Page 1

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

FLT

ÔÔ

Ô

ÔÔ

Series FlexSwitch

ÔÔ

Ô

ÔÔ

Flow, Level, Temperature

Switch/Monitor

Doc. No. 06EN003246 Rev. B

Notice of Proprietary Rights

This document contains confidential technical data, including trade

secrets and proprietary information which are the property of Fluid

Components Intl (FCI).

Disclosure of this data to you is expressly conditioned upon your assent

that its use is limited to use within your company only (and does not

include manufacture or processing uses). Any other use is strictly

prohibited without the prior written consent of FCI.

FLTÔ uses FCI's Proprietary FLEXSWITCHÔ Technology.

Patent 4,967,593

© Copyright 1996 Fluid Components Intl

a limited liability company

All Rights Reserved

9/29/94

Page 2

CUSTOMER COMMITMENT PLEDGE

We will work closely with our customers to provide the best products and service

• at a competitive value

• on time

• with unquestioned support

in full compliance with our COMPLETE CUSTOMER COMMITMENT.

COMMITMENT TO QUALITY

In keeping with the overall commitment of management and employees of Fluid Components Intl to Total Quality

Management, the publications department expresses its pledge and mission to you, our customer:

“To support the creation and publication of world-class technical material which is technically accurate and

practical, concise and user-friendly, attractive and professional in appearance, and consistent in form, format,

content, and style.”

QUALITY IMPROVEMENT

FLUID COMPONENTS INTL

We appreciate your comments and suggestions which support our effort to constantly improve our product and

services. Please address comments and suggestions to your nearest field representative or in-house technical

support representative. Thank you.

FCI Technical Publications Department

Doc. No. 06EN003246 Rev. B iii FLTÔ Series FlexSwitchÔ

Page 3

FLUID COMPONENTS INTL

CUSTOMER SERVICE/TECHNICAL SUPPORT

FCI provides full in-house technical support for our products 7 a.m. to 5 p.m. PST, Monday through Friday

(excepting holidays and an annual plant closure between Christmas and New Year's day). Also, additional

technical representation is provided by FCI field representatives. Before contacting one of our field or in-house

representatives, please ensure that you have performed the troubleshooting techniques outlined in this document.

By Mail

Fluid Components Intl

1755 La Costa Meadows Dr.

San Marcos, CA 92069

Attn: Customer Service Department

By Phone

Contact the FCI regional representative in your area. If your are unable to contact the field representative

or are unable to satisfactorily resolve the situation, contact the FCI Customer Service Department at

1 (800) 854-1993, toll free.

By Fax

To describe your problems in a more graphic or pictorial manner, send your fax including your phone or

fax number to your regional representative. Again FCI is available through facsimile if you have

exhausted your possibilities with the authorized factory representative. Our fax number is

(760) 736-6250; it is available 7 days a week, 24 hours a day.

International Support

For product information or product support outside the contiguous United States, Alaska, or Hawaii,

contact your country’s FCI International Representative or the one nearest to you. See the list on

following pages.

Appendix C contains a detailed explanation of the FCI customer service policy on returns, adjustments, in-field or

factory repair, in- or out-of-warranty.

FLTÔ Series FlexSwitchÔ

iv Doc. No. 06EN003246 Rev. B

Page 4

FLUID COMPONENTS INTL

REVISIONS

REV. DESCRIPTION DATE AUTHOR

A

Added Revision Page. Revised Table of Contents.

Chapter 1 Theory of Operation: Changed wording; signal conditioner to control

circuit.

Chapter 1 Specifications: Revised Specification information .

Chapter 3 Page 3-1, Heater Cut-Off: Revised description.

Chapter 3 Table 3-1: Corrected typographical error. Deleted an incorrect statement.

Chapter 3 Figure 3-1: Added potentiometer call out R5 to the figure.

Chapter 3 Table 3-3A: Changed asterisk information.

Chapter 3 Tables 3-3A, 3-3B: Changed wattage values.

Appendix A Figure A-1, A-7 and A-8: Updated drawings.

Appendix A Figures A-1, A-4, A-5, A-7 and A-9: Changed the figure captions to

correctly identify the figures.

Appendix A Added Figures A-13, A-14 and A-15.

Appendix C Pages C-1, C-3, C-4 and C-5: Changed wording; Attachment to

Document. Added paragraph to clarify that documents are indeed added

to the appendix.

1/24/95

R. Sanders

Appendix D Page D-2, Step 5. Corrected jumper number and added a reference to

Figure 3-1.

Appendix D Table D-1: Changed wattage and a voltage values.

B Added Appendix E CE Mark information. Added information on FLT93-C 2-25-96 R. Sanders

and FLT93-L. Added remote relay wiring information. Change bars have also

been added to draw attention to new information.

Doc. No. 06EN003246 Rev. B vii FLTÔ Series FlexSwitchÔ

Page 5

FLUID COMPONENTS INTL

Contents

1. General Information

2. Installation

Description ........................................................................................................................... 1 - 1

Theory of Operation ............................................................................................................. 1 - 1

Sensing Element .................................................................................................................. 1 - 1

Control Circuit ..................................................................................................................... 1 - 1

Technical Specifications ...................................................................................................... 1 - 2

Receiving/Inspection ............................................................................................................ 2 - 1

Packing/Shipping/Returns ................................................................................................... 2 - 1

Factory Calibration Note ...................................................................................................... 2 - 1

Pre-Installation Procedure ................................................................................................... 2 - 1

Use Standard ESD Precautions .................................................................................... 2 - 1

Prepare or Verify Sensing Element Location ............................................................... 2 - 2

Verify Dimensions ........................................................................................................ 2 - 2

Verify Sensing Element Flow Direction and Placement Orientation (Flow) ............. 2 - 2

Verify Sensing Element Flow Direction and Placement Orientation (Level) ............ 2 - 2

Install the Sensing Element ................................................................................................. 2 - 2

Male NPT Mounting ..................................................................................................... 2 - 2

Flange Mounting ........................................................................................................... 2 - 3

Packing Gland Assembly .............................................................................................. 2 - 3

In-Line NPT Assembly ................................................................................................. 2 - 3

Sanitary Assembly ........................................................................................................ 2 - 4

Install and Wire the Enclosure ............................................................................................ 2 - 4

Minimum Wire Size ..................................................................................................... 2 - 4

Wiring the Local Enclosure .......................................................................................... 2 - 5

Wiring at the Remote Enclosure .................................................................................. 2 - 6

Locate the Remote Hardware Location ........................................................................ 2 - 6

Wiring Remote Enclosure with Auxiliary Relay.......................................................... 2 - 7

Wiring a Remote Control Circuit To A Auxiliary Relay Board .................................. 2 - 8

Wiring Output Signal Terminals ......................................................................................... 2 - 8

3. Operation

Factory Default Jumper Configuration ................................................................................ 3 - 1

Configuration Jumpers ......................................................................................................... 3 - 1

Heater Cut-Off ...................................................................................................................... 3 - 1

Alarm Set Point Adjustment ................................................................................................ 3 - 2

Numerical Adjustment Versus Adjustment by Observation ........................................ 3 - 2

Numerical Set Point Adjustment ......................................................................................... 3 - 3

Air/Gas Flow Applications ........................................................................................... 3 - 4

Wet/Dry Liquid Level Applications ............................................................................. 3 - 7

Temperature Applications ............................................................................................ 3 - 8

Liquid Flow Applications ............................................................................................. 3 - 10

Adjustment by Observation .................................................................................................. 3 - 12

Flow Applications ......................................................................................................... 3 - 12

Level Applications ........................................................................................................ 3 - 12

Temperature Applications ............................................................................................ 3 - 13

Converting Temp Out Voltage to Temp in Degrees F ................................................. 3 - 19

Fail Safe Alarm Setting ....................................................................................................... 3 - 20

Low Flow Alarm Setting .............................................................................................. 3 - 20

High Flow Alarm Setting ............................................................................................. 2 - 20

Low Level Alarm Setting ............................................................................................. 3 - 20

High Level Alarm Setting............................................................................................. 2 - 20

4. Maintenance

Maintenance ......................................................................................................................... 4 - 1

Calibration .................................................................................................................... 4 - 1

Electrical Connections .................................................................................................. 4 - 1

FLTÔ Series FlexSwitchÔ

viii Doc. No. 06EN003246 Rev. B

Page 6

Remote Enclosure ......................................................................................................... 4 - 1

Electrical Wiring .......................................................................................................... 4 - 1

Sensing Element Connections ...................................................................................... 4 - 1

Sensing Element Assembly .......................................................................................... 4 - 1

5. Troubleshooting

Tools Needed ........................................................................................................................ 5 - 1

Quick Check ......................................................................................................................... 5 - 1

Non-maintenance Observations ........................................................................................... 5 - 1

Check Serial Numbers .................................................................................................. 5 - 1

Check Input Power ........................................................................................................ 5 - 1

Check the Instrument Installation ................................................................................ 5 - 1

Check for Moisture ....................................................................................................... 5 - 1

Check Application Design Requirements .................................................................... 5 - 2

Troubleshooting the Flow Element ..................................................................................... 5 - 2

Troubleshooting the Flow Transmitter ................................................................................ 5 - 2

Spares ................................................................................................................................... 5 - 4

Defective Parts ..................................................................................................................... 5 - 4

Customer Service ................................................................................................................. 5 - 4

Appendix A. Drawings

Outline Drawings ................................................................................................................. A - 1

Appendix B. Glossary

Abbreviations and Explanation of Terms ............................................................................ B - 1

FLUID COMPONENTS INTL

Figures

Appendix C. Customer Service

Policy and Procedures .......................................................................................................... C - 1

Appendix D. Temperature Compensation

Temperature Compensation Procedure................................................................................ D - 1

Appendix E. CE Conformance

CE Conformance Information ............................................................................................. E - 1

Figure 1-1. View of the Sensing Element ............................................................................................. 1 - 1

Figure 2-1. NPT Pipe Thread Mount .................................................................................................... 2 - 2

Figure 2-2. Flange Mount ......................................................................................................................2 - 3

Figure 2-3. FLT93-L In-line Flow Element ..........................................................................................2 - 4

Figure 2-4. FLT93-C Sanitary Flow Elements ......................................................................................2 - 4

Figure 2-5. Local Wiring Diagram ........................................................................................................ 2 - 5

Figure 2-6. Remote Wiring Diagram ....................................................................................................2 - 6

Figure 2-7. Auxiliary Relay Board Wiring Diagram ............................................................................2 - 7

Figure 3-1. 5294 Control Circuit Jumper Locations .............................................................................3 - 2

Figure 3-2. 5294 Control Circuit Component Locations ......................................................................3 - 4

Figure 3-3. Flow Application Signal Output ......................................................................................... 3 - 5

Figure 3-4. Level Application Signal Output ........................................................................................3 - 7

Figure 3-5. Low Flow Fail Safe Alarm.................................................................................................. 3 - 20

Figure 3-6. High Flow Fail Safe Alarm ................................................................................................. 3 - 20

Figure 3-7. Low Level Fail Safe Alarm ................................................................................................. 3 - 21

Figure 3-8. High Level Fail Safe Alarm ................................................................................................3 - 21

Figure 5-1. Troubleshooting Chart ........................................................................................................5 - 3

Figure A-1. Local Enclosure, NEMA Type 4X and Hazardous Location ............................................A - 1

Doc. No. 06EN003246 Rev. B ix FLTÔ Series FlexSwitchÔ

Page 7

FLUID COMPONENTS INTL

Figure A-2. Local Enclosure NEMA Type 4X ...................................................................................... A - 1

