Page 1

Installation, Operation and Maintenance

GF03 Flowmeter Series

[

]

Doc 06EN003352

Page 2

Page 3

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

1. General Information

2. Installation

3. Operation

Description ................................................................................................................................. 1

Theory of Operation ................................................................................................................. 1

Sensing Element ........................................................................................................................ 1

Flow Transmitter ....................................................................................................................... 2

Technical Specification ............................................................................................................ 2

Receiving/Inspection ................................................................................................................ 5

Packing/Shipping/Returns ....................................................................................................... 5

Factory Calibration Note .......................................................................................................... 5

Pre-Installation Procedure ....................................................................................................... 5

Install Flow Element ................................................................................................................. 6

Install Transmitter ..................................................................................................................... 8

Customer Wiring ....................................................................................................................... 9

Wiring Diagram, Remote with Veri-Cal ............................................................................... 10

Wiring Diagram, Remote ......................................................................................................... 11

Introduction ................................................................................................................................13

Start-Up Procedure ................................................................................................................... 13

Operation .................................................................................................................................... 13

Advanced Features .................................................................................................................... 27

Calibration Functions, Menu 7.0............................................................................................ 36

Veri-Cal, In-Situ Calibration Verification ............................................................................ 36

4. Maintenance

5. Troubleshooting

6. Appendices

Maintenance ............................................................................................................................... 39

Equipment Needed .................................................................................................................... 41

Quick Check............................................................................................................................... 41

In-Depth Troubleshooting - The Flow Element................................................................... 42

In-Depth Troubleshooting - The Flow Transmitter ............................................................. 43

In-Depth Troubleshooting - The Installation........................................................................ 44

In-Depth Troubleshooting - The Process .............................................................................. 44

Defective Parts ........................................................................................................................... 47

Spares .......................................................................................................................................... 47

Customer Service ...................................................................................................................... 47

Appendix A - Outline Drawings and Wiring Diagrams ..................................................... 49

Appendix B - Glossary of Terms ............................................................................................ 51

Appendix C - Customer Service ............................................................................................. 55

NOTICE OF PROPRIETARY RIGHTS: This document contains confidential technical data, including trade secrets and

proprietary information which is the property of Fluid Components International LLC (FCI). Disclosure of this data to you

is expressly conditioned upon your assent that its use is limited to use within your company only (and does not include

manufacture or processing uses). Any other use is stricly prohibited without prior written consent of FCI.

Doc. No. 06EN003352 Rev. B Model GF03 Flow Meter

Page 4

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

THIS PAGE INTENTIONALLY LEFT BLANK

Model GF03 Flow Meter Doc. No. 06EN003352 Rev. B

Page 5

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

1. General Information

Description

Theory of Operation

This document describes the procedures required to install, operate, maintain, and troubleshoot

the Model GF03 Flowmeter. There are a wide range of possible configurations and information

related to the optional features. The flowmeter is composed of a remote thermal dispersion

sensing transducer (flow element) connected to a microprocessor-based electronics control

and display package (flow transmitter). The flow element is attached to the flow transmitter

thru a cable of up to 1000 feet or 300 meters (remote instrument).

The instrument is designed to operate in gaseous flow metering environments. The flowmeter

is factory calibrated to handle a range of flows.

The primary flow element consists of two thermowells of the same size, shape and mass. One

thermowell contains a platinum RTD and a heater element. The other contains one RTD. The

RTD located with the heater element is called the active RTD. The other RTD is referred to

as the reference RTD. Since the active RTD is embeded in the heater, the temperature of the

active thermowell is always above the temperature of the process media. The temperature at

the reference RTD is the temperature of the process media. When the process media is flowing

past the active RTD a quantity of heat is carried off into the flow stream. The amount of heat

taken from the active RTD is a function of the process media mass flow rate. A ∆T

(temperature) exists between the two thermowells and a proportional ∆R (ohms resistance)

exists between the active and the reference RTDs. The ∆R is measured by the flow transmitter.

The relationship of ∆R to the calibrated flow rate is calculated by the flow transmitter and is

converted into both analog and digital outputs.

The Gas Compensation element provides a ∆R value similar to the primary flow element. This

value is a no-flow ∆R based on the thermo physical properties of the gas mixture minus any

flow component. This value is used to correct gas composition changes in the Transmitter

microprocessor.

Sensing Element

The standard sensing element is an all welded 316L stainless steel insertion probe. The

element consists of the primary flow element located on the end of the probe and the

compensator element located in the insertion pipe. The optional Veri-Cal inlet tube runs

the length of the insertion pipe exiting into the base of the primary flow element. This tube

allows the Veri-Cal system to distribute a repeatable flow rate on the primary flow element

for calibration verification purposes.

Figure 1 - Flow Element

Doc. No. 06EN003352 Rev. B 1 Model GF03 Flow Meter

Page 6

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

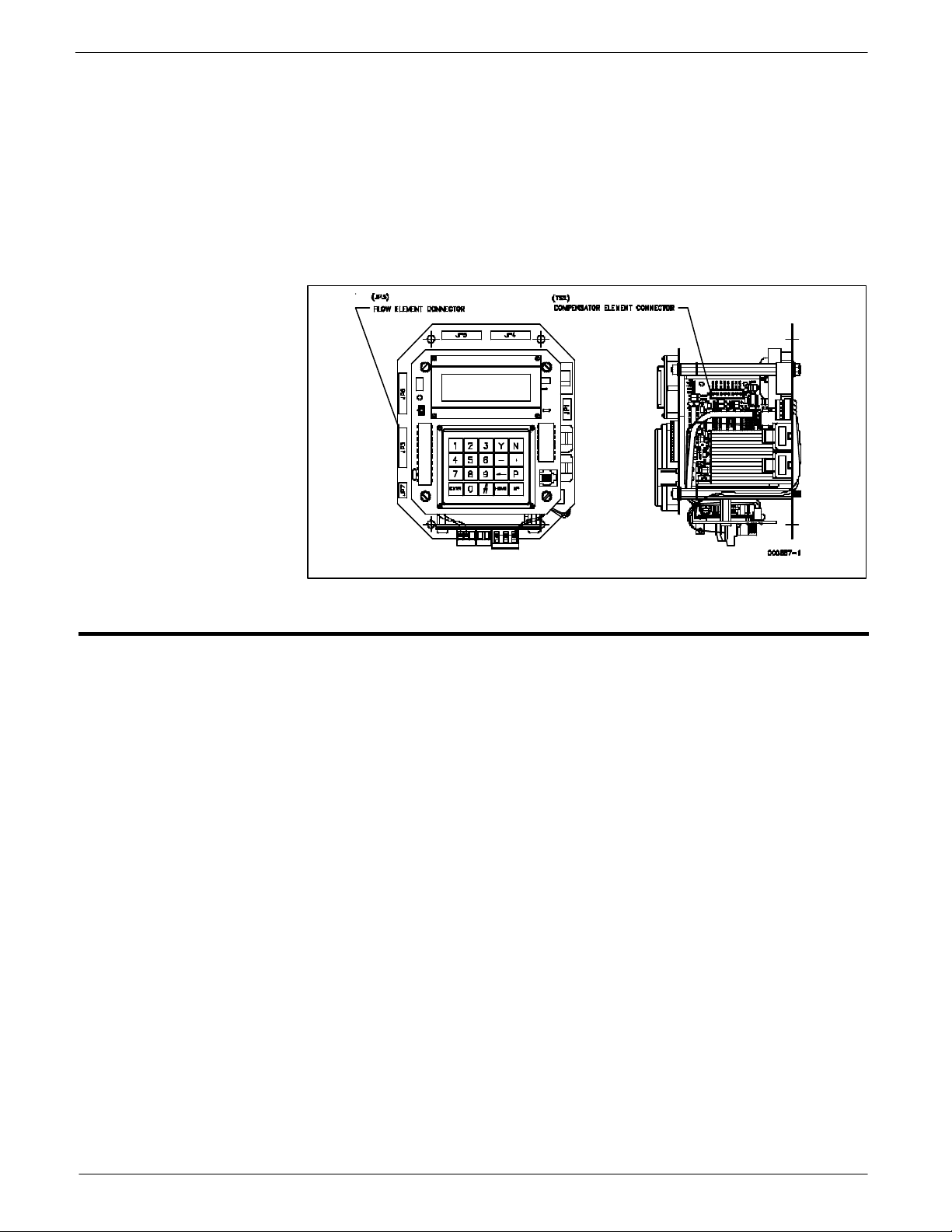

Flow Transmitter

The other component of the flowmeter is the flow transmitter. The basic functions of the flow

transmitter are to provide power to the flow element, measure the Differential Temperature

(∆T) between the two RTDs as a function of resistance, amplify and linearize the Differential

Resistance (∆R) measurement of the flow element and provide a proportional output signal.

This output signal is calibrated to the flow rate as a function of standard velocity or volume.

To perform these functions, microprocessor-based electronic circuitry is employed to acquire

the analog voltage signals from the RTDs, digitize and interpret the information.

The microprocessor-based electronics provides maximum flexibility and ease of operations

with a menu-driven selection of control, monitoring, display and driver options.

Technical

Specifications

Figure 2 - Flow Transmitter

INSTRUMENT

Flow Range:

Insertion Flow Element: 0.5 to 275 SFPS [0.20 to 84 NMPS]

— Air at standard conditions; 70°F [21.1°C] and 14.7 psia [1.01325 bar (a)].

Media: All gases that are compatible with the flow element material.

Accuracy:

Flow: ±2% to 5% of reading above 1 SFPS in open stack environments.

Temperature: ±2°F (display only, flow rate must be greater than 5 AFPS)

Repeatability:

Flow: ±0.5% reading

Temperature: ±1°F (flow rate must be greater than 5 AFPS)

Turndown Ratio:

Standard: Factory set and field adjustable from 2:1 to 600:1 within calibrated flow range.

