Page 1

Installation, Operation and Maintenance

®TM

Nuclear Qualifi ed FLT 93

Flow, Level, Temperature Switch/Monitor

Models: FLT93F, FLT93L, FLT93S

Series FlexSwitch

[

]

Doc 06EN003409

Page 2

FLT® Series FlexSwitch

TM

This document contains confi dential technical data, including trade secrets and proprietary information which is the property of Fluid

Notice of Proprietary Rights

Components International LLC (FCI). Disclosure of this data to you is expressly conditioned upon your assent that its use is limited to use within your company only (and does not include manufacture or processing uses). Any other use is strictly prohibited without the prior written consent of FCI.

© Copyright 2011 by Fluid Components International LLC. All rights reserved.

Manufactured in accordance with one or more of the following patents: 5,600,528; 6,340,243. FCI is a registered trademark of Fluid Components International LLC. Information subject to change without notice.

Fluid Components International LLC

Page 3

FLT® Series FlexSwitchTM 06EN003409 Rev. -

Table of Contents

1 GENERAL ...................................................................................................................................................................................................7

Description................................................................................................................................................................................................................... 7

Theory of Operation ..................................................................................................................................................................................................... 7

Sensing Element .......................................................................................................................................................................................................... 7

Control Circuit .............................................................................................................................................................................................................. 7

Technical Specifi cation ................................................................................................................................................................................................ 8

2 INSTALLATION .........................................................................................................................................................................................11

Receiving/Inspection ................................................................................................................................................................................................... 11

Packing/Shipping/Returns ........................................................................................................................................................................................... 11

Factory Calibration Note.............................................................................................................................................................................................. 11

Pre-Installation Procedure ........................................................................................................................................................................................... 11

Use Standard ESD Precautions ................................................................................................................................................................................ 11

Prepare or Verify Sensing Element Location ............................................................................................................................................................ 11

Verify Dimensions .................................................................................................................................................................................................... 11

Verify Sensing Element Flow Direction and Placement Orientation (Flow Application) ......................................................................................... 11

Verify Sensing Element Flow Direction and Placement Orientation (Level Application) ........................................................................................ 12

Install the Sensing Element......................................................................................................................................................................................... 12

Male NPT Mounting ................................................................................................................................................................................................. 12

Flange Mounting ...................................................................................................................................................................................................... 12

Packing Gland Assembly .......................................................................................................................................................................................... 13

In-line NPT Assembly (FLT93-L) ............................................................................................................................................................................... 13

Install and Wire the Enclosure(s) ............................................................................................................................................................................. 14

Minimum Wire Size.................................................................................................................................................................................................. 14

Enclosures Covers .................................................................................................................................................................................................... 14

Cable and Conduit Entry Devices ............................................................................................................................................................................. 14

Wiring the Local Enclosure ..................................................................................................................................................................................... 15

Wiring The Remote Enclosure.................................................................................................................................................................................. 15

Locate the Remote Hardware Location.................................................................................................................................................................... 15

Wiring Remote Enclosure with Auxiliary Relay ....................................................................................................................................................... 16

Wiring A Remote Control Circuit To An Auxiliary Relay Board ................................................................................................................................ 16

Wiring Output Signal Terminals .................................................................................................................................................................................. 17

3 OPERATION ...............................................................................................................................................................................................19

Factory Default Jumper Confi guration ........................................................................................................................................................................ 19

Confi guration Jumpers ................................................................................................................................................................................................ 19

Heater Cut-Off ............................................................................................................................................................................................................. 19

Alarm Set Point Adjustments ...................................................................................................................................................................................... 20

Numerical Adjustment Versus Adjustment by Observation .................................................................................................................................... 20

Numerical Alarm Set Point Adjustment ...................................................................................................................................................................... 22

Air/Gas Flow Applications ....................................................................................................................................................................................... 22

Wet/Dry Liquid Level Applications .......................................................................................................................................................................... 24

Liquid Flow Applications .......................................................................................................................................................................................... 26

Adjustment by Observation ......................................................................................................................................................................................... 28

Flow Applications ..................................................................................................................................................................................................... 28

Fluid Components International LLC 3

Page 4

06EN003409 Rev. - FLT® Series FlexSwitch

TM

Level Applications .................................................................................................................................................................................................... 28

Temperature Applications ........................................................................................................................................................................................ 29

Converting Temp Out Voltage to Temperature in Degrees F or Degrees C .............................................................................................................. 31

Fail Safe Alarm Setting .............................................................................................................................................................................................. 37

Low Flow Alarm Settings ......................................................................................................................................................................................... 37

High Flow Alarm Settings ........................................................................................................................................................................................ 37

Low Level Alarm Settings (Sensing Element Normally Wet) ................................................................................................................................. 38

High Level Alarm Settings (Sensing Element Normally Dry) .................................................................................................................................. 38

4 MAINTENANCE .......................................................................................................................................................................................39

Maintenance ................................................................................................................................................................................................................ 39

Calibration ................................................................................................................................................................................................................ 39

Electrical Connections .............................................................................................................................................................................................. 39

Remote Enclosure ..................................................................................................................................................................................................... 39

Electrical Wiring ....................................................................................................................................................................................................... 39

Sensing Element Connections.................................................................................................................................................................................. 39

Sensing Element Assembly ...................................................................................................................................................................................... 39

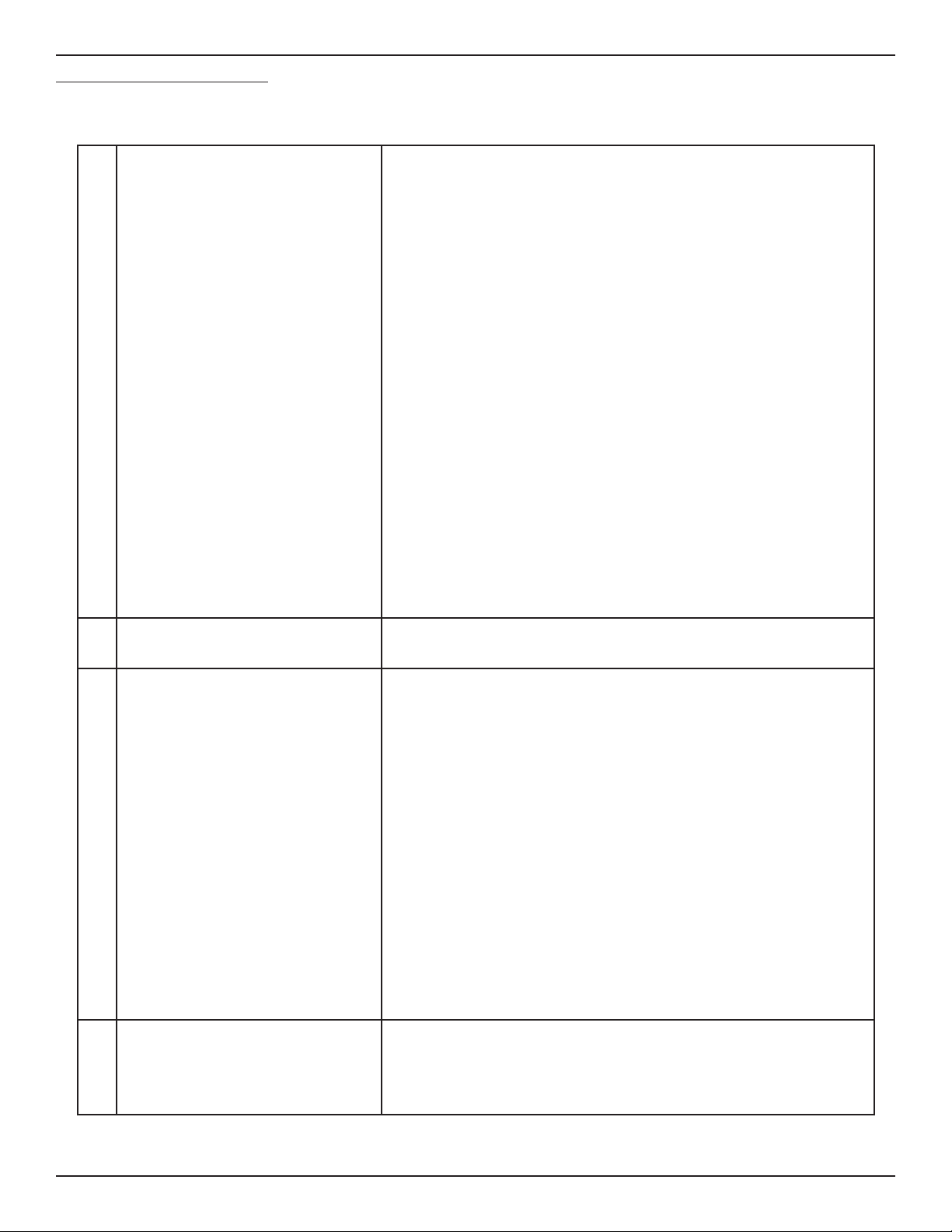

5 TROUBLESHOOTING .............................................................................................................................................................................. .41

Tools Needed ............................................................................................................................................................................................................ 41

Quick Check .............................................................................................................................................................................................................. 41

Non-maintenance Observations............................................................................................................................................................................... 41

Check Serial Numbers .............................................................................................................................................................................................. 41

Check Input Power .................................................................................................................................................................................................... 41

Check the Instrument Installation ............................................................................................................................................................................ 41

Check for Moisture ................................................................................................................................................................................................... 41

Check Application Design Requirements ................................................................................................................................................................. 41

Troubleshooting the Flow Element .............................................................................................................................................................................. 42

Troubleshooting the Flow Transmitter ......................................................................................................................................................................... 43

Spares ....................................................................................................................................................................................................................... 44

Defective Parts ......................................................................................................................................................................................................... 44

Customer Service ..................................................................................................................................................................................................... 44

4 Fluid Components International LLC

Page 5

FLT® Series FlexSwitchTM 06EN003409 Rev. -

APPENDIX A DRAWINGS ........................................................................................................................................................................ .45

APPENDIX B GLOSSARY ..........................................................................................................................................................................47

APPENDIX C TEMPERATURE COMPENSATION ...................................................................................................................................49

Introduction .................................................................................................................................................................................................................. 49

Factory Temperature Compensation Settings ............................................................................................................................................................. 49

Field Temp Comp Calibration ....................................................................................................................................................................................... 50

APPENDIX D CUSTOMER SERVICE ........................................................................................................................................................53

Customer Service/ Technical Support ...................................................................................................................................................................... 53

Warranty Repairs or Returns .................................................................................................................................................................................... 53

Non-Warranty Repairs or Returns ............................................................................................................................................................................ 53

Return to Stock Equipment....................................................................................................................................................................................... 54

Field Service Procedures .......................................................................................................................................................................................... 54

Field Service Rates ................................................................................................................................................................................................... 54

Return Authorization Request ................................................................................................................................................................................ 55

Fluid Components International LLC 5

Page 6

FLT® Series FlexSwitch

TM

INTENTIONALLY LEFT BLANK

6 Fluid Components International LLC

Page 7

FLT® Series FlexSwitchTM GENERAL

1 GENERAL

Description

The FLT Series models are multipurpose measurement instruments. The FLT Series models that are included in this manual are FLT93-S, FLT93-F,

FLT93-HT and FLT93-L. Each model is a single instrument that is capable of detecting fl uid fl ow and temperature. It is also able to detect liquid level

or fl uid media interfaces. The instrument has two fi eld adjustable alarm set points, two buffered voltage outputs, as well as a built-in calibration

circuit. The output of the alarm set points are 6 amp relay contacts that can be used to control customer process applications. An optional 10 amp

relay contacts can be used to control the customer process application. One buffered voltage output is available for fl ow or level monitoring and the

second buffered voltage output is available for temperature monitoring.