Figure A-3. Remote Enclosure NEMA Type 4X .................................................................................. A - 1

Figure A-4. Remote Enclosure NEMA Type 4 and Hazardous Location ............................................. A - 2

Figure A-5. Remote Enclosure, Killark, NEMA Type 4 and Hazardous Location ..............................A - 2

Figure A-6. 1/4, 3/4 or 1 Inch NPT Process Connection ......................................................................A - 2

Figure A-7. Flanged Process Connection ..............................................................................................A - 3

Figure A-8. Low Pressure Packing Gland .............................................................................................A - 3

Figure A-9. Flanged Low Pressure Packing Gland Process Connection ...............................................A - 3

Figure A-10. 1-1/4 Inch Medium Pressure Packing Gland Connection ................................................ A - 4

Figure A-11. Flanged Medium Pressure Packing Gland Process Connection ...................................... A - 4

Figure A-12. 1/4 Inch Process Connection ............................................................................................A - 4

Figure A-13. Wire Pigtail Process Connection ...................................................................................... A - 5

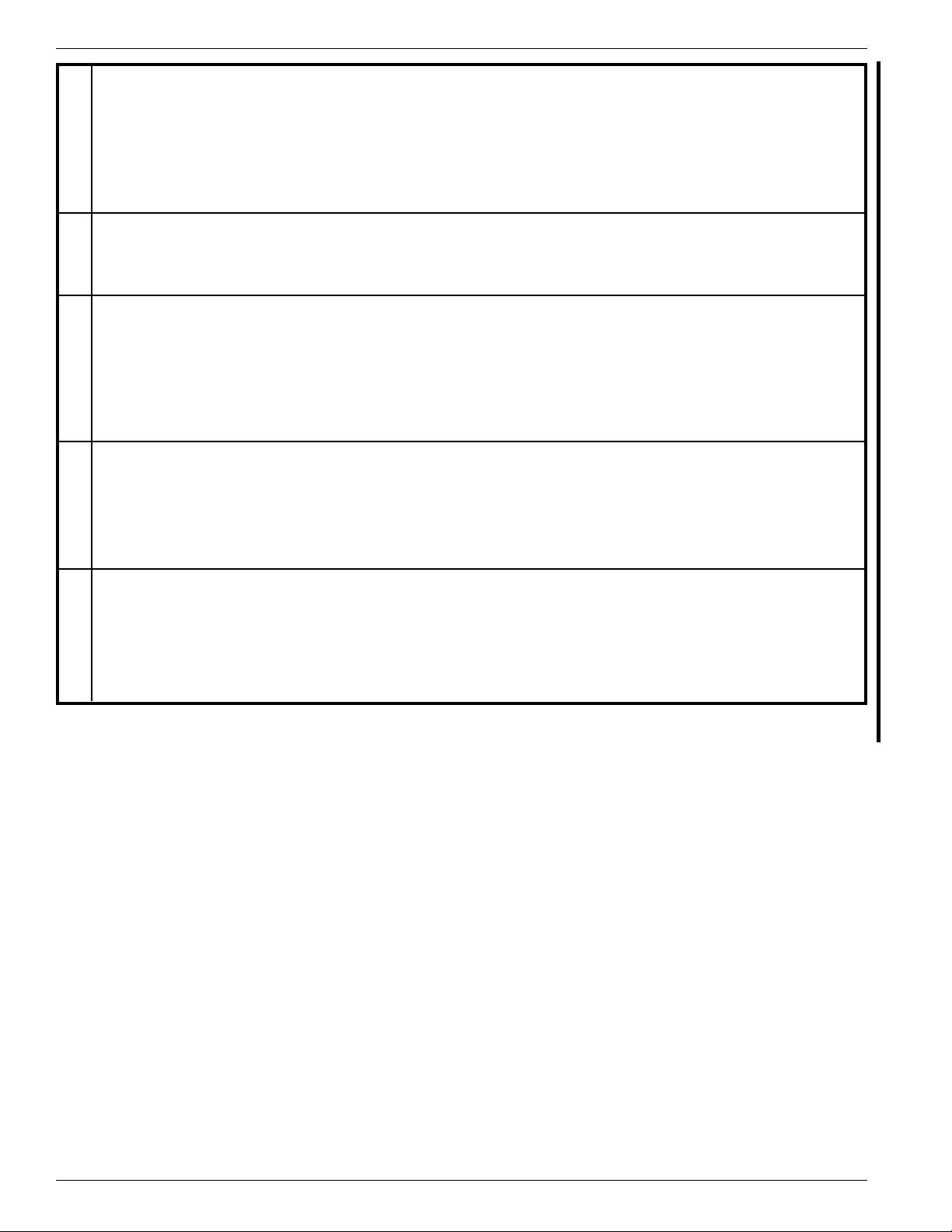

Figure A-14. Injection Tube with Tee Fitting ....................................................................................... A - 5

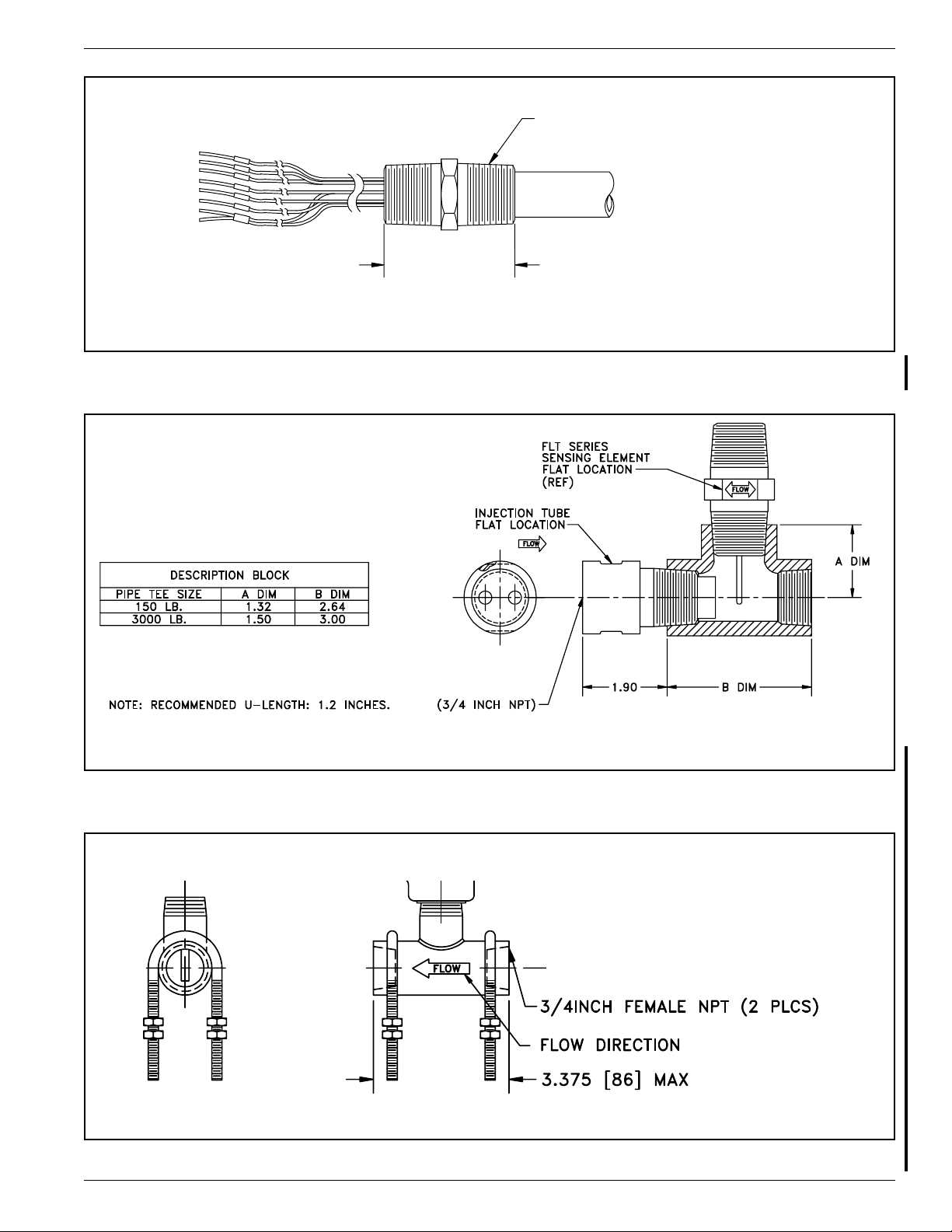

Figure A-15. 3/4 Inch Female NPT FLT93-L With U-Bolt Bracket Kit ..............................................A - 5

Figure A-16. 1 Inch NPT FLT93-L .......................................................................................................A - 6

Figure A-17. 1 Inch RF Flanged FLT93-L............................................................................................ A - 6

Figure A-18. FLT93-C Sanitary Removable Clamp Instrument .......................................................... A - 6

Figure A-19. FLT93-C Sanitary Clean-In-Place Instrument ................................................................A - 7

Figure A-20. FLT93 Auxiliary Relay ....................................................................................................A - 7

Figure A-21. FLT93 PWB Module ........................................................................................................ A - 8

Figure D-1. Sensing Element Calibration Connections ........................................................................ D - 3

Tables

Table 2-1. Maximum AWG Number ....................................................................................................2 - 5

Table 3-1. Standard Jumper Default Configuration .............................................................................. 3 - 1

Table 3-2. Input Power .......................................................................................................................... 3 - 3

Table 3-3A. Selectable Heater Wattage Control ....................................................................................3 - 3

Table 3-3B. Fixed Heater Wattage Control ............................................................................................3 - 3

Table 3-4. Application ...........................................................................................................................3 - 3

Table 3-5. Relay Energization ...............................................................................................................3 - 3

Table 3-6. Relay Contact Configuration ................................................................................................ 3 - 3

Table 3-7. Temperature Versus Voltage Output .................................................................................... 3 - 14

Table 5-1. Resistance at Control Circuit Terminal Block Socket ......................................................... 5 - 2

Table 5-2. Resistance at Flow Element Enclosure Terminal Block ..................................................... 5 - 2

Table D-1. Heater Voltage Settings .......................................................................................................D - 3

Table D-2. Temp Comp Factor Table .................................................................................................... D - 5

FLTÔ Series FlexSwitchÔ

x Doc. No. 06EN003246 Rev. B

Page 8

Symbols

The following symbols are used throughout the manual to draw attention to items or procedures that require

special notice or care.

FLUID COMPONENTS INTL

Warning:

Caution:

Note:

Warns of possible personal danger to those handling the equipment.

Cautions against possible equipment damage.

Contains important information.

Doc. No. 06EN003246 Rev. B xi FLTÔ Series FlexSwitchÔ

Page 9

CHAPTER 1 - GENERAL INFORMATION FLUID COMPONENTS, INTL

1. General Information

Description

The FLT Series models are multipurpose measurement instruments. The FLT Series models that are included in

this manual are FLT93-C, FLT93-F, FLT93-L and FLT93-S. Each model is a single instrument that is capable of

detecting air flow, fluid flow and temperature. It is also able to detect liquid level or fluid media interfaces. The

instrument has two field adjustable alarm set points, two buffered voltage outputs, as well as a built-in calibration

circuit. The output of the alarm set points are 6 amp relay contacts that can be used to control customer process

applications. One buffered voltage output is available for flow or level monitoring and the second buffered voltage

output is available for temperature monitoring.

