Flo-tech Classic Operating Manual

Turbine Flow Sensors

Activa, Ultima, Classic and Quad

SEN-UM-00987-EN-04 (March 2019)

User Manual

Turbine Flow Sensors, Activa, Ultima, Classic and Quad

CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Connections for Standard Magnetic Pickup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Connections for IFC (Intelligent Frequency Converter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Electrical Connections for Optional Pressure and Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flow Sensors with IFC Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Activa Series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ultima Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Classic Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Quad Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Flow vs. Pressure Drop Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Activa and Ultima Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Classic Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Quad Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Activa and Ultima Sensor Arrays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Classic Flow Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Quad Flow Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Activa and Ultima Flow Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Classic Flow Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Quad Flow Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page ii March 2019

Introduction

INTRODUCTION

Flo-tech turbine flow sensors measure the flow rate of hydraulic fluid and compatible liquids. Built to withstand rigorous

hydraulic applications, these flow sensors are available in anodized aluminum and zinc plated Stressproof® steel bodies. Port

types vary by body material, but include a choice of SAE, BSPP, Code 61 and Code 62, 4-bolt flanged options.

Typical applications for the turbine flow sensors include:

• Fluid characteristic measurement on test stands

• Stationary hydraulic system monitoring

• Feedback for hydraulic system control

• Advance warning of impending component failure

• Mobile hydraulic system diagnosis

Flo-tech offers four different flow sensor models. Each of these models is available in a wide selection of flow ranges and

port sizes.

Activa Sensor Array Classic Flow Sensor

Features: Features:

• Four flow ranges

• Four port sizes

• Accuracy of ±1% reading @ 32 cSt

• Pressures up to 5800 psi (400 bar)

• Temperatures up to 300° F (150° C)

• 4…20 mA or 0…5V DC output for flow

• 4…20 mA output for pressure and temperature

Ultima Sensor Array Quad Flow Sensor

Features: Features:

• Four flow ranges

• Four port sizes

• Accuracy of ±1% full scale

• Pressures up to 5800 psi (400 bar)

• Temperatures up to 300° F (150° C)

• Frequency output for flow

• 4…20 mA output for pressure and temperature

• Eight flow ranges

• Eight port sizes

• Accuracy of ±1% full scale

• Pressures up to 6000 psi (414 bar)

• Temperatures up to 300° F (150° C)

• Frequency output for flow

• Four flow ranges

• Two port sizes

• Accuracy of ±1% full scale

• Pressures up to 6000 psi (414 bar)

• Temperatures up to 300° F (150° C)

