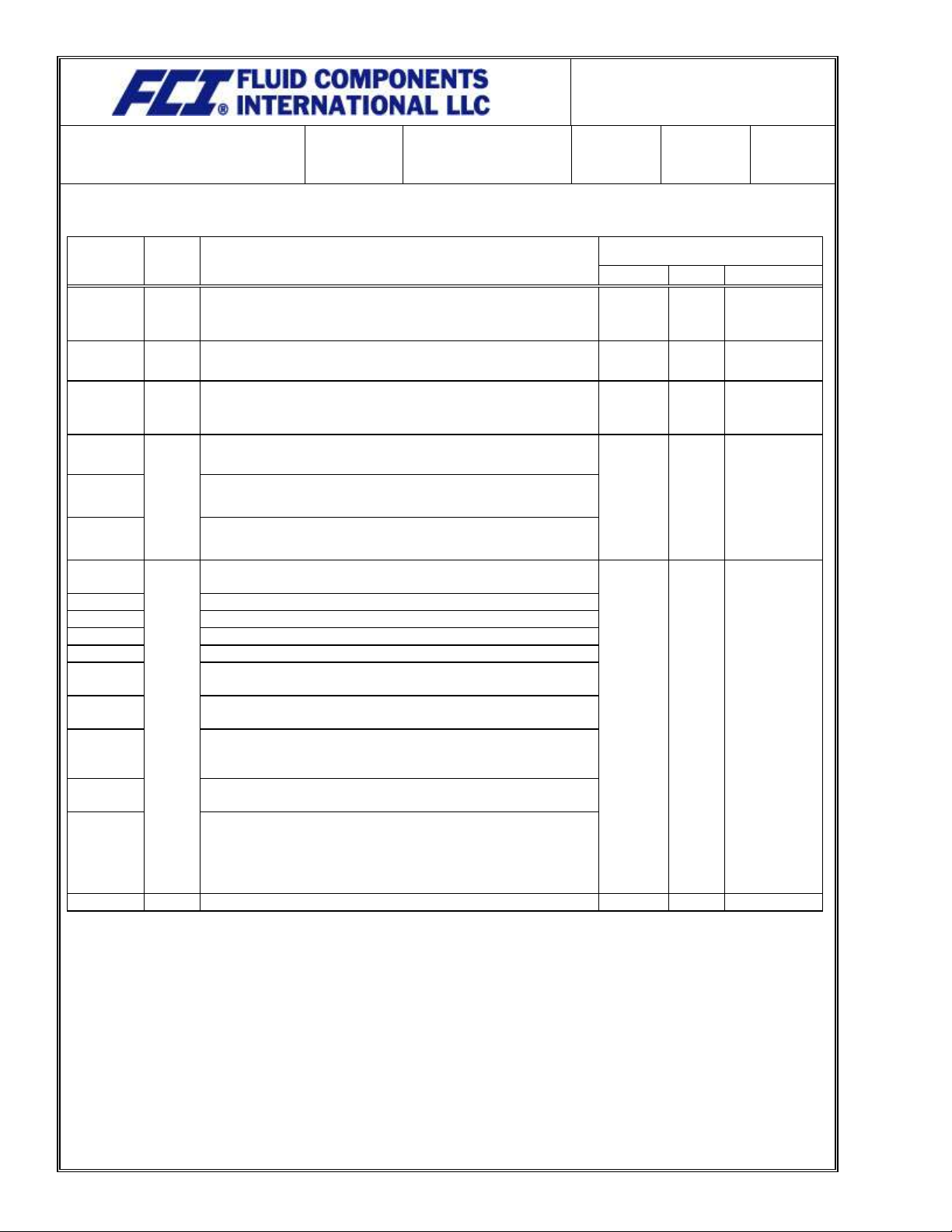

REVISION PAGE

Location

REV

DESCRIPTION

APPROVALS

DATE

QA

CO.MGMT.

N/A A COMPLETELY REVISED from QA Manual 8003 Rev. K.

Changed to new numbering system. Initial release at new number

is Rev. A

7-1-97

SM

DMQ

DMF

B Revised to incorporate process changes required as a result of

installing a new business system

2-03-98

SM

DMQ

DF

C Completely revised to incorporate AS9100 and ISO9001

requirements. Made changes to what is now “Section Three”,

(previous “Control Manual in its entirety).

8-24-00

REO

DMQ

REO

2 of

Section 2

D

Added the second paragraph in “1.0 Scope”

10-9-00

REO

DMQ

REO

All, (four

places)

Changed “AS9100” to include “AS9000”, i.e., “AS9000/AS9100”.

2-03-98

SM

DMQ

DF

28 of

Section 2

Added “customers and” (regulatory authorities …) to the last

sentence in 4.16.

8-24-00

REO

DMQ

REO

All E Renumbered pages as necessary

7-31-02

REO

DMQ

REO

v Added (customer and Field Services)

viii Added and corrected “NQA-1” references

ix Updated Org Chart

x Reformatted, deleted 04QA704027, added several procedures.

2 Added second paragraph to 1.0

17 of

Section 1

Added “Notification” paragraph to 4.14.3

12 of

Section 3

Changed the reference from 04QA704027 to 01DM000064 in

paragraphs 5.3 & 5.4

14 of

Section 3

Deleted sentence pertaining to superscript on Op –Sheet and

changed reference from 04QA704027 to 01DM000064 in

paragraph 5.9.

16 of

Section 3

Added sentence pertaining to ASME Certificate to paragraph 7.1.1

17 of

Section 3

Added reference to Quality Assurance Procedure 04QA704032 to

paragraph 7.3

F

Completely revised

8-19-03

REO

DMQ

Page 5

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

v

CURRENT

REVISION

L

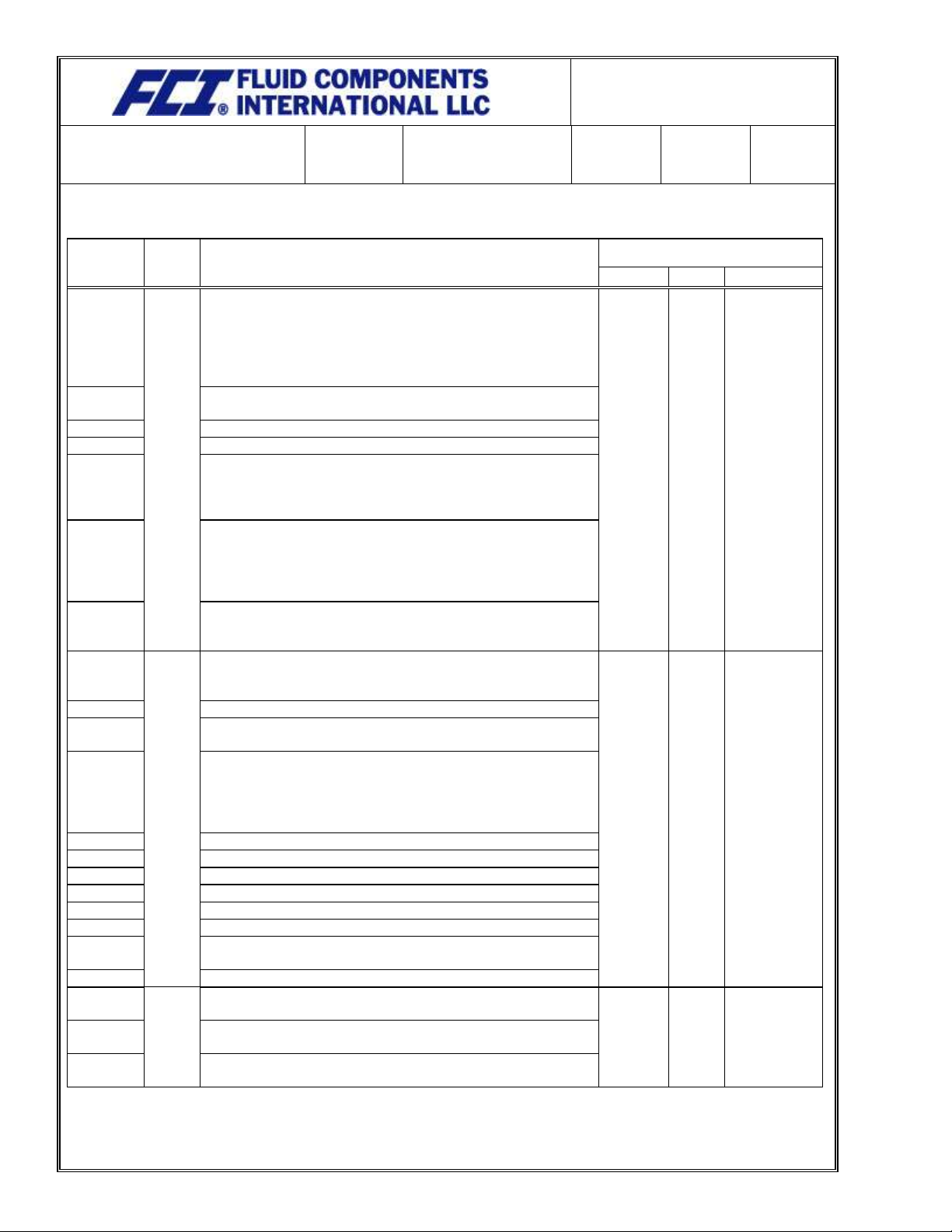

Location

REV

DESCRIPTION

APPROVALS

DATE

QA

CO.MGMT.

vi, x, xi,

section 2

pages 2,

10, 15, 16,

20, 22, &

23

G

Made references to 8100.7 in Appendix B and where applicable in

Section 2 of the manual per FAA request.

09/30/05

REO

DMQ

REO

ii Updated company‟s name

vi

Added “Industrial” to Controlled projects paragraph

ix

Change “ATEX” to “EX” in Appendix A

x

Deleted QAP 04QA704025, procedure was inactivated.