Theory of Operation

The flow switch is a fixed position, single-point flow, level, interface and temperature switch. The operation of the

sensing element is based upon the thermal dispersion principle: A low-powered heater is used to produce a

temperature differential between two Resistance Temperature Detectors (RTDs). The RTD temperature differential

varies as a function of forced convection for flow measurement and as a function of fluid thermal conductivity for

level and interface measurement. The measurement of the fluid's temperature is obtained from the non-heated

RTD.

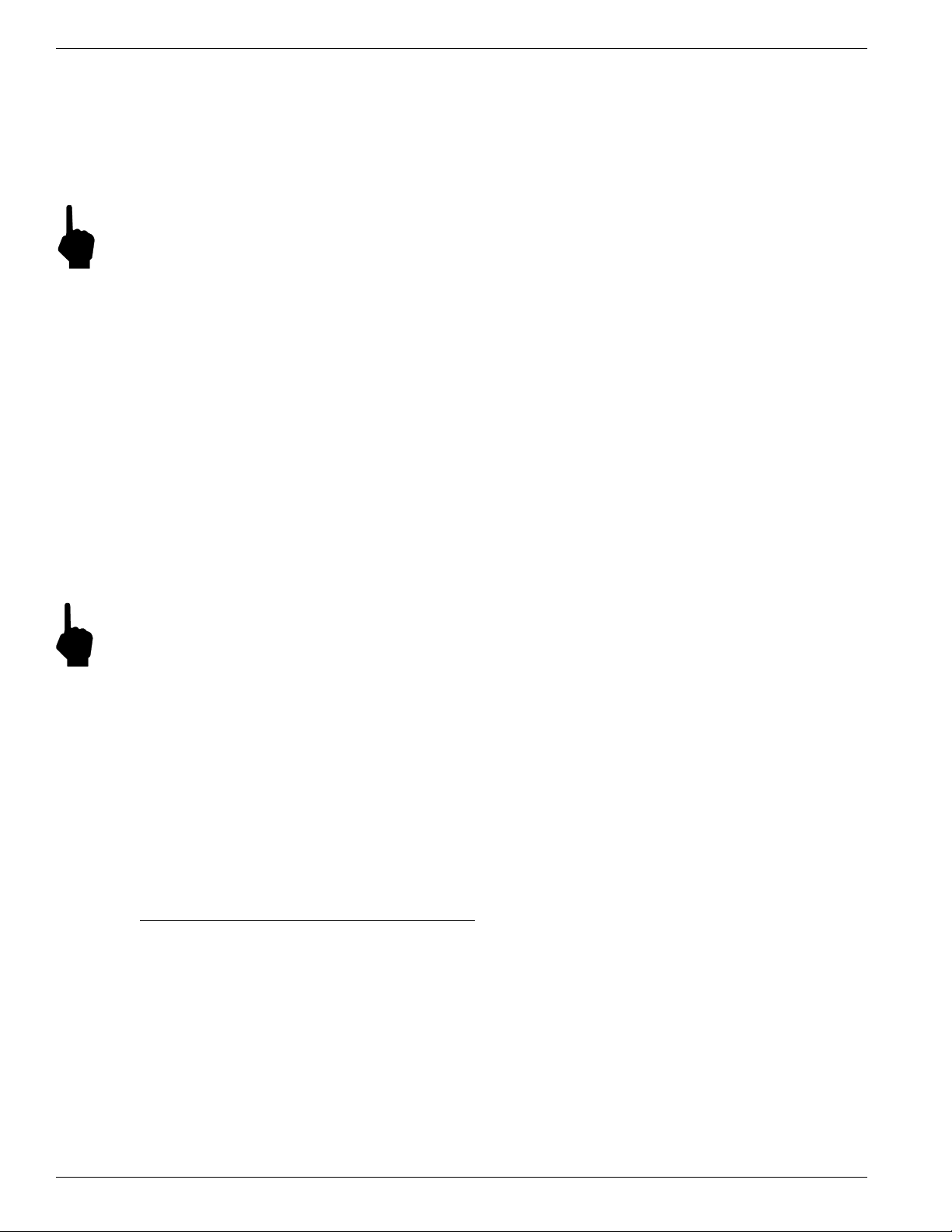

Sensing Element

The sensing element consists of two thermowells (hollow tubes) that when inserted into the flow process allows an

unimpeded flow inside the process line. The top thermowell has a self-heated RTD inserted into it. The bottom

thermowell has a reference RTD inserted into it. In order to correctly orient the sensing element a flow arrow has

been etched onto the threaded portion of the sensing element. See Figure 1-1 for a view of the sensing element.

Control Circuit

The control circuit converts the sensing element's RTD temperature differential into an analog DC voltage signal.

Dual comparators monitor the sensing element signal and activates the relay alarm circuits if the signal exceeds an

adjustable set point.

The control circuit contains all the removable jumpers that configure the instrument to perform as needed by the

customer.

Doc. No. 06EN003246 Rev. B

Figure 1-1 View of the Sensing Element

1 - 1

FLTÔ Series FlexSwitchÔ

Page 10

FLUID COMPONENTS, INTL CHAPTER 1 - GENERAL INFORMATION

Technical Specifications

• Process Connection

3/4 inch male NPT standard. 1 inch BSP, 1 inch

male NPT, 1/4 inch male NPT (FLT93-F only),

flanged mounting, spool piece with 3/4 inch NPT tee

or retractable sensing element available.

• Insertion Length

Beginning as low as 0.9 inches (23 mm). Standard as

well as custom lengths are available.

• Sensing Element Material

All wetted surfaces are 316 Stainless steel, with allwelded construction. Hastelloy C-276, Monel 400

and electro-polished stainless steel surface preparation

optionally available. Titanium is optionally available

on the FLT93-S configuration only.

• Operating Temperature

Control circuit:

Ambient: -40 to 140°F (-40 to 60°C).

Sensing element:

Standard temperature configuration:

-40 to 350°F (-40 to 177°C).

Medium temperature configuration:

-100 to 500°F (-73 to 260°C).

High temperature configuration:

-100 to 850°F (-73 to 454°C).

• Operating Pressure

Hydrostatically proof pressure tested to 3500 psi

(241.3 bar) at 70°F (21.1°C). De-rated with

temperature, the maximum recommended operation

service is 2350 psi (162 bar) at 500°F (260°C).

Higher ratings available with special construction and

test certification.

• Flow Range

From 0.01 to 5 fps (0.006 to 0.15mps) with fluid or

0.25 to 120 fps (0.076 to 38.1 mps) with gas,

depending upon model.

• Signal Output

Buffered voltage output available as a standard for

temperature and either flow or level/interface. The

minimum load impedance is 100 K ohms.

• Accuracy

Switch point accuracy:

Up to ± 2% of the switch point

velocity.

Monitoring accuracy:

±5 % reading (or ±0.04 fps, 0.012 mps,

which ever is larger for liquid applications

and ±2 fps, 0.061 mps, which ever is larger

for gas applications).

Level accuracy:

Down to ±0.1 inch (±0.25 cm)

Temperature accuracy:

Up to ±2 °F, (±1.1°C) depending upon

application. Higher accuracy is available

with factory calibration.

• Repeatability

±0.5% of monitor reading.

Up to ±0.05 inch (±0.13 cm) of level depending on

model.

±1.0°F, (±0.56°C) of temperature.

• Response Time

Alarm set point may be set as low as 0.5 seconds.

Alarm reset may be as low as 2.5 seconds.

• Input Power

Field or factory selectable for 115 Vac ±15V, 13VA

100 mA maximum; 230 Vac ±30V 14 VA 50mA

maximum; 24 Vac +2 to -6V 12.5 VA 485 mA

maximum; or 24 Vdc +6, to -3V, 7 watts, 230 mA

maximum. 100 Vac ±10 V is optionally available.

All AC Power is 50 to 60 Hz. Power applied is

indicated by an LED.

• Heater Power

Field or factory selectable for specific fluid service

requirements.

• Relay Rating

Dual alarm SPDT or single alarm DPDT field

configurable 6 amp resistive at 240 Vac, 115 Vac or

24 Vdc. Options available on auxiliary relay board

are 2 amp or 10 amp DPDT, plastic sealed, 0.5 amp

DPDT hermetically sealed.

• Enclosure

FLTÔ Series FlexSwitchÔ

Hazardous Location Class I, II, Div. 1, 2 Groups B, C,

D, E, F, and G. NEMA type 4X optionally available.

• Electronics

Part Number: 5294- _ _ _ FlexSwitch™

• Agency Approvals

Factory Mutual and CSA system approved.

CENELEC (hazardous location only) system

approved. Approved CE marking.

1 - 2

Doc. No. 06EN003246 Rev. B

Page 11

CHAPTER 2 - INSTALLATION FLUID COMPONENTS, INTL

2. Installation

Receiving/Inspection

• Unpack carefully.

• Verify that all items in the packing list are received and are correct.

• Inspect all instruments for damage or contaminants prior to installation.

If the above three items are satisfactory, proceed with the installation. If not, then stop and contact a customer

service representative.

Packing/Shipping/Returns

These issues are addressed in Appendix C - Customer Service.

Factory Calibration Note

The instrument is factory calibrated to the applications as specified at the time of order. There is no need to perform

any verification or calibration steps prior to installing and placing the instrument in service unless the application has

been varied.

Pre-Installation Procedure

Warning: Only qualified personnel should install this instrument. Install and follow safety procedures in

accordance with the current National Electrical Code. Ensure that power is off during installation.

Any instances where power is applied to the instrument will be noted in this manual. Where the

instructions call for the use of electrical current, the operator assumes all responsibility for

conformance to safety standards and practices.

Caution:

Use Standard ESD Precautions

Use standard ESD precautions when opening an instrument enclosure or handling the control circuit. FCI

recommends the use of the following precautions: Use a wrist band or heel strap with a 1 megohm resistor connected

to ground. If the instrument is in a shop setting there should be static conductive mats on the work table and floor

with a 1 megohm resistor connected to ground. Connect the instrument to ground. Apply antistatic agents to hand

tools to be used on the instrument. Keep high static producing items away from the instrument such as non-ESD

approved plastic, tape and packing foam.

The instrument contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions

when handling the control circuit. See below, for ESD details.

The instrument is not designed for weld-in-place applications. Never weld to a process connection or a

structural support.

Damage resulting from moisture penetration of the control circuit or flow element enclosure is not

covered by product warranty.

The above precautions are minimum requirements to be used. The complete use of ESD precautions can be found in

the U.S. Department Of Defense Handbook 263.

Doc. No. 06EN003246 Rev. B 2 - 1 FLTÔ Series FlexSwitchÔ

Page 12

FLUID COMPONENTS, INTL CHAPTER 2 - INSTALLATION

Prepare or Verify Sensing Element Location

Prepare the process pipe for installation, or inspect the already prepared location to ensure that the instrument will fit

into the system.

Review the requirement for the supply power and alarm circuit connections.

Verify Dimensions

Verify the instrument's dimensions versus the process location to be sure of a correct fit. Also see Appendix A for

dimensions.