Temperature Compensation:

Standard: ±30°F [±-1°C] Optional: ±100°F [±38°C]

Agency Approvals (Pending):

FM, CSA, CE MARK, (EMC Directive 89/336/EEC), ATEX, CCE, CRN.

Calibration: Performed on NIST traceable equipment.

FLOW ELEMENTS

Material of Construction: All-welded 316L stainless steel. Elements with pressure

transducer have braze and 300 series SST.

Operating Pressure: 0 to 250 psig [0 to 17 bar (g)]

Operating Temperature: Process temperature -40°F to 350°F [-40°C to 177°C];

Process Connection: 1” male NPT, Flange (ANSI), Packing Gland 1-1/4” NPT or Flanged.

Model GF03 Flow Meter 2 Doc. No. 06EN003352 Rev. B

Page 7

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

FLOW TRANSMITTER

Operating Temperature: 0 to 140°F [-18 to 60°C]

Input Power: 115 Vac ± 15 V; 230 Vac ± 30 V; 22 to 30 Vdc; 23 Watts Max.

Output Signal

Analog:

Two independent, AC power isolated, which can be set as follows:

4-20 mA, 600 ohm maximum load

0-10 Vdc, 5000 ohm minimum load

0-5 Vdc, 2500 ohm minimum load

1-5 Vdc, 2500 ohm minumum load

One optional pressure output:

4-20 mA, 600 ohm maximum load

One gas compensator output:

4-20 mA, 600 ohm maximum load.

Two programmable 10 amp (115 Vac or 24 Vdc) relay switch points.

Communication Port: EIA-232 [RS-232C]

Display: 4 line/20 character per LCD line, indicating flow rate and process temperature

and/or totalized flow.

Communicator(optional): Hand held plug-in interface (model FC88).

Remote Enclosure

Standard: NEMA/CSA Type 4X (equivalent to IP66) Fiberglass

Option: Aluminum rated for hazardous location use Class I and II, Division 1 and 2,

Group B, C, D, E, F, G (previously referred to as NEMA 7 and EEx d IIB) resists the

effects of weather and corrosion.

Doc. No. 06EN003352 Rev. B 3 Model GF03 Flow Meter

Page 8

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

THIS PAGE INTENTIONALLY LEFT BLANK

Model GF03 Flow Meter 4 Doc. No. 06EN003352 Rev. B

Page 9

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

2. Installation

Receiving / Inspection

Packing / Shipping

and Returns

Factory Calibration

Note

Pre-Installation

Procedure

w Unpack carefully, observe Electro-Static Discharge (ESD) precautions if handling the

flow transmitter.

w Inspect for damage to the flow element and the flow transmitter.

w Verify that all items in the packing list were received and are correct.

w Verify the Delta R Data Sheet and the Instrument Information Sheet are present.

If the above items are satisfactory then proceed with installation. If not, then stop and

contact the FCI customer service representative for instructions.

These issues are addressed in Appendix C - Customer Service.

The flowmeter is factory calibrated to the flow range specified in the order. There is no

need to perform any verification or calibration steps prior to installing and placing the

flowmeter in service.

Caution:

The flow transmitter contains electrostatic discharge (ESD) sensitive

devices. Use standard ESD precautions when handling the flow transmitter.

See below for ESD details.

The GF Series Flowmeter is not designed for weld-in-place applications. Never

weld into the installation or to a structural support.

Use Standard ESD Precautions

Use standard ESD precautions when opening an instrument enclosure or handling the flow

transmitter. FCI recommends the use of the following precautions: Use a wrist band or heel

strap with a 1 megohm resistor connected to ground. If the instrument is in a shop setting there

should be static conductive mats on the work table and floor with a 1 megohm resistor

connected to ground. Connect the instrument to ground. Apply antistatic agents to hand tools

to be used on the instrument. Keep high static producing items away from the instrument such

as non-ESD aproved plastic, tape and packing foam.

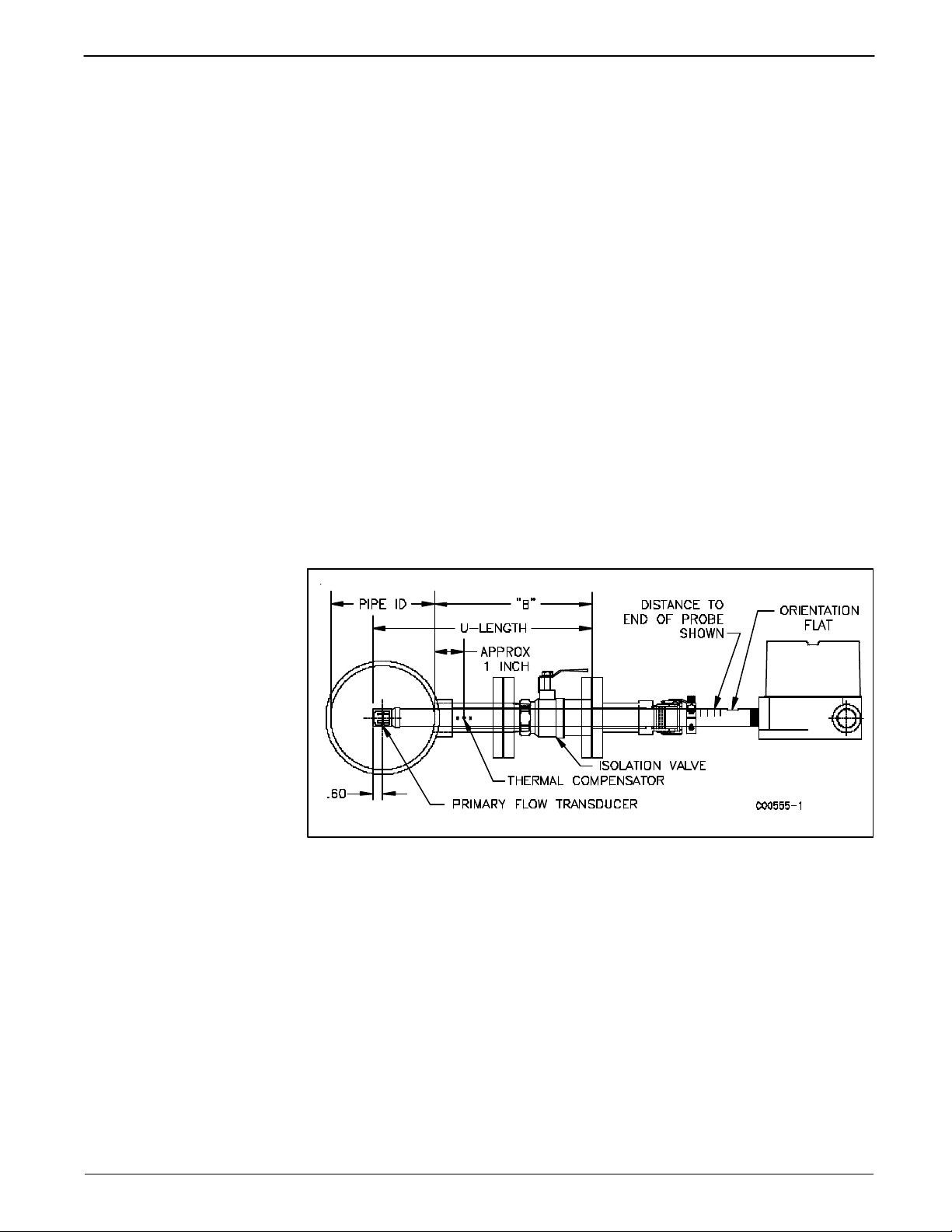

Prepare or Verify Flow Element Location

Prepare the media process pipe for installation or inspect the already prepared location to

ensure the instrument will fit into system. Prepare the necessary sealants or gaskets to provide

a leak proof installation.

The U-length should be double checked when installing the flow element into the process

media. The U-length is determined at the factory order time and is the distance that places

the flow element head center line in the center line of process media. See Figure 3. The greatest

accuracy is achieved when the flow element is mounted at least 20 diameters downstream and

10 diameters upstream from any bends or interference in the process pipe or duct.

Doc. No. 06EN003352 Rev. B 5 Model GF03 Flow Meter

Page 10

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Verify Serial Numbers

Verify the flow element and flow transmitter have the same serial number, as they are to be

installed as a matched set.

Verify Dimensions

Verify the flow element and flow transmitter dimensions as shown in Appendix A.

Verify Flow Direction for Flow Element Orientation and Placement

Note: Correct flow element placement in the measurement stream is vital for obtaining

accurate flow readings. Before mounting the flow element, check the options

ordered for correct orientation and insertion length at the planned site of installation.

The flow element thermowells must be positioned in the same orientation to the process flow

as they were during calibration (refer to the Instrument Information Sheet). Failing to install

the flow element correctly may reduce the accuracy of the flowmeter. Be sure the flow arrow

points in the direction of flow.

The flow element thermowells are to be placed as shown in Figure 3, with the end of the

shroud 0.6 inches past center line.

There is a flat area machined perpendicular to the thermowell plane. Adjust the flow element during installation so the flat area is parallel, with in ±2°, to the direction of process

media flow.

Adjustable / Retractable

Flow Element Assembly

Caution: Do not over-tighten the flow element. The RTD's can be

dammaged if the flow element is forced into the far wall of the

pipe or vessel.

Select one of the following installation procedures which is applicable to the unit being

installed.

NPT and flange packing gland mounts are available. The valve assembly with appropriate

connections are typically customer supplied. Follow the pipe or flange mounting procedure

below.

NPT Pipe Mounting

w Apply sealant compatible with the process media to male threads. Carefully insert into

process mount. Threads are right-handed. Tighten with an open-end wrench on the

hexagonal surface provided. Rotate until snug.