Theory of Operation

The fl ow switch is a fi xed position, single-point fl ow, level, interface and temperature switch. The operation of the sensing element is based upon

the thermal dispersion principle: A low-powered heater is used to produce a temperature differential between two Resistance Temperature Detectors (RTDs). The RTD temperature differential varies as a function of forced convection for fl ow measurement and as a function of fl uid thermal

conductivity for level and interface measurement. The measurement of the fl uid’s temperature is obtained from the non-heated RTD.

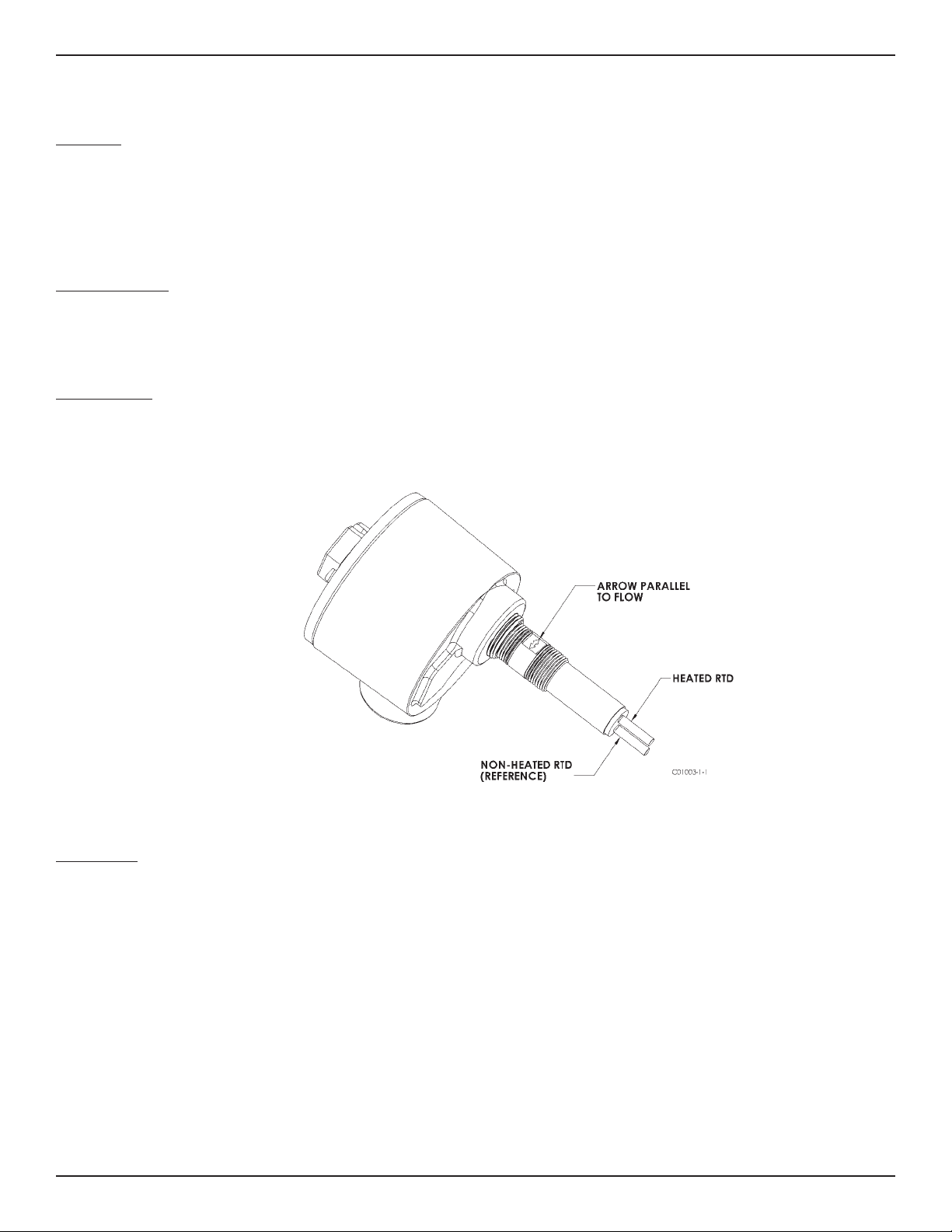

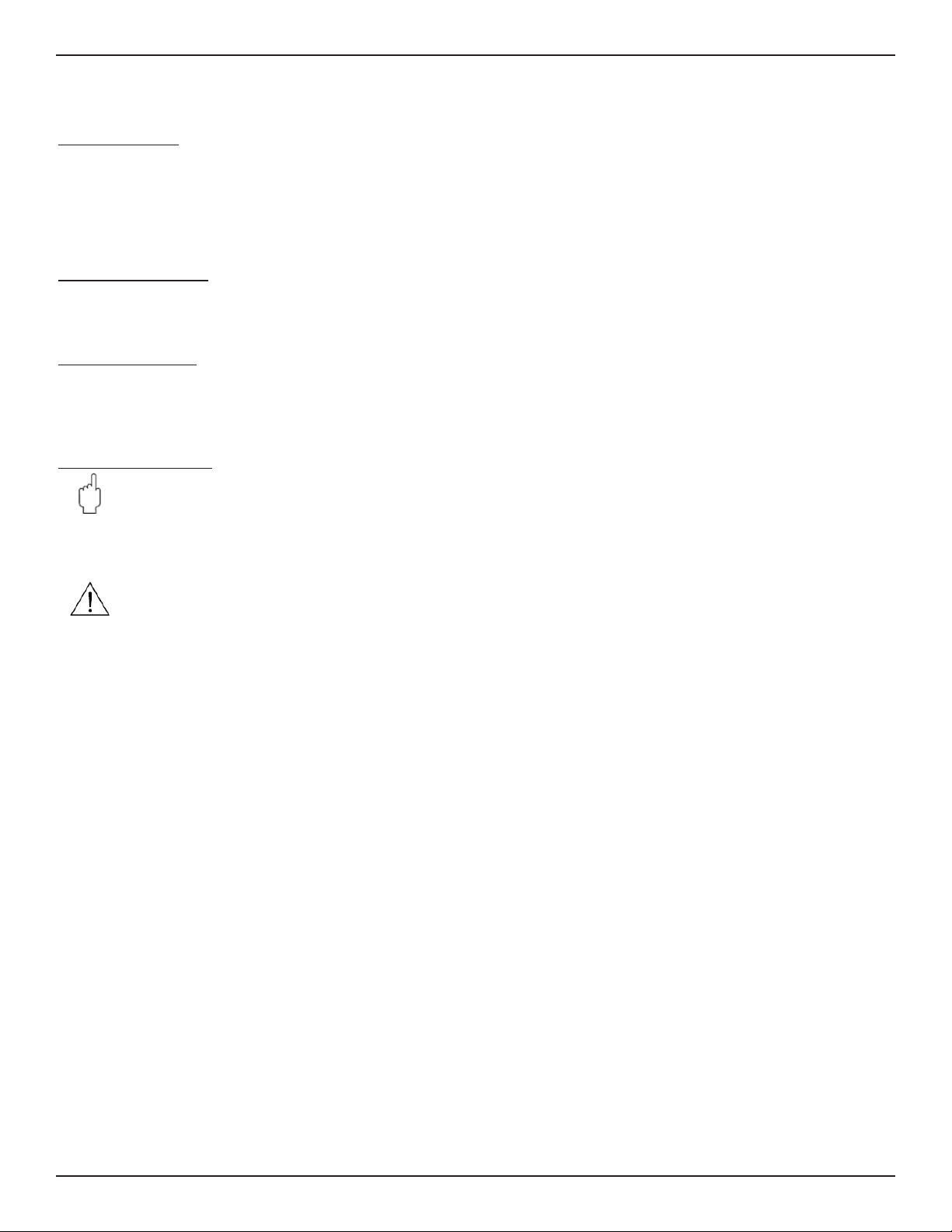

Sensing Element

The sensing element consists of two thermowells (hollow tubes) that when inserted into the fl ow process allows an unimpeded fl ow inside the

process line. The top thermowell has a self-heated RTD inserted into it. The bottom thermowell has a reference RTD inserted into it. In order to

correctly orient the sensing element a fl ow arrow has been etched onto the threaded portion of the sensing element. See Figure 1-1 for a view of the

sensing element.

Figure 1-1 View of the Sensing Element

Control Circuit

The control circuit converts the sensing element’s RTD temperature differential into an analog DC voltage signal. Dual comparators monitor the

sensing element signal and activates the relay alarm circuits if the signal exceeds an adjustable set point.

The control circuit contains fi eld removable jumpers that confi gures the instrument to perform in the fi eld as needed by the customer.

Fluid Components International LLC 7

Page 8

TECHNICAL SPECIFICATIONS FLT® Series FlexSwitch

Technical Speci cation

TM

Application

Flow rate and /or level /interface and temperature sensing in liquid,

gas and slurry applications.

Sensing Elements

Process Connection

Models S and F

3/4 inch male NPT standard; optional 1 inch BSP, 1 inch male

NPT, 3/4 inch Male NPT (FLT93-F only); fl anges, or spool pieces.

Model L

1” male NPT or 3/4” female NPT, both ends with orifi ce;

fl anges optional.

Insertion Length

Models S and F

Available in standard lengths of 1.2” [30mm], 2” [51mm],

4” [102mm], 6” [152mm], 9” [229mm], 12” [305mm],

18” [457mm] and custom-specifi ed lengths.

Model L

3.375” [86mm] in-line body length

Sensing Element

Models S and F

All wetted surfaces are 316L stainless steel with all-welded

construction. Hastelloy C, Monel 400, electro-polished

stainless steel and titanium (FLT93-S only) are optionally

available.

Model L

All wetted surfaces are 316L stainless steel with all-welded

construction. Hastelloy C, Monel 400 and titanium are

optionally available.

Operating Temperature

Sensing Element:

All Models

Standard temperature confi guration:

-40°F to +350°F [-40°C to +177°C]

Medium temperature confi guration:

-100°F to +500°F [-73°C to +260°C]

Model S Only

High temperature confi guration:

-100°F to +850°F [-73°C to +454°C]

Control Circuit:

All Models

Ambient -40°F to +140°F [-40°C to + 60°C]

Operating Pressure

Models S, F and L

2350 psig [ 162 bar(g)] maximum at 500°F [260°C]

1450 psig [100 bar(g)] maximum at 850°F [454°C]

Control Circuit Features

Control Circuit

Standard: Plug-in, socket mounted with dual alarm/trip epoxy sealed

relays.

Optional: Rack-mount confi guration (card cage or enclosure not

included)

Output Signal

Analog DC voltage related to fl ow or level / interface signal and

proportional to temperature, standard.

Input Power

Field selected or pre-confi gured in the factory to 115 Vac (±15),

230 Vac (±30, 50 to 60 Hz), 24 Vdc (+4, -3) or 24 Vac (+2, -6);

100 Vac ±10 optionally available. LED indicates power on.

Power Consumption

AC units, 13 VA maximum; DC units, 7 watts maximum.

Heater Power

Field or factory selected to optimize switching performance and

rangeability and selectable for specifi c fl uid service requirements.

7 watts power consumption, 230 mA maximum.