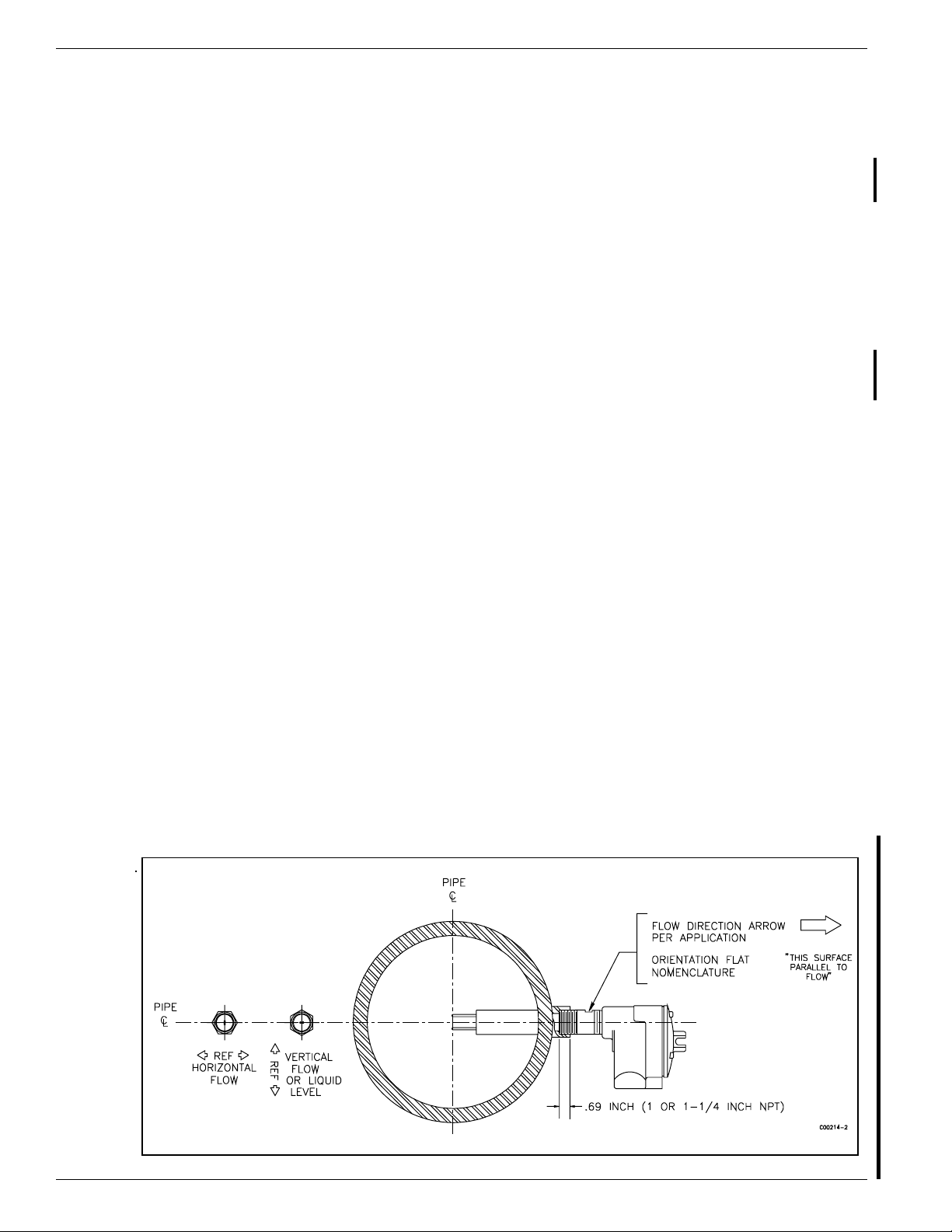

Verify Sensing Element Flow Direction and Placement Orientation (Flow Application)

For flow detection, the sensing element surface marked with direction arrows should be oriented parallel to the

process flow. The flow can be from either direction. See the appropriate figure in Appendix A for the flow arrow

marking.

Mount the sensing element at least 20 diameters downstream and 10 diameters upstream from any bends or

interference in the process pipe or duct to achieve the greatest accuracy.

For liquid flow service, the sensing element should be located in the process pipe so that the thermowells are always

completely wet.

When mounted in a tee or section of pipe larger than the normal process pipe, position in a vertical run of pipe with

flow upward. This will prevent air or gas bubbles from becoming trapped at the sensor assembly.

Vertical positioning with flow downward is only recommended for higher flow rate applications (consult FCI).

Verify Sensing Element Flow Direction and Placement Orientation (Level Application)

If the sensing element is side-mounted on the process vessel, then the surface marked with direction arrows should be

vertically oriented.

If the sensing element is top- or bottom-mounted on the process vessel, the orientation of the surface marked with

direction arrows does not matter.

Install the Sensing Element

Male NPT Mounting

When mounting the sensing element to the process pipe, it is important that a lubricant/sealant be applied to the male

threads of all connections. Be sure to use a lubricant/sealant compatible with the process environment. All

connections should be tightened firmly. To avoid leaks, do not overtighten or cross-thread connections. See

Figure 2-1 and the appropriate figure in Appendix A for proper mounting.

Figure 2-1. NPT Pipe Thread Mount

FLTÔ Series FlexSwitchÔ 2 - 2 Doc. No. 06EN003246 Rev. B

Page 13

CHAPTER 2 - INSTALLATION FLUID COMPONENTS, INTL

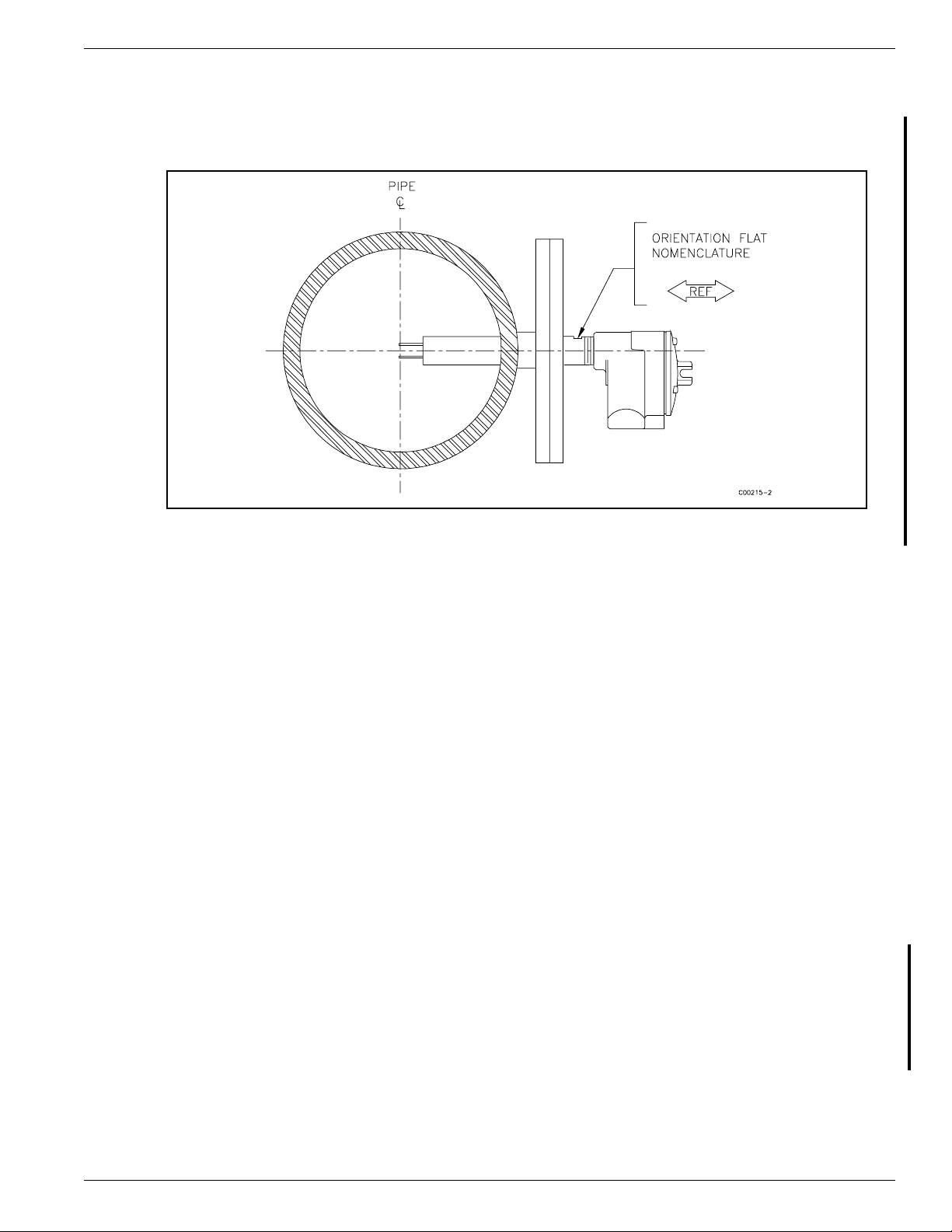

Flange Mounting

For flange mounted sensing elements, attach the process mating flange with care. The correct orientation of the

sensing element must be maintained to ensure optimum performance or calibration. See Figure 2-2 and the

appropriate drawings in Appendix A.

Figure 2-2. Flange Mount

Packing Gland Assembly

Applications involving the use of a packing gland (low or medium pressure) should refer to the drawings in

Appendix A for additional detail.

1. Threaded or flanged packing gland mounts are available. The valve assembly with appropriate connections are

customer supplied. Follow the male NPT mounting procedure above to attach the pipe thread portion or flange

mounting portion as applicable.

2. Tighten the packing nut until the internal packing is tight enough so that the friction fit on the shaft is adequate

to prevent leakage but not prevent the shaft from sliding. Position the etched flow arrow parallel with the flow

(±1° of level) and position the flow arrow so it is pointing in the direction of the flow.

3. Proceed to insert the probe into the process media line. Use the adjusting nuts on the all-thread to pull the

sensing element into proper predetermined depth position.

4. Tighten the opposing lock nuts on the all-threads. Tighten the packing nut another half to full turn until tight

(approximately 65 to 85 ft-lbs [88 to 115 N-m] torque).

5. Rotate the split ring locking collar to line up with the connecting strap welded to the packing nut. Tighten the

two 1/4-28 hex socket cap screws on the split ring locking collar.

Reverse these steps for removal.

