Page 1

OEM MASS FLOW SWITCH

Installation and Operation Guide

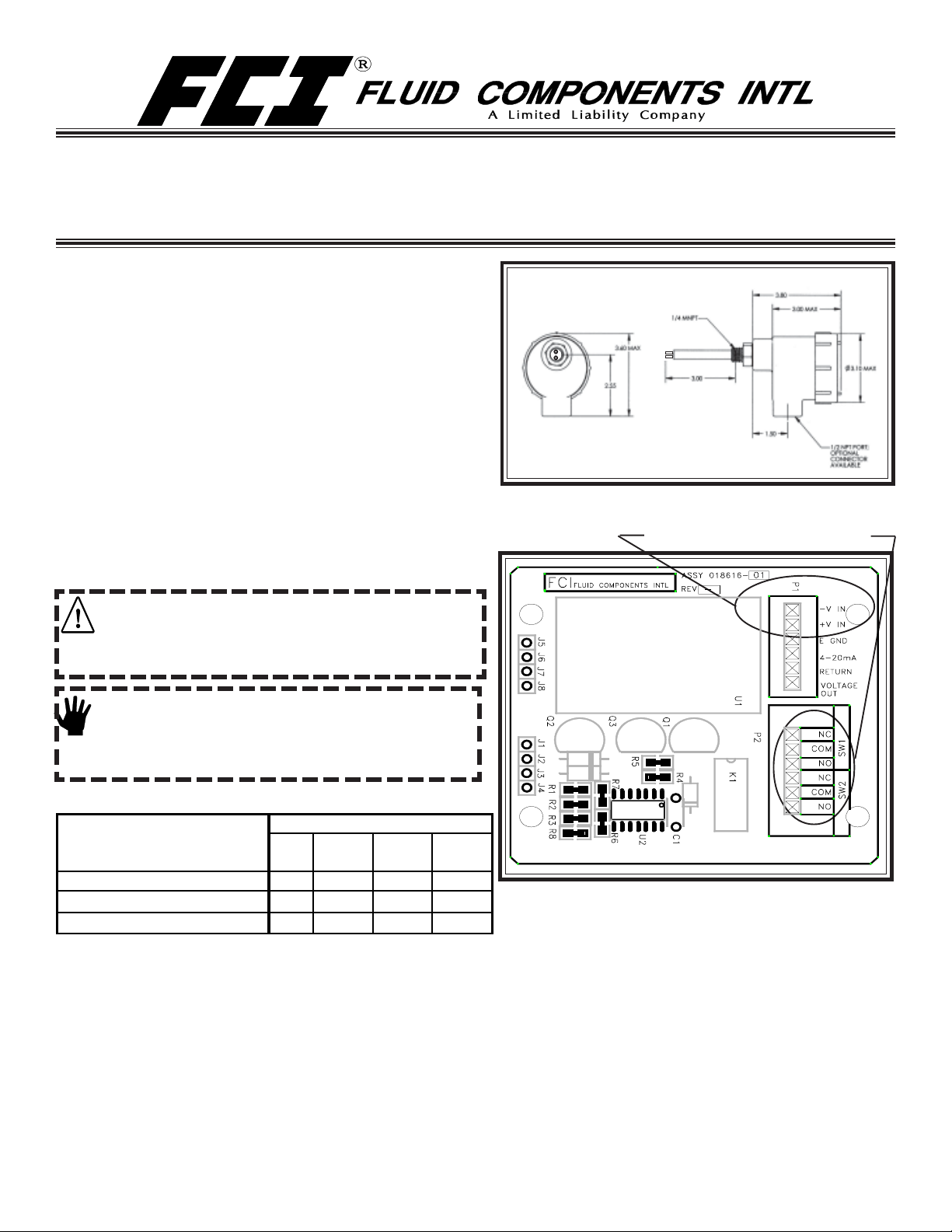

INSTRUMENT INSTALLATION

The OEM Mass Flow Switch is an insertion instrument capable of

monitoring gas or liquid flow in a wide range of processes for purposes of

switching at a preset alarm switch point. This set point is fully adjustable

in the field. The instrument can be top or side mounted. The process

connection is male 1/4 inch NPT (or 1/2 inch NPT compression fitting). See

the installation outline drawing below for mounting dimensions.