• Frequency output for flow

Page 3 March 2019 SEN-UM-00987-EN-04

Operating Principle

OPERATING PRINCIPLE

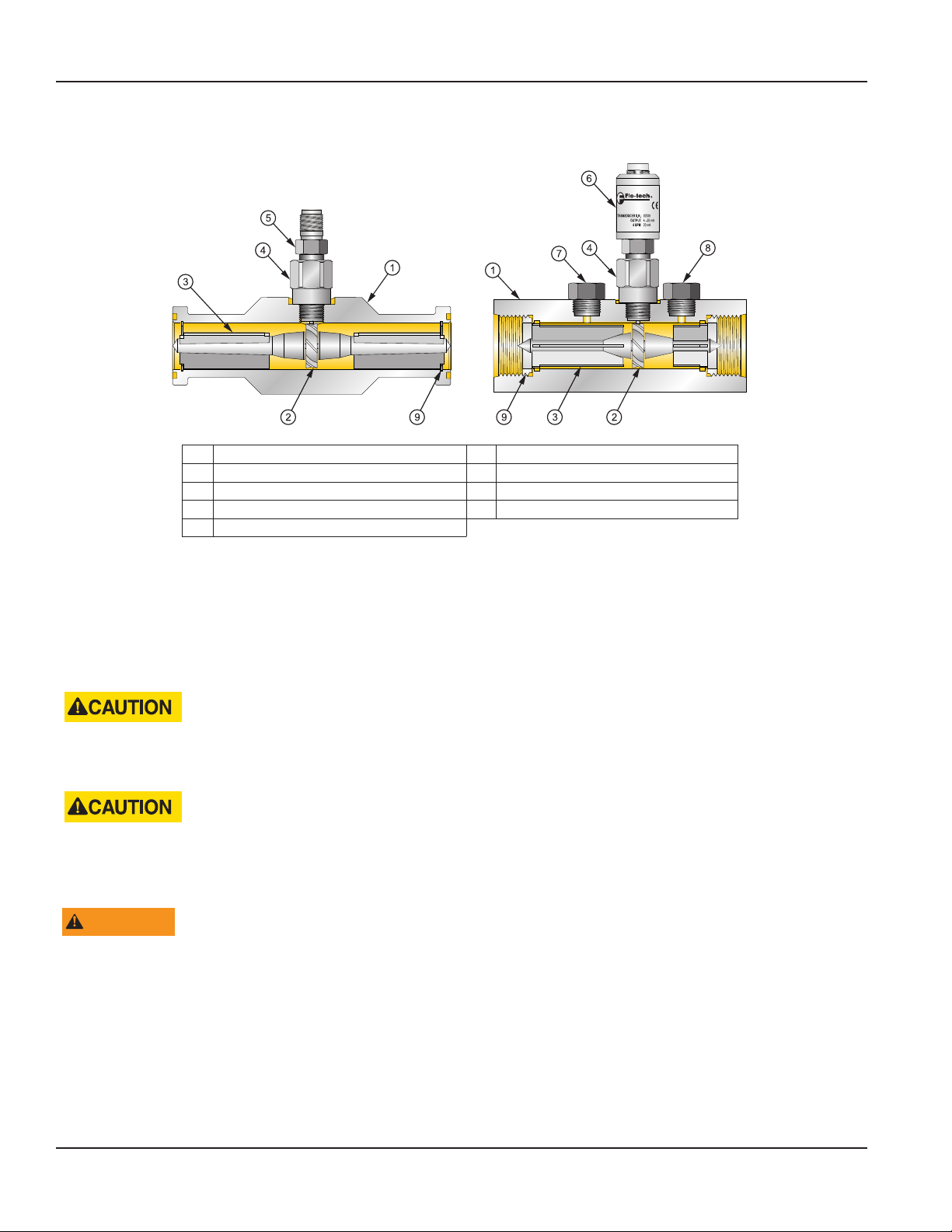

1 Housing 6 Signal Converter (analog output)

2 Turbine Rotor 7 Pressure Port Adapter

3 Rotor Supports 8 Temperature Port Adapter

4 Lock Nut 9 Retaining Rings

5 Magnetic Pickup (frequency output)

Turbine flow sensors measure the flow rate of hydraulic fluid and compatible liquids. As fluid flows through the sensor it turns

the turbine rotor, and as the turbine blades pass the magnetic pickup a frequency signal is generated. This frequency signal is

proportional to the flow rate and can be transmitted to Flo-tech’s digital displays or converted to an analog output. Optional

sensors allow measurement of pressure and temperature.

INSTALLATION

THIS PRODUCT SHOULD BE INSTALLED AND SERVICED BY TECHNICALLY QUALIFIED PERSONNEL TRAINED IN

MAINTAINING INDUSTRIAL CLASS FLOW INSTRUMENTATION AND PROCESSING EQUIPMENT.

READ INSTRUCTIONS THOROUGHLY BEFORE INSTALLING THE FLOW SENSOR. IF YOU HAVE ANY QUESTIONS

REGARDING PRODUCT INSTALLATION OR MAINTENANCE, CALL YOUR LOCAL SUPPLIER OR THE FACTORY FOR MORE

INFORMATION.

WARNING

DO NOT USE MALE PIPE THREADS (NPT) INTO SAE STRAIGHT THREAD PORTS. USING MALE PIPE THREADS (NPTF)

WITH A FLOW SENSOR POSSESSING SAE STRAIGHT THREAD O-RING PORTS WILL NOT CREATE A PROPER SEAL AND

IS POTENTIALLY DANGEROUS. PIPE THREADS INSERTED INTO AN SAE STRAIGHT THREAD PORT ONLY ALLOW THE

ENGAGEMENT OF ONE OR TWO THREADS. NO AMOUNT OF TIGHTENING OR THREAD SEAL WILL STOP THE LEAKING

OR MAKE THE INSTALLATION SAFE. FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS PERSONAL

INJURY OR DEATH AND/OR DAMAGE TO THE EQUIPMENT.