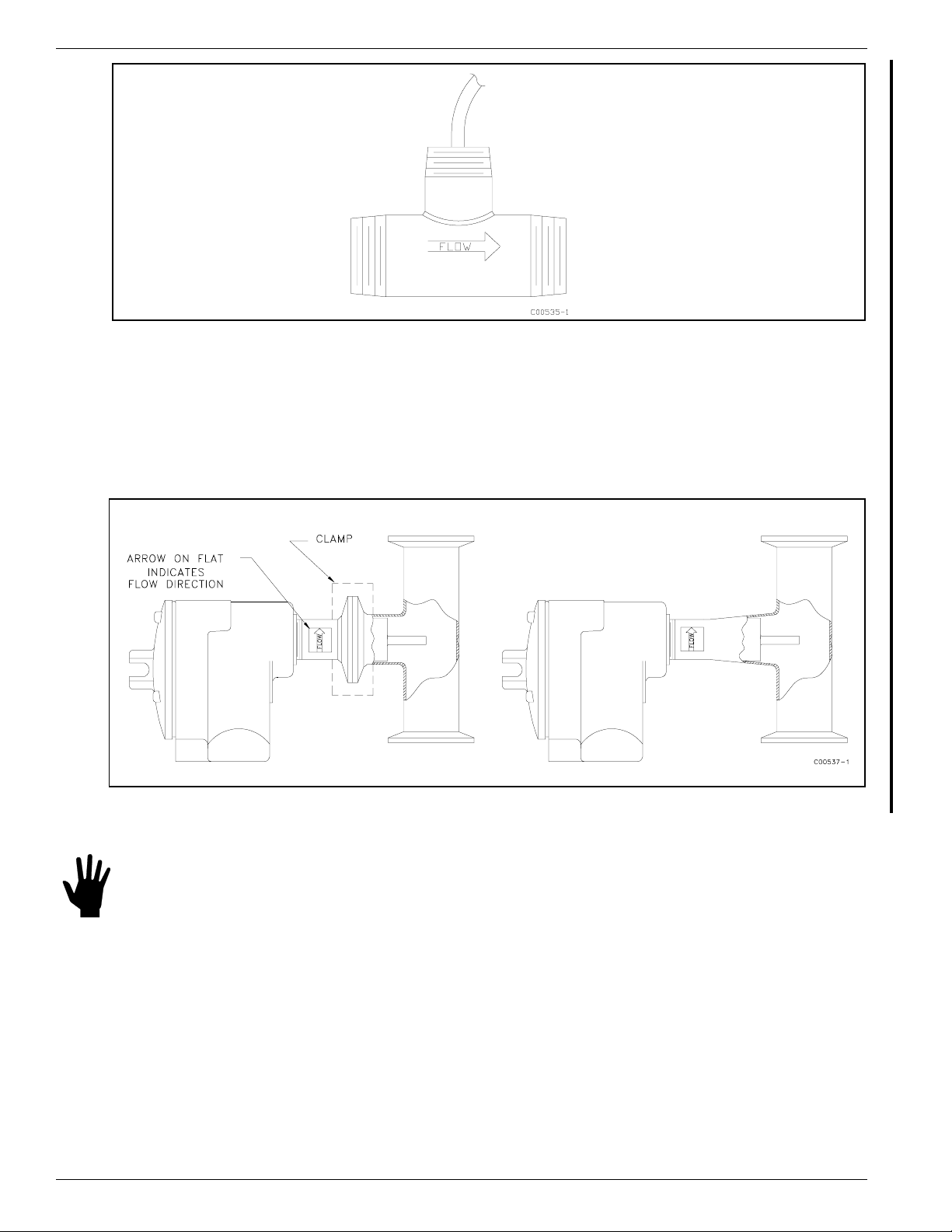

In-line NPT Assembly (FLT93-L)

The body length of the in-line assembly should be verified to be sure the assembly will fit into the process line. See

the appropriate figure in Appendix A to determine the assemblies length. The direction of flow is important for

proper operation. There is a flow direction arrow on the in-line pipe that is to point in the direction of flow. See

Figure 2-3 for the correct orientation.

Doc. No. 06EN003246 Rev. B 2 - 3 FLTÔ Series FlexSwitchÔ

Page 14

FLUID COMPONENTS, INTL CHAPTER 2 - INSTALLATION

Figure 2-3. FLT93-L In-line Flow Element

Sanitary Assembly (FLT93-C)

The instrument is inserted into the process connection with a removable clamp fittings. The Removable Clamp (RC)

sanitary assembly contains a removable clamp connection to the flow element. The Clean-In-Place (CIP) sanitary

assembly has the flow element directly welded into the process stand pipe. Otherwise these instruments function

exactly the same as an FLT93-F or FLT93-S. See Appendix A for an outline dimensions of the instruments.

Figure 2-4 also shows the sanitary assemblies.

Figure 2-4. FLT93-C Sanitary Flow Elements (RC and CIP Respectively)

Install and Wire the Enclosure(s)

Caution:

In applications where the sensing element is located in an explosive environment, isolate the conduit

before it leaves the environment. A potting Y may be used to provide the isolation.

Pulling wires can cause damage to the control circuit. Therefore, remove the control circuit from the

enclosure and use extreme care when pulling wires into the enclosure.

Mount and wire the control circuit either locally or remotely (option) by following the local or remote enclosure

procedure below.

Minimum Wire Size

Table 2-1 shows the smallest (maximum AWG number) copper wire that is used in the electrical cables. Use a lower

gauge of wire for less of a voltage drop. Contact FCI concerning greater distances than those listed in the table. The

sensing element cable must be shielded. If the cable is spliced the shield wire must be continued through the splice.

If a terminal block is used, the shield must have its own terminal.

FLTÔ Series FlexSwitchÔ 2 - 4 Doc. No. 06EN003246 Rev. B

Page 15

CHAPTER 2 - INSTALLATION FLUID COMPONENTS, INTL

Table 2-1. Maximum AWG Number

GWArofecnatsiDmumixaM

noitcennoC

.tf01

)m3(

.tf05

)m51(

.tf001

)m13(

.tf052

)m67(

.tf005

)m251

.tf0001

)m503(

rewoPCA222222028161

)A2(yaleR822202612101

*seriWtnemelEwolF220202818181

.ylnotekcoslortnocehtotdetcennoceriwdleihsehthtiwelbacdedleihsaseriuqeR*

Wiring the Local Enclosure

This procedure is for instruments with the control circuit located in the sensing element enclosure.

1. Remove the control circuit from its socket. Do not remove the control circuit socket. Removal of the control

circuit socket may cause damage to the instrument.

2. Install conduit between the local enclosure and the power source and monitoring circuit. Provide watertight

hardware and apply thread sealant to all connections to prevent water damage.

Warning:

3. When connecting the relay wiring, do so with complete understanding of what the process requires of the

instrument. The instrument has dual SPDT or single DPDT relay output contacts dependent on the jumper

configuration for each alarm switch point. For the relay logic, refer to Figure 2-5. Also refer to Table 3-5 and

Table 3-6 in Chapter 3 - Operation. Relay contacts are shown with the relays de-energized. Wire in accordance

with the system requirements.

Ensure that all power is off before wiring any circuit.

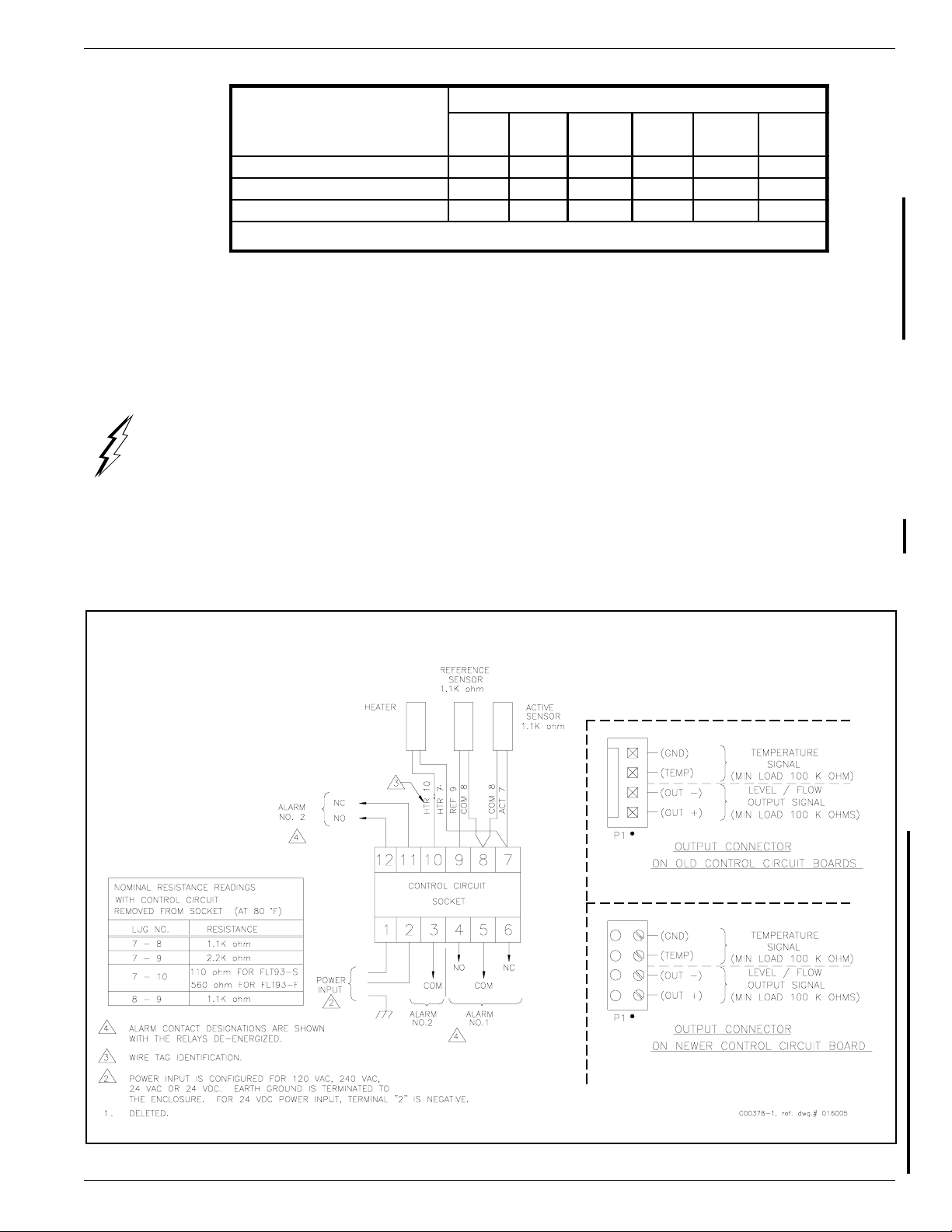

Figure 2-5. Local Wiring Diagram

Doc. No. 06EN003246 Rev. B 2 - 5 FLTÔ Series FlexSwitchÔ

Page 16

FLUID COMPONENTS, INTL CHAPTER 2 - INSTALLATION

Wiring The Remote Enclosure

This procedure is for instruments with the control circuit located remotely from the sensing element.

Locate the Remote Hardware Location

Appendix A shows the remote enclosure along with the physical dimensions to properly mount it. Select a location

for the remote enclosure within a 1000 feet (305 m) of the sensing element. Pigtail sensing elements can not be

located more than 10 feet (3 m) from the enclosure unless the pigtail is extended with the proper size cable listed in

Table 2-1. If the cable is extended the cable connections should be located in a junction box with a 6 position

terminal block. All 5 conductors and the shield must have its own termination. The remote enclosure should be

easily accessible with enough room to open the enclosure cabinet cover at any time. Secure the remote enclosure

solidly to a vertical surface capable of providing support. Use appropriate hardware to secure the enclosure.

1. Remove the control circuit from the remote enclosure.

2. Run a five-conductor, shielded cable from the local enclosure to the remote enclosure. Use Table 2-1 to

determine which wire gauge to use.