Figure 3 - NPT Pipe Mount

Model GF03 Flow Meter 6 Doc. No. 06EN003352 Rev. B

Page 11

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Flange Mounting

w Attach the process mating flange with care. The correct orientation of the flow element

must be maintained to ensure the calibrated accuracy.

w Verify that the process media flow is in the same direction as the arrow on the FLAT.

w Apply the appropriate gasket and/or sealant to flange mount as required.

w Mate flow element flange to process mount keeping flat oriented properly.

w Attach with bolt, two flat washers, lock washer and nut for each bolt hole, apply lubricant/

sealant to male threads and torque. Refer to ANISI B16.5 specifications.

General Mounting

w Tighten packing nut until internal packing is tight enough so that the friction fit on the

shaft is adequate to prevent leakage but not prevent the shaft from sliding. Position the

flat horizontal with arrow in direction of process flow.

w Proceed to insert the flow element into process media line. For the medium pressure

packing gland use the adjusting nuts on the all-thread to pull the flow element into proper

predetermined depth position.

w Tighten the opposing lock nuts on the all-threads. Tighten the packing nut another 1/2

to 1 turn until tight (approximately 65 to 85 ft-lbs torque).

w Rotate split ring locking collar to line up with connecting strap welded to packing nut.

Tighten the two 1/4-28 hex socket cap screws on the split ring locking collar. Open valve

- check for process media leakage.

w Reverse these steps for removal.

Figure 4 - Flange Mount

Doc. No. 06EN003352 Rev. B 7 Model GF03 Flow Meter

Page 12

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Install

Transmitter

Warning: Installation of an FCI instrument should only be performed by properly trained

personnel in accordance with the current edition of the National Electrical

Code. Ensure that all power is off. Any instances where power should be

applied to the instrument will be noted in this manual. Where the instructions

call for the use of electrical current, the operator assumes all responsibility for

conformance to safety standards and practices.

Caution: In applications where the flow element is located in an explosive environment,

isolate the conduit before it leaves the environment. A potting "Y" may be used

to provide the isolation.

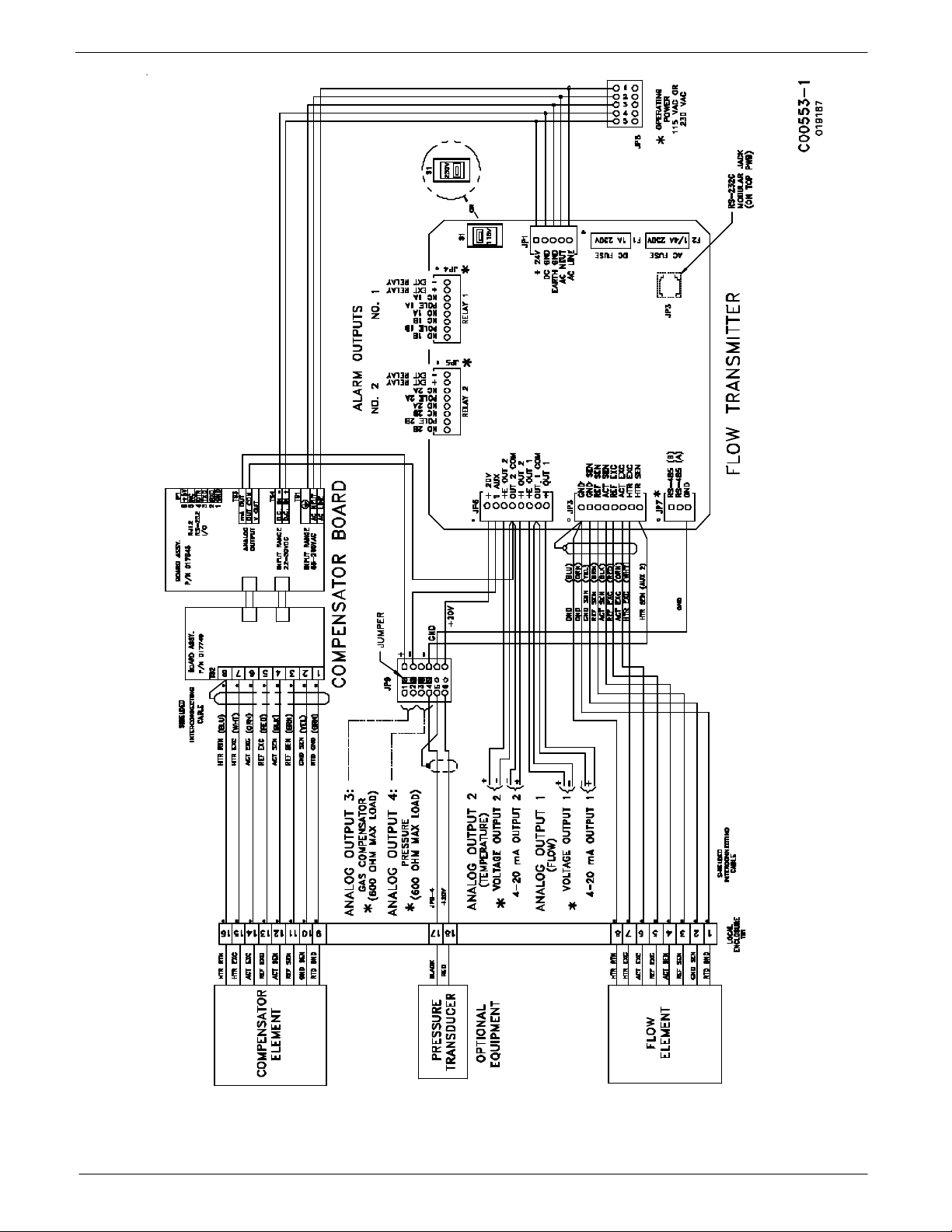

Remote Hardware

See Appendix A for the remote enclosure along with the physical dimensions so the flow

transmitter can be properly mounted.

Note: The factory recommends removal of the transmitter while pulling the necessary

cables; this will prevent damaging the circuit boards or their components. To

remove the transmitter unbolt the four outermost screws on the transmitter

mounting plate.

Power Connection Information

Conduit Routing

All electrical connections are to be made through the female NPT openings in the flow

transmitter's enclosure. FCI strongly recommends that all electrical cables be run through an

appropriate conduit for the protection of the instrument and personnel. Refer to the

appropriate wiring diagram.

Protection of the electronics from moisture is an important consideration. Keep the entry of

the conduit into the enclosures in the downward direction so condensed moisture that collects

in the conduit will not drain into the enclosure. In addition, FCI recommends sealing off the

conduit with a potting Y or other sealing method to prevent moisture from entering the

enclosure.

Minimum Wire Size

Table 1 shows the smallest (maximum AWG number) copper wire which should be used

in the electrical cables. Use a lower gauge of wire for less of a voltage drop. Contact FCI

concerning greater distances than those listed in the chart.

Connection

AC Power 22 22 22 20 18 16

Relay

(2A at 220 VAC)

Relay

(10A at 120VAC or 24

VDC)

Flow Element Wires for

Remote Option *

Pressure Transducer 24 24 24 22 22 18

10 ft.

(3 m)

24 22 20 16 12

22 16 12 Not Recommended

24 24 24 22 22 18

50 ft.

(15 m)

Maximum Distance for AWG

100 ft.

(31 m)

250 ft.

(76 m)

500 ft.

(152 m)

1000 ft.

(305 m)

Not

Recommended

Table 1 - Interconnecting Wire Size

* Requires two 8 conductor shielded cables. The shield is connected to the GND pin of

JP3 of the flow transmitter. The other end of the shield is left floating (no connection

to the terminal block).

Model GF03 Flow Meter 8 Doc. No. 06EN003352 Rev. B

Page 13

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Input Power

The flow transmitter is powered by 115 VAC, 230 VAC or 24VDC (only one power source

is needed). If 115 VAC is used, wire it directly to JP8 and position switch S1 to be in the 115V

position. If 230 VAC is used, position switch S1 to be in the 230V position and then wire the

power directly to JP8. If 24 VDC is used, it is wired directly to JP8 as shown on the wiring

diagram.

The installation of an AC line disconnect switch (and possibly a fuse) between the power

source and the flowmeter is strongly recommended. This facilitates easy power disconnection

during calibration and maintenance procedures as well as an added safety feature.

Remote Transmitter

Route all interconnecting wiring into the remote transmitter enclosure. Ensure wires are

long enough with sufficient service loops to eliminate excessive strain on the terminal

connections. Connect Flow and Analyzer element cables as shown on wiring diagram.

The display orientation varies for different transmitter configurations, but the termination

block for the element connection remains the same. If the Veri-Cal option was ordered,

wire the pressure transducer as shown on the wiring diagram.

Figure 5 - Electronics Assembly

Customer Wiring

Jacks JP3 (top circuit board), JP4, JP5, JP6 and JP7 are for customer use and are

described in Table 2.

JACK / NOMENCLATURE DESCRIPTION

JP3 (top circuit board)

RS-232 (EIA-232) Serial Port

JP4 Relay Output 1

and

JP5 Relay Output 2

JP6 Analog Output

Doc. No. 06EN003352 Rev. B 9 Model GF03 Flow Meter

Table 2 - Customer Wiring

Used in conjunction with equipment compatible

with an RS-232 (EIA-232) serial port. See Chapter

3 for more details.

Factory pre -programmable relay contacts. Two

normally closed contacts are available (double pole,

single throw relay) per jack. External relays can be

connected to the +EXT and -EXT pins in each jack.

Recommended relays are 18Vdc, 0.1A. max at 180

or more ohms pull i n current.

There are two factory pre -programmable signals

which are voltage and/or current. The 1 AUX and

+20V pin is a customer option for the use as a

dynamic correction factor. See Chapter 3 for more

information.

