Flo-tech Flo-Check USB Installation & Programming Instructions

Hydraulic System Analyzer

Installation & Programming Instructions

8635 Washington Avenue ■ Racine, WI 53406

Tel: 800-433-5263 or 262-639-6770

Fax: 800-245-3569 or 262-639-2267

E-Mail: info@fl o-tech.com

www.fl o-tech.com

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

Table of Contents

Overview..........................................................................................................................................................................4

Specifi cations ..................................................................................................................................................................4

Material .....................................................................................................................................................................4

Power ........................................................................................................................................................................5

Environmental ...........................................................................................................................................................5

Performance .............................................................................................................................................................5

Calibration .................................................................................................................................................................5

Model Number Designations .....................................................................................................................................6

General Information ..................................................................................................................................................6

Installing the Software .....................................................................................................................................................7

Connecting the Hydraulic Analyzer to Your Computer for the First Time.........................................................................7

Software Overview ..........................................................................................................................................................8

Running the Software and Viewing Real-Time Data .......................................................................................................9

Recording Measurements to a File..................................................................................................................................9

To Record a File ......................................................................................................................................................10

To Start Recording a File while in Run Mode ..........................................................................................................11

When Entering Run or Record Mode ......................................................................................................................11

Recording Modes ....................................................................................................................................................11

Log Interval ....................................................................................................................................................................12

Changing Measurement Units .......................................................................................................................................12

Using the Graph ............................................................................................................................................................13

Viewing Graph History ............................................................................................................................................13

Displaying and Hiding Individual Graph Plots .........................................................................................................13

Adjusting the Graph Scales ....................................................................................................................................13

Displaying Graph Gridlines .....................................................................................................................................13

Clearing the Graph ..................................................................................................................................................13

Using the Alarms ...........................................................................................................................................................13

Changing Alarm Settings ........................................................................................................................................14

Resetting the Alarms ...............................................................................................................................................14

Viewing Alarm History .............................................................................................................................................15

Saving/Loading Software Confi gurations ......................................................................................................................16

To Save a Software Confi guration ..........................................................................................................................16

To Load a Software Confi guration ...........................................................................................................................16

Calibration .....................................................................................................................................................................17

To Reset Zero for the Pressure Transducer ............................................................................................................17

To Reset Factory Calibration Defaults ....................................................................................................................17

Test Procedures.............................................................................................................................................................18

Standard Test Conditions ........................................................................................................................................18

"Tee" Test ................................................................................................................................................................18

Inline System Test ...................................................................................................................................................20

Control Valve and Bi-directional Hydraulic Motor Test ............................................................................................21

Bi-directional Cylinder Test......................................................................................................................................23

Hydrostatic Transmission Diagnostics ....................................................................................................................24

Other Test Procedures ............................................................................................................................................25

Maintenance / Troubleshooting .....................................................................................................................................26

Load Valve ..............................................................................................................................................................26

Flow .........................................................................................................................

Burst Discs ..............................................................................................................................................................26

Flow vs Pressure Drop Charts.......................................................................................................................................28

Return Goods Authorization ..........................................................................................................................................29

Waste Electrical and Electronic Equipment (WEEE) Directive ......................................................................................29

Warranty ........................................................................................................................................................................30

...............................................26

Form No. 05-SGN-PM-00191 02/12 Page 3

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

Overview

The Flo-Check® USB Hydraulic System Analyzer can be used as a stationary or portable tester for both industrial

and mobile hydraulic system diagnostics, and analysis of the prognostic health of a hydraulic system. It features fl ow,

pressure, and temperature sensors that are monitored by a data acquisition module. This module records the operating

parameters of the system and transfers them to the user’s laptop via the USB port.

The custom software utility is a Windows

and Windows 2000. This intuitive software confi gures the displayed information into user-selected engineering units

and provides real-time graphics with instantaneous readings and trends for all three measurement parameters. The

software also permits the data to be saved for export into a spreadsheet program.

The Hydraulic System Analyzer is powered through the USB port of a PC making it easy to setup and ideal for portable

applications. Interfaced to the PC application, the Hydraulic Analyzer offers a straightforward method of monitoring

system parameters complete with data acquisition.

