Flo-tech USB Specifications

Flo-Check® USB Hydraulic System Analyzer

Simultaneously Measures Flow, Pressure and Temperature

SPECIFICATIONS

Performance

Flow:

Accuracy ±1% of reading @ 32 cSt

Repeatability ±0.2%

Pressure:

Accuracy <±0.5% BFSL

Stability <±0.25% of full scale

Zero Offset <±2% of full scale

TC Zero and TC Span <±1.5% of full scale

Response Time 0.2 milliseconds

Temperature:

Calibration Error (25 °C) ±1 °C

Absolute Error (over full range of sensor, 0 to 150 °C)

• Flow accuracy ±1% of reading @ 32 cSt

• Field selectable US or metric readings

• High and low set point alarms for ow, pressure and

temperature

• Captures pressure spikes up to 10,000 PSI

(0.2 milliseconds duration)

• Exports saved data to Microsoft Excel

spreadsheet programs

• USB powered

• Easy to use, plug and play

• Calculates hydraulic power

• Select continuous monitoring or capture data manually

• Logs up to 12 hours

• Records alarm history

The Flo-Check Hydraulic System Analyzer can be used

as a stationary or portable tester for both industrial and

mobile hydraulic system diagnostics, and analysis of the

prognostic health of a hydraulic system. It features ow,

pressure and temperature sensors that are monitored by a

data acquisition module. This module records the operating

parameters of the system and transfers them to the user’s

laptop via the USB port.

The custom software utility is a Windows

which is compatible with Windows Vista

Windows 2000, and Windows 7. This intuitive software

congures the displayed information into user-selected

engineering units and provides real-time graphics with

instantaneous readings and trends for all three measurement

parameters. The software also permits the data to be saved

for export into a spreadsheet program.

The Hydraulic System Analyzer is powered through the USB

port of a PC, making it easy to set up and ideal for portable

applications. Interfaced to the PC application, the Hydraulic

Analyzer offers a straightforward method of monitoring

system parameters complete with data acquisition.

®

and other

®

-based application

®

, Windows XP,

Without Calibration ±3 °C

With Calibration ±1.6 °C

Nonlinearity ±0.4 °C

Repeatability ±0.1 °C

Data Acquisition:

Sample Rate 10 kHz

PC Screen Update/Record Rate

Flow 1 second (average 10K samples)

Temperature 1 second (average 10K samples)

Pressure 1 second (min, max, average 10K samples)

Power

USB Power: +5 VDC (supplied through USB port

USB Voltage Tolerance: +4.6 VDC min, +5.25 VDC max

Current: 100 mA, typ

of a PC)

Environmental

Pressure Rating: 6000 PSI (414 Bar) maximum with a 3:1

safety factor; capable of 10,000 PSI

transients

Operating Pressure: <6000 PSI (414 Bar, 41.4 MPa,

420 kg/cm²); capable of 10,000 PSI

transients

Internal Valve By-pass: 7500 PSI ∆P

Pressure Drop: See ∆P charts on page 14

Fluid Temperature: -40 to +300 °F (-40 to +150 °C)

Ambient Temperature: +32 to +185 °F (0 to +85 °C)

Storage Temperature: -40 to +185 °F (-40 to +85 °C)

Humidity: 0-90%, non-condensing

Material

Housing: 6013-T351 Aluminum; anodized

Turbine Rotor: T416 Stainless steel

Rotor Supports: 6061-T6 Aluminum alloy

Seals: Viton® standard; EPR optional

Ball Bearings: 440C Stainless steel

Hub Cones: 6061-T6 Aluminum alloy

Temperature Probe: T303 Stainless steel

Valve: 12L14 Steel body with 303 SS seat

Spool/Sleeve: 12L14 Steel

Magnetic Pick-up:

Body T303 Stainless Steel

Nut T303 Stainless Steel

Electronic Case: Cold rolled steel; black zinc plate

with clear seal

Ports: SAE Straight thread O-ring boss, female,

J1926/1; ISO1179 (BSPP)

