Page 1

Fluid Components Intl

7. Commissioning

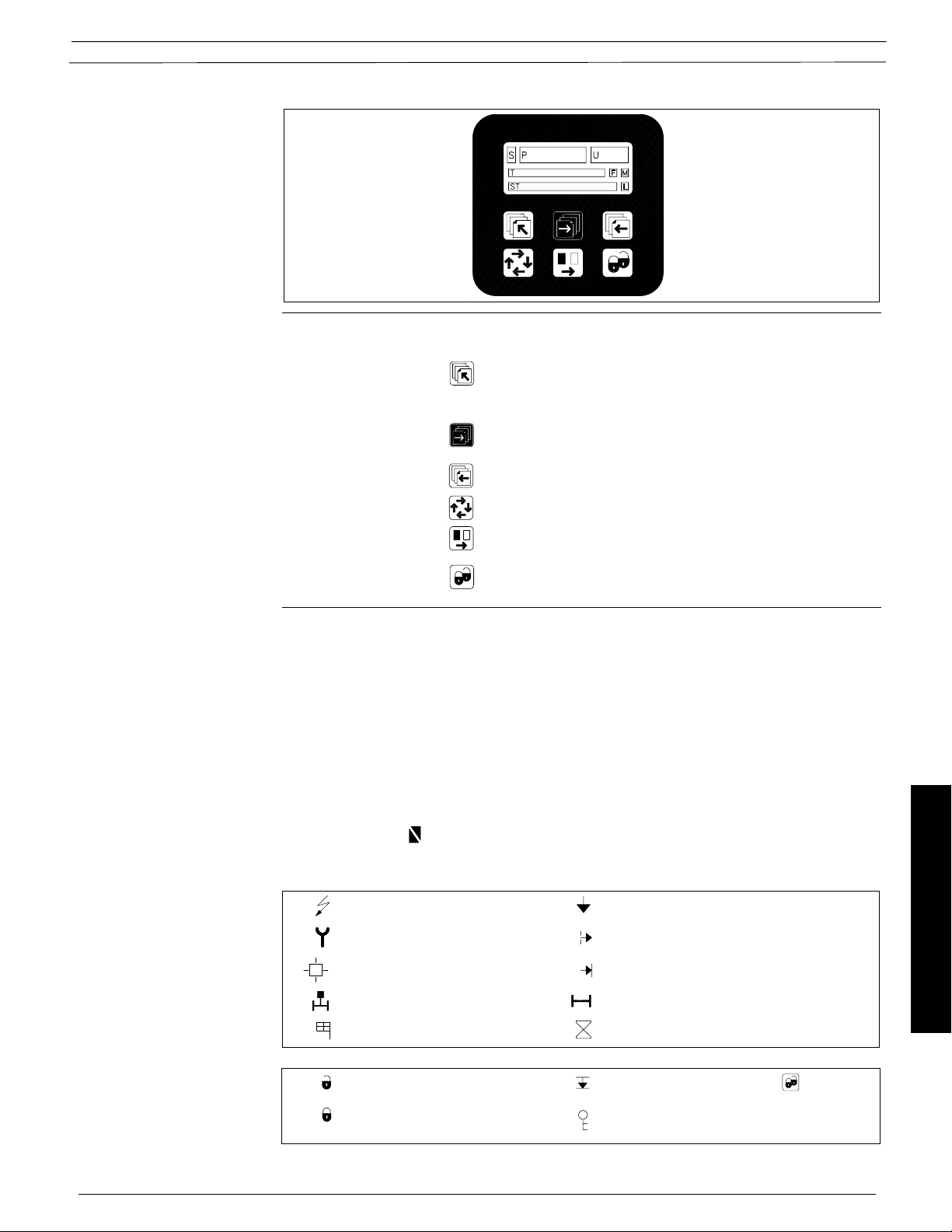

7.1 Keypad and display

layout

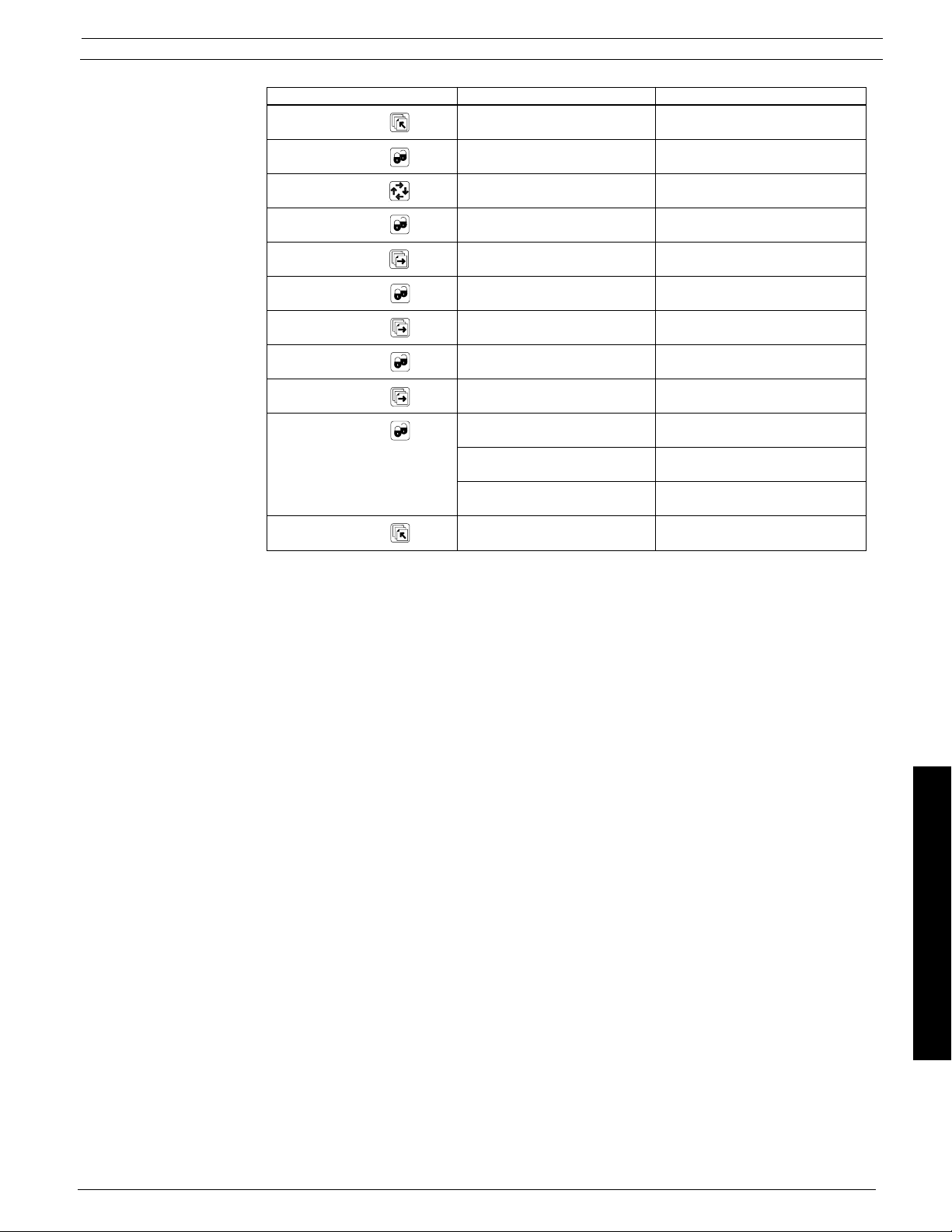

Keypad The keypad is used to set the flowmeter. The function of the keys are as follows:

Display

TOP UP KEY This key (hold 2 sec.) is used to switch between operator

menu and setup menu. In the converter setup menu, a short

press will cause a return to the previous menu.

FORWARD KEY This key is used to step forward through the menus. It is the

only key normally used by the operator.

BACKWARD KEY This key is used to step backward through the menus.

CHANGE KEY This key changes the settings or numerical values.

SELECT KEY This key selects the figures to be changed.

LOCK/UNLOCK KEY This key allows the operator to change settings and gives

access to submenus.

The display is alphanumerical and indicates flow values, flowmeter settings and error messsages.

The upper line is for primary flow readings and will always show either mass flowrate, volume

flowrate, density, temperature, totalizer 1 or totalizer 2. The line is divided into 3 fields.

S: Sign field

P: Primary field for numerical value

U: Unit field

The center line is the title line (T) with individual information according to the selected operator or

setup menu.

The lowest line is the subtitle line (ST) which either will add information to the title line or keep

individual information independent of the title line.

Document 06EN003327 Rev. -

F: The alarm field. Two flashing triangles will appear by a fault condition.

M: The mode field. The symbols indicate the following.

Communication mode Basic settings

Service mode Output

Operator menu External input

Product identity Sensor characteristic

Language mode Reset mode

L: The lock field. Indicates the function of the lock key.