®

-based application which is compatible with Windows Vista®, Windows XP

Specifi cations

Material

Housing: 6013-T351 Anodized aluminum

Turbine Rotor: T416 Stainless steel

Rotor Supports: 6061-T6 Aluminum

Seals: Viton

Ball Bearings: 440 C Stainless steel

Hub Cones: 6061-T6 Aluminum alloy

Temperature Probe: T303 Stainless steel

Valve: 12L14 Steel body with 303 SS seat

Spool/Sleeve: 12L14 Steel

Straightening Sections: 6061-T6 Aluminum

Ports: SAE Straight thread O-ring boss, female, J1926/1; BSPP ISO1179

Magnetic Pick-up

Body: 12L14 Steel, electroless nickel plate

Nut: 12L14 Steel, electroless nickel plate

Electronic Case: Cold rolled steel, black zinc plate with clear seal

®

standard; EPR optional

Power

USB Power: +5 VDC (supplied through USB port of a PC)

USB Voltage Tolerance: +4.6 VDC min, +5.25 VDC max

Current: 100 mA, typ

Environmental

Pressure Rating: 6000 PSI (414 Bar) maximum with a 3:1 safety factor;

capable of 10,000 PSI (689 Bar) transients

Operating Pressure: <6000 PSI (414 Bar, 41.4 MPa, 420 kg/cm²);

capable of 10,000 PSI (689 Bar) transients

Internal Valve By-pass: 7500 PSI DP

Pressure Drop: See ∆P charts on page 28

Fluid Temperature: -4 to +300 °F (-20 to +150 °C)

Ambient Temperature: +32 to +185 °F (0 to +85 °C)

Storage Temperature: -40 to +185 °F (- 40 to +85 °C)

Humidity: 0-90%, non-condensing

Page 4 Form No. 05-SGN-PM-00191 02/12

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

Performance

Flow

Accuracy: <±1% of reading @ 32 cSt

Repeatability: ±0.2%

Pressure

Accuracy: <±0.5% BFSL

Stability: <±0.25% of full scale

Zero Offset: <±2% of full scale

TC Zero and TC Span: <±1.5% of full scale

Response Time: 0.2 milliseconds

Temperature

Absolute Error: ±2.7 °F (±1.5 °C)

(over range of 0 to 185 °F)

Nonlinearity: ±0.7 °F (±0.4 °C)

Repeatability: ±0.2 °F (±0.1 °C)

Data Acquisition

Sample Rate: 10 kHz

PC Screen Update/Record Rate

Flow: 1 second (average 10K samples)

Temperature: 1 second (average 10K samples)

Pressure: 1 second (min, max, average 10K samples)

Calibration

Testers are calibrated with 0.876 specifi c gravity, 150 SUS (32 cSt) Mobil / DTE 24 hydraulic oil. Standard calibration

is done using 5 points and is traceable to NIST, ISO 9001. An optional 10 point calibration can be performed for

increased accuracy.

