Page 1

Page 2

FS10 Series

This document contains confidential technical data, including trade secrets and proprietary information which is the property of Fluid Components International LLC (FCI).

Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only (and does not include manufacture or

processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

© Copyright 2011 by Fluid Components International LLC. All rights reserved. FCI is a registered trademark of Fluid Components International LLC. Information subject to change without notice.

Notice of Proprietary Rights

Fluid Components International LLC

Page 3

FS10 Series 06EN003394 Rev. D

Table of Contents

Technical Specification ................................................................................................................................................................................3

1 INSTRUMENT DESCRIPTION AND IDENTIFICATION .........................................................................................................................4

2 INSTRUMENT INSTALLATION ................................................................................................................................................................4

Special Conditions for Safe Use: .....................................................................................................................................................................................4

Mounting Orientation .......................................................................................................................................................................................................5

3 INSTRUMENT WIRING .............................................................................................................................................................................6

Recommended Minimum Wire Gauge ............................................................................................................................................................................6

Grounding .........................................................................................................................................................................................................................6

Input Power, 24 Vdc ..........................................................................................................................................................................................................6

4 POWER UP, FUNCTIONAL VERIFICTAION AND ADJUSTMENT ........................................................................................................6

Switching Inductive Loads................................................................................................................................................................................................9

5 SET-UP AND OPERATION ......................................................................................................................................................................13

FS10 Function Overview .................................................................................................................................................................................................13

FS10 Field Quick Setup Procedure..................................................................................................................................................................................14

FS10 Button Controls ......................................................................................................................................................................................................15

Normal set-up and operation using the button interface ..............................................................................................................................................16

Bank Selection of Stored Parameters (Function 4) .....................................................................................................................................................16

Flow Switch Operation ...................................................................................................................................................................................................17

Minimum Flow Setting (Function 6) ............................................................................................................................................................................17

Maximum Flow Setting (Function 7) ...........................................................................................................................................................................17

Static/Dynamic Mode Option (Function 5) ..................................................................................................................................................................17

Trip Point Adjust (Function 1 or 2) ...............................................................................................................................................................................17

There are two ways to set the trip point using the buttons. .....................................................................................................................................17

Additional Switch Settings.............................................................................................................................................................................................17

Failsafe Position (Function 3) ......................................................................................................................................................................................17

Hysteresis (Function 8 and 9) ......................................................................................................................................................................................17

Time Delay (Function 10 or 11) ....................................................................................................................................................................................18

Alarm Simulation (Function 12) ...................................................................................................................................................................................18

Keypad Lockout (Function 13)......................................................................................................................................................................................18

Filter Setting (Function 14) ..........................................................................................................................................................................................18

Save to Bank (Function 15) ..........................................................................................................................................................................................18

Output and Display Parameters......................................................................................................................................................................................19

PC Interface and Command Line Interface Configurations ...........................................................................................................................................22

FS10 Communication Options .....................................................................................................................................................................................22

Password Protection....................................................................................................................................................................................................22

Flow Rate Indication on PC Interface ..........................................................................................................................................................................22

Power Supply Interface Kit..........................................................................................................................................................................................22

PC Interface Software .................................................................................................................................................................................................23

PC Interface Software .................................................................................................................................................................................................25

Fluid Components International LLC 1

Page 4

06EN003394 Rev. D FS10 Series

FS10 Serial Interface ......................................................................................................................................................................................................26

Command Line Interface Commands..............................................................................................................................................................................28

6 MAINTENANCE AND TROUBLESHOOTING .......................................................................................................................................32

Maintenance ...............................................................................................................................................................................................................32

Troubleshooting ...........................................................................................................................................................................................................32

APPENDIX A APPROVALS ........................................................................................................................................................................34

APPENDIX B AUXILIARY DRAWINGS ....................................................................................................................................................38

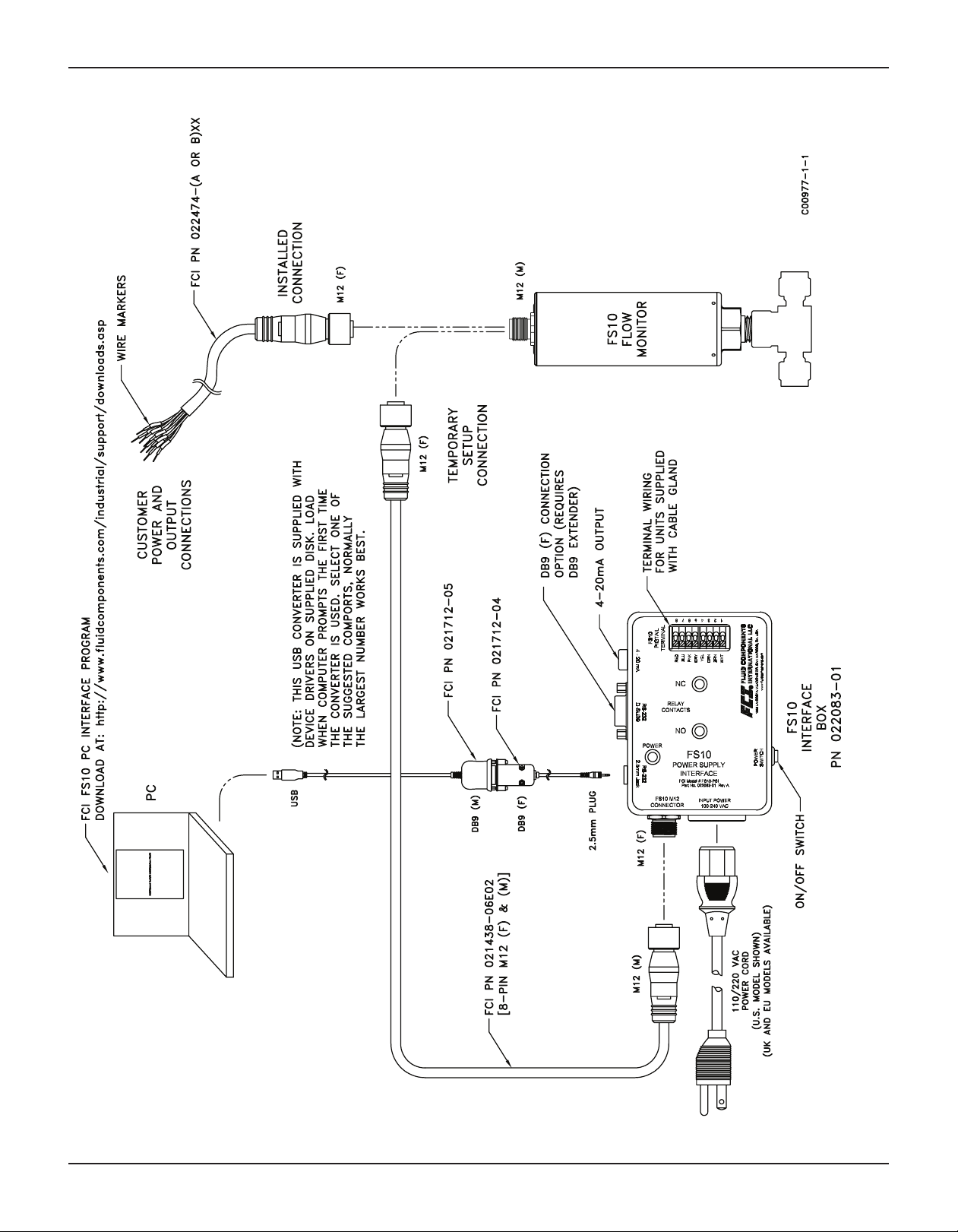

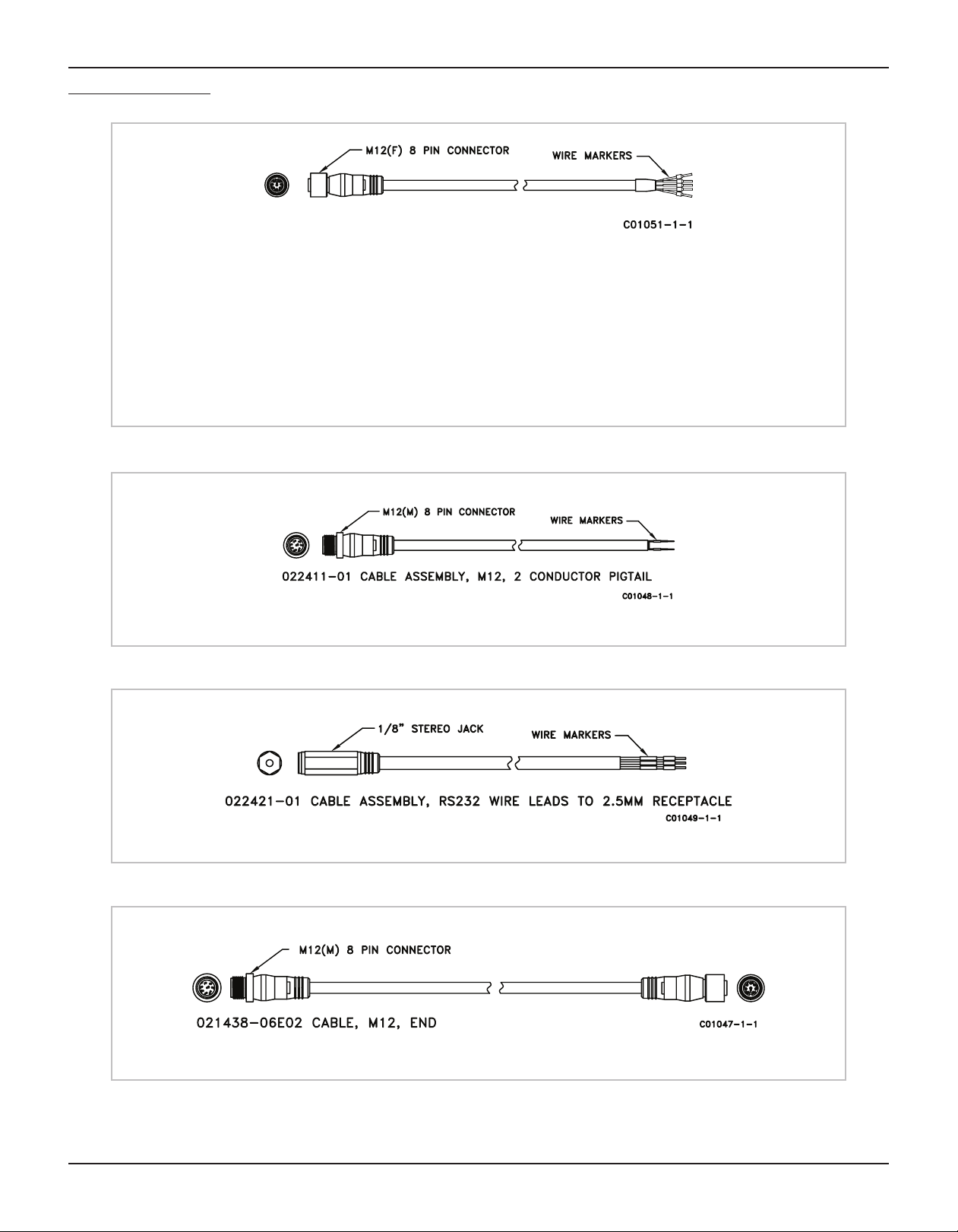

PC Interface Kits .............................................................................................................................................................................................................41