Ready for change Access to submenu (Press )

Value locked RESET MODE: Zero setting of

51 FlexCOR

totalizers and initialization of setting

™ Model CMF Series

Commissioning

Page 2

Fluid Components Intl

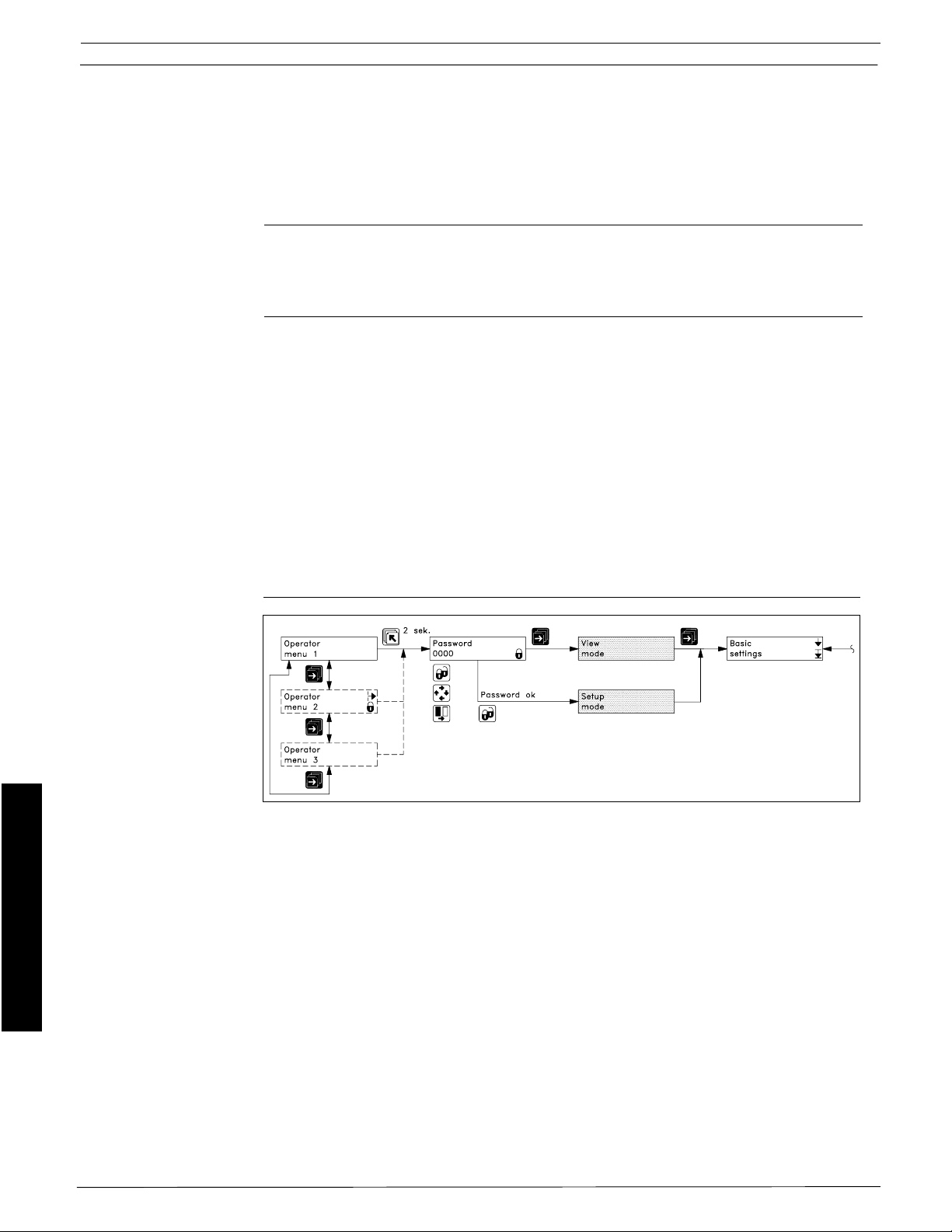

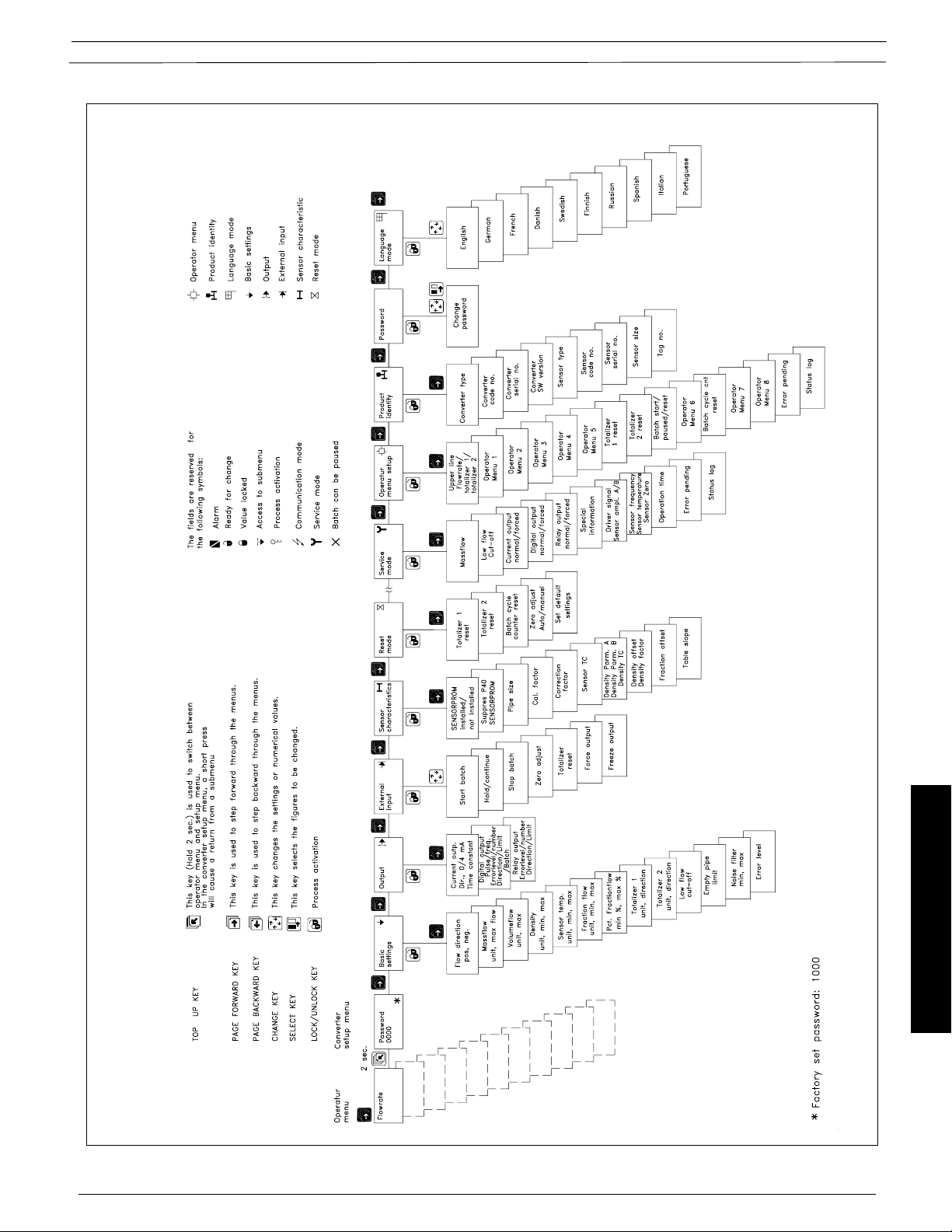

7.2 Menu build-up

The menu structure of a specific type of transmitter is shown in a menu overview map.

Details of how a specific parameter is set is shown in a menu detail map for the specific parameter.

The menu structure is valid for the title and subtitle line only. The upper line is for primary readings

only and will always be active with either mass flow rate, volume flowrate, density, temperature,

totalizer 1 or totalizer 2.

The menu is built up in two parts. An operator menu and a setup menu.

Operator menu

The operator menu is for daily operation. The operator menu is customized in the operator menu

setup. The signal converter always starts in the operator menu no. 1. The page forward and page

backward keys are used to step through the operator menus.

Setup menu

The setup menu is for commissioning and service only.

The setup menu is accessed by pressing the top up key for 2 seconds. The setup menu will operate

in two modes:

- View mode

- Setup mode

View mode is a read only mode. The pre-selected settings can only be scanned.

Setup mode is a read and write mode. The pre-selected settings can be scanned and changed.

Access to the setup mode is protected with a password. The factory set password is 1000.

Access to a submenu in the set up menu is gained by the lock key. A short press on the top up key

will bring back the previous menu. A long press (2 sec.) on the top up key will exit the setup menu

and bring back the operator menu no. 1.

7.2.1 Password

Commissioning

The SETUP MENU can be operated in two different modes:

VIEW MODE (Read only)

CHANGE MODE (Read and write mode)

The view mode is always accessed by pressing the forward key when in the password menu.

Access to change mode is protected by a user code. The user code is factory set to 1000, but can

be changed to any value between 1000 and 9999 in the change password menu.

The factory setting of 1000 can be re-established as follows:

- Switch off power suppply

- Press the TOP UP key while switching on the power supply

The user code is reset to 1000.