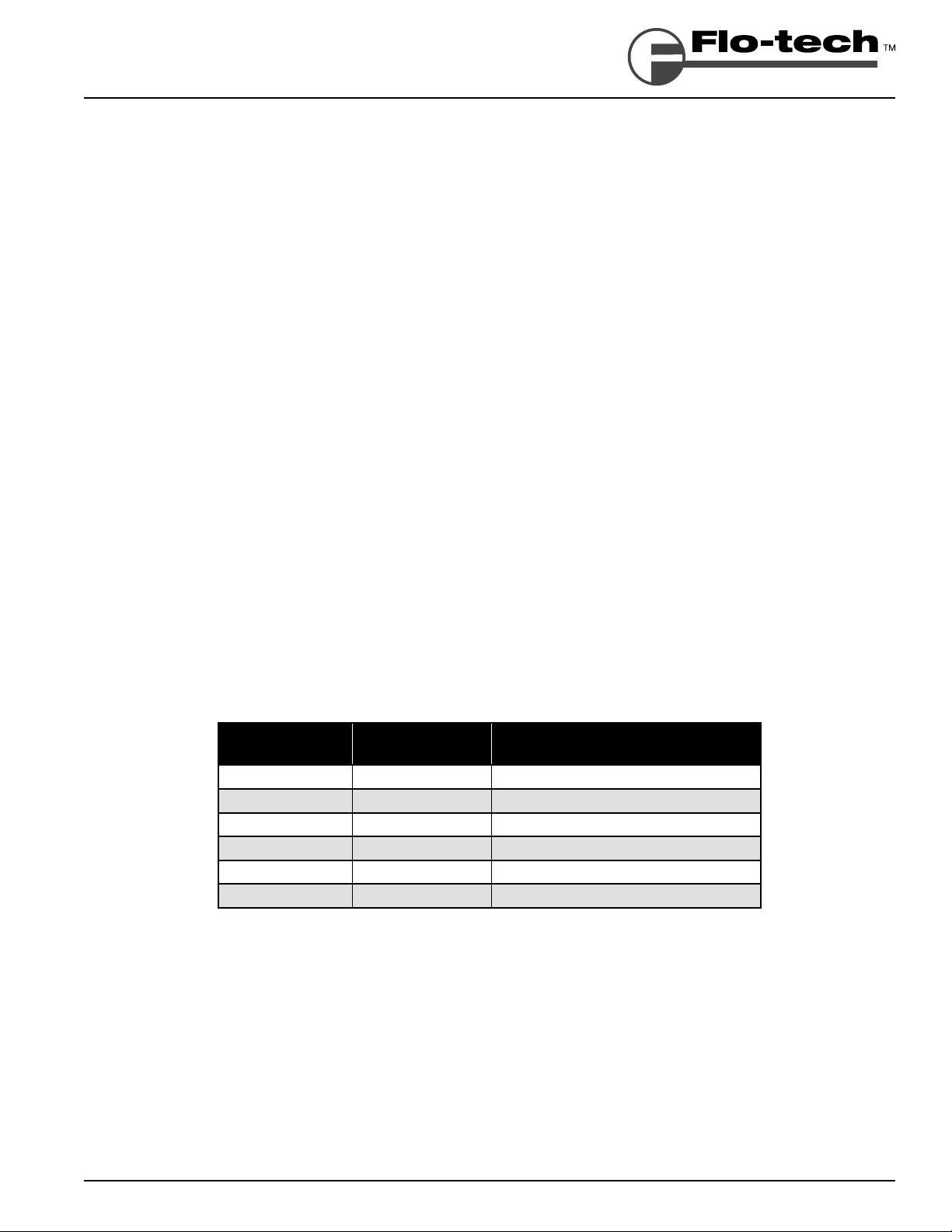

Model Number Designations

MODEL

NUMBER

F7164 SAE 12 2 - 30 GPM

F7160 SAE 16 3 - 85 GPM

F7161 SAE 24 7 - 199.9 GPM

F7165 G-3/4 7.5 - 113.6 LPM

F7162 G-1 15 - 321 LPM

F7163 G-1-1/2 26 - 757 LPM

NOMINAL

PORT SIZE

FLOW

RATE

Form No. 05-SGN-PM-00191 02/12 Page 5

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

CAUTION

Read instructions thoroughly before installing the tester. If you have any questions regarding product installation or

maintenance, call your local supplier or the factory for more information.

General Information

The power measurements are derived from the product of fl ow and pressure.

H.P. = GPM × PSI H.P. = liters/min × kg/cm²

1714 456.2

H.P. = liters/min × Bar H.P. = liters/min × MPa

447.40 44.74

kW = liters/min × kg/cm² kW = liters/min × Bar

611 600

kW = liters/min × MPa

60

1. Make all tests at the same operating temperature to ensure consistency of results. A typical operating

temperature for mobile machinery is 150 °F (66 °C).

2. Testing will be easier and faster if quick disconnect couplers are used to install the Flo-Check USB Hydraulic

System Analyzer.

3. Complete descriptions of the following basic hydraulic tests using the Flo-Check USB Hydraulic System

Analyzer can be found starting on page 18:

a. "Tee" Test

b. Inline System Test

c. Control Valve and Bi-directional Hydraulic Motor Test

d. Bi-Directional Cylinder Test

e. Hydrostatic Transmission Diagnostics

CAUTION

The information in this manual is for general application only. Any information furnished by the manufacturer of the

machine’s hydraulic components should be followed. Specifi c systems may require specifi c test procedures.

4. A preliminary check of the hydraulic system’s oil supply, pump speed, oil lines, and cylinder rods, as well as

an external leak check, should be made prior to installing the Flo-Check.

