Page 1

CHAPTER 2 - INSTALLATION FLUID COMPONENTS INTL

2. Installation

Receiving/Inspection

• Unpack carefully, observe Electro-Static Discharge (ESD) precautions if handling the flow transmitter.

• Inspect for damage to the flow element and the flow transmitter.

• Verify that all items in the packing list were received and are correct.

• Verify the Delta R Data Sheet and the Instrument Information Sheet are present in the plastic page protector

found in the back of the manual.

If the above items are satisfactory then proceed with installation. If not, then stop and contact the FCI customer

service representative for instructions.

Packing/Shipping/Returns

These issues are addressed in Appendix C - Customer Service.

Factory Calibration Note

The flowmeter is factory calibrated to the flow range specified in the order. There is no need to perform any

verification or calibration steps prior to installing and placing the flowmeter in service.

Pre-Installation Procedure

Warning:

Caution:

Install the flowmeter with properly trained personnel only. Perform the installation according to

the current edition of the National Electrical Code. Ensure that all power is OFF. Any instances

where power is to be applied to the flowmeter will be noted in this manual. Where the

instructions call for the use of power, the operator assumes all responsibility for conformance to

safety standards and practices.

The flowmeter is not designed for weld-in-place applications. Never weld to process connection

or a structural support.

Damage resulting from moisture penetration of the local or remote enclosure is not covered by

product warranty.

The flow transmitter contains electrostatic discharge (ESD) sensitive devices. Use standard ESD

precautions when handling the flow transmitter. See below for ESD details.

Use Standard ESD Precautions

Use standard ESD precautions when opening an instrument enclosure or handling the flow transmitter. FCI

recommends the use of the following precautions: Use a wrist band or heel strap with a 1 megohm resistor connected

to ground. If the instrument is in a shop setting there should be static conductive mats on the work table and floor

with a 1 megohm resistor connected to ground. Connect the instrument to ground. Apply antistatic agents to hand

tools to be used on the instrument. Keep high static producing items away from the instrument such as non-ESD

approved plastic, tape and packing foam.

The above precautions are minimum requirements to be used. The complete use of ESD precautions can be found in

the U.S. Department of Defense Handbook 263.

Doc. No. 003162 Rev. F 2 - 1 Models MT86, MT86HT

Page 2

FLUID COMPONENTS INTL CHAPTER 2 - INSTALLATION

Verify Serial Numbers

Verify that the local (flow element terminal strip) enclosure, remote enclosure and flow transmitter control circuit

serial numbers match. If they do not match, incorrect measurements will be made.

When multiple local enclosures are connected to one remote enclosure, each local enclosure serial number has a

suffix that represents the flow element number. For example, if two local enclosures are connected to a remote

enclosure, the local enclosure will have a base serial number of 123, then the first local enclosure would have the

serial number 123-1. The second local enclosure would have the serial number 123-2.

Prepare or Verify Flow Element Location

The flow element location should have been previously determined before the time of order. Mounting the flow

element in a position different than originally determined may cause reading errors.

The shape of the flow element is cylindrical with a diameter of 2.00 inches (50.8 mm). The flow element length

(U-length) is customer specified. The recommended diameter for the clearance hole needed to mount the flow

element is 2.16 inches (54.8 mm).

For the best performance, prepare an additional support for flow elements that are longer than 2 feet (61 cm). See

Figure A-3 for the recommended connection.

Verify Dimensions

Verify the customer specified flow element U-length and instrument mounting interface dimensions are correct for

the application. Compare the instrument hardware, Appendix A and the process interfaces for fit.