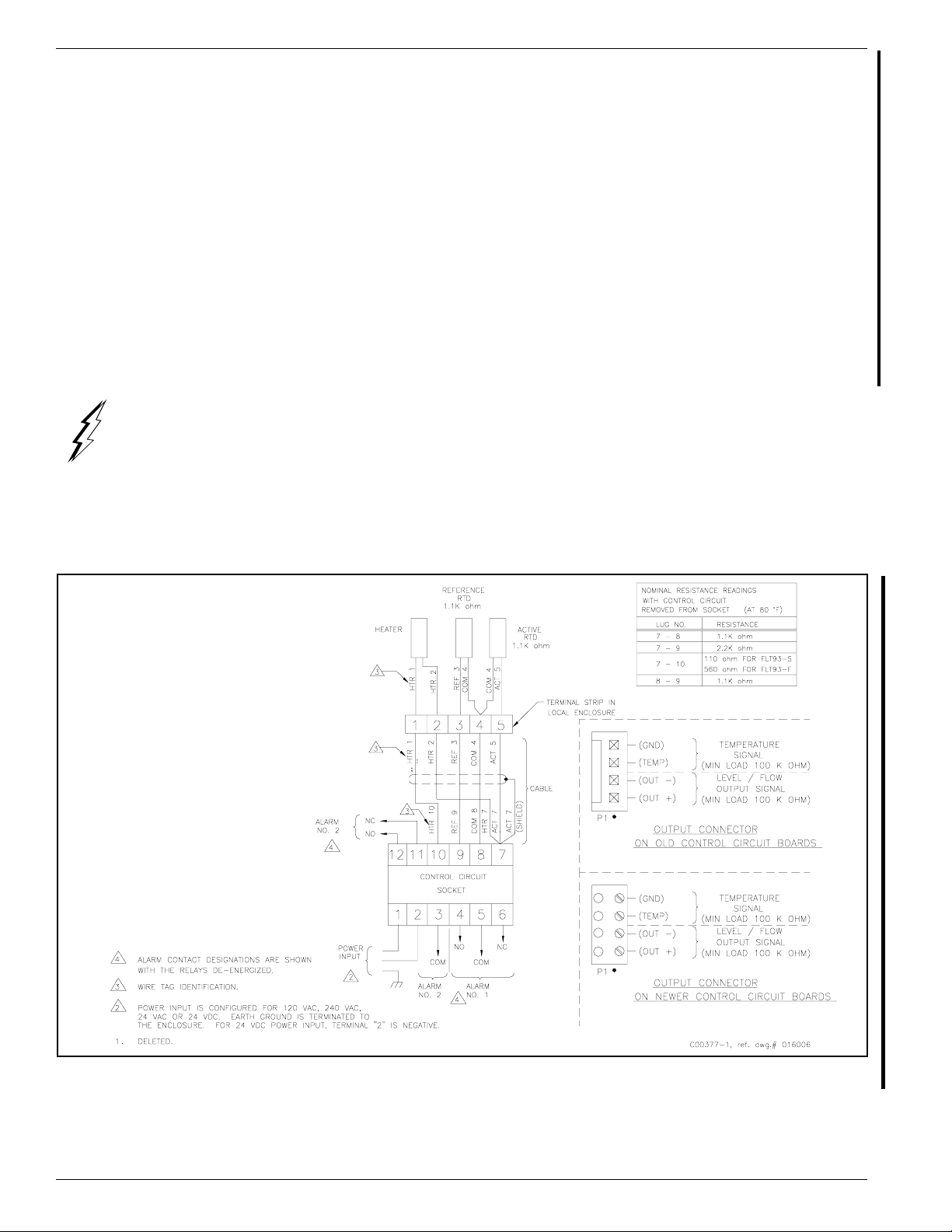

3. Wire between the local and remote enclosures according to Figure 2-6.

Warning:

Ensure that all power is off before wiring any circuit.

4. When connecting the relay wiring, do so with complete understanding of what the process requires of the

instrument. The instrument has dual SPDT or single DPDT relay output contacts dependent on the jumper

configuration for each alarm switch point. For the relay logic, refer to Figure 2-6. Also refer to Table 3-5 and

Table 3-6 in Chapter 3 - Operation. Relay contacts are shown with the relays de-energized. Wire in accordance

with the system requirements.

Figure 2-6. Remote Wiring Diagram

FLTÔ Series FlexSwitchÔ 2 - 6 Doc. No. 06EN003246 Rev. B

Page 17

CHAPTER 2 - INSTALLATION FLUID COMPONENTS, INTL

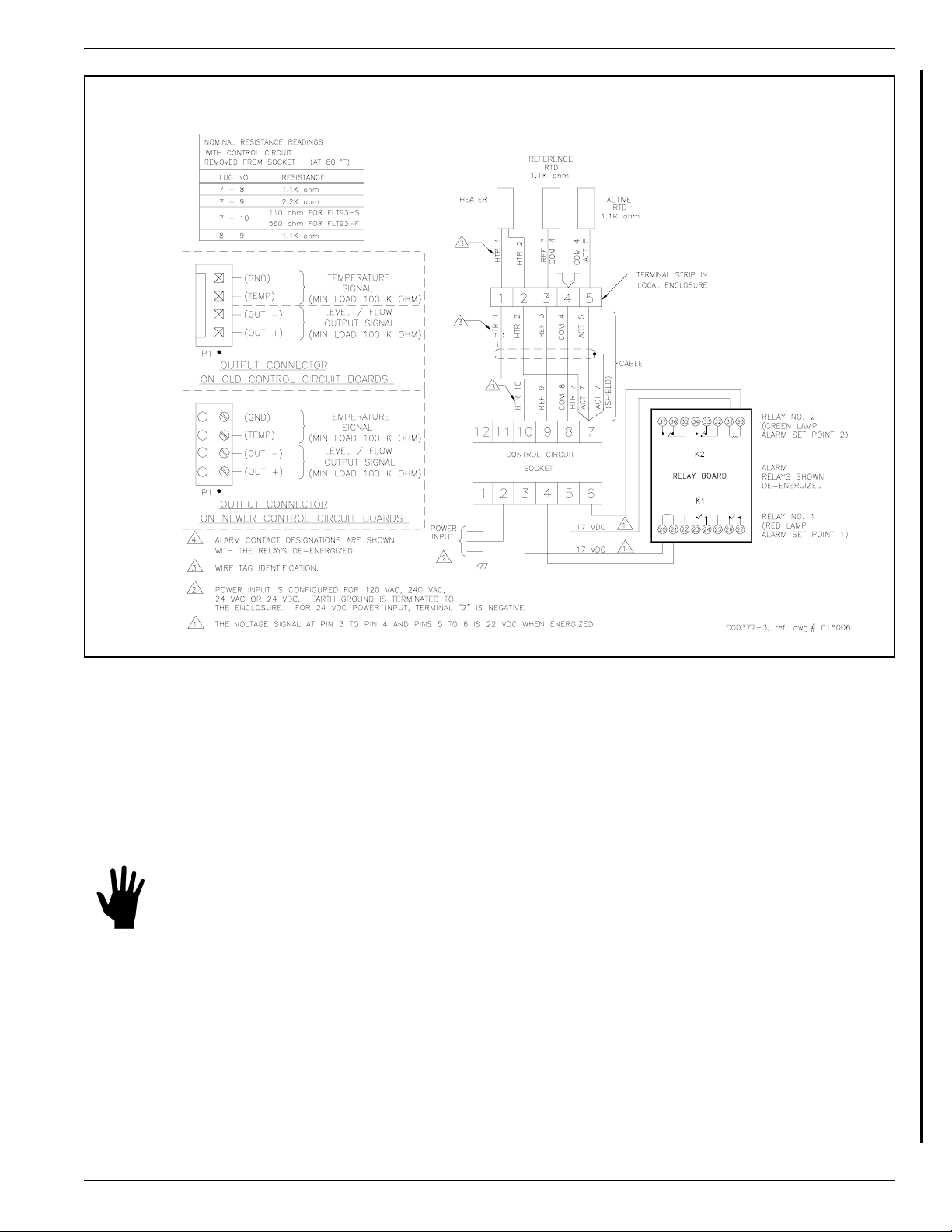

Figure 2-7. Auxiliary Relay Board Wiring Diagram

Wiring Remote Enclosure with Auxiliary Relay

Refer to the "Wiring the Remote Enclosure" section to run the cable between the local and remote enclosures. In

most cases the auxiliary relay board is in the same enclosure as the control circuit. Both boards are mounted on the

same panel and have been wired together at the factory. This configuration can be ordered without an enclosure

which can be supplied by the customer.

The alarm connections are made at the auxiliary relay board where each alarm is driving a DPDT relay.

Caution:

This configuration uses a control circuit that provides a switching voltage signal instead of relay contacts. The

switch voltage is wired from the control circuit socket to the auxiliary relay board actuating the relays.

The auxiliary relay board has several relay options that can be ordered. The options are as follows:

Do not connect any loads to the control circuit socket. Damage will occur to the control circuit if the

alarm circuit is energized.

Be sure the correct relay board has been ordered for the correct output. See the following paragraph.

• Dry to 2 amps at 115 Vac or 28Vdc, Dry to 1 amp at 230 Vac (relay is enclosed in a plastic sealed cover).

• 100mA to 10mA at 115 Vac or 28Vdc, 50mA to 3 amps at 230 Vac (relay is enclosed in a plastic sealed cover).

• Dry to 0.5 amps at 115 Vac, hermetically sealed relay.

Doc. No. 06EN003246 Rev. B 2 - 7 FLTÔ Series FlexSwitchÔ

Page 18

FLUID COMPONENTS, INTL CHAPTER 2 - INSTALLATION

Make sure that the proper relays have been selected for the intended load. See Appendix A for the auxiliary relay

board configuration drawing.

When connecting the relay wiring, do so with complete understanding of what the process requires of the instrument.

The instrument has dual DPDT or single 4PDT relay output contacts dependent on the jumper configuration for each

alarm switch point. For the relay logic, refer to Figure 2-5. Also refer to Table 3-5 and Table 3-6 in

Chapter 3 - Operation. Relay contacts are shown with the relays de-energized. Wire in accordance with the system

requirements.

The control circuit can be ordered with switching voltage outputs without ordering a relay board. This can be used

with customer supplied relays or any other device that has a differential input. The output voltage is 17 Vdc and will

drive a load as low as 1500 ohms. Refer to Figure 2-7 for the output terminals.

Wiring A Remote Control Circuit To An Auxiliary Relay Board

1. Run a four-conductor cable from the control circuit to the auxiliary relay board if the board was not factory

installed. Use the wiring diagram in Figure 2-7 to wire the boards together.

2. Attach the customer wiring as desired using Figure 2-7 as a wiring guide.

Wiring for this configuration is the same as the sensing element wiring to the control circuit on a remote instrument.

Wiring Output Signal Terminals

Two output signals are provided on the control circuit at P1. The signal voltage at positions 1 and 2 represents the

process change. The signal voltage at positions 3 and 4 is proportional to the temperature at the sensing element.

See Figures 2-5 through 2-7. See also Chapter 3 for the physical layout of the control circuit.

Caution:

Do not ground terminal 2 of P1. (Terminal 2 is the negative lead of the process signal.) This terminal

is 9 volts above the control circuit ground. The peripheral using this signal must have a differential

input.

These voltages can be used by other peripherals with a minimum load of 100K ohms. The terminal block can be

wired with between gauge 26 and 18 wire (22 gauge wire is normally used). The maximum recommended length of

wire is 1000 feet. Shielding is required on any length of cable. The shield must be terminated at position 4 on P1.

Early versions of the FLT93 require a connecting harness that was supplied with each instrument. The harness can

be ordered if it is missing. The FCI part number is 015664-01. Newer versions of the FLT93 require a supplied

terminal plug.

FLTÔ Series FlexSwitchÔ 2 - 8 Doc. No. 06EN003246 Rev. B

Page 19

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

3. Operation

Caution: The control circuit contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions

when handling the control circuit. See Chapter 2, Operation, for ESD details.

Factory Default Jumper Configuration

Unless a custom factory setup or calibration is specified, the instrument is delivered in a standard factory

configuration. The standard default jumper configuration is shown in Table 3-1.

Table 3-1. Standard Jumper Default Configuration

rewoPtupnI.)6Jdna5J,2J(caV032

S-39TLF

rewoPretaeH

F-39TLF

smralAforebmuN.stcatnocTDPSfotesenosahmralahcaE.)32J(owT

DELdeR1.oNmralA

62R.toPtnioPteS

neerG2.oNmralA

.toPtnioPteSDEL

52R

)31J(

)41J(

.)72J(tewrowolf

.)52J(erutarepmetwoleb

:yletamixorppatatniopteS

,erutarepmetdradnatsrof)C121(F052

,erutarepmetmuidemrof)C062(F005

.snoitacilppaleveldiuqilroriarofsttaw57.0

.snoitacilppaleveldiuqilroriarofsttaw52.0

tadezigreneyaleR.)02J(slangislevelrowolfrotinomotteS

dezigreneyaleR.)91J(slangiserutarepmetrotinomotteS

.)ylnOS-39TLF(erutarepmethgihrof)C454(F058

If the order included custom factory setup and calibration, leave all settings alone. The instrument is ready for

service without changes.

