Page 1

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

3. Operation

Caution:

Introduction

The flowmeter has been configured and calibrated to customer specifications. Each flowmeter contains distinct

operating limits and units of measurement. This chapter will show how to determine and manipulate the

configuration of the flowmeter.

Start Up

Verify the wiring before applying power. Also verify the correct power connections have been made to the flow

transmitter.

1. Apply Power.

2. Wait 5 minutes for the unit to warm-up and stabilize.

3. The flowmeter evaluates sensing points as out-of-range until they have warmed up to operating temperature.

The flow transmitter contains electrostatic discharge (ESD) sensitive devices. Use standard ESD

precautions when handling the flow transmitter. See Chapter 2, Installation for ESD details.

The flowmeter displays a system status message of "Check Heads" until all sensing points are functioning

within their calibrated range. This status message should change to the normal display of "System OK" within

the 5 minute warm-up period. The output signal displayed should be representative of the estimated or

calculated current process media flow.

4. The unit automatically enters the flow metering mode and the display sets to normal operation.

The flowmeter outputs should now indicate the mass flow rate in the desired units of measure.

In the event that the display or the "System OK" message does not appear, or the values are out-of-range or

obviously incorrect, then turn the power off and proceed to Chapter 5 - Troubleshooting.

Using the MT91 Software with Display

Display

The flowmeter contains a 4 x 20 character LCD display. Flow rate, temperature, and system status are all accessible

through the display.

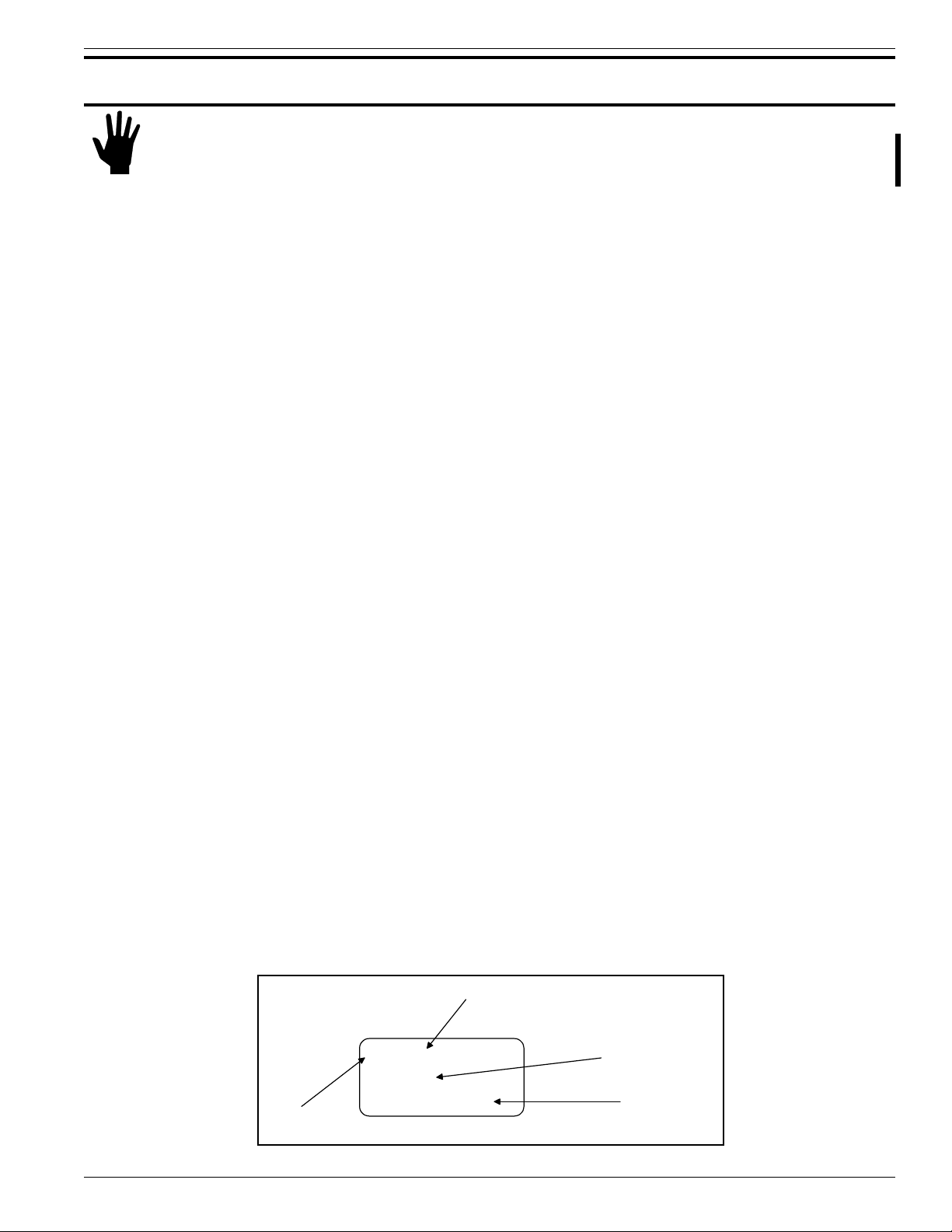

Menu Window

Four components make up the menu window. They are the menu level, title, selections, and prompt line. These

components are illustrated in Figure 3-1. The top line displays a menu level and title. Lines two and three are used

to scroll through available options. The prompt line indicates which menu commands are appropriate.

2.1.1 FLOW

1=Velocity

2=Volume

Menu Code

N=MORE UP HOME

Title

Available Selections

Prompt Line

C00219-1

Figure 3-1. The Menu Window

Doc. No. 003185 Rev. B 3 - 1

Model MT91 Multipoint Flowmeter

Page 2

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

The menu level is a numeric reference which identifies each window of the menu structure. The menu level in

Figure 3-1 indicates that the user is three levels deep (Level 2, sublevel 1, sub-sub-level 1). This example code can

be associated functionally as 2(SETUP).1(DISPLAY).1(FLOW). Occasionally, the depth of the menu makes

displaying the complete menu level impractical. When this happens, the special character “>” indicates that the

menu level may be deeper than the code indicates (e.g. “2.2.3.1>RLY[1] MODE” ).

The title gives the user a better idea of where the system is within the menu structure. Some titles are informative

enough to completely describe the menu function, while other titles are ambiguous unless the parent menus are

known.

Other Window Types

Another common window encountered is a non-scrolling menu. The window is similar to the menu window except

that does not scroll and all choices are contained within the window. The current selection (if there is one) is also

contained in the parenthesis to the left of the question mark.