Typical Service Sensing Element Power (W)

Gas or Air S-Style 0.75

F-Style 0.25

Liquids S-Style 3.0

The above typical service power selections are for reference

only. Depending on application requirements, surface temperature

rating requirements, and rangeability expectations, alternate power

selections may be recommended. Other intermediate power selections can be made. Consult installation manual for recommendations

in your service.

Relay Rating

Dual SPDT or single DPDT fi eld confi gurable 6 amp resistive at 115

Vac, 240 Vac or 24 Vdc; hermetically sealed relay confi gurations

optionally available.

Electrical Enclosure

Aluminum (epoxy coated) or optional stainless steel. Enclosures are

rated for hazardous location use (Class I and II, Division 1 and 2,

Group B, C, D, E, F and G; and EEx d IIC) and resists the effect of

weather and corrosion (NEMA and CSA Type 4X and equivalent to

IP66).

For Flow Service

Setpoint Range

Model S

Water-based Liquids:

0.01 FPS to 0.5 FPS [0.003 MPS to 1.52 MPS]with 0.75 watt heater;

0.01 FPS to 3.0 FPS [0.003 MPS to 0.9 MPS] with 3.0 watt heater.

Hydrocarbon-based Liquids:

0.01 FPS to 1.0 FPS [0.003 MPS to 0.3 MPS] with 0.75 watt heater;

0.01 FPS to 5.0 FPS with [0.003 MPS to 1.5 MPS] with 3.0 watt

heater.

Air/Gas:

0.25 SFPS to 120 SFPS [0.08 NMPS to 37 NMPS] with 0.75 watt

heater at standard conditions; 70°F [21.1°C], 14.7 psia [1.013

bar(g)].

Other Fluids: Contact the factory for approximate rangeability.

Model F

Air/Gas:

0.25 SFPS to 120 SFPS [0.08 NMPS to 37 NMPS] 0.75 watt heater

at standard conditions; 70°F [21.1°C], 14.7 psig [1.013 bar(g)].

Model L

Water-based Liquids: 0.015 cc/sec to 50 cc/sec

Hydrocarbon-based Liquids: 0.033 cc/sec to 110 cc/sec

Air/Gas: 0.6 cc/sec to 20,000 cc/sec

8 Fluid Components International LLC

Page 9

FLT® Series FlexSwitchTM TECHNICAL SPECIFICATIONS

Factory Calibrated Switch Point Accuracy

Any fl ow rate within the instrument fl ow range may be selected as a

setpoint alarm. A factory-calibrated setpoint adjustment may be

optimally preset with accuracy of ±2% of setpoint velocity over an

operating temperature range of ±50°F [±28°C].

Monitoring Accuracy

Based on a measured output voltage over the entire fl ow range, an

operating temperature range of ±50°F [±28°C], and an operating

pressure range of ±100 psig [±7 bar(g)]:

Liquids: ±5% reading or ±0.04 SFPS [±0.012 NMPS],

whichever is larger

Gases: ±5% reading or ±2 SFPS [±0.61 NMPS], whichever is larger

Repeatability

±0.5% reading

For Level/Interface Service

Accuracy

Model S

±0.25° [±6.4 mm]

Model F

±0.1° [±2.5 mm]

Repeatability

Model S

±0.125° [±3.2 mm]

Model F

±0.05° [±1.3 mm]

Nuclear Safety Certi cation

FLT93 sensor elements were qualifi ed for harsh environment applications under the guidelines of iEEE-323, iEEE-344 and iEEE-382.

Radiation Exposure

Models S and F

2x108 rads

High Temperature

5x107 rads

Electronics Module [5294] qualifi ed for radiation harsh

5x105 rads

Seismic Level

Models S and F

3g ZPA’s

High Temperature

8g ZPA’s

Shipping Weight (approximate)

Integral: 8 lb [3.6 kg]

Remote: 13 lb [5.9 kg]

For Temperature Service

Accuracy

±2.0°F [±1°C] with fi eld setpoint adjustment. Monitoring accuracy

±3.5°F [±2°C] with standard curve fi t output voltage operation

across the selected instrument temperature range. Higher accuracy

available with factory calibrations.

Repeatability

±1.0°F [±0.6°C]

The above accuracy is based on liquid or slurry service and in

gas service with a minimum 1 SFPS [0.3 NMPS] velocity past the

sensing element or with the heater deactivated for temperature

sensing service only.

MTBF: 190 years

SIL: SIL-2 compliant, safe failure fraction (SFF) 82% to 84%

Factory Application-Speci c Set-up and

Setpoint Calibration

Standard instrument factory default setting, unless otherwise

selected at order entry, will be as follows:

• 115 Vac input power for all FM Approved units. 230 Vac for all

other agency approval units.

• Dual SPDT alarms set for:

• Alarm No. 1: Preset for fl ow or level and to de-energize with

decreasing conditions.

• Alarm No. 2: Preset to de-energize for increasing temperature at

10 °F [5 °C] below the maximum instrument process temperature.

• Heater power at 0.25 watt on Model F or 0.75 watt on Model S.

• Calibration switch set at “operate.”

Factory calibration including set-up for specifi c service, process

fl uid and alarm conditions optionally available. Contact factory for

fl uid handling capabilities.

Fluid Components International LLC 9

Page 10

FLT® Series FlexSwitch

TM

INTENTIONALLY LEFT BLANK

10 Fluid Components International LLC

Page 11

FLT® Series FlexSwitchTM INSTALLATION

2 INSTALLATION

Receiving/Inspection

• Unpack carefully.

• Verify that all items in the packing list are received and are correct.

• Inspect all instruments for damage or contaminants prior to installation.

If the above three items are satisfactory, proceed with the installation. If not, then stop and contact a customer service representative.

Packing/Shipping/Returns

These issues are addressed in Appendix D - Customer Service.

Factory Calibration Note

The instrument is factory calibrated to the applications as specifi ed at the time of order. There is no need to perform any verifi cation or

calibration steps prior to installing and placing the instrument in service unless the application has been varied.

Pre-Installation Procedure

Warning: Only qualifi ed personnel should install this instrument. Install and follow safety procedures in accordance with the current

National Electrical Code. Ensure that power is off during installation. Any instances where power is applied to the instrument will be noted in this manual. Where the instructions call for the use of electrical current, the operator assumes all

responsibility for conformance to safety standards and practices.

Caution: The instrument contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling the

control circuit. See below, for ESD details.

The instrument is not designed for weld-in-place applications. Never weld to a process connection or a structural support.

Damage resulting from moisture penetration of the control circuit or fl ow element enclosure is not covered by product warranty.

Use Standard ESD Precautions

Use standard ESD precautions when opening an instrument enclosure or handling the control circuit. FCI recommends the use of the following precautions: Use a wrist band or heel strap with a 1 megohm resistor connected to ground. If the instrument is in a shop setting there

should be static conductive mats on the work table and fl oor with a 1 megohm resistor connected to ground. Connect the instrument to

ground. Apply antistatic agents to hand tools to be used on the instrument. Keep high static producing items away from the instrument such

as non-ESD approved plastic, tape and packing foam.

The above precautions are minimum requirements to be used. The complete use of ESD precautions can be found in the U.S. Department Of

Defense Handbook 263.

Prepare or Verify Sensing Element Location

Prepare the process pipe for installation, or inspect the already prepared location to ensure that the instrument will fi t into the system.

Review the requirement for the supply power and alarm circuit connections.

Verify Dimensions

Verify the instrument’s dimensions versus the process location to be sure of a correct fi t. Also see Appendix A for dimensions.

Verify Sensing Element Flow Direction and Placement Orientation (Flow Application)

For fl ow detection, the sensing element surface marked with direction arrows should be oriented parallel to the process fl ow. The fl ow can

be from either direction.

Mount the sensing element at least 20 diameters downstream and 10 diameters upstream from any bends or interference in the process pipe

or duct to achieve the greatest accuracy.

For liquid fl ow service, the sensing element should be located in the process pipe so that the thermowells are always completely wet.

When mounted in a tee or section of pipe larger than the normal process pipe, position in a vertical run of pipe with fl ow upward. This will

prevent air or gas bubbles from becoming trapped at the sensor assembly.

Vertical positioning with fl ow downward is only recommended for higher fl ow rate applications (consult FCI).

Fluid Components International LLC 11

Page 12

INSTALLATION FLT® Series FlexSwitch

Verify Sensing Element Flow Direction and Placement Orientation (Level Application)

If the sensing element is side-mounted on the process vessel, then the surface marked with direction arrows should be vertically oriented.

If the sensing element is top- or bottom-mounted on the process vessel, the orientation of the surface marked with direction arrows does not

matter.

Install the Sensing Element

Male NPT Mounting

When mounting the sensing element to the process pipe, it is important that a lubricant/sealant be applied to the male threads of all connections. Be sure to use a lubricant/sealant compatible with the process environment. All connections should be tightened fi rmly. To avoid

leaks, do not overtighten or cross-thread connections. See Figure 2-1 for proper mounting.

TM

Figure 2-1 NPT Pipe Thread Mount

Flange Mounting

For fl ange mounted sensing elements, attach the process mating fl ange with care. The correct orientation of the sensing element must be

maintained to ensure optimum performance or calibration. See Figure 2-2.

Figure 2-2 Flange Mount

12 Fluid Components International LLC

Page 13

FLT® Series FlexSwitchTM INSTALLATION

Packing Gland Assembly

1. Threaded or fl anged packing gland mounts are available. The valve assembly with appropriate connections are customer supplied. Follow the male NPT mounting procedure above to attach the pipe thread portion or fl ange mounting portion as applicable.

2. Tighten the packing nut until the internal packing is tight enough so that the friction fi t on the shaft is adequate to prevent leakage but

not prevent the shaft from sliding. Position the etched fl ow arrow parallel with the fl ow (±1° of level) and position the fl ow arrow so it is

pointing in the direction of the fl ow.

3. Proceed to insert the probe into the process media line. Use the adjusting nuts on the all-thread to pull the sensing element into proper

predetermined depth position.

4. Tighten the opposing lock nuts on the all-threads. Tighten the packing nut another half to full turn until tight (approximately 65 to 85

ft-lbs [88 to 115 N-m] torque).

5. Rotate the split ring locking collar to line up with the connecting strap welded to the packing nut. Tighten the two 1/4-28 hex socket cap

screws on the split ring locking collar.

Reverse these steps for removal.

