Page 1

CHAPTER 2 - INSTALLATION FLUID COMPONENTS INTL

2. Installation

Receiving/Inspection

• Unpack carefully.

• Verify that all items in the packing list are received and are correct.

• Inspect all instruments for damage or contaminants prior to installation.

If the above three items are satisfactory, proceed with the installation. If not, then stop and contact a customer

service representative.

Packing/Shipping/Returns

These issues are addressed in Appendix C - Customer Service

Required Materials

Appropriate wire, cable, conduit, and a mating interface on the vessel.

Note:

Potting Y's for all the interconnecting wires are recommended when installing the instrument. Other

requirements may vary based on local wiring codes. An appropriate mating surface on the vessel is

also required.

Pre-Installation Procedure

Warning:

Caution:

Only qualified personnel should install this instrument. Install and follow safety procedures in

accordance with the current National Electrical Code. Ensure that power is off during

installation. Any instances where power is applied to the instrument will be noted in this manual.

Where the instructions call for the use of electrical current, the operator assumes all responsibility

for conformance to safety standards and practices.

The control circuit contains electrostatic discharge (ESD) sensitive devices. Use standard ESD

precautions when handling the control circuit. See below for ESD details.

The instrument is not designed for weld-in-place applications. Never weld to process connection

or a structural support.

Damage resulting from moisture penetration of the local enclosure is not covered by product

warranty.

Use Standard ESD Precautions

Use standard ESD precautions when opening an instrument enclosure or handling the level transmitter. FCI

recommends the use of the following precautions: Use a wrist band or heel strap with a 1 megohm resistor connected

to ground. If the instrument is in a shop setting there should be static conductive mats on the work table and floor

with a 1 megohm resistor connected to ground. Connect the instrument to ground. Apply antistatic agents to hand

tools to be used on the instrument. Keep high static producing items away from the instrument such as non-ESD

approved plastic, tape and packing foam.

Doc. No. 06EN003264 Rev. A 2 - 1 Models 12-64/8-66 Basic Switch

Page 2

FLUID COMPONENTS INTL CHAPTER 2 - INSTALLATION

The above precautions are minimum requirements to be used. The complete use of ESD precautions can be found in

the U.S. Department of Defense Handbook 263.

Verify Installation Location

Prepare the vessel for installation, or inspect the already prepared location to ensure that the instrument will fit into

the system. Prepare the necessary sealants or gaskets to provide a leakproof installation for the application if

required. The location of the 12-64 that should have been prepared at the time of order should be at least 20 pipe

diameters downstream and 10 pipe diameters upstream from any bends or interference in the process pipe or duct to

achieve the greatest accuracy.