Page 14

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Figure 6 - Wiring Diagram, Remote with Veri-Cal

Model GF03 Flow Meter 10 Doc. No. 06EN003352 Rev. B

Page 15

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Figure 7 - Wiring Diagram, Remote

Doc. No. 06EN003352 Rev. B 11 Model GF03 Flow Meter

Page 16

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

THIS PAGE INTENTIONALLY LEFT BLANK

Model GF03 Flow Meter 12 Doc. No. 06EN003352 Rev. B

Page 17

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

3. Operation

Introduction

Start Up Procedure

Operation

The flowmeter has been configured and calibrated to custom specifications. Each flowmeter

contains distinct operating limits and units of measurement. This chapter will show how to

determine and manipulate the configuration of the flowmeter.

1. After the wiring has been verified, apply power to the flowmeter. (No special instructions

for instrument shutdown; turn operating power off.)

2. Then wait 10 minutes for warm-up. During this period the flowmeter may indicate high

flow.

3. After power up the instrument automatically enters the flow metering mode and the

display sets to normal operation.

Display

The flowmeter contains a 4 x 20 character LCD display. Flow rate, temperature, and system

status are all accessible through the display.

Initialization Window

When power is applied to the flowmeter the display will briefly show the initialization

window. See Figure 8.

FCI GF03

Initializing

Wait, Please

V1.00 Dec 16, 2003

Version Number and

Revision Date

C00549-1

Figure 8 - Initialization Window

Normal Mode Window

The flowmeter upon power up defaults to the normal mode of operation and begins to display

the flow rate, the temperature, the total flow (if enabled ) and the current system status. The

Normal Operation display is shown in Figure 9.

Flow Units

Temperature

Totalizer

Sample

Rate

ModeRelay

C00239-2

Output

Channel #

Flow Rate

CH1: 5056.3 SCFM

CH2: 71.2 °F

435226 SCF

Σ =

(grp1)(ed)(norm)(m)

Group #

Status

Figure 9 - Normal Operation Display

Doc. No. 06EN003352 Rev. B 13 Model GF03 Flow Meter

Page 18

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Menu Window

The menu is made up of 4 components. They are the menu level, title, selections, and prompt

line. These components are illustrated in Figure 10. The top line displays a menu code and

title. Lines 2 and 3 are used to scroll through the available selections. The prompt line

indicates which menu commands are appropriate.

Title

Menu

Level

2.1 ANALOG SETUP

1=Setup Port 1

2=Setup Port 2

UP HOME

Available

Selections

Prompt

Line

C00435-1

Figure 10 - Menu Window

The menu code is a numeric reference that identifies each window of the menu

structure. The menu code in Figure 10 indicates that the user is two levels deep

(Level 2, sublevel 1). The menu structure will be explained further in Menu

Organization.

The title gives the user a better idea of where the system is within the menu structure. Some

titles are informative enough to completely describe the menu function, while other titles are

ambiguous unless there is knowledge of the parent menus.

The middle two lines display the available selection. The number of choices is often more than

the two displayed. Pressing the N (next) or P (previous) keys on the keypad will scroll the

selections up or down. To choose a function from the available selections press the

corresponding number on the keypad.

The prompt line displays appropriate menu control key strokes for that menu level. Pressing

N, the (N)ext key, will scroll the display down. Pressing P, the (P)rv or Previous key, will

scroll the display up. Pressing the UP key shifts the current menu level up one. Pressing the

HOME key goes straight to the 0.0 MAIN MENU.

Other Window Types

Another common window encountered is shown in Figure 11. The window is similar to the

Menu Window except that it does not scroll and all choices are contained within the window.

The current selection (if there is one) is also contained in the parenthesis to the left of the

question mark.

Press the corresponding number in the Available Sections for the choice of display.

Menu Level

Current

Selection

Title

3.1.2 STD VOLUME

1 = Cu feet 2 - Cu meter

3 = Liters

(CF)s ?

C00241-1

Available

Selections

Prompt

Line

Figure 11 - Non-Scrolling Menu Window

Model GF03 Flow Meter 14 Doc. No. 06EN003352 Rev. B

Page 19

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

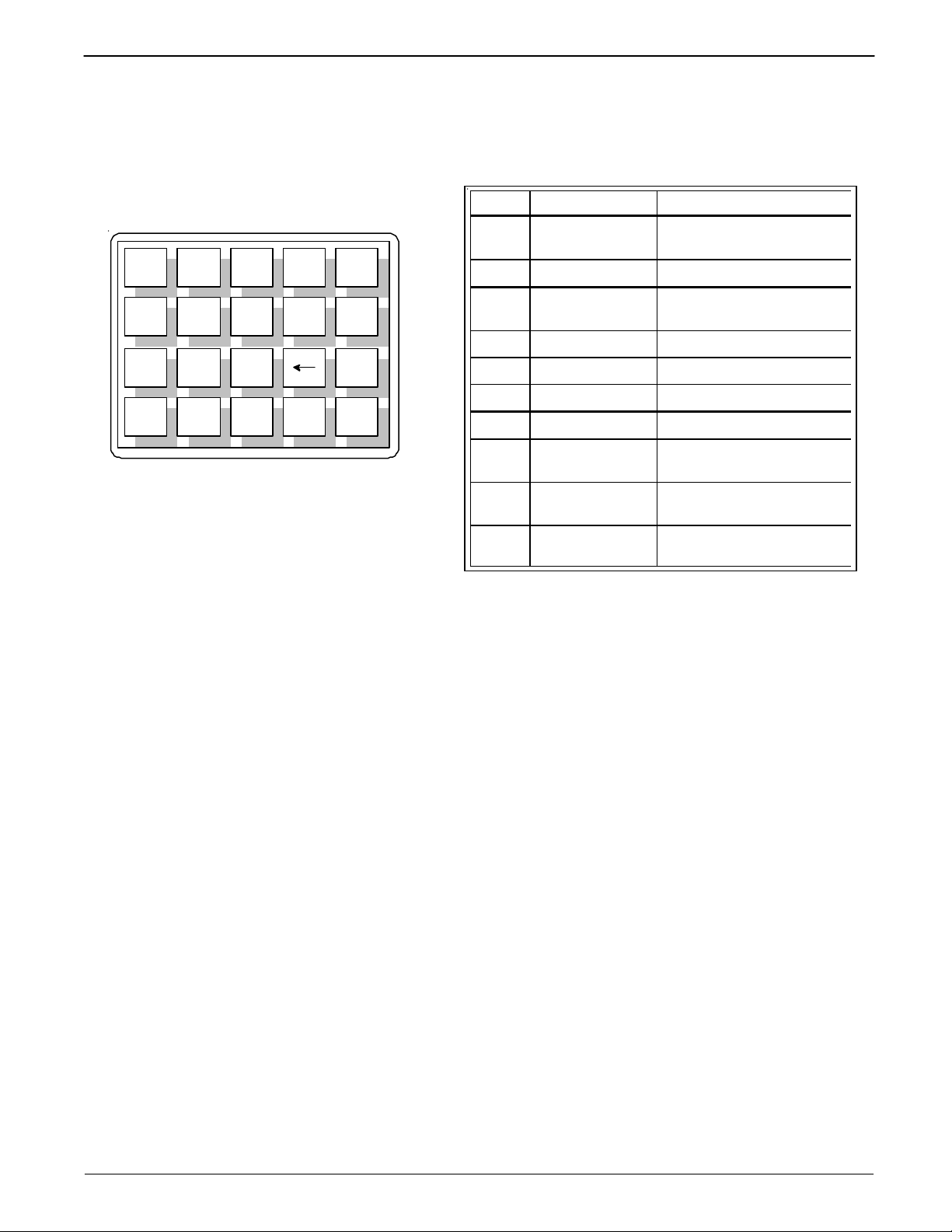

Menu Control

The prompt line displays appropriate key strokes for that menu level. If a key is pressed that

is not valid for that menu, Invalid Response will flash briefly across the prompt line. The key

pad layout is shown in Figure 12.

Key Key Name Action

1 2 3 Y N

4 5 6

7 8 9 P

ENTR

0 #

_

HOME

Figure 12 - Key Pad

See Table 3 for key pad assignments. At any time, the HOME key can be pressed and the main

menu will display. HOME can be used to escape from most routines, restart a progression into

the menu structure, or quickly change from one area of the menu to another.

When (N)ext is displayed on the prompt line, more than two menu selections are available.

Press N to scroll through all the selections.

The UP key, will back-out of a menu level. The menu moves back one level each time the UP

key is pressed. The UP key only functions when UP is displayed on the prompt line.

To make a selection, press the numeric key associated with the desired menu selection. The

selection does not have to be displayed, but it must be one of the available selections.

Every path through the menu will eventually cause control to pass from the menu structure

to a routine that performs a task such as change a parameter value, initiate a test, or calibrate

the system hardware. When the system is operating outside the menu structure, there are

subtle differences in the user interface. For example, the UP key may have no affect or the

prompt line won't appear.

.

UP

C00220-1

0 - 9 Numeric

Y Yes Enter a yes response

N No or (N)ext

- Minus Enter a minus sign

Decimal Point Enter a decimal point

Back Space Moves cursor back one space

P (P)rv or Previous Scrolls to the previous screen

ENTR Enter

HOME Home

UP Up

Selects options and enters

numbers

Enter a no response or scrolls

to the next screen

Enters a numeric value or

response

Returns to the Main Menu or

escapes from routines

Move current menu up one

level

Table 3 - Key Assignments for the GF Series Key Pad

Doc. No. 06EN003352 Rev. B 15 Model GF03 Flow Meter

Page 20

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Menu Organization

The menu structure is divided into 8 major groups. The first menu option places the flow

transmitter's display into the Normal Display mode. When the system is in this mode, flow

and temperature measurements are displayed. While in the Normal Display mode, pressing

any key will cause the main menu to display. Figure 13 shows the entire menu structure.

Menu selections two through eight allow the configuration of the flowmeter to be checked

and manipulated. Table 4 summarizes the functions contained in each menu group.

Group Name Function

2.0 Port Setup

Sets analog outputs, set relay switch point and

configure the auxiliary input.