022083-02 Power Supply/Interface Box Kit ...................................................................................................................................................................42

022083-01 Power Supply/Interface Box.........................................................................................................................................................................42

PC Interface Components ...............................................................................................................................................................................................43

Board Connectors - OEM ................................................................................................................................................................................................44

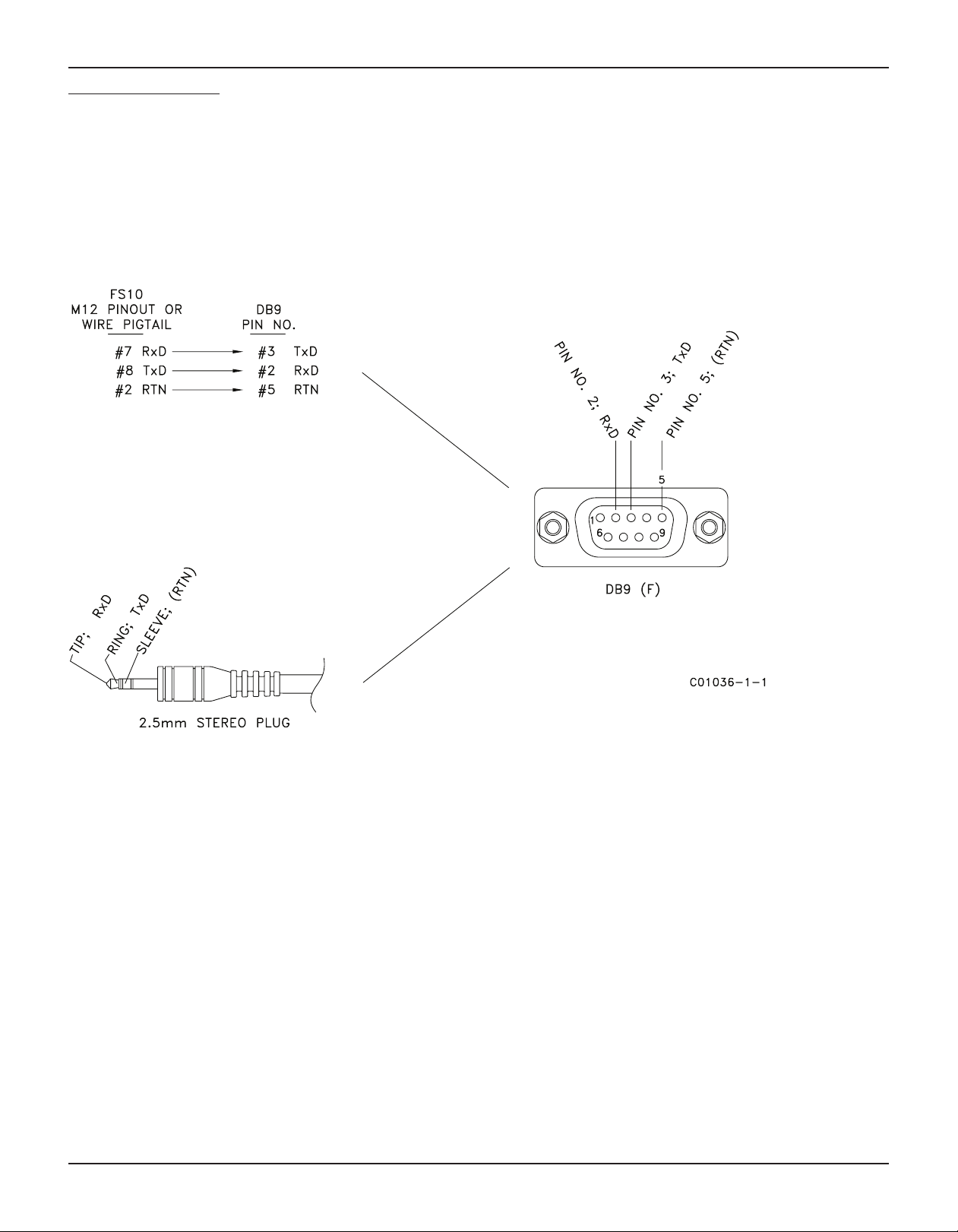

DB9 Connection Schematic ............................................................................................................................................................................................45

APPENDIX C CUSTOMER SERVICE ......................................................................................................................................................... 46

Customer Service/ Technical Support .........................................................................................................................................................................46

Warranty Repairs or Returns .......................................................................................................................................................................................46

Non-Warranty Repairs or Returns ...............................................................................................................................................................................46

Extended Warranty ......................................................................................................................................................................................................47

Return to Stock Equipment..........................................................................................................................................................................................47

Field Service Procedures .............................................................................................................................................................................................47

Field Service Rates ......................................................................................................................................................................................................47

Return Authorization Request ...................................................................................................................................................................................48

2 Fluid Components International LLC

Page 5

FS10 Series

Technical Specification

Instrument

Media Compatibility

All gases and liquids compatible with 316L stainless steel and

hastelloy C22.

Process Connection

1/4” NPT; compatible with 1/4”, 3/8” and 1/2” tube tee,

1/4” tube tee with 1/8” injection tube adapters and SP76 adapter

(FCI part number 019897-01)

Flow Sensitivity/Range:

Air / Gas Liquids

CC / Min SCFH CC / Min GPH

Min Max Min Max Min Max Min Max

1/8” tube adapter with

0.0625” ID injection tube

1/8” tube adapter with

0.0940” ID injection tube

1/4” tube tee 50 20,000 0.10 40 4.00 100.00 0.07 1.70

SP76 adapter 50 20,000 0.10 40 4.00 100.00 0.07 1.70

3/8” tube tee

1/2” tube tee

10 2,000 0.02 5 0.70 18.00 0.01 0.30

25 5,000 0.05 10 1.50 40.00 0.03 0.60

180

50,000 0.40 100

375

100,000 0.80 200

14.00

350.00 0.20 5.50

30.00

750.00 0.50 12.00

Repeatability:

± 0.5% of reading

Temperature Coefficient

For temperatures > ± 30 °F [± 16 °C]

Gas: Maximum ± 0.025% of reading/°F up to 500 °F

[± 0.05% of reading/°C up to 260 °C]

Liquid: Maximum ± 0.2% of reading/°F up to 250 °F

[± 0.367% of reading/°C up to 121 °C]

Turndown Ratio: 5:1 to 100:1

Agency Approvals

FM, FMc: Nonincendive, Class I Division 2 Groups A, B, C, D;

Class II, Division 2 Groups E, F, G; Class III,

T4@Ta=71°C Type 4X

ATEX, IEC: Nonincendive for gas and dust, Zone 2

II 3 G Ex nA IIC T4 Gc

II 3 D Ex tc IIIC T 81°C Dc

IP64

CE Mark

Transmitter/Electronics

Enclosure

NEMA 4X [IP64], anodized aluminum

Operating Temperature

-40 °F to 160 °F [-40 °C to 71 °C]

Output Signals

Standard:

(1) Relay (SPDT, 1A @ 24 Vdc); [1A @ 24 Vdc / 120 Vac, FM and

FMc only] or (1) Open Collector N-Channel MOSFET (100 mA);

(1) 4-20 mA * (500 Ω max. load). User scalable, general purpose,

un-calibrated output proportional to flow rate for trend monitoring.

(1) RS232C Serial I/O

(For linearized, calibrated analog outputs see FCI thermal mass

flow meter products)

* Fault indication per NAMUR NE43 guidelines, user selectable

high (> 21.0 mA) or low (< 3.6 mA)

Other Digital Comms: Contact FCI

Display

10 LED array, red; sequential lighting proportional to flow trend and

flashes at setpoint

User Interface

Two top-mounted push buttons to program switch/trip point, zero and

span setting, relay hysteresis and time delay; button operation may

be user disabled to prevent unwanted changes; all set-up functions

also programmable via RS232C port

Input Power

24 Vdc (21.5 Vdc to 30 Vdc); maximum 2.5 watts

Remote Configuration

Transmitter/electronics may be remote-mounted from flow element

using interconnecting cable; remote flow element available with

potted cable in 6’, 15’ or 30’ [2m, 5m or 10m] length and M12 connection plug at electronics; optional extended temperature service to

500 °F [260 °C] with selection of PTFE jacketed cable.

Flow Element

Materials of Construction (Wetted parts) 316L stainless steel with

Hastelloy C-22 thermowells; optional, all Hastelloy-C22 probe

assembly

Operating Temperature

Standard: -40 °F to 250 °F [-40 °C to 121 °C]

Optional: -40 °F to 500 °F [-40 °C to 260 °C]; remote configuration

only

Operating Pressure

Tube tee fitting: 500 psig [34 bar (g)]

SP76 adapter: Per SP76 manifold specifications up to 500 psig

[34 bar (g)] maximum

Fluid Components International LLC 3

Page 6

FS10 Series

1 INSTRUMENT DESCRIPTION AND IDENTIFICATION

The FS10A is a universal flow monitor and switch specifically designed for gas and liquid process analyzer sampling systems. The FS10A is a fast

responding, highly repeatable sensor which installs easily into a standard tube tee fitting or SP76 (NeSSI) modular manifold.