Corrected procedure # “07QA04044” to “04QA704044”

Corrected procedure # “04QA404062” to “04QA704062”

Renumbered index

xi

Corrected manual # “007QA070003” to “07QA070003”

Deleted “20” from the 8100.7 reference column for procedure

04QA704091. (No such paragraph exists)

Renumbered index

Updated company‟s name

xii

Updated procedure number reference to correlate to renumbering

of index on pages xi and xii

Added note to explain the number references

Sect 1;2

H

Revised the end of the first paragraph in 1.0 – Scope from “quality

system as it relates to all projects not identified as Controlled” to

“minimum quality system requirements”

09/30/05

REO

DMQ

REO

Sect 1;2

Included reference to “Ex” representative in paragraph 1.0 – Scope

Sect 1; 18

& 19

Included reference to “Ex” representative and 10 year record

retention requirement in 8.3 – Notification

Sect 3;2

Included the “B” in “Appendix B” in paragraph 1.1

Corrected “Appendix B of the manual” to Appendix D of the

manual” in paragraph 1.1

Corrected “Appendix B of the manual” to “Appendix A of the

manual” in paragraph 1.1

Sect 3;2

Updated company‟s name in paragraphs 1.1, 2.1 and 2.2

Sect 3;3

Updated company‟s name in paragraph 2.2

Sect 3; 4

Updated company‟s name in paragraphs 2.6 and 3.1

Sect 3;5

Updated company‟s name in paragraph 3.5

Sect 3;6

Updated company‟s name in paragraph 4.1

Sect 3;12

Updated company‟s name in paragraph 5.1

Sect 3;14

Updated company‟s name in paragraph 9.1

Sect 3;21

Updated company‟s name in paragraph 18.3

Sect. 7.1.

revised the end of paragraphs “(a)” & (b) to add

“Planning”

APX B

J

Made references in Appendix B and where applicable

per UL AS9100/ISO Audit request 2006

9/11/06

REO

REO

Sec 3

7.1.1

EDITED 7.1.1 APPROVED VENDORS LIST

requirements of ANSI/ISO/ISE 17025

Page 6

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

vi

CURRENT

REVISION

L

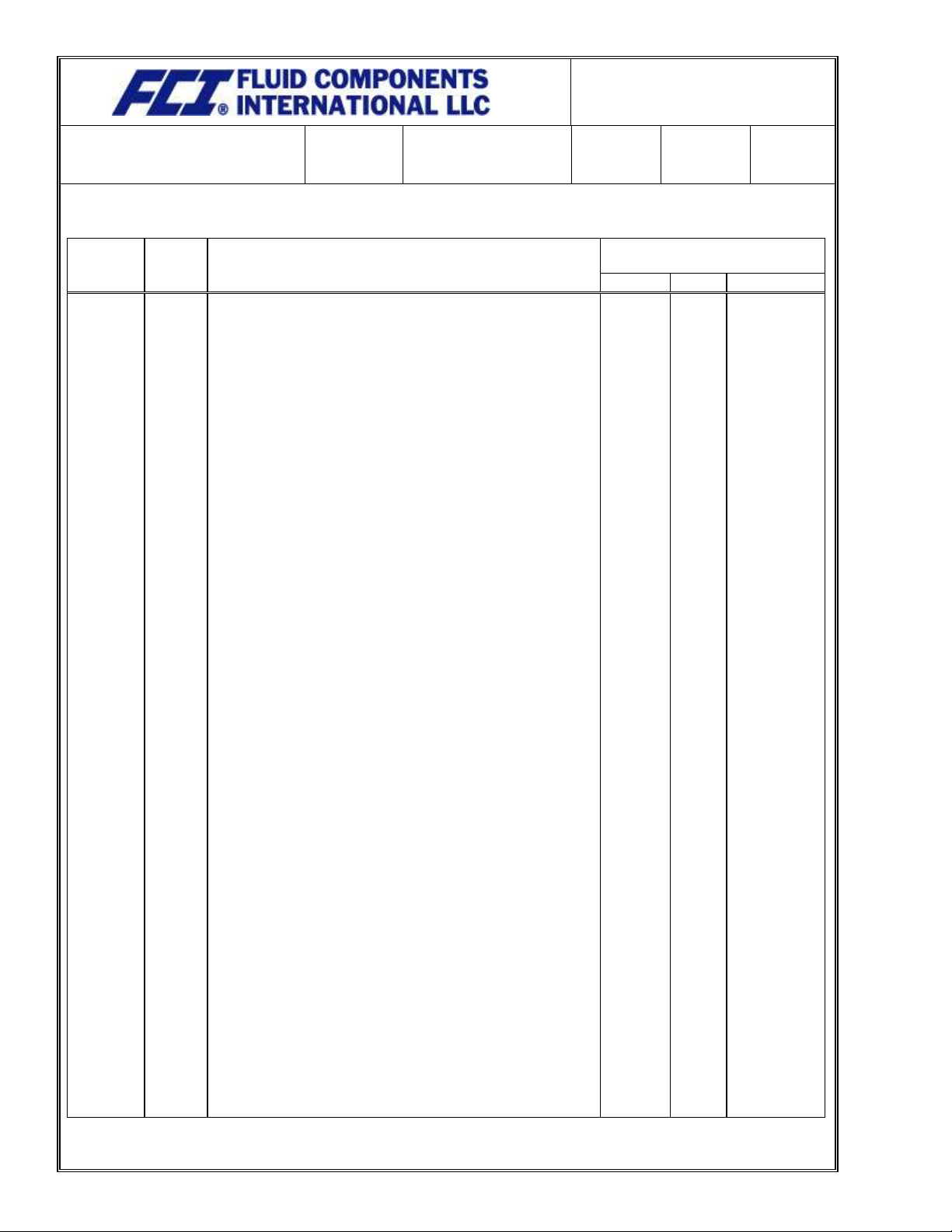

Location

REV

DESCRIPTION

APPROVALS

DATE

QA

CO.MGMT.

APXD

K

updated table of contents, added new revision page, added “EX

Representative” to Appendix D, deleted “pr” , Sec. 2 8.3 and

“DQS100” from 8.3, Changed all ISO9000 references from Rev.

A to “current rev.” Section 2, 3.0 added “Note” Removed

“Conformal Coat” from section 9.1(section 3) as a special

process. Removed personnel qualifications for Conformal Coat

from section 9.2

Revised Section 1 and 2 to ISO9001 2008 and AS9100C

respectively. Added new FAA regulations 21.137, etc. to Section

2.

Revised the org chart Appendix A and updated Appendix B.

Updated Appendix C.

Revised pages vi, vii, xv, and xviii

11/10/10

BC

REO

REO

Header

vii

APNX A

APNX B

APNX C

APNX D

Section 1

8.3

Section 2

8.2.3c

Section 2

8.2.4

Section 3

1.1

Section 3

2.2

Section 3

2.3

L

Changed Date of Origin to Date

Updated to current specification list. Removed reference to MILI-45208.

Organization Chart Revised.

Added Risk Management & Return to Service

Revised “Validation of Processes for Production and Service

Provision/ Special Procedure” to “Special Processes”

Revised Interrelationship Diagram per 2011 AS9100 Findings

Revised President responsibility for acting as QA Manager.

Added Director of Administration & Quality

Added Administering the ESD material to QA Staff.

Added Identifying Critical… to Nuclear Qualification Engineer

Added DMIR and Return-to-Service.

Removed Quality Engineer/Supervisory position

Corrected Production Test to Test and reporting to Engineering.

Changed 8.3 for EN13980:2002 Section 8.3 b & c

Duplicate information removed “c) Identify and control the

nonconforming product” and 8.2.3.e.

Revised “reorganized” to “recognized”, typographical error.

Removed reference to a specific revision 2000 for ISO and NQA-

1.

Removed reference to Rev A & B of the Manual.

Changed Yearly to Annual.

10/8/12

BT

REO

Page 7

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

vii

CURRENT

REVISION

L

Location

REV

DESCRIPTION

APPROVALS

DATE

QA

CO.MGMT.

Section 3

2.4

Section 3

2.6

Section 3

3.4

Section 3

3.5

Section 3

4.1

Section 3

5.1

Section 3

5.2

Section

5.3

Section 3

5.4

Section 3

Section 3

6.3.1

Section 3

6.3.2

Section 3

7.1

Section 3

7.1.1

Section 3

7.1.2

Section 3

7.2

L

Added “as required by contract.”

Aded “Manual Section 3.”

Added reference to procedure 04QA704091

Removed sentence “The same individual…verification and

analysis.”

Replaced “Fluid Components International LLC”, with “the

Company‟s.”

Revised first three sentences.

Removed requirement to send drawings and certified shippers.

Reworded redirection to paragraph 5.2

Removed the word “some”.

Added “A Process Sheet…the Operation Sheet.”

Removed reference to Process Manual.

Removed Process Manuals Replaced with the document control

system.

Replaced reference to “FCI” to “the Company”

Revised Document Change Notice to Engineering Change

Notice and DCN to ECN.

Replaced DCN with ECN.

Corrected reference to QR, Test Reports…

Replaced The Quality Department…

Added “Audits”

Complete revision.

Added “& Approved Vendor List(AVL)”

Added “Vendor performance…” and reference to listing

08QA080002.

Corrected procedure 04QA704046.

Removed “items as described in”

Replaced „purchased on “Commercial” Purchase Order‟

Replaced “transferred to “re-evaluated”

10/8/12

BT

REO

Page 8

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

viii

CURRENT

REVISION

L

Location

REV

DESCRIPTION

APPROVALS

DATE

QA

CO.MGMT.

Section 3

7.3

Section 3

7.4

Section 3

8.1

Section 3

8.2

Section 3

9.1

Section 3

10.2

Section 3

12.2

Section 3

16.2

Section 3

16.4

Section 3

17

Section 3

18.3

L

Removed third paragraph on Certified Shipper.

Replaced reference the obsolete table to the current database.

Removed See QAP 04QA704025 for more details on Parts List.

Removed explanation of Limited Life…

Corrected the Serialization system to show the current Business

System generated

Removed “utilized by FCI…”

Corrected the “When additional processes…”

Corrected “Currently Welding and Soldering…”

Corrected “according” to “accordance”

Corrected wording in the first sentence.