FlexCOR™Model CMF Series 52

Document 06EN003327 Rev. -

Page 3

Fluid Components Intl

Document 06EN003327 Rev. -

53 FlexCOR

Commissioning

™ Model CMF Series

Page 4

Fluid Components Intl

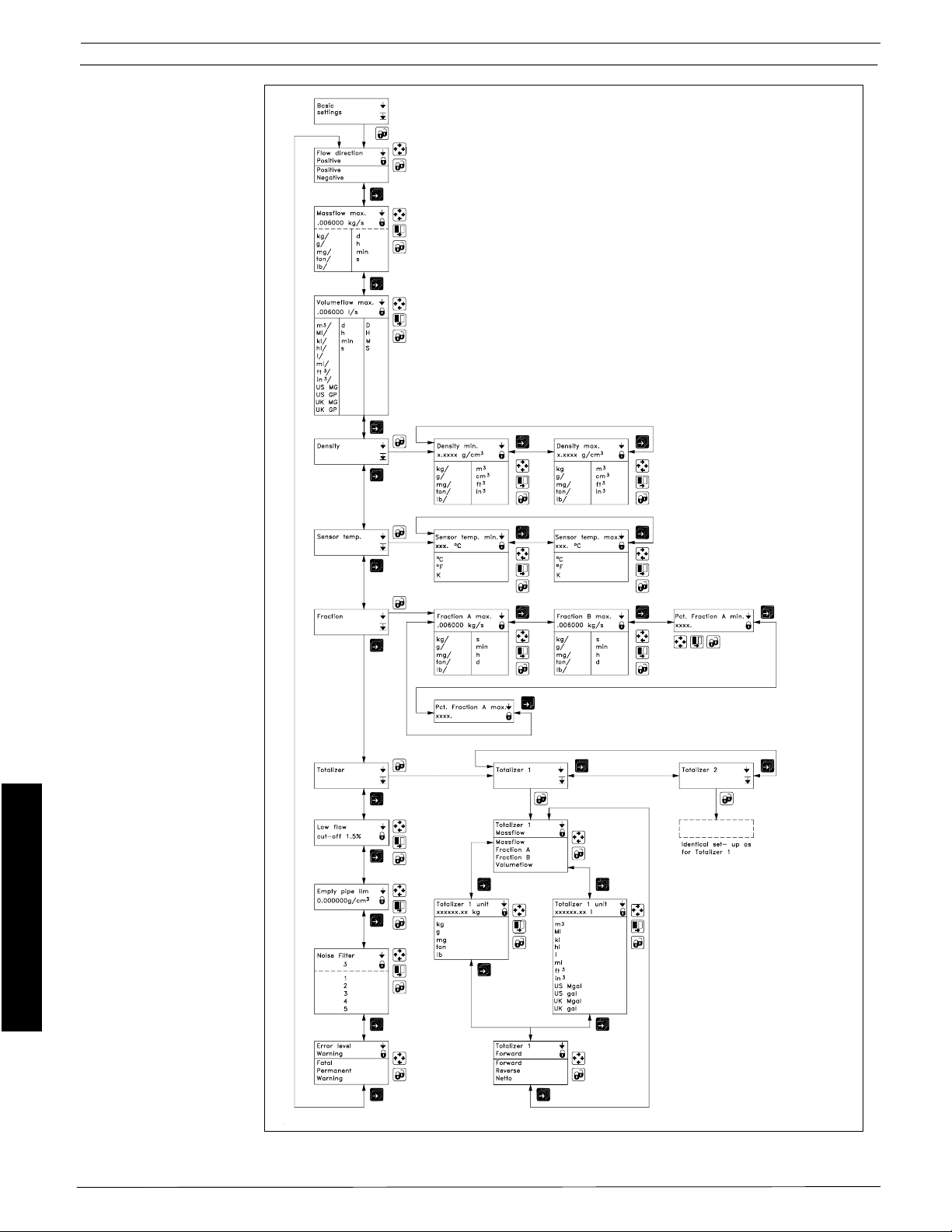

7.4 Basic settings

Menu detail

Commissioning

FlexCOR™Model CMF Series 54

Document 06EN003327 Rev. -

Page 5

Fluid Components Intl

Basic settings

Menu description

Setting of min./max.

values and units

Example; programming

of max. mass flow

The basic setting menu is used for basic configuration of the mass flow meter with a choice of units,

minimum and maximum limits for display and analog/digital outputs for all measurement

parameters, i.e. mass flow, volume flow, fraction, temperature and density.

Numerical values are entered by placing the cursor in the field that is to be set using the SELECT

key. Press unlock and the value can be changed using the change key. The desired value is locked

by activating LOCK.

Positioning of the decimal point is carried out by placing the cursor below the decimal point using

the SELECT key. The position can be set using the set key. The LOCK key is activated and the

decimal point is now positioned.

Selecting the unit: Place the cursor below the unit using SELECT key. Set the desired unit using

CHANGE key. Activate the LOCK key to save the setting. Place the cursor below the time scale

using SELECT key and choose the desired time scale using CHANGE, then save the desired value

by activating the LOCK key.

The maximum and minimum values set will then apply to all current and frequency/pulse outputs,

e.g. where the min. value will correspond to 0/4 mA depending on the setting of the current output

and the max. will correspond to 20 mA.

As example we want to change the default setting of the maximum mass flow on a CMF-A from

20 Kg/h to .45 lb/min.

Keypad operation Implementation Display on Transmitter

Push for 2 sec. To access the Password

user password 0000

Push once To unlock password CHANGE

0000

Push once To enter 1000 as CHANGE

password 1000

Push once To lock password and to CONV.SETUP MODE>

enter the menu Basic settings

Push once To enter basic setting Flow direction

submenu Positive

Push once To go to mass flow Massflow max.

max. setting 000020. kg/h

Push once To change num. Massflow max.

value 000020. kg/h

Push 4 times To move the cursor Massflow max.

to the num. position 000020. kg/h

Push Until 4 appears Massflow max.

000040. kg/h

Push once To move the cursor to Massflow max.

the next num. position 000040. kg/h

Push Till 5 appears Massflow max.

000045. kg/h

Push once To move the cursor to Massflow max.

the decimal point 000045. kg/h

Push To position the decimal Massflow max.

point correct 0000.45 kg/h

Push 3 times To move cursor Massflow max.

to "Kg" unit 0000.45 kg/h

Push twice To change units to lb. Massflow max.

0000.45Lb/h

Push once To move cursor to Massflow max.

the "h" unit 0000.45Lb/h

Push 3 times To change "h" to "min" Massflow max.

0000.45 Lb/min

Push To lock the new setting Massflow max.

of the mass flowmeter 000.45 Lb/m

Push twice Transmitter reverts to

standard operation

Commissioning

Document 06EN003327 Rev. -

55 FlexCOR

™ Model CMF Series

Page 6

Fluid Components Intl

Setting the totalizer

Setting the low-flow cut-off

Setting the empty pipe limit

Setting the noise filter

Setting the error level

The instrument is equipped with two independent totalizers that can be set for totalizing mass flow,

fraction A, faction B or volume.

Forward: only flow in a positive direction is totalized.

Reverse: only flow in a negative flow direction is totalized.

Net: the total net flow is measured.

In certain applications flow signals are not required below a given flow. In this menu a

0 to 10% cut-off of the maximum flow can be selected. By default the meter is set to 1.5%.

If detection of an empty pipe or of a density value is needed, it can be set under this menu option.

If the set density value is measured this will activate a relay or the digital output. In addition will

be recorded in the error log.

The instrument carries out signal processing internally using a patented FFT (Fast Fourier

Transformation) algorithm. This technology allows noisy sensor signals to be filtered. For

example, if the instrument is exposed to a strongly pulsating flow, varying pumping frequencies

or strong pressure gradient, etc. this can in certain cases result in noise on the pick-up signals,

with measurement error as a result. This measurement error can be reduced by increasing the

filtration under the menu option noise filter. Setting 5 represents the maximum possible filtration

and setting 1 represents the minimum possible filtration.

The instrument contains a particularly informative error monitoring system that the user can

configure according to need. The system is described in more detail in the section on error

handling.

Commissioning

FlexCOR™Model CMF Series 56

Document 06EN003327 Rev. -

Page 7

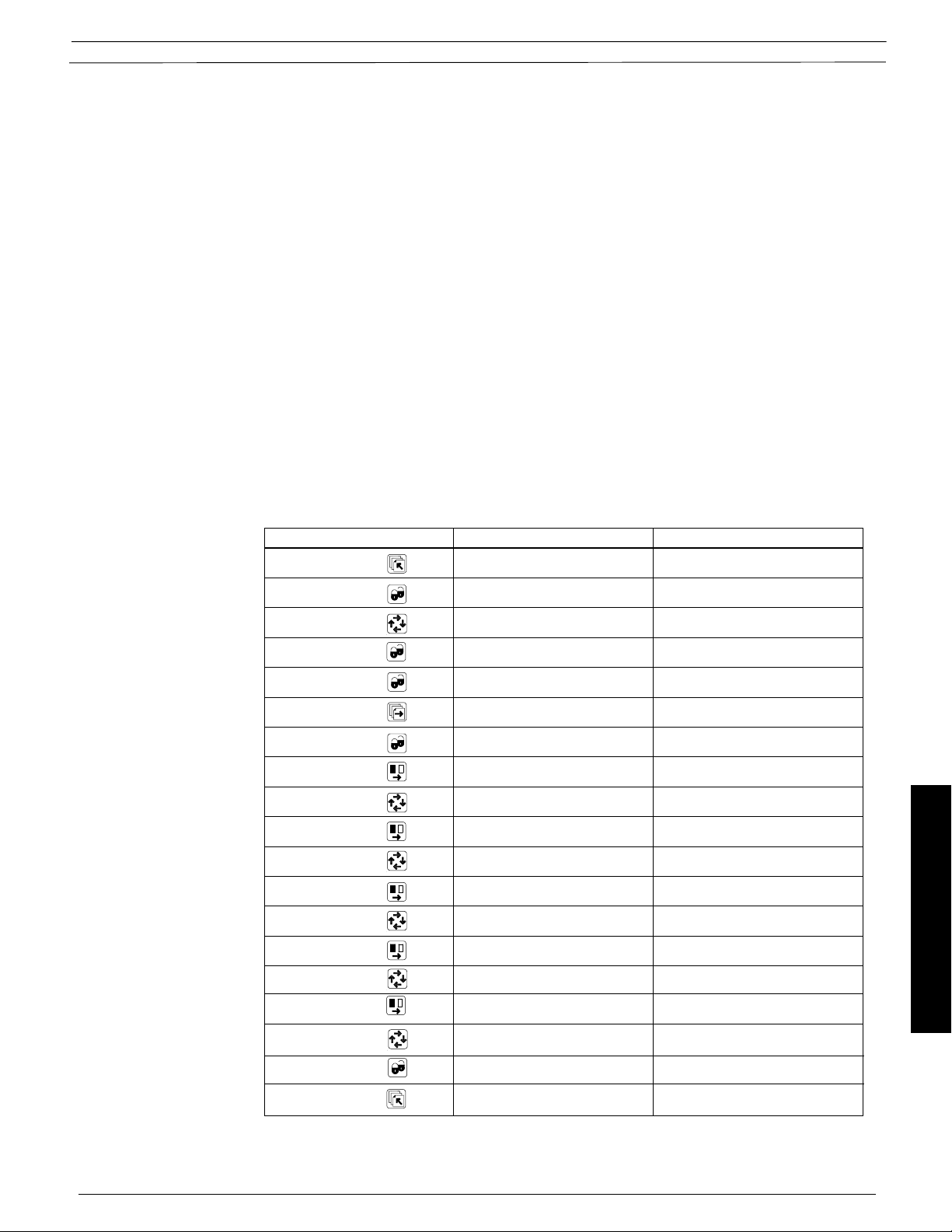

7.5.1 Outputs setting

menu

Current output

Fluid Components Intl

Menu detail

The current output should be set to off when not used, otherwise an error will be pending if the meter

detects an open loop.