Sets the units of measure for the displayed flow

3.0 Display Setup

rate, temperature and total flow. Sets the sample

rate.

4.0 Miscellaneous

Sets the current calibration group. Configures

the Corrector. Sets the user password.

5.0 Verify Displays system variables to the screen.

6.0 Diagnostics Factory use only.

7.0 Calibration Displays Delta R in ohms.

8.0 Normalize Board Factory use only.

The Port Setup, Display Setup and Miscellaneous groups is where most activity is concentrated.

The Verify, Diagnostics, Calibration and Normalize Board groups are used primarily for

diagnostics and factory calibration.

Normal Operation

The flowmeter upon power up defaults to this mode. During normal operation the flow rate

and the temperature is displayed. The total flow is displayed if it is enabled and few system

configuration parameters are shown. Figure 9 is the Normal Operation display.

The first and second lines contain the current flow rate and temperature. The total flow is

displayed on the third line only if it is enabled. The last line contains the current Group

number (see the Multiple Groups section in Advanced Features), the relay status, the mode

of operation and the sample rate.

The relays status shows either e (energized) or d (de-energized). The letters correspond to

the first and second relays, respectively. The mode of operation is norm for normal, auto for

Auto-Select or link for Link Groups. (See Advanced Features for explanation of these

modes). The sample rate is slow (s), medium (m) or fast (f).

Table 4 - Menu Functions

Model GF03 Flow Meter 16 Doc. No. 06EN003352 Rev. B

Page 21

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

0.0 MAIN MENU

1 = Normal Operation

2 = Port Setup

3 = Display Setup

4 = Miscellaneous

5 = Verify

6 = Diagnostics

7 = Calibration

8 = Normalize Board

2.0 PORT SETUP

1 = Analog Output

2 = Relays

3 = Comm Output

4 = Aux Input

3.0 DISPLAY SETUP

1 = Flow Setup

2 = Temperature Setup

3 = Totalizer Setup

4 = Sample Rate

4.0 MISCELLANEOUS

1 = Set Group

2 = Corrector Setup

3 = Password Setup

5.0 VERIFY

1 = All

2 = Flow

3 = Totalizer

4 = Area

5 = Temperature

6 = Ports

7 = Relay

8 = Calibration

9 = Corrector

2.1 ANALOG SETUP

1 = Setup Port 1

2 = Setup Port 2

2.2 RELAY SETUP

1 = Setup Relay 1

2 = Setup Relay 2

3 = Test Relays

2.3 COMM PORT OUTPUT

1 = Set PC/Handheld

2 = Set 485 Address

2.4 AUX INPUT

1 = Enable/Disable

2 = Enter Aux.

3 = Test Input

4.1 SET GROUP

1 = Set Group

2 = Set Auto-Select

3 = Enable Auto-Select

4.2 CORRECTOR SETUP

1 = Enable/Disable

2 = Enter Corr

3 = Verify Corr

4.3 PASSWORD SETUP

1 = Enable/Disable

2 = Edit Password

CH1: 5056.3 SFCM

CH2: 71.2 F

Σ = 435226 SCF

(grp1) (dd) (mode N) (m)

Normal Operation

3.1 FLOW SETUP

1 = Mass

2 = Std Volume

3 = Velocity

3.2 TEMP SETUP

1 = Set Temp Units

2 = Set TCal Add

3 = Set TCal Mult

4 = Verify

3.3 TOTALIZER SETUP

1 = Enable/Disable

2 = Flow Units

3 = Reset

4 = Verify

5 = Totalizer Prescale

6 = Display Group Summ

7 = Aggregate Tot Mode

6.0 DIAGNOSTICS

1 = Output Tests

2 = Circuit Tests

7.0 CALIBRATION

1 = Show Delta R

2 = Show Raw Data

3 = Set Calibration

4 = Veri-Cal

8.0 NORMALIZE BOARD *

1 = Set Heater

2 = Set ACT/REF

3 = Set Outputs

4 = Board Version

5 = Set Defaults

* Requires Factory Password

7.3 SET CALIBRATION

1 = Set Coeff Group

2 = Set Sensor Type

3 = Set Flow Coeff's

4 = Set Temp Coeff's

5 = Standard Density

6 = Set Limits

7 = Link Groups

8 = Verify

6.2 CIRCUIT TESTS

1 = Gain

2 = Temp

3 = TA/D Mode

4 = Switches

5 = Heater Current

8.3 SET OUTPUTS

1 = Calibrate Outputs

2 = Test Outputs

MENU 11-17-03.VSD

Figure13 - Menu Structure

Doc. No. 06EN003352 Rev. B 17 Model GF03 Flow Meter

Page 22

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Quick Operation Procedure

Input power is the only thing needed to operate the instrument. If a modification to the factory

setup is needed then continue with this section.

In order to use Table 5, an assumption has been made that the password is enabled (this is the

factory preset condition).

For proper operation of the flowmeter all the information in the Analog Output category needs

to be entered as a group, also all of the information in the Flow Rate Units category needs to

be entered (do not skip steps).

If mistakes in data entry are made, press the back arrow key to correct the mistake.

Table 5 - Quick Operation Procedure

Function Desired * Keys to Press ** Comments

Main Menu Press any key

Main Menu Press OME THEN 1

(1) NORMAL

OPERATION

SET PASSWORD

(1) Enable / Disable

Press HOME then 1 To get the normal display.

Press HOME, 4, 3, 1. Then

enter user password. Then press

ENTR, HOME

To get from the normal display to the

main menu.

To get from other menus to the main

menu in most cases. In some cases

(when shown) press ENTR. Then

HOME.

The factory recommends that the

password be disabled before any

information is entered to speed up the

process. (Default password: 123)

PORT 1: MODE

(1) 4-20mA (2) 0-5V

(3) 1-10V (4) 1-5V

PORT 1: UNIT

(1) FLOW (2)

TEMP

PORT 1: F.S.

PORT 1: ZERO

PORT 2: MODE

(1) 4-20mA (2) 0-5V

(3) 1-10V (4) 1-5V

PORT 2: UNIT

(1) FLOW (2)

TEMP

ANALOG OUTPUTS

Press HOME, 2, 1, 1, 1. Then 1

or 2 or 3 or 4 or ENTR. Then 5,

Y or N. HOME

Press HOME, 2, 1, 1, 2. Then 1

or 2. Then 5, Y or N, HOME

Press HOME, 2, 1, 1, 3. Then

press in a numeric value. Then

press ENTR, 5, Y or N, HOME

Press HOME, 2, 1, 1, 4. Then

press in a numeric value. Then

press ENTR, 5, Y or N, HOME

Press HOME, 2, 1, 2, 1. Then 1

or 2 or 3 or 4 or ENTR. Then 5,

Y or N. HOME

Press HOME, 2, 1, 2, 2. Then 1

or 2. Then 5, Y or N, HOME

Press the key that best matches the

analog input to the peripherals from

Jack JP6 of the Flow Transmitter. Press

ENTR only if previous values are

correct.

Press the key that matches the

condition to be measured.

Enter the numeric full-scale value that

is expected to occur. The value needs

to be between the values shown on the

second and third lines of the display.

Press ENTR without inputting a

numeric value only if previous values

are correct.

Enter the numeric zero scale value that

is expected to occur. The value needs

to be between the values shown on the

second and third lines of the display.

Press ENTR without inputting a

numeric value only if previous values

are correct.

Press the key that best matches the

analog to the peripherals from Jack JP6

of the Flow Transmitter. Press ENTR

only if previous values are correct.

Press the key that matches the

condition to be measured.

Model GF03 Flow Meter 18 Doc. No. 06EN003352 Rev. B

Page 23

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Table 5 - Quick Operation Procedure

Function Desired * Keys to Press ** Comments

Enter the numeric full-scale value

that is expected to occur. The value

needs to be between the values

shown on the second and third lines

of the display. Press ENTR without

inputting a numeric value only if

previous values are correct.

Enter the numeric zero scale value

that is expected to occur. The value

needs to be between the values

shown on the second and third lines

of the display. Press ENTR without

inputting a numeric value only if

previous values are correct.

PORT 2: F.S.

PORT 2: ZERO

Press HOME, 2, 1, 2, 3. Then

press in a numeric value. Then

press ENTR, 5, Y or N, HOME

Press HOME, 2, 1, 2, 4. Then

press in a numeric value. Then

press ENTR, 5, Y or N, HOME

FLOW RATE UNITS

MASS UNITS

(1) LB (2) KG

(3) TNS

Std Volume

(1) Cu Feet (2) Cu Meter

(3) Liters

Std Velocity

SET PASSWORD

(1) Enable / Disable

* NUMBERS IN PARENTHESIS ARE KEYS TO BE PRESSED

** Y = SAVE PERMANENTLY OR N = DO NOT SAVE

Press HOME, 3, 1, 1. Then 1 or 2

or 3, then in the TIME UNITS

menu press 1 or 2 or 3 or 4, then

in the AREA menu press 1 or 2,

then 1 or 2 or 3 or 4. Then enter a

numeric value. Press ENTR, any

key, any key, Y or N, HOME.

Press HOME, 3, 1, 2. Then 1 or 2

or 3, then in the TIME UNITS

menu press 1 or 2 or 3 or 4, then

in the AREA menu press 1 or 2,

then 1 or 2 or 3 or 4. Then enter a

numeric value. Press ENTR, any

key, any key, Y or N, HOME.

Press HOME, 3, 1, 3. Then in the

LENGTH UNITS menu press 1

or 2. In the TIME UNITS menu

press 1 or 2 or 3 or 4, then any

key, Y or N, HOME.

Press HOME, 4, 3, 1 then HOME

Enter the flow rate, using the

necessary mass units needed along

with the units per time and the pipe

diameter or area. ENTR can be

used if the values are already

correct.

Enter the standard volume in Cubic

Feet, Cubic Meters, or Liters along

with the units per time and the pipe

diameter or area. ENTR can be

used if the values are already

correct.