2 INSTRUMENT INSTALLATION

The FS10 is marked with a flow direction arrow or “A” etched onto the sensor element. It is located on the flattened area of the sensor body

close to the housing or on the assembled tee. In 1/4 and 3/8 inch tube tees, the “A” should be mounted upstream of the flow to maximize sensitivity

at low flow rates (flow into the “A”). Larger line sizes should follow the flow arrow direction. Refer to Table 1 for optimum results. Where the flow

tube is not included with the sensor assembly, the orientation mark must be parallel to flow (±3°). For liquid vertical flows in particular, FCI

recommends the sensor element be installed where flow is in the up direction. In vertical low flow gas applications, flow in the

down direction is recommended.

As a level device, the orientation mark can be perpendicular or parallel to the liquid level. The sensor element may be installed top mount 90° to

the liquid surface. The sensor element can be at any angle as long as the flow direction follows the flow arrow. Liquid applications where the flow

element is positioned other than horizontally, FCI recommends the flow go in the up direction.

CAUTION: To minimize the possibility of damage, leave the protective covers over the sensing area until the time of installation. Take

extra precaution with the sensing elements and surface when installing.

For NPT process connections, apply the appropriate sealant compatible with the process media to the male threads. Tighten until the orientation

mark is positioned correctly. Check for leaks.

Special Conditions for Safe Use:

a. Provisions shall be made to prevent the rated voltage being exceeded by transient disturbances of more than 40%.

b. For applications in explosive atmospheres caused by air/dust mixtures, cable and conduit entries used shall provide a degree of ingress

protection of at least IP 54 according to EN 60529.

c. When the temperature under rated conditions exceeds 158 °F [70 °C] at the cable or conduit entry point, or 176 °F [80 °C] at the branching

point of the conductors, the temperature specification of the selected cable shall be in compliance with the actual

measured temperature.

d. Cable gland assemblies are factory tightened – do not adjust; M12 connectors assembled finger-tight. Mencom MDC-8MR-PG9 or equal

M12 connector is used on FS10A.

4 Fluid Components International LLC

Page 7

FS10 Series

Mounting Orientation

Flow Direction

“A” (Active) mark

Upstream

Sensors parallel

Left to Right Flow Example in 1/4 and 3/8 inch tube tees

For optimum sensitivity in low flow applications, probes should

be installed with the “A” (Active) sensor positioned upstream.

Horizontal lines: gas or liquid.

Vertical lines: gas - flow must be down

liquid - flow must be up

Flow Direction Arrow

Sensors perpendicular

Right to Left Flow Example in 1/2 inch or greater tube or

pipe tee

Probes mounted into 1/2 inch or greater tees are installed with

the sensors positioned perpendicular to the flow path in the

tee. “A” (Active) should be facing up in side mount horizontal

configurations. These sensors may also be marked with a flow

direction arrow.

Diagram 1

Fluid Components International LLC 5

Page 8

FS10 Series

3 INSTRUMENT WIRING

Only qualified personnel are to wire or test this instrument. The operator assumes all responsibilities for safe practices while wiring or troubleshooting. One of the following wiring instruction and diagrams illustrate the requirements for power input, alarm and analog outputs and safety instructions for the unit being installed.

ALERT: The Instrument contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling the

instrument.

Recommended Minimum Wire Gauge

The following wire gauge chart specifies the correct wire for the distance to the power source or loads. Note that the open collector option is limited

to 50 ft. It is also recommended that the open collector cable is shielded and that it is not run in the same conduit with the power source or the relay

load.

I/O Wiring Gauge vs. Distance

Maximum Diameter (guage)

Connection

Input Power (24 Vdc nominal) 24 24 22 22 20 18

Relay Output (1 amp contacts) 18 16 14 12 10 X

10 ′ 50 ′ 100 ′ 250 ′ 500 ′ 1000 ′

(3 m) (15 m) (30 m) (76 m) (152 m) (305 m)

Open Collector Output 24 22 X X X X

4-20 mA Output 24 24 22 22 20 18

Table 1

Grounding

The switch must be properly grounded for safety and operational reasons.

The circuit board is tied to the enclosure case internally and both are tied to the probe assembly. If the installation pipe or vessel is not properly

grounded, connection to earth ground may be connected at the output connector, i.e. M12 or cable pigtail. Use the recommended wire gauge specified for the input power and distance listed in the chart above. Do not connect the earth ground to DC ground (terminals marked “GND”,

“COM” or “-”).

Input Power, 24 Vdc

FCI recommends installing an input power disconnect and a fuse near the instrument to interrupt power during installation, maintenance, calibration, alarm selection and troubleshooting procedures. Conduit should also be installed according to the local electrical codes or hazardous location

requirements.

Attach the power leads according to the Input/Output connection schematic on the following page. If the unit has an M12 interface, verify that the

mating connector pin numbers match the designations of the wiring diagram. If the unit is supplied with a cable pigtail, the flying leads should be

connected via an approved terminal block or connector in an electrically safe and approved conduit box.

Attach the wires to the relay and other functions as needed. The relay contact conditions are shown in the alarm state (de-energized). The relay’s maximum rating is 1 amp 24Vdc, 120 Vac (FM only), 24 Vdc (ATEX), resistive loads.

Refer to the next section for the set point and alarm state settings.

4 POWER UP, FUNCTIONAL VERIFICTAION AND ADJUSTMENT

Before Applying power to the instrument, it is recommended that a third party inspect the installation workmanship. Make sure wires are not pinched

or frayed. Check for matching serial numbers on the sensing element and the control circuit. Verify that the power and alarm circuits are properly

connected. Review the instrument configuration and its application.

Units supplied with LED’s will have at least one LED on or slowly blinking to indicate power on. Apply power and look for the power indicator light.

After power is established let the instrument warm up for 5 minutes. Refer to set-up on following pages. The switch must be properly grounded for

safety and operational reasons.

6 Fluid Components International LLC

Page 9

FS10 Series

Fluid Components International LLC 7

Page 10

FS10 Series

8 Fluid Components International LLC

Page 11

FS10 Series

(OEM)

Switching Inductive Loads

If the FS10A relay contacts are to be used to energize or de-energize an external relay, diode suppression must be used across the external relay coil.

Use the guidelines in the following example to select the proper diode.

A Tyco Electronics relay K10P-11D15-24 is used as a slave relay. The DC coil voltage is specified at 24 Vdc and the specification indicates a coil

resistance of 650Ω. The DC coil current is calculated by dividing the Rated coil power by the Rated Voltage Vdc or dividing the Rated Voltage Vdc by

the Coil resistance. In this case the current through the coil will be around 37mA (24/650). Refer to the K10P-11D15-24 data sheet.

It is recommended the Diode Reverse Voltage (Vr) rating be twice or greater the voltage across the relay and the diode forward current (IF) rating be

greater than the relay current. Diodes 1N914 or 1N4148 meet these limits for this case.

Fluid Components International LLC 9

Page 12

FS10 Series

10 Fluid Components International LLC

Page 13

FS10 Series

FS10 Flow Element Options

Fluid Components International LLC 11

Page 14

FS10 Series

FS10 Remote Enclosure and Connector Options

12 Fluid Components International LLC

Page 15

FS10 Series

5 SET-UP AND OPERATION

FS10 Function Overview

The FS10 flow monitor may come configured for use as a flow or temperature meter. The output of the switch configuration is a SPDT relay contact or

binary collector to ground [N-channel MOSFET] output (sync). A 4-20 mA output signal is also active as a signal reference. In the transmitter configuration, either the flow or temperature functions may be assigned to the 4-20 mA output. The table below shows the possible output configurations,

including the status of the LED bar display.

Output Configuration [Field Selectable with PC Interface Kit]

Configuration 4-20 ma Output Relay on/off Output LEDs

1

(default)

Corresponds to Flow

measurement

Controls Relay switch on/off

from Flow

Reflects Flow. Flashing LED

indicates Relay Limit.

4 Corresponds to Temp

measurement

5 Corresponds to Temp

measurement

Controls Relay switch on/off

from Flow

Controls Relay switch on/off

from Flow

Reflects Temperature. No

Relay Limit indication.

Reflects Flow. Flashing LED

indicates Relay Limit.

Table 2

• Flow measurement will be mapped using CUST_FLOW_MIN and CUST_FLOW_MAX in the 4-20 mA output configuration.

• Temperature measurement will be mapped using CUST_TEMP_MIN and CUST_TEMP_MAX in the output configuration and reflected

in the 4-20 mA output when configuration 4 or 5 is selected. The default temperature range mapped to the 4-20 mA

output is 0 °F to 250 °F [-17.8 °C to 121 °C]. Rescaling temperature output may be performed with the PC interface program.

The output configuration setting is normally factory set but may be changed in the field if required. Caution should be used when making any

configuration changes, as the monitor may not have been properly calibrated to accommodate the new setting. Only the RS232 interface may

be used to make a change in output configuration.

Fluid Components International LLC 13

Page 16

FS10 Series

FS10 Field Quick Setup Procedure

Quick Setup Mode *

This feature permits field setting the critical zero and span parameters of the FS10A with a single push of the button and throttling the process flow

over the desired range to capture the low and high ends. All defaults applicable to a low flow indication/alarm application apply along with a

trip-point default setting at 30% of span.

To activate the Quick Setup Mode (QSM), simply press and hold for at least 10 seconds:

“ – “ button, for process fluids that are gases or very low flow liquid hydrocarbons

“ + “ button, for process fluids that are liquids or high velocity gases (+50% sensor excitation).

The first three and last three LEDs will alternately flash to acknowledge entry into the Quick Setup Mode. The FS10A is now cued to remember the

lowest and highest flow signal it sees while in this mode. Pressing either button momentarily exits into the normal operating mode and saves the

detected limits as the zero and span. LED’s 1 and 10 and corresponding trip point LED will alternately flash (3 sec), indicating zero and span have

been properly set.

A minimum span setting of 0.05% is required to save new parameters. If minimum span is not reached during QSM, the first two, middle two and

last two LEDs will flash; indicating an error (3 sec) and resume last operation without saving new parameters.

Recommendations

Gas applications

The high flow limit or span setting is normally the most difficult to stabilize in a gas application, therefore simulating the desired high flow rate at

normal process conditions and allowing it to stabilize before entering into the QSM is recommended. Using in-line valves or other throttling means,

establish the desired full scale flow rate and allow system to stabilize. Now enter into the QSM (FS10 immediately captures this high flow signal)

and then slowly throttle the flow down until the zero flow setting is reached (i.e. valve closed, no flow). Allow to stabilize, then momentarily press

either button to save parameters and return to normal operating mode with the new scaled operating range established.