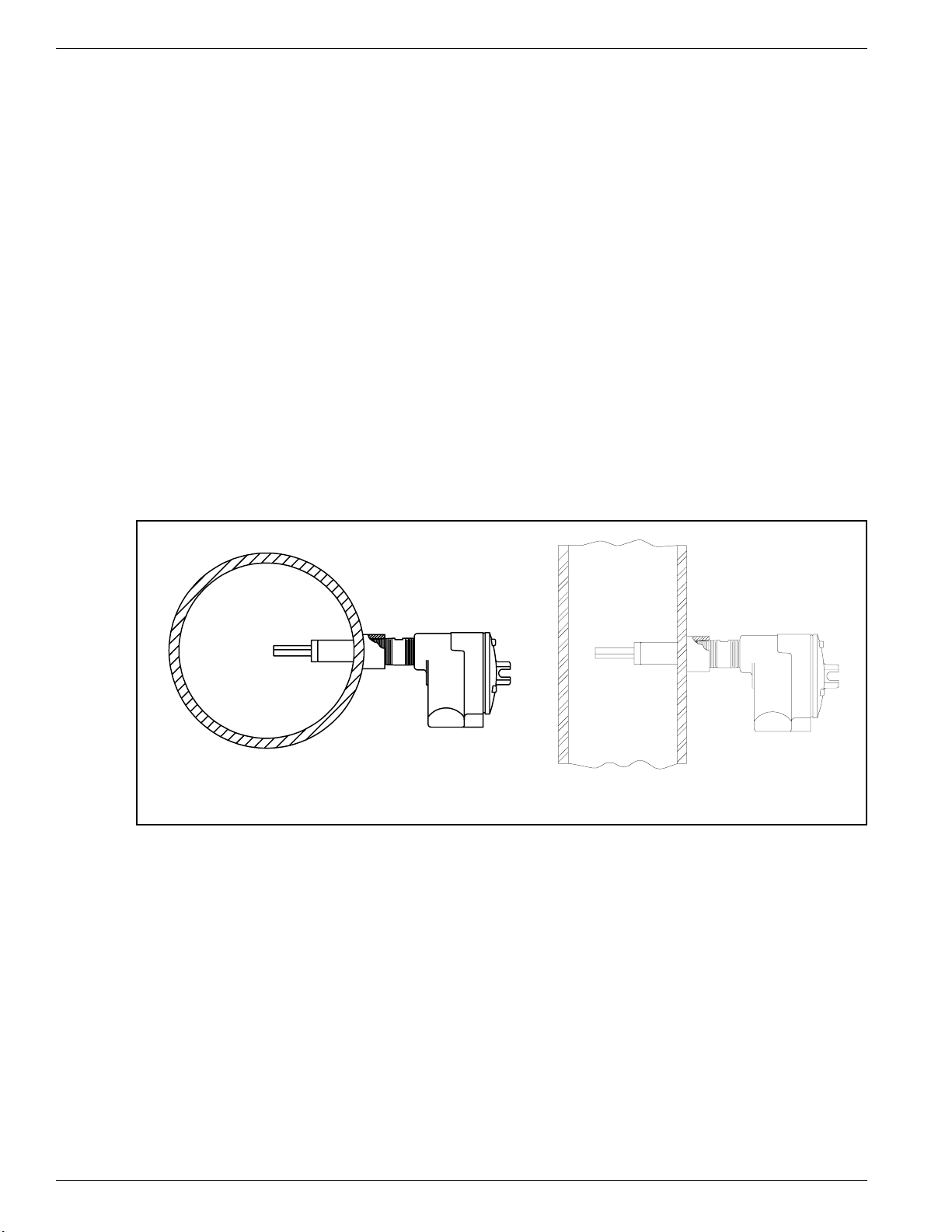

Sensing Element Installation

Install the sensing element in the process piping at the desired location. Verify that the flat area machined into the

sensing element is flat and level. If the flat is present it is machined on the sensing element near where it is screwed

into the enclosure. "FLAT UP & LEVEL" is also etched on the flat surface.

Apply a lubricant/sealant compatible with the process to all threads. Use a pipe wrench for 1-1/4 inch (32 mm) NPT

and larger connections, or an open-end wrench for 1-1/4 inch (32mm) NPT and smaller connections. All

connections should be tightened firmly. To avoid leaks, do not overtighten or cross-thread connections. The figures

in Appendix A and Figure 2-1, show this configuration.

If the sensing element is mounted in a downward direction, moisture build up in the enclosure needs to be avoided.

FCI recommends that an O-ring be used on the enclosure cover. In addition, attached conduits must be isolated by

using a conduit potting Y.

12-64 BASIC 8-66 BASIC

C00166-1C00033-1

Figure 2-1. Sensing Element Threaded Mounting

Control Circuit Installation

The configuration of the instrument is with the control circuit already installed in the local enclosure (the control

circuit is physically mounted with the sensing element).

Wiring Installation

Conduit Routing

All socket and/or terminal block connections are to be made through the 1 inch female NPT openings in the

enclosure. FCI strongly recommends that all electrical cables be run through an appropriate conduit for the

protection of the instrument and personnel.

Protection of the control circuit from moisture is an important consideration. Keep the entry of the conduit into the

Models 12-64/8-66 Basic Switch 2 - 2 Doc. No. 06EN003264 Rev. A

Page 3

CHAPTER 2 - INSTALLATION FLUID COMPONENTS INTL

enclosures in the downward direction so condensed moisture that collects in the conduit will not drain into the

enclosure. The local enclosure may be turned not more than 180° using the threads on the sensing element stand

pipe to gain an acceptable orientation. In addition, FCI recommends sealing off the conduit with a potting Y or other

sealing method to prevent moisture from entering the enclosure.

Minimum Wire Size

Table 2-1 shows the smallest gauge (maximum AWG number) copper wire used in the electrical cables that connect

the instrument to the customer alarms and to power. Use a lower gauge of wire for less of a voltage drop. Contact

FCI concerning greater distances than those listed in the table.

Table 2-1. Interconnecting Cable Size (AWG)

Maximum Distance for AWG

Connection

10 ft.

(3m)

50 ft.

(15m)

100 ft.

(31m)

250 ft.

(76m)

500 ft.

152m)

1000 ft.

(305m)

AC Power 22 22 22 20 18 16

Relay (2A) 24 22 20 16 12 10

Cable Connections

Note:

The installation of an AC line switch between the AC power source and the instrument is

recommended. This facilitates easy power disconnection for maintenance, troubleshooting and is an

added safety feature.

Connect the relay output to the customer alarm per the following procedure:

1. Remove the control circuit from it's socket.

2. Install conduit between the local enclosure, the power source and monitoring circuit. Provide watertight

hardware and apply thread sealant to all connections to prevent water damage.

Warning:

Ensure that all power is off before wiring any circuit.

3. When connecting the relay wiring, do so with complete understanding of what the process requires of the

instrument. The instrument has double pole, double throw relay output contacts. See Appendix A, Figure A-2.

For the relay logic, refer to Table 2-2 and in Chapter 3 refer to Figure 3-2. Relay contacts are shown in the relay

de-energized. Wire in accordance with the system requirements.

4. Connect the specified operating power and earth ground to the socket and ground lug. Refer to Figure A-2 for

connection information.

5. Plug the control circuit back into it's socket.

6. Verify proper installation. Ensure that the assemblies are secure and the wiring is correct.

Table 2-2. Relay Energization

JUMPER POSITION RELAY STATE

J 12 RELAY DE-ENERGIZED AT NO FLOW / DRY

J13 RELAY DE-ENERGIZED AT FLOW / WET

Doc. No. 06EN003264 Rev. A 2 - 3 Models 12-64/8-66 Basic Switch

Page 4

FLUID COMPONENTS INTL CHAPTER 2 - INSTALLATION

Models 12-64/8-66 Basic Switch 2 - 4 Doc. No. 06EN003264 Rev. A

Loading...

Loading...