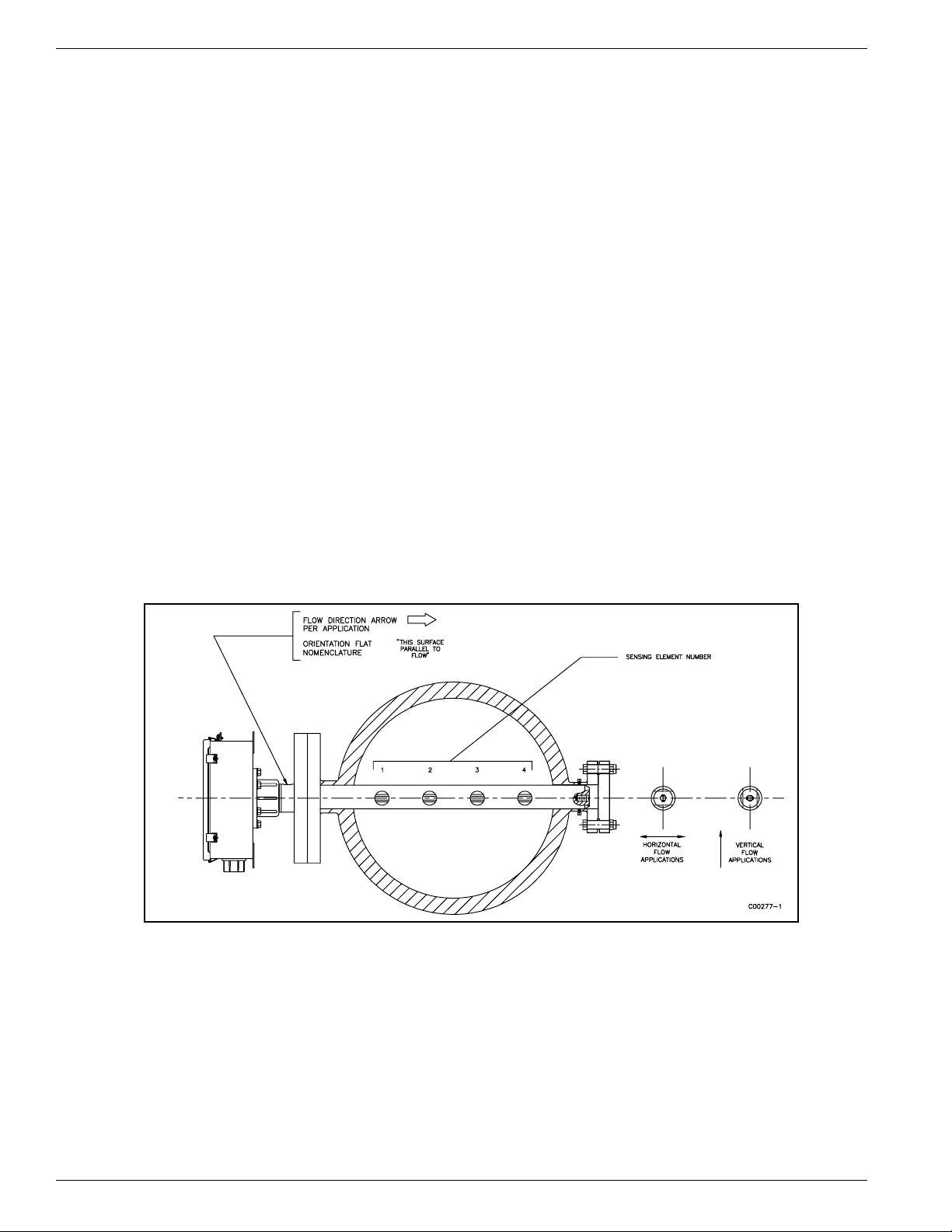

Verify Flow Direction for Flow Element Orientation and Placement

The flow element comes with a FLAT area machined on the flow element near the enclosure. There is a FLOW

ARROW etched in the FLAT. The FLOW ARROW indicates the direction of flow. See Figure 2-1 for details.

Figure 2-1. Flow Element Showing FLAT Area

Align the flow element so the FLAT is parallel to the direction of flow. Also, align the FLOW ARROW to point in

the direction of flow. Failure to correctly install the flow element will reduce the accuracy of the flowmeter.