Page 4 January 2014

Flo-Check® USB Hydraulic System Analyzer

Simultaneously Measures Flow, Pressure and Temperature

SOFTWARE

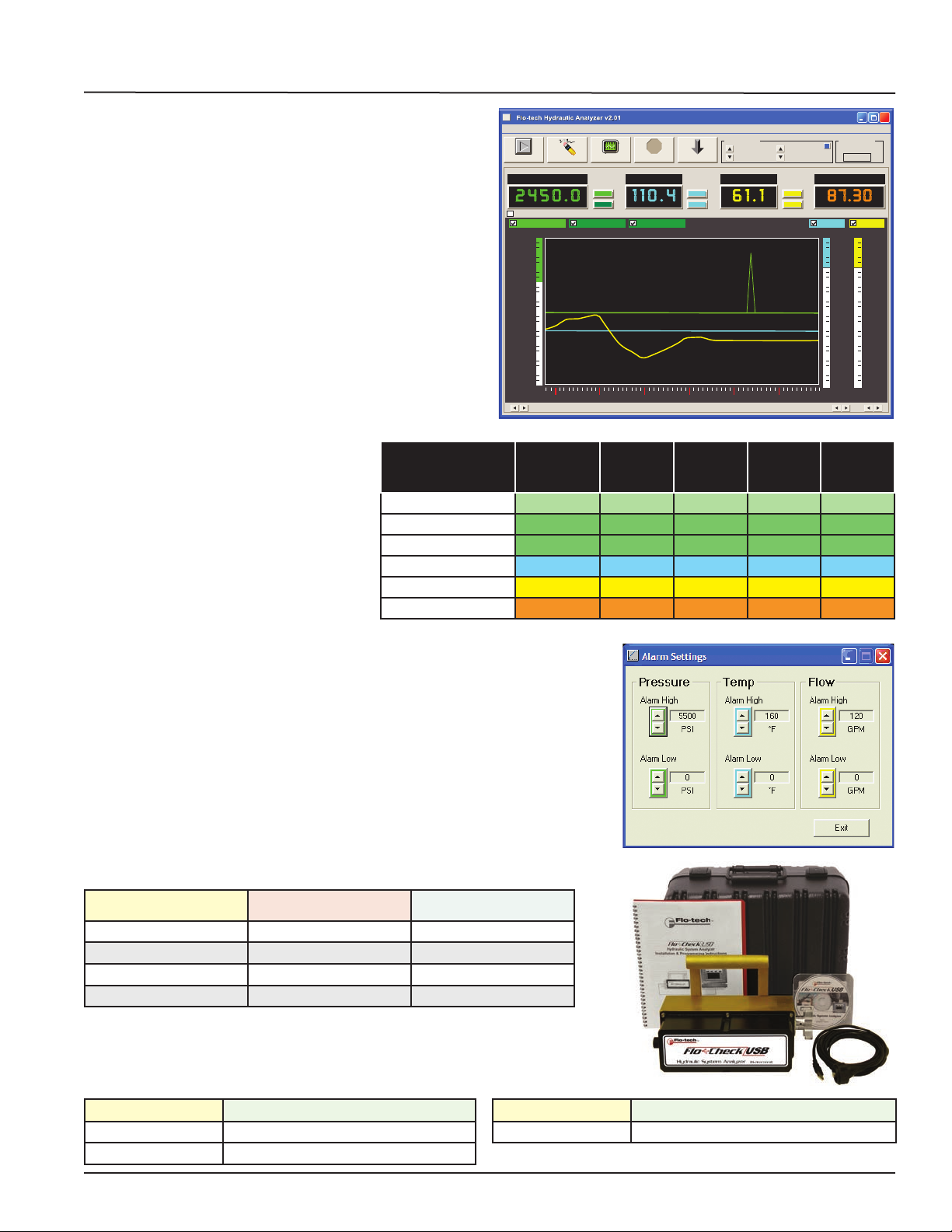

The Flo-tech Analyzer software provides a real-time graphical

and digital interface for monitoring and/or recording pressure,

temperature and ow rate parameters from the Hydraulic

Analyzer. In addition to the graphical and digital displays, the

main screen also consists of a menu bar, buttons with common

functions and alarm indicators.