Page 6 Form No. 05-SGN-PM-00191 02/12

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

Installing the Software

To install the software package on your computer, perform the following steps:

1. Close all applications you have running.

2. Insert the Flo-Check USB Hydraulic System Analyzer CD into your CD drive.

If you have the auto-run feature enabled on your computer, the installation prompts will automatically be

displayed.

Note: If auto-run is not enabled, use Windows Explorer to navigate to the root directory on the CD. Doubleclick on the setup.exe fi le to begin the installation.

3. Follow the installation prompts to complete the installation.

4. After a successful installation, a dialog will be displayed asking to restart the computer.

Select Yes.

Note: If you wish to wait to reboot the computer, select ‘No’. However, you will need to reboot before initial

use for proper operation.

5. The installation creates two shortcuts on the computer; one on the desktop and the second in the START –

PROGRAMS – FLO-TECH Windows menu.

Connecting the Hydraulic Analyzer to Your Computer for the First Time

The Flo-Check USB Hydraulic System Analyzer connects to your computer through a USB port. A cable is shipped

with the unit, but any standard USB A Male to USB B Male cable can be used. The initial connection is easy and uses

standard drivers within Windows that do not require special driver installation by the operator.

► The Hydraulic Analyzer interface uses the Microsoft Human Interface Driver (HID). This driver is installed

with Windows operating systems that support USB.

► The fi rst time you connect the device to your PC, your computer automatically detects it and confi gures the

necessary drivers. No third-party device drivers need to be installed.

► The Hydraulic Analyzer interface is plug-and-play. You can connect it to the computer before or after you

install the software, and without shutting the computer off.

Note: Before connecting the Hydraulic Analyzer to the computer, download and install the latest Microsoft Windows

updates. For Windows XP, there is a Hotfi x KB822603 that is installed to address a serious error within Windows XP

and the use of USB devices.

To connect the Hydraulic Analyzer to your computer:

1. Connect the USB cable to the Hydraulic Analyzer and then plug the other end into a USB port on the

computer.

2. The fi rst time the Hydraulic Analyzer is connected to the computer, several “Found New Hardware” balloons

or dialogs pop up. This is normal.

3. Once the Hardware has been found and installed, the last balloon or dialog states “Your new hardware is

installed and ready to use.” At this point, the Hydraulic Analyzer interface has been successfully installed and

can be used with the software application.