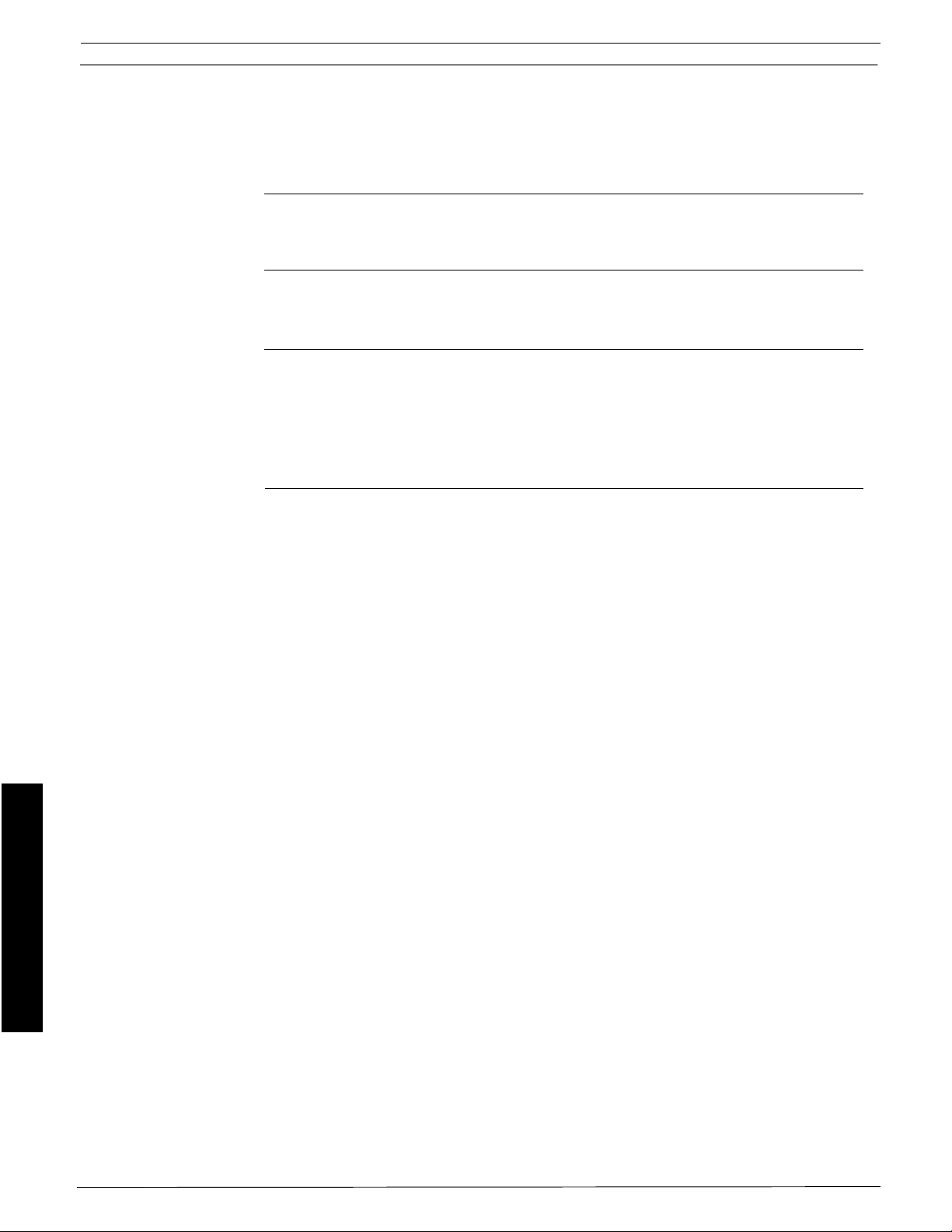

Digital output

Pulse

Digital output

Frequency

The digital output menu can be used for generating a frequency proportional output signal, for

pulse signal (totalizing), indicating error level/number, limit or flow direction or as batch output. Only

one function can be implemented for each output section.

Document 06EN003327 Rev. -

57 FlexCOR

Commissioning

™ Model CMF Series

Page 8

Fluid Components Intl

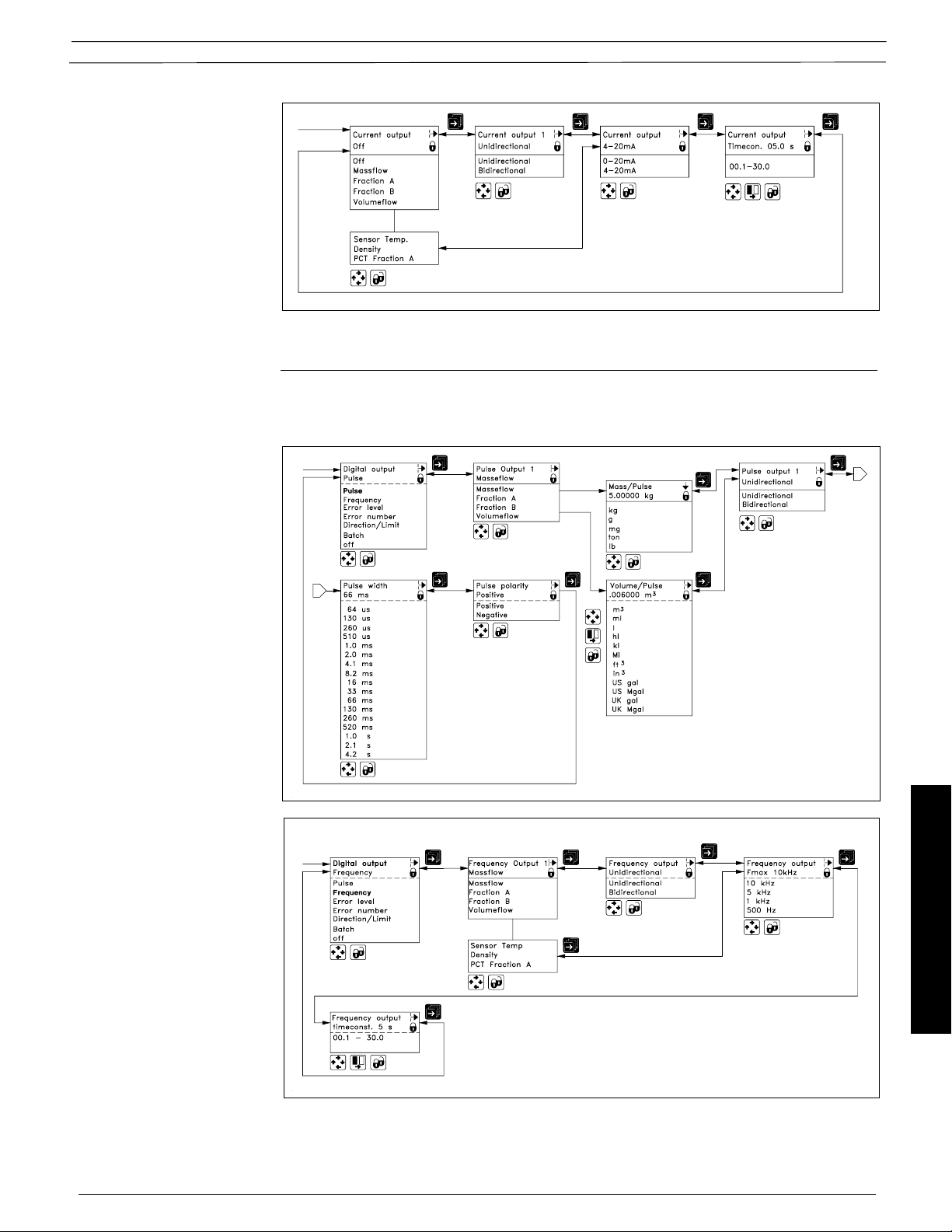

Digital output

Error level

Digital output

Error number

Digital output

Limit/direction

Menu detail

If the error statusis to be output at the digital output there

are two options. Select error level to output the system’s

current error status or error number if a specific error is

to be indicated by the digital output.

Both types of error message are described in more

detail in the section error system.

Acceptance level is set in the basic settings.

