Page 1

CHAPTER 1 - GENERAL INFORMATION FLUID COMPONENTS INTL

1. General Information

Description

The MT86 and MT86HT is an air and gas mass multipoint flowmeter that incorporates a flow element(s) that is

connected to a flow transmitter. Together they are designed to measure the mass flow in pipes, ducts or stacks. The

flowmeter accurately measures the irregular flow profiles found in pipes, ducts or stacks. An MT86 or MT86HT

measures flow from up to eight individual sensing points. An average of the individual flow signals gives an output

signal that represents the total mass flow. This output signal will operate up to four different output modules of

choice.

Operating Principles

The flowmeter has flow elements containing sensing points that are connected to the flow transmitter (control circuit

boards) by a wiring harness. The flow elements and the flow transmitter are usually separated by some distance that

in some cases can be up to 1000 feet (300m). The output that comes from the flow transmitter goes to the customer's

applications, such as valve control circuitry, alarms or meters. The operational theory of the flow element sensing

points and the flow transmitter are as discussed below.

Flow Element

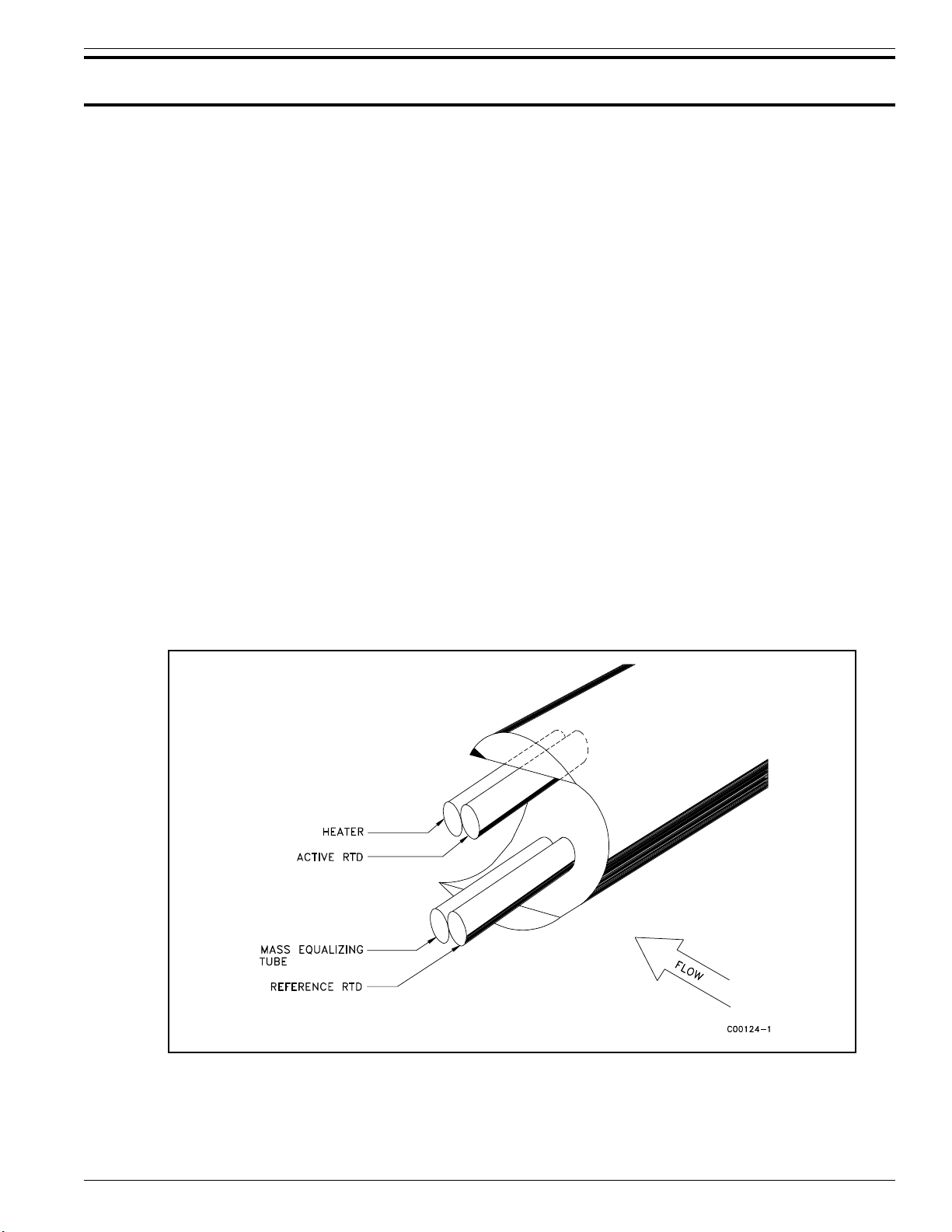

The flow element consists of 2 to 8 sensing points. Each sensing point has two pairs of thermowells (metal tubes) of

the same size and shape. Each pair of thermowells is welded together. One thermowell pair has a heating element

placed in one tube and an active Resistance Thermal Detector (RTD) placed in the other tube. The other thermowell

pair has a reference RTD placed in one tube and an empty thermowell tube that is for mass equalization. See

Figure 1-1 for a cut away view of one sensing point.