Enter the standard velocity in feet

or meters per unit time.

The factory recommends the

password be enabled with this step

after the above information has

been completed.

Doc. No. 06EN003352 Rev. B 19 Model GF03 Flow Meter

Page 24

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Configuring the

Flowmeter

There are several parameters that can be modified to customize the system. This section

describes how the flowmeter can be customized to best fit requirements.

Password Protection

Before the flowmeter configuration is customized, access to the system parameters must be

gained. Two levels of password protection affect access to these parameters.

w Factory Level

The highest level of protection requires a system password for access. This password

prevents the user from inadvertently changing variables associated with the system

calibration or other parameters that require factory resources to properly set.

w User Level

The second level of protection requires a user password for access. This password

provides the user with the ability to limit access to parameters that affect the way the

system operates. The default user password is 123 and can be changed to any combination

of up to 12 characters in length.

Both levels of password protection can be enabled or disabled. When the system leaves the

factory, the factory level and user passwords are enabled. No password is required to enable

a level of protection, but the appropriate password is required to disable protection.

NOTE:

w To edit the user password:

1. From the Main Menu press 4. The 4.0 MISCELLANEOUS menu title will appear.

2. Press 3, Password Setup.

3. Press 2, Edit Password.

4. If password protection is enabled enter the current password.

5. Enter the new password of up to 12 characters.

6. When prompted to Save Permanently enter Y for yes.

The user password is set to 123 when the system is shipped.

Selecting

Units of Measure

w To enable and disable the password protection:

1. From the Main Menu press 4. The 4.0 MISCELLANEOUS menu title will appear.

2. Press 3, Password Setup.

3. Press 1, Enable/Disable Password.

4. Enter the user password if prompted to do so.

5. The password protection will be toggled on or off depending on its previous state.

The flowmeter measures the flow rate and stream temperature of the process media. The

display can be set to present the flow rate and temperature in a variety of units. The factory

will set the units of measure to those specified at order entry time. There are other units of

measure that can be chosen. Two units that will appear are m and mm. The letter m stands for

1000 and mm stands for 10,000. Menu level 3.1 provides the options for changing the output

units of measure. The units of measure can be selected for temperature at menu level 3.2. The

units of measure for the totalizer are available at menu level 3.3.

NOTE:

By answering the prompt, Save permanently?, with a N or by pressing the HOME

key, the flowmeter will revert to the previously saved units of measure when the

power is cycled.

Model GF03 Flow Meter 20 Doc. No. 06EN003352 Rev. B

Page 25

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

w To choose a new unit of measure for flow rate:

1. From the Main menu press 3. The 3.0 DISPLAY SETUP menu title will appear.

2. Press 1, the Flow Setup option.

3. At this point there are three choices, Mass, Std Volume and Std Velocity. Table 6

summarizes the choices contained in Mass, Std Volume and Std Velocity.

4. By pressing 1, 2, or 3, the display will prompt the user to enter the user password (if it is

enabled) and then the respective mass, volume or length units from Table 6. Enter the

desired measurement type. For example, pressing 1 will show the following display:

1=LB, 2=KG or 3=TNS.

5. Enter the desired time units, seconds, minutes, hours or days.

6. If Mass or Std Volumetric units have been selected, enter the pipe cross-sectional area.

There is the option of entering the area directly or, for circular pipes, entering the inside

diameter.

7. Enter the desired area units.

8. Enter the pipe area or the pipe inside diameter. Press any key twice.

9. When prompted to Save permanently enter Y for yes.

NOTE:

The term Std refers to standard or standard conditions. Standard volume refers to

the space a gas occupies at a defined pressure and temperature. The factory uses

14.7 psia and 70°F as its standard conditions. Std Velocity is defined as the

standard volumetric flow rate divided by the pipe cross-sectional area.

Table 6 - Flow Rate Units of Measure

Selection Units Description

LB/Time

Mass

Std Volume

Std Velocity

w To choose a new unit of measure for temperature:

KG/Time

TNS/Time

SCF/Time

NCM/Time

NL/Time

SF/Time

NM/Time

Pounds per Unit time. Time units are seconds, minutes, hours or days.

Kilograms per unit time.

Metric Tonnes (1000 Kilograms) per unit time.

Standard Cubic Feet per unit time.

Normal Cubic meters per unit time.

(Normal is the metric equivalent of Standard.)

Normal liters per unit time.

Standard feet per unit time.

Normal meters per unit time.

1. From the Main menu press 3. The 3.0 DISPLAY SETUP menu title will appear.

2. Press 2, the Temperature Setup option.

3. Press 1 to change the units for temperature.

4. After entering the user password (if it is enabled) there will be 4 choices: (°F) degrees

Fahrenheit, (°C) degrees Celsius, (K) Kelvin and (R) Rankine. Press the appropriate

number corresponding to the desired temperature units.

5. When prompted to Save permanently enter Y for yes.

Doc. No. 06EN003352 Rev. B 21 Model GF03 Flow Meter

Page 26

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

w To choose a new unit of measure for total flow:

1. From the Main menu press 3. The 3.0 DISPLAY SETUP menu title will appear.

2. Press 3, the Totalizer Setup option.

3. Press 2, Flow Units, to change the units for total flow.

4. There is the option of standard volumetric units or mass units. See Table 6 for a

description of the available choices. Press 1 or 2.

5. After entering the user password (if it is enabled) the user will be prompted with

standard volumetric or mass units. Enter the desired total flow units.

6. The user will be prompted to enter the pipe cross-sectional area. The user has the

option of entering the area directly or, for circular pipes, entering the inside

diameter. Enter the method desired.

7. Enter the desired area units.

8. Enter the value of the pipe area or the pipe inside diameter. Press any key twice.

9. When prompted to Save permanently enter Y for yes.

w To choose Totalizer Prescaler for total flow:

1. From the Main menu press 3. The 3.0 DISPLAY SETUP menu title will appear.

2. Press 3, the Totalizer Setup option.

3. Press 7, Totalizer Prescaler, to change between prescale values of 0, .001 or 1000.

4. Press 0 for no prescale, or press 1 for a prescale value of .001, or press 2 for a prescale

value of 1000.

In this mode the totalizer will be displayed with a fixed decimal place.

w To choose Display Group Sum for total flow:

1. From the Main menu press 3. The 3.0 DISPLAY SETUP menu title will appear.

2. Press 3, the Totalizer Setup option.

3. Press 8, the Display Group Sum.

The totalized flow for the first group will be displayed. Pressing any key will display

the totalized flow for the second group if the second group is enabled. Pressing any

key will display the totalized flow for the third group if the third group is enabled.

The group totals will be displayed regardless if they have been initialized. These

values can be reset by switching to each group and individually resetting each one or

doing a reset all from menu 3.3.3.

w To choose Aggregate Tot Mode for total flow:

1. From the Main menu press 3. The 3.0 DISPLAY SETUP menu title will appear.

2. Press 3, the Totalizer Setup option.

3. Press 9, Aggregate Tot Mode, to turn on or off the aggregate total mode.

This setting is saved in EEPROM and recalled when the system is reset. When the

aggregate mode is enabled, the following parameters must be the same for all the

groups that are linked; totalizer prescale, and the totalizer units. If all the parameters

do not match, the totalizer display will show "AGGREGATE TOT ERROR".

Model GF03 Flow Meter 22 Doc. No. 06EN003352 Rev. B

Page 27

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Setting Analog Outputs

The flowmeter has two, independent analog signal outputs. The outputs can be set to represent

flow rate or temperature. The flowmeter signal outputs have been configured according to the

application information supplied to the factory at the time of order. However, the outputs can

be re-scaled anywhere within the calibrated flow range. The ouputs can be independently set

to one of the four ranges: 4 to 20 mA, 0 to 5 V, 0 to 10 V, or 1 to 5 V. A typical configuration

is presented in Table 7.

The signal range varies linearly with change in flow rate as shown in Figure 14. Minimum

Port No. Mode Type Zero Full-Scale (F.S.)

1 4 to 20mA Flow 0 SF/S 150 SF/S

2 4 to 20mA Temp -50°F 150°F

Table 7 - Typical Signal Output Configuration

signal output can be set to indicate a flow of zero. This is often referred to as a zero-based

signal output. A minimum signal that represents a value greater than zero is referred to as nonzero based.

Figure 14 - Signal Output versus Flow Rate

NOTE: The flowmeter inherently has a minimum, non-zero flow rate that it is able to

detect. Therefore, setting the minimum signal output (referred to as Zero in Menu

2.1.1) to zero will create a step in the output. This step corresponds to the flow

where the flowmeter begins accurate measurement. Turndown ratios ( turndown

is defined as the maximum flow rate divided by the minimum flow rate) smaller

than 10:1 will have a large step change thus reducing the usable signal range.

Doc. No. 06EN003352 Rev. B 23 Model GF03 Flow Meter

Page 28

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

w To re-scale the signal outputs:

1. From the Main menu press 2. The 2.0 PORT SETUP menu title will appear.

2. Press 1, the Analog Output option.

3. Press 1 or 2, corresponding to the analog port to be re-scaled.

4. After entering the user password (if it is enabled), press 1 to change the analog

output mode. Select the signal mode. (The current selection is shown in

parenthesis to the left of the question mark.)

5. Press 2 to change the analog output type. Press 1 for an output signal based on

flow. Press 2 for an output signal based on temperature.

6. Press 3 to change the maximum or Full Scale (F.S.) flow rate. Enter a maximum

flow rate value within the specified range.

7. Press 4 to change the zero flow rate. Enter a minimum flow rate value within

the specified range. A value of zero is valid.

8. Press 5 to save and exit to the previous menu level. Press Y when asked to save

permanently.

There are two double pole, double throw relays on the flowmeter. They can be set to

respond to changing flow rates or changing temperatures.

There are four types of switching schemes to choose from. These are referred to as Above,

Below, Outside, and Inside. Each switch point can be set to have hysteresis and a time delay.