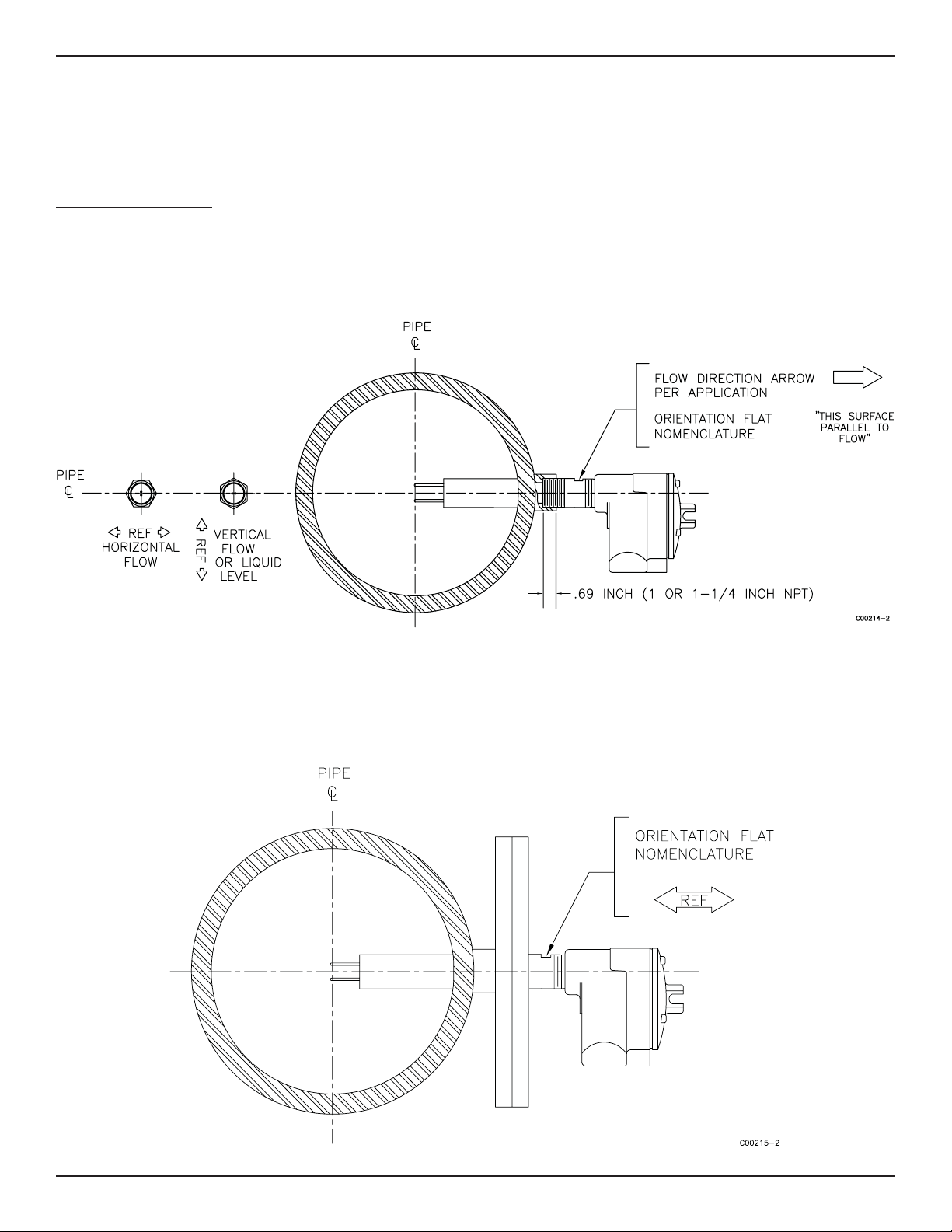

In-line NPT Assembly (FLT93-L)

The body length of the in-line assembly should be verifi ed to be sure the assembly will fi t into the process line. The direction of fl ow is important for proper operation. There is a fl ow direction arrow on the in-line pipe that is to point in the direction of fl ow. See Figure 2-3 for the

correct orientation.

If the instrument is a butt weld assembly, be sure to do the following: Remove the circuit board, properly ground the fl ow element before

welding, GTAW is highly recommended.

Figure 2-3 FLT93-L In-Line Flow Element

Fluid Components International LLC 13

Page 14

INSTALLATION FLT® Series FlexSwitch

Install and Wire the Enclosure(s)

TM

Caution:

In applications where the sensing element is located in an explosive environment, isolate the conduit before it leaves the

environment. A potting Y may be used to provide the isolation.

Pulling wires can cause damage to the control circuit. Therefore, remove the control circuit from the enclosure and use

extreme care when pulling wires into the enclosure.

Mount and wire the control circuit either locally or remotely (option) by following the local or remote enclosure procedure below.

Minimum Wire Size

Table 2-1 shows the smallest (maximum AWG number) copper wire that is used in the electrical cables. Use a lower gauge of wire for less of

a voltage drop. Contact FCI concerning greater distances than those listed in the table. The sensing element cable must be shielded. If the

cable is spliced the shield wire must be continued through the splice. If a terminal block is used, the shield must have its own terminal.

Enclosures Covers

All enclosure covers must be in place and securely closed to achieve environmental and safety classifi cations.

All circular thread-on covers should be tightened about 1/3-turn past hand tight.

Cover locks must be in place and secure if required by a particular approval.

Note: Nitrile (buna-N) O-rings are standard on the circular thread covers;n these O-rings have a 250°F (121°C) maximum useage

temperature.

A Viton O-ring [400°F (204°C) max. temp.] is available for the thread-on covers; these O-rings have a 500°F (260°C) maximum useage temperature.

To receive a Viton O-ring, provide FCI with the following information:

• Shipping address

• Quantity required

• Desired P/N:

Use P/N 000391-01 for the single conduit port enclosure (Local)

Cable and Conduit Entry Devices

The cable and conduit entry devices and blanking elements shall be of a certifi ed fl ameproof type EEx d, suitable for the conditions of use and

correctly installed. With the use of conduit entries a ceiling device shall be provided immediately on the entrance of the device.

All cable glands and conduit fi ttings, includign conduit plugs, must meet or exceed the area approval where the unit is being installed.

Maximum Distance for AWG

Connection

10 ft.

(3m)

50 ft

(15m)

100 ft.

(31m)

250 ft.

(76m)

500 ft.

(152m)

1000 ft.

(305m)

AC/DC Power 22 22 22 20 18 16

Relay (6A) 28 22 20 16 12 10

Flow Element Wires* 22 20 20 18 18 18

* Requires a shielded cable with the shield wire connected to the control socket only.

Table 2-1 Maximum AWG Number

14 Fluid Components International LLC

Page 15

FLT® Series FlexSwitchTM INSTALLATION

Wiring the Local Enclosure

This procedure is for instruments with the control circuit located in the sensing element enclosure.

1. Remove the control circuit from its socket. Do not remove the control circuit socket. Removal of the control circuit socket may cause

damage to the instrument.

2. Install conduit between the local enclosure and the power source and monitoring circuit. Provide watertight hardware and apply thread

sealant to all connections to prevent water damage.

Warning:

3. When connecting the relay wiring, do so with complete understanding of what the process requires of the instrument. The instrument

has dual SPDT or single DPDT relay output contacts dependent on the jumper confi guration for each alarm switch point. For the relay

logic, refer to Figure 2-5. Also refer to Table 3-5 and Table 3-6 in Chapter 3 - Operation. Relay contacts are shown with the relays deenergized. Wire in accordance with the system requirements.

Ensure that all power is off before wiring any circuit.

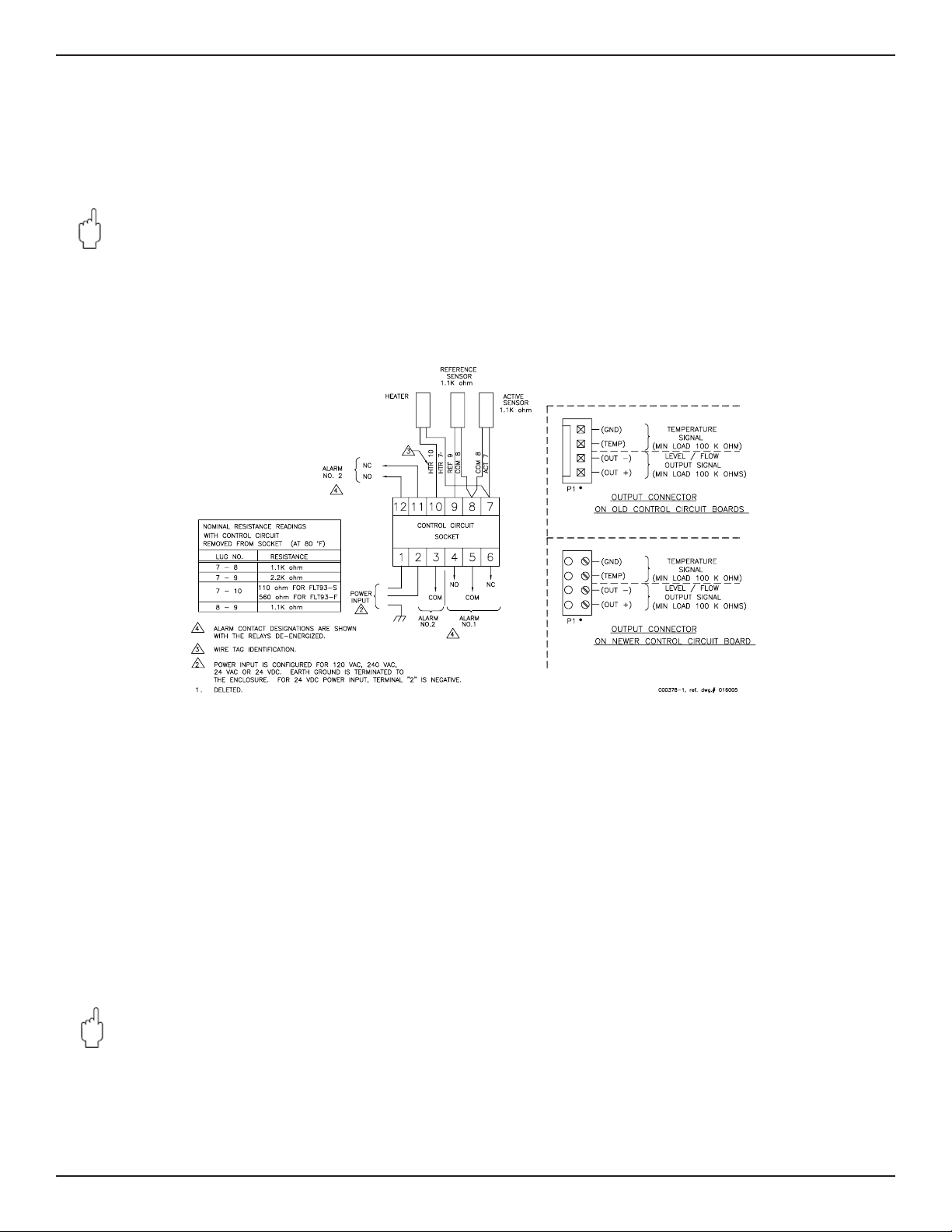

Figure 2-5 Local Wiring Diagram

Wiring the Remote Enclosure

This procedure is for instruments with the control circuit located remotely from the sensing element.

Locate the Remote Hardware Location

Select a location for the remote enclosure within a 1000 feet (305 m) of the sensing element. Pigtail sensing elements can not be located

more than 10 feet (3 m) from the enclosure unless the pigtail is extended with the proper size cable listed in Table 2-1. If the cable is extended the cable connections should be located in a junction box with a 6 position terminal block. All 5 conductors and the shield must have

its own termination. The remote enclosure should be easily accessible with enough room to open the enclosure cabinet cover at any time.

Secure the remote enclosure solidly to a vertical surface capable of providing support. Use appropriate hardware to secure the enclosure.

1. Remove the control circuit from the remote enclosure.

2. Run a fi ve-conductor, shielded cable from the local enclosure to the remote enclosure. Use Table 2-1 to determine which wire gauge to

use.