Added the option for a CPAR.

Removed DR are mostly…

Replaced 04QA704013 with Quality system Database; Quality

Records.

Added Critical Safety Characteristics Evaluation.

10/8/12

BT

REO

Date of effectivity for Revision L is April 8th, 2014

Burt Tanaka

2014.04.29

16:43:54 -07'00'

Page 9

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

ix

CURRENT

REVISION

L

Scope of Work

FCI manufactures Flow, Liquid Level, Temperature and Pressure Instrumentation, and Flow

Conditioners.

Quality Management System

This Quality Manual provides an overview of FCI‟s quality system and identifies the processes

used to ensure that our products and servicing (customer and Field Services) meet specified

requirements. The processes described in this Manual are aimed at achieving customer

satisfaction by preventing nonconformities at all stages of design, product realization, service, and

delivery.

The Quality Manual shall be in English and is available in the database system.

FCI has developed and implemented a quality management system, based on the ISO 9001 and

AS9100 (current revision), the Quality System Requirements of 10CFR50 Appendix B, 14CFR

Part 21.137 (a)-(n) and the basic Quality System Requirements of ANSI NQA-1-2000 to support

our quality policy. This Manual defines the quality management system. Procedures and work

instructions provide additional detail. Procedures address the “what, when and where” and

include responsibilities, objectives, and activities for each applicable function in the company.

Those procedures referring to particular revisions of the above standards shall be viewed as

complying with the current standards and not limited to the revisions that are referenced. Work

instructions provide step-by-step details on performing specific tasks, and include criteria for

determining compliance.

Customer specific requirements, which are not addressed by the current quality system, are

considered on an individual project/contract/order basis, and communicated throughout FCI as

required.

The Quality Management system at FCI has been developed to accommodate three levels of

quality management. The level of quality management to be applied to a specific

project/contract/order is set at Contract Review and is suitably identified thereafter. The three

levels are defined as follows:

Industrial “Controlled” Projects: These projects include (but are not limited to) Nuclear Safety.

These types of projects/contracts/orders adhere to all the requirements of ISO 9001as defined in

Section One of this manual, the Quality System Requirements of 10CFR50 Appendix B, and the

basic Quality System Requirements of ANSI NQA-1as defined in Section Three of this manual.

These projects/contracts/orders and all associated data and documentation have the unique

identification of “Controlled”.

Aerospace Projects: These projects include all Aerospace identified projects. These types of

projects/contracts/orders adhere to all the requirements of ISO 9001, AS9100, and the Quality

System Requirements of 14CFR Part 21.137 (a)-(n) as defined in Section Two of this manual.

Page 10

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

x

CURRENT

REVISION

L

These projects/contracts/orders and all associated data and documentation are also identified as

“Controlled”.

All Other Projects:These projects include (but are not limited to) Commercial projects. These

types of projects/contracts/orders adhere to all the requirements of ISO 9001 as defined in section

one of this manual. Any and all projects/contracts/orders, data, and/or documentation not

identified as “Controlled” is deemed to fall within this level of quality management.

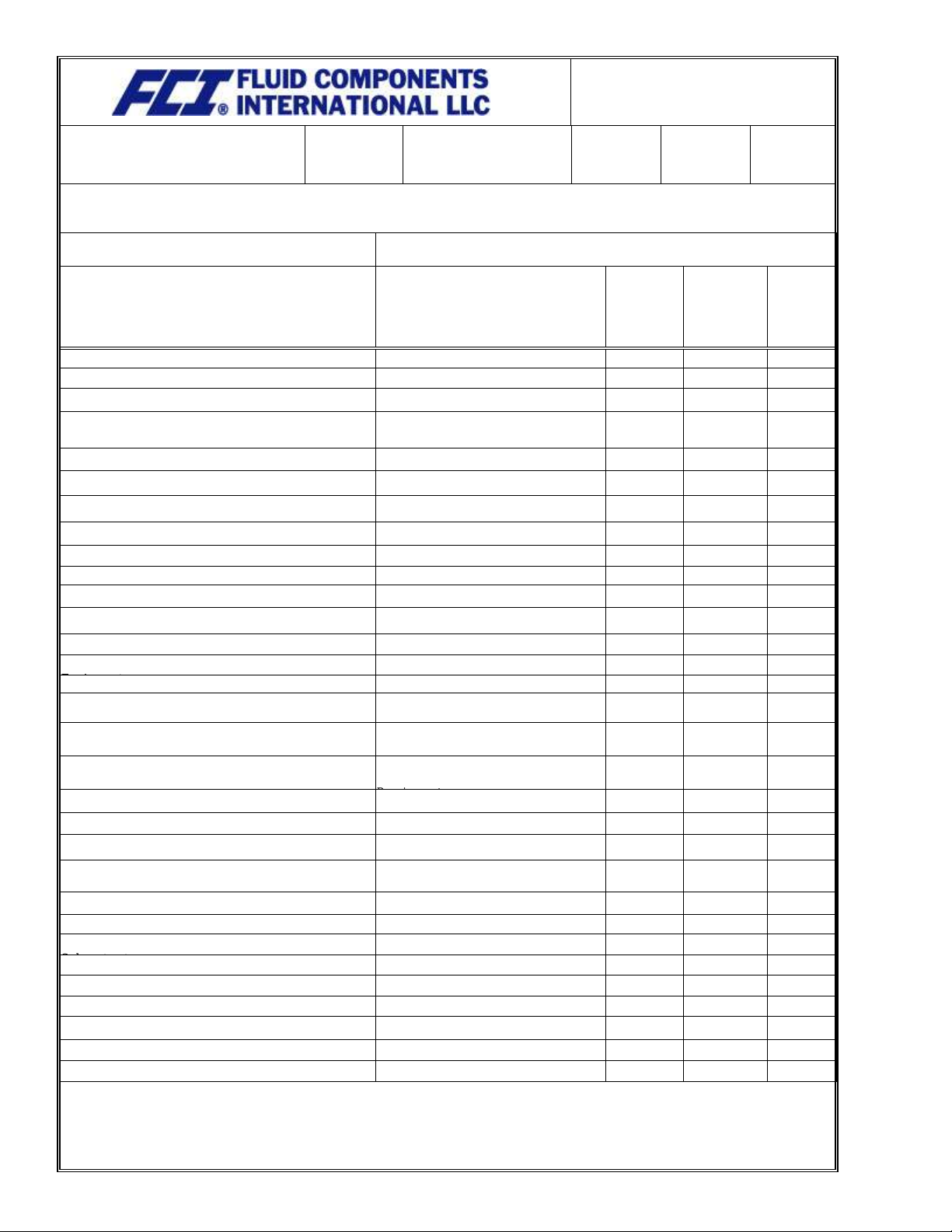

Hierarchy of Quality System Documents

Quality Manual: Level 1 document that provides a general overview of the quality

system and defines the quality policy.

Quality System Procedures: Level 2 documents that provide more detailed

explanation of the quality system elements and describe the structure of the quality

system.

Work Instructions: Level 3 documents that provide step-by-step instructions for

executing activities.

Quality Records: Level 4 documents or data that contain the data, charts, checklists,

or other records which demonstrate conformance to specified requirements and the

effective operation of the quality system.

Page 11

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xi

CURRENT

REVISION

L

Level 1

Level 2

Level 3

Level 4

Management definition of POLICIES

that support its quality system

Processes that define WHAT is done

to meet quality system requirements

Documents that describe HOW processes

are performed (more detail than Level 2)