If custom factory setup or calibration was not ordered, configure the control circuit using the jumper tables

(Tables 3-2 to 3-6) and then follow the set point adjustment section that is appropriate for the application.

Configuration Jumpers

If the order did not specify for the control circuit to be factory configured, the standard configuration can be changed

using Figure 3-1 and Table 3-2 though Table 3-6. The factory default configuration is shown as being underlined.

Heater Cut-Off

The 5294 control circuit has a heater cutoff switch that limits the skin temperature of the sensing element to a

temperature differential of approximately 150°F (66°C) above the process temperature. In the case where the

instrument is used as a gas flow switch, and the heater wattage is set too high, the temperature differential (DT)

between the RTDs may exceed the usable input range of the control circuit. The usable input range can also be

exceeded in the case where the instrument is used in liquid flow applications where the heater wattage is set at the

highest value, and when the sensing elements go dry. When the temperature differential is less than 150°F (66°C)

the heater automatically turns back on. The yellow power indicator LED (DS3) turns on and off with the heater for a

visual indication of the heater state. The LED will alternate between on and off until the condition iss corrected.

Doc. No. 06EN003246 Rev. B 3 - 1 FLTÔ Series FlexSwitchÔ

Page 20

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

Figure 3-1. 5294 Control Circuit Jumper Locations

The reason for operation in the above extreme conditions is that the input signal range is at the widest point making

the alarm set point adjustment easier to perform. If the heater does cycle the operator may need to use the next lower

wattage setting.

In some applications it is desirable to set the heater wattage high, even though the sensing element goes into the

heater cutoff mode. An example is when the instrument is used to detect the interface of two liquids. These liquids

may have viscosities that will have signals very close to each other. In order to have the maximum signal difference

between the signals the heater wattage is set to its maximum. If the sensing element detects a dry condition the

control circuit will indicate a heater cutoff condition. The sensing element will not be dammaged if it is left dry with

the maximum heater wattage. The alarms can be set so one alarm will switch at the interface and one alarm can

detect when the element goes dry.

Alarm Set Point Adjustments

Numerical Adjustment Versus Adjustment by Observation

An alarm set point is established using either numerical adjustment or adjustment by observation. The adjustment by

observation requires the customer to establish normal process operation and adjust the alarm set point relative to this

condition. The numerical approach requires measuring normal and alarm process conditions with a voltmeter and

setting up the instrument in the calibrate mode based on these values. The adjustment by observation requires less

time to establish the alarm set point. The numerical adjustment requires control of the process as well as additional

time to establish the alarm set point. Use the adjustment procedure that is the most appropriate for the application

requirement.

FLTÔ Series FlexSwitchÔ 3 - 2 Doc. No. 06EN003246 Rev. B

Page 21

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Table 3-2. Input Power

Table 3-4. Application

REPMUJ

1JNITUOTUOTUO

2J

3JNITUOTUOTUO

4JTUOTUONITUO

5J

6J

7JTUOTUOTUONI

8JTUOTUOTUONI

9JTUOTUONITUO

CAV031-001CAV062-002CAV62-81CDV03-12

TUONITUOTUO

NINITUOTUO

TUONININI

TCELESREWOP

Table 3-3A. Selectable Heater Wattage Control

REPMUJ23J21J*31J*41J33J

TNEMELEF-39TLF

EGATTAW

)RTHMHO065(

TNEMELES-39TLF

EGATTAW

)RTHMHO011(

75.0

STTAW

3

STTAW

25.0

STTAW

57.1

STTAW

94.0

STTAW

57.0

STTAW

LEVEL/WOLF.PMET

1.ONMRALA02J

12J

2.ONMRALA81J91J

Table 3-5. Relay Energization

REPMUJ

1.ONMRALA

72J

62J

2.ONMRALA

52J

02.0

72.0

FFO

STTAW

FFO

STTAW

42J

Table 3-6. Relay Contact Configuration

WOL,WOLFWOLHTIWDEZIGRENE-EDYALER

.ERUTAREPMETHGIHRO)YRD(LEVEL

HGIH,WOLFHGIHHTIWDEZIGRENE-EDYALER

ERUTAREPMETWOLRO)TEW(LEVEL

WOL,WOLFWOLHTIWDEZIGRENE-EDYALER

.ERUTAREPMETHGIHRO)YRD(LEVEL

HGIH,WOLFHGIHHTIWDEZIGRENE-EDYALER

.ERUTAREPMETWOLRO)TEW(LEVEL

*J13 is standard for FLT93-S and

J14 is standard for FLT93-F.

Table 3-3B. Fixed Heater Wattage Control

REPMUJ31J41J33J

TNEMELEF-39TLF

EGATTAW

)RTHMHO065(

TNEMELES-39TLF

EGATTAW

)RTHMHO011(

.A.N

57.0

STTAW

02.0

STTAW

.A.NFFO

Numerical Alarm Set Point Adjustment

The control circuit has two mutually exclusive alarms; they are identified as Alarm No. 1 and Alarm No. 2. Each has

an alarm set point adjustment potentiometer and LED indicator. Both alarms can be setup for one of three

applications; flow, level/interface, or temperature. The following application specific adjustment procedures are

generic and can be used for setting either or both alarms. Use Figure 3-2 to help locate the important setup

components (potentiometers, LEDs, etc.).

32J )MRALAREPYALERENO(TDPSLAUD

22J)2.ONMRALASELBASID(TDPDELGNIS

FFO

Doc. No. 06EN003246 Rev. B 3 - 3 FLTÔ Series FlexSwitchÔ

Page 22

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

Air/Gas Flow Applications

Figure 3-2. 5294 Control Circuit Component Locations

1. Remove the instrument's enclosure cover.

2. Ensure the configuration jumpers on the control circuit are correct for this application. See Tables 3-3

through 3-6.

3. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

4. Apply power to the instrument. Verify the yellow LED is on and allow the instrument fifteen minutes to

warm-up.

5. Verify the mode switch is in the RUN position.

6. Attach a DC voltmeter to the P1 terminal block with the positive (+) lead to position one and the negative (-)

lead to position two.

Note:

The terminal block can be unplugged from the control circuit to facilitate easy connections. The terminal

block is used in late production instruments. Early production instruments used a mating cable and

connector. If a cable and connector are required use FCI part number 015664-01 to order.

7. Establish the normal process flow condition and allow the signal to stabilize.

Note:

The output signal at connector P1 will vary inversely with changes in the process flow rate. The output

signal level is relative to the type of process media being measured and the heater wattage setting. See

Figure 3-3.

FLTÔ Series FlexSwitchÔ 3 - 4 Doc. No. 06EN003246 Rev. B

Page 23

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Figure 3-3. Flow Application Signal Output

8. Record the normal flow signal value.

Normal Flow Signal = ________ volts DC

9. Follow either the Detecting Decreasing Flow or the Detecting Increasing Flow procedure for each flow

application alarm.

Detecting Decreasing Flow (low flow alarm)

1. Stop the process flow and allow the signal to stabilize.

2. Record the no-flow signal. (The no-flow signal should be greater than the normal flow signal.)

No-Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and no-flow output signals. (i.e.; If the normal

signal is 2.000 volts and the no-flow signal is 5.000 volts, then the calculated set point would be 3.500 volts.)

4. Record this value.

Calculated Set Point = ________ volts DC

Note:

The calculated set point must be at least 0.020 volts greater than the normal signal to ensure that the alarm

will reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No.2)

slowly clockwise just until the LED turns on .

OR

If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

counterclockwise until the LED turns off and then slowly clockwise just until the LED turns on.

8. If this is the only flow application alarm to be setup, then skip to the Continue With the Air/Gas Flow

Procedure.

Doc. No. 06EN003246 Rev. B 3 - 5 FLTÔ Series FlexSwitchÔ

Page 24

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

Detecting Increasing Flow (high flow alarm)

1. Establish the excessive process flow condition and allow the signal to stabilize.

2. Record the high flow signal. (The high flow signal should be less than the normal flow signal.)

High Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and high flow output signals. (i.e., If the

normal signal is 2.000 volts and the high flow signal is 1.000 volts, then the calculated set point would be 1.500

volts.)

4. Record this value.

Calculated Set Point = ________ volts DC

Note:

The calculated set point must be at least 0.020 volts less than the normal signal to ensure that the alarm will

reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is on, turn the set point adjustment potentiometer ( R26 for alarm No. 1 or R25 for alarm No. 2)

slowly counterclockwise just until the LED turns off.

OR

If the LED is off, turn the set point adjustment potentiometer ( R26 for alarm No. 1 or R25 for alarm No. 2)

clockwise until the LED turns on and then slowly counterclockwise just until the LED turns off.

Continue With the Air/Gas Flow Procedure

1. Slide the mode switch to the RUN position.

2. Establish the normal process flow condition. For low-flow alarm setups, the status LED should be off. For high

flow alarm setups, the status LED should be on.

3. Establish the process alarm condition and monitor the voltmeter display.

4. When the output signal passes through the calculated set point value, the status LED should turn on for low-flow

alarms, off for high flow alarms, and the relay contacts should change state.

5. Reestablish the normal process flow condition. Both the LED and the relay contacts should reset.

6. Disconnect the voltmeter from P1.

7. Replace the enclosure cover.

Note:

The alarm can be set for a specific flow rate. Follow the Air/Gas Flow Application procedure up to step 7

except establish the specific flow rate rather than the normal flow. The output signal will be the set point

value. Determine whether the alarm should actuate with decreasing or increasing flow and skip to the

appropriate step 4 in Detecting Decreasing Flow or Detecting Increasing Flow, respectfully. Enter the

specific flow rate value as the set point. Then follow the Continue With the Air /Gas Flow Procedure steps.

The relay logic default configuration is set for the relay coil to be de-energized when the flow signal voltage

is greater than the set point value. (i.e., Assume that the normal process flow condition has been

established. In this state, the relay coil will be energized if the alarm has been set for low-flow detection

and de-energized if the alarm has been set for high flow detection.) A recommendation is to have the relay

coils energized when the process condition is normal. This will enable the alarm to close or open the

contacts in case of a power failure.

FLTÔ Series FlexSwitchÔ 3 - 6 Doc. No. 06EN003246 Rev. B

Page 25

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Wet/Dry Liquid Level Applications

1. Remove the instrument's enclosure cover.

2. Ensure the configuration jumpers on the control circuit are correct for this application. See Tables 3-3

through 3-6.

3. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

4. Apply power to the instrument. Verify the yellow LED is on and allow the instrument fifteen minutes to

warm-up.

5. Verify the mode switch is in the RUN position.

6. Attach a DC voltmeter to P1 with the positive (+) lead to position one and the negative (-) lead to position two.

Note:

The terminal block can be unplugged from the control circuit to facilitate easy connections. The terminal

block is used in late production instruments. Early production instruments used a mating cable and

connector. If a cable and connector are required use FCI part number 015664-01 to order.

7. Raise the process fluid level so the sensing element is wet.

8. Allow the output signal to stabilize and record the wet condition value.

Wet Condition Signal = ________ volts DC

Note:

The output signal at P1 is relative to the type of process media detected. See Figure 3-4.

9. Lower the process fluid level so the sensing element is dry.

10. Allow the output signal to stabilize and record the dry condition value. (The dry signal should be greater than

the wet signal.)