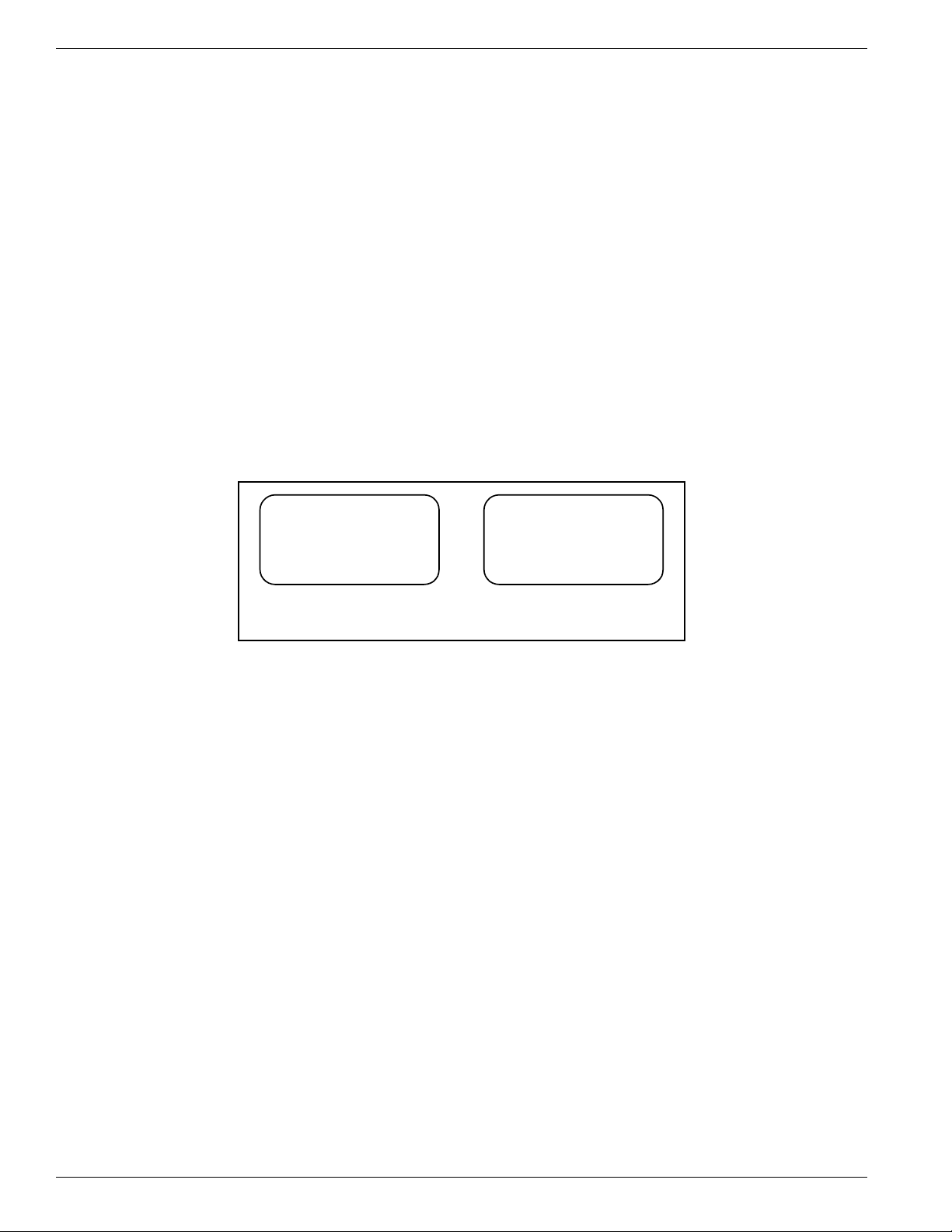

Menu Control

The prompt line and available selections display key strokes for that menu level. If a key is pressed that is not valid

for that menu, the screen will stay the same. The key pad layout is shown in Figure 3-2.

0-9 Enter numbers

Y Yes to prompts

1 2 3 Y N

4 5 6

7 8 9 P

ENTR

0 #

_

HOME

.

UP

C00220-1

N No to prompts; more display

- minus sign

. decimal point

←

P no special use

ENTR accepts current value

HOME return to main menu

UP backup one menu level

backspace

Figure 3-2. Keypad Layout

Table 3-1. Key Functions

See Table 3-1 for key pad assignments. At any time, press the HOME key to display the main menu.

HOME can be used to escape from calibration routines, restart a progression into the menu structure, or

quickly change from one area of the menu to another.

When N=MORE is displayed on the prompt line, more than two menu selections are available. Press N to

scroll through all the selections.

When UP is displayed on the prompt line, the UP key can be used to back out of menus. The menu moves

back one level each time the UP key is pressed.

To make a selection, press the numeric key associated with the desired menu selection. The selection does

not have to be displayed, but it must be one of the available selections.

Every path through the menu will eventually cause control to pass from the menu structure to a routine that

performs a task such as change a parameter value, initiate a test, or calibrate the system hardware. Some of

these routines still provide selections that emulate the menu structure. When the system is operating outside

the menu structure, there are subtle differences in the user interface. For example, the UP key may have no

affect or the prompt line won't appear.