Forms, reports or data that demonstrate

compliance to quality system requirements

Quality Manual

Work

Instructions

Procedures

Quality Records

Quality System Documentation Structure

Page 12

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xii

CURRENT

REVISION

L

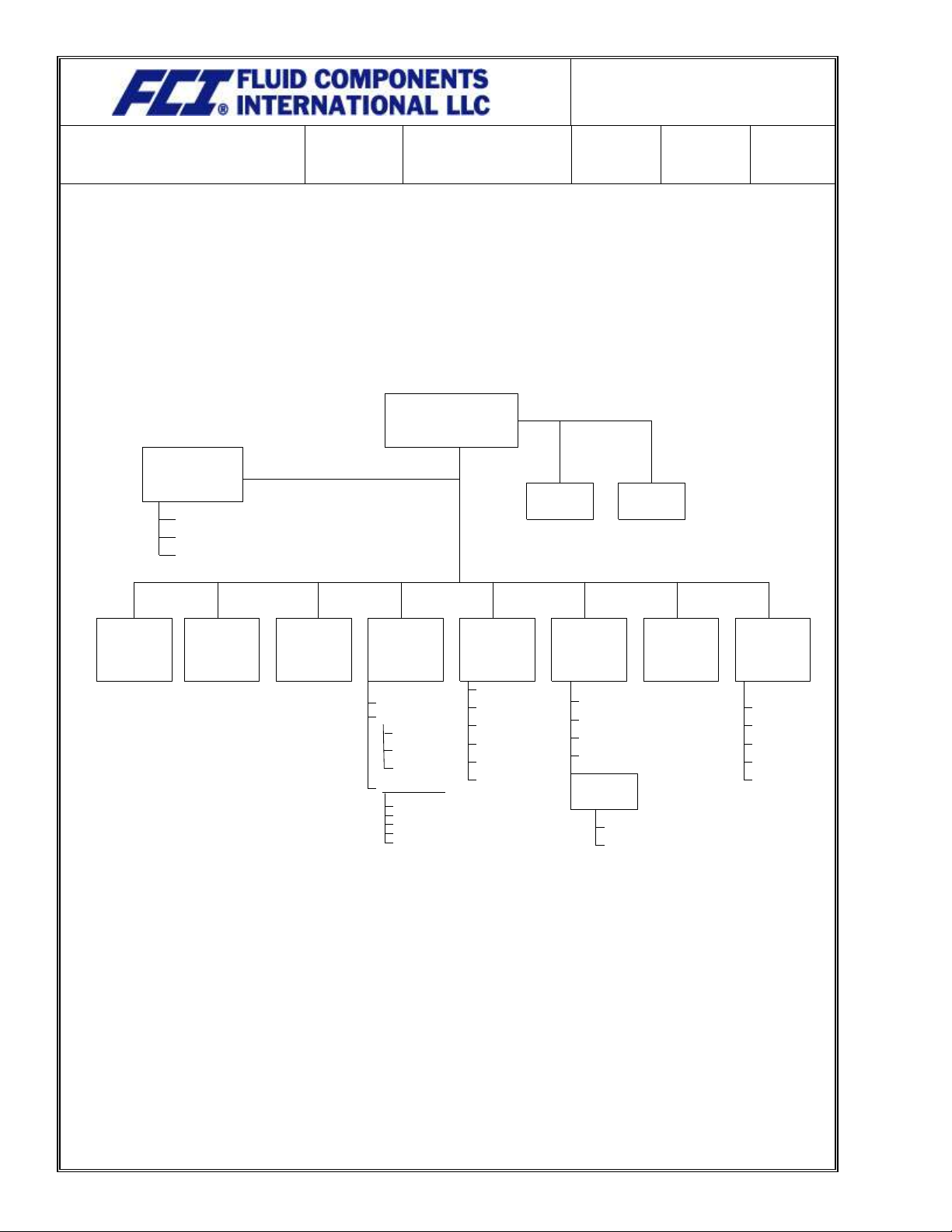

Appendix A: FCI Organization Chart

President & CEO

Executive

Assistant

General Manager

Aerospace Division

Manager

Marketing

Director

Human

Resources

Director

Manufacturing

Aero Production

Aero Engineering

Aero Sales & Service

Industrial Production

Manager

OEM Business

Development

Director

Of

Engineering

Director

Administration

&

Quality

Director

Finance

Director

Sales & Customer

Service

Document

Management

Engineering

Test

Vortab Engineer

Nuclear Qualification

Engineering

Quality Control

Information Systems

Legal

Facilities

Sales

Contract Mgmt

Cust. Service

Order Entry

Metrology

EX Representative

Management Rep

Planning

Material Control Mgr

Purchasing

Assembly

Circuit Board

Fabrication

Welding

Manufacturing Engr

DMIR

Return to

Service

QA Manager

Machining

Material Control

Page 13

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xiii

CURRENT

REVISION

L

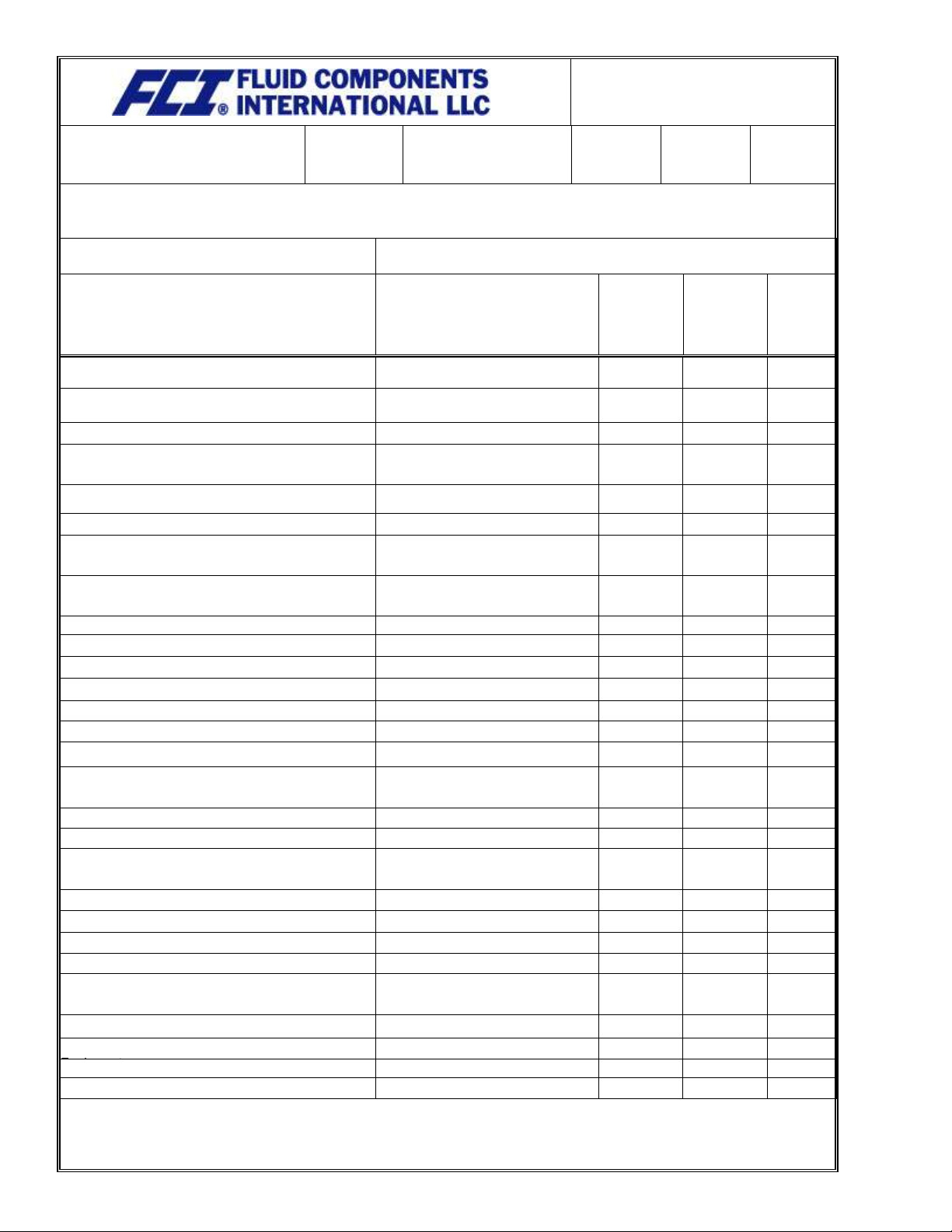

Appendix B: Interrelation of Quality System and ISO 9001/AS9100; FAR Clauses; and NQA-1.

Manual Sections

Level 1 & 2 Documents

Section 1 ISO9001

Section 2 AS9100

Section 3 NQA-1

AS / ISO

FAR Clauses

NQA-1 &

10CFR50

Appendix B

Quality Manual

Quality Management System

4.1

Quality Manual

Documentation Requirements

4.2.1

07QA070003, Quality Manual

Quality Manual

4.2.2 1

01DM000064/01DM000025, Engineering Document

Control

Control of Documents

4.2.3

21.137(b)

6

04QA704007, 04QA704102, Quality System

Control of Documents

4.2.3 6.2

04QA704013, Control of Quality Records

Control of Records

4.2.4

21.137(k)

17

04QA704052, Project Notebooks

Control of Records

4.2.4 17

04QA704078, Back-Up Procedure

Control of Records

4.2.4 17

Quality Manual

Management Responsibility

5.1 - 5.5.3

04QA704062, Management Review

Management Review

5.6.1 - 5.6.3

2.2

Quality Manual

Resource Management

6.1

04QA704034,Competence, Awareness, and Training

Human Resources

6.2.1- 6.2.2

2.6

04QA704097, Preventive Maintenance of the Building

Infrastructure

6.3 --

04QA704086, Preventive Maintenance of Process

Infrastructure

6.3 --

Quality Manual

Work Environment

6.4

Quality Manual

Planning

7.1-7.1.4

04QA704103, Risk Management

Risk Management

7.1.2,8.5.

3

04QA704002, Order Entry Procedure

Customer - Related Processes Identification of Product Related

7.2.1 3.1

04QA704005, Contract Review

Review of Product Requirements

7.2.2 3.1

Quality Manual

Customer Communication

7.2.3

04QA704091, Design and/Or Development

Design / Development

7.3.1 - 7.3.6

3

01DM000010, Design & Development Changes / ECO

Design and Development Changes

7.3.7

21.137(a)

3.5

04QA704044, Vendor Surveys

Purchasing Process

7.4.1

21.137(c)

7.1

04QA704077, Evaluation of Subcontractors

Purchasing Process

7.4.1 7.1.2

04QA704077, 04QA704046, Evaluation of

Purchasing Process

7.4.1 7.1

04QA704003, Purchasing Information

Purchasing Information

7.4.2 4

04QA704094, Signature Authorization

Purchasing Information

7.4.2 4

04QA704058, Plastic Coated Sensor Head Testing

Verification of Purchased Product

7.4.3

04QA704032, Testing Wetted Surfaces

Verification of Purchased Product

7.4.3 7.3

04QA704064, Hardness Testing

Verification of Purchased Product

7.4.3 7.3

04QA704001, Receiving Inspection

Verification of Purchased Product

7.4.3 8.1, 10

Page 14

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xiv

CURRENT

REVISION

L

Manual Sections

Level 1 & 2 Documents

Section 1 ISO9001

Section 2 AS9100

Section 3 NQ-A-1

AS / ISO

FAR 21.137

NQA-1

04QA704026, In-Process Inspection

Verification of Purchased

Product/Processing

7.4.3 8.1, 10

04QA704020, Job Orders

Production – Control

7.5.1

21.137(d)

5.2

04QA704048, Foreign Object Prevention

Production – Control

7.5.1 --

04QA704050, Return of Controlled Items for

Repair/Rework

Production – Control

7.5.1 10

04QA704074, Aerospace Return Items

Production – Control

7.5.1 --

04QA704079, Field Service/Installation Procedure

Production – Control

7.5.1 --

04QA704080, Repair Procedure

Commercial/Non-Safety

Production – Control

7.5.1 --

04QA704082, Production and Service Provision /

Process Control Procedure: Non-Controlled Jobs

Production – Control

7.5.1 --

04QA704084, Tooling Procedure

Production – Control

7.5.1 --

04QA704049, First Article

Production Validation

7.5.1,8.2.4

-

04QA704026, In-Process Inspection

Production - Validation

7.5.2 10

04QA704039, Welder Qualification

Production - Validation

7.5.2 9.2

04QA704057, Workmanship Standard

Production - Validation

7.5.2 9.2

04QA704088, Special Processes

Production - Validation

7.5.2 9.1

04QA704024, Issuing Stamps

Id & Traceability

7.5.3

45.15

14.3

04QA704067, Issuing Serial Numbers to Mil/Aero

Units

Id & Traceability

7.5.3 --

04QA704085, Product Id

Id & Traceability

7.5.3 --

04QA704055, Customer Property

Customer Property

7.5.4 7.6

04QA704018, Standard Handling, Packaging &

Shipping

Product Preservation

7.5.5

21.137(j)