Liquid applications

To optimize the performance of the FS10A in liquids, it is critical to establish a stable zero setting under a packed line (full) condition. It is

recommended the FS10A be operating and allowed to come to equilibrium with a downstream valve closed and the line completely filled with the

process fluid and no flow. At this point, enter into the QSM (FS10 immediately captures this low flow signal), and then slowly open the downstream

valve to allow flow up to the maximum span desired. Momentarily press either button to save parameters and return to normal operating mode with

the new scaled operating range established.

In some cases the high liquid flow signal will saturate before reaching the high flow that is simulated, but the FS10A will save the highest value it is

capable of sensing in that application and use it as the high end limit.

Trip point

By factory default, the trip-point is set to 30% of the established span when using the Quick Setup Mode. This may be changed in the field using

the standard button commands (refer to Functions 1 and 2 under Normal set-up and operation using the button interface in the operating manual).

Alternatively, the QSM factory trip-point default of 30% of span may be changed in the field using the PC interface program before entering into the

QSM. Selecting the factory setup option at order will also permit designating an alternative customer desired default value at the factory. Note, this

value is always a % of the established span and alters any previous trip point that may have been attained on a previous setup.

Note, the 4-20mA output and relay trip will continue to operate at the previously set range while in the Quick Setup Mode

Summary

1. Activate QSM: Press “-“ button (gas) or “+” button (liquid) minimum 10 seconds (LEDs will acknowledge entry into QSM).

2. Throttle flow valve to simulate zero and full scale flow.

3. Press either button momentarily to save parameter values and exit into normal operating mode.

* FS10A with Firmware version 4.0 or greater

14 Fluid Components International LLC

Page 17

FS10 Series

FS10 Button Controls

It is recommended the unit be powered-up for 10-15 minutes before making changes to any of the flow settings.

General Control Description

The FS10 control “functions” can be accessed through the two buttons by:

1. Entering “function selection”

2. Selecting the desired function to adjust

3. Adjusting the function control

4. Exiting to normal operation

1. To Enter “Function Selection” mode:

a. Press and hold both buttons down for 3 seconds

b. When “function selection” is entered, all the LEDs will flash “on”, then

c. The first function (LED # 1) will be illuminated

2. “Function Selection” mode:

Once the unit is in “function selection” mode, the buttons take on new controls:

• The “-“ and “+” buttons will step (increment down or up respectively) through the different functions. The current function number will

be indicated on the LED blinking at the slow rate.

• Holding either the “+” or “-“ for 3 seconds will “select” the current function to be adjusted.

3. When a Function has been selected for adjustment:

After selecting the desired function by pushing and holding either the “-” or “+” button for 3 seconds the LEDs will flash at a faster rate. The

pattern of the LEDs will either reflect the current value of the parameter being adjusted, or the “ready to capture” pattern for parameters to be

captured (see specific function descriptions for details).

The buttons will either increment or decrement the function parameter, or capture a value for the corresponding parameter.

4. To exit out of the current function, push and hold both buttons down for 3 seconds. The LEDs will indicate that you are once again in “function

election” mode, and the current mode will have incremented to the next function. To exit completely (into operational mode), press the two

buttons simultaneously for 3 seconds once again.

Note: Function #4 (load a bank) and function #15 (save to a bank), requires holding either button for 3 seconds to load or save.

Holding both buttons will exit either function without performing the operation.

Button Operation

1 Enter “function selection” Push and hold both buttons simultaneously 3 seconds

2 Select desired “function” Push “+” or “-“ to step through (LEDs indicate function #)

3a. Enter “function adjust” Push and hold either “-“ or “+” button 3 seconds

3b. Adjust within function Follow instructions for particular function entry

4a. Exit “function adjust” Push and hold either “-” or “+” button 3 seconds (now in “function selection”

operation)

select operation]

4b. Exit “function selection” Push and hold both buttons simultaneously 3 seconds (now in normal operation)

[NOTE: Function #4 or #15 requires holding both buttons to exit into function

Table 3

Fluid Components International LLC 15

Page 18

FS10 Series

Normal set-up and operation using the button interface

Refer to Table 5, Button Controls to address the following functions in the field.

Bank Selection of Stored Parameters (Function 4)

Select function 4 to change bank selection of stored parameters. The FS10 has 7 storage banks. Banks 1-6 are factory set defaults of common

applications or specific factory calibrations. Bank 7 is available for user saved parameters. Refer to complete FS10 configuration number to

determine the factory supplied bank setting. Note, an error pattern will result when selecting through the banks if the bank contains no valid

calibration parameters.

Units that do not come factory calibrated use Universal Setting A from Bank 1 as the settings for operational Bank 0. These parameters cover

the entire range (delta R) of the device. Therefore, spans and trip-points can be set in the field using this bank regardless of process fluid.

Once a unit is set-up in the field, the changed parameters now in Bank 0 may be stored to bank 7 using Function 15 and later retrieved using

Function 4 if unwanted changes were made in the interim

Bank Default Values

Bank No.

0 FS10 Current Active Parameters

1 Universal Default Setting A - Low flow

sensitivity

2 Air/Gas -40 °F to 250 °F (1/4 ″ tube and SP76

adapter)

3 Universal Setting B - High flow gas,

liquids

4 Water/Glycol -40 °F to 250 °F

5 Reserved for custom calibration

6 Reserved for custom calibration

7 User defined and stored

Process Fluid Range Setting

Un-calibrated output - low sensor excitation power setting

Full range gas or liquid

1 SFPS to 50 SFPS (200 cc/min to 10,000 cc/min, [0.4 SCFH to 20 SCFH] in

1/4 “ tube) – trend accuracy 10% full scale

Un-calibrated output – 1.5X sensor excitation power setting

Full range liquid and gas

0.02 SFPS to 0.5 SFPS (4 cc/min to 100 cc/min [0.001 GPM to 0.03 GPM] in

1/4” tube) – trend accuracy 10% full scale

Table 4

16 Fluid Components International LLC

Page 19

FS10 Series

Flow Switch Operation

Units supplied without factory trip point setting should be scaled in situ before setting the trip point. Default Universal Setting A from Bank

1 is recommended for most low flow sampling gas or liquid service. Gas and liquid service applications where higher flow rate detection is

required may select Universal Setting B from Bank 3.

Scaling is performed in the following order:

Minimum Flow Setting (Function 6)

Select function 6 to capture the minimum flow rate. In liquids, optimum performance is achieved by setting the Minimum Flow to a full line at

no flow. If possible, with liquids, slightly pressurize the pipe and block the flow using valves to assure a full and static condition. Capturing the

no-flow value in Function 6 establishes the zero point.

Maximum Flow Setting (Function 7)

Run the process at maximum flow and use this function to capture the maximum flow in gas or liquid. Since liquids transfer heat very efficiently, depending on the sensor assembly and fluid, maximum signal level will likely be achieved at flow rates under 2 feet per second,

though the actual flow in the tube may be higher. Capturing the maximum flow effectively establishes the span in the installation.

Note: Be sure to pause at least 30 seconds before capturing zero and span to assure unit has reached equilibrium.

Static/Dynamic Mode Option (Function 5)

This option provides dynamic ranging (span setting) of the unit for purposes of calibration. It is intended to aid the user in ranging the FS10 in

cases where the maximum flow is fluctuating and difficult to capture or requires action away from the FS10 installation.

Select button Function 5 to change between static and dynamic mode for setting the maximum span value

[CUST_FLOW_MAX]. The “static” default setting is used to capture the maximum flow in Function 7. If function 5 is changed to “dynamic”

setting, the FS10 will constantly update the maximum span value to reflect the maximum flow. The span setting increases (re-scales) to match

an increasing process flow and remains at the highest level achieved as long as the unit remains powered.

Important Note: When Function 5 is changed to Dynamic Mode, the span immediately drops to the value of the trip-point setting

and climbs from that point with flow. Therefore, a trip point should be captured (Function 2) at a flow lower than

the anticipated max span flow before placing unit in Dynamic Mode. Once the user is satisfied the maximum flow

is captured in Dynamic Mode, the unit should be switched back to Static Mode. The established span will remain.

CAUTION: A loss of power while in Dynamic Mode results in resetting the CUST_FLOW_MAX to the original trip

point value. Dynamic mode is not recommended if the application may see spiking flows or wet conditions in gas

applications that could result in a temporary and false indication of what the maximum flow should be.

Trip Point Adjust (Function 1 or 2)

There are two ways to set the trip point using the buttons.

Function 1 uses the LEDs as indicators to set the trip point in 10% increments within the established span.

Function 2 may be used to set the precise trip point by “capturing” the exact process flow rate. In liquids, make certain the desired trip

point is within the set operating range. That is, when capturing at the trip-point, the LEDs should be showing no greater than 90% flow.

NOTE: The trip-point setting is saved in feet/sec, therefore, changing the span later may alter the relative position of the flashing LED

indicating the trip-point value.

Low flow alarm applications with relay energized above the trip point (default setting): the trip point LED will flash quickly when the flow is

below the trip point. The LED flashes at a slower rate when the flow is at or above the trip-point.

Additional Switch Settings

Failsafe Position (Function 3)

This function establishes the state of the relay during normal operation and alarm condition. It is common to set the failsafe so that the relay

is “energized” or activated under normal operating conditions. An alarm condition (trip point activated) results in the de-energized state. That

assures an alarm state if power is lost to the device as well.

If the relay is bypassed and the device is used with the solid-state binary output, the system should be set up so a no-power condition results

in an alarm state. The transistor should be “on” under normal operating conditions, resulting in an approximate 5 Vdc signal to ground. Power

loss or alarm condition, results in 0 Vdc to ground.

Hysteresis (Function 8 and 9)

In the case of the flow switch, hysteresis is defined as the difference in signal level between turning on the relay and turning it off. If the

hysteresis is set to zero, that point is the same and can result in chattering, rapidly turning the relay on and off, in slow moving processes. A

hysteresis level is applied to minimize the possibility of chattering around the trip point. It is set as a percent of the trip-point value.