Form No. 05-SGN-PM-00191 02/12 Page 7

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

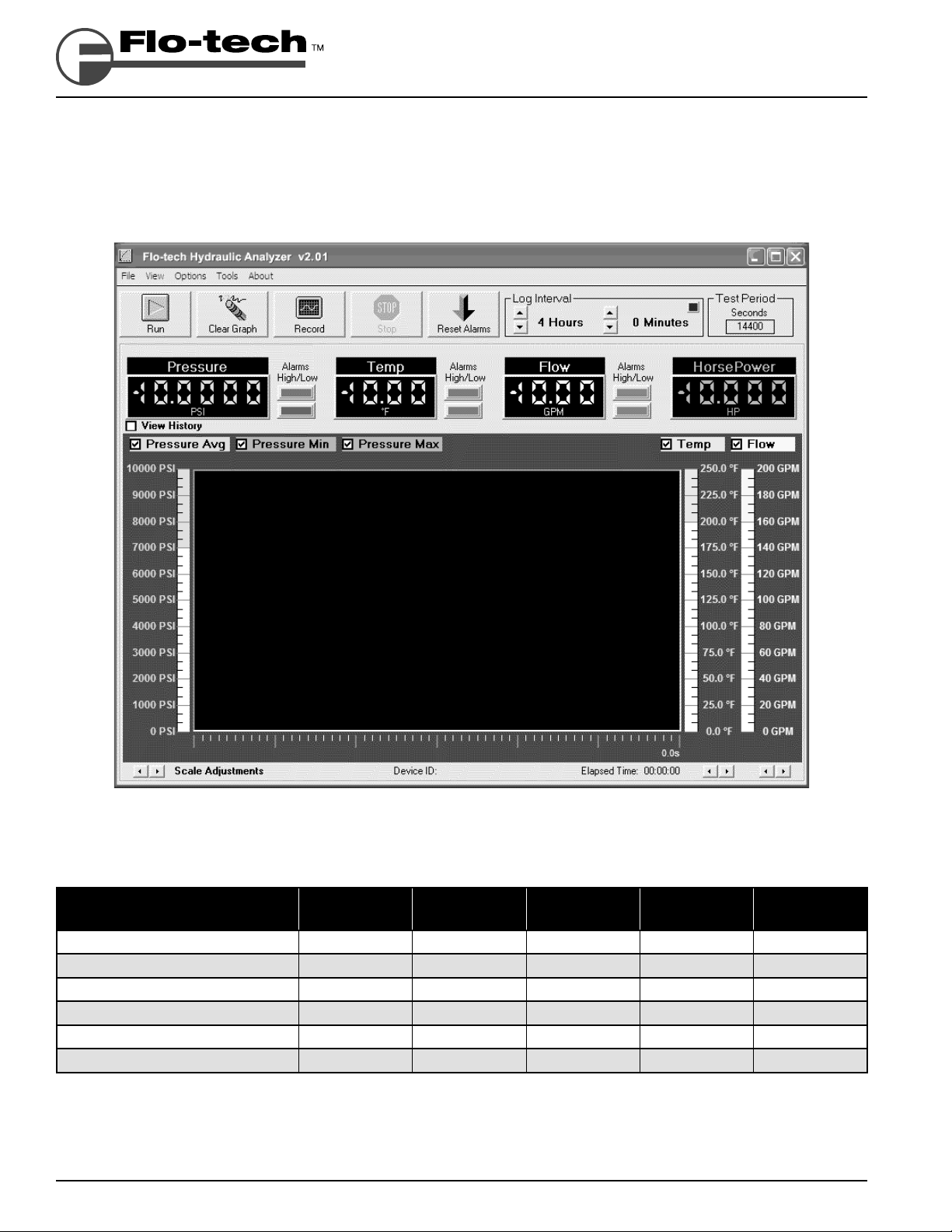

Software Overview

The software provides a real-time graphical and digital interface for monitoring and/or recording pressure, temperature,

and fl ow rate parameters from the Hydraulic Analyzer. In addition to the graphical and digital displays, the main screen

also consists of a menu bar, buttons with common functions, and alarm indicators.

FIGURE 1 - Flo-Check USB Hydraulic Analyzer Screenshot

Measurement

(over a 1 second time period)

Average Pressure Green ●●●●

Minimum Pressure Dark Green ●●

Maximum Pressure Dark Green ●●

Average Temperature Blue ●●●●

Average Flow Rate Yellow ●●●●

Average Power Orange ●●

TABLE 1 - Measurement Display and Record Features

Page 8 Form No. 05-SGN-PM-00191 02/12

Color

Indication

Alarm

Indication

Digital

Indication

Graphical

Display

Record to

File

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

Running the Software and Viewing Real-Time Data

1. Connect the USB cable from the Hydraulic Analyzer to the computer.

Note: This is required before starting the software. This allows the software application to detect a connected

unit.

2. Start the software application by double-clicking on the Flo-tech Hydraulic Analyzer icon on your desktop.

3. Press the Run button.

Data will be displayed on the digital displays and the strip-chart will be updated once per second.