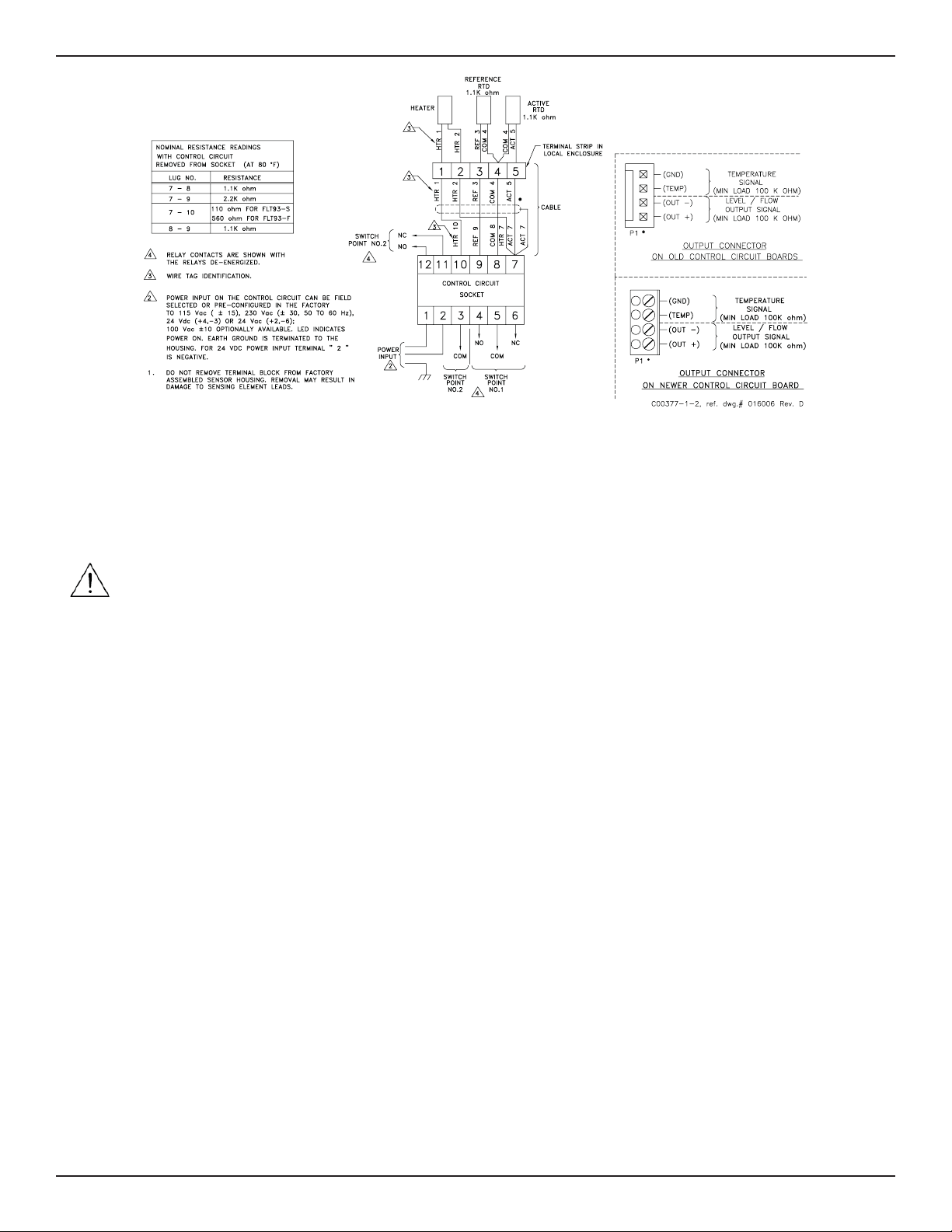

3. Wire between the local and remote enclosures according to Figure 2-6.

Warning: Ensure that all power is off before wiring any circuit.

4. When connecting the relay wiring, do so with complete understanding of what the process requires of the instrument. The instrument

has dual SPDT or single DPDT relay output contacts dependent on the jumper confi guration for each alarm switch point. For the relay

logic, refer to Figure 2-6. Also refer to Table 3-5 and Table 3-6 in Chapter 3 - Operation. Relay contacts are shown with the relays deenergized. Wire in accordance with the system requirements.

Fluid Components International LLC 15

Page 16

INSTALLATION FLT® Series FlexSwitch

Figure 2-6 Remote Wiring Diagram

relay board is in the same enclosure as the control circuit. Both boards are mounted on the same panel and have been wired together at the

factory. This confi guration can be ordered without an enclosure which can be supplied by the customer.

The alarm connections are made at the auxiliary relay board where each alarm is driving a DPDT relay.

TM

Caution:

Do not connect any loads to the control circuit socket. Damage will occur to the control circuit if the alarm circuit is

energized.

Be sure the correct relay board has been ordered for the correct output. See the following paragraph.

This confi guration uses a control circuit that provides a switching voltage signal instead of relay contacts. The switch voltage is wired from

the control circuit socket to the auxiliary relay board actuating the relays.

The auxiliary relay board has several relay options that can be ordered. The options are as follows:

• Dry to 2 amps at 115 Vac or 28Vdc, Dry to 1 amp at 230 Vac (relay is enclosed in a plastic sealed cover).

• 100mA to 10mA at 115 Vac or 28Vdc, 50mA to 3 amps at 230 Vac (relay is enclosed in a plastic sealed cover).

• Dry to 0.5 amps at 115 Vac, hermetically sealed relay.

Make sure that the proper relays have been selected for the intended load. See Appendix A for the auxiliary relay board confi guration

drawing.

When connecting the relay wiring, do so with complete understanding of what the process requires of the instrument. The instrument has

dual DPDT or single 4PDT relay output contacts dependent on the jumper confi guration for each alarm switch point. For the relay logic, refer

to Figure 2-5. Also refer to Table 3-5 and Table 3-6 in Chapter 3 - Operation. Relay contacts are shown with the relays de-energized. Wire in

accordance with the system requirements.

The control circuit can be ordered with switching voltage outputs without ordering a relay board. This can be used with customer supplied

relays or any other device that has a differential input. The output voltage is 17 Vdc and will drive a load as low as 1500 ohms. Refer to

Figure 2-7 for the output terminals.

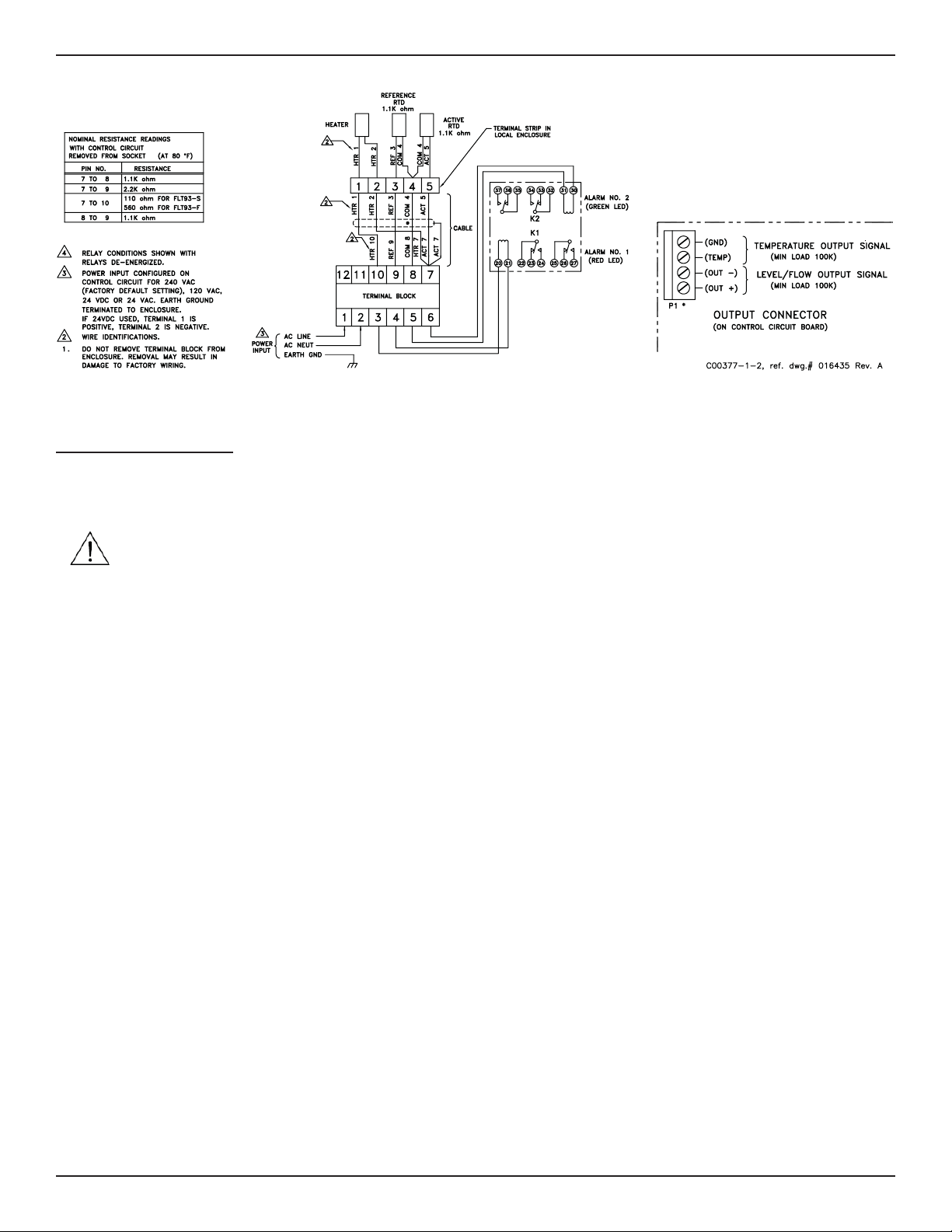

Wiring A Remote Control Circuit To An Auxiliary Relay Board

1. Run a four-conductor cable from the control circuit to the auxiliary relay board if the board was not factory installed. Use the wiring

diagram in Figure 2-7 to wire the boards together.

2. Attach the customer wiring as desired using Figure 2-7 as a wiring guide.

Wiring for this confi guration is the same as the sensing element wiring to the control circuit on a remote instrument.

16 Fluid Components International LLC

Page 17

FLT® Series FlexSwitchTM INSTALLATION

Figure 2-7 Auxilliary Relay Board Wiring Diagram

Wiring Output Signal Terminals

Two output signals are provided on the control circuit at P1. The signal voltage at positions 1 and 2 represents the process change. The

signal voltage at positions 3 and 4 is proportional to the temperature at the sensing element. See Figures 2-5 through 2-7. See also Chapter

3 for the physical layout of the control circuit.

Caution: Do not ground terminal 2 of P1. (Terminal 2 is the negative lead of the process signal.) This terminal is 9 volts above the

control circuit ground. The peripheral using this signal must have a differential input.

These voltages can be used by other peripherals with a minimum load of 100K ohms. The terminal block can be wired with between gauge

26 and 18 wire (22 gauge wire is normally used). The maximum recommended length of wire is 1000 feet. Shielding is required on any

length of cable. The shield must be terminated at position 4 on P1.

Early versions of the FLT93 require a connecting harness that was supplied with each instrument. The harness can be ordered if it is missing.

The FCI part number is 015664-01. Newer versions of the FLT93 require a supplied terminal plug.

Fluid Components International LLC 17

Page 18

INSTALLATION FLT® Series FlexSwitch

TM

INTENTIONALLY LEFT BLANK

18 Fluid Components International LLC

Page 19

FLT® Series FlexSwitchTM OPERATION

3 OPERATION

Caution: The control circuit contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling

the control circuit. See Chapter 2, Operation, for ESD details.