Fluid Components International LLC 17

Page 20

FS10 Series

The hysteresis may be applied above the trip point or below the trip point. As an example, if set above the trip-point in an application requiring low flow detection, the relay will change state as the signal falls below the trip point, but will not reset until it reaches the trip-point

value plus the added hysteresis value. The default setting is hysteresis above the trip-point and set at 2% of trip-point value. If changes are

required to the default, see how the hysteresis is applied in Function 8 and set the value in Function 9. Any value hysteresis may be applied

through the RS232 PC or command line interface. The button functions are limited to settings between 0% and 10% in 1% increments.

Time Delay (Function 10 or 11)

A time delay may be applied to the trip-point in one of two ways. The time delay may be applied to activate (Function 10) the relay after the

trip-point has been reached, or may be applied to de-activate (Function 11) the relay after the trip-point has been reached. The time starts

as the trip-point is reached and counts down as long as the trip-point value is retained. The relay then changes state. If the trip-point was

reached, but not maintained during this period, the time delay resets and the relay does not change state. The default value is zero seconds

and may be increased in 1-second increments up to 10 seconds with the buttons (time delays considerably higher are achievable through the

RS232 interface >65k secs).

Function 10 operation (relay change of state is delayed this amount [sec.] after signal reaches trip-point) is normally used in applications

where false trips may occur due to turbulent or cyclic flow action or in wet dry applications where splashing during vessel filling, for example,

may cause premature actuation. Proper setting of the time delay in this mode can be very effective in preventing problematic nuisance trips.

Function 11 operation (relay change of state is delayed this amount [sec] after signal leaves trip-point) may also be used in cyclic flow conditions. Another possible use may be to fill a vessel after a low level is reached. For example, the level reaches the low level trip-point; the

relay immediately changes state and is set to actuate a solenoid valve that begins the filling action. A time delay may be set that corresponds

to the time needed to fill the vessel.

Important: The time delay function is dependent on the Failsafe Position (Function 3). Therefore, select the proper mode of

delay based on relay being activated in normal operation and de-activated in the alarm condition. These selections

are likely to be different when alarm settings are for low flow (or dry) verses high flow (or wet) applications.

Alarm Simulation (Function 12)

This function is used to force the output to the highest or lowest value, resulting in a change of relay state as well. Alarm simulation may be

useful in testing the system in which the FS10 is installed.

Keypad Lockout (Function 13)

This function changes the time required to depress the two buttons to enter into the set-up mode from the default 3 seconds to 10 seconds

(and back). Total button lockout may be achieved through the digital interface program via the RS232 connection.

Filter Setting (Function 14)

A filter is applied to the raw input signal (delta R). It is used to smooth the output against fluctuating or turbulent flow conditions. The range

of the filter setting is 3-100. The default setting is 18 and reduces the time response by < 2 seconds. A setting of 100 will provide the maximum dampening of the signal and decreases the response time approximately 10 seconds. Settings from 3 to 100 may be applied using the

RS232 PC interface or command line interface. The buttons permit changes of values 3, 18, 30, 50 and 100 only.

Save to Bank (Function 15)

Set-up configurations may be saved to bank 7. After the FS10 is field configured, storing the parameter settings to bank 7 is performed in this

function.

18 Fluid Components International LLC

Page 21

FS10 Series

Output and Display Parameters

Diagram 2

Fluid Components International LLC 19

Page 22

FS10 Series

Table 5 Button Controls

0 = LED off, 1 = LED on

Function # Function

Name

1

2

3 Failsafe

Trip Point

Adjust

Trip Point

Capture

LED Pattern Parameter

1000000000

- +

1100000000

- +

1110000000

- +

RELAY_LIMIT

RELAY_LIMIT

RELAY_POLAR

LED Pattern for

Parameter

1 – indicates current

value relative to full

scale

1 – indicates current

value relative to full

scale

0000011111 = “on”

above (default)

1111100000 = “on”

below

Description

Button controls adjust relay trip point in

10% increments.

When entering this function the “ready

to capture” LED pattern will be presented

(0101010101). Pressing either button will

“capture” precisely the current flow value

as the new relay trip point.

Selects whether the relay is “on” (energized) if the flow value is above the relay

trip point, or if the relay is “on” (energized) when the flow value is below the

relay trip point. Pressing the buttons will

toggle between the two options (default

= “on” above trip point -- typical for low

flow alarm).

Select and load a bank of configuration

Bank

4

5

6

Selection

of Stored

Parameters

Static or

Dynamic

Range

Selection

Minimum

Flow Cap-

ture

1111000000

- +

1111100000

- +

1111110000

- +

CAL_DATA_INDEX

DISPLAY_RANGE_MODE

CUST_FLOW_MIN

1 – indicates current

index (1..7)

1111100000 =

“static”

0000011111 =

“dynamic”

1 – indicates current

value relative to full

scale

parameters. If the bank corresponding to

the selected index has not been set, the

“error pattern” (1100110011) will display.

Use “+” or “-” to move to a bank that has

desired parameters populated for loading

into active bank (0). **

Selects the output range function static/

dynamic. If “static” mode, then the output range is defined by the CUST_FLOW_

MIN and CUST_FLOW_MAX parameters.

If “dynamic” mode the CUST_FLOW_

MAX will adjust if the flow value is

greater than the current maximum value.

Default value is “static.”

When entering this function the “ready

to capture” LED pattern will be presented

(0101010101). Pressing either button will

“capture” the current flow value as the

new display “zero” point.

When entering this function the “ready

to capture” LED pattern will be presented

Maximum

7

20 Fluid Components International LLC

Flow Cap-

ture

1111111000

- +

CUST_FLOW_MAX

1 – indicates current

value relative to full

scale

(0101010101). Pressing either button will

“capture” the current flow value as the

new display “maximum flow” point. Note:

this mode is only valid if the DISPLAY_

RANGE_MODE (5) is “static.”

Page 23

FS10 Series

10

11

Hysteresis

Applied

8

Above or

Below Trip

1111111100

- +

RELAY_HYSTERESIS_

EFFECT

Point

Maximum

9

Hysteresis

Value

1111111110

- +

RELAY_HYSTERESIS

Time Delay

to

Activate

Relay or

1111111111

- +

RELAY_TURN_ON_

DELAY

Binary Pulse

Time Delay

to

De-activate

Relay or

1000000001

- +

RELAY_TURN_OFF_

DELAY

Binary Pulse

0000011111 = apply

above

1111100000= apply

below

1 – indicates current

value relative to

maximum 10%

hysteresis (MAX_

HYSTERESIS)

1 – indicates current

value relative to

maximum delay

(MAX_DELAY)

1 – indicates current

value relative to

maximum delay

(MAX_DELAY)

Selects whether the hysteresis is to be

applied above (default) or below the

relay trip point. Pressing the buttons will

toggle between the two options.

Buttons adjust the value of the dead

band effect. Increments in 1 percent

of trip-point value. Default setting is

2% of trip-point. Button range 0-10%.

Wider range available through RS232

interface.

Time delay from when flow

measurement is greater/less than relay

trip point, to turn on relay. Increments

and decrements in 1 second steps [Max

default setting 10 seconds when using

buttons].*

Time delay from when flow

measurement is greater/less than relay

trip point, to turn off relay. Increments

and decrements in 1 second steps [Max

default setting 10 seconds when using

buttons].*

12

13

14

15

Alarm

Simulation

Keypad

Lockout

1100000001

- +

1110000001

- +

Filter

Setting 1111000001

- +

Save To

Bank

1111100001

- +

BTN_ENTER_TIMEOUT

INPUT_FILTER_COUNT

0000011111= output

“max”

1111100000= output

“min”

1111100000 = 3

seconds

0000011111= 10

seconds

LED 1 on = setting 3

LEDs 1-3 on = 18

LEDs 1-5 on = 30

LEDs 1-7 on = 50

LEDs 1-10 on = 100

1111111000=7

Alarm simulation mode. Pressing the “+”

button forces “maximum” (corresponds

to A_OUT_DAC_COUNT_100) 4-20 mA

output. Pressing “-” forces “minimum”

(corresponds to A_OUT_DAC_

COUNT_0) 4-20 mA output.

Relay output will correspond with

RELAY_POLAR setting.

Keypad lockout time. Pressing the

buttons toggles between either 3

seconds or 10 seconds to hold both

buttons to enter “function selection”

mode.

Input filtering count: Default = 18.

“-” decreases filter, min. = 3.

“+” increases filter, max. = 100.

Filter value 18 reduces response

time <2 sec

User preset. Save current active

parameters (in 0 bank) to user bank

location 7. (Hint- use “-” button to

quickly move to FUNCTION 15 from

FUNCTION position 1). **

* Maximum time delay may be up to 65,000 seconds when using RS232 command line or PC interface.

** Function #4 (load a bank) and function #15 (save to a bank), requires holding either button for 3 seconds to load or save.

Holding both buttons will exit either function without performing the operation.

Fluid Components International LLC 21

Page 24

FS10 Series

PC Interface and Command Line Interface Congurations

FS10 Communication Options

In addition to the button interface, the FS10 may be addressed directly through the RS232 interface. This type of communication offers

convenient access to all user available parameters. There are two methods for interfacing through the RS232 connections:

1. A Windows PC Interface program is available that allows reading and writing to all user available functions and parameters.

2. A Command Line Interface through a HyperTerminal (MS) type program will access all functions and parameters (see RS232 Interface

Reference Table on the following pages).

In both cases the parameters are accessed directly through the RS232 terminals. Depending on the hardware configuration selected, the

RS232 signals are available through any of the following:

1. M12 pins - for units supplied with M12 power and output (I/O) connector

2. 8-wire cable units - for units supplied with cable pigtail, terminate to 3 wires

3. 2.5mm phone jack connector - available on remote mount units only

IMPORTANT NOTE: RS232 RxD, RS232 TxD and SIGNAL RETURN (3-connections) must be used to for effective

communication.

An RS232 to 9 pin serial (DB9) to USB interface cable is available from FCI to connect directly to a PC or PLC. An RS232 interface from either

of the 3 configurations above is available from the table on the following page. NOTE: The USB interface cable is supplied with a device

driver disk. Depending on the computer operating system, installation may be necessary for communication. Entry of the USB port # will be

requested. It is normally the highest value listed.