Figure 15 illustrates the four switch point schemes with arbitrary hysteresis assigned.

Switching schemes, Above and Below change relay states when the flow or temperature

Setting the Relays

crosses the switch point value. The outside and inside schemes contain a range wherein the

relay changes states.

Flow

or

Temperature

ON

OFF

Above

Switch point

Deactivation

OFF

Below

ON

OFF

Outside

}

ON

Hysterisis

Figure 15 - Relay Switch Point Schemes

OFF

ON

Inside

C00225-2

Model GF03 Flow Meter 24 Doc. No. 06EN003352 Rev. B

Page 29

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

w To set the relays:

1. From the Main menu press 2. The 2.0 PORT SETUP menu title will appear.

2. Press 2, the Relay Setup option.

3. Press 1 or 2, corresponding to the relay to be set.

4. After entering the user password (if it is enabled), press 1, Unit, to select the

switching parameter. Press 1 to switch on flow rate or press 2 to switch on

temperature. (The current selection is shown in parenthesis to the left of the question

mark.)

5. Press 2, Activate On, to select the switching scheme desired (See Figure 13). Press

1 for an Above, press 2 for Below, press 3 for Inside or press 4 for Outside.

Depending on the choice made, enter 1 or 2 switch point values. For example, if

Inside has been chosen, the user will then be prompted to enter a low range switch

point and a high range switch point. The values entered must be within the displayed

allowable range.

6. Press 3 to change the switch delay. Delay pauses the change in relay state when a

switch point is crossed. The value entered is approximately equal to seconds.

7. Press 4 to change the dead band or hysteresis of the switch point (See Figure 13). The

dead band or hysteresis has a value of flow rate or temperature depending on whether

switch on changes in flow rate or temperature have been chosen.

8. Press 5 to save and exit to the previous menu level. Press Y when asked to save

permanently.

Testing the Relays

Checking the

Current Setup

From the keypad, the relay state can be switched. This can be used to test the interface with

relays. This is also described in Chapter 5 Troubleshooting.

w To test the relays:

1. From the Main menu press 2. The 2.0 PORT SETUP menu title will appear.

2. Press 2, the Relay Setup option.

3. Press 3, for the Test Relays option.

4. Pressing 1 or 2 will toggle the states of the respective relays. The present state of the

relays are displayed in parenthesis.

The functions within menu level 5.0 provides a quick means of displaying the current

system parameters for the flowmeter. The flow rate and temperature units of measure, the

state of the analog outputs and relays or other critical information can be viewed from this

menu.

w To view the flow range, the flow rate units of measure and the area:

1. From the Main menu press 5. The 5.0 VERIFY menu title will appear.

2. Press 2, the Flow option. The sequence of information will be displayed to the screen

as shown in Figure 14. Press Enter twice to proceed. The first line of screen 1 is the

window title. Line 2, the Flow Factor is the conversion factor from the internal units

of measure (SF/S) to the desired units. Lines 3 and 4 show the flow range and the

current flow units. Screen 2 shows the standard density of the flow stream.

3. Press 4, the Area option. Screen 3, shown in Figure 14 will appear. The second line

shows the pipe area and units. The third line is the inside diameter of the pipe. (The

third line will appear only if the pipe I.D. is entered. If Std Velocity flow units are

used the Area option is not available.)

Doc. No. 06EN003352 Rev. B 25 Model GF03 Flow Meter

Page 30

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

FLOW

Flow Factor: 5.30

0.530 to 1591

SCFM

Window 1 Window 2

Figure 16 - Flow and Area Verification

NOTE: The flowmeter does not measure standard density. This number is entered through

menu level 7.3.5. The standard density displayed in menu 5.2 must be equivalent

to the standard density of the process media. The factory has entered the process

standard density supplied at the time of order. The standard density factor is only

used when calculation mass flow units.

w To view the temperature and totalizer units of measure:

1. From the Main menu press 5. The 5.0 VERIFY menu title will appear.

2. Press 5 to view the current units for temperature. Press 3 to view the current units for

the total flow. (If the totalizer is disabled the display will only show No Totalizer.)

The information will be displayed to the screen as shown in Figure 17.

TEMPERATURE:

Temp units: °F

FLOW

Standard Density:

0.07497 LBM/FT3

SCF

AREA/PIPE I.D.

Area = 12.73 sq in

I.D.=4.026 in

HIT anykey to EXIT

Window 3

C00243-1

Totalizer Units:

Tcal Add = 0.000

Tcal Mult = 1.000

HIT any key to EXIT

Window 1 Window 2

C00244-1

Figure 17 - Temperature, Totalizer Verification Display

Line 2 of screen 1 shows the current units for temperature. Lines 3 and 4 display the offset

and multiplier to the measured temperature. See Advanced Features for a detailed explanation.

Screen 2 shows the total flow units.

w To view the analog output parameters:

1. From the Main menu press 5. The 5.0 VERIFY menu title will appear.

2. Press 6, the Ports option. The two screens in Figure 18 are identical except for the

port number. Line 2 is the current signal output mode. Line 3 shows the full scale

flow rate or temperature value and the appropriate units. Line 4 is the zero value.

Press any key for screen 2.

PORT 1

Mode: 4-20 mA

F.S. : 1591 SCFM

ZERO: 0.00 SCFM

Mode: 4-20 mA

F.S. : 150 °F

ZERO: -50 °F

Window 1 Window 2

Figure 18 - Analog Output Verification

PORT 2

C00245-1

Model GF03 Flow Meter 26 Doc. No. 06EN003352 Rev. B

Page 31

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

w To view the relay switching parameters:

1. From the Main menu press 5. The 5.0 VERIFY menu title will appear.

2. Press 7, the Relay option. The two screens in Figure 19 describe how the two relays

will react to changes in flow rate or temperature. Screen 1, line 1 is the current status

of relay 1. Line 2 shows that the relay will change states when the flow rate exceeds

100 SCFM. The last line displays a hysteresis (H) of 5 SCFM and a delay of about

3 seconds. Screen 2, line 1 is the current status of relay 2. Line 2 and 3 shows that

the relay will switch states on changes in temperature (°F). The state of the relay will

change when the temperature is inside the temperature range of -50 to 150 °F. The

last line displays a hysteresis (H) of 2 °F and a delay of about 1 second.

Advanced Features

RELAY 1: OFF

Above 100 SCFM

RELAY 2: ON

°F (Inside)

-50 to 150

H: 5.00 D: 3.00

Window 1 Window 2

Figure 19 - Relay Staus Verification Display

The remainder of this chapter contains topics that may not be applicable to every user of the

flowmeter. In most cases the flowmeter will be ready for use straight out of the box. However,

there may be an application where the advanced features of the flowmeter may be needed.

This section discusses how to correct for bias errors due to non-ideal installations, how to

communicate with the flowmeter through the serial port, and how to use the multiple

calibration options.

Flow Rate Correction Equation

The flow rate correction equation or corrector is used to bias the flow rate output. The

correction equation contained in the flowmeter allows the user to correct for bias errors due

to non-ideal installation effects. The correction equation is applied to the measured flow rate

and then this corrected flow rate is used to drive the analog outputs and manipulate the relays.

The flow rate shown on the display is also the corrected value. Figure 20 describes how the

correction equation is applied.

The correction equation for the flowmeter is shown below.

H: 2.00 D: 1.00

C00246-1

m

= F1 + (F2 x mo )+ (F3 x m

new

2

)+( F4 x m

o

3

)

o

where mo = Measured Flow Rate

Fi = Correction Equation Coefficients (

m

= Corrected Flow Rate

new

Doc. No. 06EN003352 Rev. B 27 Model GF03 Flow Meter

= 1 through 4 )

i

Page 32

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

C00248-1

Measured flow

rate

Is the

correction

equation

Yes

Apply correction

equation

enabled?

NO

Corrected flow rate

Apply other

corrections (see

Aux. Input)

Manipulate

analog outputs

and relays

C00247-2

Figure 20 - Correction Factor

Application fo the correction equation will be illustrated in the following example. Through

analysis of the process flow stream it is determined that the flow rate must be multiplied by

1.056 to output the desired value.

The correction equation takes the following form:

m

= 0 + (1.056 x mo) + (0 x m

new

Therefore m

= 1.056 x m

new

o

o

2

)+ (0 x m

3

)

o

Where F1 = 0

F2 = 1.056

F3 = 0

F4 = 0

A more complicated situation would be where the multiplication factor varies with flow rate.

Figure 21 shows the variation of desired flow rate versus the measured flow rate.

50

40

Desired

Flow Rate

30

20

10

0

0 20 40 60

Measured Flow Rate

Figure 21 - Desired Flow Rate versus Measured Flow Rate

Model GF03 Flow Meter 28 Doc. No. 06EN003352 Rev. B

Page 33

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

The relationship between the measured and the desired flow rates was determined through a

least squares analysis. The coefficients for the above relation are:

F1 = -7.5672 F2 = 2.09253

F3 = -0.037082 F4 = 0.0003505

w To enter the correction equation coefficients and to enable it:

1. From the Main menu press 4. The 4.0 MISCELLANEOUS menu title will appear.

2. Press 2, the Corrector Setup option.

3. Press 2, the Enter Corr option, to enter the Correction Equation coefficients

4. Enter the user password (if it is enabled). Press 1 to enter the coefficient F1. Press

2 for F2 and so on to F4. Press 5 to verify the entries.