Install Flow Element

Install the flow element for the type of process connection used. Follow one of the next paragraphs to install the

flow element. If applicable, connect the end of the flow element to a recommended mechanical support. See

Figure A-1 for the end connection.

Models MT86, MT86HT 2 - 2 Doc. No. 003162 Rev. F

Page 3

CHAPTER 2 - INSTALLATION FLUID COMPONENTS INTL

Threaded Mounting

Note: When mounting the flow element, use a lubricant or sealant applied to the male threads of all NPT

connections. The lubricant or sealant and process environment should be compatible. Make sure all

the process connections are tight. To avoid leaks do not over tighten or cross-thread the connections.

1. Verify end hardware is loose if present. Carefully insert the flow element into the process mount. Align the

flow element with the end support if present.

2. Verify that the process media is in the same direction as the FLOW ARROW on the FLAT that is near the local

enclosure.

3. The threads are right-handed. Place pipe wrench on un-threaded portion of metal shaft. Rotate until snug and

continue to turn until the FLAT is parallel to the process flow. Apply even pressure so as not to disfigure the

nipple.

Caution:

Do not apply any leverage to the local enclosure itself.

4. Tighten all connections. Tighten all end hardware if present.

Flanged Mounting

1. Verify end hardware is loose if present. Carefully insert the flow element into the process mount. Align the

flow element with the end support if present.

2. Attach the process mating flange with care. Maintain the correct orientation of the flow element to ensure

flowmeter accuracy.

3. Verify that the FLOW ARROW points in the same direction as the process media flow, and the FLAT is parallel

to flow.

4. Apply the appropriate gasket and/or sealant to the flange mount faces as required.

5. Attach with a bolt, two flat washers, lock washer and nut for each bolt hole; apply lubricant/sealant to male

threads and torque. For correct hardware and torque, refer to ANSI B16.5 specifications.

6. Tighten all of the connections.

Install Flow Transmitter

Caution:

For flow elements in explosive environments, isolate the conduit before it leaves the environment.

Use a potting "Y" to provide the isolation.

Mounting the Remote Enclosure

Figure A-1 shows the flowmeter enclosure with the physical dimensions for mounting of the flow transmitter

enclosure.

Note:

The factory recommends removal of the flow transmitter control circuitry while pulling the necessary

cables; this will prevent damaging electronic components. To remove the circuit boards unbolt the four

outermost screws on the mounting plate.

Doc. No. 003162 Rev. F 2 - 3 Models MT86, MT86HT

Page 4

FLUID COMPONENTS INTL CHAPTER 2 - INSTALLATION

Power Connection Information

Conduit Routing

All electrical connections are to be made through the 1 inch female NPT opening in the remote enclosure. FCI

strongly recommends that all electrical cables be run through an appropriate conduit for the protection of the

flowmeter and personnel. See Figure 2-2 for the wiring diagram.

The flow transmitter design requires the power and output conduit to connect with the remote enclosure's left access

port and the local enclosure conduit to connect with the right access port(s).

Protection of the flow transmitter from moisture is important. Keep the entry of the conduit into the enclosures in the

downward direction so condensed moisture that collects in the conduit will not drain into the enclosure. The local

enclosure may not be turned more than 180° using the threads on the enclosure to gain an acceptable orientation. In

addition, FCI recommends sealing off the conduit with a potting Y or other sealing method to prevent moisture from

entering the enclosures.

Minimum Wire Size

Table 2-1 shows the smallest (maximum AWG number) copper wire which should be used in the electrical cables.

Use a lower gauge of wire for less of a voltage drop. Contact FCI concerning greater distances than those listed in

the chart.

Table 2 -1. Interconnecting Cable Size (AWG)

Maximum Distance for AWG

Connection

10 ft.

(3m)

50 ft.

(15m)

100 ft.

(31m)

250 ft.

(76m)

500 ft.

152m)

1000 ft.