13.3

04QA704019, Final Cleaning

Product Preservation

7.5.5 13.2

04QA704048, Foreign Object Prevention

Product Preservation

7.5.5 --

04QA704053, Dated Coded Materials

Product Preservation

7.5.5 7.4, 8.1

04QA704081, Storage

Product Preservation

7.5.5 13.1

04QA704010, Special Handling, Storage &

Shipping

Product Preservation

7.5.5 13.3.1

04QA704006, Calibration Program

Control of Monitoring / Measuring

7.6 12.1

04QA704029, Evaluation of Measuring & Test

Control of Monitoring / Measuring

7.6

21.137(f)

12.3

04QA704063, Inspection History

Measurement, Analysis & Improvement

8.1 --

04QA704076, On Time Delivery

Measurement, Analysis & Improvement

8.1 --

Page 15

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xv

CURRENT

REVISION

L

Manual Sections

Level 1 & 2 Documents

Section 1 ISO9001

Section 2 AS9100

Section 3 NQ-A-1

AS / ISO

FAR 21.137

NQA-1

04QA704098, Customer Satisfaction

Customer Satisfaction

8.2.1 --

04QA704008, Audits

Audits

8.2.2

21.137(l)

18.1, 18.2

04QA704054, Auditor Qualification

Audits

8.2.2 303 & /2S-3

Quality Manual

Monitoring & Measurement Processes

8.2.3

04QA704026, In-Process Inspection

Monitoring & Measurement Product

8.2.4

21.137(g)

21.137(n)

&

21.137(e)

8.1, 10.1

04QA704038, Final Inspection

Monitoring & Measurement Product

8.2.4 8.1, 10.1

04QA704058, Plastic Coated Sensor Head Testing

Monitoring & Measurement Product

8.2.4 8.1, 10.1

04QA704105, Return to Service Aero PMA Parts

Monitor & Measurement of Product

8.2.4 --

04QA704004, Control of Nonconforming Product

Control of Nonconforming Product

8.3

21.137(h)

15

04QA704011, 10 CFR 21.3 Reporting

Control of Nonconforming Product

8.3 15.3

04QA704075, Reporting to the FAA

Control of Nonconforming Product

8.3

21.137(n)

--

Quality Manual

Analysis of Data

8.4 & 8.1

21.137(n)

Quality Manual

Continual Improvement

8.5.1

04QA704070, Vendor Corrective Action

Corrective Action

8.5.2 16.1

04QA704083, Corrective and Preventive Action

Corrective Action

8.5.2 - 8.5.3

21.137(i),

21.137(m)

and

21.137(n)

16

04QA704070, Vendor Corrective Action

Preventive Action

8.5.3

04QA704093, Customer Response

Preventive Action

8.5.3 16

04QA704071, Commercial Grade Item Testing

-- 7.5

06QA020013, Qualification Verification Analysis

-- 3.4

06QA020014, Nuclear Item Dedication Plan

-- 7.5

*Paragraphs 425 & 612 are met by the procedures referenced, no cross-reference to the manual

paragraphs. Paragraph 612 is also met by manual paragraph 7.4.

Note: all “04QA” number sequences listed in this manual reflect Fluid Components International LLC‟s current

numbering system. The core number of the document is 704xxx, which remains the same regardless of the

prefix added. Some of the quality assurance procedures listed in this manual have not been revised since

the implementation of the 04QA system; therefore this note serves as notice that the document with the

core number 704xxx, regardless of the prefix represents the same document.

Page 16

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xvi

CURRENT

REVISION

L

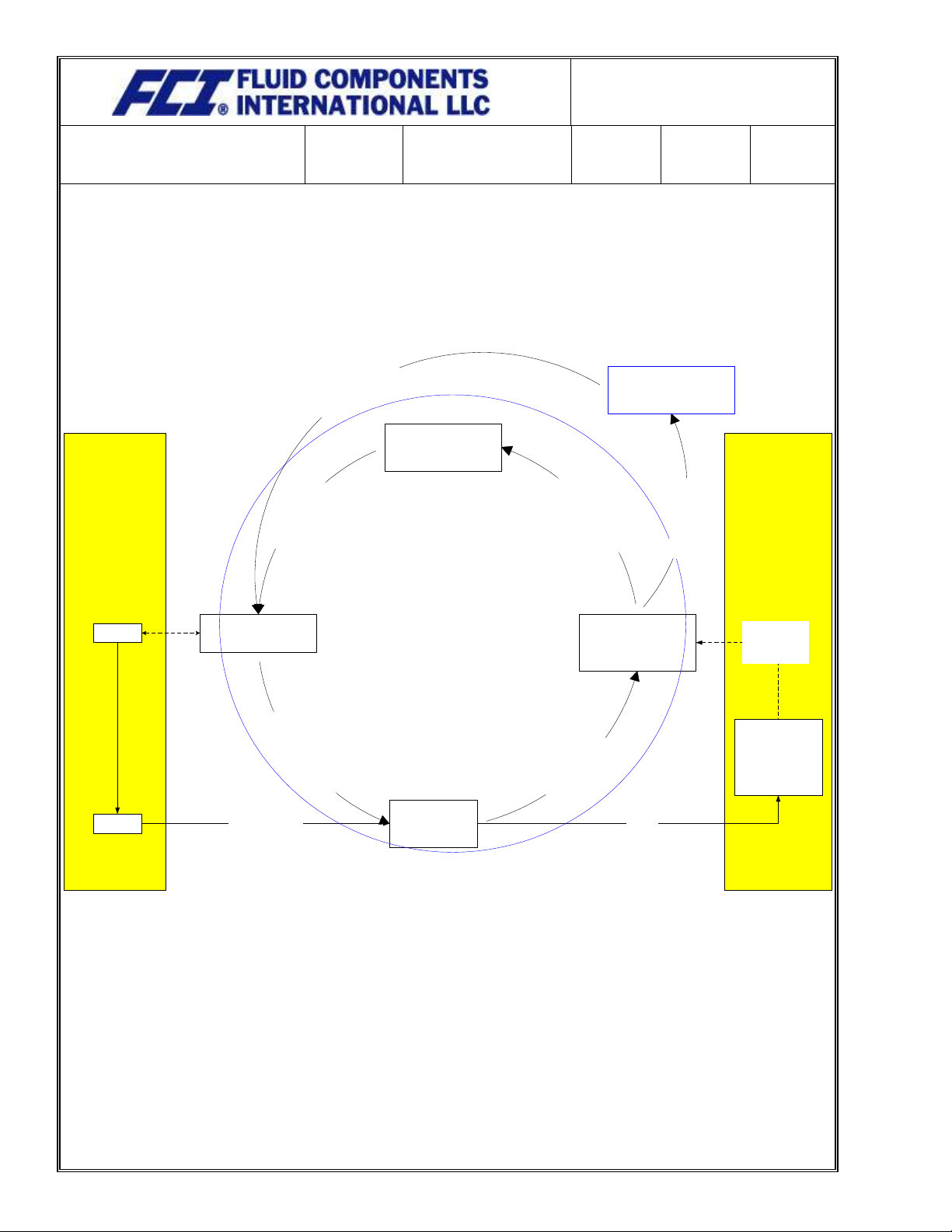

Appendix C: Interrelationships Diagram

Management

Responsibility

(23)

QMS Continuous Improvement

(10, 23, 30)

Continuous Improvement

Process Improvement

Teams

Risk Analysis 04QA704103

Resource Management

QM 07QA070003 Sec

6.1

Management

Responsibility

QM 07QA070003 Sec

5.5

Measurement,

Analysis,

& Improvement

QM 07QA070003 8.1,

8.4

Product

Realization

QM 07QA070003

Sec 7 & 8

Customers

Order

Acknowledgement

Contract Review

Customers

Product

Delivery Reports

CPARs

Customer

Reports

Satisfaction

Management Review

04QA704062 &

QM 07QA070003 Sec 5.6

Discrepancy Reports

Supplier Reports

Reports to Management Review

Reports to

Improvement Teams

Improvement Requests

Objectives & Policies

Improvements to the Process

Quotatio

n

Contrac

t

A description of the interaction between the processes of the quality management system:

Page 17

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xvii

CURRENT

REVISION

L

Appendix D: Structure, Responsibility, and Authority of the Quality Management System

President

The President is responsible, through the Director of Administration & Quality and the

Quality Assurance Manager, for the authorization and implementation of the Quality

Management System throughout the company, including:

The overall responsibility for the definition of, and adherence to, the quality policy.

Establishing quality goals and monitoring progress to ensure continued suitability and

effectiveness of the quality management system.

Providing the necessary resources to maintain the quality management system.

Conducting management reviews of the quality management system.

Monitor the audit team for timely completion of the annual Internal Quality Assurance

Program audit.

The President shall resolve matters regarding quality that the Director of Administration &

Quality and the Quality Assurance Manager determines necessary to bring to the attention of

executive management or cannot be resolved to the satisfaction of the Quality Assurance

Manager by any other means.

Director of Administration & Quality

In support of the President, the Director of Administration & Quality is responsible for:

Overseeing the Quality, Maintenance and Information Technology departments.

Providing counsel to the President when requested, and in support of the Company.

The Director of Administration & Quality shall act as the Quality Assurance Manager in

the Quality Assurance Manager‟s absence.

Quality Assurance Manager

In support of the President and Director of Administration & Quality, the Quality Assurance

Manager is responsible for:

Administering the Quality Management System and defining, measuring, and

maintaining the overall effectiveness and enforcement of the Program.