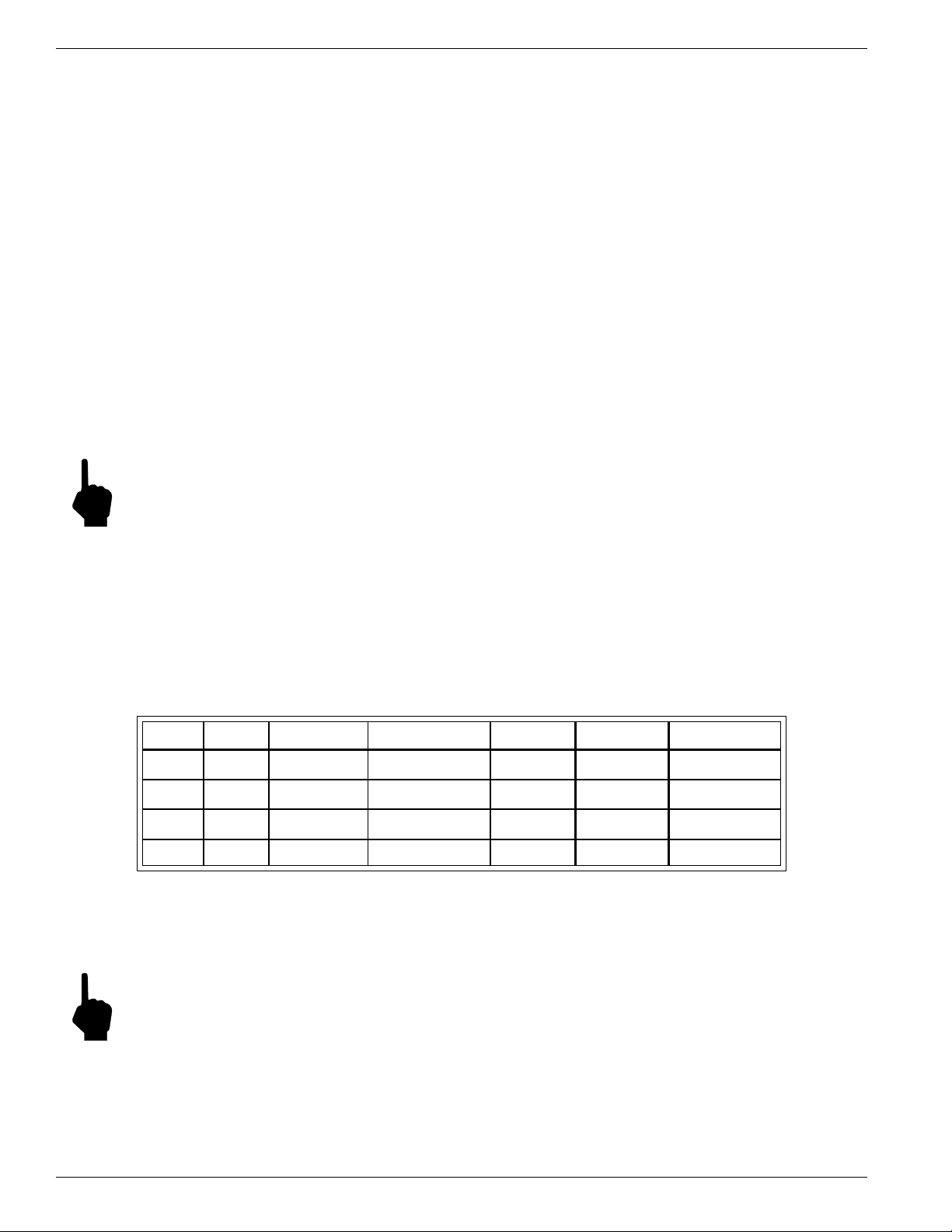

Menu Organization

The top level of the menu is shown in Figure 3-3. The menu structure is divided into four major groups, a

display function, and the revision display.

Model MT91 Multipoint Flowmeter

3 - 2 Doc. No. 003185 Rev. B

Page 3

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

• The first menu option places the units display into the normal display mode. When the system is in this mode,

flow and/or temperature measurements are displayed. While in the normal display mode, pressing any key will

cause the main menu to display.

• The Setup group presents the options for customizing the system inputs and outputs. Most of the settings will

be made through menus in this group.

• The diagnostics group provides displays that help isolate problems and test the system integrity.

• The calibration group is used primarily by factory technicians, but there are displays that can be helpful to the

customer.

• The verify group provides a means to view the values of important system parameters.

• Finally, the firmware version is available for display.

0.0 MAIN MENU

1=Normal Display

2=Setup

3=Diagnostics

4=Calibration

5=Verify

6=Version

7=Time Delay

Normal Display

CH1: 47.8 SF/S

CH2: 89.2 F

K1 K2

System OK

2.0 SETUP

1=Display

2=Outputs

3=Communications

4=Configuration

5=Password

6=Clock

3.0 DIAGNOSTICS

1=System Status

2=Output Tests

3=Calibration Tests

4=Schedule Tests

4.0 CALIBRATION

1=Cal Initialize

2=Cal Inputs

3=Cal Outputs

4=Cal Flow

5.0 VERIFY

1=Verify Setup

2=Verify Cal

Version x.xx

Release Date

dd-mm-yy

2.1 DISPLAY

1=Flow

2=Temperature

3=Screen Setup

2.2 OUTPUTS

1=Assign Heads

2=Analog

3=Relays

4=Filter

5=Corrections

2.3 COMMUNICATIONS

1=Mode

2=Baud

3=Protocal

4=RS-485 Address

2.4 CONFIGURATION

1=Setup User Config

2=Setup Factory Cfg

3=Save Config

2.5 PASSWORD

1=Change User PW

2=Enable PW

2.6 SET CLOCK

1=Set Clock

2=Auto Offset

5.1 VERIFY SETUP

1=Flow

2=Temp

3=Outputs

4=Communication

5.2 VERIFY CAL

1=Inputs

2=Outputs

3=Flow

3.1 SYSTEM STATUS

1=Sensors

2=Heaters

3.2 OUTPUT TESTS

1=Analog Output Test

2=Relay Test

3.3 CALIBRATION

TESTS

1=Start Test

2=Display Results

3.4 SCHEDULE TESTS

1=Calibration Drift

2=Enable Auto Test

4.1 CAL INITIALIZE

1=All Cal Parms

2=Input Cal Parms

3=Output Cal Parms

4=Flow Cal Parms

5=Misc Cal Parms

4.2 CAL INPUTS

1=Sensor Type

2=Excitation

3=Heaters

4=Normalize to R

5=Unipolar rR & dR

6=Bipolar rR & dR

7=Display dV &dV

4.3 CAL OUTPUTS

1=Analog Outputs

7.0 TIME DELAY

Enter Minutes:

(1)

?

7.0 TIME DELAY

Output Frozen

Press any key to stop

Time Left: 0:07

Figure 3-3 Menu Flowchart

Doc. No. 003185 Rev. B 3 - 3

4.4 CAL FLOW

1=Coefficients

2=Limits

3=Temp Comp

4=Offset

C00221-1.vsd

Model MT91 Multipoint Flowmeter

Page 4

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

Quick Custom Setup

In order to use the quick operation procedure, an assumption has been made that the password is enabled (this is the

factory preset condition).

If mistakes in data entry are made, press the back arrow key to correct mistake.

Menu level refers to the sequence of key to press to reach a particular function from the MAIN MENU. For

example, to go to menu level 2.2.1, press HOME, 2, 2, and 1.

Y/N refers to Y Save Permanently or Change Parameter or N Do Not Save Permanently or Do Not Change

Parameter.

Using Main Functions

MAIN MENU Press HOME.

Returns user to MAIN MENU. In some cases, it may be necessary to press

HOME more than once.

NORMAL DISPLAY menu level 1.

To view the NORMAL DISPLAY

DelR and RefR menu level 4.2.5

To view a sensing point's raw signal DelR and RefR. When prompted, enter

the number of the sensing point to be viewed.

PASSWORD menu level 2.5.1.2

Enable or Disable the PASSWORD

PASSWORD menu level 2.5.1.1

Change the user PASSWORD. If the password protection is enabled, the

user must enter the current password.

Selecting Units of Measurement

After reaching the menu level, select the combination of units that will produce the desired end result.

Velocity units menu level 2.1.1.1

Length 1=FT, 2=M and

Time 1=Sec, 2=Min, 3=Hrs, 4=Day

Volume units menu level 2.1.1.2

Volume 1=SCF, 2=NCM, 3=NLP

Area 1=Square Feet, 2=Square Meters

Area Value enter the area of the duct

Time 1=Sec, 2=Min, 3=Hrs, 4=Day

Mass units menu level 2.1.1.3

Mass 1=LBM, 2=KG, 3=TON, 4=TONNE

Area 1=Square Feet, 2=Square Meters

Area Value enter the area of the duct

Time 1=Sec, 2=Min, 3=Hrs, 4=Day

Temperature units menu level 2.1.2

Model MT91 Multipoint Flowmeter

1=°F 2=°C 3=K 4=°R

3 - 4 Doc. No. 003185 Rev. B

Page 5

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Setting Up Analog Outputs

Sensing Point Outputs menu level 2.2.1

Channel 1=Chan 1 2=Chan 2

After selecting a channel, the menu automatically provides new

selections to assign sensing points.

