Flo-tech MC4000 Specifications

Diagnostic Test Equipment

MC4000 Handheld Hydraulic System Analyzer

DESCRIPTION

The Flo-tech MC4000 handheld hydraulic system analyzer has

inputs for two pressure sensors, one temperature sensor, one

flow sensor, and one active pick-up for RPM measurements. Four

sensors can be connected at the same time and the measurements

displayed in four windows of the LCD display in preselected

process units according to US or DIN norms. The display supports

English, French, German, Italian, and Spanish languages. Language

is selected when ordering.

When operating in the datalogger mode, measurement results

are stored in an internal 2.5 MB memory space. Each stored

measurement also contains the day, date, and time derived from an

internal real-time clock.

Stored measurements are available at the meter’s USB data port

and can be uploaded to a Windows® PC using the MC4CON

software utility. The MC4CON program permits bi-directional

communication for uploading the records to the PC and for

downloading the commands from the PC to MC4000.

All parameters can be set using the keys on the front panel.

Pressure units can be programmed in bar or psi. The flow and

rpm measurements are scaled by using programmable constants.

Additionally, three-point flow calibration for the turbine sensors is

available. For offset adjustment, the Tare function can be activated

to set the display to zero at non-zero inputs.

Hydraulic horsepower is automatically calculated from the

measured pressure and the flow. The horsepower units are

displayed as either hp or kW, depending on menu selection.

ACCESSORIES

A comprehensive set of accessories is available for the MC4000. Use

these accessories to expand the capabilities of the MC4000. For a

complete list of available accessories see the MC4000 Parts List.

FEATURES

• Handheld hydraulic analyzer offers instant and

recordable diagnostics

• Hydraulic horsepower calculations

• Measures fast transients

• Flow sensor linearization

• 2.5 MB data logging capacity

• Five sensor inputs, including:

◊ Turbine flow sensor

◊ Two pressure sensors

◊ Temperature sensor

◊ RPM speed indicator

TST-DS-00023-EN-03 (July 2014)

Product Data Sheet

Diagnostic Test Equipment, MC4000 Handheld Hydraulic System Analyzer

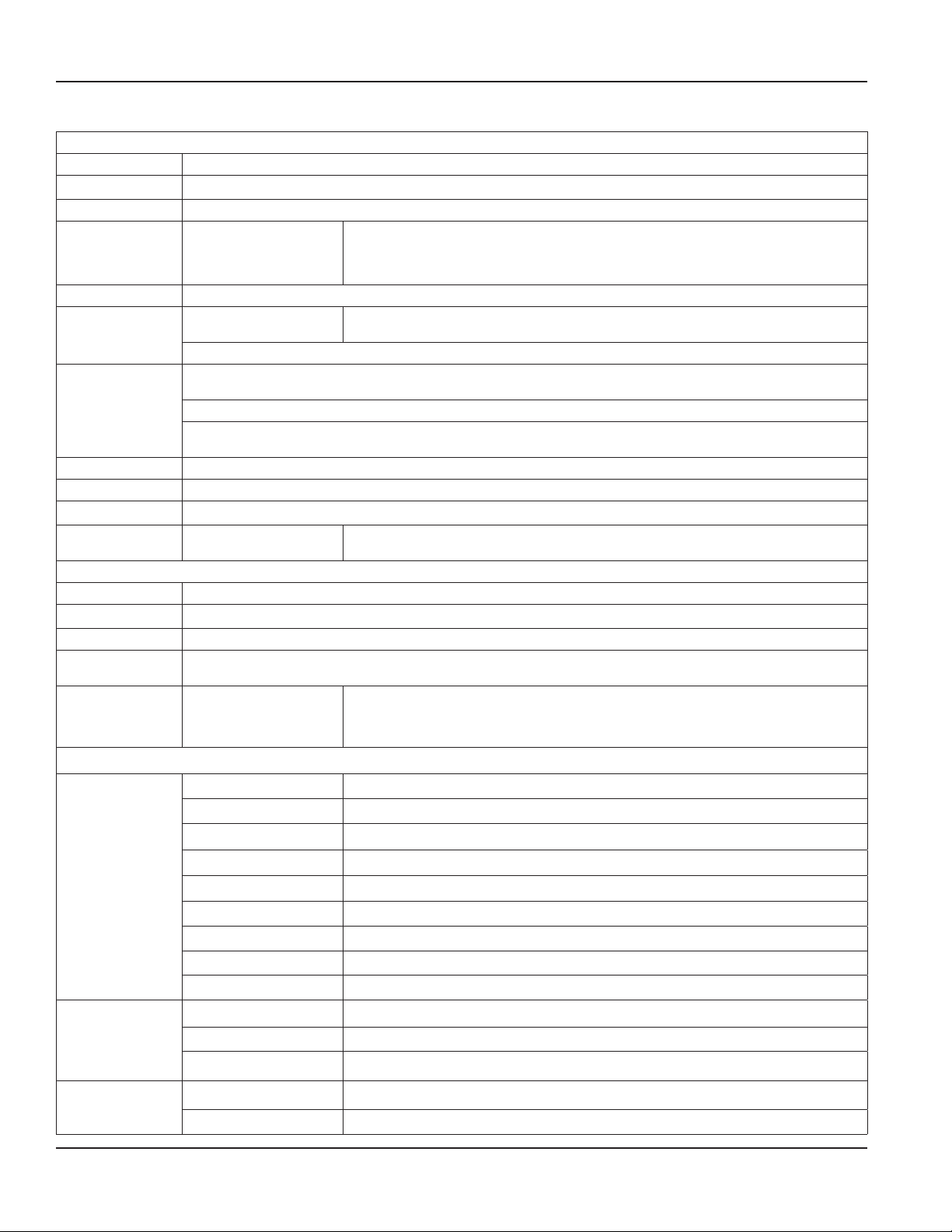

SPECIFICATIONS

Display

Accuracy ±0.1% + 1 digit from midrange

A to D 16-bit, Linearity ± (1 LSB + 1 digit)

Display Graphic LCD display with back light, 128 x 64 pixels; back light auto-off function

Flow

Inputs

Keypad Nine keys on the front; backlight is illuminated for 30 seconds after any key is pressed

Power

Memory

Tare Pressure channels P1 and P2 are independently set to zero

Connections Two eight-pin, 12 mm sensor plugs, USB data connection, battery charging connection

Indicators Green LED between the two sensor plugs indicates power to the battery charging circuit

Environmental

Sensors

Accuracy ± 1% of reading @ 32 cSt

Repeatability ± 0.2%

Pressure max 5800 psi (400 bar) max; 5000 psi (345 bar) max for SAE 20 and G 1-1/4 size models

Turbine response

time

Pressure (P1/P2)

Temperature ( T)

RPM

Battery

Charger

A fully charged battery permits about four hours of operation with two pressure sensors connected and the backlight switched off

2.5 MB of datalogging memory can store up to 80,000 samples in all four signal channels, calculated power, date and time; the

sampling rate is selectable from 1 s…120 min

Peak & valley functions stores the maximum and the minimum values of the P1 and P2 pressure sensors

Two fast transients recorders with a sampling rate of 1 ms and a capacity of 240,000 measurements monitor pressure sensor P1.

The recording trigger threshold is programmable between 0…100%

Ambient Temperature

Humidity

≤200 ms

10 mV…5V

Dual 4…20 mA

Pt-100 –50…500° C

5…24V active pickup; range 30…60,000 rpm

6V, 2 Ah

100…240V AC

–22…158° F (–30…70° C).

0…90% non-condensing.

sine wave from turbine; frequency range 0.5…10 kHz scalable

P-P

Environmental

Materials

Turbine

Pickup

Pressure Sensor

Fluid Temperature

Ambient Temperature

Humidity

Housing 6013-T651 anodized aluminum

Turbine rotor T416 stainless steel

Rotor supports 6061-T6 aluminum alloy

Rotor shaft T303 stainless steel

Ball bearings 440 C stainless steel

Hub cones 6061-T6 aluminum alloy

Retaining rings 6061-T6 aluminum allow

Adapters/plugs 6061-T6 anodized aluminum

Seals Buna N

Housing 6016-T6 nickel plated

Nut T303 stainless steel

Connector Brass

Case 300 Series stainless steel

Diaphragm 17-4 PH stainless steel

–4…300° F (–20…150° C)

–22…158° F (–30…70° C)

0…90% non-condensing

Page 2 July 2014

Loading...

Loading...