4. Press the Stop button when fi nished to halt the collection of data.

Recording Measurements to a File

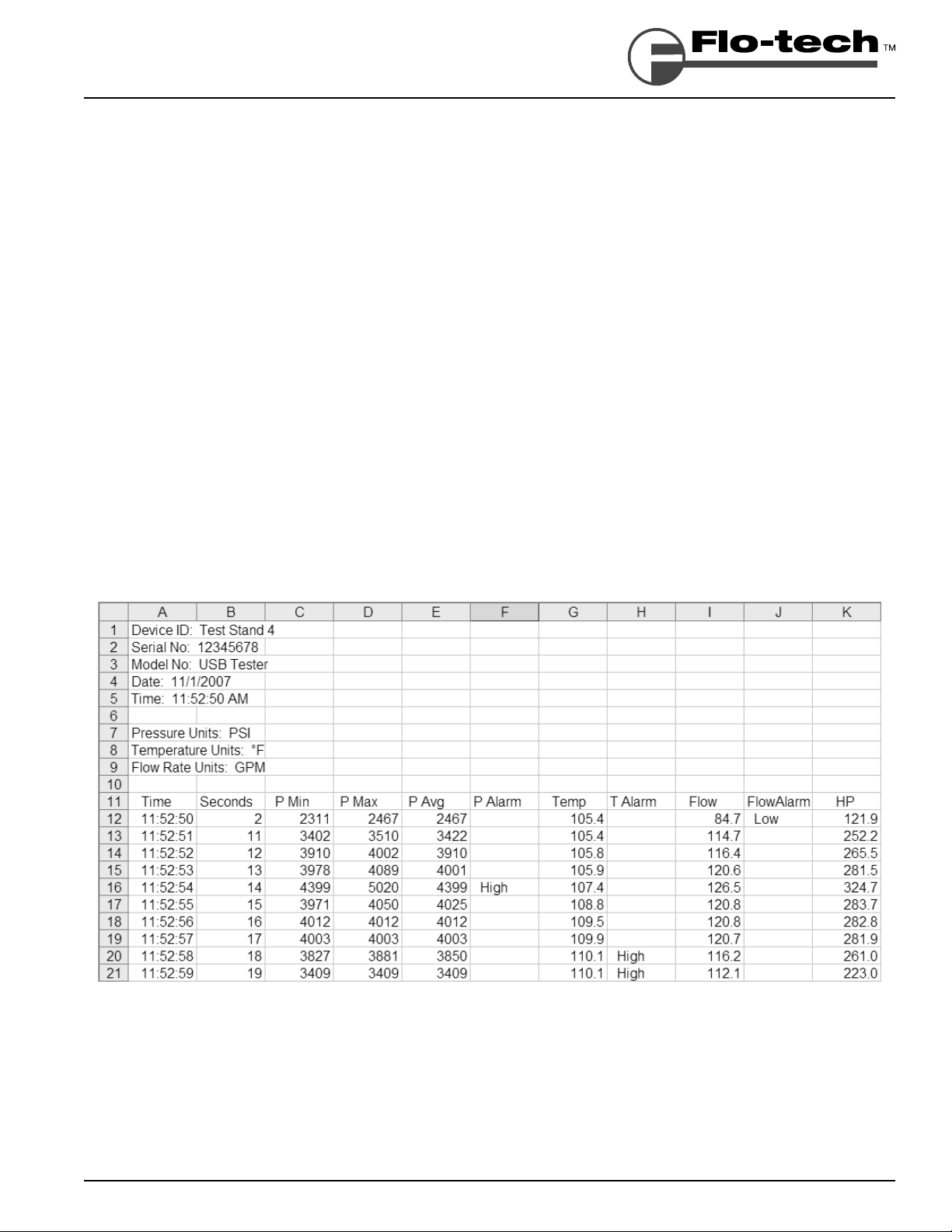

All measurements can be saved to a comma separated value (.csv) fi le. This fi le type is a generic text fi le with the data

separated by commas and can be read by many spreadsheet applications such as Excel

These spreadsheet programs can then re-graph and manipulate the data.

All measurements taken (as shown in Table 1 on page 8) are saved once per second to the fi le. For example, recording

for 2 minutes would yield 120 points of data. Even though data points are only recorded once per second, pressure

spikes and dips are captured by recording the maximum or minimum pressure during each measurement period.

Therefore, the precise shape of the pressure spike is not recorded but its amplitude and the time it occurred are both

recorded.

®

and Corel® Quattro Pro®.

FIGURE 2 - Example File

Form No. 05-SGN-PM-00191 02/12 Page 9

Flo-Check® USB Hydraulic System Analyzer

Installation & Programming Instructions

To Record a File

1. Connect the USB cable from the Hydraulic Analyzer to the computer.

Note: This is required before starting the software. This allows the software application to detect a connected

unit.