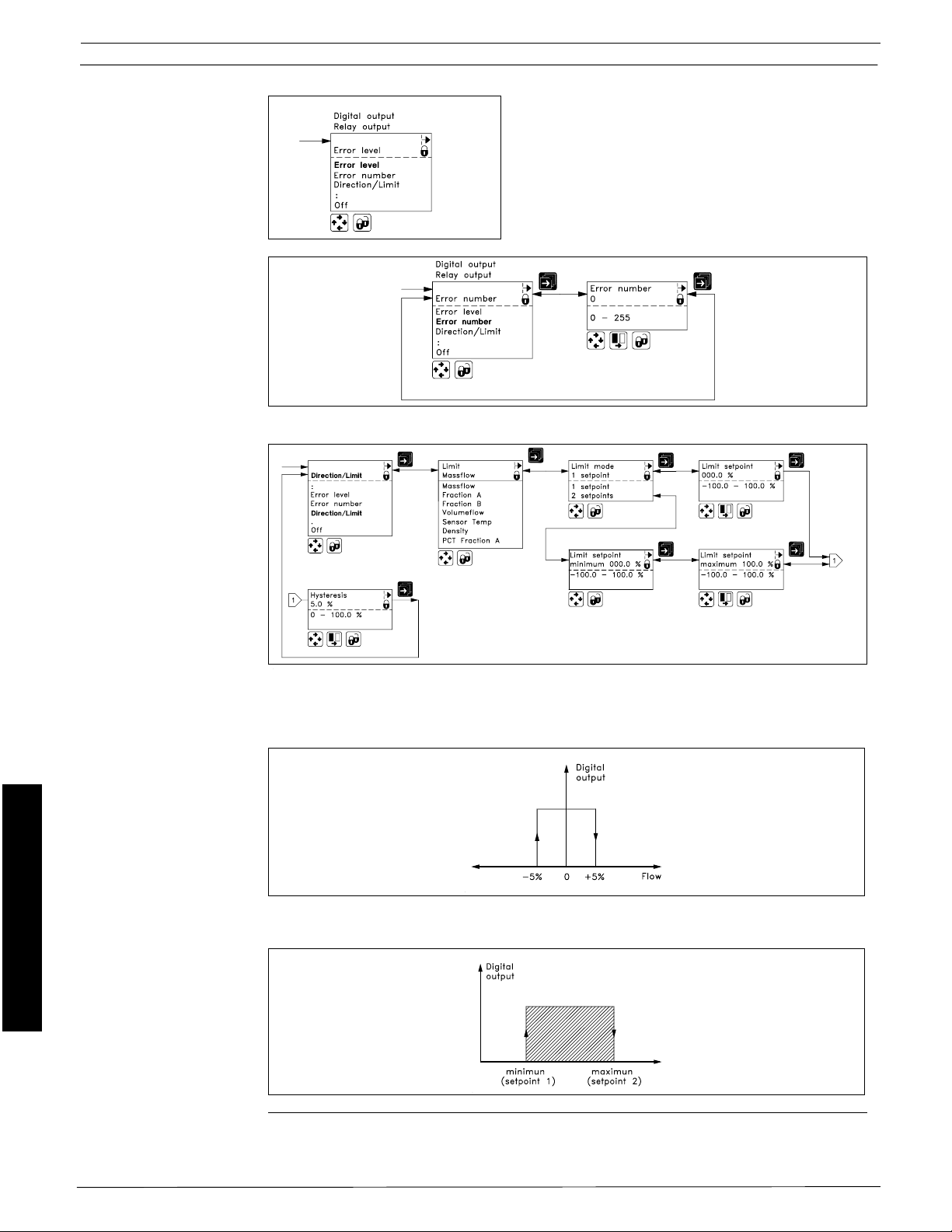

Digital output

Flow direction

1 set point

2 set points

Commissioning

2 separate set points

Limit switches are available for both digital and relay output and can be used for mass flow, fraction,

volume flow, temperature or density.

To set the output to show flow direction then select: 1 set point at 0% flow; hysteresis 5%.

To have a flow, temperature, density or fraction area monitored via the digital output then select

2 set points.

If 2 set points have to activate two separate outputs, each set point has to be selected individually

one for digital output and the other for relay output.

FlexCOR™Model CMF Series 58

Document 06EN003327 Rev. -

Page 9

Digital output

Batch menu

Fluid Components Intl

Menu detail

Batch

Menu description

Batch menu

Batching can be set to mass or volume. The desired quantity is called the batch quantity.

Batch compensation allows addition/subtraction of a fixed quantity in order to compensate for

valve delays, etc.

Compensation to be carried out dynamically, i.e. independently of the flow rate in the system, the

transmitter can calculate the system’s time constant – this is known as the lead const.

Batch time error is used to monitor that a batch is executed within the specified period, which is

set by max. batch time. If the batch is not completed within the time set an error message will output

by the Errorlog/pending.

Batch overrun error monitors that the quantity passing through the valve when it is closed does

not exceed the quantity set. This function can detect irregular valve function due to blockage, failure

to close due to wear, etc. The error is notified by the errorlog/pending function.

Batch counter is used to set the batch display. If up is selected the display counts from 0 up to

the selected batch quantity. If down is selected it counts down from batch quantity to 0 for each

batch. The operator can follow the progress when running in a batch application.

Commissioning

Document 06EN003327 Rev. -

59 FlexCOR

™ Model CMF Series

Page 10

Fluid Components Intl

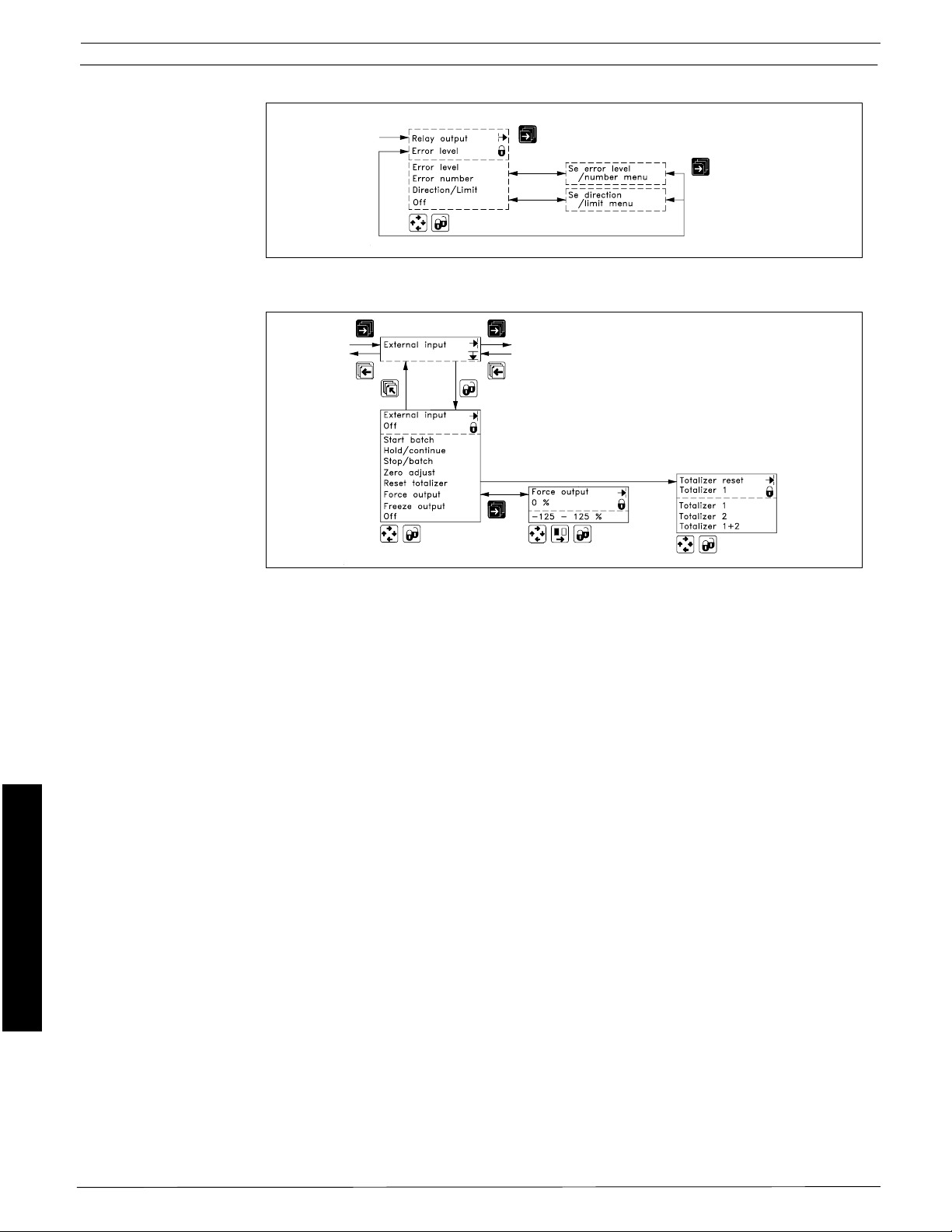

7.5.2 Relay output

7.5.3 External input

Menu detail

The output functions error level, error number and direction/limit can also be implemented on the

relay output. Programming of the realy output is identical as is the digital output.

Commissioning

External input menu

The transmitter has one digital input available. If the input is activated with a logic signal

(11 - 30 V d.c.) the meter carries out the activity selected under the menu option. The following

functions can be selected:

Start batch. If the transmitter is used for batching this can be activated automatically by this

function.

Hold/continue is also used in connection with batching and on being activated for the first time

will pause the batch. When activated again it will continue the batch.

Stop batch will stop the batch, i.e. the digital output goes to logic 0. The batch is then reset.

Zero adjust activates the automatic 0-point adjustment.

Reset totalizer can be used to reset internal totalizer 1, 2 or both.

Force output forces all outputs to adopt the value selected in the menu. For example, if 100% is

selected, this means that on activation of external output the current output will show 20 mA and

the frequency output will show 10,000 kHz if set to 0 - 10 kHz.

Freeze input freezes all the current measured values in the display and outputs.

FlexCOR™Model CMF Series 60

Document 06EN003327 Rev. -

Page 11

7.5.4 Sensor

characteristics

Fluid Components Intl

Menu detail

Correction factors

When the SENSORPROM® memory unit is installed only the parameters correction factor,

density offset, fraction offset and table slope can be changed.

If you wish to change the mass flow measurement a percentage shift can be set under the menu

option correction factor. The change affects all flow-related values.

If you wish to change the density measurement a percentage shift can be set under the menu option

density factor.

If an offset needs to be added to the density measurement this is done with density offset.

If the fraction flowmeter function is used it is possible to customize the function in accordance with

the following equation:

Fraction = Ax + B, where

A = Table slope

B = Fraction offset

x = Measured fraction

Commissioning

Document 06EN003327 Rev. -

61 FlexCor

™ Model CMF Series

Page 12

Fluid Components Intl

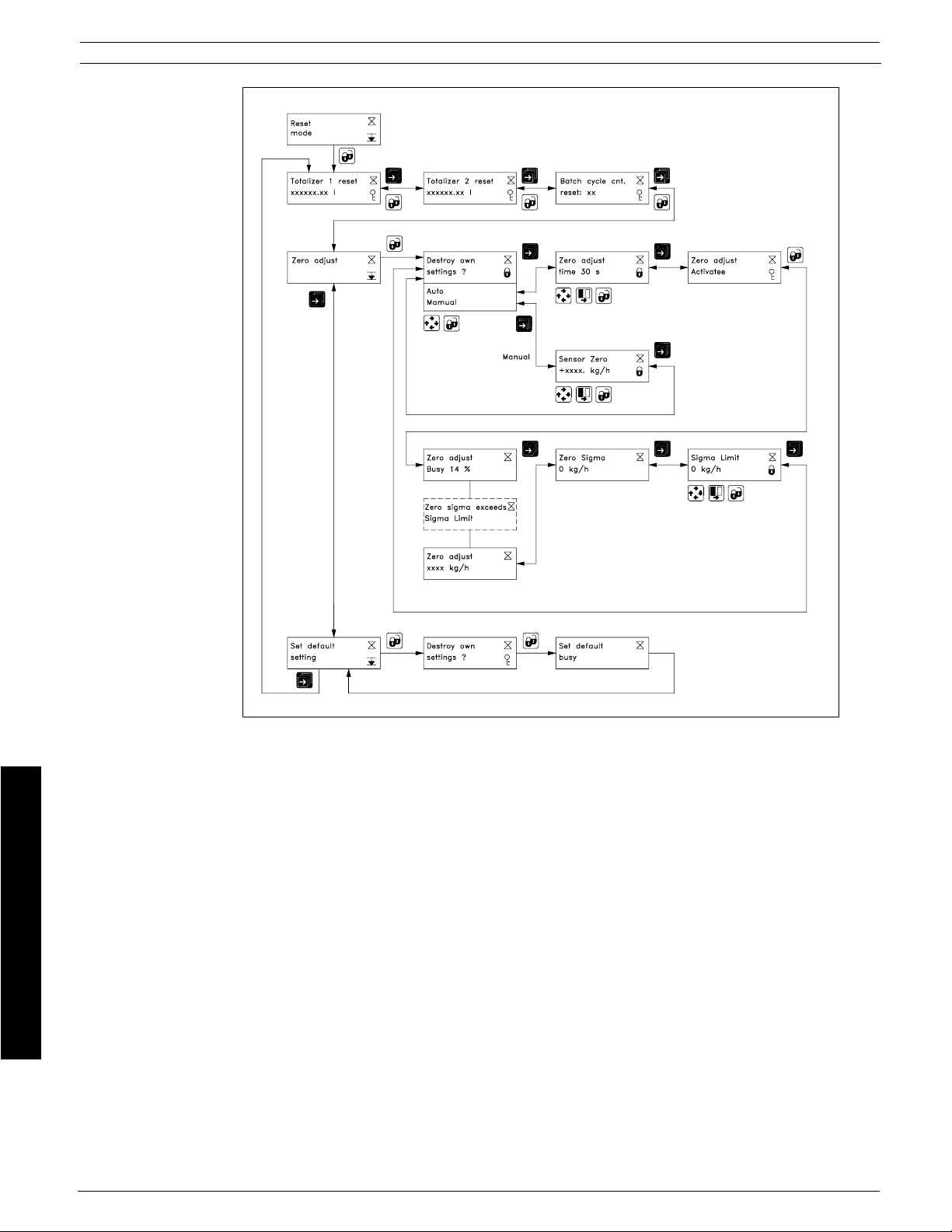

7.5.5 Reset mode

Menu detail

Reset mode

Menu description

Commissioning

Reset mode

In the reset mode menu the totalizer 1 and 2 and the batch cycle counter can be reset.

0-point adjustment

0-point adjustment of the flow meter is done in the zero adjust menu. The adjustment can be made

automatically where the meter measures and calculates the correct 0-point. In manual mode the

0-point can be programmed if this is known. Normally the automode is used.

Zero adjust time determines the period of time for the automatic 0-point adjustment. As default

a period of 30 sec. is used which normally is enough for a stable 0-point mesurement. If the

flowmeter is used where small flow rates are measured very accurately, a longer integration time

can be selected, to obtain better 0-point measurement.

Setting the 0-point is carried out by activating zero adjust. A number of individual 0-point

measurements are made. The 0-point found is shown as zero adjust. The value zero sigma

shows the standard deviation of the individual measurements made. The standard deviation (zero

sigma) must be within a window, which is pre-defined by Fluid Components Intl. This window is

called sigma limit. If the standard deviation is outside the window the following message is shown

in the display: “Zero sigma exceeds sigma limit”. In this case check the installation, ensure that

the pipe is full and that there is absolute 0-flow present. Then repeat the 0-point adjustment. The

new 0-point is automatically stored in the SENSORPROM

®

and will remain at power down

situations.

FlexCor™ Model CMF Series 62

Document 06EN003327 Rev. -

Page 13

Example; setting the

0-point

Fluid Components Intl

Keypad operation Implementation Display

Push for 3 sec. To access the Password

user password 0000

Push once To unlock password CHANGE

0000

Push once To enter 1000 as CHANGE

password 1000

Push once To lock password and to CONV.SETUP MODE>

enter the menu Basic settings

Push 4 times To go to reset Reset

mode menu mode

Push once To enter the reset Totalizer 1 reset

mode menu xxx. G

Push twice To go to zero Zero adjust

adjust menu

Push once To enter the zero Zero adjust

adjust menu Auto

Push twice To go to zero Zero adjust

adjust activation +xxxxxx kg/h

Push once To activate the 0-point Zero adjust

adjustment routine +xxxxxx kg/h

Transmitter preforms Counting up from 0

0-point adjustment to 100%

New 0-point is calculated Zero adjust

and stored in SENSORPROM

Push twice/ Transmitter reverts to

hold 3 sec. standard operation

â

+yyyyyy kg/h

Menu detail

Document 06EN003327 Rev. -

63 FlexCor

Commissioning

™ Model CMF Series

Page 14

Fluid Components Intl

7.5.6 Service mode

Menu detail

Commissioning

All previous settings are re-initialized when service mode is exited using the top up key.

The error system

The error system is divided into an error pending list and a status log list. Time is gained as days,

min. and hours since the error has occurred.

The first 9 pending errors are stored in error pending. When an error is removed it is removed from

error pending.

The last 9 errors are stored in the error log. When an error is removed it is still kept in error log. Errors

in error log is kept in 180 days.

Error pending and error log are accessible when enabled in the operator menu.

FlexCOR™Model CMF Series 64

Document 06EN003327 Rev. -

Page 15

Fluid Components Intl

Service mode

Menu description

Service mode

The service mode menu can be used to check the flowmeters operation or as diagnostic tools

for trouble shooting.

Flow rate indicates the actual flow rate in %, while tests are being conducted in SERVICE MODE.

Low flow cut-off can be used to supress fluctuating flow transients while experimenting.

Current output can be used to simulate a given flow, temperature, density signal etc. The feature

can be used to check/calibrate connected equipment. Under current output forced a value

between 0 and 24 mA can be set.

If 3 current outputs are used the function can also be used for identification of the individual outputs

by activating these in turn.

Digital output can also be simulated. If the output is selected as limit functions or batch a high or

low state can be simulated. If the digital output is used as flow, density or temperature output, a

signal of 1 to 12,500 Hz can be simulated.

Relay output is used to simulate the relay as on or off.

Special information is used for making diagnosis of the sensor function under the present

operating conditions. This makes it possible to reveal errors caused by errors in the sensor itself

or errors due to application conditions disturbing the sensor function.

Driver signal indicates the current which is necessary to drive the sensor. The driver current is

dependant of sensor size. In the table below the typical values for normal operation conditions are

displayed. The driver current will increase if there is damping in the application, such as air/gas

bubbles, hydraulic generated noise such as flow pulsations or dampning created by mechanical

noise such as vibrations. The driver output circuit can deliver 36 mA maximum.

Size Driver frq. [Hz] Driver current [mA]

CMF - A 120 12

CMF - B 110 7

CMF - C 135 15

CMF - D 165 15

CMF - E 125 10

CMF - F 125 12

Pick-up 1/2 amplitude indicates the signal level at the two pick-up’s. In normal operation

conditions the level should be greater than 50 mV. A lower value indicates damping in the system

and can be due to air/gas bubbles in the sensor.

The signal on pick-up 1 and 2 should be within the same value ±20 mV. A bigger difference

indicates noise in the system due to hydraulic or mechanical errous conditions.

Sensor frequency gives the resonant frequency of the sensor in Hz. The frequency is dependent

on dimension as well as the density of the liquid measured, see table below. Values more than

±20 Hz away of the values in the table indicate problems, check cabling, connection and operation

conditions.

Sensor temperature gives the actual temperature of the sensor. The function can be used to see

whether possible errors occur because the sensor is exposed to an excessively high temperature.

Futhermore, errors due to missing/wrong connection of the temperature transmitter between

sensor and converter can be detected.

Sensor zero can be used to check whether the zero point of the meter is satisfactory.

Operating time indicates how many days the signal converter has been in operation.

Commissioning

Document 06EN003327 Rev. -

65 FlexCOR

™ Model CMF Series

Page 16

Fluid Components Intl

7.5.7 Operator menu

setup

Menu setup

The upper line is always active and can never be deselected.

Commissioning

The two lower lines are for individual operator information. The forward key is used by the operator

to scroll through information.

- A closed lock key in the operator menu setup, means that the menu is enabled when viewing

the operator menu.

- A open lock key symbol, means that the menu is not available in the operator menu.

The middle line can either be used as a heading “Text line” for the lower line, or as a value reading.

A flow reading can be individually selected for each menu.

The lower line may be used for an additional flow reading to the reading already available in the

upper line.

FlexCOR™Model CMF Series 66

Document 06EN003327 Rev. -

Page 17

7.5.8 Product identity

7.5.9 Change password

Fluid Components Intl

Menu setup

Software version of add-on module is only available if the add-on module has been installed.

7.5.10 Language mode

Commissioning

Document 06EN003327 Rev. -

67 FlexCOR

™ Model CMF Series

Page 18

Fluid Components Intl

7.5.11 HART

communication

(Add-on module)

®

Menu setup

Commissioning

FlexCOR™Model CMF Series 68

Document 06EN003327 Rev. -

Page 19

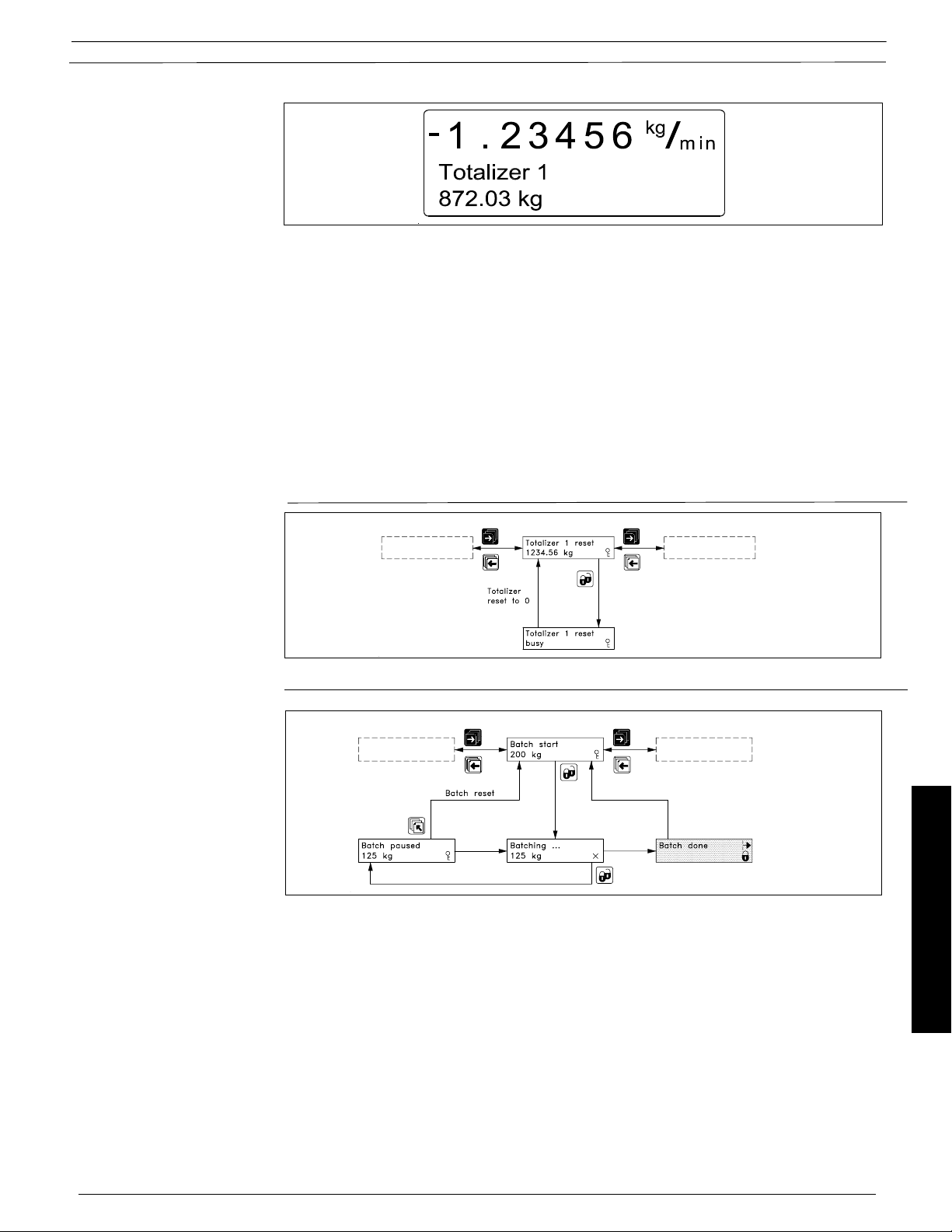

7.6.1 Operator menu

Flowrate

Fluid Components Intl

The 1st displayline will always be active and show the value enabled in the operator menu setup.

- Massflow rate, volumeflow rate, density, temperature, totalizer1, totalizer2

- Totalizer 2

nd

The 2

and 3th display lines are individually set in the operator menu. The page forward key steps

through the enabled settings.

- Mass flow rate

- Volume flow rate

- Density

- Temperature

- Totalizer

- Totalizer reset

- Batch control

- Batch cycle counter

- Batch cycle counter reset.

7.6.2 Totalizer

7.6.3 Batch

A totalizer is reset by pressing the lock key when the corresponding totalizer reset window is open.

A batch can be started, paused or stopped from the operator menu, in addition to the externally

operated batch control. The batch is controlled using the lock and the top up keys.

Commissioning

The lock key:

- Starts the batch

- Holds the batch (pause) when pressed during batching

- Continue the batch when pressed during a pause.

Batch cycle counter

Batch cycle counter reset

Document 06EN003327 Rev. -

The top up key resets a batch completely during a pause.

The accumulated number of performed batches can be viewed when enabled in the operator

menu setup.

The batch cycle counter is reset by pressing the lock key in the “batch cycle cnt reset” menu.

69 FlexCOR

™ Model CMF Series

Page 20

Fluid Components Intl

7.7.1 Parameters

Commissioning

Parameter Factory setting Settings available

Password

Password 1000 1000 – 9999

Basic settings

Flow direction Positive Positive, negative

Massflow max. Dim. dependent Dim. dependent

- Weight units Dim. dependent mg, g, kg, ton, lb

- Time units Dim. dependent s, min, h, d

Volumeflow max. Dim. dependent Dim. dependent

- Volume units Dim. dependent m3, ml, l, hl, kl, Ml, ft3, in3, US G, US MG,

UK G, UK MG

- Time units Dim. dependent s, min, h, d

Density

- Minimum +0.1 g/cm

- Maximum +2.0 g/cm

3

3

-20000.0 kg/m3 - +20000.0 kg/m

-20000.0 kg/m3 - +20000.0 kg/m

3

3

- Weight units g mg, g, kg, ton, lb

- Time units cm

3

cm3, m3, ft3, in

3

Sensor temp.

- Minimum -50 °C -250 °C - +250 °C

- Maximum +250 °C -250 °C - +250 °C

- Temperature units °C °C, °F, K

Fraction A/B max. Application dependent Application dependent

- Weight units kg mg, g, kg, ton, lb

- Time units h s, min, h, d

Totalizer 1 Mass flow Mass flow, fraction A, fraction B, volume flow

Forward Forward, reverse, net

Dim. dependent mg, g, kg, ton, lb

Totalizer 2 Volume flow Mass flow, fraction A, fraction B, volume flow

Forward Forward, reverse, net

Dim. dependent m3, ml, l, hl, kl, Ml, ft3, in3, US G, US MG,

UK G, UK MG

Low flow cut off 1.5 % 0 – 9.9 %

Empty pipe limit Dim. dependent -20000.0 g/cm3 - +20000.0 g/cm

3

Noise filter 3 1 (min.) to 5 (max.)

Error level Warning Fatal, permanent, warning

Output

Current output 1 O ff Mass flow, fraction A, fraction B, volume flow,

sensor temp., density, pct. fraction A, off

- Direction Unidirectional Unidirectional, bidirectional

- Output mode 4 – 20 mA 0 - 20 mA, 4 - 20 mA

- Time constant 5 s 0 – 30 s

Digital output 1 Pulse Pulse, frequency, error level, error number,

direction/limit, batch, off

Pulse Mass flow Mass flow, fraction A, fraction B, volume flow

- Amount/pulse Dim. dependent Dim. dependent

- Pulse polarity Positive Positive, negative

- Pulse width 66 ms 64 us, 130 us, 260us, 510 us, 1.0 ms, 2.0 ms,

4.1 ms, 8.2 ms, 16 ms, 33 ms, 66 ms, 130 ms,

260 ms, 520 ms, 1.0 s, 2.1 s, 4.2 s

Frequency Of f Mass flow, fraction A, fraction B,

volume flow, sensor temp., density, pct.

fraction A

- Direction Unidirectional Unidirectional, bidirectional

- Max. frequency 10 kHz 500 Hz, 1 kHz, 5 kHz, 10 kHz

- Time constant 5 s 0 – 30 s

Error number Off 0 - 255

FlexCOR™Model CMF Series 70

Document 06EN003327 Rev. -

Page 21

Fluid Components Intl

Direction/limit Of f Mass flow, fraction A, fraction B, volume flow,

sensor temp., density, pct. fraction A

- Limit mode 1 set point 1 set point, 2 set points

- Setpoint(s) 0 % (0/100 %) -100 – 100 %

- Hysteresis 5 % 0 – 100 %

Batch Mass, fraction A, fraction B, volume

- Quantity 5 kg , 5 l 0 – 9999999 kg, 0 – 9999999 l

- Compensation 0 kg , 0 lq -100000 – 100000 kg, -100000 – 100000 l

- Counter Down Up, down

Relay output 1 O ff Error level, error number, direction/limit, off

External input

External input Off Start batch, hold/continue (batch), stop batch,

zero adjust, totalizer reset, force output,

freeze output, off

Sensor characteristics

Correction factor 1 -99.999999 – 99.999999

Density offset 0 -9999.9999 – 9999.9999 kg/m

Density factor 1 -9.999999 – 9.999999

Fraction offset 0 -9999.9999 – 9999.9999 kg/h

Table slope 1 -9999.9999 – 9999.9999

3

Language English English, German, French, Danish, Swedish,

Finish, Spanish, Russian, Italian, Portugese

Operator menu

Primary field Mass flow Mass flow, volume flow, fraction A, pct. fraction

A, fraction B, totalizer 1, totalizer 2, sensor

temp., density

Title/subtitle line Mass flow Massf low, mass flow %, volume flow, volume

flow %, fraction A text, fraction A, fraction A %,

fraction B text, fraction B, fraction B %, pct.

fraction A, density, sensor temp, totalizer 1,

totalizer 2, batch cycle cnt.

7.7.2 Dimension-dependent factory setting

Sensor Mass flow Volume flow Pulse output & factory setting

type Factory Factory Mass Pulse Totalizer Volume Pulse Totalizer

setting Min. Max. setting Min. Max. pr. pulse unit pulse pr. pulse unit pulse

kg/h kg/h unit unit

CMF - A 20 125 20 125 1 g g 1 ml ml

CMF - B 75 - 500 75 - 500 1 g g 1 ml ml

CMF - C 300 - 2000 300 - 2000 10 g g 10 ml ml

CMF - D 1500 - 10000 1500 - 10000 1 kg kg 1 l l

CMF- E 7500 - 50000 7500 - 50000 1 kg kg 1 l l

CMF - F 25000 - 100000 25000 - 100000 10 kg kg 10 l l

Commissioning

Document 06EN003327 Rev. -

71 FlexCOR

™ Model CMF Series

Page 22

Fluid Components Intl

7.8.1 Error handling

Error system

The converter system is equipped with an error and status log system with 4 groups of information.

- Information without a functional error

- Warnings which may cause malfunction in the application. The cause of the error may

disappear on its own

- Permanent errors which may cause malfunction in the application.

- Fatal error which is essential for the operation of the flowmeter

2 menus are available in the service and operator menus for registration of information and errors

- Error pending

- Status log

Error pending

The first 9 standing errors are stored in “error pending”. When an error is removed it clears from

“error pending”.