5. Press 6 to exit.

6. Press 1 to enable to Corrector. (To disable the Corrector press 1 again.)

The Auxiliary Input

The flowmeter has one analog signal input port that can be used to directly manipulate the flow

rate output. This signal input port is called the auxiliary input. The signal measured by the

flowmeter allows for the correction of errors that may be caused by changes such as process

composition. The factory has determined from the application data supplied at the time of

order whether the flowmeter would benefit from using the auxiliary input. If the auxiliary

input is not used in the flowmeter the following section can be skipped. If the auxiliary input

is used, all the internal settings necessary have been entered into the flowmeter. The following

is a description of the internal and external workings of the auxiliary input.

w To determine if the flowmeter is set to use the auxiliary input:

1. From the Main menu press 2. The 2.0 PORT SETUP menu title will appear.

2. Press 4, the Aux Input option.

3. Press 2, the Enter Aux option. Enter the user password (if it is enabled).

4. Press 5, the Verify option. The variables AUX 1, 2 and 3 will appear.

5. Press ENTR and DISABLED or ENABLED will be on the third line. If ENABLED

is displayed then the flowmeter has been configured to use the auxiliary input.

The auxiliary input is accessed at terminal JP6 located on the lower circuit board. Figure 22

illustrates the auxiliary input connected to a current source. If OUT 1 COM is not easily

accessible then use JP6 OUT 2 COM, JP7 GND, JP1 DC GND OR JP3 GND. They are

electrically the same signal ground point. The range of this source is most likely 4-20mA.

+20V

JP6

1 AUX

+E OUT 2

OUT 2 COM

+I OUT 2

+E OUT 1

OUT 1 COM

+I OUT 1

C00249-1

Figure 22 - Auxiliary Input Wiring Diagram

Doc. No. 06EN003352 Rev. B 29 Model GF03 Flow Meter

Page 34

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

The flowmeter measures the applied current input, converts it to a digital value and makes a

correction to the measured flow rate. The corrected flow rate is used to drive the analog

outputs and manipulate the relays. The flow rate shown on the display is also the corrected

value. Figure 23 charts the process.

The auxiliary input port monitors the signal input level and converts it to a digital value. This

digital value can be displayed from menu level 2.4.3, the Auxiliary Test Input function.

DR

Aux Input

Enb

NO

DR

= DR

corr

Flow = f (DR

YES

) Aux Input

corr

Mode = DR?

NO

Enb

NO

Flow corr = Flow

Output

Flow

corr

DR

YES

YES

= KA DR

corr

NO

Mode = Flow ?

Flow corr = K

C00548-1

YES

A

Flow

Figure 23 - Auxiliary Input Process

w To view the digital representation of the current input:

1. Apply a current to the auxiliary input as shown in Figure 22.

2. From the Main menu press 2. The 2.0 PORT SETUP menu title will appear.

3. Press 4, the Aux Input option.

4. Press 3, the Test Input option. The digital representation of the current input is

displayed on the second line.

The approximate relationship between current input and the digital value displayed in menu

level 2.4.3 is:

Digital Value = Current Input x 51.1

The digital value is used to manipulate the measured flow rate. This digital value is used to

calculate a factor that is multiplied by the measured flow rate. The factor is calculated using

the following relationship:

KA = A1 + (A2 x s) + (A3 s2) + (A4 x s)

where s = Digital Value

Ai = Correction Factor Coefficients ( i = 1 through 4 )

KA = Correction Factor

NOTE: Ai is used for clarity in the manual. The flowmeter uses Fj as the Correction Factor

Coefficient.

The Auxiliary Input Equation coefficients are determined by the factory from the data

supplied at the time of order entry.

Model GF03 Flow Meter 30 Doc. No. 06EN003352 Rev. B

Page 35

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

Serial

Communications

The flowmeter has one RS-232 port. The data stream is sent at a rate of 9600 baud with no

parity, 8 bit characters and 1 stop bit. The baud rate is fixed and cannot be changed. All

operations accessible through the keypad are also available through the serial port. The serial

port, designated as JP3, is located on the lower right corner of the upper circuit board. The

connection is a RJ-11 phone jack. Figure 24 represents the connection between the serial port

and the host device.

A serial communications kit containing adapter plugs are available from FCI for both the DB9 and DB-25 connectors which allow the use of standard 6 wire phone line cord between the

RJ-11 serial port and the host device. The order number for the DB-9 Connector kit is 014108-

01. Serial communication software is provided with each connector.

NOTE: The standard phone line used must be a reversing type and not a straight-through

type of cable.

GF Series Serial Port

RJ-11 Phone Jack

6

5

4

3

2

1

+5V

NC

DTR

TXD

RXD

GND

RJ-11 Pin

Description

1

2

3

4

5

6

RJ-11 Pin

Description

IBM PC

DB-9 Connector

DCD

DTR

TXD

RXD

GND

IBM PC

DB-25 Connector

1

4

3

2

5

Data Carrier Detect

Data Termial Ready

Transmit Data

Receive Data

Ground

+5V

NC

DTR

TXD

RXD

GND

1

2

3

4

5

6

DCD

DTR

TXD

RXD

GND

Data Carrier Detect

20

Data Termial Ready

8

Transmit Data

3

Receive Data

2

Ground

7

C00251-1

Figure 24 - Wiring Diagram, DB-9 an DB-25 PC Connectors

The serial port input/output stream duplicates the actions of the keypad and the LCD display.

Commands sent through the serial port to manipulate the flowmeter are exactly equivalent to

the keypad sequences. Data coming out of the serial port is equivalent to the data sent to the

display. Remote communication with the flowmeter consists of character sequences that

duplicate actions taken at the keypad. For example, the string H 2 4 2 5 produces the same

results as pressing HOME, 2, 4, 2, 5 from the keypad. Figure 25 is an example of code written

in Quick Basic that extracts the flow rate and the temperature through the serial port.

A common communication problem is over writing flowmeter serial buffer. If the buffer is

overwritten the last characters sent are lost. If the flowmeter does not respond as expected

to a command, slow down the data flow from the user PC or control device.

Doc. No. 06EN003352 Rev. B 31 Model GF03 Flow Meter

Page 36

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

' Serial Communication example

' Fluid Components Intl

' This program places the flowmeter into normal

' operation and displays the current flow rate and

' temperature.

DEFINT A-Z

ON ERROR GOTO error.trap

COLOR 7, 1 ' Set screen color.

CLS

Quit$ = CHR$(0) + CHRS$(16) ' Value returned by INKEY$

' when ALT+q is

pressed.

' Set up screen and turn cursor off.

LOCATE 24, 1, 0

PRINT STRING$(80, "_");

LOCATE 25, 1

PRINT TAB(30); "Press ALT+q to quit";

VIEW PRINT 1 TO 23 ' Print between lines 1 & 23.

' Open communications (9600 baud, no parity, 8-bit data,

' 1 stop bit, 256-byte input buffer):

OPEN "COM1:9600,N,8,1,RS,CS,DS,CD,OP10000,RB2000" FOR RANDOM AS

#1 LEN =512

PRINT#1, "H"; ' Send a HOME command.

(Send ' another

also.)

x! = TIMER ' Wait for response. (A long

DO UNTIL TIMER - x! 3 ' wait is not necessary after

LOOP ' most commands.)

PRINT #1, "H"; ' Send another HOME

command

x! = TIMER ' Wait again

DO UNTIL TIMER - x! 3

LOOP

PRINT #1, "1"; ' Normal Operation

DO ' Main communications loop.

KeyInput$ = INKEY$ ' Check the keyboard.

IF KeyInput$ = Quit$ THEN ' Exit the loop if the user

EXIT DO ' PRESSED alt+q.

END IF

GFINPUT$ = "" ' Empty the two working

moreGFInput$ = "" 'strings

Figure 25 - Series Serial Communication Code Example

Model GF03 Flow Meter 32 Doc. No. 06EN003352 Rev. B

Page 37

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

IF NOT EOF(1) THEN

' LOC(1) gives the number of characters waiting.

GFInput$ = GFInput$ + INPUT$ (LOC(1), #1)

' Gather at least one full display of information

IF INSTR(GFInput$, "CH1:") THEN

DO UNTIL INSTR(more GFInput$, "CH:")

moreGFInput$ = moreGFInput$ + INPUT$(LOC(1), #1)

LOOP

GFInput$ = GFInput$ + moreGFInput$

' Parse and print the flow rate and temperature

n% = INSTR(GFInput$, "CH:")

FlowRate! = VAL(MID$(GFInput$, n% +5))

n% = INSTR(GFInput$, "CH2:")

Temperature! = Val(MID$(GFInput$, n% + 5))

PRINT FlowRate!, Temperature!

END IF

Multiple Groups

END IF

LOOP

CLOSE ' End communications.

END

error.trap:

RESUME NEXT

Figure 25 - Series Serial Communication Code Example Cont’d

The flowmeter is calibrated at the factory in a test stand that duplicates or models the

customer application. The calibration process produces the information needed to relate

RTD signal to an actual mass flow rate. That calibration information is entered into the

flowmeter. Information about the customer's process such as pipe inside diameter and the

process standard density is also entered. Situations exist where a pipe or duct may have two

or more distinct process flow streams or the flowmeter needs to be used in more than one

installation. The flowmeter can accommodate three sets of calibration information, therefore

it can be used to monitor multiple flow streams or used in multiple installations. Each set of

calibration information is called a Group. The factory has determined from the application

data supplied at the time of order whether the flowmeter would benefit from using multiple

Groups . If multiple Groups are not used in the flowmeter the following section can be

skipped. If multiple Groups are used, all the information necessary has been entered into the

flowmeter. However, the method and conditions that determine the current Group can be

altered.

w To determine if the flowmeter is set to use the Multiple Groups:

From the Main menu press 1. The flowmeter will enter the normal mode of operation. If the

mode on the last line of the window (see Figure 9) is Auto, or Link then the flowmeter

contains multiple calibration groups.

If the mode is normal or Norm is displayed in the normal operation window, the flowmeter

may still contain multiple calibration groups.

Doc. No. 06EN003352 Rev. B 33 Model GF03 Flow Meter

Page 38

FLUID COMPONENTS INTERNATIONAL LLC http://www.fluidcomponents.com

w To determine if the flowmeter is set to use the Multiple Groups in Normal

mode: