Flo-tech MC4000 Operating Manual

Turbine Flow Meter

MC4000 Handheld Hydraulic System Analyzer

TST-UM-00017-EN-03 (February 2015)

User Manual

Turbine Flow Meter, MC4000 Handheld Hydraulic System Analyzer

Page ii February 2015

User Manual

CONTENTS

Product Unpacking And Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Programming Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Supplementary Measurements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Peak and Valley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure Dierence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Two Point Flow Sensor Calibration Using the New Lin Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Three Point Flow Sensors Linearizing Using the New Tab Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MC4CON Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Menu Tabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Datalogger Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Troubleshooting Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Page iii February 2015

Product Unpacking And Inspection

PRODUCT UNPACKING AND INSPECTION

Upon receipt of the product, perform the following unpacking and inspection procedures.

OTE:N If damage to the shipping container is evident upon receipt, request the carrier to be present when the product

is unpacked.

1. Carefully open the shipping package, follow any instructions that may be marked on the exterior. Remove all cushioning

material surrounding the product and carefully lift the product from the package.

2. Save the package and all packing material for possible use in reshipment or storage.

3. Visually inspect the product and applicable accessories for any physical damage such as scratches, loose or broken parts or

any other sign of damage that may have occurred during shipment.

OTE:N If damage is found, request an inspection by the carrier’s agent within 48 hours of delivery and file a claim with the

carrier. A claim for equipment damage in transit is the sole responsibility of the purchaser.

INTRODUCTION

The MC4000 has inputs for two pressure sensors, one temperature sensor, one flow sensor, and one active pickup for RPM

measurements. The MC4000 allows simultaneous connection of four sensors with the measurements displayed in four

individual LCD windows using preselected process units according to US or DIN norms. The display supports English and one

of the following languages selected at the time of order: Spanish, German, Italian, or French.

An internal rechargeable battery powers the MC4000. A green LED indicates a completely charged battery. A fully charged

battery permits four hours of operation with two pressure sensors connected. With the charger connected, the battery

charges while also allowing use of the instrument. An optional automobile style power cable is available for operation from a

car battery.

When in Datalogger mode, the MC4000 stores data in an internal 2.5 MB memory space. Each stored measurement contains

the day and date from the instruments real time clock.

The MC4CON software utility transfers stored measurements via a USB data port to a Windows PC. The MC4CON program

permits bi-directional communication not only for uploading recorded data to a PC, but also for downloading commands

from the PC to the MC4000.

All parameters can also be set using the buttons on the instrument’s front panel. Pressure units are programmed in psi or bar.

The flow and rpm measurements are scaled using programmable constants. Additionally, three point flow calibration for the

turbine sensors is available. When activated, the pressure tare function allows offset adjustments and the sets the display to

zero at non-zero pressure inputs.

Hydraulic horsepower is automatically calculated from the measured pressure and flow. Horsepower displays as either HP or

kW depending on the selected units.

Page 4 February 2015TST-UM-00017-EN-03

Introduction

Operating Principle

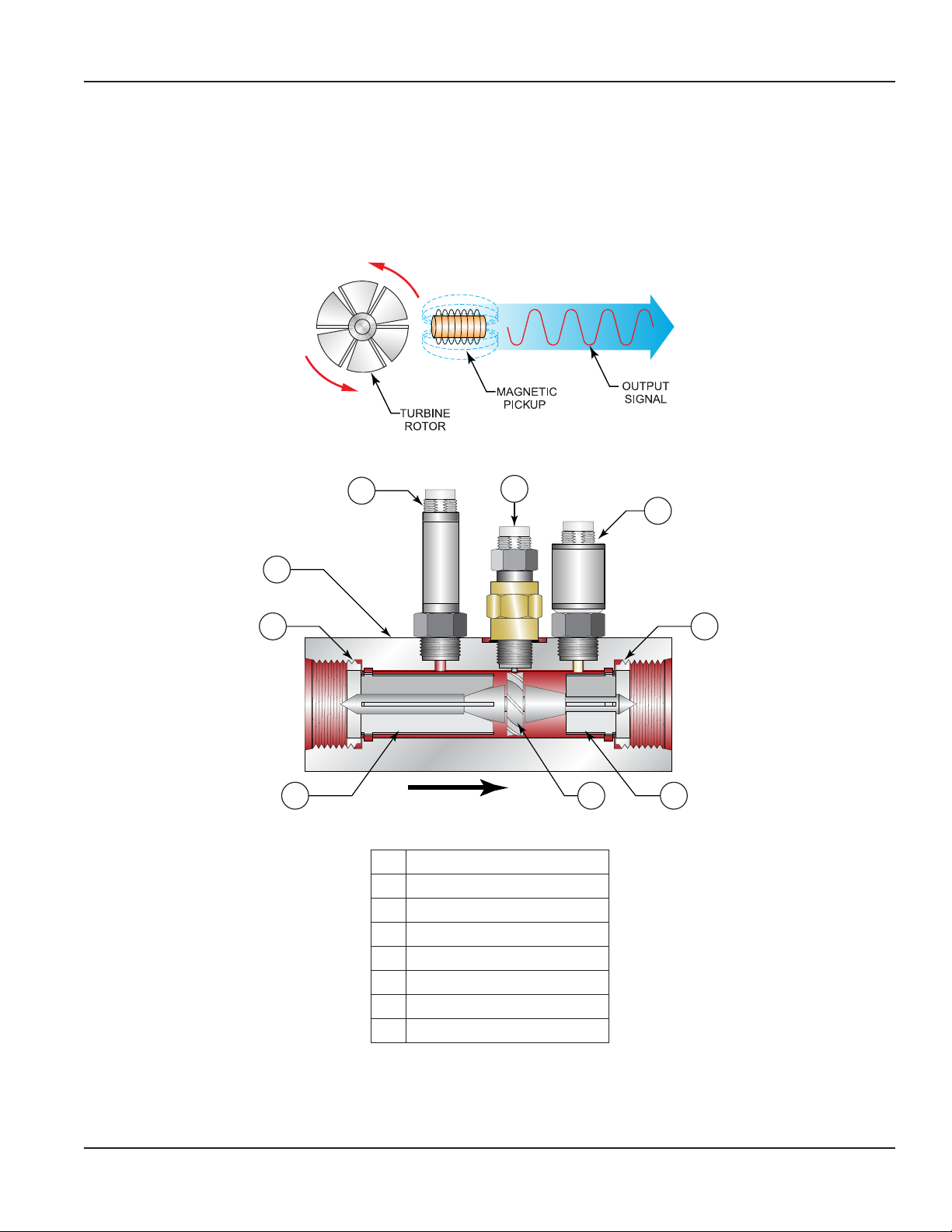

Fluid entering the meter passes through the inlet flow straightener, which reduces its turbulent flow pattern and improves the

fluid’s velocity profile. Fluid then passes through the turbine, causing it to rotate at a speed proportional to the fluid velocity.

As each turbine blade passes through the magnetic field, the blade generates an AC voltage pulse in the pickup coil at the

base of the magnetic pickup (see Figure 1). These pulses produce an output frequency proportional to the volumetric flow

through the meter. The output frequency represents flow rate and/or totalization of fluid passing through the turbine flow

meter. For a complete component orientation, see Figure 2.

Figure 1: Schematic illustration of electric signal generated by rotor movement

8

1

2

7

33

Flow Direction

Figure 2: Typical cross section of sensor array

1 Magnetic pickup

2 Temperature sensor

3 Retaining ring

4 Downstream rotor

5 Turbine rotor

6 Upstream rotor

7 Meter body

8 Pressure sensor

456

Page 5 February 2015 TST-UM-00017-EN-03

Connections

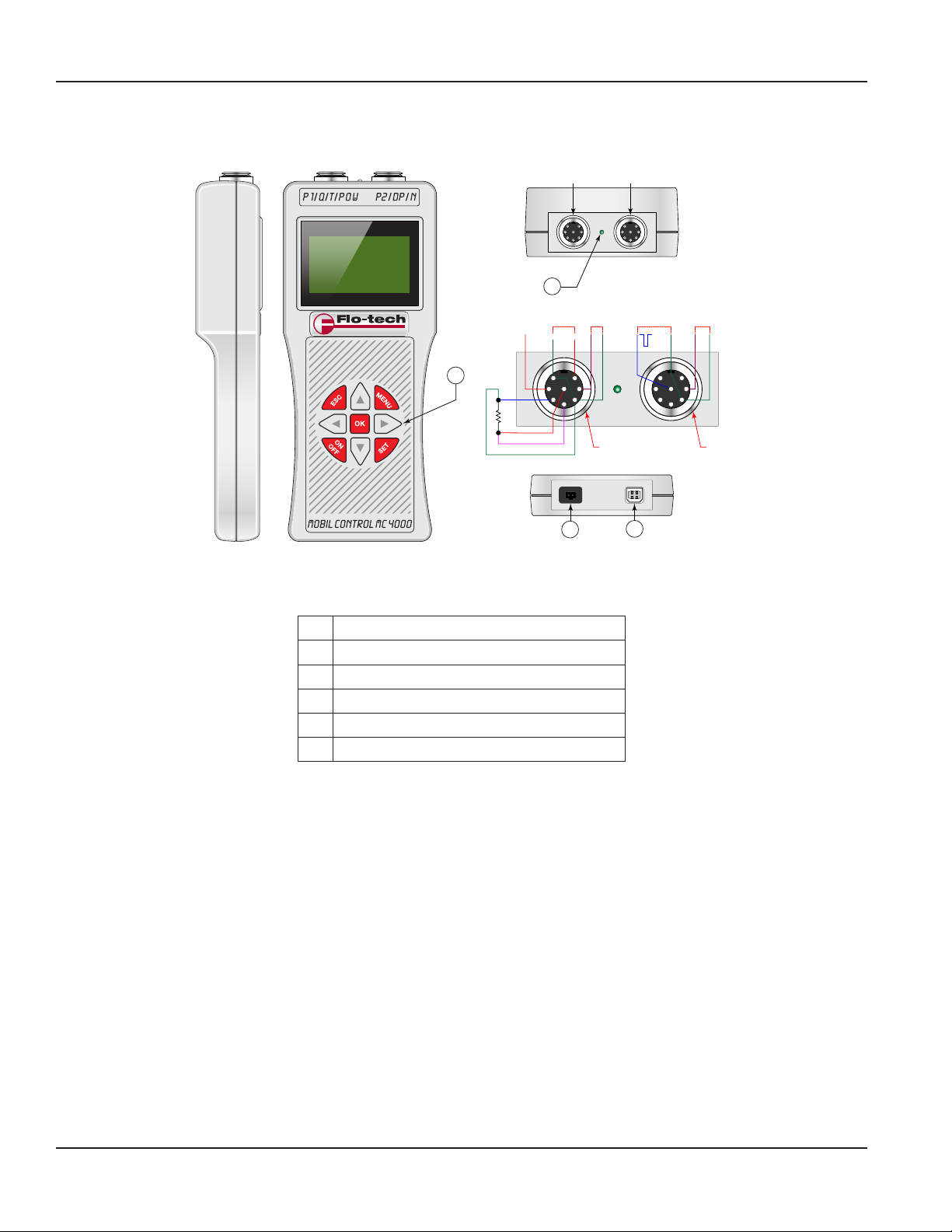

CONNECTIONS

1

11 V

to GND

Flow

Sensor

Excitation

2

S-

Pt-100

E+

S+

E-

10 mV

7

3

5

Figure 3: MC4000 controls and connections

P1

4-20 mA

T2

P2RPM Pulses

GND

T1

4-20 mA

GND

GND

6

7

1

8

3

4

5

2

T2

4

T1

(+) (-)

6

1

8

4

2

3

1 Battery charging indicator

T1 Flow, pressure and temperature sensors

T2 Auxiliary pressure sensor

2 Keypad

3 Battery charging

4 USB–B port

Table 1: Controls and connections locations

INSTALLATION

Check the interior of the meter for foreign material. Make sure the turbine rotor spins freely prior to installation. Additionally,

check and clear fluid lines of all debris.

Page 6 February 2015TST-UM-00017-EN-03

Operation

OPERATION

Measuring Mode

OTE:N Any reference to the P2 pressure sensor assumes installation of the optional pressure sensor in the system.

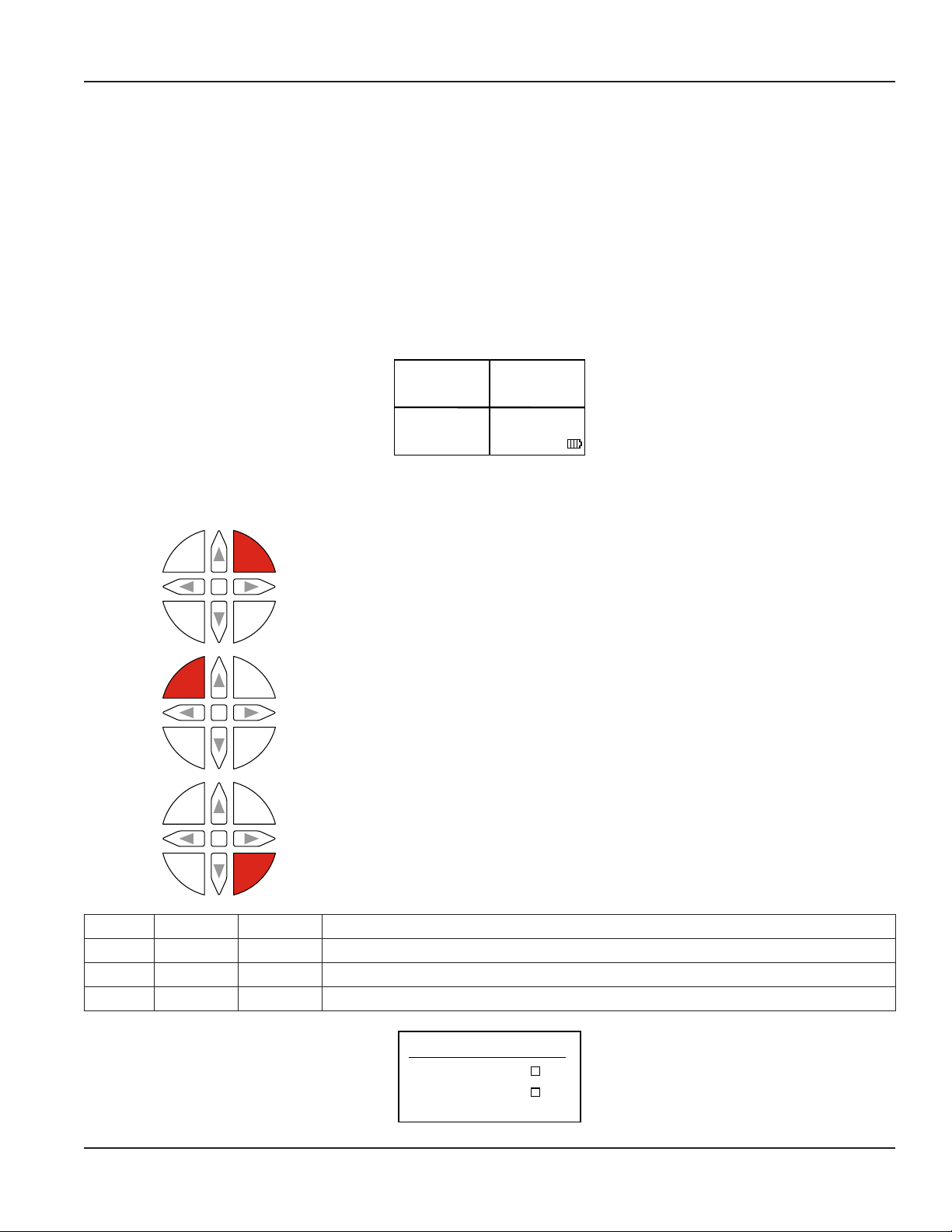

Start the MC4000 by pressing ON OFF. The MC4000 performs a self-test and displays the version number of the firmware

and the unit's serial number. Additionally the setup parameters, the battery capacity, date, time ,and free memory are also

available. After the startup routine, the instrument automatically goes into measuring mode.

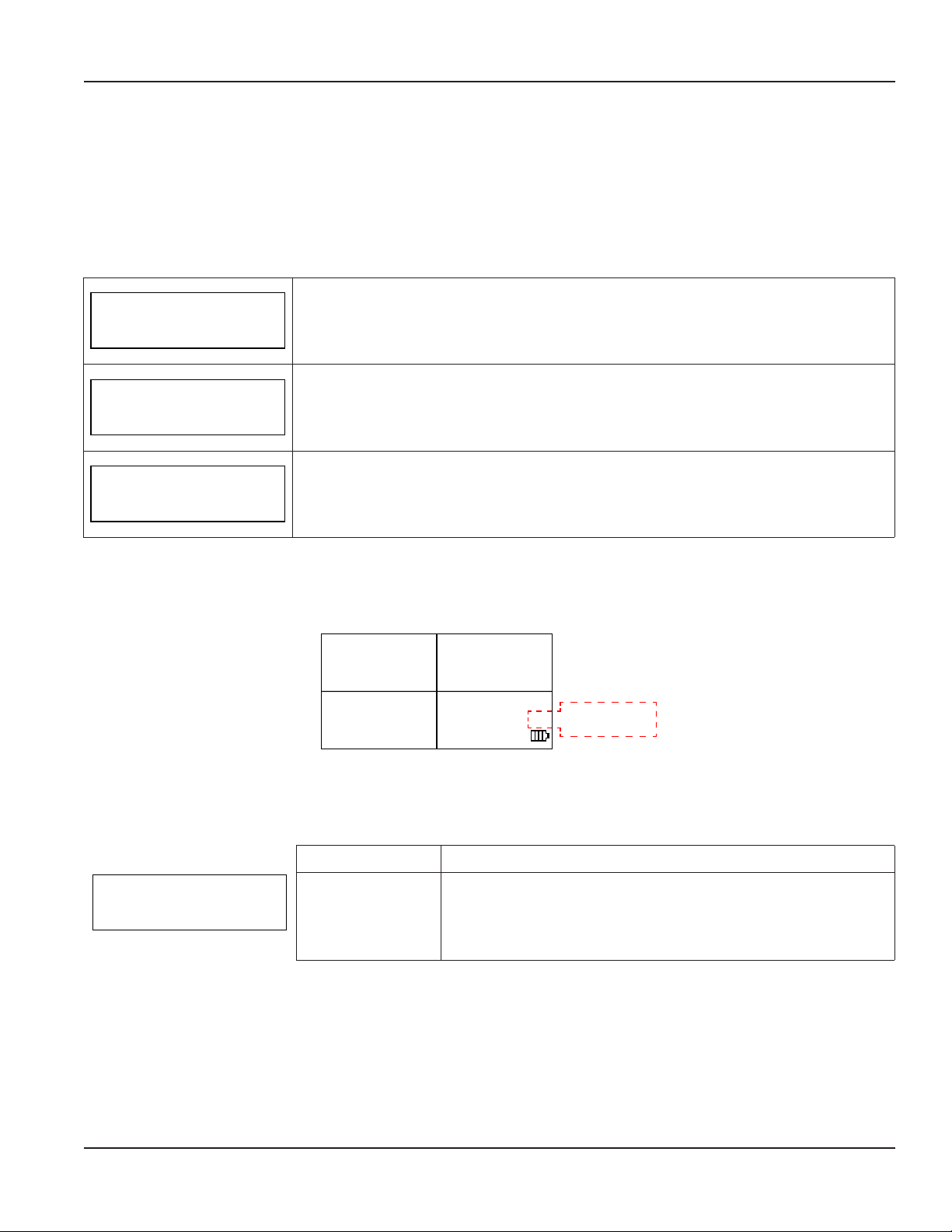

Four windows divide the screen. The two left windows show pressure measurements. The right upper window measures

the temperature and the right lower window shows flow or the rpm. Menu commands select the flow (Q) or the rpm (N).

Three dashes in a window indicates the absence of a sensor. A battery symbol in the lower right display corner indicates the

battery capacity.

Function buttons MENU, ESC and SET

MENU

OK

SET

MENU

OK

SET

MENU

OK

SET

OFF

OFF

OFF

ESC

ON

ESC

ON

ESC

ON

P1 bar

74.32

P2 bar

76.12

Figure 4: Display in measuring mode

T °C

86.5

Q l/min

38.4

• Access menu commands.

• Scroll through menu options, press and hold to automatically scroll through

menu options at one second intervals.

• Backwards menu steps.

• Press three times to switch to measuring mode.

• Activate tare in both P1 and P2 pressure channels

OFFSET P1 SET Set pressure P1 to zero – Tare P1

OFFSET P1 RES Cancel the tare function – No Tare P1

OFFSET P2 SET Set pressure P2 to zero – Tare P2

OFFSET P2 RES Cancel the tare function – No Tare P2

OFFSET

OFFSET P1 SET

OFFSET P1 RES

OFFSET P2 SET

OFFSET P2 RES

Page 7 February 2015 TST-UM-00017-EN-03

Operation

P1 bar

124.3

P1-P2 bar

13.5

PW kW

38.4

P2 bar

24.1

P1 bar

82.2

Q l/min

13.4

T °C

83.3

P2 bar

108.7

P2 bar

64.6

P1 bar

124.3

P1 bar

82.2

T °C

83.3

Q l/min

13.4

P2 bar

4.1

P2 bar

64.6

P1 bar

12.3

P1 bar

12.3

P1-P2 bar

13.55

PW kW

38.4

P2 bar

4.1

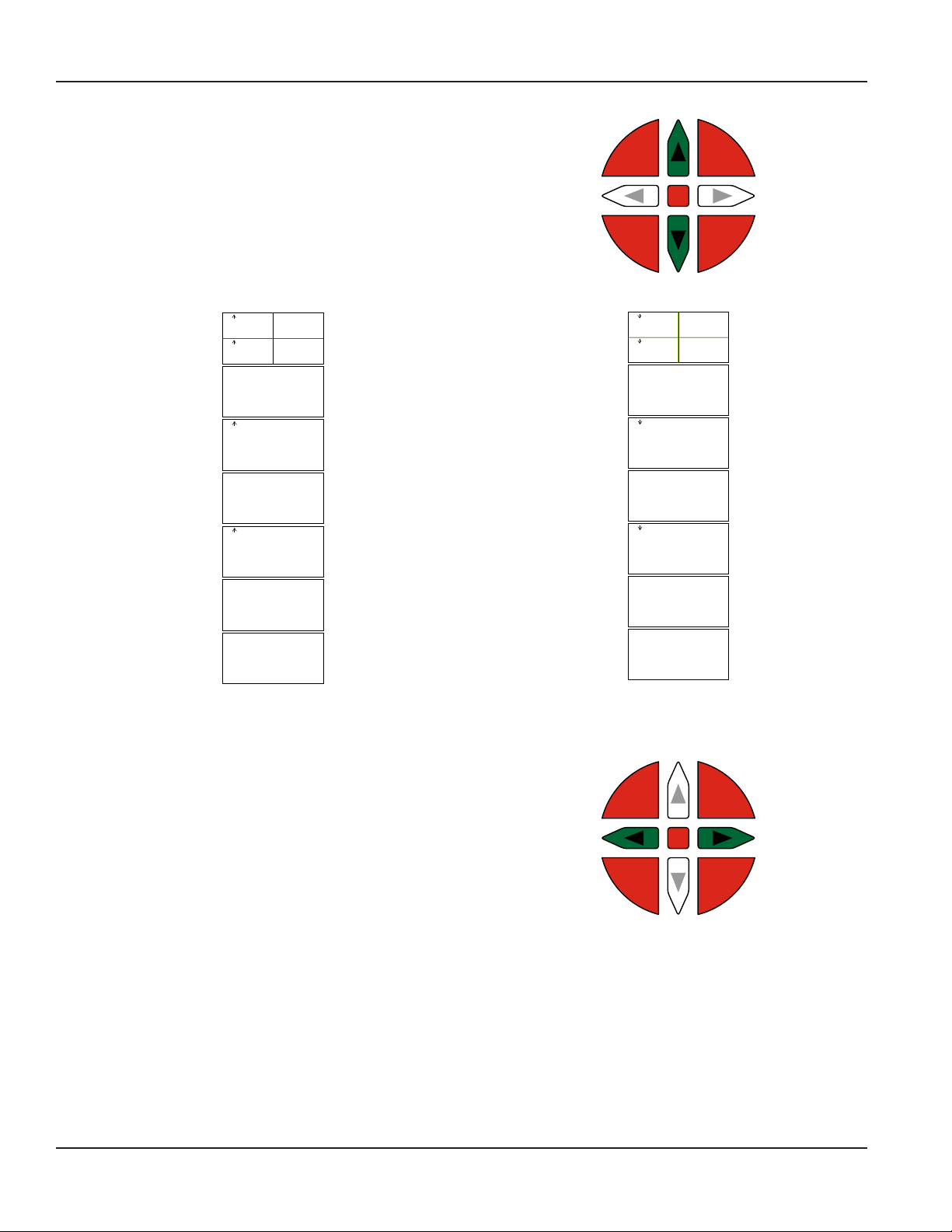

Up and Down Arrow Buttons

Press UP or DOWN to view any of following display modes:

• Peak & valley, pressure difference, power

• Large display mode for pressure P1 or P2

• Large display mode for temperature

• Large display mode for flow and rpm

ESC

OFF

MENU

OK

ON

SET

Large display modes display in this sequence by pressing UP.

Large display modes display in this sequence by

Left and Right Arrow Buttons

• Pressing LEFT resets the peak & valley memory.

• Pressing RIGHT returns to measuring mode.

Page 8 February 2015TST-UM-00017-EN-03

pressing DOWN.

MENU

ESC

OK

ON

OFF

SET

Operation

Programming Menu

Press MENU to open the programming menu. Continue to press MENU to scroll through the user settings and measurement

parameters on the display. Press UP or DOWN to scroll through the options available for each parameter. Press OK to store

any new settings, the display will read DATA STORED. Press ESC to scroll backwards through the menu choices. Press ESC three

times to return to measuring mode.

Datalogger

The datalogger parameter allows you to start, stop or delete recorded measurement sessions.

DATALOGGER

STORE OFF

DATALOGGER

STORE ON

DATALOGGER

STORE DELETE

The internal memory can save all displayed measurements and permits 224 individual records at a total capacity of 2.5 MB.

To start a new datalogging session, press OK at the STORE ON prompt. After starting a new datalogging session, press ESC to

switch the display to measuring mode. In measuring mode, an M icon indicates an active datalogging session, see Figure 5.

Stored datalogging sessions can be uploaded to a computer, using the USB data port, for further processing.

This command stops recording the datalogging information to memory. Press OK to stop

an active datalogging session. The screen will display DATA STORED.

This command starts recording data at a selected interval rate, see "Save Interval" below.

Each record automatically adds the date and time from an internal real time clock. To start a

new datalogging session press OK. The screen will display DATA STORED.

This command deletes all stored data. To delete data press OK, the unit will display ERASE

DATA ? Press OK again to confirm the request. The screen will display DATA ERASED.

P1 bar

74.32

P2 bar

76.12

T °C

86.5

Q l/min

M

38.4

Logging Active

Indication

Figure 5: Active datalogging session display

Save Interval

The save interval is the time between two consecutive recording cycles set in fixed increments as shown below.

Selection Function

SAVE INTERVAL

1 s

1s, 2s, 5s, 15s, 30s,

60s, 120s, 300s, 600s,

1200s, 1800s, 2700s,

3600s, 7200s

This command sets the time, in seconds, between two recording

cycles. Press UP or DOWN to scroll through each interval, when

the correct interval is displayed, press OK to select the interval. The

screen will display DATA STORED.

Page 9 February 2015 TST-UM-00017-EN-03

Loading...

Loading...