Sensing Points 1=Add All Heads 2=Add Head 3=Del All Heads

4=Del Head 5=View Assigned 6=Save

An "X" will mark on the display to show which sensing points are assigned

to the selected channel. To keep changes, user must save assignments.

Output Parameters menu level 2.2.2

Channel 1=Chan 1 2=Chan 2

After selecting a channel, the menu automatically provides new

selections to set output parameters.

Output Signal* 1=0-5V 2=0-10V 3=4-20mA

Mode 1=Flow 2=Temp

Full Scale enter a value

Port Zero enter a value

*Set Jumpers to match. See Chapter 2.

Setting Up Relays

Relays 1 and 2 can be set as switch points or test/status parameters. If relays 1 or 2 are used for switch

points, their mode must correspond to their respective analog output channels. (e.g. If relay 1 is set to

be a flow switch point, then analog output channel 1 must be in the flow mode.) If relays 1 or 2 are set

to flow or temperature modes, the user MUST set switch point and hysteresis parameters. If this is not

done, a chattering noise will be heard. Relay 3 and 4 can only be set as test/status parameters.

Relay Mode menu level 2.2.3.1

Relay 1=Rly #1 2=Rly #2 3=Rly #3 4=Rly #4

After selecting a relay, the menu automatically provides new

parameters to set the mode.

1=View Mode 2=Flow 3=Temperature

4=System Status 5=Zero Test 6= Span Test.

Switch Points menu level 2.2.3.2

Relay 1=Rly #1 2=Rly #2 3=Rly #3 4=Rly #4

After selecting a relay, the menu automatically provides new

parameters to set the switch point.

1=View Sw. Pt. 2=Above 3=Below

4=Inside 5=Outside

Hysteresis menu level 2.2.3.3

Relay 1=Rly #1 2=Rly #2 3=Rly #3 4=Rly #4

Doc. No. 003185 Rev. B 3 - 5

Model MT91 Multipoint Flowmeter

Page 6

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

In-Depth Custom Setup Procedure

When a flowmeter leaves the factory, it is configured to the application information know at the time of order. At

installation time; however, changes to the factory settings may be necessary. There are several parameters that can

be modified to customize the system. This section describes how to customize the flowmeter.

Menu level refers to the sequence of key to press to reach a particular function from the MAIN MENU. For

example, to go to menu level 2.2.1, press HOME, 2, 2, and 1.

Each time a system parameter is changed, the display will prompt the user to save the change. For the change to

endure through power off periods or a system reset, press Y. For a temporary change, press N. When changes are

not saved, the user can restore the previous settings by cycling the input power or pressing any key for more than 10

seconds to reset the system.

In most cases, the existing value of the parameter that is changing will be displayed. If no change is required, press

ENTR, select it again, or press HOME.

Since the flowmeter has multiple inputs and outputs, some parameters are stored in groups. For example, the analog

output parameters apply to both channels one and two. The menu level to change the analog output parameters will

prompt the user to select a channel. After making changes to that channel, back out of and re-enter the menu level to

make changes to the other channels. Use either the UP key or the HOME key to back out of the menu level.

Password Protection

Before customizing the flowmeter configuration, the customer must have access to the system parameters. Two

levels of password protection affect access to these parameters.

Factory Level

The highest level of protection requires a factory password for access. This password prevents inadvertent changes

to variables associated with the system calibration, sensing point type, and other parameters that require factory

resources to properly set.

User Level

The second level of protection requires a user password for access. This password provides the customer with the

ability to limit access to parameters that affect the way the system operates.

Both levels of password protection can be enabled or disabled. When the system leaves the factory, the factory level

protection will be enabled and the user level will be left disabled. No password is required to enable a level of

protection, but the appropriate password is required to disable protection.

Note:

The user password is set to “123” when the system is shipped.

Ø To edit the user password

1. Go to menu level 2.5.1 (SetupÞ PasswordÞ Change User PW).

2. If current user password if it is enabled, enter the current password, then press ENTR.

3. Enter desired password, then press ENTR.

Ø To enable and disable user password protection

1. Go to menu level 2.5.2 (SetupÞ PasswordÞ Enable PW).

2. If user password is already enabled, enter password. Select 2=Disable to disable password.

3. If user password is not enabled, select 1=Enable to enable the password.

Model MT91 Multipoint Flowmeter

3 - 6 Doc. No. 003185 Rev. B

Page 7

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Selecting Units of Measure

Internally, the unit will always work in units of standard feet per second (SF/S) and degrees Fahrenheit (°F). The

user can choose from several types of units for display and output scaling. Table 3-2 shows the units of measure and

their abbreviations for temperature and flow.

Table 3-2. Units of Measure and Abbreviations

Temperature Length* Volume* Mass Time

Fahrenheit (°F) feet (SF) cubic feet (SCF) pounds mass (LB) seconds (S)

Celsius (°C) meters (NM) cubic meters (NCM) kilograms (KG) minutes (M)

Kelvin (K) liters (NLP) English ton (TON) hours (H)

Rankine (°R) metric tonnes (TONNE) days (D)

*Length and Volume units are based on FCI standard conditions (70°F and 14.7 PSIA); therefore,

the units are preceded with an S.

A sequence of selections is required to set a new unit of measure for flow. At each step through this process, the

existing unit will be displayed, even if it’s undefined, and the user will be prompted to change it. Only Y or N will be

acceptable responses to the prompts. To properly set new units, complete the menu entries until the new flow unit is

displayed. If the change is only temporary, don’t save any settings during the process.

Note:

If only some of the settings in this process are saved, the units of measure may be incorrect after a system

reset or power up.

The output may not conform to the units displayed if after partially completing the selection of new units,

HOME or the hardware reset are used to exit the process.

Ø To set a new unit of measure for flow rate:

1. Go to menu level 2.1.1 (SetupÞ DisplayÞ Flow). Select from the following three options: 1 Velocity,

2=Volume, or 3=Mass and then follow the corresponding procedure below.

w To set velocity units:

2. Select 1=Velocity.

3. The program will prompt the user to change the units of length first. Select from the following units: 1=Feet or

2=Meters.

4. The program will prompt the user to change the units of time next. Select from the following units: 1=Seconds,

2=Minutes, 3=Hours, 4=Day. The units of velocity will display, press any key to exit to menu level 2.1.1.

w To set volume units:

2. Select 2=Volume.

3. The program will prompt the user to change the units of volume first. Select from the following units:

1=SCF - standard cubic feet, 2=NCM - normal cubic meters, or 3=NLP - normal liter per.

4. The program will prompt the user to change the units of area. Select from the following units: 1=Square Feet or

2=Square Meters.