Identifying resources to maintain the quality management system.

Reporting to the President on a yearly basis as to the effectiveness of the Quality

Management System.

Reviewing organizational requirements and providing recommendations for changes.

Directing and auditing quality-related activities; and, reporting to and advising the

President and executive staff on quality matters.

Page 18

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xviii

CURRENT

REVISION

L

Ensuring the quality management system is maintained through appropriate audits, tests,

inspections, and surveys.

Leading and initiating actions to prevent the occurrence of any nonconformities relating

to product, process, and quality management system.

Reporting quality and nonconformance data and trends.

The Quality Assurance Manager delegates quality responsibilities to persons and

organizations within the company. (References to the Quality Assurance Manager

throughout this manual and the supplementary Quality Assurance Procedures shall mean the

Quality Assurance Manager or the Quality Assurance Manager's Representative.)

To liaise with the notified body responsible for the assessment of the quality system in case

of changes to the quality system, together with the EX representative

Managers and Supervisors

Actively support those responsible for implementing and improving the quality management

system.

Ensure the quality policy is fully supported, understood, implemented, and maintained at

appropriate levels of their organizations.

Ensure appropriate supporting procedures are documented and followed throughout their

respective departments.

Ensure adequate resources and prioritization; assign trained personnel to perform work and

verification activities including internal audits, and work affecting product quality.

When appointing a designee to act on their behalf for the purposes of any element of this

quality system, ensure the person appointed is adequately trained and given sufficient

organizational freedom and authority to execute the responsibility.

Initiate “stop shipment” as appropriate to prevent nonconformance, and then,

Initiate a documented corrective action procedure.

Maintain the “stop” until receipt of authorization and associated data and documentation to

release the “stop”.

Employees

Understand and support the quality policy and the appropriate elements of the quality

management system for their areas of work

Dedicate their efforts to the reduction, elimination, and prevention of quality deficiencies

Initiate action to prevent the occurrence of nonconformities related to product, process, and

quality system.

Page 19

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xix

CURRENT

REVISION

L

Specific Task performed throughout the organization

Quality Assurance Staff (Reports directly to the Quality Assurance Manager) has

responsibility for the following:

Reviewing, approving, and generating instructions, procedures, & forms,

Reviewing, approving internal and customer Purchase Orders,

Compiling project record notebooks,

Administering the Discrepancy Report program,

Auditing, and

Training and certifying personnel performing activities affecting quality.

Administering the ESD program.

Metrology Department (Reports to the Inspection Supervisor)

All in-house calibration of Measuring and Test Equipment shall be performed under the

direction of the Metrology Department. The Metrology Department is responsible for all

Measuring and Test Equipment and shall assure that the equipment is maintained in

accordance with Quality Assurance Procedure 04QA704006, “Calibration program”.

The Metrology Department is also responsible for generating calibration procedures for

Measuring and Test Equipment calibrated in house.

Contract Manager has authority and responsibility for the following:

Assuring that all contractual items, terms, and conditions are identified complied with

and/or met.

Participating as a Material Review Board member,

Acting as a drawing checker, and reviewing and approving Operation Sheets, Test

Procedures, and Test Reports for conformance with contractual requirements and FCI

practices.

Act as the primary liaison between the customer and FCI once a contract has been

accepted and obtaining customer response on all documents and drawings sent to the

customer for approval.

Director Of Engineering/Engineering Manager Staff

Ultimately responsible for design control.

Responsible for incorporating customer specifications, codes, standards, and

requirements into all approval and sub-assembly drawings to be used by the Production

and Quality Assurance/Control Departments.

Responsible for the generation of Operations Sheets, Process Sheets, Process Manuals,

and other such instructions and procedures required by the Production Department to

Page 20

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xx

CURRENT

REVISION

L

consistently build quality products.

Has the responsibility of controlling copies of the above referenced documents and

ensuring only current or specified revisions are used during the manufacturing process.

Engineering shall also ensure that obsolete or expired documents have been removed

from the factory floor.

Has the authority to participate as a member of the Material Review Board Committee.

Under the direction of Quality Control Metrology and Engineering, the Engineering Test

Group may be responsible for the calibration and maintenance of Flow Stands and

Measuring & Test Equipment used to calibrate product.

Nuclear Qualification Engineering (QE)

Responsible for maintaining qualification of Safety-Related Class 1E product through the

use of Similarity Analyses, Testing, and other appropriate methods.

Responsible for overseeing qualification test programs.

Participating in drawing reviews and the Material Review Board to address qualification

related issues.

Identifying critical characteristics for Commercial Grade Dedication of Components and

services.

Directors Of Manufacturing/Manufacturing Manager

Operations Management is responsible for the activities of the Planning, Purchasing,

Material Control, and Production.

Planning

Planners have the responsibility to schedule projects through the factory areas, obtain

controlled documents, requisition items, and issue Job Orders needed for each contract.

Purchasing

Purchasing is responsible for purchasing items, services, and equipment in accordance

with specific instructions and requirements.

Material Control

Material Control is responsible for all inventories; for providing items as required to fill

orders and maintaining lot control of items so identified. Material Control also has the

responsibility for receiving parts and outside processed goods as well as all aspects of

shipping product.

Page 21

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xxi

CURRENT

REVISION

L

Production

The Production groups perform the fabrication and assembly of shippable product in

accordance with applicable instructions, procedures, and drawings. Production is also

responsible to record the work and processing performed as required by these documents.

Test

Test shall perform all calibrations of instruments supplied to the customer. All

calibrations and tests shall be in accordance with the applicable contract requirements and

approved procedures. Test shall also perform such other tests as requested by the

Engineering, Production, or Quality Assurance Departments.

EX Representative

The EX Representative shall have the following responsibilities and authority:

Effective monitoring, dissemination, review and implementation of the latest applicable

technical knowledge

Effective coordination of activities with respect to products intended for use in

potentially explosive atmospheres

To liaise with the notified bodies in case of changes to the design in the EC-Type

Examination Certificate and the technical documentation

To liaise with the notified body responsible for the assessment of the quality system in

case of changes to the quality system, together with the Quality Assurance representative.

Authorize the initial approval and changes to related drawings

Authorize concessions if it does not take the product outside the design as defined in

the EC-Type Examination Certificate

Communicate information to the customer of special conditions or limitations

Participate in the Management Review Meeting

Page 22

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

DATE

10-8-2012

SECTION

-

PAGE

xxii

CURRENT

REVISION

L

Designated Manufacturing Inspection Representative (DMIR)

The DMIR shall be responsible to verify conformity by inspecting parts to be released per

the Production Approval Holder (FCI). The release is to conform to various sections of

14 CFR 183.31 as authorized and limited to the Official Certificate of Authority. The

authorization is limited to the Function Codes 01, 03, 05, 06, and 07.

Return-to-Service Inspector

The Return-to-Service Inspector shall be responsible for returning Aerospace PMA parts

used for aircraft and has been rebuilt or altered under the FAA Part 43, section 43.3(j).

Authorization is based on FCI‟s Production Certificate and FAA-Parts Manufacturing

Approval. Return-to-Service Aerospace PMA parts follow the procedure 04QA704105.

Personnel authorized to Return-to-Service under this provision are limited to the

“Personnel Authorized for Return –to-Service” attached to this manual.

Page 23

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

1

CURRENT

REVISION

L

SECTION ONE

DESCRIPTION

PAGE

1.0 Scope

2

2.0 Reference Documents

2

3.0 References

2

4.0 Quality Management System

2

5.0 Management Responsibility

4

6.0 Resource Management

7

7.0 Product Realization

9

8.0 Measurement, Analysis, and Improvement

16

Page 24

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

2

CURRENT

REVISION

L

1.0 SCOPE

The requirements described in this section, Section One, of the Quality Manual

provide an overview of FCI‟s minimum quality system requirements.

Issuance and changes to the manual shall be performed in accordance with

“Document and Data Control, paragraph 4.2.3 of this section of the manual.

Changes to this Manual that substantially effect the Quality System e.g. Change

of Quality Assurance Manger or EX Representative (ATEX, IECEx, etc.),

Certifications i.e. ISO, etc., shall be submitted to a Notified Body (ATEX, IECEx,

etc.) by the appropriate Representative (EX Representative, Management

Representative, Quality Assurance Manager, etc.) if required by the standard.

In addition, FCI shall know and understand the monitoring requirements and

applicable performance criteria for AMS and the impact of these requirements on

instrument design, manufacturing and certification pursuant to EN15267.

2.0 REFERENCED DOCUMENTS

This manual is supplemented by numerous procedures as identified in Appendix

“B” and referenced throughout this manual. Procedures other than those

referenced may also be used to implement the Quality Management system.

3.0 REFERENCES

ISO 9001 (current revision), Quality management systems - Requirements

4.0 QUALITY MANAGEMENT SYSTEM

4.1 GENERAL

FCI has established, documented, implemented, and maintains and continually

improves a quality management system in accordance with the requirements of

ISO 9001.

To implement the quality management system FCI will:

a) Determine the processes needed for the quality management system and their

application throughout the organization,

b) Determine the sequence and interaction of these processes,

c) Determine criteria and methods needed to ensure that both the operation and

control of these processes are effective,

d) Ensure the availability of resources and information necessary to support the

operation and monitoring of these processes,

Page 25

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

3

CURRENT

REVISION

L

e) Measure, monitor and analyze these processes, and

f) Implement action necessary to achieve planned results and continual

improvement of these processes.

FCI manages these processes in accordance with the requirements of the ISO

9001International Standard.

Where FCI chooses to outsource any process that affects product conformity with

requirements, the organization ensures control over such processes. The type and

extent of control to be applied to these outsourced processes shall be defined

within the quality management system.

4.2 DOCUMENTATION REQUIREMENTS

4.2.1 GENERAL

Documentation for the quality management system includes:

a) Documented statements of a quality policy and quality objectives,

b) A quality manual,

c) Documented procedures and records required by ISO 9001,

d) Documents including records determined by FCI to be necessary to ensure

the effective planning, operation and control of its processes.