Dry Condition Signal = ________ volts DC

11. Determine the set point by calculating the average of the wet and dry output signals. (i.e., If the wet signal is

0.200 volts and the dry signal is 4.000 volts, then the calculated set point would be 2.100 volts.)

12. Record this value.

Calculated Set Point = ________ volts DC

Note:

The calculated set point must be at least 0.015 volts greater than the wet signal and 0.020 volts less than the

dry signal to ensure that the alarm will reset.

Figure 3-4. Level Application Signal Output

Doc. No. 06EN003246 Rev. B 3 - 7 FLTÔ Series FlexSwitchÔ

Page 26

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

13. Slide the mode switch to the CALIBRATE position.

14. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

15. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

16. Follow either the Detecting Dry Condition or the Detecting Wet Condition for each level application alarm.

Detecting Dry Condition (low level alarm)

If the status LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm

No. 2) slowly clockwise just until the LED turns on.

OR

If the status LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

counterclockwise until the LED turns off and then slowly clockwise just until the LED turns on.

Detecting Wet Condition (high level alarm)

If the status LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

slowly counterclockwise just until the LED turns off.

OR

If the status LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm

No. 2) clockwise until the LED turns on and then slowly counterclockwise just until the LED turns off.

17. Slide the mode switch to the RUN position. The status LED should be on if the sensing element is dry and off if

the sensing element is wet.

18. Monitor the voltmeter display while raising or lowering the process fluid level. When the output signal passes

through the set point, the status LED should change states and the relay contacts should change state.

19. Reestablish the normal level condition. Both the LED and relay contacts should reset.

20. Disconnect the voltmeter from P1.

21. Replace the enclosure cover.

Note:

The relay logic default configuration is set for the relay coil to be de-energized when the level signal is

greater than the set point value. (i.e., The relay coil will be de-energized when the sensing element is dry.)

A recommendation is to have the relay coils energized when the process condition is normal. This will

enable the alarm to close or open the contacts in case of a power failure.

Temperature Applications

For temperature versus voltage values, see Table 3-7 located at the rear of this chapter. These values have an

accuracy of ±5°F (2.78°C). There is also a conversion formula later in this chapter to convert the temperature output

voltage to degrees fahrenheit. If a factory calibration chart was ordered look for it in the plastic page protector at the

back of this manual. Make sure the serial number of the chart matches the instrument to be adjusted.

1. Remove the instrument's enclosure cover.

2. Ensure the configuration jumpers on the control circuit are correct for this application. See Tables 3-3

through 3-6.

Caution:

If both alarms are to be used for temperature, then remove the heater control jumper from the heater, control

header. The jumper may be stored on the control circuit by plugging it across J12 and J14. Placing the

jumper here will not turn on the heater. If one alarm is for temperature and the other is for flow or level,

then set the heater power according to the application. Use alarm No. 2 for the temperature alarm. See

Table 3-3.

FLTÔ Series FlexSwitchÔ 3 - 8 Doc. No. 06EN003246 Rev. B

Page 27

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

3. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

4. Apply power to the instrument. Verify the yellow LED is on. Allow the instrument fifteen minutes to warm-up.

5. Verify the mode switch is in the RUN position.

6. Attach a DC voltmeter to P1 with the positive (+) lead to position 3 and the negative (-) lead to position 4.

Note:

The terminal block can be unplugged from the control circuit to facilitate easy connections. The terminal

block is used in late production instruments. Early production instruments used a mating cable and

connector. If a cable and connector are required use FCI part number 015664-01 to order.

7. Establish the normal process temperature condition and allow the signal to stabilize.

8. Record the normal temperature signal value.

Normal Temperature Signal = ________ volts DC

Note:

The output signal at connector P1 will vary proportionally with the process temperature.

9. Follow either the Detecting Increasing Temperature or the Detecting Decreasing Temperature procedure for

each temperature application alarm.

Detecting Increasing Temperature (high temperature alarm)

1. Slide the mode switch to the CALIBRATE position.

2. Adjust the calibrate potentiometer (R24) until the voltmeter equals the desired temperature signal in Table 3-7.

3. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

slowly clockwise just until the LED turns on.

OR

If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

counterclockwise until the LED turns off and then slowly clockwise just until the LED turns on.

If this is the only temperature application alarm to be setup, then skip to the Continue With the Temperature

Application procedure.

Detecting Decreasing Temperature (low temperature alarm)

1. Slide the mode switch to the CALIBRATE position.

2. Adjust the calibrate potentiometer (R24) until the voltmeter equals the normal temperature signal.

3. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

slowly counterclockwise just until the LED turns off.

OR

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

clockwise until the LED turns on and then slowly counterclockwise just until the LED turns off.

Continue With the Temperature Applications

1. Slide the mode switch to the RUN position.

2. Establish the normal process temperature condition. For the high temperature alarm setups, the status LED

should be off at normal temperatures. For the low temperature alarm setups, the status LED should be on at

normal temperatures.

Doc. No. 06EN003246 Rev. B 3 - 9 FLTÔ Series FlexSwitchÔ

Page 28

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

3. Establish the process alarm condition and monitor the voltmeter display.

4. When the output signal passes through the set point value, the status LED should turn on for high temperature

alarms, off for low temperature alarms, and the relay contacts should change state.

5. Reestablish the normal process temperature condition. The LED and relay contacts should reset.

6. Disconnect the voltmeter from P1.

7. Replace the enclosure cover.

Note:

The relay default configuration is for the relay coil to be de-energized when the temperature signal is greater

than the set point value. (i.e., Assume that the normal process temperature condition has been established.

In this state, the relay coil will be energized.)

Liquid Flow Applications

1. Remove the instrument's enclosure cover.

2. Check to make sure the input power jumpers match the power to be applied to the instrument. See Table 3-2.

3. As necessary, set the following control circuit configuration jumpers. See Tables 3-3 through 3-6.

Application: J20 or J18 (Flow/Level) for alarm No. 1 or No. 2, respectively.

Heater Power: J32 (3 watts for FLT93-S or 0.57 watts for FLT93-F).

4. Apply power to the instrument. Verify the yellow LED is on. Allow the instrument fifteen minutes to warm-up.

5. Verify the mode switch is in the RUN position.

6. Attach a DC voltmeter to P1 connector with the positive (+) lead to position one and the negative (-) lead to

position two.

Note:

The terminal block can be unplugged from the control circuit to facilitate easy connections. The terminal

block is used in late production instruments. Early production instruments used a mating cable and

connector. If a cable and connector are required use FCI part number 015664-01 to order.

The output signal at connector P1 will vary inversely with changes in the process flow rate. The output

signal level is also relative to the type of process media being measured. See Figure 3-3.

7. Establish the normal process flow condition and allow the signal to stabilize.

8. Record the normal flow signal value.

Normal Flow Signal = ________ volts DC

9. Follow either the Detecting Decreasing Flow or Detecting Increasing Flow procedure for each Liquid flow

application alarm.

Detecting Decreasing Flow (low flow alarm)

1. Stop the process flow and allow the signal to stabilize.

2. Record the no-flow signal. (The no-flow signal should be greater than the normal flow signal.)

No-Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and no-flow output signals. (i.e.; If the normal

signal is 0.080 volts and the no-flow signal is 0.300 volts, then the calculated set point would be 0.190 volts.)

4. Record this value.

Calculated Set Point = ________ volts DC

FLTÔ Series FlexSwitchÔ 3 - 10 Doc. No. 06EN003246 Rev. B

Page 29

CHAPTER 3 - OPERATION FLUID COMPONENTS INTL

Note:

The calculated set point must be at least 0.020 volts greater than the normal signal to ensure that the alarm

will reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

slowly clockwise just until the LED turns on.

OR

If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

counterclockwise until the LED turns off and then slowly clockwise just until the LED turns on.

8. If this is the only flow application alarm to be setup, then skip to Continue With the Liquid Flow Applications

procedure.

Detecting Increasing Flow Rate (high flow alarm)

1. Establish the excessive flow condition and allow the signal to stabilize.

2. Record the high flow signal. (The high flow signal should be less than the normal flow signal.)

High Flow Signal = ________ volts DC

3. Determine the set point by calculating the average of the normal and high flow output signals. (i.e.; If the

normal signal is 0.080 volts and the high flow signal is 0.030 volts, then the calculated set point would be 0.055

volts.)

4. Record this value.

Calculated Set Point = ________ volts DC

Note:

The calculated set point must be at least 0.020 volts less than the normal signal to ensure that the alarm will

reset.

5. Slide the mode switch to the CALIBRATE position.

6. Adjust the calibrate potentiometer (R24) until the voltmeter equals the calculated set point.

7. For the appropriate alarm, determine whether the status LED is on or off (red for No. 1 or green for No. 2).

If the LED is on, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

slowly counterclockwise just until the LED turns off.

OR

If the LED is off, turn the set point adjustment potentiometer (R26 for alarm No. 1 or R25 for alarm No. 2)

clockwise until the LED turns on and then slowly counterclockwise just until the LED turns off.

Continue With the Liquid Flow Applications

1. Slide the mode switch to the RUN position.

2. Establish the normal process flow condition. For low-flow alarm setups, the status LED should be off. For high

flow alarm setups, the status LED should be on.

3. Establish the process alarm condition and monitor the voltmeter display.

4. When the output signal passes through the calculated set point value, the status LED should turn on for low-flow

alarms, off for high flow alarms, and the relay contacts should change state.

5. Reestablish the normal process flow condition. Both the LED and the relay contacts should reset.

Doc. No. 06EN003246 Rev. B 3 - 11 FLTÔ Series FlexSwitchÔ

Page 30

FLUID COMPONENTS INTL CHAPTER 3 - OPERATION

6. Disconnect the voltmeter from P1.

7. Replace the enclosure cover.

Note:

The alarm can be set for a specific flow rate. Follow the Liquid Flow Application Procedure above to

establish the specific flow rate rather than the normal flow. The output signal will be the set point value.

Determine whether the alarm should actuate with decreasing or increasing flow and skip to the appropriate

step, 4 of either Decreasing Flow Rate or Increasing flow rate. Enter the specific flow rate value as the set

point and then follow the Continue With the Liquid Flow Application procedure steps.

The relay logic default configuration is set for the relay coil to be de-energized when the flow signal is

greater than the set point value. (i.e., Assume that the normal process flow condition has been established.

In this state, the relay coil will be energized if the alarm has been set for low-flow detection and deenergized if the alarm has been set for high flow detection.)

Adjustment by Observation

Note:

Flow Applications

The control circuit has two mutually exclusive alarms; they are identified as Alarm No. 1 and Alarm No. 2

and each has a set point adjustment potentiometer and LED indicator. Each alarm can be setup for one of

three applications: flow, level/interface, or temperature. The following application specific adjustment

procedures are generic and can be used for setting either or both alarms. The mode switch must be in the

RUN position. Use Figure 3-2 to help locate the adjustment potentiometers and LEDs.

1. Ensure that the instrument has been properly installed in the pipeline. Fill the pipeline so the sensing element is

surrounded by the process medium.

2. Apply power to the instrument and allow fifteen minutes for the sensing element to become active and stabilize.

3. Flow the pipeline at the normal or expected rate. Remove the enclosure cover to allow access to the control

circuit to make adjustments.

Detecting Decreasing Flow (low flow alarm)

If the status LED is off, turn the set point adjustment potentiometer clockwise until the LED turns on. With the LED

on, slowly turn the potentiometer counterclockwise one turn past the point at which the LED just turns off. The

potentiometer may have up to one-quarter turn of hysteresis, therefore, if the mark is overshot, the procedure should

be repeated.

Detecting Increasing Flow (high flow alarm)