There is an orientation mark etched onto the hexagonal surface of the

element. The flow element must be located with the orientation mark

parallel to flow. Apply an appropriate sealant to the male threads when

connecting the flow element to the process. Tighten the element until it is

hand tight. Use a wrench to rotate the element until the flow arrow on the

hexagonal flat is in the direction and parallel to flow, ±2°. The enclosure

should be located so that the conduit port is in a downward direction. This

is to prevent moisture from collecting in the enclosure.

INSTRUMENT WIRING

Caution:

Only qualified personnel are to wire or test this instrument. The

operator assumes all responsibilities for safe practices while wiring or

troubleshooting.

Installation Outline Diagram

18 to 36 Vdc Optional Relay

Alert:

The instrument contains electrostatic discharge (ESD) sensitive

devices. Use standard ESD precautions when handling the flow

transmitter.

Recommended Minimum AWG Wire Table

Maximum Distance for AWG

Connection

Input Power 22 20 18 16

4-20 Output (600 Ohm Max.) 18 18 16 14

Voltage Output 18 16 N/R N/R

Use the following steps to wire the instrument:

l FCI recommends installing an input power disconnect switch and fuse

near the instrument to interrupt power during installation, maintenance,

calibration, alarm selection and troubleshooting procedures.

l Ensure the power is off to the instrument before wiring the instrument.

l Conduit or other protective sheathing should be connected to the

1/2 inch ports of the enclosure. See the above Minimum AWG Wire

Table to determine the size of wire to use versus the distance the wire

has to be run.

10 ft. 50 ft. 100 ft. 250 ft.

(3M) (15M) (76M) (76M)

Customer Wiring Diagram

l Unscrew and remove the top cover of the instrument. Lift the

circuit board assembly by pulling up on the white plastic pull

tie wrap. The customer connections are near the top of the

circuit board. Be careful not to stress the wires that are

connected to the circuit board.

l Connect 24 VDC input power to P1 +V IN and -V IN.

l Connect the 4-20mA output terminals as required.

l Push the board back into the enclosure and replace the top cover.

l Turn power on to operate the instrument.

Page 2

FLUID COMPONENTS INTL OEM MASS AIR FLOW

TROUBLESHOOTING

Verify that the wiring is correct. Contact FCI Technical Service if problems still persist. The Telephone Number is 1 800 854-1993, or

(760) 744-6950.

GENERAL SPECIFICATIONS

Material of Construction: Element; 300 Series Stainless Steel Enclosure; Diecast Epoxy Coated Aluminum.

Operating Temperature: Flow Element; Low Temp. -40 to +350°F (-40 to +177°C) High Temp. to 500 °F (260°C)

Electronics; -40 to +140°F (-40 to +60°C)

Safety Proof Pressure: 500 psig.

Input Power: 18 - 36 Vdc

Repeatability: 0.5% of reading

Mounting: Vertical or horizontal

Service: Air or gas (depends on calibration)

Enclosure Classification: UL Class 1 and 2, Div 1 & 2, Groups C, D, E, F, G

Approvals: CE Mark

ALARM SWITCH POINT SET-UP

The set point may be adjusted blindly or with a volt meter to see relative flow and establish a reference point.

In RUN MODE:

0-25mA related to flow.

0-10Vout related to temperature.

Green LED on = power on (run mode).

Red LED indicates fail-safe setting.

Red LED ON = relay de-energized on flow (or wet condition) BELOW the alarm set point.

Red LED OFF = relay de-energized on flow (or dry condition) ABOVE the alarm set point.

CALIBRATION MODE:

To enter calibration mode, press both buttons simultaneously once.

Both LED’s will be off.

Use either output to monitor the alarm set point.

0-10Vout represents the Set Point.

0-25mA represents the Set Point.

Press both buttons simultaneously to exit CALIBRATION MODE and toggle the fail-safe mode.

The Green LED is on and the Red LED is either on or off, indicating fail-safe setting as described above.

To change fail-safe setting, press both buttons simultaneously twice.

Notice of Proprietary Rights

This document contains confidential technical data, including trade secrets and proprietary information which are the property of Fluid Components

Intl (FCI). Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only (and does

not include manufacture or processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

Visit FCI on the Worldwide Web: www.fluidcomponents.com

1755 La Costa Meadows Drive, San Marcos, California 92069 USA - 760-744-6950 - 800-854-1993 - Fax 760-736-6250

© Copyright 2002 Fluid Components Intl a limited liability company All Rights Reserved Document Number: 06EN003337 Rev. -

Loading...

Loading...