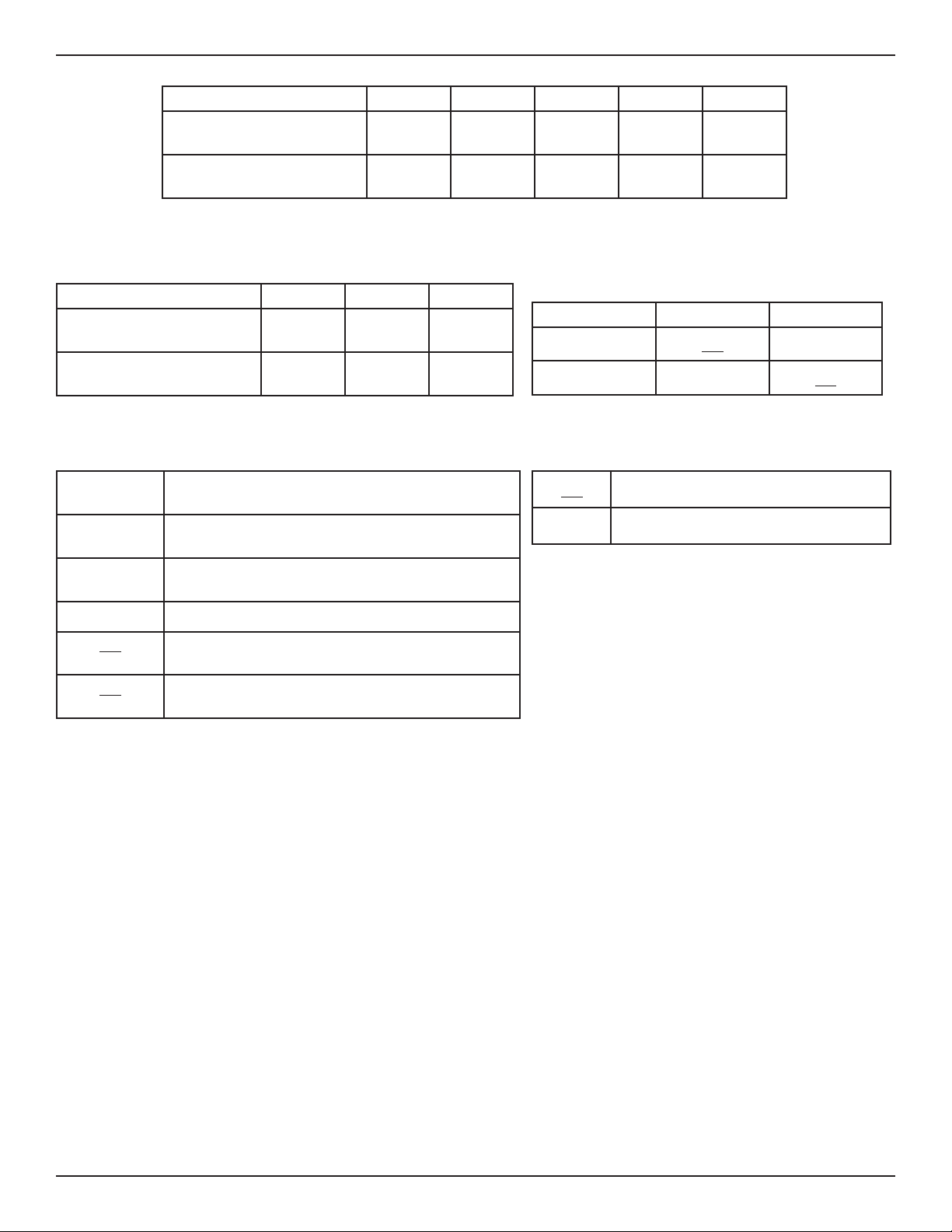

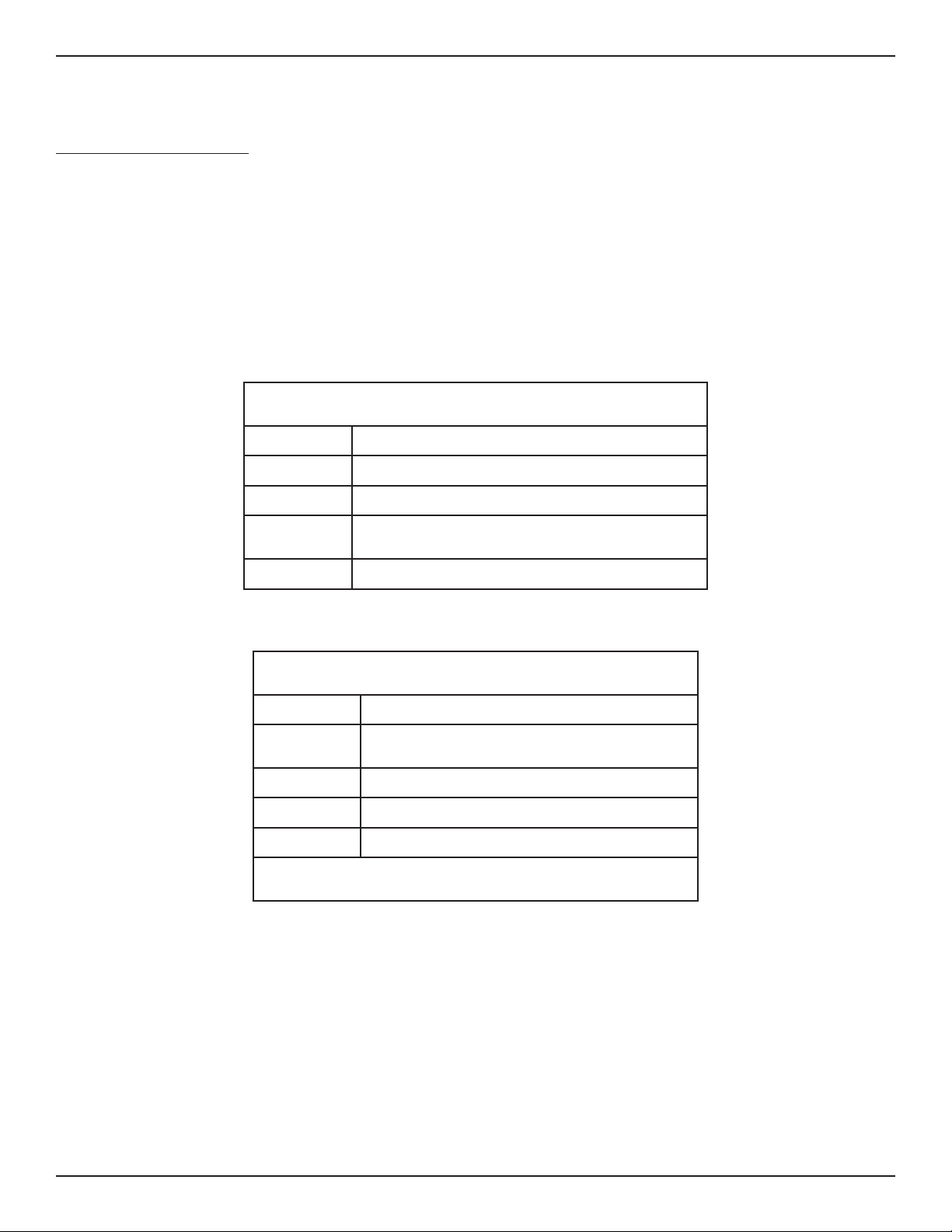

Factory Default Jumper Con guration

Unless a custom factory setup or calibration is specifi ed, the instrument is delivered in a standard factory confi guration. The standard default

jumper confi guration is shown in Table 3-1.

Input Power Factory Confi gured

Heater Power

Number of Alarms Two (J23). Each alarm has one set of SPDT contacts

Alarm No. 1 Red LED

Set Point Pot, R26

Alarm No. 2 Green LED

Set Point Pot, R25

FLT93-S 0.75 watts for air or liquid level applications. (J13)

FLT93-F 0.25 watts for air or liquid level applications. (J14)

Set to monitor fl ow or level signals (J20). Relay energized at fl ow or wet (J27)

Set to monitor temperature signals (J19). Relay energized below temperature (J25).

Set point at approximately:

250 F (121 C) for standard temperature,

500 F (260 C) for medium temperature,

850 F (454 C) for high temperature (FLT93-S Only)

Table 3-1 Standard Jumper Defaul Confi guration

If the order included custom factory setup and calibration, leave all settings alone. The instrument is ready for service without changes.

If custom factory setup or calibration was not ordered, confi gure the control circuit using the jumper tables (Tables 3-2 to 3-6) and then follow the set point adjustment section that is appropriate for the application.

Con guration Jumpers

If the order did not specify for the control circuit to be factory confi gured, the standard confi guration can be changed using Figure 3-1 and

Table 3-2 though Table 3-6. The factory default confi guration is shown as being underlined.

Heater Cut-Off

The 5298 control circuit has a heater cutoff switch that limits the skin temperature of the sensing element to a temperature differential of

approximately 150°F (66°C) above the process temperature. In the case where the instrument is used as a gas fl ow switch, and the heater

wattage is set too high, the temperature differential (DT) between the RTDs may exceed the usable input range of the control circuit. The usable input range can also be exceeded in the case where the instrument is used in liquid fl ow applications where the heater wattage is set at

the highest value, and when the sensing elements go dry. When the temperature differential is less than 150°F (66°C) the heater automatically turns back on. The yellow power indicator LED (DS3) turns on and off with the heater for a visual indication of the heater state. The

LED will alternate between on and off until the condition is corrected.

The reason for operating in the above extreme conditions is that the input signal range is at the widest point making the alarm set point

adjustment easier to perform. If the heater does cycle the operator may need to use the next lower wattage setting.

In some applications it is desirable to set the heater wattage high, even though the sensing element goes into the heater cutoff mode. An

example is when the instrument is used to detect the interface of two liquids. These liquids may have viscosities that will have signals very

close to each other. In order to have the maximum signal difference between the signals the heater wattage is set to its maximum. If the

sensing element detects a dry condition the control circuit will indicate a heater cutoff condition. The sensing element will not be dammaged

if it is left dry with the maximum heater wattage. The alarms can be set so one alarm will switch at the interface and one alarm can detect

when the element goes dry.

Fluid Components International LLC 19

Page 20

OPERATION FLT® Series FlexSwitch

TM

Figure 3-1 5298 Control Circuit Jumper Locations

Alarm Set Point Adjustments

Numerical Adjustment Versus Adjustment by Observation

An alarm set point is established using either numerical adjustment or adjustment by observation. The adjustment by observation requires

the customer to establish normal process operation and adjust the alarm set point relative to this condition. The numerical approach requires

measuring normal and alarm process conditions with a voltmeter and setting up the instrument in the calibrate mode based on these values.

The adjustment by observation requires less time to establish the alarm set point. The numerical adjustment requires control of the process

as well as additional time to establish the alarm set point. Use the adjustment procedure that is the most appropriate for the application

requirement.

Jumper

100-130 VAC 200-260VAC 18-26VAC 21-30VDC

J1 IN OUT OUT OUT

J2 OUT IN OUT OUT

J3 IN OUT OUT OUT

J4 OUT OUT IN OUT

J5 IN IN OUT OUT

Power Select - Factory Installed

J6 OUT IN IN IN

J7 OUT OUT OUT IN

J8 OUT OUT OUT IN

J9 OUT OUT IN OUT

Table 3-2 Input Power

20 Fluid Components International LLC

Page 21

FLT® Series FlexSwitchTM OPERATION

Jumper

FLT93-F ELEMENT WATTAGE

(560 OHM HTR)

FLT93-S ELEMENT WATTAGE

(110 OHM HTR)

Table 3-3A Selectable Heater Wattage Control

J13 is standard for FLT93-S and J14 is standard for FLT93-F

Jumper

FLT93-F ELEMENT WATTAGE

(560 OHM HTR)

FLT93-S ELEMENT WATTAGE

(110 OHM HTR)

Table 3-3B Fixed Heater Wattage Control

Jumper ALARM NO. 1

J27 RELAY DE-ENERGIZED WITH LOW FLOW, LOW LEVEL

(DRY) OR HIGH TEMPERATURE.