Password Protection

Factory settings are protected with a level 1 factory password. End user settings are protected with a level 2 password. The following

password will provide access and allow changes to any level 2 parameters: 19113

Refer to Table 7 for parameter command reference. Access to all level 2 (user configurable) parameters are available through the FC10 PC

interface software.

Flow Rate Indication on PC Interface

Units will read values in percent, trend with flow and be repeatable. The PC interface provides a convenient means of capturing zero, span

and trip-point settings in lieu of using the buttons.

Power Supply Interface Kit

FCI offers an interface kit that makes it easy to connect to a notebook computer in the field. Kit PN number 022083-02 is described on page

32 of this manual. It may also be used to simply power up the unit using an AC connection. Relay function and 4-20 mA output may be

monitored using this interface.

22 Fluid Components International LLC

Page 25

FS10 Series

PC Interface Software

Typical screen shots using the Windows based PC interface

DISPLAY WINDOW

SET-UP WINDOW

Move mouse cursor over description

to uncover additional notes

SET-UP / FLOW RANGE WINDOW

Capture Zero and Full Scale Flow

Fluid Components International LLC 23

SET-UP / SWITCH POINT SET-UP WINDOW

Set trip-point with Capture button or by entering % of span

Page 26

FS10 Series

SET-UP / TEMPERATURE RANGE WINDOW

Range temperature output if using 4-20 mA out as

temperature indication

SET-UP / CAL BANK SET-UP WINDOW

Saving/retrieving calibrations to and from banks

SET-UP / OUTPUT CONFIGURATION WINDOW

Select 4-20 mA and LED mapping (flow or temperature)

24 Fluid Components International LLC

DIAGNOSTICS WINDOW

Page 27

FS10 Series

PC Interface Software

Typical screen shots using the Windows based PC interface

DIAGNOSTICS / CALIBRATION

PARAMETERS WINDOW

DIAGNOSTICS / RAW VALUES

WINDOW

UTILITIES / NAMUR SETTINGS

Fluid Components International LLC 25

QUICK SETUP

Page 28

FS10 Series

FS10 Serial Interface

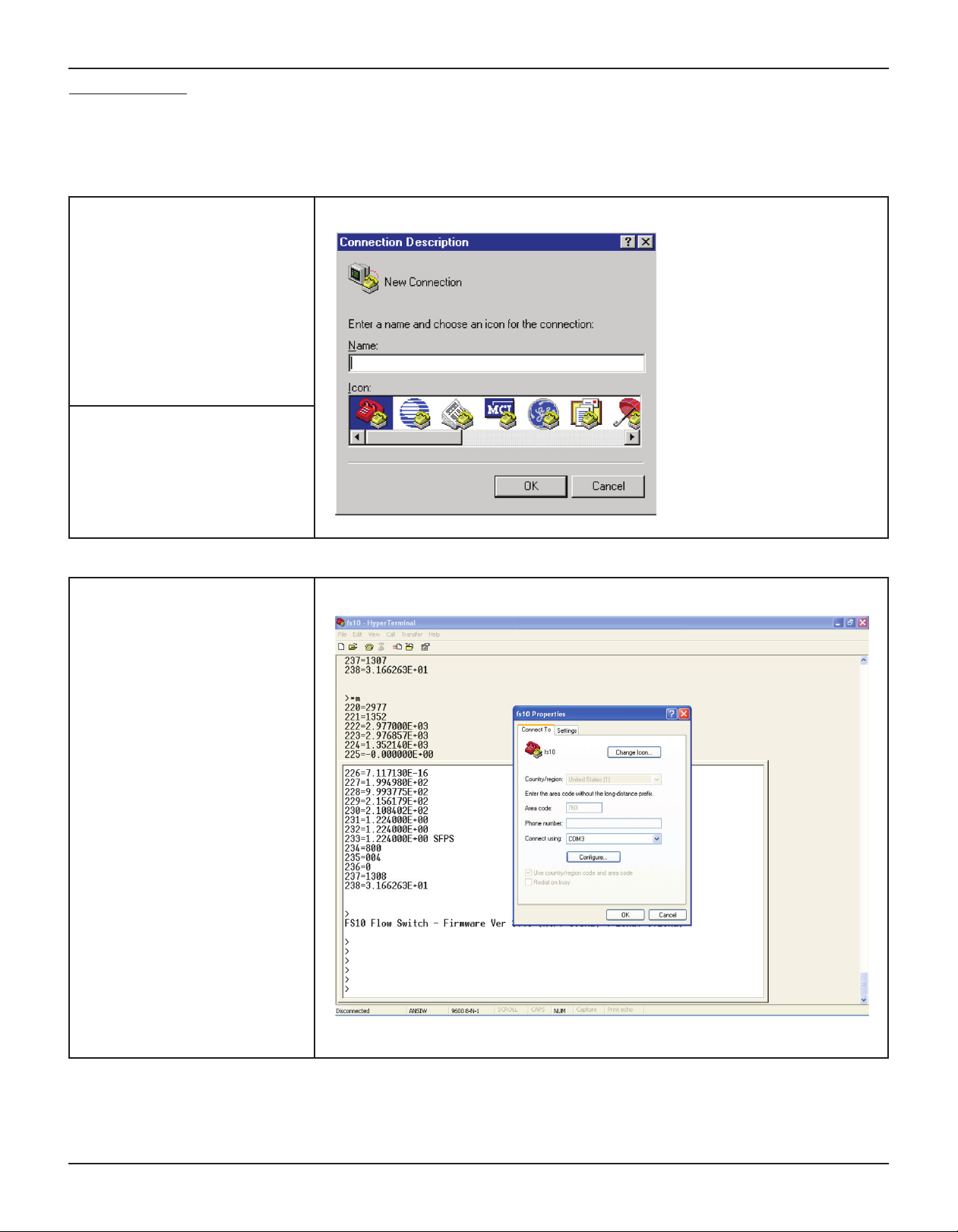

Interface example using HyperTerminal set-up:

HyperTerminal, which comes with Windows95, 98, Me, NT, 2K XP & Windows 7 and can be used to communicated directly with the FS10.

To set up HyperTerminal to interface with computer modem:

1. Start the HyperTerminal .exe program

(hypertrm.exe). Click on START, then

ACCESSORIES, then COMMUNICATIONS, then HYPERTERMINAL, then

choose the HyperTerminal entry that

does not have an .ht extension.

Note: Some Windows versions

store HyperTerminal as an

Accessory.

2. This brings up this dialog.

Enter a name (such as “FS10”)

Select any ICON.

Click OK

3. This dialog will appear. Click the

selection arrow on the “Connect

using” list box, and select the COM

port your modem is connected to –

not the modem name.

When you select the COM port,

the phone number to dial boxes are

grayed.

Click OK

26 Fluid Components International LLC

Page 29

FS10 Series

4. The COM port properties box comes

up. Make sure that you set the Bits

per second to 9600.

The other defaults shown here are

correct.

Click OK.

5. You now get the HyperTerminal window where you are able to control

your modem with commands.

Type *MEAS - you should get these

return values from FS10. You’re ready

to go!

When you end the session, make

sure to say YES to save the settings. A new icon will be created in

the HyperTerminal folder with your

session-name.ht. This is a shortcut

on your desktop for easy access, and

you never need to repeat these setup

steps.

Fluid Components International LLC 27

Page 30

FS10 Series

Command Line Interface Commands

INFO Read version information (Hardware, Firmware, Date code, other values (#1.. #45). [The values in items

1 through 45 are listed]

MEAS Read most recent flow measurement values (#220..#238). [The values in items 220 through 238 are listed]

RCFG B Read configuration parameters (#80..#132) from bank B (0..9). [Example: *RCFG 7 (to read bank 7 parameters)]

SAVE B Save currently active parameters to bank B (0..9) (Level 2 – Field password required). [Example: *SAVE 7]

RCL B Recall parameters from bank B as the active parameters. (Level 2 – Field password required). [Example: *RCL 7]

PASSWD NNNN To enter the password for either Level 1 (Factory) or Level 2 (Field). [Example *PASSWD 19113]

EXIT To exit the current password level (undo having entered a password). The current parameters will automatically be

saved to Bank 0 upon exit.

NNN=<value> Update item #NNN (1..238) in the “active” (RAM) parameters with value. Value may be either integer or floating

point (scientific notation). [Example 1: *228=1.100119E+03 enters value 1.100119E+03 into item 228, Example 2:

*1=002 enters 002 into item1, Example 3: *110=800 enters 800 into item 110]

B:NNN Read item #NNN (1..238) in Bank B (0..9). For items #1..#45, and items #220..#238 the Bank is ignored. If no bank is

specified, the currently active (RAM) parameters will be accessed. [Example 1: *7:85 returns item 85 from bank 7 in

this form: 7:85>5.053665E-02, Example 2: *8:119 returns item 119 from bank 8 in this form: 8:119=030]

28 Fluid Components International LLC

Page 31

FS10 Series

Table 7 RS232 Interface Reference Table

Bank Item # Item Name Description R/W Type Size

1 HW_REV Hardware Version R int 1 N/A

2 FW_REV Firmware Revision R int 1 N/A

3 YY Date Code, Year R int 1 N/A

4 MM Date Code, Month R int 1 N/A

5 DD Date Code, Date R int 1 N/A

6 S_N Sequence Number R int 2 N/A

7 RESERVED1 Reserved 1 int 1

Default

Password

Level

11 FREQ_MAX_OUT For output modes 2, 3, 6, & 7 sets the

maximum frequency output

14 BTN_ENTER_TIMEOUT Keypad lockout time period (sec) R/W int 2 3 Lev 2

35 TAG Customer Tag Number R/W char. 20 Lev 2

36 UNITS_K Conversion factor applied to

flow_final_out to compute

flow_final_units

37 UNITS_ID Units identifier associated with

UNITS_K conversion factor

38 PIPE_ID

39 USER_ID2 User identification field R/W char. 20 Lev 2

40 USER_ID3 User identification field R/W char. 20 Lev 2

41 USER_ID4 User identification field R/W char. 20 Lev 2

45 RTD_TYPE Reference sensor RTD type: 1= 1000

46 NAMUR_ENABLE Enables/Disables NAMUR_Level

User Field: Pipe identification

ohm, 2= 500 ohm, 3= 100ohm

(0=disabled; 1= enabled low, <3.6mA ;

2= enabled high, >21mA)