5. The user will be prompted to change the value of the area. Enter a numeric value for the area.

6. The user will be prompted to change the units of time. Select from the following units: 1=Seconds, 2=Minutes,

3=Hours, or 4=Day. The selected units of volume will display, press any key to exit to menu level 2.1.1.

Doc. No. 003185 Rev. B 3 - 7

Model MT91 Multipoint Flowmeter

Page 8

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

w To set mass units:

2. Select 3=Mass.

3. The user will be prompted to change the units of mass first. Select from the following units:

1=LBM - pounds mass, 2=KG - kilograms, 3=TON - English ton, or 4=TONNE - metric ton.

4. The user will be prompted to change the units of area. Select from the following units:

1=Square Feet or 2=Square Meters.

5. The user will be prompted to change the value of area. Enter numeric value for area.

6. The user will be prompted to change the units of time. Select from the following units: 1=Seconds, 2=Minutes,

3=Hours, 4=Day. The units of mass will display, press any key to exit to menu level 2.1.1.

Ø To set a new unit of measure for temperature:

1. Go to menu level 2.1.2 (SetupÞ DisplayÞ Temperature).

2. Select from the following units: 1=°F - degrees Fahrenheit, 2=°C - degrees centigrade, 3=K - Kelvin, or

4=°R - degrees Rankine.

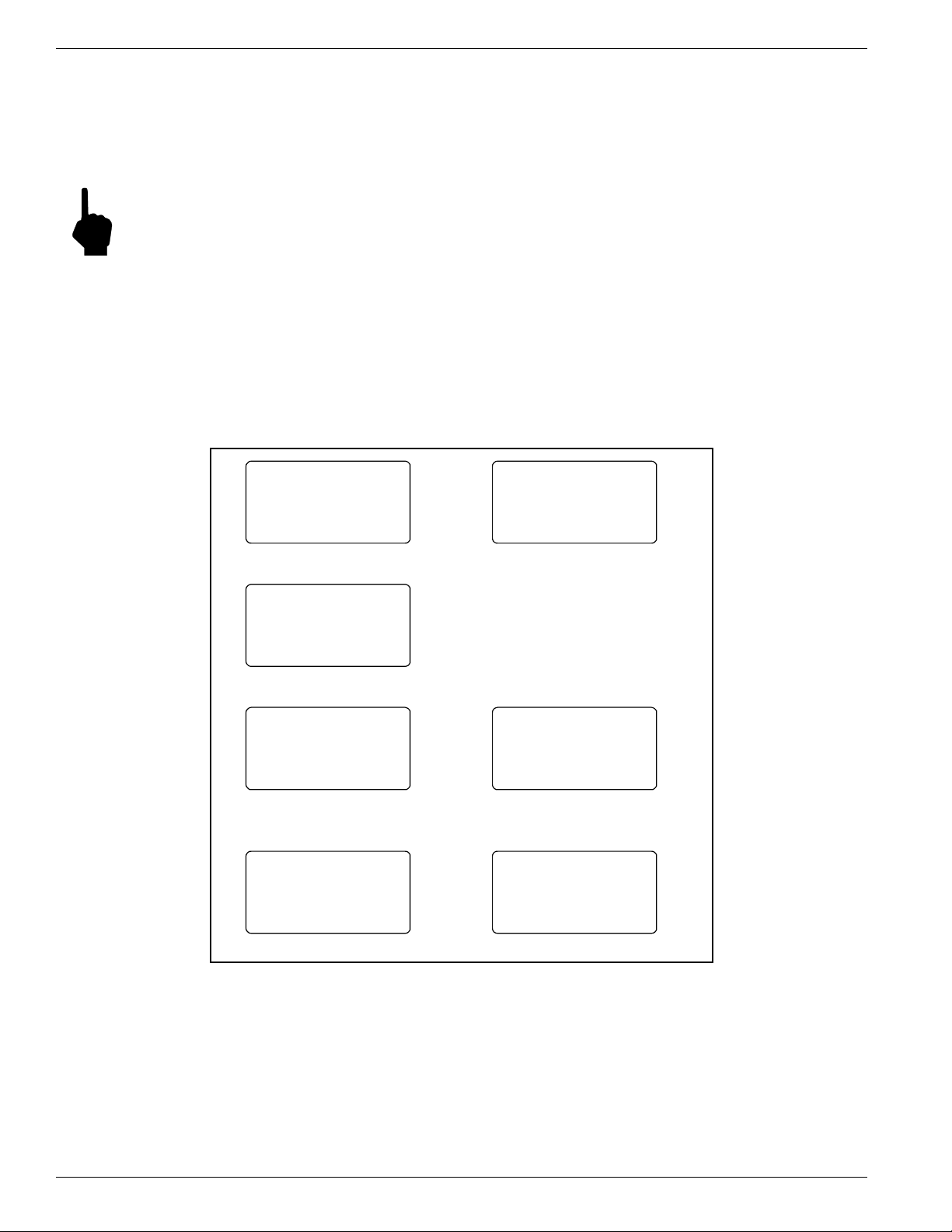

Selecting the Normal Display Screen

There are two formats for displaying flow information. These formats are referred to as screen 1, and screen 2.

Figure 3-4 shows an example of both screens.

CH1: 21320 LB/H

CH2: 96.2F

K1 K2

SYSTEM OK

Sensor[1]=65.4SF/S

Sensor[2]=63.2SF/S

Sensor[3]=66.0SF/S

Sensor[4]=65.2SF/S

Screen 1 Screen 2

C00222-1

Figure 3-4. Normal Display Screen 1 and Screen 2

Screen 1 provides numeric output for the two analog channels.

Screen 2 provides for the display of velocity at four points simultaneously. Many systems use only four points. This

display is useful when comparing the instrument with a Pitot traverse, or observing the flow profile.

Ø To select screen 1 or 2:

1. Go to menu level 2.1.3 (SetupÞ DisplayÞ Screen Setup).

2. Select from the following options: 1=Screen 1 or 2=Screen 2.

Assigning Sensing Points to Outputs

The first step to processing a sensing point input is to assign the sensing point to an output channel. There are two

channels in the flowmeter. Assign any combination of one to sixteen sensing points signals to either or both

channels.

Ø To assign sensing points to outputs:

1. Go to menu level 2.2.1 (SetupÞ OutputsÞ Assign Heads).

2. Select output channel, 1=Chan 1 or 2=Chan 2.

3. Select from the following options:

1=Add All Heads - this will assign all sensing points to the selected output channel;

2=Add Head - this will assign one sensing point at a time, the user can enter up to 16 different sensing points;

3=Del All Heads - this is used to clear all assigned sensing points from the selected channel;

4=Del Head - this is used to delete one sensing point at a time; or

5=View Assigned - the user can view the current sensing points assigned to the selected channel for 2 seconds.