The acceptance level for “error pending” can be individual configured to a particular application.

The acceptance level is set in the “basic setting” in the setup menu.

Acceptance levels

- Fatal error: Fatal errors are registered as errors

- Permanent errors (Permanent and fatal errors are registered as errors)

- Warning (Default value): Warnings, permanent and fatal errors are registered as errors

The error information is displayed in the title and subtitle line. The title line will show the time since

occurrence of error. The subtitle line will flash between an error text and a remedy text. The error

text will indicate type of error (I, W, P or F), error no. and the error text. The text will inform the operator

of the action to take to remove the error.

Commissioning

Status Log

Like “error pending” except that information, warnings, permanent and fatal errors are always

stored in the “status log”. The “status log” stores the last 9 message during the last 180 days.

Alarm field

The alarm field on the display will always flash with an error pending.

Error output

The digital and relay output can be individually activated by an error (error level). The relay output

is default selected to error level. An output can also be selected to activate on a single error number.

The alarm field, error output and error pending will always operate together.

The analog output will turn to a 1 mA level when in the 4-20 mA mode.

Operator menu

Error pending and status log are as default enabled in the operator menu.

FlexCOR™Model CMF Series 72

Document 06EN003327 Rev. -

Page 23

Fluid Components Intl

7.8.2 List of error

numbers

Error Error text #Comment Outputs Input

No. Remedy text status status

1 I1 - Power on

OK Power on has activated Active Active

2 I2 - Add-on Module

Applied A new module has been added to the system Active Active

3 I3 - Add-on Module An add-on module is defective or has been removed.

Install This can also be an internal add-on module Active Active

4 I4 - Param. corrected A less vital parameter in the converter has been

OK replaced by its default value Active Active

20 W20 - Totalizer 1 During initialization the check of the saved totalizer

Reset manually value has failed. It is not possible to rely on the

20 W20 - Totalizer 2 During initialization the check of the saved totalizer

Reset manually value has failed. It is not possible to rely on the

21 W21 - Pulse overflow Actual flow is too big compared with pulse width and Reduced

Adjust pulse settings mass/pulse pulse width Active

22 W22 - Batch timeout Duration of batching has exceeded a predefined Batch out-

Check installation max. time put on zero Active

23 W23 - Batch overrun Batch quantity has exceeded a predefined maximum Batch out-

Check installation overrun mass or volume put on zero Active

24 W24 - Batch neg. flow

Check flow direction Negative flow direction during batch Active Active

30 W30 - Flowsaturated

Adjust max. flow Flow is above Q

31 W31- Empty pipe Pipe is empty Zero Active

32 W32 - Temp. to high The temperature of the fluid has exceeded the max.

Adjust temperature temperature rating of the sensor (180 °C) Active Active

33 W33 - Temp. to low The temperature of the fluid has exceeded the min.

Adjust temperature temperature rating of the sensor (-50 °C) Active Active

34 W34 - Zero Adj. fail The zero-point adjustment values are outside the limit

Check flow = zero because there is not zero flow in the sensor. Check

35 W35 - Current Out 1 Current output exceeds 120%. Ensure that the sensor is

Check max. settings correctly sized and check max. flow setting Active Active

36 W36 - Freq/Pulse Out1 Freq/Pulse output exceeds 120%. Ensure that the sensor

Check max. settings is correctly sized and check max. flow setting Active Active

40 P40 - SENSORPROM

Insert SENSORPROM® unit not installed Active Active

41 P41 - Parameter range A parameter is out of range.

Switch off and on The error will disappear at the next power-on Active Active

42 P42 - Current output Current loop is disconnected or the loop resistance

Check cables is too big Active Active

43 P43 - Internal error Internal error

Switch off and on Active Active

49 P49 - Protec. viol. Too many errors occured at the same time.

Switch off and on Some errors are not detected correctly Active Active

50 P50 - Temp. cable Error in temperature sensor, check cables and

Check cable connectors Active Active

51 P51 - Pick-up 1 Pick-up 1 amplitude too low. Check cables or application

Check cable/install. for damping (air/gas in liquid) Active Active

52 P52 - Pick-up 2 Pick-up 2 amplitude too low. Check cables or application

Check cable/install. for damping (air/gas in liquid) Active Active

60 F60 - CAN comm. error CAN bus communication error. An add-on module, the

Converter/add-on module display module or the converter is defective Zero Inactive

61 F61 - SENSORPROM

Replace unit Active Active

62 F62 - SENSORPROM

Replace product ID. The SENSORPROM

63 F63 - SENSORPROM

Replace unit Active Active

70 F70 - Pick-up phase Check cables/polarity Active Active

71 F71 - Driver phase Check cables/polarity Active Active

80-83 F80, 81, 82, 83 - Internal error Restart or replace Active Active

84 F84 - Sensor level Pick-up amplitud saturated Active Active

97 F97 - Add-on module to old Replace Active Active

®

®

®

®

saved totalizer value. The totalizer value must be

reset manually in order to rely on future readings Active Active

saved totalizer. The totalizer value must be reset

manually in order to rely on future readings Active Active

settings Max. 120 % Active

max.

zeroflow conditions, valves, pumps etc. Active Active

err. It is not possible to rely on the data in SENSORPROM

ID The SENSORPROM® unit ID do not comply with the

type of product. Zero Inactive

It is not possible to read from the SENSORPROM

®

unit is from another

®

®

Commissioning

Document 06EN003327 Rev. -

Error code level:

W = Warning, F = Fatal, P = Permanent

73 FlexCOR

™ Model CMF Series

Page 24

Fluid Components Intl

8. Trouble shooting

8.1 Transmitter

Symptom Output Error Cause Remedy

signals code

Empty display Minimum 1. Supply voltage 1. Check supply voltage

2. Transmitter defective 2. Replace Transmitter

No flow signal Minimum 1. Current output deselected 1. Activate current output

2. Digital output deselected 2. Activate digital output

3. Reverse flow direction 3. Change direction

W31 Measuring pipe empty Ensure that the measuring

pipe is full

F60 Internal error Replace Transmitter

Undefined P42 1. No load on current output 1. Check cables/connections

2. Transmitter defective 2. Replace Transmitter

P41 Initializing error Switch off Transmitter, wait

5 seconds and switch on again

Indicates flow Undefined Measuring pipe empty Select empty pipe limit

with no flow Ensure that the measuring

in pipe pipe is full of liquid

Unstable Unstable 1. Pulsating flow 1. Increase time constant

flow signal

2. Air bubbles in medium 2. Ensure medium does not

contain air bubbles

3. Vibrations 3. Ensure that the sensor is

mounted on a rigid frame

without vibrations

4. Pump noise 4. Ensure that pump

frequency is different from

resonance frequency of

sensor

Measuring error Undefined Faulty zero-point Make new zero-point

adjustment

Loss of totalizer OK W20 Initializing error Reset totalizer manually

T. s.

data

FlexCOR™ Model CMF Series 74

P40 No SENSORPROM® unit Install SENSORPROM® unit

F61 Deficient SENSORPROM

unit

F62 Wrong SENSORPROM

unit

F63 Defective SENSORPROM

unit

F80-83 Loss of internal data Replace Instrument

Maximum W30 Flow exceeds 120% of Q

W21 Pulse overflow

· Mass/pulse too small Change mass/pulse

· Pulse width too large Change pulse width

®

Replace SENSORPROM® unit

®

Replace SENSORPROM® unit

®

Replace SENSORPROM® unit

max.

Check Q

(Basic Settings)

max.

Document 06EN003327 Rev. -

Page 25

Fluid Components Intl

8.2 Check for air in the

system

In case of large air collections non-homogenesously distributed in the sensor, the air in the liquid

can disturb the flowmeter and lead to incorrect measurement, whereas homogenesously

distributed air and solids will not disturb measurement.

1) 0-point unstable or exceeding limit (SIGMA LIMIT, refer to reset menu)

2) Measurement of mass flow rate incorrect ?

3) Output signal unstable

4) Error symbol on (type W31, W34, F70, F71)

If one or more of the above symptoms is observed, the cause can be that there is air in the liquid.

Air in the system can be checked through the following tests:

1. Use of Service Mode

Go to the service mode menu and read the values under the menu driver amplitude. Compare

the values with the table listed in section 7.5. If the current is higher than specified it might be

because there are air bubbles in the liquid.

2. Increase of pump pressure

Close the valve, if any, after the sensor. Start the pump and consequently increase the pump

pressure. If the 0-point becomes more stable there are non-homogenseously distributed air

bubbles in the system.

3. Connection of pick-up signals in parallel (only possible for 19“ versions)

The fault can also be found by connecting pick-up 1 and pick-up 2 in parallel. Move the leads on

terminal 85 to terminal 87 on the connection PCB. This will send the same pick-up signal into both

channels in the converter.

If the 0-point becomes more stable by one of the above mentioned examples the conclusion is

that there is air in the system which affects the flowmeter operation.

8.3 Check of 0-point

accuracy

Air generation souces

The air can typically be generated by the following causes:

1) Suction pressure of pump too low (pump cavitates)

2) Blocked filter or other obstruction ahead of sensor. This can produce cavitation and air

formation

3) Volatile liquid producing air bubbles at low pressure

4) Pressure in sensor too low because too low a pressure in the piping after the sensor

5) Incorrect location of sensor, refer to Chapter 4 "Installation of sensor".

Check whether the 0-point is within the accuracy specifications given by Fluid Components Intl.

Check as follows:

Go to the basic settings menu, set low flow cut-off to 0%. Go to totalizer 1, select bidirectional mode

and select massflow.

Go back to operator menu, reset the totalizer 1 (if selected in the operator menu, otherwise reset

the totalizer in the reset menu).

Go to totalizer 1 in the operator menu and monitor the value. The totalizer now displays the actual

0-point of the system. Read the totalizer value after 1 min. mutiply the value with 60, this will give

the value xxxx.x kg/h. This can for the sensor dimension in question be compared with the

specifications given under Section 2.3 “Meter uncertainty”, max. zero point error.

Document 06EN003327 Rev. - 75 FlexCOR™ Model CMF Series

T. s.

Loading...

Loading...