R/W float 4 2000.0 Lev 2

R/W float 4 1.0 Lev 2

R/W char. 10 SFPS Lev 2

R/W char. 20 Lev 2

R/W int 1 1 Lev 2

R/W int 1 0 Lev 2

50 QSM1_BANK Quick setup mode bank for button 1 R/W int 1 .05 Lev 2

52 QSM1_PERCENT_SPAN Default trip point level as percent of

established span

53 QSM2_BANK Quick setup mode bank for button 2 R/W int 1 .05 Lev 2

55 QSM2_PERCENT_SPAN Default trip point level as percent of

established span

0..9 107 CUST_FLOW_MIN Customer Flow_Final Limit Min. in SFPS R/W float 4 1.224 Lev 2

0..9 108 CUST_FLOW_MAX Customer Flow_Final Limit Max in SFPS R/W float 4 120.0 Lev 2

Fluid Components International LLC 29

R/W float 4 30 Lev 2

R/W float 4 30 Lev 2

Page 32

FS10 Series

Table 7 RS232 Interface Reference Table continued

Password

Bank Item # Item Name Description R/W Type Size

0..9 112 RELAY_LIMIT Relay Limit (SFPS) R/W float 4 65.0 Lev 2

Default

Level

0..9 113 RELAY_HYSTERESIS Relay Hysteresis

(% of #112 [RELAY_LIMIT])

0..9 114 RELAY_HYSTERESIS_

EFFECT

0..9 115 RELAY_POLAR Relay Polarity (1 - Active High,

0..9 116 RELAY_TURN_ON_DELAY Relay Turn-on Delay (secs)

0..9 117 RELAY_TURN_OFF_DELAY Relay Turn-off Delay (secs) 65K secs

0..9 118 DISPLAY_RANGE_MODE Display range either static (0):

0..9 119 INPUT_FILTER_PERIOD Time constant for input filtering (secs) R/W int 1 3 Lev 2

0..9 120 MAX_HYSTERESIS Maximum hysteresis value for

Hysteresis either above or below set

point

0 - Active Low)

65K secs max. Restricted by #121

value when using buttons

max. Restricted by #121 value when

using buttons

based on zero flow and max flow. Or

dynamic (1): based on zero flow, with

auto-adjust (peak hold) for max flow

buttons as % of #112 (trip-point)

R/W float 4 2.0 Lev 2

R/W int 1 0 = below Lev 2

R/W int 1 1 Lev 2

R/W int 1 0 Lev 2

R/W int 1 0 Lev 2

R/W int 1 0 = static Lev 2

R/W float 4 10.0 Lev 2

0..9 121 MAX_DELAY Maximum delay for turn on/

turn off delays (sec); effects

button operation only

0..9 122 FLOW_K1 "K1" factor applied R/W float 4 0.0 Lev 2

0..9 123 FLOW_K2 "K2" factor applied R/W float 4 1.0 Lev 2

0..9 124 FLOW_K3 "K3" factor applied R/W float 4 0.0 Lev 2

0..9 125 FLOW_K4 "K4" factor applied R/W float 4 0.0 Lev 2

0..9 126 CUST_TEMP_MIN Customer Temperature final

Min. limit

0..9 127 CUST_TEMP_MAX Customer Temperature final

Max. limit

220 FLOW_COUNT_RAW Raw ADC Counts for Flow

Sampling

221 REF_COUNT_RAW Raw ADC Counts for

REFERENCE Sampling

222 FLOW_COUNT_ADJ Temp. Compensated Flow ADC counts R float 4 N/A N/A

R/W int 2 10 Lev 2

R/W float 4 0.0 Lev 2

R/W float 4 0.0 Lev 2

R int 2 N/A N/A

R int 2 N/A N/A

30 Fluid Components International LLC

Page 33

FS10 Series

Table 7 RS232 Interface Reference Table continued

Bank Item # Item Name Description R/W Type Size

223 FLOW_COUNT_FILT Adjusted, filtered Flow ADC counts R float 4 N/A N/A

224 REF_COUNT_FILT Adjusted, filtered Ref ADC counts R float 4 N/A N/A

225 dR_OHM Delta R in milliOhm R float 4 N/A N/A

226 REF_OHM Reference R in milliOhm R float 4 N/A N/A

227 dR_OHM_NORM Normalized dR milliOhm R float 4 N/A N/A

228 refR_OHM_NORM Normalized refR milliOhm R float 4 N/A N/A

229 dR_OHM_PCED Power Corrected dR in milliOhm R float 4 N/A N/A

Default

Password

Level

230 dR_OHM_TCED Temp Compensated dR in

milliOhm

231 FLOW_FINAL Temp Comp_ed and N-L

Corrected Flow

232 FLOW_FINAL_OUT

233 FLOW_FINAL_UNITS FLOW_FINAL_OUT adjusted by

234 A_OUT_DAC_COUNT Analog Output DAC Count R int 2 N/A N/A

235 DISPLAY_COUNT COUNT to Be Displayed on LED Bar

236 DIO_BIT_PATTERN LED/Button Bit Pattern R int 2 N/A N/A

237 BOARD_TEMP_COUNT Raw ADC Counts for On-Board Temp

238 REF_TEMP Computed Temperature (deg. F) R float 4 N/A N/A

FLOW_FINAL used for analog output

(adjusted for customer limits)

UNITS_K

Gragh

Sensor Sampling

R float 4 N/A N/A

R float 4 N/A N/A

R float 4 N/A N/A

R float 4 N/A N/A

R int 1 N/A N/A

R int 2 N/A N/A

Fluid Components International LLC 31

Page 34

FS10 Series

6 MAINTENANCE AND TROUBLESHOOTING

Maintenance

ypically required for the sensing element. If the process media sticks to the process pipes (or tank) the sensing element should be cleaned in

the same manner and frequency as the process pipe (or tank). Occasionally check for moisture in the control circuit housing and wiring connections. Check for proper functionality and response time.

Troubleshooting

If the instrument is not operating, go through the installation and adjustment procedures and verify proper installation. If the instrument

fails after some time in service and it has been checked, or if it fails to operate at start up and the installation has been verified, contact your

authorized FCI service representative.

If FCI representative cannot be reached, contact FCI Technical Service. If the instrument is to be returned, obtain a Return Authorization. The

form contains a declaration of decontamination cleaning information that the instrument must comply with before it is shipped to FCI. The

telephone number in the US is 1-800-854-1993 or 1-760-744-6950 or email: techsupport@fluidcomponents.com

32 Fluid Components International LLC

Page 35

FS10 Series

Intentionally Left Blank

Fluid Components International LLC 33

Page 36

FS10 Series

APPENDIX A APPROVALS

EC DECLARATION OF CONFORMITY Model FS10

We, Fluid Components International LLC, located at 1755 La Costa Meadows Drive, San Marcos, California

92078-5115 USA, declare under our sole responsibility that the FS10 Flow Switch Flow Monitor Product

Family, to which this declaration relates, are in conformity with the following standards and Directives.

Directive 94/9/EC ATEX

IECEX Scheme

Certified by KEMA Quality B.V. (0344): Utrechweg 310, 6812 AR, Arnhem, The Netherlands

EC-Type Examination Certificates:

KEMA 10ATEX0142X satisfies EN 60079-0:2009, EN 60079-15:2005, EN 60079-31:2009 requirements for

use in hazardous areas.

IECEx KEM 10.0067X satisfies IEC 60079-0:2007-10, IEC 60079-15:2005-03, IEC 60079-31:2008

requirements for use in hazardous areas.

Hazardous Areas Approval KEMA 10ATEX0142X and IECEx KEM 10.0067X for:

II 3 G Ex nA IIC T4 Gc

II 3 D Ex tc IIIC T81°C Dc

Directive 2004/108/EC EMC

Immunity specification

Emissions specification

Directive 97/23/EC Pressure Equipment

The FS10 Model does not have a pressure bearing housing and is therefore not considered as pressure

equipment by itself according to article 1, section 2.1. The Model FS10 is in conformity with the sound

engineering practices as defined in the Pressure Equipment Directive (PED) 97/23/EC article 3, paragraph 3.

Issued at San Marcos, California USA

September 2011

______________________________________

Eric Wible, Engineering Manager

: EN 61000-6-2: 2005

: EN 61000-6-4: 2007

Eric Wible

2011.09.20

11:53:50 -07'00'

Flow/Liquid Level/Temperature Instrumentation

1755 La Costa Meadows Drive, San Marcos, California 92078 USA 760-744-6950 800-854-1993 760-736-6250

Visit FCI on the Worldwide Web: www.fluidcomponents.com

European Office: Persephonestraat 3-01 5047 TT Tilburg – The Netherlands – Phone 31-13-5159989 Fax 31-13-5799036

Doc no. 23EN000021A

34 Fluid Components International LLC

Page 37

FS10 Series

Intentionally Left Blank

Fluid Components International LLC 35

Page 38

FS10 Series

Safety Instructions for the use the FS10 flowmeter in Hazardous Areas

Approval KEMA 10ATEX0142 X / IECEx KEM 10.0067X for:

Category II 3 G for Gas protection Ex nA IIC T4

Category II 3 D for Dust protection IP64 Ex tc IIIC T 81ºC Dc

The FS10 series consist of a sensing element and associated integral or remote mounted electronics.

Relation between ambient temperature, process temperature and temperature class is as follows:

1) Ambient temperature range (Ta): -40°C … +71°C

2) Maximum process temperature (Tp): 121°C (integral version)

260°C (remote version)

3) Electrical data: Power supply - 21.5…30 VDC, 2.5 Watts Max

Dansk Sikkerhedsforskrifter Italiano Normative di sicurezza

Deutsch Sicherheitshinweise Nederlands Veiligheidsinstructies

English Safety instructions Português Normas de segurança

Υπ Υπ_δεί_εις ασφαλείας

Español Instrucciones de seguridad

Suomi Turvallisuusohjeet Svenska Säkerhetsanvisningar

Français Consignes de sécurité

DK Dansk- Sikkerhedsforskrifter

Disse sikkerhedsforskrifter gælder for Fluid Components, FS10 EF-typeafprøvningsattest-nr. KEMA 10ATEX0142X/IECEx

KEM10.0067(attestens nummer på typeskiltet) er egnet til at blive benyttet i eksplosiv atmosfære kategori II 3 GD.