Model MT91 Multipoint Flowmeter

3 - 8 Doc. No. 003185 Rev. B

Page 9

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

2.2.1 CHAN 1 HEADS

1 . . . 5 . . . . 0 . . . . 5 .

x x x x . . . . . . . . . . . . .

Enter Head #?

C00223-1

Figure 3-5 Assign Heads Displays

4. Figure 3-5 shows the display when adding or deleting heads. The ‘x’ signifies a selected head. To add or delete

a head, enter the number of the head, then press ENTR. When finished, press ENTR again without an entry.

5. Select 6=Save to ensure survival of the changes through resets and power cycles.

Setting Analog Outputs

The analog output channels are defined by four parameters: zero, minimum flow, maximum flow, and full scale.

Figure 3-6 shows how these parameters affect the output.

Figure 3-6. Analog Output

Full scale represents the flow or temperature value that corresponds with the maximum output signal.

Zero represents the flow or temperature value that corresponds with the minimum signal output. Minimum signal

output can be set to indicate a flow of zero. This is often referred to as a zero-based signal output. A minimum

signal that represents a value greater than zero is referred to as non-zero based.

Minimum and maximum flow are factory set parameters that do not appear as options in this menu level. Until the

minimum flow value is reached, the output will remain at the zero level. Once the minimum flow threshold is met or

exceeded, the output signal will jump to the value determined by the zero and full scale settings.

Output signal is physically selected with a jumper setting as described in Chapter 2. 0-5 Vdc, 0-10 Vdc and 4-20

mA are the available options.

Mode defines the channel as a flow or temperature output.

Ø To set analog outputs:

1. Go to menu level 2.2.2 (SetupÞ DisplayÞ Analog). Select 1=Chan 1 or 2=Chan 2.

2. Select 1=Output Signal. Then select from the following options: 1=0-5V, 2=0-10V, or 3=4-20mA.

3. Select 2=Mode. Then select from the following options: 1=Flow or 2=Temp.

4. Select 3=Full Scale. Enter a numeric value, then press ENTR to accept it.

5. Select 4=Port Zero. Enter a numeric value, then press ENTR to accept it.

Note:

If a different output signal is selected other than the factory calibrated output, a re-calibration of the analog

output board will be necessary. See following procedure. Ensure that the corresponding jumper is placed

in the correct position. See Chapter 2 for jumper positions.

Doc. No. 003185 Rev. B 3 - 9

Model MT91 Multipoint Flowmeter

Page 10

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

Ø To calibrate the analog output boards:

The analog output board calibration parameters are saved on the controller board. Therefore, analog output boards

are not interchangeable.

Tools needed:

DVM (4 1/2 digit minimum)

Calibrated 250W resistor

1. Turn off the power to the flowmeter.

2. Set both jumpers on the analog output board to the output type selected above.

3. Connect a DVM to the appropriate connection of the analog output board. Use a precision 250ohm resistor if

the output is 4 to 20mA.

4. Apply power to the flowmeter.

5. Go to menu level 2.2.2 (SetupÞ OutputsÞ Analog). Select the Channel 1. Press 1 to select output signal.

6. Select appropriate signal type. Save selection if signal type was changed.

7. Go to menu level 4.3.1 (CalibrationÞ CalOutputsÞ Analog Outputs). Select Channel 1.

8. Press keys as indicated to reach 4mA for 4-20mA output signal or press ENTR (0) for 0-5Vdc output signal and

0-10Vdc output signal.

Note:

The DVM may read 20-30mV for 0-10Vdc output signal or 10-15mV for 0-5Vdc output signal.

9. Press keys as indicated to reach 20mA for 4-20mA output signal or press keys as indicated to reach 5.000Vdc

for 0-5Vdc output signal or press keys as indicated to reach 10.00Vdc for 0-10Vdc output signal.

10. Repeat steps 5 through 9 for Channel 2.

Setting Discrete Outputs

Four sets of relay contacts provide the user with discrete outputs. The relays can be assigned to the parameters

marked in Table 3-3.

Table 3-3. Relay Assignment by Parameters

Relay # Flow Temperature Calibration Test Zero Test Span Test System Status

1

2

3

4

♦ ♦ • • • •

♦ ♦ • • • •

• • • •

• • • •

Dependent on analog outputs

♦

Ø To set discrete outputs

1. Go to menu level 2.2.3.1 (SetupÞ OutputsÞ RelaysÞ Mode)

2. Select the relay to be set: 1=Rly #1, 2=Rly #2, 3=Rly #3, or 4=Rly #4.

Note:

Model MT91 Multipoint Flowmeter

Only relays 1 and 2 can be set as switch points.

3 - 10 Doc. No. 003185 Rev. B

Page 11

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

3. Select from the following options:

1=View Mode - this can be used to verify current setup;

2=Flow - select this if a switch point is going to be set;

3=Temperature - select this if a switch point is going to be set;

4=System Status - this relay is used to notify the customer when the "System OK" is no longer displayed;

5=Zero Test - this is used with the Calibration Testing discussed in the next section. During the zero test phase

(4mA), the Zero Test relay is closed.

6=Span Test - this is used with the Calibration Testing discussed in the next section. During the full scale test

phase (20mA), the Span Test relay is closed.

During the mid range test phase (12mA), both the Zero and Span Test Relays are closed.

If assigned, the test/status relays are ready to be connected to customer equipment.

When assigned to flow or temperature, relays 1 and 2 are affiliated directly with analog output channels 1 and 2,

respectively. For this reason, relay 1 can only be assigned as a flow or temperature switch point when analog output

channel 1 is assigned as a flow output for flow switch or temperature output for temperature switch. The same

applies to relay 2.

Switch points are not appropriate for the test/status parameters since they are already discrete signals. Relays 1 and 2

can be assigned as switch points or as test/status parameters. As switch points, when the signal level crosses into a

specified range, the relay will activate. Hysteresis can be set to prevent the relay from chattering at the switch point

threshold.

The user can choose from four sets of switch point ranges. These are referred to as above, below, inside, and

outside. With hysteresis, the relay will deactivate at a different threshold than at which it activates. Figure 3-7

illustrates the four switch point ranges with arbitrary hysteresis assigned.

Flow

or

Temperature

Figure 3-7. Relay Switch Points Schemes

ON

OFF

Above

Switch point

Deactivation

OFF

Below

ON

OFF

Outside

}

ON

Hysterisis

OFF

Inside

ON

C00225-1

Ø To set the switch points and hysteresis:

1. Go to menu level 2.2.3.2 (SetupÞ OutputsÞ RelaysÞ Switch Points). Relays 1 or 2 must be in a flow or

temperature mode. See above section.

2. Select 1=Rly #1 or 2=Rly #2. To view the current switch point settings select 1=View Sw. Pt. To set the switch

point follow one of the procedures below.

a. Select 2=Above to activate the relay above a switch point value. Enter a numeric value for the upper

limit of the switch point. Press ENTR to accept the value.

b. Select 3=Below to activate the relay below a switch point value. Enter a numeric value for the lower

limit of the switch point. Press ENTR to accept the value.

c. Select 4=Inside to activate the relay if flow or temperature values approach the switch point from the

outside going inside. Enter a numeric value for the upper limit of the switch point range. Press ENTR

to accept the value. Enter a numeric value for the lower limit of the switch point range. Press ENTR to

accept the value.