2. Start the software application by double-clicking on the Flo-tech Hydraulic Analyzer icon on your desktop.

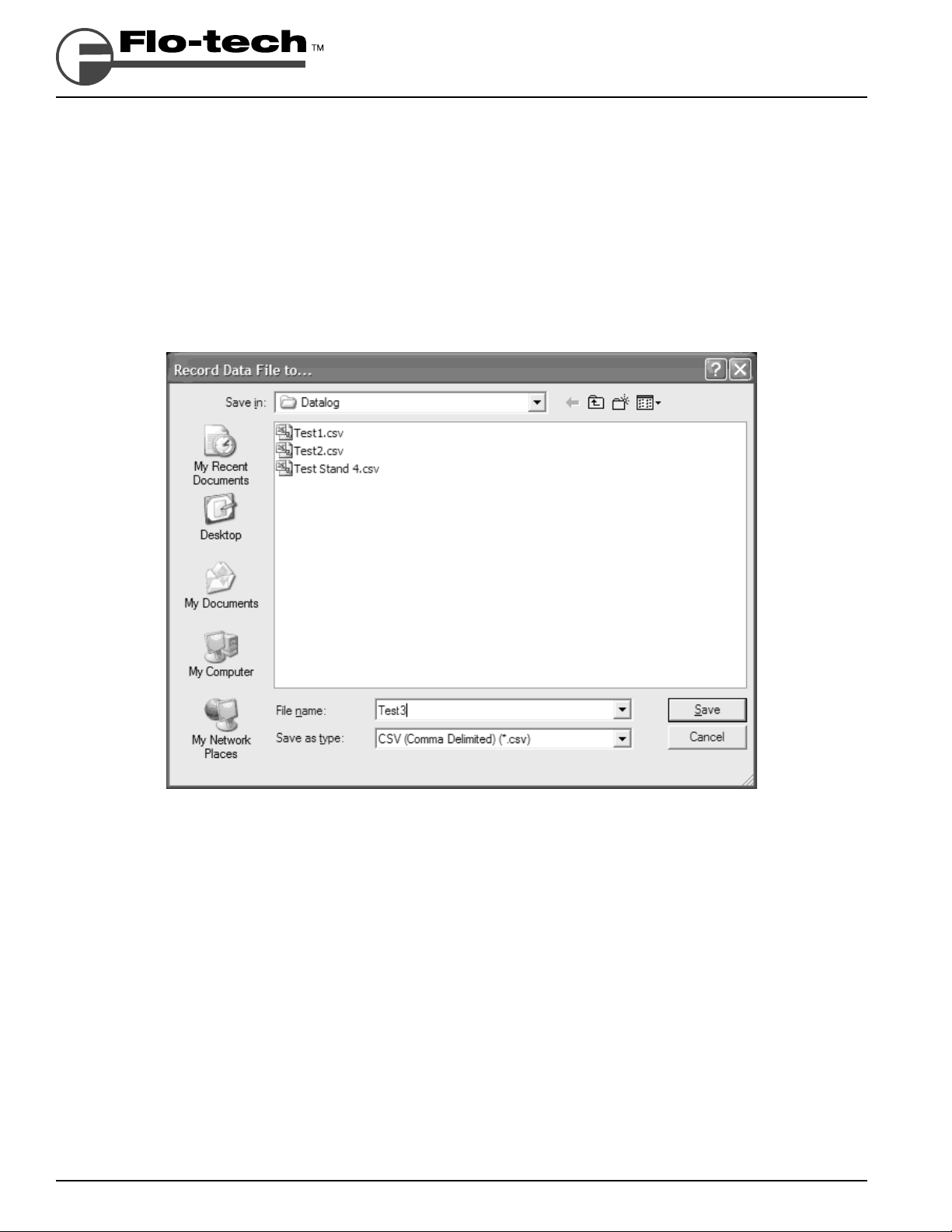

3. Press the Record button.

4. A dialog box will be displayed asking you to name the fi le you wish to create and where to save it. Type a

name in the File Name: textbox and press the Save button.

FIGURE 3 - Record Data File to... Screenshot

Note: The default location for saving a log fi le for Windows XP and Windows 2000 is:

C:\Documents and Settings\<user name>\My Documents\Flo-tech\Hydraulic Analyzer\Datalog

The default location for saving a log fi le for Windows Vista

®

is:

C:\Users\<user name>\Documents\Flo-tech\Hydraulic Analyzer\Datalog

Note: If you wish to record over an existing fi le, double-click on the fi le from the list.

Data will be displayed on the digital displays and the strip-chart will be updated once per second. The message

Recording… is also displayed under the Run button to indicate the software is in Record mode rather than run

mode. It’s important to note that data is not recorded if the fi le is already open by another application such as

®

Excel

.

5. Press the Stop button when fi nished to halt the collection of data.

Page 10 Form No. 05-SGN-PM-00191 02/12

Loading...

Loading...