4.2.2 QUALITY MANUAL

A quality manual is established and maintained that includes the following:

a) The scope of the quality management system, including details of, and

justification for, any exclusions,

b) The documented procedures established for the quality management system,

or reference to them (See Appendix B), and

c) A description of the interaction between the processes of the quality

management system (See Appendix C).

4.2.3 CONTROL OF DOCUMENTS

Documents required for the quality management system are controlled.

A documented procedure is established to define the controls needed:

a) To approve documents for adequacy prior to issue,

b) To review, update as necessary, and re-approve documents,

Page 26

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

4

CURRENT

REVISION

L

c) To ensure that changes and the current revision status of documents are

identified,

d) To ensure that relevant versions of applicable documents are available at

points of use,

e) To ensure that documents remain legible and readily identifiable,

f) To ensure that documents of external origin determined by FCI to be

necessary for the planning and operation of the Quality Management System

are identified and their distribution controlled,

g) To prevent the unintended use of obsolete documents, and to apply suitable

identification to them if they are retained for any purpose.

4.2.4 CONTROL OF QUALITY RECORDS

Records are established to provide evidence of conformity to requirements and of

the effective operation of the quality management system. Records will remain

legible, readily identifiable, and retrievable. FCI shall establish a documented

procedure to define the controls needed for the identification, storage, protection,

retrieval, retention time, and disposition of records.

5.0 MANAGEMENT RESPONSIBILITY

5.1 MANAGEMENT COMMITMENT

Top management provides evidence of its commitment to the development and

implementation of the quality management system and continually improving its

effectiveness by:

a) Communicating to the organization via email, presentations, postings,

and/or a newsletter the importance of meeting customer as well as statutory,

and regulatory requirements,

b) Establishing the quality policy,

c) Ensuring that quality objectives are established,

d) Conducting management reviews, and

e) Ensuring the availability of resources.

5.2 CUSTOMER FOCUS

Top management ensures that customer requirements are determined and are met

with the aim of enhancing customer satisfaction. (See section 7.2.1, and 8.2.1)

Page 27

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

5

CURRENT

REVISION

L

5.3 QUALITY POLICY

Top management ensures that the quality policy:

a) Is appropriate to the purpose of the organization,

b) Includes a commitment to meeting requirements and to continually improve

the effectiveness of the quality management system,

c) Provides a framework for establishing and reviewing quality objectives,

d) Is communicated and understood within the organization, and

e) Is reviewed for continuing suitability.

FCI‟s quality policy is as follows:

“To continually meet and exceed customer expectations and requirements for

products and services and to continually improve the effectiveness of the quality

management system.”

5.4 PLANNING

5.4.1 QUALITY OBJECTIVES

Top management ensures that quality objectives, including those needed to meet

requirements for product, are established at relevant functions and levels within

the organization. The quality objectives are measurable and consistent with the

quality policy.

5.4.2 QUALITY PLANNING

Top management ensures that:

a) The planning of the quality management system is carried out in order to

meet the requirements given in 4.1, as well as the quality objectives, and

b) The integrity of the quality management system is maintained when changes

to the quality management system are planned and implemented.

Page 28

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

6

CURRENT

REVISION

L

5.5 RESPONSIBILITIES, AUTHORITY, AND COMMUNICATION

5.5.1 RESPONSIBILITY AND AUTHORITY

Top Management ensures that responsibilities and authorities are defined and

communicated within the organization through this Quality Manual (also see

Appendix A and D) and individual organizational charts at the departmental level.

5.5.2 MANAGEMENT RESPONSIBILITY

Top Management has appointed (by virtue of this document) the Quality

Assurance Manager as the Management Representative. This individual is a

member of the management structure of FCI. Irrespective of other responsibilities

the Management Representative has the responsibility and authority that includes:

a) Ensuring that processes needed for the quality management system are

established, implemented and maintained,

b) Reporting to top management on the performance of the quality

management system and any need for improvement, and

c) Ensuring the promotion of awareness of customer requirements throughout

the organization.

5.5.3 INTERNAL COMMUNICATION

Top management ensures that appropriate communication processes are

established within the organization and that communication takes place regarding

the effectiveness of the quality management system. This includes the posting of

Quality Objective data to communicate information to the employee population

regarding the effectiveness of the quality management system.

5.6 MANAGEMENT REVIEW

5.6.1 GENERAL

Top management reviews the quality management system, at planned intervals, to

ensure its continuing suitability, adequacy, and effectiveness. This review

includes assessing opportunities for improvement and the need for changes to the

quality management system, including the quality policy and quality objectives.

Records from management reviews are maintained.

5.6.2 REVIEW INPUT

The input to management review includes information on:

Page 29

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

7

CURRENT

REVISION

L

a) Results of audits,

b) Customer feedback,

c) Process performance and product conformity,

d) Status of preventive and corrective actions,

e) Follow-up actions from previous management reviews,

f) Changes that could affect the quality management system, and

g) Recommendations for improvement.

5.6.3 REVIEW OUTPUT

The outputs from the management review include any decisions and actions

related to:

a) Improvement of the effectiveness of the quality management system and its

processes,

b) Improvement of product related to customer requirements, and

c) Resource needs.

6.0 RESOURCE MANAGEMENT

6.1 PROVISION OF RESOURCES

FCI determines and provides the resources needed;

a) To implement and maintain the quality management system and continually

improve its effectiveness, and

b) To enhance customer satisfaction by meeting customer requirements.

On an annual basis, the Directors submit all proposed resource needs for the

upcoming fiscal year to the Chief Financial Officer (CFO). These proposed

resource needs include, the infrastructure and resources needed to:

a. Achieve conformity to product requirements,

b. Implement and maintain the quality management system and continually

improve its effectiveness, and

c. Enhance customer satisfaction by meeting customer requirements.

The President, with input from other corporate entities, determines the

departmental budgets. The approved departmental budgets document the

determination of the infrastructure and resources needed.

Page 30

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

8

CURRENT

REVISION

L

The individual Directors then provide the needed resources based on the approved

annual departmental budgets.

The CFO maintains the individual departmental budgets on the corporate server

by date for a minimum of two years.

6.2 HUMAN RESOURCES

6.2.1 GENERAL

Personnel performing work affecting product quality are competent on the basis

of appropriate education, training, skills, and experience.

6.2.2 COMPETENCY, AWARENESS, AND TRAINING

FCI will:

a) Determine the necessary competence for personnel performing work

affecting conformity to product requirements,

b) Where applicable, provide training or take other actions to satisfy the

necessary competencies,

c) Evaluate the effectiveness of the actions taken,

d) Ensure that personnel are aware of the relevance and importance of their

activities and how they contribute to the achievement of the quality

objectives, and

e) Maintain appropriate records of education, training, skills, and experience.

6.3 INFRASTRUCTURE

FCI determines, provides, and maintains the infrastructure needed to achieve

conformity to product requirements. Infrastructure includes, as applicable:

a) Buildings, workspace and associated facilities;

b) Process equipment (both hardware and software), and

c) Supporting services (such as transport or communication).

6.4 WORK ENVIRONMENT

It is each departmental manager/supervisor‟s responsibility to determine and

manage the work environment needed to achieve conformity to product

requirements.

Page 31

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

9

CURRENT

REVISION

L

7.0 PRODUCT REALIZATION

7.1 PLANNING OF PRODUCT REALIZATION

FCI plans and develops the processes needed for product realization. Planning of

product realization is consistent with the requirements of the other processes of

the quality management system.

The planning of the processes for realization to determine the following occurs as

appropriate:

a) Quality objectives and requirements for the product during the Design and

Planning Phase;

b) The need to establish processes, documents, and provide resources specific

to the product during the Design and Planning Phase;

c) Required verification, validation, monitoring, inspection and test activities

specific to the product and the criteria for product acceptance during the

Design and/or Planning Phase;

d) Records needed to provide evidence that the realization processes and

resulting product meet requirements.

Output from this planning is in a form suitable for FCI‟s method of operations and

may be (but is not limited to) the following:

Quality System Procedures and/or Documentation

MRP Data

Delivery Method Information

Quality Objectives

Organizational Infrastructure

Department Specific Documentation

Product Realization Documentation

7.2 CUSTOMER RELATED PROCESSES

7.2.1 IDENTIFICATION OF PRODUCT RELATED REQUIREMENTS

FCI determines:

a) Requirements specified by the customer, including the requirements for

delivery and post delivery activities,

b) Requirements not stated by the customer but necessary for intended or

Page 32

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

10

CURRENT

REVISION

L

specified use, where known,

c) Statutory and regulatory requirements related to the product, and

d) Any additional requirements determined by the organization.

7.2.2 REVIEW OF PRODUCT REQUIREMENTS

FCI reviews the requirements related to the product. This review is conducted

prior to FCI‟s commitment to supply a product to the customer and ensures that:

a) Product requirements are defined,

b) Contract or order requirements differing from those previously expressed

are resolved, and

c) The organization has the ability to meet the defined requirements.

Records of the results of the review and actions arising from the review are

maintained.

Where the customer provides no documented statement of requirements, the

customer requirements are confirmed by FCI before acceptance.

Where product requirements are changed, FCI ensures that relevant documents

are amended and that relevant personnel are made aware of the changed

requirements.

7.2.3 CUSTOMER COMMUNICATION

FCI determines and implements effective arrangements for communicating with

customers in relation to:

a) Product information,

b) Enquiries, contracts or order handling, including amendments, and

c) Customer feedback, including customer complaints.

Effective arrangements include (but may not be limited to) the following:

a) Pre-Sales: All customer communication is forwarded to the Sales

Department, and

b) Post-Sales: All customer communication is forwarded to the Customer

Service Department.

Page 33

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

11

CURRENT

REVISION

L

7.3 DESIGN AND/OR DEVELOPMENT

7.3.1 DESIGN AND/OR DEVELOPMENT PLANNING

FCI plans and controls design and/or development of the product.

Design and/or development planning determines:

a) Stages of design and/or development,

b) Review, verification and validation activities appropriate to each design

and/or development stage, and

c) Responsibilities and authorities for design and/or development.