Doc. No. 003185 Rev. B 3 - 11

Model MT91 Multipoint Flowmeter

Page 12

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

d. Select 5=Outside to activate the relay if flow or temperature values go outside the switch point range.

Enter a numeric value for the lower limit of the switch point range. Press ENTR to accept the value.

Enter a numeric value for the upper limit of the switch point range. Press ENTR to accept the value.

4. Select 3=Hysteresis from menu level 2.2.3 Relays.

5. Select 1=Rly #1 or 2=Rly #2. Enter a numeric value for the desired deactivation of the switch point. The

display will read "Recovers xxx", this is the deactivation point. Press ENTR to accept the value.

Note:

The factory recommends that the password be enabled after making changes to the system parameters if it

has been disabled.

Daily Calibration Testing

The calibration error test interrupts the normal flow metering process to test for shifts or changes in parameters that

affect the calibrated accuracy of the flowmeter. This test can be manually initiated by using the keypad to make a

selection from the system menu, or it can be scheduled to automatically occur periodically with a 24-hour interval.

Both channels of the analog output card are driven to set values during the test. Figure 3-8 shows the screens that

will display during the calibration test sequence.

SELF TESTING

Heaters are OFF

2 minute 4 mA out

HOME to exit

A

SELF TESTING

Heaters are OFF

2 minute 12 mA out

HOME to exit

B

SELF TESTING

Heaters are ON

3 minute warmup

HOME to exit

E

SELF TESTING

Heaters are OFF

2 minute 20 mA out

HOME to exit

SELF TESTING

Balancing Sensor 1

Please Wait

Press Home to Exit

D

Figure 3-8. Calibration Test Display Screens

UNBALANCED HEADS

1 . . . 5 . . . . 0 . . . . 5 .

x . . . . . . . . . . . . . . .

(x = suspect)

FC

Bal Dev = 0.00%

Low Dev = 0.00%

Mid Dev = 0.00%

Hi Dev = 0.00%

G

C00280-1

While screen A is displayed, the analog outputs are at a 4 mA or 0 Vdc level. While screen B is displayed, the

analog outputs are at a 12 mA, 2.5 Vdc or 5 Vdc. While screen C is displayed, the analog outputs are at 20 mA, 5

Vdc, or 10 Vdc. Each of these screens and corresponding outputs are sustained for two minutes. Screen D will

display for each sensing point that is assigned to the flowmeter. From this point until the conclusion of the test, the

analog output will be fixed at 4 mA. When screen E displays, the system has completed the calibration test and the

heaters have been turned back on.

Model MT91 Multipoint Flowmeter

3 - 12 Doc. No. 003185 Rev. B

Page 13

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Ø To manually initiate the Calibration Test

1. Go to menu level 3.3.1 (DiagnosticsÞ Calibration TestsÞ Start Test). The sequence of screens A through E will

display.

2. To view the results of the test, select 2=Display Results, from the menu level 3.3. If the system is unable to

balance out one of the sensing points, the suspect head will be noted with an x as shown in screen F. If no

balance problems occurred, screen F will not display. Finally, screen G displays the deviation of the stimulated

signals from the expected results.

Ø To set up the automatic Daily Calibration Test

w Set the time of day.

1. Go to menu level 2.6 (SetupÞ Clock). Enter the hour and press ENTR.

2. Enter the minutes and press ENTR.

3. Press any key to exit.

w Set the time of the test.

1. Go to menu level 3.4 (DiagnosticsÞ Schedule Tests).

2. Select 1=Calibration Drift.

3. Enter the hour and press ENTR.

4. Enter the minutes and press ENTR.

5. Enter the seconds and press ENTR.

w Enable the automatic test.

1. Go to menu level 3.4 (DiagnositcsÞ Schedule Tests).

2. Select 2=Enable Auto Test.

3. Select 1=Enable or 2=Disable.

With the daily automatic test enabled, the calibration drift test will run the same time each day. The normal outputs

will be driven to test values and the calculated results will be available for display.

Advanced Features

The remainder of this chapter contains topics that may not be applicable to every user of the flowmeter. In most case

the flowmeter will be ready for use straight out of the box. However, there may be instances where the advanced

features of the flowmeter may be needed. This section discusses how to correct for bias errors due to non-ideal

installations and how to communicate with the flowmeter through the serial port.

Flow Rate Correction Equation

The flow rate correction equation or corrector is used to bias the flow rate output. The correction equation contained

in the flowmeter allows the user to correct for bias errors due to non-ideal installation effects. The correction

equation is applied to the measured flow rate and then this corrected flow rate is used to drive the analog outputs and

manipulate the relays. The flow rate shown on the display is also the corrected value. The correction equation for

the flowmeter is shown below.

m C Cm Cm Cm

=+ × + × + ×

new

()()()

120 30

2

3

40

where m0= Measured Flow Rate

Ci= Correction Equation Coefficients (i = 1 through 4)

Default configuration is C1= 0, C2= 1, C3= 0, and C4= 0.

m

= Corrected Flow Rate

new

Doc. No. 003185 Rev. B 3 - 13

Model MT91 Multipoint Flowmeter

Page 14

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

Application of the correction equation will be illustrated in the following example. Through analysis of the process

flow stream it is determined that the flow rate must be multiplied by 1.056 to output the desired value. The

correction equation takes the following form.

Example:

mmmmm

new

(. )( )( ) .

=+ × + × + × = ×0 1 056 0 0 1 056

00

2

3

0

0

where C1 = 0

C2 = 1.056

C3 = 0

C4 = 0

A more complicated situation would be where the multiplication factor varies with the flow rate. Figure 3-9 shows

the variation of desired flow rate versus the measured flow rate.

50

40

Desired

Flow Rate

30

20

10

0

0 204060

Measured Flow Rate

C00248-1

Figure 3-9. Desired Flow Rate Versus Measured Flow Rate

The relationship between the measured and the desired flow rates was determined through a least squares analysis.

The coefficients for the above relation are:

C1 = -7.5672 C2 = 2.09253

C3 = -0.037082 C4 = 0.0003505

Ø To enter the correction equation coefficients and enable it:

1. Go to menu level 2.2.5 (SetupÞ OutputsÞ Corrections).

2. Press 2=Enter Correction. Enter the user password (if it enabled).

3. Enter all the desired coefficients. When complete, press 6=Verify and Save. Scroll through the displayed

coefficients then save them if they are correct.

4. Press ENTR and then 1=Enable. Select 1=Enable or 2=Disable.

Offset Adjustment of Sensing Points

Using the offset adjustment allows the customer to shift the calculated flow rate up or down to agree with another

reference instrument. FCI uses a balanced order polynomial equation to map the sensing point information to a

curve. The general form of this equation is shown below.