1) Ex-anlæg skal principielt opstilles af specialiseret personale.

2) FS10 skal jordforbindes.

D A Deutsch-Sicherheitshinweise

Diese Sicherheitshinweise gelten für die Fluid Components, FS10 flowmeter gemäß der EG-Baumusterprüfbescheinigung Nr.

KEMA 10ATEX0142X/IECEx KEM10.0067(Bescheinigungsnummer auf dem Typschild) der Kategorie II 3 GD.

1) Die Errichtung von Ex-Anlagen muss grundsätzlich durch Fachpersonal vorgenommen werden.

2) Der FS10 muß geerdet werden.

GB IRL English- Safety instructions

These safety instructions are valid for the Fluid Components, FS10 flowmeter to the EC type approval certificate no KEMA

10ATEX0142X/IECEx KEM10.0067 (certificate number on the type label) for use in potentially explosive atmospheres in Category II

3 GD.

1) The installation of Ex-instruments must be made by trained personnel.

2) The FS10 must be grounded.

GR Υπ_δεί_εις ασφαλείας

Αυτές οι οδηγίες ασφαλείας ισχύουν για τα Ροόµετρα της Fluid Components τύπου FS10 που φέρουν Πιστοποιητικό Εγκρίσεως

Ευρωπαϊκής Ένωσης, µε αριθµό πιστοποίησης KEMA 10ATEX0142X/IECEx KEM10.0067(ο αριθµός πιστοποίησης βρίσκεται πάνω

στην ετικέτα τύπου του οργάνου) για χρήση σε εκρηκτικές ατµόσφαιρες της κατηγορίας II 3 GD.

1) Η εγκατάσταση των οργάνων µε αντιεκρηκτική προστασία πρέπει να γίνει από εξειδικευµένο προσωπικό.

2) Το όργανο τύπου FS10 πρέπει να είναι γειωµένο.

36 Fluid Components International LLC

Page 39

FS10 Series

FIN Suomi - Turvallisuusohjeet

Nämä turvallisuusohjeet koskevat Flud Components, FS10 EY-tyyppitarkastustodistuksen nro. KEMA 10ATEX0142X/IECEx

KEM10.0067 (todistuksen numero näkyy tyyppikilvestä) käytettäessä räjähdysvaarallisissa tiloissa luokassa II 3 GD.

1) Ex-laitteet on aina asennettava ammattihenkilökunnan toimesta.

2) FS10 on maadoitettava.

F B L Consignes de sécurité

Ces consignes de sécurité sont valables pour le modèle FS10 de la société Fluid Components (FCI) conforme au certificat

d’épreuves de type KEMA 10ATEX0142X/IECEx KEM10.0067(numéro du certificat sur l’étiquette signalétique) conçu pour les

applications dans lesquelles un materiel de la catégorie II3GD est nécessaire.

1) Seul un personnel spécialisé et qualifié est autorisé à installer le matériel Ex.

2) Les FS10 doivent être reliés à la terre.

I Italiano - Normative di sicurezza

Queste normative di sicurezza si riferiscono ai Fluid Components, FS10 secondo il certificato CE di prova di omologazione n° KEMA

10ATEX0142X/IECEx KEM10.0067(numero del certificato sulla targhetta d’identificazione) sono idonei all’impiego in atmosfere

esplosive applicazioni che richiedono apparecchiature elettriche della Categoria II 3 GD.

1) L’installazione di sistemi Ex deve essere eseguita esclusivamente da personale specializzato.

2) I FS10 devono essere collegati a terra.

NL B Nederlands - Veiligheidsinstructies

Deze veiligheidsinstructies gelden voor de Fluid Components, FS10 overeenkomstig de EG-typeverklaring nr. KEMA

10ATEX0142X/IECEx KEM10.0067 (nummer van de verklaring op het typeplaatje) voor gebruik in een explosieve atmosfeer

volgens Categorie II 3GD.

1) Installatie van Ex-instrumenten dient altijd te geschieden door geschoold personeel.

2) De FS10 moet geaard worden.

P Português - Normas de segurança

Estas normas de segurança são válidas para os Fluid Components, FS10 conforme o certificado de teste de modelo N.º KEMA

10ATEX0142X/IECEx KEM10.0067(número do certificado na plaqueta com os dados do equipamento) são apropriados para

utilização em atmosferas explosivas categoria II 3 GD.

1) A instalação de equipamentos em zonas sujeitas a explosão deve, por princípio, ser executada por técnicos qualificados.

2) Os FS10 Flexmasster precisam ser ligados à terra.

E Español - Instrucciones de seguridad

Estas indicaciones de seguridad son de aplicación para el modelo FS10 de Fluid Components, según la certificación CE de modelo

Nº KEMA 10ATEX0142X/IECEx KEM10.0067para aplicaciones en atmósferas potencialmente explosivas según la categoría II 3

GD (el número decertificación se indica sobre la placa informativa del equipo).

1) La instalación de equipos Ex tiene que ser realizada por personal especializado.

2) Los FS10 tienen que ser conectados a tierra.

S Svenska - Säkerhetsanvisningar

Säkerhetsanvisningarna gäller för Fluid Components, Flödesmätare typ FS10 enligt EG-typkontrollintyg nr KEMA

10ATEX0142X/IECEx KEM10.0067 (intygsnumret återfinns på typskylten) är lämpad för användning i explosiv gasblandning i

kategori II 3 GD.

1) Installation av Ex- klassade instrument måste alltid utföras av fackpersonal.

2) FS10 måste jordas.

Fluid Components International LLC 37

Page 40

FS10 Series

APPENDIX B AUXILIARY DRAWINGS

38 Fluid Components International LLC

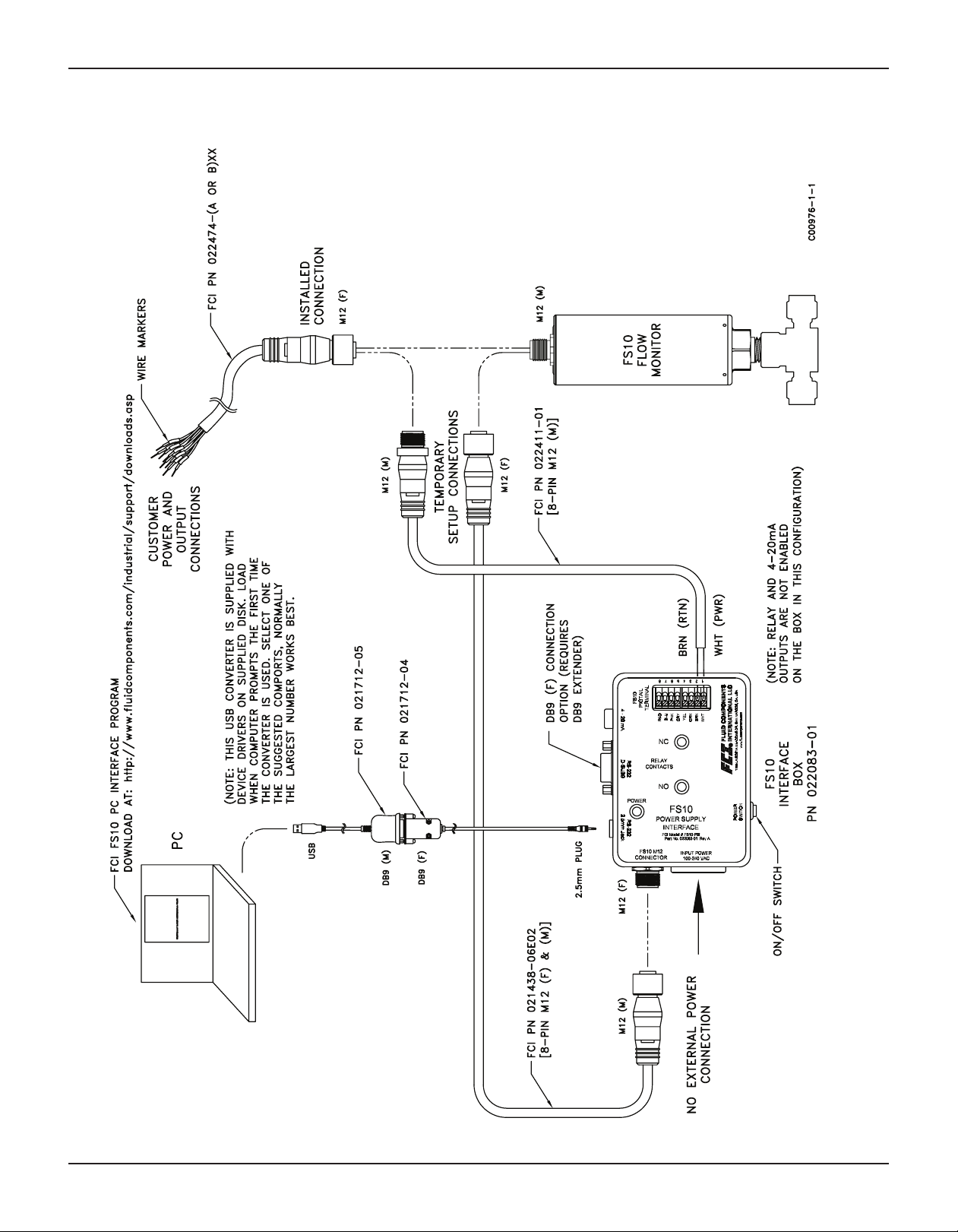

RS232 Interface Box Hookup - Using Installed DC Power to FS10A

Page 41

FS10 Series

Fluid Components International LLC 39

RS232 Interface Box Hookup - External AC Power Available

Page 42

FS10 Series

40 Fluid Components International LLC

RS232 to Computer Hookup Using Installed Power and Wiring

Page 43

FS10 Series

PC Interface Kits

Fluid Components International LLC 41

Page 44

FS10 Series

022083-01 Power Supply/Interface Box

A

B

C

D

E

F

022083-02 Power Supply/Interface Box Kit

A PN 022083-01 Power Supply/Interface Box

B PN 021712-05 DB9 to USB Converter with USB PC driver disk

C PN 021712-04 2.5mm plug to DB9

D PN 021438-06E02 interconnecting cable, 2 meters, M12(m) and M12(f) end connections

E PN 022411-01 M12 (M) to power leads #1 PWR and #2 RTN