Interfaces between different groups involved in design and/or development are

managed to ensure effective communication and clear assignment of

responsibility.

Planning output is updated, as appropriate, as the design and/or development

progresses.

7.3.2 DESIGN AND/OR DEVELOPMENT INPUTS

Inputs relating to product requirements are determined and records maintained.

These include:

a) Functional and performance requirements,

b) Applicable regulatory and legal requirements,

c) Applicable information derived from previous similar designs, and

d) Any other requirements essential for design and/or development.

These inputs are reviewed for adequacy. Incomplete, ambiguous, or conflicting

requirements are resolved.

7.3.3 DESIGN AND/OR DEVELOPMENT OUTPUTS

The outputs of the design and/or development shall be in a form that is suitable

for verification against the design and/or development inputs and shall be

approved prior to release.

Design and/or development output:

a) Meets the design and/or development input requirements,

b) Provides appropriate information for purchasing, production, and service

provisions,

c) Contains or references product acceptance criteria,

Page 34

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

12

CURRENT

REVISION

L

d) Specifies the characteristics of the product that are essential to its safe and

proper use.

7.3.4 DESIGN AND/OR DEVELOPMENT REVIEW

At suitable stages, systematic reviews of design and/or development is performed

in accordance with planned arrangements to:

a) Evaluate the ability of the results of design and development to meet

requirements, and

b) Identify problems and propose necessary actions.

Participants in such reviews include representatives of functions concerned with

the design and/or development stage(s) being reviewed. The results of the

reviews and any necessary actions are maintained.

7.3.5 DESIGN AND/OR DEVELOPMENT VERIFICATION

Verification is performed in accordance with planned arrangements to ensure the

design and development outputs have met the design and/or development input

requirements. The results of the verification and any necessary actions are

maintained.

7.3.6 DESIGN AND/OR DEVELOPMENT VALIDATION

Design and/or development validation is performed in accordance with planned

arrangements to ensure that resulting product is capable of meeting the

requirements for the specified application or intended use, where known.

Wherever practicable, validation is completed prior to the delivery or

implementation of the product. Records of the results of the validation and any

necessary actions are maintained.

7.3.7 CONTROL OF DESIGN AND/OR DEVELOPMENT CHANGES

Design and/or development changes are identified and records maintained. The

changes are reviewed, verified and validated, as appropriate, and approved before

implementation. The review of design and development changes includes

evaluation of the effect of the changes on constituent parts and product already

delivered.

Records of the results of the review of changes and any necessary actions are

maintained.

Page 35

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

13

CURRENT

REVISION

L

7.4 PURCHASING

7.4.1 PURCHASING PROCESS

FCI ensures that purchased product conforms to specified purchase requirements.

The type and extent of control applied to the supplier and the purchased product is

dependent upon the effect of the purchased product on subsequent product

realization or the final product.

FCI evaluates and selects suppliers based on their ability to supply product in

accordance with the organization‟s requirements. Criteria for selection,

evaluation, and re-evaluation are established. Records of the results of

evaluations and any necessary actions arising from the evaluation are maintained.

7.4.2 PURCHASING INFORMATION

Purchasing information describes the product to be purchased, including where

appropriate:

a) Requirements for approval of product, procedures, processes, and

equipment,

b) Requirements for qualification of personnel, and

c) Quality management system requirements

FCI ensures the adequacy of specified purchase requirements prior to their

communication to the supplier.

7.4.3 VERIFICATION OF PURCHASED PRODUCT

FCI establishes and implements the inspection or other activities necessary for

ensuring that purchased product meets specified purchase requirements.

Where FCI or its customer intends to perform verification at the supplier‟s

premises, the organization will state the intended verification arrangements and

method of product release in the purchasing information.

7.5 PRODUCTION AND SERVICE PROVISION

7.5.1 CONTROL OF PRODUCTION AND SERVICE PROVISION

FCI plans and carries out production and service provisions under controlled

conditions. Controlled conditions include, as applicable:

a) The availability of information that describes the characteristics of the

product,

Page 36

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

14

CURRENT

REVISION

L

b) The availability of work instructions, as necessary,

c) The use of suitable equipment,

d) The availability and use of measuring and monitoring devices,

e) The implementation of monitoring and measurement,

f) The implementation of product release, delivery, and post-delivery

activities.

7.5.2 VALIDATION OF PROCESSES

FCI validates any processes for production and service where the resulting output

cannot be verified by subsequent measurement or monitoring; and as a

consequence, deficiencies become apparent only after the product is in use or the

service has been delivered (aka Special Processes).

Validation demonstrates the ability of the processes to achieve planned results.

FCI establishes arrangements for these processes including, as applicable:

a) Defined criteria for review and approval of the processes,

b) Approval of equipment and qualification of personnel,

c) Use of specific methods and procedures,

d) Requirements for records, and

e) Revalidation.

7.5.3 IDENTIFICATION AND TRACEABILTY

Where appropriate, FCI identifies the product by part number throughout product

realization.

FCI identifies the status of the product with respect to measurements and

monitoring requirements on the associated Operation Sheet or in the Business

System.

Where traceability is a requirement, FCI controls and records the unique

identification of the product via the Receiving Inspection, In Process Inspection,

Job Order, and Final Inspection procedures.

7.5.4 CUSTOMER PROPERTY

FCI exercises care with customer property (including intellectual property and

personal data) while it is under the organization‟s control or being used by the

Page 37

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

15

CURRENT

REVISION

L

organization. FCI identifies, verifies, protects, and safeguards customer property

provided for use or incorporation into the product. Occurrence of any customer

property that is lost, damaged, or otherwise found to be unsuitable for use is

recorded and reported to the customer and records maintained.

7.5.5 PRESERVATION OF PRODUCT

FCI preserves the product during internal processing and delivery to the intended

destination in order to maintain conformity to requirements. As applicable, this

preservation includes identification, handling, packaging, storage, and protection.

Preservation also applies to constituent parts of a product.

7.6 CONTROL OF MEASURING AND MONITORING DEVICES

FCI determines the monitoring and measurements to be undertaken and the

measuring and monitoring equipment needed to provide evidence of conformity

of product to determined requirements.

FCI establishes processes to ensure the monitoring and measurement can be

carried out and are carried out in a manner that is consistent with the monitoring

and measurement requirements.

Where necessary to ensure valid results, measuring equipment is:

a) Calibrated or verified at specified intervals, or prior to use, against

measurement standards traceable to international or national standards;

where no such standards exist, the basis used for calibration or verification

is recorded,

b) Be adjusted or re-adjusted as necessary,

c) Be identified in order that the calibration status is determined,

d) Be safeguarded from adjustments that would invalidate the measurement

result, and

e) Be protected from damage and deterioration during handling, maintenance,

and storage.

In addition, FCI assesses and records the validity of the previous measuring

results when the equipment is found not to conform to requirements. FCI takes

appropriate action on the equipment and any product affected. Records of the

results of calibration and verification are maintained.

When used in the monitoring and measurement of specified requirements, the

ability of computer software to satisfy the intended application is confirmed. This

is undertaken prior to initial use and reconfirmed as necessary.

Page 38

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

16

CURRENT

REVISION

L

8.0 MEASUREMENT, ANALYSIS AND IMPROVEMENT

8.1 GENERAL

FCI plans and implements the monitoring, measurement, analysis, and

improvement processes needed:

a) To demonstrate conformity to product requirements,

b) To ensure conformity of the quality management system, and

c) To continually improve the effectiveness of the quality management system.

This includes determination of applicable methods, including statistical

techniques, and the extent of their use.

8.2 MEASUREMENT AND MONITORING

8.2.1 CUSTOMER SATISFACTION

As one of the measurements of the performance of the quality management

system, FCI monitors information relating to customer‟s perception as to whether

FCI has met customer requirements. The methods for obtaining and using this

information are determined.

8.2.2 INTERNAL AUDIT

FCI conducts internal audits at planned intervals to determine whether the quality

management system:

a) Conforms to the planned arrangements, to the requirements of the ISO 9001

International Standard, and to the quality management system requirements

established by FCI,

b) Is effectively implemented and maintained.

The audit program is planned, taking into consideration the status and importance

of the processes and areas to be audited, as well as the results of previous audits.

The audit criteria, scope, frequency, and methods are defined. Selection of

auditors and conduct of audits will ensure objectivity and impartiality of the audit

process. Auditors will not audit their own work.

A documented procedure shall be established to define the responsibilities and

requirements for planning and conducting audits, establishing records and

reporting results.

The management responsible for the area being audited ensures that any

necessary corrections and corrective actions are taken without undue delay to

Page 39

DOCUMENT NUMBER

07QA070003

SUBJECT

Quality Manual

CAGE CODE

64818

Date

10-8-2012

SECTION

1

PAGE

17

CURRENT

REVISION

L

eliminate detected nonconformities and their causes. Follow-up activities shall

include the verification of the actions taken and the reporting of verification

results.

8.2.3 MEASUREMENT AND MONITORING OF PROCESSES

FCI applies suitable methods for monitoring and, where applicable, measurement

of the quality management system processes. These methods shall demonstrate

the ability of the processes to achieve planned results. When planned results are

not achieved, correction and corrective action is taken, as appropriate.

8.2.4 MEASUREMENT AND MONITORING OF PRODUCT

FCI measures and monitors the characteristics of the product to verify that

product requirements have been met. This is carried out at appropriate stages of

the product realization process in accordance with planned arrangements.

Evidence of conformity with the acceptance criteria is maintained. Records

indicate the person(s) authorizing release of product for delivery to the customer.

The release of product and delivery of service to the customer shall not proceed

until the planned arrangements have been satisfactorily completed, unless

otherwise approved by a relevant authority and, where applicable, by the

customer.

8.3 CONTROL OF NONCONFORMING PRODUCT

FCI ensures that product which does not conform to requirements is identified and

controlled to prevent unintended use or delivery. A documented procedure shall

be established to define the controls and related responsibilities and authorities for

dealing with nonconforming product.