21 2

=++++

Flow C R C R C C R C R

Model MT91 Multipoint Flowmeter

−−

∆∆ ∆∆

12345

()() ()()

3 - 14 Doc. No. 003185 Rev. B

Page 15

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

)

l

Figure 3-10 illustrates the effect of adding an offset of plus 1 ohm and adding an offset of minus 1 ohm to the raw

signal.

Delta-R versus Flow

100.00

80.00

60.00

40.00

Flow (SF/S

20.00

0.00

0.00 2.00 4.00 6.00 8.00 10.00 12.00 14.00 16.00

Delta R (Ohms)

Figure 3-10. Delta-R Versus Flow Rate

Flow

Plus 1 Ohm

Mi nus 1 Ohm

Ø To enter an offset value:

1. Go to menu level 4.4.4 (CalibrationÞ Cal FlowÞ Offset).

2. Select 1=Offset Values. Enter sensing point number and value of desired offset. Units are always in ohms.

3. Select 2=Enable Offset.

Applying the Filter

For applications with noisy flow profiles, the filter can be used to reduce jumps or oscillations in the output signal.

The flowmeter takes samples of the flow rate periodically at each active sensing point. If the current value jumps up

when the next sample is taken, applying the filter can help smooth this jump out. The rate at which a sample is taken

depends on the number of active sensing points. The more sensing points that are active, the longer the intervals

between samples.

The filter strength acts stronger with increasing interval time. A filter strength of 2 for a 4-point system takes twice

as long to apply than a filter strength of 2 for a 2-point system. See Figure 3-11.

45

40

35

30

25

20

15

Flow Signa

10

Vc

Vs

Vn

5

0

012345678910111213141516171819202122232425

Time

2-point system, Filter = 2

4-point system, Filter = 2

No Filter

Figure 3-11. Effects of Filter on Flow Signal Versus Time

Doc. No. 003185 Rev. B 3 - 15

Model MT91 Multipoint Flowmeter

Page 16

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

The filter uses the following equation to adjust the output signal.

−()

VV

=+

VV

nc

sc

f

V

= New or desired value

n

Vc = Current Value

Vs = Sample Value

f

= Filter Strength

Ø To change the filter strength:

1. Go to menu level 2.2.4 (SetupÞ OutputsÞ Filter).

2. Enter desired filter strength.

Serial Communications

The flowmeter has one serial port that can be configured to use one of three EIA standard interfaces: EIA-232C,

EIA-422, or EIA-485. The data transfer rate can be set to either 4800, 9600, or 19200 baud. The number of bits in a

character is set to eight, and no parity bit is used.

Ø To use serial communications:

1. Go to menu level 2.3.3 (SetupÞ CommunicationsÞ Protocol).

2. Select 1=Pro1 or 3=Pro 3. Protocol 1 is a command and response protocol. Protocol 2 is not defined. Protocol

3 is a limited command and response protocol used to extract flow and raw signal data for up to 4 sensing points.

3. Set the data transfer rate, character bits, and parity bit on the host system.

4. To use protocol 1, refer to Table 3-4 for a list of commands and responses. These commands must be entered in

capitalized letters to be recognized by the system.

5. To use protocol 3, use the single character 'F' (flow) followed by a carriage return to display 4 sets of flow

values. Use the single character 'R' (resistance) to display 4 sets of sensing point resistance values.

Time Delay

The time delay function freezes the outputs for an operator specified time period.

Ø To use time delay:

1. Go to menu level 7.0 (Time Delay).

2. Enter the amount of time in minutes desired for the delay length.

3. The instrument will count down the time, while freezing the output. Any key can be pushed to exit the time

delay. When the time has expired the instrument will continue with normal operation.

Model MT91 Multipoint Flowmeter

3 - 16 Doc. No. 003185 Rev. B

Page 17

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Table 3-4. Commands and Responses for Protocol 1

Command System Response Description

SFPnn X.XXXXXXXXX Linear flow in SF/S for sensor nn

SFOPn X.XXXXXXXXX Average flow of output n (see SFUNI)

STPnn X.XXXXXXXXX Standard Temperature (F) of sensor nn

STOPn X.XXXXXXXXX Average temp of output n (see STUNI)

SSHnn X Status of sensor nn. 1 - ok, 0 - not ok

SCBnn X.XXXXXXXXX Bias offsets for sensor nn ( Ohms )

SC1nn X.XXXXXXXXX Linearization coefficient 1 for sensor nn

SC2nn X.XXXXXXXXX Linearization coefficient 2 for sensor nn

SC3nn X.XXXXXXXXX Linearization coefficient 3 for sensor nn

SC4nn X.XXXXXXXXX Linearization coefficient 4 for sensor nn

SC5nn X.XXXXXXXXX Linearization coefficient 5 for sensor nn

SI1nn X.XXXXXXXXX Reference Gain cal. factor for sensor nn

SI2nn X.XXXXXXXXX Reference Offset cal. factor for sensor nn

SI3nn X.XXXXXXXXX Active Gain cal. factor for sensor nn

SI4nn X.XXXXXXXXX Active Offset cal. factor for sensor nn

SMNnn X?? Minimum delta-r for sensor nn

SMXnn X?? Maximum delta-r for sensor nn

SCTnn X.XXXXXXXXX Temperature compensation adjustment

SCFnn X.XXXXXXXXX Correction factor to flow output

SAREA X.XXXXXXXXX Area of duct

SAUNI TTTTT???? Units of measure for area

SFUNI TTTT?? Units of measure for flow

SFFAC X.XXXXXXXXX Conversion factor SF/S to ????

SPMPn TTTT Mode of output n. FLOW or TEMP

SPOPn TTTT?? Analog output type for output n

SPSPn X.XXXXXXXXX Span value for output n in ??? units

SP0Pn X.XXXXXXXXX Zero value for output n in ??? units

STUNI T Units of measure for temperature

STMPF X.XXXXXXXXX Conversion multiplier for temperature

STADF X.XXXXXXXXX Conversion offset for temperature

SRRnn X.XXXXXXXXX Reference resistance for sensor nn

SRDnn X.XXXXXXXXX Delta-R resistance for sensor nn

SSCEM XXXX Hex code for heads which won't balance

SBCEM X.XXXXXXXXX Percent (FS) deviation from balance cal test

SLCEM X.XXXXXXXXX Percent (FS) deviation from Low Flow cal. test

SMCEM X.XXXXXXXXX Percent (FS) deviation from Mid Flow cal test

SHCEM X.XXXXXXXXX Percent (FS) deviation from High Flow cal test

????? ? RESPONSE TO UNKNOWN COMMAND

Doc. No. 003185 Rev. B 3 - 17

Model MT91 Multipoint Flowmeter

Page 18

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

Model MT91 Multipoint Flowmeter

3 - 18 Doc. No. 003185 Rev. B

Loading...

Loading...