J26 RELAY DE-ENERGIZED WITH HIGH FLOW, HIGH LEVEL

(WET) OR LOW TEMPERATURE.

Jumper ALARM NO. 2

J13 J14 J33

N.A.

0.75

WATTS

J32 J12 J13 J14 J33

0.57

WATTS

3

WATTS

0.20

WATTS

N.A. OFF

0.52

WATTS

1.75

WATTS

OFF

0.49

WATTS

0.75

WATTS

ALARM NO. 1 J20 J21

ALARM NO. 2

J23 DUAL SPDT (ONE RELAY PER ALARM)

J22 SINGLE DPDT (DISABLES ALARM NO. 2)

Table 3-6 Relay Contact Confi guration

0.20

WATTS

0.27

WATTS

FLOW/LEVEL TEMP

Table 3-4 Application

OFF

OFF

J18 J19

J25 RELAY DE-ENERGIZED WITH LOW FLOW, LOW LEVEL

(DRY) OR HIGH TEMPERATURE.

J24 RELAY DE-ENERGIZED WITH HIGH FLOW, HIGH LEVEL

(WET) OR LOW TEMPERATURE.

Table 3-5 Relay Energization

Fluid Components International LLC 21

Page 22

OPERATION FLT® Series FlexSwitch

Numerical Alarm Set Point Adjustment

The control circuit has two mutually exclusive alarms; they are identifi ed as Alarm No. 1 and Alarm No. 2. Each has an alarm set point adjustment potentiometer and LED indicator. Both alarms can be setup for one of three applications; fl ow, level/interface, or temperature. The

following application specifi c adjustment procedures are generic and can be used for setting either or both alarms. Use Figure 3-2 to help

locate the important setup components (potentiometers, LEDs, etc.)

TM

Figure 3-2 5298 Control Circuit Component Locations

Air/Gas Flow Applications

1. Remove the instrument’s enclosure cover.

2. Ensure the confi guration jumpers on the control circuit are correct for this application. See Tables 3-3 through 3-6.

3. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

4. Apply power to the instrument. Verify the yellow LED is on and allow the instrument fi fteen minutes to warm-up.

5. Verify the mode switch is in the RUN position.

6. Attach a DC voltmeter to the P1 terminal block with the positive (+) lead to position one and the negative (-) lead to position two.

Note: The terminal block can be unplugged from the control circuit to facilitate easy connections.

7. Establish the normal process fl ow condition and allow the signal to stabilize.

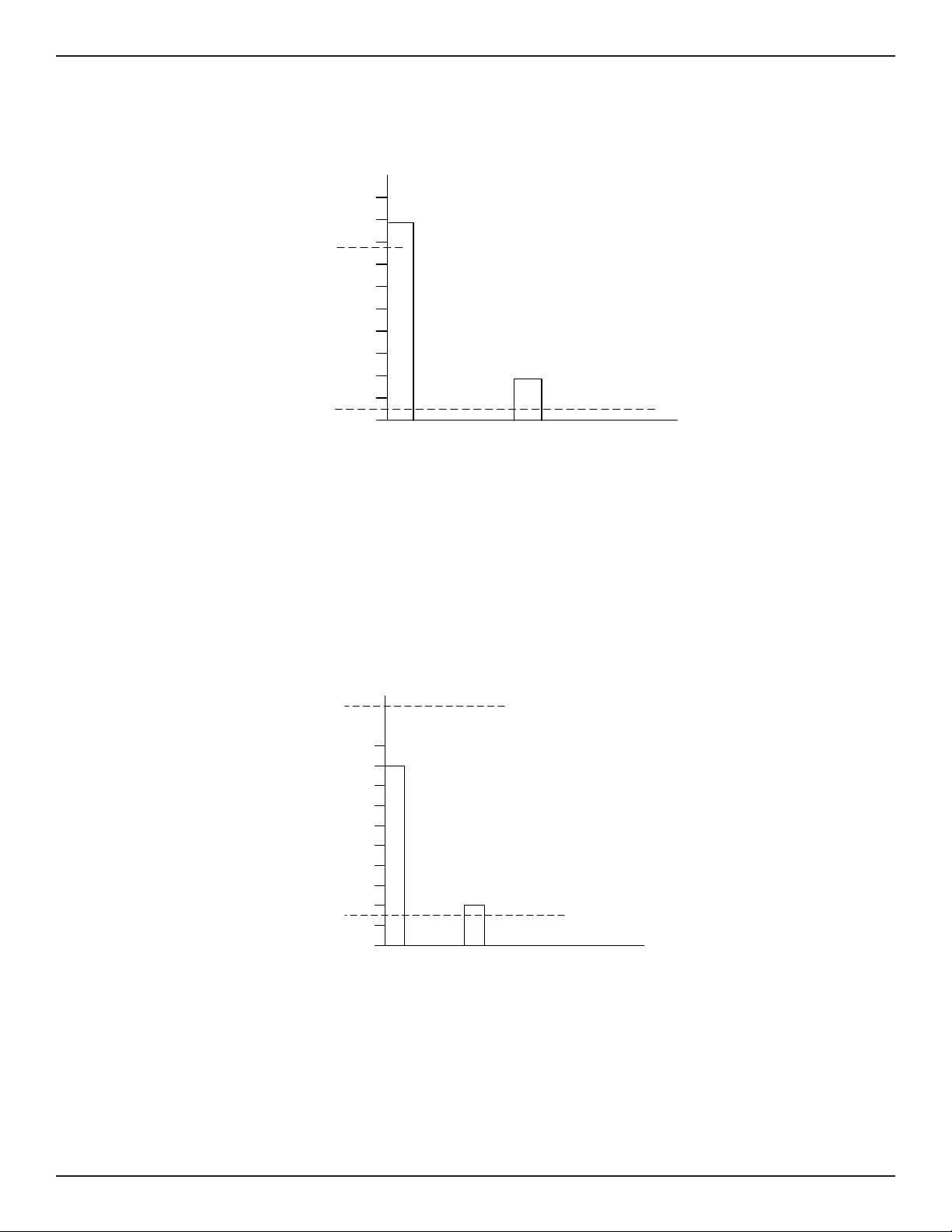

Note: The output signal at connector P1 will vary inversely with changes in the process fl ow rate. The output signal level is relative to

the type of process media being measured and the heater wattage setting. See Figure 3-3.

8. Record the normal fl ow signal value.

Normal Flow Signal = ________ volts DC

9. Follow either the Detecting Decreasing Flow or the Detecting Increasing Flow procedure for each fl ow application alarm.

22 Fluid Components International LLC

Page 23

FLT® Series FlexSwitchTM OPERATION

AIR OR GAS

Potentiometer

(POT)

OIL

WATER

OUTPUT VOLTAGE

0

FLOW

ABOVE SETPOINT

LED OFF

BELOW SETPOINT

Figure 3-3 Flow Application Signal Output

Detecting Decreasing Flow (low fl ow alarm)

1. Stop the process fl ow and allow the signal to stabilize.

2. Record the no-fl ow signal. (The no-fl ow signal should be greater than the normal fl ow signal.)

FIELD ADJUSTABLE

SET POINT

R25 AND R26

Adjust

Clockwise,

Turns

LED ON

LED ON

SET POINT

Adjust

Counter-

clockwise,

Turns

LED OFF

C00204-1-2

No-Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and no-fl ow output signals. (i.e.; If the normal signal is 2.000 volts and

the no-fl ow signal is 5.000 volts, then the calculated set point would be 3.500 volts.)

4. Record this value.

Calculated Set Point = ________ volts DC

Note: The calculated set point must be at least 0.020 volts greater than the normal signal to ensure that the alarm will reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No.2) slowly clockwise just until the

LED turns on.

OR

If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) counterclockwise until the LED

turns off and then slowly clockwise just until the LED turns on.

8. If this is the only fl ow application alarm to be setup, then skip to the Continue With the Air/Gas Flow Procedure.

Detecting Increasing Flow (high fl ow alarm)

1. Establish the excessive process fl ow condition and allow the signal to stabilize.

2. Record the high fl ow signal. (The high fl ow signal should be less than the normal fl ow signal.)

High Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and high fl ow output signals. (i.e., If the normal signal is 2.000 volts

and the high fl ow signal is 1.000 volts, then the calculated set point would be 1.500 volts.)

Fluid Components International LLC 23

Page 24

OPERATION FLT® Series FlexSwitch

4. Record this value.

Calculated Set Point = ________ volts DC

Note: The calculated set point must be at least 0.020 volts less than the normal signal to ensure that the alarm will reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is on, turn the set point adjustment potentiometer ( R26 for alarm No. 1 or R25 for alarm No. 2) slowly counterclockwise just

until the LED turns off.

OR

If the LED is off, turn the set point adjustment potentiometer ( R26 for alarm No. 1 or R25 for alarm No. 2) clockwise until the LED turns

on and then slowly counterclockwise just until the LED turns off.

Continue With the Air/Gas Flow Procedure

1. Slide the mode switch to the RUN position.

2. Establish the normal process fl ow condition. For low-fl ow alarm setups, the status LED should be off. For high fl ow alarm setups, the

status LED should be on.

3. Establish the process alarm condition and monitor the voltmeter display.

4. When the output signal passes through the calculated set point value, the status LED should turn on for low-fl ow alarms, off for high

fl ow alarms, and the relay contacts should change state.

5. Reestablish the normal process fl ow condition. Both the LED and the relay contacts should reset.

6. Disconnect the voltmeter from P1.

7. Replace the enclosure cover.

TM

Note: The alarm can be set for a specifi c fl ow rate. Follow the Air/Gas Flow Application procedure up to step 7 except establish the

specifi c fl ow rate rather than the normal fl ow. The output signal will be the set point value. Determine whether the alarm

should actuate with decreasing or increasing fl ow and skip to the appropriate step 4 in Detecting Decreasing Flow or Detecting Increasing Flow, respectfully. Enter the specifi c fl ow rate value as the set point. Then follow the Continue With the Air /

Gas Flow Procedure steps.

The relay logic default confi guration is set for the relay coil to be de-energized when the fl ow signal voltage is greater than

the set point value. (i.e., Assume that the normal process fl ow condition has been established. In this state, the relay coil

will be energized if the alarm has been set for low-fl ow detection and de-energized if the alarm has been set for high fl ow

detection.) A recommendation is to have the relay coils energized when the process condition is normal. This will enable the

alarm to close or open the contacts in case of a power failure.

Wet/Dry Liquid Level Applications

1. Remove the instrument’s enclosure cover.

2. Ensure the confi guration jumpers on the control circuit are correct for this application. See Tables 3-3 through 3-6.

3. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

4. Apply power to the instrument. Verify the yellow LED is on and allow the instrument fi fteen minutes to warm-up.

5. Verify the mode switch is in the RUN position.

6. Attach a DC voltmeter to P1 with the positive (+) lead to position one and the negative (-) lead to position two.

Note: The terminal block can be unplugged from the control circuit to facilitate easy connections.

24 Fluid Components International LLC

Page 25

FLT® Series FlexSwitchTM OPERATION

7. Raise the process fl uid level so the sensing element is wet.

8. Allow the output signal to stabilize and record the wet condition value.

Wet Condition Signal = ________ volts DC

Note: The output signal at P1 is relative to the type of process media detected. See Figure 3-4.