The software offers the following options:

• View real time pressure, temperature, ow rate and power

measurements

• Record all measurements to a le

• Choice of recording all measurement points or capturing

points manually

• Selection of all measurement units, US or metric

• Ability to adjust display of graph data

• High/Low alarm indicators set by the operator

All measurements taken can be saved once

per second to a comma separated value (.csv)

le for export into a spreadsheet program. For

example, recording for 2 minutes would yield

120 points of data. Even though data points

are only recorded once per second, pressure

spikes and dips are captured by recording the

maximum or minimum pressure during each

measurement period. Therefore, the precise

shape of the pressure spike is not recorded

but its amplitude and the time it occurred are

both recorded.

Measurement

(over a 1 second

time period)

Average Pressure Green

Minimum Pressure Dark Green

Maximum Pressure Dark Green

Average Temperature Blue

Average Flow Rate Yellow

Average Power Orange

File View Options Tools About

Run Clear Graph

Pressure Temp Flow Horse Power

2450.0 87.30110.4 61.1

PSI

View History

Pressure Avg PressureMin PressureMax

5000.0 PSI

—

4500.0 PSI

—

4000.0 PSI

—

3500.0 PSI

—

3000.0 PSI

—

2500.0 PSI

—

2000.0 PSI

—

1500.0 PSI

—

1000.0 PSI

—

500.0 PSI

—

0 PSI

—

990.0s 1000.0s 1010.0s 1020.0s 1030.0s 1040.0s

Record Stop Reset Alarms

Alarms

High/Low

Color

Indication

STOP

°F GPM HP

Alarm

Indication

Log Interval

Alarms

High/Low

Digital

Indication

4 Hours 0 Minutes

Alarms

High/Low

Elapsed Time=00:17:28

Graphical

Display

• • • •

• •

• •

• • • •

• • • •

• •

Test Period

Seconds

14400

Temp Flow

300.0 °F

—

270.0 °F

—

240.0 °F

—

210.0 °F

—

180.0 °F

—

150.0 °F

—

120.0 °F

—

90.0 °F

—

60.0 °F

—

30.0 °F

—

0.0 °F

—

Record to

File

200.0 GPM

—

180.0 GPM

—

160.0 GPM

—

140.0 GPM

—

120.0 GPM

—

100.0 GPM

—

80.0 GPM

—

60.0 GPM

—

40.0 GPM

—

20.0 GPM

—

0.0 GPM

—

×

Graphs

The graph on the main screen contains more than 60 points of data. Previous data

points are saved in memory and can be viewed at any time. Adjustments can be

made to optimize data that is displayed by hiding individual graph plots, adjusting the

scale of each plot or adding horizontal gridlines to the graph.

Alarms

There are three sets of High/Low alarm indicators on the main screen which monitor

pressure, temperature and ow rate. Alarm indicators ash if the current system

measurements exceed the alarm limits set by the operator and continue to ash

when the current system measurements return to normal to alert the operator that an

alarm condition occurred. Alarms must be reset manually to acknowledge the alarm

condition.

ORDERING INFORMATION

MODEL NUMBER ¹ NOMINAL PORT SIZE FLOW RANGE

F7160 SAE 16 3 - 85 GPM

F7161 SAE 24 7 - 199.9 GPM

F7162 G 1 15 - 321 LPM

F7163 G 1-1/2 26 - 757 LPM

¹ Each Flo-Check Hydraulic System Analyzer includes a 16.4 ft. (5 M) USB,

A male to B male (IP 68) connection cable, CD-Rom of the software utility, and

complete operating instructions packaged in a protective carrying case.

ACCESSORIES

MODEL NUMBER DESCRIPTION

F001109 5-Point Calibration Certicate ²

F001110 10-Point Calibration Certicate ²

MODEL NUMBER DESCRIPTION

F1614-7500 Pressure Relief Disc, 7500 PSI (1 per Tester)

² Certicates are traceable to NIST, ISO 9001.

Page 5 January 2014

Loading...

Loading...