(305m)

AC Power 22 22 22 20 18 16

Relay (2A) 28 22 20 16 12 10

Relay (10A) 22 16 12 8

6

Not

Recommend

Flow Element Wires* 24 24 24 22 22 18

*Requires a shielded cable. The shield is connected to the GND pin of TS_ of the input board. The

other end of the shield is left floating (no connection to the flow element enclosure).

The standard cable provided is 22AWG.

Flow Transmitter Wiring Connections

See the wiring diagram in Figure 2-2 for the flow element wiring to the input boards. Run separate excitation and

sense wires for the ACTIVE, REFERENCE, and GROUND connections. The flowmeter will not operate properly

without these connections. If the ACTIVE and REFERENCE wires are reversed the flowmeter will output incorrect

flow rates. Use shielded cable with all signal applications. Connect the shield to the input board only and not to the

flow element terminal strip. Connect the shield to pin 1 of TS_ on the input board.

The connector for sensing point 1 must be plugged into the innermost connector on the input board which is plugged

into P1 of the control board. Sensing point 2 is connected to the outermost connector of the same input board.

Sensing point 3 is plugged into the innermost connector on the input board which is plugged into P2 of the control

board. Sensing points 4 through 8 are plugged in the same manner.

Make the customer connections to the output modules (relay logic, current or voltage).

Models MT86, MT86HT 2 - 4 Doc. No. 003162 Rev. F

Page 5

CHAPTER 2 - INSTALLATION FLUID COMPONENTS INTL

Figure 2-2. MT86, MT86HT Wiring Diagram

Doc. No. 003162 Rev. F 2 - 5 Models MT86, MT86HT

Page 6

FLUID COMPONENTS INTL CHAPTER 2 - INSTALLATION

Input Power

Warning:

Note:

The output terminals are not power isolated with use of 24 Vdc as a power source.

Before inserting the cable core into the terminal strip connector, first turn the terminal screws 10 turns

counterclockwise. If this is not done, there is a possibility of inserting the wires between the top half of

the clamps and the frames instead of between the two clamp segments.

FCI strongly recommends installing an AC line disconnect switch (and possibly a fuse) between the power source

and the flowmeter. The line switch is an easy way to remove power for calibration and maintenance procedures.

Also the line switch is an added safety feature.

100 Vac, 115 Vac, 230 Vac or 24 Vdc is the power source for the flowmeter (use only one power source). Wire the

power directly to the power supply terminal strip TS1.

Isolated Output Option and 4-20 mA Adjustment

An isolated 4 to 20 milliampere (mA) output is an available option. The isolated output is available by connecting a

loop powered isolator module to the transmitter output. Figure 2-9 shows the isolator output module. The module

has its own set of output terminals which provide an isolated 4 to 20mA output equal to the non-isolated instrument

output. This one-to-one current isolation is used to prevent instrumentation ground loops. See Figures 2-10 or 2-11

for the appropriate wiring diagram to install the isolated output module.

Use of the isolator module will add a small signal conversion error to the instrument output and limit the output load

to 350 ohms. The module must be adjusted in the field to the specific customer load. A red LED on the module

indicates when loop power is applied.

1. Connect the customer load with a milliampere meter in series with the output terminals of the isolators. Observe

the correct wiring polarity.

2. Connect a milliampere meter in series with the input terminals. Observe the correct wiring polarity.

3. Apply power to the instrument. Initiate a full process media flow. Allow a 10 minute warm-up period.

4. Adjust the isolator output span potentiometer (see Figure 2-3 for placement) so both of the milliampere meters

read the same.

5. This completes the output isolator setup. Turn off the power, remove the milliampere meters and reconnect the

wiring.

Figure 2-3. Isolator Output Module

Installation Quick-Check List

1. Verify that serial numbers match.

2. Be sure the FLAT and FLOW ARROW are properly oriented.

3. Insure there are no leaks at the process connection.

4. Verify that the wiring is properly connected per the wiring diagram.

Models MT86, MT86HT 2 - 6 Doc. No. 003162 Rev. F

Loading...

Loading...