The two pairs of thermowells are physically separated by a distance that allows the process media to flow between

them and yet prevents thermal interaction between the two pair.

Figure 1-1. Cut-Away View of One Sensing Point

Doc. No. 003162 Rev. F 1 - 1

Models MT86, MT86HT

Page 2

FLUID COMPONENTS INTL CHAPTER 1 - GENERAL INFORMATION

Flow Transmitter

The flow transmitter measures the voltage differential (DV) produced by the temperature differential (DT) between

the active and reference RTDs for each individual sensing point. The flow transmitter amplifies the DV signal and

converts it into a signal that is temperature compensated and linearized. The linearized signals from the sensing

points are then averaged together and converted into the final output signal (4-20 mA, 0-5 Vdc, 0-10 Vdc, etc.) as

specified by the customer.

The flow transmitter has a diagnostic alarm. If a problem exists with a sensing point, a Light-Emitting-Diode (LED)

on the control board will flash to notify the customer.

Technical Specifications

• Process connection

2 inch male NPT or 2 inch 150 lb. raised-face

carbon steel flange.

• Number of sensing points

Up to and including 8 sensing points.

• Insertion length

The duct dimensions at the measurement site

determine the insertion U-Length.

• Material of construction

All wetted parts are 316 stainless steel with nickelbraze, per MIL-B-7883 using AMS 4777

• Local enclosure (flow element

terminal strip enclosure)

NEMA 4 enclosure with 1 inch female NPT

connection ports.

• Operating pressure

Standard MT86 is 0-50 PSIG or higher on

application.

• Operating temperature

Standard flow element: -50 to 350°F (-46 to

177°C).

High temperature (HT) element: -50 to 850°F

(-46 to 454°C).

• Remote enclosure (flow transmitter

control circuit enclosure)

NEMA 4 enclosure with 1 inch female NPT

connection ports.

• Input power

Standard 100-130 Vac or 200-270 Vac, 50/60 Hz,

50 watt maximum. Optional 24 Vdc, 50 watt max.

• Output signal

4-20 mA current loop capable of driving a 1000

ohm load. Optional:

10-50 mA, 400 ohm load max.

0-5 Vdc, 2 mA current max.

1-5 Vdc, 2 mA current max.

0-10 Vdc, 2 mA current max.

• Interconnecting cable

24 AWG (min.) 8-conductor shielded cable with

PVC insulation (100 feet maximum). Longer

distances are possible using a heavier gauge wire

for the heater circuit (see Table 2-1).

• Turn down ratio

2:1 to 100:1 within flow element range customer

specified.

• Accuracy

Flow transmitter: 0 to +150°F (-18 to 66°C) with

LCD or -50 to 150°F (-46 to 66°C) without LCD.

• Flow range

0.25 to 150 fps in gas under standard conditions

(14.7 PSIA @ 70°F).

• Flow element assemblies

± 3% of full scale at the temperature of calibration;

±5% of full scale with temperature compensation

over a range spanning 200°F. Manufacturer

determines the accuracy for specific duct

configurations upon submittal of a fully completed

Multipoint Mass Flowmeter Application Data

Sheet.

• Repeatability

May have 1, 2, 3 or 4 separate flow element

assemblies. Must contain a minimum of 2 sensing

points per flow element.

• Approvals

± 1% of full scale.

F.M., C.S.A., and CENELEC approvals are

available for all MT Series Multipoint Mass

Flowmeters.

Models HT86, HT86HT 1 - 2 Doc. No. 003162 Rev. F

Page 3

CHAPTER 1 - GENERAL INFORMATION FLUID COMPONENTS INTL

Options

• Enclosures

Explosion-proof NEMA 7 electrical enclosure is

available for both the flow element and flow

transmitter that complies with NEC Code, Class I,

Divisions 1 & 2, Groups C & D; Class II, Divisions

1 & 2, Groups E, F, & G.

• Flow Display Indicators

1) A three-and-one-half digit Flow Rate Display.

2) An eight digit Flow Totalizer Display.

• Available Outputs (up to four

module circuit boards)

Switch point: DPDT relay at 2 or 10 amp,

115 Vac.

Milliamp driver:

Current loop, 4-20 or 10-50 mA.

Analog voltage output:

0-5, 0-10, or 1-5 Vdc.

Remote sensor diagnostic alarm:

SPDT relay, 6A at 115 Vac.

• Rate Limit Board

Permits adjustment of the rate of change of the

output signal with respect to the rate of change of

the input signal. This option is used when the

measured flow is fluctuating and a stable output

signal is needed.

• Mass-to-Volume Converter

Changes the mass flow signal to a signal

representing actual cubic feet per minute or feet per

second (actual velocity).

• Accessories

The FC81 Field Calibrator simplifies calibration

verification of an MT86/MT86HT in the field.

This device provides the variable resistance

required to input a Delta "R" test value and a

digital read-out of the test output signal.

Doc. No. 003162 Rev. F 1 - 3

Models MT86, MT86HT

Page 4

FLUID COMPONENTS INTL CHAPTER 1 - GENERAL INFORMATION

Models HT86, HT86HT 1 - 4 Doc. No. 003162 Rev. F

Loading...

Loading...