Page 4 March 2019SEN-UM-00987-EN-04

Installation

Installation Recommendations

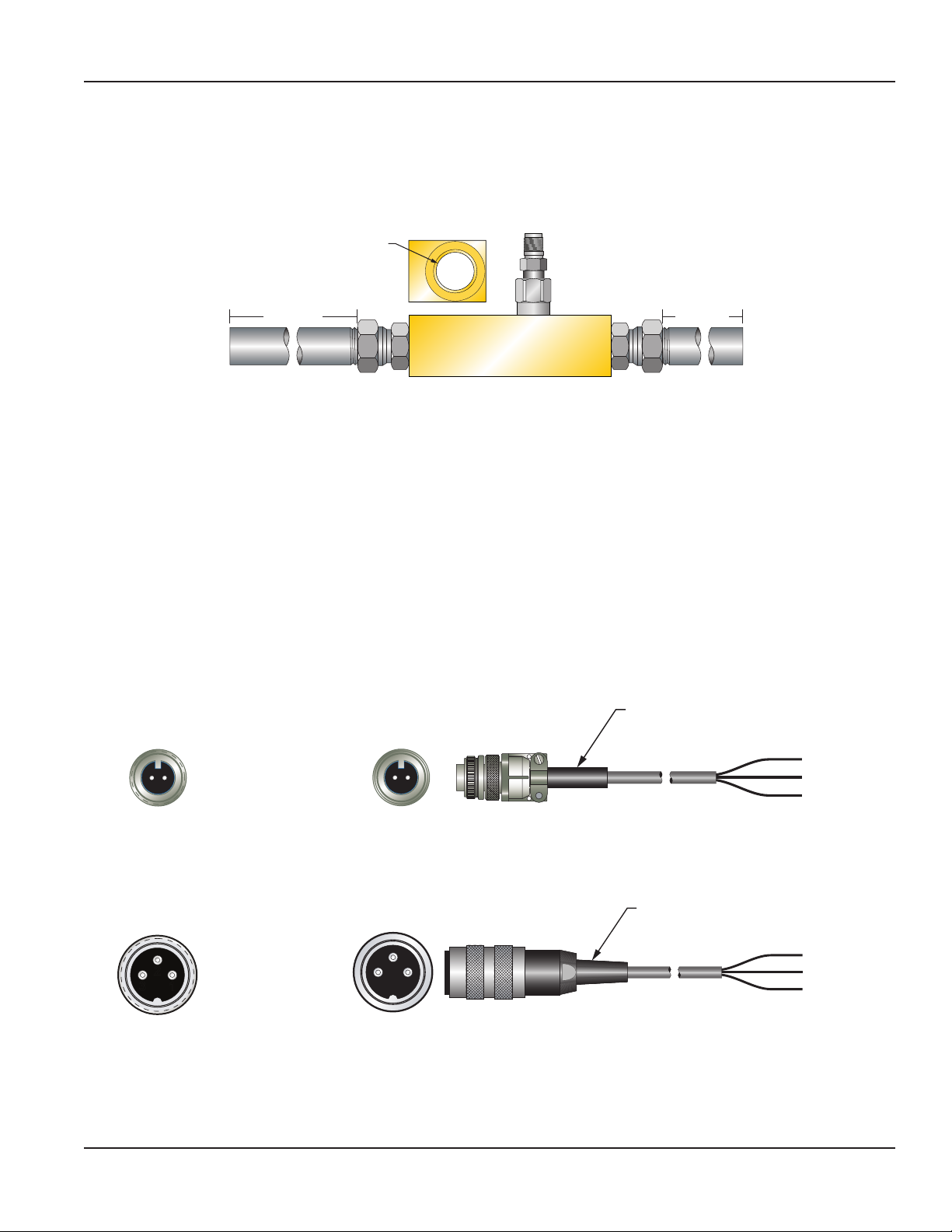

The in-line flow sensor is a simple device to install. However, the following measures are recommended for reliable,

trouble-free operation:

1. Provide at least 10 port diameters of upstream straight pipe with no obstructions to the ow sensor and at least 5

diameters of downstream pipe. The pipe should be of the same diameter as the nominal port size.

1" PORT

(25.4 mm)

END VIEW

10 PORT DIAMETERS

10" (254 mm)

IN

5 PORT DIAMETERS

5" (127 mm)

Example:

An FSC-1000 has a 1 in. (25.4 mm) port. The unobstructed upstream length should be at least 10 in. (254 mm) and the

downstream length should be at least 5 in. (127 mm).

2. Choose a position for the ow sensor that is not at the lowest level in the system. Placing the ow sensor at a higher

elevation in the system will avoid collection of debris, sediment and dirt in the ow sensor.

3. Use a lter. All applications should be ltered to at least 40 micron.

4. Do not install a ow sensor directly in-line with the outlet of a pump, as pressure pulsations can react with the turbine.

Install the sensor after another component, observing the 10 port diameter rule.

5. Do not adjust the magnetic pickup on the ow sensor. This is calibrated at the factory. Further adjustment will cause a

decrease in performance or damage to the sensor.

6. Do not exceed the working temperature range of –4…300° F (–20…150° C). Higher temperatures will damage the

magnetic pickup and lower temperatures will limit the rotation of the turbine.

Electrical Connections for Standard Magnetic Pickup

Standard Magnetic Pickup with Frequency Output, 2-pin Connector

Cable Assembly

F2832-6 6 ft

F2832-15 15 ft

B

B (BLACK) –

A

A (RED)

+

B A

(BLACK) –

(RED)

+

(WHITE) N.C.

Magnetic Pickup

Male Connector

2

1

3

Magnetic Pickup

Male Connector

Top of

F2832 Cable

Standard Magnetic Pickup with Frequency Output, 3-pin Connector

1 (WHITE) N.C.

2 (BLACK) –

3 (RED) +

2

3

1

Top of

F6234 Cable

Cable Assembly

F6234-6 6 ft

F6234-15 15 ft

(BLACK) –

(RED)

+

(WHITE) N.C.

Page 5 March 2019 SEN-UM-00987-EN-04

Loading...

Loading...