9. Lower the process fl uid level so the sensing element is dry.

10. Allow the output signal to stabilize and record the dry condition value. (The dry signal should be greater than the wet signal.)

Dry Condition Signal = ________ volts DC

11. Determine the set point by calculating the average of the wet and dry output signals. (i.e., If the wet signal is 0.200 volts and the dry

signal is 4.000 volts, then the calculated set point would be 2.100 volts.)

12. Record this value.

Calculated Set Point = ________ volts DC

Note: The calculated set point must be at least 0.015 volts greater than the wet signal and 0.020 volts less than the dry signal to

ensure that the alarm will reset.

FIELD ADJUSTABLE

SET POINT

AIR OR GAS

OIL

OUTPUT VOLTAGE

Potentiometer

(POT)

A

I

R

T

O

W

A

T

E

R

DIESEL

WATER

R25 AND R26

Adjust

R

I

A

O

T

R

E

T

A

W

LED ON

ABOVE SETPOINT

LED OFF

BELOW SETPOINT

Clockwise,

Turns

LED ON

SET POINT

Adjust

Counter-

clockwise,

Turns

LED OFF

0

TIME

C00070-1-2

Figure 3-4 Level Application Signal Output

13. Slide the mode switch to the CALIBRATE position.

14. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

15. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

16. Follow either the Detecting Dry Condition or the Detecting Wet Condition for each level application alarm.

Detecting Dry Condition (low level alarm)

If the status LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) slowly clockwise just

until the LED turns on.

OR

If the status LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) counterclockwise until

the LED turns off and then slowly clockwise just until the LED turns on.

Fluid Components International LLC 25

Page 26

OPERATION FLT® Series FlexSwitch

Detecting Wet Condition (high level alarm)

If the status LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) slowly counterclockwise

just until the LED turns off.

OR

If the status LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) clockwise until the LED

turns on and then slowly counterclockwise just until the LED turns off.

17. Slide the mode switch to the RUN position. The status LED should be on if the sensing element is dry and off if the sensing element is

wet.

18. Monitor the voltmeter display while raising or lowering the process fl uid level. When the output signal passes through the set point, the

status LED should change states and the relay contacts should change state.

19. Reestablish the normal level condition. Both the LED and relay contacts should reset.

20. Disconnect the voltmeter from P1.

21. Replace the enclosure cover.

Note: The relay logic default confi guration is set for the relay coil to be de-energized when the level signal is greater than the set

point value. (i.e., The relay coil will be de-energized when the sensing element is dry.) A recommendation is to have the

relay coils energized when the process condition is normal. This will enable the alarm to close or open the contacts in case

of a power failure.

TM

Liquid Flow Applications

1. Remove the instrument’s enclosure cover.

2. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

3. As necessary, set the following control circuit confi guration jumpers. See Tables 3-3 through 3-6.

Application: J20 or J18 (Flow/Level) for alarm No. 1 or No. 2, respectively.

Heater Power: J32 (3 watts for FLT93-S or 0.57 watts for FLT93-F).

4. Apply power to the instrument. Verify the yellow LED is on. Allow the instrument fi fteen minutes to warm-up.

5. Verify the mode switch is in the RUN position.

6. Attach a DC voltmeter to P1 connector with the positive (+) lead to position one and the negative (-) lead to position two.

Note: The terminal block can be unplugged from the control circuit to facilitate easy connections.

The output signal at connector P1 will vary inversely with changes in the process fl ow rate. The output signal level is also

relative to the type of process media being measured. See Figure 3-3.

7. Establish the normal process fl ow condition and allow the signal to stabilize.

8. Record the normal fl ow signal value.

Normal Flow Signal = ________ volts DC

9. Follow either the Detecting Decreasing Flow or Detecting Increasing Flow procedure for each Liquid fl ow application alarm.

Detecting Decreasing Flow (low fl ow alarm)

1. Stop the process fl ow and allow the signal to stabilize.

2. Record the no-fl ow signal. (The no-fl ow signal should be greater than the normal fl ow signal.)

No-Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and no-fl ow output signals. (i.e.; If the normal signal is 0.080 volts and

the no-fl ow signal is 0.300 volts, then the calculated set point would be 0.190 volts.)

4. Record this value.

Calculated Set Point = ________ volts DC

26 Fluid Components International LLC

Page 27

FLT® Series FlexSwitchTM OPERATION

Note: The calculated set point must be at least 0.020 volts greater than the normal signal to ensure that the alarm will reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) slowly clockwise just until the

LED turns on.

OR

If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) counterclockwise until the LED

turns off and then slowly clockwise just until the LED turns on.

8. If this is the only fl ow application alarm to be setup, then skip to Continue With the Liquid Flow Applications procedure.

Detecting Increasing Flow Rate (high fl ow alarm)

1. Establish the excessive fl ow condition and allow the signal to stabilize.

2. Record the high fl ow signal. (The high fl ow signal should be less than the normal fl ow signal.)

High Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and high fl ow output signals. (i.e.; If the normal signal is 0.080 volts

and the high fl ow signal is 0.030 volts, then the calculated set point would be 0.055 volts.)

4. Record this value.

Calculated Set Point = ________ volts DC

Note: The calculated set point must be at least 0.020 volts less than the normal signal to ensure that the alarm will reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

8. If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) slowly counterclockwise just

until the LED turns off.

OR

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2) clockwise until the LED turns on

and then slowly counterclockwise just until the LED turns off.

Continue With the Liquid Flow Applications

1. Slide the mode switch to the RUN position.

2. Establish the normal process fl ow condition. For low-fl ow alarm setups, the status LED should be off. For high fl ow alarm setups, the

status LED should be on.

3. Establish the process alarm condition and monitor the voltmeter display.

When the output signal passes through the calculated set point value, the status LED should turn on for low-fl ow alarms, off for high

fl ow alarms, and the relay contacts should change state.

4. Reestablish the normal process fl ow condition. Both the LED and the relay contacts should reset.

5. Disconnect the voltmeter from P1.

6. Replace the enclosure cover.

Fluid Components International LLC 27

Page 28

OPERATION FLT® Series FlexSwitch

Note: The alarm can be set for a specifi c fl ow rate. Follow the Air/Gas Flow Application procedure up to step 7 except establish the

specifi c fl ow rate rather than the normal fl ow. The output signal will be the set point value. Determine whether the alarm

should actuate with decreasing or increasing fl ow and skip to the appropriate step 4 in Detecting Decreasing Flow or Detecting Increasing Flow, respectfully. Enter the specifi c fl ow rate value as the set point. Then follow the Continue With the Air /

Gas Flow Procedure steps.

The relay logic default confi guration is set for the relay coil to be de-energized when the fl ow signal voltage is greater than

the set point value. (i.e., Assume that the normal process fl ow condition has been established. In this state, the relay coil

will be energized if the alarm has been set for low-fl ow detection and de-energized if the alarm has been set for high fl ow

detection.) A recommendation is to have the relay coils energized when the process condition is normal. This will enable the

alarm to close or open the contacts in case of a power failure.

Adjustment by Observation

Note: The control circuit has two mutually exclusive alarms; they are identifi ed as Alarm No. 1 and Alarm No. 2 and each has a set

point adjustment potentiometer and LED indicator. Each alarm can be setup for one of three applications: fl ow, level/interface, or temperature. The following application specifi c adjustment procedures are generic and can be used for setting either

or both alarms. The mode switch must be in the RUN position. Use Figure 3-2 to help locate the adjustment potentiometers

and LEDs.

Flow Applications

1. Ensure that the instrument has been properly installed in the pipeline. Fill the pipeline so the sensing element is surrounded by the

process medium.

2. Apply power to the instrument and allow fi fteen minutes for the sensing element to become active and stabilize.

3. Flow the pipeline at the normal or expected rate. Remove the enclosure cover to allow access to the control circuit to make adjustments.

TM

Detecting Decreasing Flow (low fl ow alarm)

If the status LED is off, turn the set point adjustment potentiometer clockwise until the LED turns on. With the LED on, slowly turn the potentiometer counterclockwise one turn past the point at which the LED just turns off. The potentiometer may have up to one-quarter turn of

hysteresis, therefore, if the mark is overshot, the procedure should be repeated.

Detecting Increasing Flow (high fl ow alarm)

If the status LED is on, turn the set point adjustment potentiometer counterclockwise until the LED turns off. With the LED off, slowly turn the

potentiometer clockwise one-half turn past the point at which the LED just turns on. The potentiometer may have up to one-quarter turn of

hysteresis, therefore, if the mark is overshot, the procedure should be repeated.

Signal Output for Flow Applications

The output signal at connector P1 varies inversely with fl ow rate. The output signal level is also relative to the type of process media, see

Figure 3-3.

Level Applications

1. Ensure that the instrument has been properly installed in the vessel.

2. Apply power to the instrument and allow fi fteen minutes for the sensing element to become active and stabilize.

3. Remove the enclosure cover to allow access to the control circuit to make adjustments.

Detecting Dry Condition (adjustment with sensing element wet)

Verify that the sensing element is wet. If the status LED is off, turn the set point adjustment potentiometer clockwise until the LED turns on.

With the LED on, slowly turn the potentiometer counterclockwise one turn past the point at which the LED just turns off. The potentiometer

may have up to one-quarter turn of hystereses, therefore, if the mark is overshot, the procedure should be repeated.

28 Fluid Components International LLC

Page 29

FLT® Series FlexSwitchTM OPERATION

Detecting Wet Condition (adjustment with sensing element dry)

Caution: Give consideration to the fact that air or gas fl owing over the sensing element may decrease the output signal resulting in

a false alarm. If the sensing element is exposed to air or gas fl ow in the dry condition, or where the process media is highly

viscous, make set point adjustments in the wet condition only.

Field adjustments made in the dry condition should be performed in the actual service environment or within a condition that approximates

that environment. Provision should be made for the worst case condition of air or gas fl ow on the sensing element. If the status LED is on,

turn the set point adjustment potentiometer counterclockwise until the LED turns off. (If the LED cannot be turned off, the instrument must be

set in the wet condition.)

With the LED off, slowly turn the potentiometer clockwise 1 turn past the point at which the LED just goes on. The potentiometer may have

up to one-quarter turn of hysteresis, therefore, if the mark is overshot, the procedure should be repeated.

Signal Output for Level Applications

The output signal at P1 is lowest in water and highest in air. See Figure 3-4.

Temperature Applications

For temperature versus voltage values, see Table 3-7 located at the rear of this chapter. These values have an accuracy of ±5°F (2.78°C).

There is also a conversion formula later in this chapter to convert the temperature output voltage to degrees fahrenheit. If a factory calibration chart was ordered look for it in the plastic page protector at the back of this manual. Make sure the serial number of the chart matches

the instrument to be adjusted.

Note: It is reccommended not to use the instrument for a dual fl ow and temperature application in air or gas unless the fl ow rate is

greater than 1.0 SFPS. (The instrument may be used for a dual fl ow and temperature application in liquids at any fl ow rate.)

When using the instrument for dual level and temperature applications, the temperature signal can be as much as 50°F

(28°C) high when the sensing element is in still air.

Turn the heater off for temperature only applications. To turn off the heater remove the heater control jumper from the

heater, control header. The jumper may be stored on the control circuit by plugging it across J12 and J14. Placing the jumper

here will not turn on the heater.

1. Remove the instrument’s enclosure cover.

2. Ensure the confi guration jumpers on the control circuit are correct for this application. See Tables 3-3 through 3-6.

3. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

4. Apply power to the instrument. Verify the yellow LED is on. Allow the instrument fi fteen minutes to warm-up.